Abstract

The aging society in many developed countries has made an ergonomic workplace design to an important topic among researchers and practitioners alike. We investigate the workplace design for order pickers that manually collect items from the shelves of a warehouse. Specifically, we treat the storage assignment, i.e., the placement of products in shelves of different height, and zoning, i.e., the partitioning of the storage space into areas assigned to separate pickers, in the fast pick area of a warehouse. A fast pick area unifies the most fast-moving items in a compact area, so that workers are relieved from unproductive travel, but face extraordinary ergonomic risks due to the frequent repetition of picking operations. Concerning the health of (aged) workers, it is crucial to reduce such risks. Thus, we define a combined ergonomic storage assignment and zoning problem with the objective of minimizing the maximum ergonomic burden among all workers. This problem is formalized, and two construction heuristics and a tabu search procedure are proposed. Our results show that neglecting ergonomic aspects and only focusing on picking performance leads to much higher ergonomic risks of the workforce.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ergonomic risks such as those of getting occupational musculoskeletal disorders (MSDs) put a significant burden on the economy. The annual compensation costs for MSDs paid by US employers, e.g., range between 15 and 20 billion US dollars (Bureau of Labor Statistics 2009) and various studies estimate the total MSD costs for the European economy to consume between 0.5 and 2% of the gross national product (Buckle and Devereux 1999). Order picking in warehouses and distribution centers is among those activities with the highest prevalence of occupational MSDs (Bureau of Labor Statistics 2014). Schneider and Irastorza (2010) quantify the risk of suffering protracted MSD for an order picker to be 75% higher compared to the average European employee. Addressing these issues, an ergonomic workplace design does not only improve the well-being of employees, but also impacts costs. For instance, cost-savings may be achievable due to lower medical costs, reduced absenteeism, higher productivity, and fewer picking errors (see, e.g., Drury et al. 1983; Lanoie and Trottier 1998).

Thus, there are some good reasons for integrating ergonomics aspects when setting up warehouse operations and the importance of doing so is widely acknowledged [especially in many developed countries facing an aging workforce (Grosse et al. 2015)]. So far, there is a general lack of specific solution concepts such as optimization approaches integrating warehouse ergonomics. The paper at hand is intended to encourage this emerging research field by a first quantitative approach.

1.1 Line picking in the fast pick area

Order picking, i.e., the retrieval of items specified by a picking list from the shelves, is among the most elementary warehouse operations. It faces high ergonomic risks because of the following characteristics:

-

Order picking is frequently repeated. Marras et al. (2010) estimate the pick frequency in different warehouse settings to range between 12 and 480 picks per person per hour. Thus, even if the ergonomic strain of a single pick seems negligible, frequently repeated they add up to a considerable ergonomic risk in the long run.

-

Lifting and lowering often cause awkward postures. For instance, Lavender et al. (2010) report on grocery distribution centers where one third of items are handled below knee height and another third above shoulder height.

-

In some industries, heavy and inconvenient items need to be handled. A good example for heavy items hardly pickable by automated devices are windshields in the automotive industry (Boysen et al. 2015). But often it is not only the pure weight of an item. The packaging may not be convenient to grip, be fragile and pliable, so that additional muscular effort is required to stabilize the load.

While the latter aspect mainly depends on the products handled in a specific warehouse, awkward postures mainly occur during low-level order picking where human pickers directly access head-high shelves without vehicle support. The frequency of picking is the highest in the fast pick area where the most fast-moving items are unified in a compact space. Consequently, we integrate ergonomics aspects into the workplace design of an order picking setting, which shows both characteristics and, thus, faces extraordinary ergonomic risks.

