Abstract

We report a method to create gold nanoparticles of different sizes and shapes using agar–agar water solution and irradiation with light from a xenon lamp, followed by ultrashort laser pulses. No additives, such as solvents, surfactants or reducing agents, were used in the procedure. Laser irradiation (laser ablation) was important to the reduction of the nanoparticles diameter and formation of another shapes. Distilled water was used as solvent and agar–agar (hydrophilic colloid extracted from certain seaweeds) was important for the stabilization of gold nanoparticles, avoiding their agglomeration. The formation of gold nanoparticles was confirmed with ultraviolet-visible absorption and TEM microscopy. The gold nanoparticles acquired spherical, prism, and rod shapes depending on the laser parameters. Variation of laser irradiation parameters as pulse energy, irradiation time and repetition rate was assessed. The relevant mechanisms contributing for the gold nanoparticles production are discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Metallic nanoparticles have attracted much attention because of their special properties and potential applications, which are results, mostly, of the high surface area and the Surface Plamon Resonance (SPR) effect (collective oscillation of surface electrons) [1, 2]. An example of metallic nanoparticles are gold nanoparticles, which can be used in bio applications classified into four areas: labeling [3, 4], delivery [5], heating [6] and sensing [7, 8]. Catalysis and ambient pollutant sensing applications are also reported [9].

Gold nanoparticles are produced mainly by chemical processes involving the use of highly toxic chemical polymers (not ecofriendly) [10]. The development of “green” techniques is of the highest importance [11]. Laser photolysis [12] is an alternative to chemical processes for the production of nanoparticles. Yao-Yu Cao et al. [13] have succeeded in fabricating silver structures with sizes smaller than 200 nm by means of a multiphoton-induced reduction technique combined with the inhibition of unwanted metallic particle growth through the use of a surfactant. Zhao et al. [14] attribute the formation of nanoparticles to a multiphoton process of 800 nm fs irradiation light, producing electrons capable of reducing \(\mathrm{AuCl}_{4}^{-}\) to Au0.

Recently, the synthesis of metal nanostructures such as nanosheets [15], nanoprisms [16], nanodisks and nanorings [17–20] also has received considerable attention, due to their unusual optical properties and potential applications.

In this work, a new technique for synthesizing gold nanoparticles is reported which, instead of using toxic chemical polymers, uses agar–agar. It is chemically inert and non-toxic. Agar–agar can be defined as a hydrophilic colloid [21] extracted from certain seaweeds of the Rhodophyceae class. It is used in food additives, as stabilizing agent and as thickener in ice cream and in canned meat. It is insoluble in cold water but soluble in boiling water. It is a mixture of polysaccharides whose basic monomer is galactose. Highly stable silver nanoparticles in agar–agar matrix as inorganic–organic hybrid were described recently in the literature [22, 23].

The purpose of this study was to synthesize gold nanoparticles by photolysis induced by ultrashort laser pulses, using agar–agar as reducer and stabilizer medium. Gold nanoparticles with different shapes (depending on the laser parameters) have been investigated.

2 Materials and methods

All the reagents were of analytical grade. Chloroauric acid (HAuCl4) and commercial agar–agar polysaccharide standard agar–agar (A-7002) were purchased from Sigma-Aldrich.

Agar–agar Gold Nanoparticles (AuNNP) solutions:

30 mg of HAuCl4 were mixed with 150 mg of agar–agar in 100 mL of distilled water at 70 °C. The process was accompanied by vigorous stirring for 5 minutes. This solution was exposed to a xenon lamp (Cermax 300 Watts, not focused and placed at 10 cm from the sample reservoir) for 5 minutes. This process was repeated with 10, 15 and 20 minutes of exposition. After xenon irradiation, the solution exposed to xenon for 10 minutes was irradiated with ultrashort pulses from an amplified Femtopower Compact Pro Ti:Sapphire laser system from Femtolasers. The pulses were centered at 800 nm, with duration of 40 femtoseconds (FWHM) and a variable repetition rate. The laser beam was focused by a 25-mm converging lens inside a 1-cm acrylic cuvette containing the solution (Fig. 1). Nine different irradiations were done; in the first three, the pulse energy was kept constant at 300 μJ, the repetition rate was 1 kHz, and the irradiation times were 5, 10 and 15 minutes. The four remaining solutions were irradiated for 5 minutes each, the pulse energies were 100, 200, 400 and 500 μJ, and the repetition rate was 1.0 kHz. Two other solutions were irradiated for 5 minutes with 300 μJ with different repetition rates, 0.5 and 2.0 kHz.

UV-Vis absorption spectra were measured by a Varian Cary 17D spectrophotometer, using 1-cm quartz cells.

A LEO 906E (Zeiss, Germany) transmission electron microscope (TEM), with images captured by a MegaView III camera and processed by the software ITEM—Universal TEM Imaging Platform (Olympus Soft Imaging Solutions GmbH, Germany) (Instituto Butantã) was used for obtaining micrographies. A drop of gold nanoparticles, dispersed in distilled water, was placed onto a carbon-coated copper grid. The excess liquid was removed using a paper wick and the deposit was dried in air prior to imaging.

3 Results and discussion

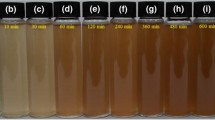

The absorption spectra of the solutions measured after illumination by the xenon lamp for 5, 10, 15 and 20 minutes are shown in Fig. 2. As can be seen in this figure, only the solutions irradiated for 10 and 15 minutes exhibit a large band, ranging from 500 to 700 nm. The solution irradiated for 10 minutes presents an absorbance peak centered at 571 nm, typical of the plasmon resonance in the Au nanoparticles. The location and shape of the plasmon resonance depend generally on the size and shape of the Au nanoparticles, and on their environment [24–26].

After irradiation with xenon lamp, samples were also irradiated with femtosecond laser. Figure 3 compares different laser irradiation energies for a fixed irradiation time of 5 minutes and a constant repetition rate of 1 kHz. We can observe that with 100 μJ of irradiation laser energy, there is an absorption band around 570 nm. Irradiating with 200 μJ, the plasmon resonance shifted to ∼540 nm. With irradiations of 300, 400 and 500 μJ, a blue shift of the first peak occurs indicating in a reduction of particle sizes but a second absorbance band can be observed around 700 nm.

It is known that the spectrum of gold nanospheres (<20 nm in diameter) shows a characteristic strong absorption band at ∼522 nm that is assigned to the dipole resonance of the gold nanospheres. On the other hand, the spectrum of gold nanorods is characterized by two bands; the short wavelength band located at around 522 nm is attributed to the transverse surface plasmon resonance [27], while the band with longer wavelength (700 nm) is attributed to the longitudinal surface plasmon resonance [28]. As the nanoparticle becomes more symmetric, the main resonance tends to be blue shifted. The short wavelength band may have some contribution from the spherical gold nanoparticles present with the nanorods.

To investigate the possibility to obtain a decrease in spherical gold nanoparticles and an increase in nanoprisms quantities, we fixed the laser energy at 300 μJ and changed the repetition rate. The results are shown in Fig. 4. It is possible to observe that the irradiation with 0.5 kHz and 300 μJ induces formation of spherical nanoparticles with similar characteristics as obtained upon irradiation with 1 kHz and 200 μJ (Fig. 3). The increase in the repetition rate resulted in changes in the nanosphere/nanorod formation rate.

