Abstract

Three Phanerochaete chrysosporium endo-1,4-β-xylanase genes were cloned and expressed in Aspergillus niger. Two of these genes, xynA and xynC, encode family 10 glycoside hydrolases, while the third, xynB, codes for a family 11 glycoside hydrolase. All three xylanases possess a type I carbohydrate-binding domain connected to the catalytic domain by a linker region. The three xylanases were purified to homogeneity by weak anion or Avicell column chromatography and subsequently characterized. The XynA, XynB and XynC enzymes have molecular masses of 52, 30 and 50 kDa, respectively. Optimal activity was obtained at pH 4.5 and 70°C with the family 10 xylanases and pH 4.5 and 60°C with the family 11 xylanase. The measured Km when using birchwood xylan as the substrate was 3.71±0.69 mg/ml for XynA and XynC and was 9.96±1.45 mg/ml for XynB. Substrate specificity studies and the products released during the degradation of birchwood xylan suggest differences in catalytic properties between the two family 10 xylanases and the family 11 xylanase.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The white rot resupinate or crust fungus Phanerochaete chrysosporium is a filamentous basidiomycete adept at the degradation of complex woody materials (Burdsall 1969). Although its lignin (Reid and Seifert 1980) and polysaccharide (Castanares 1995) hydrolyzing capabilities have been described, the purification and characterization of individual enzymes can be complicated by the presence of several enzymes with similar activities. As a result, it is often advantageous to clone and express genes coding for individual hydrolytic enzymes in a heterologous host. Using this approach, several P. chrysosporium extracellular enzymes were characterized following expression in insect cells (Johnson and Li 1991), Escherichia coli (Whitwam et al. 1995) and Pichia pastoris (Yoshida et al. 2001). However, most of the extracellular polysaccharide-degrading enzymes have yet to be characterized.

Xylans are the major hemicellulose component of wood and can constitute as much as 35% of the total dry weight of some plants. In hardwoods O-acetyl-4-O-methylglucuronoxylan is the main xylan, while in softwoods it is arabino-4-O-methylglucuronoxylan (Jacobs et al. 2001). Hardwood xylan is a complex polysaccharide with a backbone of 70–200 1,4-linked xylose residues, with 4-O methylglucoronoic acid side-chains attached to the 2 position of every 15th backbone xylose (Teleman et al. 2002). Hardwood xylans are also highly acetylated, with a ratio of about one acetyl group (mainly C-3 or C-2 position) for every two xyloses residues. Softwood xylans differ from hardwood xylans in that they have a higher content of backbone-linked 4-O-methylglucoronic acid, they are not acetylated and they have α-l-arabinofuranose units linked by α-1,3-glycosidic bonds to the C-3 position of about 12% of the backbone residues (Jacobs et al. 2001). Hydrolysis of the birchwood xylan backbone requires mainly endo-1,4-β-xylanase (EC 3.2.1.8), which catalyzes the random endohydrolysis of 1,4-β-d-xylosidic linkages, yielding xylooligosaccharides (Kulkarni et al. 1999) and exo-1,4-β-xylosidase (EC 3.2.1.37), which attacks the reducing-sugar end of the xylan polymer and xylooligosaccharides to release monomeric xylose residues (Saha 2001).

Endo-1,4-β-xylanases are found in bacteria (Panbangred et al. 1983), fungi (Kanda et al. 1985) and plants (Wu et al. 2002). The amino acid sequence has been deduced for many probable xylanases by the analysis of genomic and cDNA sequence data. Amino acid sequence comparisons of several endo-1,4-β-xylanases place most of them into families 10 and 11 of the glycosyl hydrolases (Henrissat 1991; Henrissat and Bairoch 1993, 1996). Family 10 xylanases are reported to produce smaller oligosaccharides and family 11 xylanases to be more specific. The 3-D structures of several family 10 and 11 xylanases have been resolved by crystallography (Krengel and Dijkstra 1996; Schmidt et al. 1998). The family 10 xylanases have eight-fold α/β-barrel structures whereas the family 11 xylanases consist mainly of two β-sheets forming a large pocket where the catalytic site is located. Despite their differences in structure, both family 10 and 11 members use a retaining mechanism. In addition to their catalytic domains, xylanases can include a glycosylated linker region, carbohydrate-binding domains and in rare cases acetylase domains (Kosugi et al. 2002).

This study describes the cloning and heterologous expression of three endo-1,4-β-xylanase genes from Phanerochaete chrysosporium. Each gene encodes a modular xylanase with a type I or fungal carbohydrate-binding domain (fCBD) that is separated from the catalytic domain by a low-complexity linker region. Xylanases A and C, sharing an 88% identity at the amino acid level, belong to the glycosyl hydrolase (G-H) family 10, while XynB belongs to G-H family-11. We also report the biochemical properties of these three xylanases.

Materials and methods

Strains and plasmids

Strain RP78 of P. chrysosporium, provided by Dr. Cullen of the Forest Product Laboratory (Madison, Wis.), was used as the source of genomic DNA for the amplification of endo-1,4-β-d-xylanase genes. Aspergillus niger strain N593 (cspA1, pyrG6), provided by C.J. Bos, was used as the host for heterologous protein expression. E. coli strain DH5-α was used as the host for the construction and propagation of recombinant plasmids. ANEp2, an autonomously replicating plasmid (Rosa Zito, Concordia University, Montreal) was used as the expression vector for the production of xylanases of P. chrysosporium in A. niger.