A widespread setting for organizing the picking process in the fast pick area is line picking (Walter et al. 2013; Bartholdi and Hackman 2014), which is schematically depicted in Fig. 1. Here, stock keeping units (SKUs) are picked from gravity flow racks arranged along a conveyor system. The pickers move in front of the pick-face and collect the SKUs defined by a picking order in a separate bin, which moves along the conveyor. Often an unpowered roller belt is applied, so that the pickers have to manually move the bins to accompany their tours along the pick-face. To accelerate the orientation of pickers, often, a pick-to-light system is applied to indicate the shelves where items of the current order are to be retrieved from. A typical pick rate in such a system is about 150–500 picks per person and hour (Bartholdi and Hackman 2014).

In a gravity flow rack, the shelves are tilted with integrated rollers, so that items are restocked from behind and roll to the front where they can conveniently be picked. A typical rack in the fast pick area is head-high and the number of shelf rows depends on the size of items to be stored, but typically ranges somewhere between three and twelve. From an ergonomics perspective, retrieving items from low and high shelves forces the pickers into awkward postures, so that items which are frequently required, heavy and/or inconvenient to grip should especially be stored in the middle shelves [also denoted as the golden zone (Petersen et al. 2005)].

To reduce the pickers’ unproductive travel time, a bin associated with a specific picking order is, typically, not accompanied by a single worker across the complete fast pick area, but handed over from picker to picker, who remain in their respective (disjunct) picking zones. The division of labor enabled by such a zoning strategy avoids obstructions among pickers having to overtake each other and enables a higher throughput (see Jewkes et al. 2004). However, the partitioning of the line picking area into zones also determines the set of shelves operated by each picker and, thus, his/her ergonomic burden.

To summarize, the ergonomic risks of an order picker in a line picking setting are mainly influenced by the storage assignment, i.e., the assignment of SKUs to shelves, and the zones these shelves are assigned to. Consequently, we aim at computerized solution algorithms that determine both a feasible storage assignment and zoning while minimizing the maximum ergonomic risk over all pickers of a given workforce. For quantifying ergonomic risks, we investigate an elementary approach based on a simple additive aggregation of SKU-specific risk factors and a more sophisticated one applying an established ergonomics method, i.e., the NIOSH equation (see Sect. 3.1). It is part of our computational study to investigate, in which settings what level of detail seems appropriate.

1.2 Literature review

Integrating ergonomics aspects into workplace design has been a lively topic over the recent years. Many quantitative approaches have been introduced, mainly for assembly line workplaces, which due to the frequent repetition of tasks also face high ergonomic risks. Specific planning methods have, e.g., been proposed for ergonomic line balancing (Carnahan et al. 2001; Otto and Scholl 2011; Moreira et al. 2012; Bautista et al. 2013) and the design of job rotation schedules (Carnahan et al. 2000; Costa and Miralles 2009; Otto and Scholl 2012). Comparable approaches tailored to the specific needs of warehouses and distribution centers are yet missing. Among the recent survey papers summarizing the state-of-the-art of warehousing research, e.g., provided by Rouwenhorst et al. (2000), Koster et al. (2007), Gu et al. (2007), Gu et al. (2010), only the paper of Rouwenhorst et al. (2000) explicitly mentions ergonomics aspects as an important issue for future research, but not a single quantitative planning approach is reported. This finding is also supported by another survey paper of Grosse et al. (2015), which is specifically dedicated to the human factors of warehousing. They treat ergonomics as one major human factor and outline future research issues. The storage assignment problem, which we also treat in this paper, is mentioned as an important lever for mitigating ergonomic risks. To the best of our knowledge, only Battini et al. (2016) integrate ergonomic risks into operational planning of warehouses. They, however, only report on simulation experiments with a single picker and do not apply sophisticated optimization approaches.

Without the integration of ergonomics aspects, storage assignment and zoning have vividly been treated in the warehousing literature due to the widespread applications of these systems in the real world. For instance, Koster et al. (2007) state that manual low-level order picking systems, such as used in the fast pick area, are still the most widespread in Europe and the survey of Dallari et al. (2009) revealed that 25% of the 68 surveyed warehouses in Italy apply a zoning strategy.

