Abstract

Submicron-sized NiAl2+X O4 fragments and nanocondensates of Ni-doped γ-Al2O3, Al-doped NiO and β-Ni(OH)2 were synthesized simultaneously by pulsed laser ablation of NiAl2O4 powder in water and characterized using X-ray/electron diffraction and optical spectroscopy. The NiAl2+X O4 is Al-enriched spinel with dislocations and subgrains. The Ni-doped γ-Al2O3 spinel has paracrystalline distribution (i.e., with fair constant longitudinal spacing, but variable relative lateral translations) of defect clusters and intimate intergrowth of θ-Al2O3 and 2x(\( \overline{1} \)3\( \overline{1} \)) commensurate superstructure. The Al-doped NiO has perfect cubo-octahedron shape and as small as 5 nm in size. The β-Ni(OH)2 and 1-D turbostratic hydroxide lamellae occurred as a matrix of these oxide nanoparticles. The colloidal suspension containing the composite phases has a minimum band gap of 5.3 eV for potential photocatalytic applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

NiAl2O4, having a normal spinel-type structure with Al3+ in octahedral sites and Ni2+ in tetrahedral sites or partially inversed with Al3+ in both octahedral and tetrahedral sites [1], was commonly used as high-temperature fuel cell [2] and sensor materials such as catalyst support, which can provide a stabilizing effect while maintaining a high degree of chemical inertia [3, 4]. Nickel was particularly found to have much greater stability when supported on NiAl2O4 than on other supports [3]. In general, smaller particle size has beneficial higher (typically up to 100 m2/g) specific surface area for catalytic applications of the NiAl2O4 support. Synthesis of nanosized NiAl2O4 particles is, thus, of great interest to such applications. The end members of NiAl2O4, i.e., NiO [5] and Al2O3 [6], were also used as catalytic supports.

The NiAl2O4 particles prepared by reactive sintering the powdery end members, i.e., NiO and α-Al2O3, at high temperature (1,100 °C) in air generally fall in submicron to micron size [7, 8]. As for the chemical synthesis of submicron to nanosized NiAl2O4 particles, it has been accomplished by the co-precipitation method [4], sol–gel process [9, 10], microwave treatment [11], ultrasonic treatment of precursor aqueous solution followed by high-temperature (950 °C) aging [12]. The expensive precursor phase and pollutant solution are the main shortages of these chemical methods. It is, thus, worthwhile to try an alternative clean synthesis of nanoparticles by pulsed laser ablation (PLA) in liquid.

Recently, PLA of ceramic powders in water was used for the clean synthesis of SnO2 [13] and CaCO3 [14] nanoparticles with dense structure and narrowed band gap. Here, this method is adopted to study the phase behavior of NiAl2O4 powders when subjected to PLA in water. We focused on: (1) the extent of NiAl2O4 powders fragmentation as nanosized particles without phase change, (2) the decomposition of NiAl2O4 powders as end-member nanoparticles with internal compressive stress, (3) the formation of a lamellar phase, which is related to the so-called layered double hydroxides (LDH) or anionic clays [15–18] as a precursor phase of spinel oxides [19, 20], and (4) the accompanied band gap change of the colloidal suspension.

2 Experimental

NiO (99.995 %) and Al2O3 (99.9 %) powders in 1:1 molar ratio were thoroughly mixed in a beaker filled with de-ionized water and heated at 100 °C by a hot plate coupled with magnet stirring. The uniform powder mixtures were fired at 1,600 °C for 10 h to form NiAl2O4 powders in an open-air furnace followed by furnace cooling and then grinding using agate mortal and pestle to go through a sieve of 200 mesh.

A fixed amount (0.01 g) of the sieved NiAl2O4 powders in a silica test tube (0.8 cm in inner diameter and 10 cm in length) was combined with de-ionized water of 10-mm height for a total concentration of 3.2 mg/cc and then subjected to energetic Nd-YAG-laser (Lotis, 1,064 nm, beam mode: TEM00) pulse irradiation. In such experiments, the laser beam was focused to a spot size of 0.03 mm2 on the specified water height at water level under laser pulse energy of 400 mJ/pulse using second harmonic excitation, i.e., 532 nm for better laser penetration in water. The Q-switch mode for specified pulse duration of 16 ns was adopted to achieve a peak power density of 8.35 × 1010 W/cm2 (average power density 1.33 × 104 W/cm2) at 10 Hz. Water refill and suspension shaking after every 5 min of PLA procedure were employed to ensure a uniform colloidal suspension upon energetic irradiation for an accumulated time of 30 min. The bluish colloidal suspension became dark blue and warmed up to ca. 50 °C after the PLA process (Appendix 1).