Bioinformatics analysis and predictions

We used the Blast algorithm to find the sequence of three putative xylanase genes in the genome sequence of P. chrysosporium (Joint Genome Institute, http://www.jgi.doe.gov/programs/whiterot/whiterot_mainpage.html). The A. niger endo-1,4-xylanase (accession number AF490982) gene sequence was used to find xynB, whereas xynA and xynC were found by searching with the A. oryzae endo-1,4-xylanase F3 entry (accession number JC7813). The signal peptide of each xylanase was identified using the SignalP server (http://www.cbs.dtu.dk/services/SignalP/; Nielsen et al. 1997) and the determination of conserved protein domains was performed using the NCBI CDART (Conserved domain architecture retrieval tool; http://www.ncbi.nlm.nih.gov/Structure/lexington/lexington.cgi?cmd=rpsand) and EXPAZY ScanProsite (http://us.expasy.org/tools/scanprosite/) websites (Appel et al. 1994). The pI of the proteins and potential N-glycosylation sites were identified using the PepTool software. Potential O-glycosylation sites were identified using the YinOYang site (http://www.cbs.dtu.dk/services/YinOYang). Finally, the predicted 3-D structures were generated using the Swiss-model program (http://us.expasy.org/sw3d/; Peitsch 1995; Guex and Peitsch 1997; Schwede et al. 2003).

Cloning

Three pairs of primers, complementary to the beginning and the end of the coding sequence of three P. chrysosporium xylanase genes were used to amplify genomic DNA. To facilitate cloning the PCR products into expression vector ANEp2, each forward primer contained a NheI restriction site and each reverse primer a FseI restriction site (xynA forward 5′-CCTAGCTAGCATCATGAAGCTCTCAGCCTCCTTCG-3′, reverse 5′-TCTTAGGCCGGCCCTAATTGCCGAAGCCAATAGCG-3′; xynB forward 5′-CCTAGCTAGCATCATGGTCAGCTTCAACTCCCTCC-3′, reverse 5′-TCTTAGGCCGGCCTTAGAGGCACTGGGAGTACCAG-3′; xynC forward 5′-CCTAGCTAGCATCATGTTCAAGTTCTCCGCGTCC-3′, reverse 5′-TCTTAGGCCGGCCTCATGCGCTGAAGCCAGCG-3′). The resulting PCR products and ANEp2, after digestion with FseI and NheI and dephosphorylation of the ANEp2 backbone, were ligated and transformed into E. coli. Transformed DH5α cells were selected on LB+Amp plates and three independent plasmid constructs harboring each xylanase gene were identified by restriction analysis and designated as ANEp2-xynA-1, ANEp2-xynA-2, ANEp2-xynA-3, ANEp2-xynB-1, ANEp2-xynB-2, ANEp2-xynB-3, ANEp2-xynC-1, ANEp2-xynC-2 and ANEp2-xynC-3.

Protoplasting, transformation and culturing of A. niger

A. niger protoplasts were prepared as described by Debets and Bos (1986) and transformations were performed as described by Wernars et al. (1987). Liquid cultures of A. niger were inoculated by transferring a piece of agar, which contained mycelia of the A. niger transformant of interest, from minimal medium (MM) agar plates (Käfer 1977) into a 2-l Nalgene Erlenmayer flask containing 250 ml of liquid MM with 15% (w/v) maltose as the carbon source. Both solid support and liquid cultures of A. niger were grown at 30°C. Liquid cultures were maintained at 150 rpm in a rotary shaker.

Production and purification of enzymes

The cloned xylanase genes were expressed in A. niger strain N593. After growth in liquid medium for 2 days, cultures were filtered through Miracloth to remove the mycelia and the xylanases were purified from the media as follows. The proteins were concentrated and partially purified from 250 ml of filtered media by ammonium sulfate precipitation (60% for XynA/XynC, 80% for XynB). The precipitated proteins were then resuspended in 10 ml of sodium acetate (50 mM, pH 6) or with the buffer required for the next purification step and dialyzed overnight against the same buffer at 4°C. For XynA and XynB, the dialyzed samples were purified by affinity chromatography, using Avicell as the matrix. Proteins were loaded onto the affinity column (1.5 ml bed vol.), previously equilibrated with Tris-HCl (20 mM, pH 7.5) and NaCl (4 M). After loading the proteins, the column was washed with 5 bed vol. of the equilibration buffer and 5 vol. of Tris-HCl (20 mM, pH 7.5). Bound xylanases were eluted from the column using 5 column vol. of 100% ethylene glycol (Carrard et al. 2000). Fractions containing the peak of xylanase activity were pooled and dialyzed against sodium acetate (50 mM, pH 6).