Zoning policies are mostly considered separately from the assignment of products to storage locations (e.g., Yu and Koster 2008, 2009; Koster et al. 2012). A few authors consider minimizing the workload imbalance between zones measured by the number of picks per zone. For such a setting, Parikh and Meller (2008) develop a model to determine order batching policies, i.e., how to combine multiple orders to a single picker tour (in this context also denoted as wave), such that the number of picks within a wave is about the same in each zone. The assignment of SKUs to zones is assumed to be given. Jane (2000) and Jane and Laih (2005) propose heuristic algorithms to smooth the workload imbalance among a given number of zones for sequential and synchronized picking systems. The product locations in the racks are not considered. Finally, the approach of Jewkes et al. (2004) considers storage assignment and zoning simultaneously in a line picking setting (together with the locations of the pickers’ home bases). The authors minimize the expected order cycle time, where each picker has to start and end his/her tour at the home base. They aim to minimize the average tour length of the order pickers and formulate an exact dynamic programming procedure.

1.3 Contribution and paper structure

This paper provides a quantitative planning approach that decides on the storage assignment, i.e., the placement of SKUs in shelves, and the zoning, i.e., the partitioning of the rack into work areas, in a fast pick area. Our objective is to minimize the maximum ergonomic load for a given workforce of order pickers.

First, we describe the basic optimization problem supporting the design of ergonomic workplaces in Sect. 2. An important prerequisite for this problem formulation is an appropriate measuring method for quantifying the ergonomic risks of a specific workplace. Therefore, we elaborate on existing ergonomics measuring methods in Sect. 3. For solving the optimization problem, Sect. 4 introduces two construction heuristics and a meta-heuristic (tabu search), whose computational performances are tested in a comprehensive computational study (Sect. 5). Furthermore, we address important managerial aspects. For instance, we explore the extent of ergonomic risks induced by only considering performance aspects during workplace design and compare this to the risk reduction capabilities of our approach. The final Sect. 6 concludes the paper.

2 Problem definition

Consider a fast pick area having a line picking layout. There is a given gravity flow rack, which is separated into rows \(r=1,\ldots ,R\) and columns \(c=1,\ldots ,C\) of shelves, numbered from left to right (columns) and top to bottom (rows). Thus, each specific shelf can be identified by its (r, c)-coordinate. Each shelf receives a unique SKU and set J defines all SKUs to be placed in the shelves. Without loss of generality, we assume an identical number of shelves and SKUs, i.e., \(R\cdot C=|J|\), because, usually, no shelf of the most efficient fast pick area will be left empty in the real world. If, however, empty shelves have to be considered, set J could simply be filled up with “virtual” SKUs having no ergonomic impact. To keep our problem formulation as simple as possible, we presuppose that there are no assignment restrictions and any SKU can be stored in any shelf. On the one hand, this case often occurs in the real world, because to save investment costs shelves are often of standardized size. On the other hand, integrating assignment constraints into our solution concepts is straightforward, so that we abstain from a detailed description.

Order picking is executed by a given workforce of order pickers. Each picker receives an area of successive columns that is exclusively operated by him/her. This way, obstructions of pickers moving into each other’s area are ruled out. Such an area is called a zone and a zoning defines a partition of the considered rack into a succession of non-overlapping zones. Since we presuppose a workforce of given size, we face a fixed number of zones \(Z \le C\).

In this setting, we simultaneously aim at a zoning \(\Theta \) and a storage assignment of SKUs to shelves \(\Omega \). \(\Omega \) consists of a set of triples (j, r, c), each of which defines that SKU \(j \in J\) is stored in the shelf located in a row \(r \in \{1,\ldots ,R\}\) of a column \(c \in \{1,\ldots ,C\}\). A feasible storage assignment \(\Omega \) has to follow two restrictions:

-

For each SKU \(j \in J\) we have exactly one \((j,r,c) \in \Omega \), i.e., each SKU is stored in a single shelf, and

-

for any pair of triples \((j,r,c) \in \Omega \) and \((j^\prime ,r^\prime ,c^\prime ) \in \Omega \) with \(j \ne j^\prime \) we have \(r \ne r^\prime \) and/or \(c \ne c^\prime \), because each shelf must receive a unique SKU.