The sample of particles centrifuged from the colloidal suspension for a much larger quantity was then deposited on glass for identification by X-ray diffraction (XRD, SIEMENS D5000, Cu Kα at 40 kV, 30 mA and 3 s for each 0.05° increment from 20° up to 80° of 2θ angle). The crystal structures of the individual condensates collected on Cu grids overlaid with a carbon-coated collodion film were characterized by transmission electron microscopy (TEM, JEOL 3010 at 200 kV) based on bight field image (BFI), selected area electron diffraction (SAED) and lattice imaging coupled with point-count energy-dispersive X-ray (EDX) analysis.

The UV–Visible absorption of the colloidal suspension as-formed by PLA was characterized by the instrument of U-3900H, Hitachi with a resolution of 0.1 nm in the range of 190–900 nm. Raman spectra of the centrifuged condensates were made using He–Ne laser excitation (633 nm) having a spatial resolution of 1 μm (HORIBA HR800) to identify the structure units of the condensates in the range of 200–2,000 cm−1. The centrifuged condensates were also mixed with KBr for Fourier transform infrared spectroscopy (FTIR, Bruker 66v/S, 64 scans in the range of 400–4,000 cm−1 with 4 cm−1 resolution) study of OH− signature and phase change of the NiAl2O4 powder subjected to PLA in water.

3 Results

3.1 XRD

XRD of the starting NiAl2O4 powders showed sharp diffraction peaks of the spinel structure (Fig. 1a), the same as that reported in JCPDS file #10-0339. The spinel diffraction peaks were considerably broadened and shift to higher 2θ for the powders subjected to PLA at 10 mm water/focus height for 5 min (Fig. 1b) and 20 min (Fig. 1c). Additional phases, i.e., β-Ni(OH)2 (space group P \( \overline{3} \) m1) and a turbostratic lamellar phase with a rather broad diffraction at low 2θ angle (22° different from that peaked at 21° for the silica glass substrate), also showed up after such PLA treatments in water (Fig. 1b, c).

3.2 Optical and electron microscopy

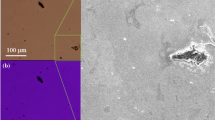

Optical polarized microscopic observation of the NiAl2O4 powders subjected to PLA at 10 mm water/focus height for 20 min showed representatively that the powders became submicrons to ca. 20 microns in size and were equiaxed with facets (Fig. 2a). The relatively large-sized NiAl2O4 spinel particles showed slight optical anisotropy (Fig. 2b), i.e., with weak interference color under crossed polarizers according to Nesse [21], presumably due to grinding and/or PLA-induced strain.

The identity of the individual spinel particles was verified by TEM BFI (Fig. 3a) and SAED (Fig. 3b) of a representative submicron-sized NiAl2+X O4 particle produced by PLA of NiAl2O4 powder at 10 mm water/focus height for 20 min, showing well-developed (1\( \overline{1} \)1) and (001) faces edge on in the [110] zone axis. This fragmented spinel particle also showed subgrain boundaries in DFI (Fig. 3c) and Al enrichment in comparison with the stoichiometric NiAl2O4 in EDX spectrum (Fig. 3d).