For XynC, which was purified first, a different method was used. After 60% ammonium sulfate precipitation, the precipitate was dissolved in Tris-HCl (20 mM, pH 8). The redissolved precipitate was then heated at 57°C for 30 min, followed by centrifugation at 10,000 g for 30 min at 4°C. The supernatant was loaded onto a weak anion exchange column (DEAE), previously equilibrated with Tris-HCl (20 mM, pH 8). Proteins were eluted from the column with a linear gradient of 0–0.4 M NaCl at a flow rate of 0.75 ml/min. Fractions containing the highest xylanase activity were pooled and dialyzed against sodium acetate (50 mM, pH 6). Electrophoresis was performed on 10% SDS-PAGE gels. Proteins were visualized either by Coomassie R250 staining or silver staining (Biorad).

Enzyme assays

Xylanase activity was assayed by measuring the production of reducing-sugar ends from birchwood xylan (Sigma) with 3,5-dinitrosalicylic acid (DNSA) reagent. Samples (50 μl) of crude or purified xylanases in sodium acetate (50 mM, pH 6) were incubated with 50 μl of 1% (w/v) birchwood xylan (Sigma) in the same buffer at 60°C. After 10 min, 50 μl of DNSA reagent were added and the samples were boiled for 10 min. Reducing sugar production was followed by measuring the absorbance at 540 nm (Sengupta et al. 2000). Using a standard curve generated with d-xylose, absorbance was converted into moles of reducing sugars produced. One unit of enzyme activity was defined as 1 μmol/min of xylose released at 60°C.

To determine the optimum pH for each xylanase, assays were performed as described above, except that sodium phosphate and citric acid buffers were used to generate a pH range of pH 3–8 (XynA/XynC assays were done at 70°C, XynB assays at 60°C). The effect of pH on enzyme stability was determined using the same buffer system that was used to determine the pH optimum. However, the enzymes were incubated for 2 h at 30°C before activity was assayed at pH 4.5. Xylanase temperature optima were determined by assaying the amount of reducing-sugar ends produced at pH 4.5. The effect of temperature on enzyme stability was determined by incubating the enzymes for 30 min at different temperatures prior to performing the enzyme assay as described above. Kinetic studies were performed at the pH and temperature optima for each xylanase using birchwood xylan (1–10 mg/ml), for which enzyme reactions followed Michaëlis–Menten kinetics. Km was determined using Lineweaver–Burk plots.

Substrate specificity and heavy metal inhibitors

The substrate specificity of the three xylanases was tested using three natural substrates (birchwood xylan, oatspelt xylan, beechwood xylan; Sigma) and three synthetic substrates [carboxymethyl cellulose (CMC), p-nitrophenyl-β-d-xylopyranoside (pNPX2; Sigma), p-nitrophenyl-β-d-cellobioside (pNPC2; Sigma)]. Enzyme assays using the natural substrates and CMC were performed as described above. Enzyme assays using pNPC2 and pNPX2 were performed as follows. Enzymes were incubated with substrates at a final concentration of 2 mg/ml in a total volume of 100 μl in Na acetate, 50 mM, pH 4.5. The reactions were stopped with 900 μl of Na2CO3 (0.1 M) and the absorbance was measured at 410 nm. One unit was defined as 1 μmol/min of pNP released at 60°C. The inhibitory effect of Cu2+, Zn2+, Mg2+, Hg2+ and Pb2+ on enzyme activity was tested by including each heavy metal (2 mM) in assays performed as described above.

Analysis of xylan and xylooligosaccharide degradation products by thin layer chromatography

The hydrolysis of birchwood, beechwood, oatspelt xylan (Sigma), xylopentaose, xylotetraose, xylotriose and xylobiose (Megazyme) was carried out in reaction volumes of 100 μl. Each xylanase (6 units/ml) was added to a 1% solution of each substrate and incubated at 37°C. Samples (10–15 μl) of each reaction mixture were analyzed by silica gel thin layer chromatography (TLC), using chloroform/acetic acid/H2O (6:7:1, by vol.) as the solvent system. Reaction products were visualized by spraying a sulfuric acid/ethanol (5:95, v/v) solution on the plate followed by baking at 110°C for 10 min (Blanco et al. 1999).

Results

Sequence analysis of the three xylanases

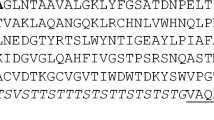

We searched the publicly available P. chrysosporium genome sequence using tblastn to identify potential xylanase genes and selected three gene sequences, xynA, xynB and xynC. First, we analyzed the deduced amino acid sequences of their proteins using CDART and Scanprosite. CDART detected a G-H family 10 domain in both XynA and XynC (Fig. 1a), a G-H family 11 domain in XynB (Fig. 1b) and a fCBD in all three proteins (Fig. 1c). The predicted fCBDs were very similar and typical of previously described fCBDs (Fig. 1c). These are small domains of 33–40 contiguous amino acids arranged in three antiparallel β-strands that bind cellulose. fCBDs are believed to act by increasing the concentration of enzymes on the substrate without affecting the catalytic properties. The carbohydrate-binding and catalytic domains in each xylanase were separated by a short (40–50 residues) low-complexity region rich in serine, threonine and proline (Fig. 1a,b). These linker regions are believed to provide flexibility (Black et al. 1996), thereby allowing the fCBD and catalytic domain to simultaneously interact with cellulose and the substrate, respectively. Scanprosite detected a conserved active site motif typical of family 10 glycosyl hydrolases in both XynA and XynC (Fig. 1a) and the bipartite active site signature typical of family 11 hydrolases in XynB (Fig. 1b).