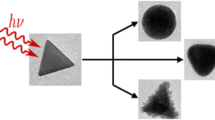

Results obtained by TEM are shown in Fig. 5. In Fig. 5a we see that 10 minutes of Xe illumination is sufficient to induce the formation of not uniform gold nanoparticles. The presence of spherical and symmetric nanoparticles (∼20 nm) is observed in Fig. 5b for a solution illuminated for 10 minutes with a Xe lamp and 5 minutes/200 μJ/1 kHz fs Ti:Sapphire laser pulses. Several nanostructures as prisms, rods and spheres can be observed in Fig. 5c for a solution irradiated for 10 minutes by Xe light and 5 minutes with 300 μJ and 1 kHz fs laser pulses. The sizes of the Au nanoparticles are reduced drastically when solutions were illuminated for 10 minutes by Xe light and 5 minutes with 500 μJ and 1 kHz fs laser pulses, as can be seen in Figs. 5d and 6.

Gold nanostructures visualized by transmission electron microscopy of (a) AuNNP irradiated by 10′ of xenon light (without laser). (b) AuNNP irradiated by 10′ of Xe light and Laser (5′ with 200 μJ and 1 kHz). (c) AuNNP irradiated by 10′ of Xe light and Laser (5′ with 300 μJ and 1 kHz). (d) AuNNP irradiated by 10′ of Xe light and Laser (5′ with 500 μJ and 1 kHz)

Based on the presented results, we understand that the production of metallic nanoparticles in the mixture of HAuCl4 and agar–agar water solution occurs according to the following steps: (1) The illumination with xenon releases electrons from the agar–agar while heating the mixture, freeing \(\mathrm{AuCl}_{4}^{-}\) ions and/or gold atoms; (2) the gold atoms form clusters; (3) due to thermal diffusion, the clusters aggregate to form polycrystals; (4) the galactose in agar–agar encapsulates the gold nanoparticles, preventing aggregation. This process leads to the production of nanoparticles with sizes between 5 and 20 nm.

Laser induces fusion and fragmentation processes [29, 30]. The materials ejected from the particles by the laser are composed by ions, atoms, and nanoparticles of different sizes, depending on the laser pulse energy. At the lowest pulse energies (<200 μJ), particles with sizes <20 nm were formed. With higher laser energy (>300 μJ), thermal electron diffusion produces stronger interaction, particles agglomeration and crystal growing. Actually the higher number of incident photons is expected to generate smaller species, thus creating a greater number of gold seeds that facilitate the ripening of particles, increasing particle size. At energies higher than 500 μJ multiphoton processes seem to be even more important and a drastic reduction in the particle sizes was observed.

4 Conclusions

This paper describes the study of gold nanoparticles of different sizes and shapes using agar–agar water solution and irradiation with light from a xenon lamp, followed by ultrashort laser pulses. Gold nanoparticles with different shapes depending on the laser parameters have been investigated. We have found that spherical and symmetrical nanoparticles (∼20 nm) can be obtained adjusting the laser parameters in 200 μJ and 1 kHz or 300 μJ and 0.5 kHz. With higher laser energy (>300 μJ and 1 kHz), thermal electron diffusion produces stronger interaction, causing particles agglomeration and an increase in the sizes of particles and production of nanoprisms, nanorods and nanospheres. At energies higher than 500 μJ multiphoton processes seem to be even more important and a drastic reduction in the particle sizes was observed.

The use of a non toxic and natural polymer agar–agar and substitution of solvents by water and reducing agents by light makes this procedure important from the point of the view of green chemistry.

References

C. Buzea, I.I. Pacheco, K. Robbie, Biointerphases 2, 17 (2007)

K.L. Kelly, E. Coronado, L.L. Zhao, G.C. Schatz, J. Phys. Chem. B 107, 668 (2003)

C.I. Brady, N.H. Mack, L.O. Brown, S.K. Doorn, Anal. Chem. 81, 7181 (2009)

S. Schlucker, ChemPhysChem 10, 1344 (2009)

L.C. Kennedy, A.S. Bear, J.K. Young, N.A. Lewinski, J. Kim, A.E. Foster, R.A. Drezek, Nanoscale Research Letters 6 (2011)