TEM of a typical submicron-sized NiAl2+X O4 particle produced by PLA of NiAl2O4 powder at 10-mm water/focus height for 20 min: a BFI and b SAED pattern showing well-developed (1\( \overline{ 1} \)1) and (001) faces edge on in the [110] zone axis, (c) DFI (g = 1\( \overline{ 1} \) \( \overline{ 1} \) as circled) showing subgrain boundaries (SGB), (d) EDX spectrum showing Al enrichment than NiAl2O4 stoichiometry

As for nanosized NiAl2+X O4 or Ni-doped γ-Al2O3 with spinel isostructure in the same TEM specimen, they were typically assembled in random orientation as a corrugated spherical particle (Fig. 4a) to give characteristic diffraction rings in SAED pattern (Fig. 4b). Point-count EDX analysis on this polycrystalline particle showed an overall composition of Ni:Al:O = 1:3.7:7.6 in atomic ratio, which can be represented by the formula ~M2O3 having M/O = 0.62, where M is ca. 20 % Ni and 80 % Al, i.e., 20 % Ni2+ in substitution for Al3+. Lattice image (Fig. 5a) coupled with 2D forward/inverse Fourier transform (Fig. 5b, c) of such spherical polycrystals showed that the individual NiAl2+X O4 or Ni-doped γ-Al2O3 phase has paracrystalline distribution of defect clusters with ca. 1 nm interspacing in the [011] zone axis of the spinel isostructure.

TEM of a typical corrugated spherical particle consisting of nanosized NiAl2+X O4 and Ni-doped γ-Al2O3 with spinel isostructure, as produced by PLA of NiAl2O4 powder at 10-mm water/focus height for 20 min, a BFI, b SAED pattern and (c) EDX spectrum indicating an overall composition of Ni:Al:O = 1:3.7:7.6 atomic ratio in the formula ~M2O3 having M/O = 0.62 and with M ca. 20 % Ni and 80 % Al, i.e., 20 % Al3+ being replaced by Ni2+ (cf. text)

TEM a lattice image enlarged from a spherical polycrystalline nanoparticle (inset) and b, c 2D forward/inverse Fourier transform of the square region, which contains Ni-doped γ-Al2O3 with the spinel-type structure having paracrystalline (denoted as P for side-band diffractions) distribution of defect clusters ca. 1 nm interspacing as viewed in the [011] zone axis in c. The same PLA specimen as in Fig. 4

Lattice image (Fig. 6a) further indicated that the Ni-doped γ-Al2O3 also occurred as individual spherical nanoparticle, which tended to be encapsulated with a turbostratic lamellar shell. The 2D forward/inverse Fourier transform from the Ni-doped γ-Al2O3 core (Fig. 6b, c) showed intimate intergrowth of θ-Al2O3 (JCPDS file 11-0517) and 2x(\( \overline{1} \)3\( \overline{1} \)) commensurate superstructure as well as misfit dislocations with (220) and (3\( \overline{1} \)1) half planes (Fig. 6). TEM lattice image (Fig. 7a) coupled with 2D forward/inverse Fourier transform (Fig. 7b, c) further identified an isolated NiO nanoparticle, which is as small as 5 nm in size with well-developed (010) and (\( \overline{1} \)11) faces sitting in a matrix of the 1D turbostratic lamellar phase more or less assembled to show Bragg diffraction.

TEM a lattice image and b, c 2D forward/inverse Fourier transform of the square region of a spherical Ni-doped and lamellae-encapsulated γ-Al2O3 particle with intimate intergrowth of θ-Al2O3 and 2x(\( \overline{ 1} \)3\( \overline{ 1} \)) commensurate superstructure (denoted as S) as well as dislocations with (220) and (3\( \overline{ 1} \)1) half planes. The same PLA specimen as in Fig. 4

TEM a lattice image and b, c 2D forward/inverse Fourier transform of the square region showing a 5-nm-sized NiO particle with well-developed (010) and (\( \overline{ 1} \)11) faces edge on in the [101] zone axis. Note 1D turbostratic lamellar phase in the matrix which showed significant Bragg diffraction contrast when well assembled (arrow). The same PLA specimen as in Fig. 4

3.3 Vibrational spectroscopy

The Raman spectra of the samples subjected to PLA at 10-mm water/focus height for 5 up to 20 min (Fig. 8) showed that the NiAl2+X O4 and Ni-doped γ-Al2O3 rich condensates/particles have Eg, T2g and A1g modes considerably different from that reported for the NiAl2O4 single or polycrystals [22] as compiled in Table 1. This indicates a considerable structure unit change of NiAl2O4 powders in accompaniment with their size miniature, densification, phase change and enhanced protonation/hydroxylation by the PLA process in water as addressed later.