Sequence alignments. a Alignment of P. chrysosporium XynA and XynC with family 10 xylanases, XlnA from Agaricus bisporus (CAB05665), XynA from Aspergilus niger (JT0608) and XynA from Thermoascus aurantiacus (AAF24127). b Alignment of P. chrysosporium XynB with family 11 xylanases, Xynp1 from Penicillium sp. (JC7307), Xyn11a from Lentinula edodes (AAL04152) and XynA from Bacillus subtilis (CAA84276). c Alignment of predicted fCBDs from Phanerochaete chrysosporium XynA, XynB and XynC with other type I CBDs, Cip2 from Trichoderma reesei (AAP57749), CBHII from T. reesei (AAG39980) and CBH from Agaricus bisporus (P49075). For a and b, conserved active site motifs and fCBDs are enclosed in solid boxes and dashed boxes, respectively. Low-complexity linker regions are indicated by horizontal arrows and active site glutamates by vertical arrows. Catalytic domains identified by CDART extend over residues 102–411 for XynA and residues 42–227 for XynB

Alignments of the deduced xylanase sequences with other family 10 and 11 xylanases (Fig. 1a,b) found that 105 of the 309 residues within the conserved catalytic domains of the five family 10 member proteins and 62 of the 185 catalytic domain residues of the family 11 xylanases were strictly conserved (Fig. 1a,b). SignalP predicted that XynA, XynC and XynB were translated as preproteins that contain 19-, 20- and 19-residue signal peptides. Without any post-translational modifications, except for cleavage of the signal peptide, the predicted molecular weights were 41.6, 28.6 and 40.3 kDa for XynA, XynB and XynC, respectively. The predicted pIs were 5.8 for XynA, 6.0 for XynB and 5.5 for XynC.

The 3-D structures of the catalytic domains of the three xylanases were generated using template structures available from the Protein data bank (Berman et al. 2000). Five templates (1goqA, 1gokA, 1gooA, 1gomA, 1gorA) derived for the Thermoascus aurantiacus xylanase TaXynA were used to generate the XynA and XynC structures (Fig. 2a). TaXynA shares 50% sequence identity with both XynA and XynC. The predicted structures of the catalytic domains of both enzymes were eight-fold α/β-barrel structures typical of family 10 xylanases (Davies and Henrissat 1995). The 3-D structure of XynB (Fig. 2b) was generated using five templates (1redA, 1reeA, 1redB, 1enxB, 1reeB) derived from the Trichoderma reesei Xyn2 protein, which shares 64.5% sequence identity with the XynB catalytic domain. The predicted XynB catalytic domain is typical of family 11 structures, which are principally composed of β-sheets (Davies and Henrissat 1995). Furthermore, the modeled catalytic domain of XynB included a substrate-binding site that was significantly more accessible than the substrate-binding sites of the two family 10 xylanases.

Predicted ribbon structures of a XynC and b XynB catalytic domains. Flat and coiled ribbon structures represent β-strand and α-helix structures. The two catalytic glutamates (presented in stick format), at 118 and 204 for XynB and at 313 and 318 for XynC, are located within the predicted active site. The scale (bottom left) represents 5 Å. A model generated for the XynA catalytic domain (not shown) is essentially identical to XynC

Cloning and testing for functional expression

The XynA, XynB and XynC DNAs obtained by PCR amplification of P. chrysosporium genomic DNA were estimated to be 1,500, 950 and 1,500 bp, respectively (data not shown). These sizes were very close to the expected sizes (1,524, 960, 1,501 bp), based on the sequenced P. chrysosporium genome. Three independent ANEp2 constructs harboring each xylanase gene were used to transform Aspergillus niger strain N593 and two independent A. niger transformants were assayed for xylanase expression. All six transformants harboring the same xylanase gene expressed similar levels of secreted xylanase (Table 1), suggesting that the various manipulations had not introduced mutations that deleteriously affected either expression or enzymatic activity. One transformant from each of the expressed xylanases was selected for detailed characterization.

Xylanase expression and purification

The three A. niger transformants (N593-ANEp2-xynA-1, N593-ANEp2-xynB-1, N593-ANEp2-xynC-1) were grown in MM medium with maltose as the carbon source. After 48 h, the medium was harvested and dialyzed as described in the Materials and methods. The secreted proteins produced by the three strains were assayed for xylanase activity. No xylanase activity was detected in the culture medium of the control strain N593-ANEp2, whereas significant activity was expressed by the three other strains (data not shown). The amount of XynB activity expressed was about 4.5-fold higher than the amount of activity expressed by the XynA and XynC transformants.

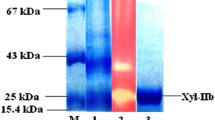

Since all the three xylanases apparently harbored fCBDs, we used Avicell chromatography as a second step for XynA and XynB purification. After Avicell chromatography, the xylanases were obtained as pure proteins with estimated masses of 52 kDa for XynA and 32 kDa for XynB (Fig. 3a,b). This second purification step confirmed that both xylanases harbored functional fCBDs. XynC was purified using another method and its mass was estimated to be 50 kDa (Fig. 3c).The experimentally determined molecular masses were significantly greater than the predicted masses of 41.6, 28.6 and 40.3 kDa. Differences between the predicted and determined masses can be explained by post-translational modifications such as glycosylation. Supporting this possibility, several potential O-glycosylation sites were located in the linker regions of all three xylanases. There is also one potential N-glycosylation site near the N-terminal end of XynB.