B. Van de Broek, N. Devoogdt, A. D’Hollander, H.-L. Gijs, K. Jans, L. Lagae, S. Muyldermans, G. Maes, G. Borghs, ACS Nano 5, 4319 (2011)

V.K. Khanna, Def. Sci. J. 58, 608 (2008)

Y.W.C. Cao, R.C. Jin, C.A. Mirkin, Science 297, 1536 (2002)

A. Fan, Y. Ling, C. Lau, J. Lu, Talanta 82, 687 (2010)

S.A. Vorobyova, A.I. Lesnikovich, N.S. Sobal, Colloids Surf., A, Physicochem. Eng. Asp. 152, 375 (1999)

V.K. Sharma, R.A. Yngard, Y. Lin, Adv. Colloid Interface Sci. 145, 83 (2009)

A. Pyatenko, M. Yamaguchi, M. Suzuki, J. Phys. Chem. B 109, 21608 (2005)

Y.-Y. Cao, N. Takeyasu, T. Tanaka, X.-M. Duan, S. Kawata, Small 5, 1144 (2009)

C.J. Zhao, S.L. Qu, J.R. Qiu, C.S. Zhu, J. Mater. Res. 18, 1710 (2003)

D.W. Wei, W.P. Qian, Y. Shi, S.H. Ding, Y. Xia, Carbohydr. Res. 342, 2494 (2007)

R.C. Jin, Y.W. Cao, C.A. Mirkin, K.L. Kelly, G.C. Schatz, J.G. Zheng, Science 294, 1901 (2001)

J. Aizpurua, L. Blanco, P. Hanarp, D.S. Sutherland, M. Kall, G.W. Bryant, F.J.G. de Abajo, J. Quant. Spectrosc. Radiat. Transf. 89, 11 (2004)

L.P. Jiang, S. Xu, J.M. Zhu, J.R. Zhang, J.J. Zhu, H.Y. Chen, Inorg. Chem. 43, 5877 (2004)

E.M. Larsson, J. Alegret, M. Kall, D.S. Sutherland, Nano Lett. 7, 1256 (2007)

Y.G. Sun, Y.N. Xia, Adv. Mater. 15, 695 (2003)

E. Gomez-Ordonez, P. Ruperez, Food Hydrocoll. 25, 1514 (2011)

S. Ghosh, R. Kaushik, K. Nagalakshmi, S.L. Hoti, G.A. Menezes, B.N. Harish, H.N. Vasan, Carbohydr. Res. 345, 2220 (2010)

E. Muthuswamy, S.S. Ramadevi, H.N. Vasan, C. Garcia, L. Noe, M. Verelst, J. Nanopart. Res. 9, 561 (2007)

I.O. Sosa, C. Noguez, R.G. Barrera, J. Phys. Chem. B 107, 6269 (2003)

A.L. Gonzalez, C. Noguez, J. Comput. Theor. Nanosci. 4, 231 (2007)

C. Noguez, J. Phys. Chem. C 111, 3806 (2007)

J. Zhu, F.K. Li, Eur. Phys. J. B 80, 83 (2011)

I. Mannelli, M.P. Marco, Anal. Bioanal. Chem. 398, 2451 (2010)

T. Hirakawa, P.V. Kamat, J. Am. Chem. Soc. 127, 3928 (2005)

H. Fujiwara, K. Sasaki, J. Appl. Phys. 86, 2385 (1999)

Acknowledgements

The authors would like to thank Nildemar Aparecido M. Ferreira and Sylvia Carneiro for the electron microscope analysis, and CNPq for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Almeida de Matos, R., da Silva Cordeiro, T., Elgul Samad, R. et al. Green synthesis of gold nanoparticles of different sizes and shapes using agar–agar water solution and femtosecond pulse laser irradiation. Appl. Phys. A 109, 737–741 (2012). https://doi.org/10.1007/s00339-012-7108-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-012-7108-y