The FTIR spectra of the NiAl2O4 powders subjected to PLA at 10 mm water/focus height for 5 and 20 min (Fig. 9a, b) showed a rather broad band at 719 cm−1, which is due to tetrahedrally coordinated Al–O stretching in view of the assignment of Jeevanandam et al. [12] for nickel aluminate spinel prepared by a sonochemical method. The additional bands at 3,415 and 1,629 cm−1 can be attributed to OH− species and absorbed water, respectively; whereas 1,382 cm−1 C–H asymmetric stretching of CH3 in the relic cleaning agent EtOH. In comparison with the nickel aluminate spinel prepared by sonochemical synthesis [12], there is a considerable shift of IR bands for the present sample (Table 2) apparently due to significant phase and size changes of NiAl2O4 powders by the PLA process in water.

3.4 UV–Visible absorption

The representative colloidal suspension prepared by PLA of NiAl2O4 powder at 10-mm water/focus height for 20 min showed a significant absorption in UV range, which corresponds to a minimum band gap of 5.32 eV based on its intersection with the base line at 232.9 nm (Fig. 10). By comparison, the minimum band gap is 5.82 eV for the starting colloidal sample based on its UV–Visible absorbance trace (not shown) [23].

4 Discussion

4.1 Phase selection during PLA of NiAl2O4 powder in water

The present experimental results indicated that NiAl2O4 powders subjected to PLA in water were either fragmented as micron-sized spinel particles with slight optical anisotropy or decomposed as atom clusters for further condensation and nucleation as hydroxides, i.e., 1D lamellar phase and β-Ni(OH)2, and close packed oxides, i.e., Al-doped NiO and Ni-doped γ-Al2O3.

The 1D lamella could improve its crystallinity to form β-Ni(OH)2, which belongs to LDH or anionic clays [15–18] known as a precursor phase of spinel oxides [19, 20]. The condensed LDH is Ni-based as β-Ni(OH)2 rather than Al-based in the present PLA of NiAl2O4 power in de-ionized water. This indicates that Ni-based LDH are the energetically favored hydroxides at nanoscale in the present aqueous conditions of the PLA process. Such conditions are: (1) Eh = 0 and pH = 7 in de-ionized water without an applied voltage, (2) temperatures around ~1,000 °C under radiant heating of the PLA process, which accounts for the coalescence of oxide nanocondensates such as originally suggested for TiO2 [24], and (3) shock pressure up to several GPa in view of the formation of dense oxides, such as α-PbO2 type SnO2 by PLA in water [13].

As for the phase selection of close packed oxides in nanosize, Ni-doped γ-Al2O3 with spinel-type structure is energetically more favorable than Al-doped NiO with rock salt-type structure. In this regard, thermodynamic considerations indicated that transition metal oxides have a lower surface energy for spinel structure (e.g., 1.44 J/m2 for Fe3O4, 1.96 J/m2 for Co3O4, 1.8 J/m2 for MgAl2O4 and 1.53 J/m2 for γ-Al2O3 with spinel isostructure) than rock salt-type structure (e.g., 3.5 J/m2 for NiO, 3.57 J/m2 for CoO, and 3.6 J/m2 for Fe0.947O) [25]. It is, thus, reasonable for Al-doped NiO nuclei to change into Ni-doped γ-Al2O3 and/or NiAl2+X O4 when the condensates were coarsened or coalesced for interdiffusion and hence composition modification. The Ni-doped γ-Al2O3 was allowed to form paracrystalline distribution of defect clusters and intimate intergrowth of θ-Al2O3 and commensurate superstructure when coarsened and stressed. Whereas α-Al2O3, with corundum-type structure and a relatively high surface energy of 2.6 J/m2 [26], is not favorable unless further coarsened to have specific surface areas <75 m2/g at temperatures such as 527 °C [26] or via kinetic phase change in a dynamic process [27]. In any case, the nanocondensates tended to assemble as spherical polycrystals upon radiant heating of the PLA process so that the total surface area can be minimized.