Purification of XynA, XynB and XynC. a SDS-PAGE analysis of XynA extracts following 60% ammonium sulfate precipitation (lane 1) and Avicell chromatography (lane 2). b SDS-PAGE analysis of XynB extracts following 80% ammonium sulfate precipitation (lane 1) and Avicell chromatography (lane 2). c Analysis of fractions obtained following the DEAE step of XynC purification. SDS-PAGE was performed on fractions 10–16 (upper panel) and xylanase activity was determined by DNSA assays on fractions 11–15 (lower panel). act. Enzyme activity

To confirm that the purified proteins were indeed XynA, XynB and XynC, we performed matrix-assisted laser desorption/ionization mass spectrometry. The three purified xylanases were subjected to SDS-PAGE and digested by trypsin; and peptide mapping of these fragments performed by mass spectrometry confirmed the identity of the purified proteins (data not shown).

Characterization of XynA, XynC and XynB

Purified preparations of the three xylanases were also used to determine their biochemical properties. The two family 10 xylanases exhibited very similar biochemical properties. The Km values of XynA and XynC, 3.42±0.69 mg/ml and 3.71±0.69 mg/ml, respectively, were not significantly different. Both family 10 xylanases exhibited maximal activity at 70°C and pH 4.5 (Fig. 4a,b). Neither XynA nor XynC lost significant activity during pre-incubation for 30 min at 60°C, but both were completely inactivated by pre-incubation at 70°C (Fig. 4c). pH stability assays found no significant loss of activity for XynA during 2-h pretreatments ranging from pH 3 to pH 8 (date not shown). Substrate specificity assays found that XynA and XynC hydrolyzed oatspelt xylan slightly better than beechwood or birchwood. Both XynA and XynC were able to weakly hydrolyze the synthetic substrates pNPX2 and pNPC2, but did not hydrolyze CMC (Fig. 4d). Activity assays performed in the presence of different heavy metals found that only Pb2+ and Hg2+ inhibited XynA and XynC at the concentration tested. Pb2+ (2 mM) acted as a weak inhibitor of XynA and XynC, since they retained about 70% of their activity when assayed in its presence. The presence of 2 mM Hg2+ strongly inhibited both XynA and XynC, reducing their activity by about 80%.

Biochemical characterization of XynA, XynB and XynC. a Effect of temperature on xylanase activity. b Effect of pH on activity. c Effect of preincubation for 30 min at the indicated temperatures on activity. For a-c, triangles represent XynA, circles XynB and squares XynC. d Relative activity of each xylanase toward various substrates where activities on oatspelt xylan represent 100%. Oatspelt, beechwood and birchwood xylan are indicated as Oat, Bee and Bir, respectively

The biochemical properties of the family 11 xylanase, XynB, were also determined. Its Km was 9.96±1.45 mg/ml when birchwood xylan was used as substrate. XynB exhibited maximal activity at 60°C and pH 4.5 (Fig. 4a,b). Thermostability assays found XynB was stable at 50°C but unstable at 70°C for the same incubation time (Fig. 4c). No significant loss of activity was observed after 2 h of incubation at pH 3–8 (data not shown). XynB exhibited a higher activity on oatspelt xylan than on beechwood and birchwood xylans and no activity was detected with the polysaccharide CMC or the synthetic substrates pNPX2 and pNPC2 (Fig. 4d). Both Pb2+ and Hg2+ acted as weak inhibitors, since XynB retained about 80% of its activity in the presence of Pb2+ and 67% of its activity when assayed in the presence of Hg2+.

Ability of the three xylanases to hydrolyze xylose polymers

XynA and XynC exhibited essentially identical enzymatic characteristics with regard to their abilities to degrade the various xylose polymers. Therefore, we present the results for only one G-H family 10 xylanase in each panel of Fig. 5. The family 10 xylanases degraded small but detectable amounts of xylotriose, but neither xylobiose nor xylotriose was efficiently degraded. Both family 10 xylanases degraded xylotetraose, producing mainly xylobiose. Of the xylooligosaccharides tested, the most efficiently hydrolyzed was xylopentaose. It was converted mainly to xylobiose and xylotriose, although a majority of xylopentaose was converted to xylobiose. Birchwood xylan hydrolysis by the family 10 members gave products which showed chromatographic mobility similar to xylobiose, xylotriose, xylotetraose and xylopentaose. However, two major products accumulated after incubation for 24 h. These migrated with a mobility similar to xylobiose and xylotetraose (Fig. 5b), suggesting these were the major end-products. Products released during the hydrolysis of two other xylans were not significantly different than those produced from birchwood xylan (Fig. 5b).

TLC analyses of reaction products. a (Left panel) Products released during 16 h of incubation of xylobiose (X2), xylotriose (X3) and xylopentaose (X5) with XynA and XynB. (Right panel) Products released from xylotetraose (X4) following incubation with XynB and XynC. b (Left panel) XynA and XynB were incubated with 1% birchwood xylan for the time indicated. (Right panel) Products released from birchwood, beechwood and oatspelt xylan incubated for 24 h with XynB and XynC. The standards used were xylose (X1), X2, X3, X4 and X5

XynB did not hydrolyze xylobiose or xylotriose under the assay conditions tested. The family 11 xylansae did convert xylotetraose into xylobiose and xylotriose and converted xylopentaose mainly into xylobiose and a small amount of xylotriose (Fig. 5a). Weak polymerase activity resulting in the production of xylose polymers with degrees of polymerization of >3 and >4 were detected when xylotriose and xylotetraose were the substrates. Degradation of birchwood xylan by XynB produced results significantly different than those obtained with the family 10 xylanases (Fig. 5b). The four principal products detected at intermediate times during hydrolysis showed chromatographic mobility similar to xylobiose, xylotriose, xylopentaose and a xylooligosaccharide with a degree of polymerization of >5. However, after 24 h of hydrolysis, the two major products that remained showed mobility similar to xylobiose and xylopentaose. Degradation products from beechwood and oatspelt xylan were not significantly different that those produced from birchwood xylan (Fig. 5b).

Discussion

The white rot fungus P. chrysosporium is a promising organism for the investigation of degrading enzymes suitable for applications in the pulp and paper industry. In this work, three xylanases from P. chrysosporium were identified, cloned, functionally expressed and characterized.

Analysis of the amino acid sequences of the three xylanases indicated that XynA and XynC belong to G-H family 10 and that XynB belongs to G-H family 11. The experimentally determined molecular masses of the family 10 xylanases were significantly greater than the mass of the family 11 xylanase. This difference in size between family 10 and family 11 members has already been reported and xylanases from family 10 are usually described as high molecular weight acidic proteins, in contrast to the smaller molecular weight and more basic family 11 xylanases (Jeffries 1996). Family 11 xylanases are therefore referred to as low molecular weight basic proteins. However, the predicted pI of XynB is relatively acidic (pI=6). Similarly low pIs have also been found for other fungal xylanases belonging to family 11 (Lin et al. 1999).

XynB exhibited greater substrate specificity than did the two G-H family 10 xylanases. Of the various substrates tested, XynB only hydrolyzed xylan and xylose polymers whereas XynA and XynC also showed activity toward pNPC2 and pNPX2. These findings are similar to those previously reported by Biely et al. 1997 who suggest that family 10 xylanases have greater catalytic versatility because their substrate-binding sites have fewer and more tolerant sub-sites than are present in the binding sites of family-11 xylanases. They also suggest that family 11 xylanases should be considered the “true” xylanases, because of their higher substrate specificity.

Another significant difference was highlighted by the products resulting from the extensive hydrolysis of birchwood xylan. XynA and XynC gave mainly products with mobility similar to xylobiose and xylotetraose, whereas XynB released mainly products with mobility similar to xylobiose and xylopentaose. Interestingly, both family 10 xylanases were able to degrade xylotretraose and XynB efficiently degraded xylopentaose. These apparently contradictory results suggest that the xylan products with chromatographic mobility similar to xylotetraose and xylopentaose are aldotetrauronic acid and aldopentauronic acid, two products of xylan degradation inefficiently cleaved by family 10 and family 11 xylanases, respectively (Bennett et al. 1998). This possibility is further supported by our results showing that, even in combination, XynB and XynC could not effectively hydrolyze these two xylan products (Fig. 5b).

At the substrate and enzyme concentrations used (Fig. 5a), the three P. chrysosporium xylanases hydrolyzed xylopentaose and xylotetraose significantly more effectively than either xylobiose or xylotriose. Xylopentaose was converted mainly into xylobiose by all three P. chrysosporiusm xylanases. All three xylanases apparently catalyze transglycosylation reactions that converted xylotriose into longer polymers that can be subsequently cleaved to yield xylobiose. This possibility was further supported by the production of xylooligosaccharides with degrees of polymerization of >4 when xylotetraose was the substrate (Fig. 5a) and the conversion of xylotriose into xylobiose when we used higher enzyme concentrations (data not shown). Our results suggesting that hydrolysis of xylopentaose, xylotetraose and xylotriose involved transglycosylation reactions support previous findings with a Thermomyces lanuginosus xylanase (Bennett et al. 1998), a Cryptococcus albidus xylanase (Biely et al. 1981) and an A. niger xylanase (Vrsanska et al. 1982).

The three P. chrysosporium xylanases possess several characteristics that are attractive for applications in pulping and papermaking. These characteristics include resistance to high temperatures, stability over a large pH range (3–8), optimum temperatures of 70°C for XynC and XynA and 60°C for XynB and an inability to degrade CMC. As suggested previously for other family 11 xylanases (Clarke et al. 1997), the relative size and higher substrate specificity of XynB suggests that it would be the best candidate of these three xylanases for use in biobleaching. Studies presently underway are testing the suitability of XynB as a biobleaching agent.