4.2 Composition and defects due to particle fragmentation and condensate doping by the PLA process

The combined optical polarized microscopy and TEM observations indicated that submicron- to micron-sized nickel aluminate spinel particles and Ni-doped γ-Al2O3 with spinel isostructure have lattice imperfections by the PLA process in water. The dislocations and subgrains of relatively large-sized NiAl2+X O4 fragments with significant Al enrichment than stoichiometric NiAl2O4 (Fig. 3) can be attributed to shock and radiant heating effects upon laser pulses in water. In fact, the fragmented NiAl2+X O4 spinel particle was determined by point-count EDX analysis to have ca. 70 mol % of Al2O3 component, i.e., Ni:Al:O = 1:2.26:4.08 atomic ratio in the formula ~NiAl2.3O4. This solubility level is close to that allowed for NiAl2+X O4 at ca. 2,000 °C according to the NiO–Al2O3 binary phase diagram (Appendix 2) [28]. However, the temperature due to radiant heating of a typical PLA process in air or water was believed to be around 1,000 °C to assemble/coalesce the oxide nanocondensates as a close packed manner analogous to the case of TiO2 [24]. Such a discrepancy can be reconciled by the shock-induced solute trapping effect to enhance solid solubility as the case of TiO2 nanocondensates with enhanced dissolution of NiO [29] and Cr2O3 [30] by the PLA process in air.

The Ni-doped γ-Al2O3 nanocondensates have paracrystalline distribution of defect clusters in spinel structure (Fig. 5) analogous to that occur in Co3−δO4 spinel with or without Zr4+ dopant by a sintering route [31, 32] and γ-Al2−δO3 condensates by PLA of oxygen-purged Al target [33]. The defect clusters in the present case of γ-Al2O3 are apparently affected by Ni dopant based on the following defect chemistry considerations.

The spinel-type γ-Al2O3 having Ni2+ dopant in the interstitial site (Ni ··i ) would be volume/charge compensated by the aluminum vacancies (V ′′′Al ) and H+ (h·) in association with noncharged oxygen atom (O xO ) to form defect clusters [Ni ··i + V ’’’Al + h· + O xO ], where the state of the individual point defect in the parenthesis is as defined, through the following equation in Kröger–Vink notation [34]:

Alternatively, Ni2+ (0.055 and 0.069 nm) could substitute for smaller-sized Al3+ (0.039 and 0.054 nm) with specified ionic radii [35] in coordination number 4 and 6, respectively, in parenthesis, to form \( {\text{Ni}}_{\text{Al}}^{\prime } \) coupled with the generation of volume compensating \( {\text{V}}_{A1}^{\prime \prime \prime } \) and charge compensating h· to form defect clusters by the following equation:

The Ni-doped γ-Al2O3 condensate then has above defect clusters (i.e., by Eqn. 1 or 2) distributed in a paracrystalline manner within the spinel lattice. The observed interspacing of the defect clusters in the Ni-doped γ-Al2O3 condensates is ca. 1 nm (Fig. 5), which is close to that observed in γ-Al2−δO3 produced by PLA of oxygen-purged Al target [33] but significantly smaller than that (ca. 3 times difference) in statically fired Co3−δO4 [31] and Zr-doped Co3−δO4 [32] with the spinel isostructure.

As for the Ni-doped γ-Al2O3 nanocondensates, it showed intimate intergrowth of θ-Al2O3 (JCPDS file 11-0517) and commensurate superstructures, which have little to do with Ni dopant (presumably <1 mol % according to the phase diagram [28]) as such coarsening-induced intergrowth and shuffling were also observed for the H+ and Al2+ doped γ-Al2O3 condensates formed by PLA of Al plate in water [36].

4.3 Internal stress of NiAl2O4 powders subjected to laser pulses in water

Regarding the stress state of the predominant spinel-type phase in the form of either nanocondensates and/or micron-sized particles, its refined lattice parameters from the sample subjected to PLA under 10-mm water/focus height for 5 and 20 min (Table 3) are 0.8016 and 0.8007 ± 0.0001 nm, respectively, which are significantly smaller than the ambient value of starting NiAl2O4 powders (0.8046 nm, JCPDS#10-0339). This indicates a significant internal compressive stress, up to 5.9 GPa based on Birch–Murnaghan equation and bulk modulus B o = 372 GPa along with its pressure derivative \( B_{\text{o}}^{{^{\prime } }} \) = 2.93 GPa as determined for stoichiometric NiAl2O4 powders by static compression experiments [37]. Such a high stress level is apparently overestimated as Al enrichment also causes a smaller cell volume for nonstoichiometric NiAl2+X O4 spinel [38].