References

Appel RD, Bairoch A, Hochstrasser DF (1994) A new generation of information retrieval tools for biologists: the example of the ExPASy WWW server. Trends Biochem Sci 19:258–260

Bennett NA, Ryan J, Biely P, Vrsanska M, Kremnicky L, Macris BJ, Kekos D, Christakopoulos P, Katapodis P, Claeyssens M, Nerinckx W, Ntauma P, Bhat MK (1998) Biochemical and catalytic properties of an endoxylanase purified from the culture filtrate of Thermomyces lanuginosus ATCC 46882. Carbohydr Res 306:445–455

Berman HM, Westbrook J, Feng Z, Gilliland G, Bhat TN, Weissig H, Shindyalov IN, Bourne PE (2000) The protein data bank. Nucleic Acids Res 28:235–242

Biely P, Kratky Z, Vrsanska M (1981) Substrate-binding site of endo-1,4-beta-xylanase of the yeast Cryptococcus albidus. Eur J Biochem 119:559–564

Biely P, Vrsanska M, Tenkanen M, Kluepfel D (1997) Endo-beta-1,4-xylanase families: differences in catalytic properties. J Biotechnol 57:151–166

Black GW, Rixon JE, Clarke JH, Hazlewood GP, Theodorou MK, Morris P, Gilbert HJ (1996) Evidence that linker sequences and cellulose-binding domains enhance the activity of hemicellulases against complex substrates. Biochem J 15:515–520

Blanco A, Diaz P, Zueco J, Parascandola P, Javier Pastor FI (1999) A multidomain xylanase from a Bacillus sp. with a region homologous to thermostabilizing domains of thermophilic enzymes. Microbiology 145:2163–2170

Burdsall HH Jr (1969) Stephanocysts: unique structures in the Basidiomycetes. Mycologia 61:915–923

Carrard G, Koivula A, Soderlund H, Beguin P (2000) Cellulose-binding domains promote hydrolysis of different sites on crystalline cellulose. Proc Natl Acad Sci USA 97:10342–10347

Castanares A, Hay AJ, Gordon AH, McCrae SI, Wood TM (1995) d-xylan-degrading enzyme system from the fungus Phanerochaete chrysosporium: isolation and partial characterisation of an alpha-(4-O-methyl)-d-glucuronidase. J Biotechnol 43:183–194

Chinen I, Oouchi K, Tamaki H, Fukuda N (1982) Purification and properties of thermostable beta-xylosidase from immature stalks of Saccharum officinarum L (sugar cane). J Biochem (Tokyo) 92:1873–1881

Clarke JH, Rixon JE, Ciruela A, Gilbert HJ, Hazlewood GP (1997) Family-10 and family-11 xylanases differ in their capacity to enhance the bleachability of hardwood and softwood paper pulps. Appl Microbiol Biotechnol 48:177–183

Davies G, Henrissat B (1995) Structures and mechanisms of glycosyl hydrolases. Structure 3:853–859

Debets AJM, Bos CJ (1986) Isolation of small protoplasts from Aspergillus niger. Fungal Genet Newsl 33:24

Guex N, Peitsch MC (1997) SWISS-MODEL and the Swiss-PdbViewer: an environment for comparative protein modelling. Electrophoresis 18:2714–2723

Henrissat B (1991) A classification of glycosyl hydrolases based on amino-acid sequence similarities. Biochem J 280:309–316

Henrissat B, Bairoch A (1993) New families in the classification of glycosyl hydrolases based on amino-acid sequence similarities. Biochem J 293:781–788

Henrissat B, Bairoch A (1996) Updating the sequence-based classification of glycosyl hydrolases. Biochem J 316:695–696

Jacobs A, Larsson PT, Dahlman O (2001) Distribution of uronic acids in xylans from various species of soft- and hardwood as determined by MALDI mass spectrometry. Biomacromolecules 2:979–990

Jeffries TW (1996) Biochemistry and genetics of microbial xylanases. Curr Opin Biotechnol 7:337–342

Johnson TM, Li JK (1991) Heterologous expression and characterization of an active lignin peroxidase from Phanerochaete chrysosporium using recombinant baculovirus. Arch Biochem Biophys 291:371–378

Kanda T, Amano Y, Nisizawa K (1985) Purification and properties of two endo-1,4-beta-xylanases from Irpex lacteus (Polyporus tulipiferae). J Biochem (Tokyo) 98:1545–1554

Käfer E (1977) Meiotic and mitotic recombination in Aspergillus and its chromosomal aberrations. Adv Genet 19:33–131

Kosugi A, Murashima K, Doi RH (2002) Xylanase and acetyl xylan esterase activities of XynA, a key subunit of the Clostridium cellulovorans cellulosome for xylan degradation. Appl Environ Microbiol 68:6399–6402

Krengel U, Dijkstra BW (1996) Three-dimensional structure of Endo-1,4-beta-xylanase I from Aspergillus niger: molecular basis for its low pH optimum. J Mol Biol 263:70–78

Kulkarni N, Shendye A, Rao M (1999) Molecular and biotechnological aspects of xylanases. FEMS Microbiol Rev 23:411–456

Liab K, Azadi P, Collins R, Tolan J, Kim JS, Eriksson KL (2000) Relationships between activities of xylanases and xylan structures. Enzyme Microbiol Technol 27:89–94

Lin J, Ndlovu LM, Singh S, Pillay B (1999) Purification and biochemical characteristics of beta-d-xylanase from a thermophilic fungus, Thermomyces lanuginosus SSBP. Biotechnol Appl Biochem 30:73–79

Mattinen ML, Kontteli M, Kerovuo J, Linder M, Annila A, Lindeberg G, Reinikainen T, Drakenberg T (1997) Three-dimensional structures of three engineered cellulose-binding domains of cellobiohydrolase I from Trichoderma reesei. Protein Sci 6:294–303

Nielsen H, Engelbrecht J, Brunak S, Heijne G von (1997) Identification of prokaryotic and eukaryotic signal peptides and prediction of their cleavage sites. Protein Eng 10:1–6

Panbangred W, Kondo T, Negoro S, Shinmyo A, Okada H (1983) Molecular cloning of the genes for xylan degradation of Bacillus pumilus and their expression in Escherichia coli. Mol Gen Genet 192:335–341

Panbangred W, Kawaguchi O, Tomita T, Shinmyo A, Okada H (1984) Isolation of two beta-xylosidase genes of Bacillus pumilus and comparison of their gene products. Eur J Biochem 138:267–273

Peitsch MC (1995) Protein modeling by e-mail. Bio/Technology 13:658–666

Reen FJ, Murray PG, Tuohy MG (2003) Molecular characterisation and expression analysis of the first hemicellulase gene (bxl1) encoding beta-xylosidase from the thermophilic fungus Talaromyces emersonii. Biochem Biophys Res Commun 305:579–585

Reid ID, Seifert KA (1980) Lignin degradation by Phanerochaete chrysosporium in hyperbaric oxygen. Can J Microbiol 26:1168–1171

Reinikainen T, Ruohonen L, Nevanen T, Laaksonen L, Kraulis P, Jones TA, Knowles JK, Teeri TT (1992) Investigation of the function of mutated cellulose-binding domains of Trichoderma reesei cellobiohydrolase I. Proteins 14:475–482

Rodionova NA, Tavobilov IM, Bezborodov AM (1983) beta-Xylosidase from Aspergillus niger 15:purification and properties. J Appl Biochem 5:300–312

Saha BC (2001) Purification and characterization of an extracellular beta-xylosidase from a newly isolated Fusarium verticillioides. J Ind Microbiol Biotechnol 27:241–245

Schmidt A, Schlacher A, Steiner W, Schwab H, Kratky C (1998) Structure of the xylanase from Penicillium simplicissimum. Protein Sci 7:2081–2088

Schneider H, Barth W, Bohme HJ (1996) Cloning and characterization of another lignin peroxidase gene from the white-rot fungus Phanerochaete chrysosporium. Biol Chem Hoppe Seyler 377:399–402

Schwede T, Kopp J, Guex N, Peitsch MC (2003) SWISS-MODEL: an automated protein homology-modeling server. Nucleic Acids Res 31:3381–3385

Sengupta S, Jana ML, Sengupta D, Naskar AK (2000) A note on the estimation of microbial glycosidase activities by dinitrosalicylic acid reagent. Appl Microbiol Biotechnol 53:732–735

Shao W, Wiegel J (1992) Purification and characterization of a thermostable beta-xylosidase from Thermoanaerobacter ethanolicus. J Bacteriol 174:5848–5853

Teleman A, Tenkanen M, Jacobs A, Dahlman O (2002) Characterization of O-acetyl-(4-O-methylglucurono)xylan isolated from birch and beech. Carbohydr Res 337:373–377

Vrsanska M, Gorbacheva IV, Kratky Z, Biely P (1982) Reaction pathways of substrate degradation by an acidic endo-1,4-beta-xylanase of Aspergillus niger. Biochim Biophys Acta 704:114–122

Wernars K, Goosen T, Wennekes BM, Swart K, van den Hondel CA, van den Broek HW (1987) Cotransformation of Aspergillus nidulans: a tool for replacing fungal genes. Mol Gen Genet 209:71–77

Whitwam RE, Gazarian IG, Tien M (1995) Expression of fungal Mn peroxidase in E. coli and refolding to yield active enzyme. Biochem Biophys Res Commun 216:1013–1017

Wu SS, Suen DF, Chang HC, Huang AH (2002) Maize tapetum xylanase is synthesized as a precursor, processed and activated by a serine protease, and deposited on the pollen. J Biol Chem 277:49055–49064

Yoshida M, Ohira T, Igarashi K, Nagasawa H, Aida K, Hallberg BM, Divne C, Nishino T, Samejima M (2001) Production and characterization of recombinant Phanerochaete chrysosporium cellobiose dehydrogenase in the methylotrophic yeast Pichia pastoris. Biosci Biotechnol Biochem 65:2050–2057

Acknowledgements

We thank Dr. Cullen for providing P. chrysosporium strain RP78, Dr. Bos for kindly providing A. niger strain N593 and Dr. Li for his expert assistance with mass spectrometry. This work was supported by NSERC Strategic and Genome Quebec/Canada grants.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by U. Kück

Rights and permissions

About this article

Cite this article

Decelle, B., Tsang, A. & Storms, R.K. Cloning, functional expression and characterization of three Phanerochaete chrysosporium endo-1,4-β-xylanases. Curr Genet 46, 166–175 (2004). https://doi.org/10.1007/s00294-004-0520-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00294-004-0520-x