The inversion parameter that measures the extent of Al occupation in tetrahedral sites of nickel aluminate spinel, increases with the increase of applied pressure up to 35 GPa [37]. Al enrichment was also known to cause nickel vacancies and ordering to form spinel superstructure of nickel aluminate [39–42]. The combined effects of internal compressive stress and Al enrichment for the spinel condensate/particle not only caused a smaller cell volume, but also significant change of structure units as manifested by the modified Raman Eg/T2g (both are Oh, i.e., m3m point group) and A1g (D4h, i.e., 4/mmm point group) vibration modes (Table 1).

4.4 Implications of optical property and phase changes of NiAl2O4 by PLA in water

The colloidal aqueous suspension containing the protonated NiAl2+X O4 fragments and newly condensed nanoparticles of 1-D lamellae, β-Ni(OH)2, Al-doped NiO and Ni-doped γ-Al2O3 by the present PLA process showed a narrower minimum band gap (5.3 eV) than the starting NiAl2O4 powder (5.8 eV) [23]. The band gap lowering can be attributed to the combined effects of internal compressive stress, protonation/hydroxylation and phase change of NiAl2O4 powders. The resultant protonated composite nanoparticles of the NiO–Al2O3 composition system by the clean PLA synthesis in water have beneficial high-specific surface area and modified band gap for potential applications as catalytic support in view of the applications of NiAl2O4 [3, 4], NiO [5] and Al2O3 [6] as catalytic supports.

5 Conclusions

-

1.

NiAl2O4 powders subjected to Q-switched laser pulses in water were fragmented as micron-sized NiAl2+X O4 spinel particles and decomposed as atom clusters for condensation nucleation as Al-doped NiO and Ni-doped γ-Al2O3 nanoparticles in a matrix of precursor hydroxides, i.e., 1D lamellae and β-Ni(OH)2.

-

2.

The NiAl2+X O4 fragments showed dislocations, subgrain boundaries and Al enrichment.

-

3.

The Al-doped NiO and paracrystalline Ni-doped γ-Al2O3 nanoparticles tended to assemble as spherical polycrystals for surface area minimization.

-

4.

The colloidal suspension containing the predominant protonated spinel phases, i.e., NiAl2+X O4 and Ni-doped γ-Al2O3, showed a lower minimum band gap for potential sensor applications, in particular as catalytic support of nickel like the case of stoichiometric NiAl2O4.

References

I. Halevy, D. Dragoi, E. Üstündag, A.F. Yue, E.H. Arredondo, J. Hu, M.S. Somayazulu, J. Phys. Condens. Matter 14, 10511 (2002)

L. Kou, J.R. Selman, J. Appl. Electrochem. 30, 1433 (2000)

A. Al-Ubaid, E.E. Wolf, Appl. Catal. 40, 73 (1988)

Y.P. Cesteros, F. Salagrem, M. Medina, J.E. Sueiras, Chem. Mater. 12, 331 (2000)

A. Villa, G.M. Veith, D. Ferri, A. Weidenkaff, K.A. Perry, S. Campisi, L. Prati, Catal. Sci. Technol. 3, 394 (2013)

G.V. Sagar, P.V. Rao, C.S. Srikanth, K.V. Chary, J. Phys. Chem. B 110, 13881 (2006)

S.R. Wang, P. Shen, J. Solid State Chem. 140, 38 (1998)

S.R. Wang, P. Shen, Mater. Sci. Eng. A 251, 106 (1998)

C.O. Arean, M.P. Mentrait, A.J.L. Lopez, J.B. Parra, Colloids Surf. A Physicochem. Eng. Aspects 180, 253 (2001)

H. Cui, M. Zayat, D. Levy, J. Non-Cryst, Solids 351, 210 (2005)

M.M. Amini, L. Torkian, Mater. Lett. 57, 639 (2002)

P. Jeevanandam, Y. Koltypin, A. Gedanken, Mater. Sci. Eng. B 90, 125 (2002)

H.D. Lu, B.C. Lin, S.Y. Chen, P. Shen, J. Phys. Chem. C 115, 24577 (2011)

P.W. Lin, C.H. Wu, Y. Zheng, S.Y. Chen, P. Shen, J. Phys. Chem. Solids 74, 1281 (2013)

K.A. Carrado, A. Kostapapas, S.L. Suib, Solid State Ion. 26, 77 (1998)

V. Rives, S. Kannan, J. Mater. Chem. 10, 489 (2000)

S. Velu, K. Suzuki, M.P. Kapoor, S. Tomura, F. Ohashi, T. Osaki, Chem. Mater. 12, 719 (2000)

Z.P. Xu, H.C. Zeng, J. Phys. Chem. B 104, 10206 (2000)

F. Cavani, F. Trifiro, A. Vaccari, Catal. Today 11, 173 (1991)

E.D. Rodeghiero, J. Chisaki, E.P. Giannelis, Chem. Mater. 9, 478 (1997)

W.D. Nesse, Introduction to optical mineralogy, 2nd edn. (Oxford University Press, Oxford, 1991)

M.A. Laguna-Bercero, M.L. Sanju′an, R.L. Merino, J. Phys. Condens. Matter 19, 186217 (2007)

Y.T. Chan, MS Thesis, National Sun Yat-sen University, Taiwan, 2013

H.D. Jang, S.K. Friedlander, Aerosol Sci. Technol. 29, 81 (1998)

A. Navrotsky, C. Ma, K. Lilova, N. Birkner, Science 330, 199 (2010)

A. Navrotsky, Geochem. Trans. 4, 34 (2003)

I.L. Liu, P. Shen, S.Y. Chen, J. Nanopart. Res. 12, 2929 (2010)

B. Phillips, J.J. Hutta, I. Warshaw, J. Am. Ceram. Soc. 46, 579 (1963)

C.N. Huang, S.Y. Chen, P. Shen, J. Phys. Chem. C 111, 3322 (2007)

C.H. Chen, C.N. Huang, S.Y. Chen, P. Shen, J. Nanopart. Res. 13, 3683 (2011)

W.H. Lee, P. Shen, J. Solid State Chem. 177, 101 (2004)

M.Y. Li, P. Shen, Mater. Sci. Eng. B 111, 82 (2004)

J.N. Pan, PhD Thesis, National Sun Yat-sen University, Taiwan, 2006

F.A. Kröge, H.J. Vink, Solid State Phys. 3, 307 (1956)

R.D. Shannon, Acta Crystallographica A 32, 751 (1976)

I.L. Liu, P. Shen, S.Y. Chen, J. Phys. Chem. C 114, 7751 (2010)

L. Halevy, D. Dragoi, E. Üstündag, A.F. Yue, J. Phys. Condens. Matter 14, 10511 (2002)

D. Keiji, I. Toshihiro, H. Yasuo, O. Toshitaka, J. Chem. Soc. Jpn. Chem. Ind. Chem. 2, 195 (2002)

E. Üstündag, R. Subramanian, R. Dieckmann, S.L. Sass, Acta Metall. Mater. 43, 383 (1995)

J. Noack, D.X. Hammer, G.D. Noojin, A. Vogel, J. Appl. Phys. 83, 7488 (1998)

J. Noack, A. Vogel, IEEE J. Quantum Electron. 35, 1156 (1999)

A. Vogel, V. Venugopalan, Chem. Rev. 103, 577 (2003)

Acknowledgments

We thank anonymous referee for constructive comments. This research was supported by Center for Nanoscience and Nanotechnology at NSYSU and partly by National Science Council, Taiwan, ROC.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Chan, YT., Wu, CH., Shen, P. et al. Nickel aluminate oxides/hydroxides by pulsed laser ablation of NiAl2O4 powder in water. Appl. Phys. A 116, 1065–1073 (2014). https://doi.org/10.1007/s00339-013-8183-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-013-8183-4