As defined above, a zoning \(\Theta \) is a partition of the column set \(\{1,\ldots ,C\}\) into a succession of disjunct subsets \(\Theta _z\) containing all columns assigned to zone \(z=1,\ldots ,Z\). A feasible partition \(\Theta \) observes the following conditions:

-

There are exactly Z zones \(\Theta _z\) each containing at least one column, so that \(|\Theta _z| \ge 1\) for all \(z=1,\ldots ,Z\) and

-

there is no overlap among zones, that is \(\max \{c \mid c \in \Theta _z\} < \min \{c \mid c \in \Theta _{z+1}\}\) for each \(z=1,\ldots ,Z-1\).

Among all feasible solutions (consisting of a feasible storage assignment and a feasible zoning), we seek one that minimizes the maximum ergonomic risk over all zones. Every worker’s MSD risk increases with a higher ergonomic stress level and the higher the risk the worse an MSD may become. Thus, our min–max objective seems well suited to limit the risk of each single worker. Note that alternative objectives, e.g., minimizing the sum of ergonomic stress, would allow to weigh off one picker’s higher risk with a lower risk of another, which seems rather unfair. The workplace of a picker is defined by all SKUs stored in his/her zone and their assignment to shelves. Therefore, we need some measuring method quantifying the ergonomic risk of each picker’s workplace. We will elaborate on such methods in Sect. 3. Let \(f(\Omega ,\Theta _z)\) be some function that quantifies the ergonomic risk of zone z according to some ergonomics measuring method. Given this function, our ergonomic storage assignment and zoning problem (dubbed ESAZ) can be formally defined as follows: Among all feasible solutions, ESAZ seeks one that minimizes

The ergonomics measuring methods known in the literature vary in their level of detail (and thus complexity). In the most basic and intuitive version, each SKU with its specific weight and pick frequency is assigned some ergonomic risk factor \(e_{jr}\) that depends on the shelf height (i.e., row r) a SKU j is assigned to. Given these SKU-specific risk factors each workplace’s risk is simply calculated by the sum of risks realized in the respective zone. We will refer to a zone’s sum of realized risks as a zone’s ergonomic load. Such a basic linear measuring function lets us specify a problem version we dub ESAZ-basic: Among all feasible solutions, ESAZ-basic seeks one that minimizes

Note that ESAZ-basic can also be formulated as a mixed-integer program. Such a formulation is given in Appendix 1. Further note that in our basic problem setting the assignment of a SKU to a specific column is not relevant, because only whether or not a SKU placed in a specific row belongs to the respective zone influences the ergonomic stress. This simplification is utilized in the mixed-integer program of Appendix 1.

Example: Consider a gravity flow rack consisting of \(R=3\) rows and \(C=5\) columns, which is operated by a given workforce of \(Z=3\) order pickers. 15 SKUs are to be stored in the shelves of the rack; their SKU-specific risk factors \(e_{jr}\) are specified in Table 1. Note that the risk factors of the upper and lower row are always higher than those of the golden zone in the middle. An optimal solution is depicted in Table 2, where \(j\,(e_{jr})\) specifies the index of the assigned SKU and the resulting ergonomic stress in each cell. The maximum ergonomic load of \(E^\prime (\Omega ,\Theta )=445\) is caused by zone 3.

Before we go on with further analyzing ESAZ, we briefly summarize and discuss the simplifying assumptions and prerequisites our problem setting is based on:

-

We have no assignment restrictions, so that each SKU fits any shelf (see above).

-

We presuppose dedicated storage where each SKU is stored in a single fixed shelf. This is the typical choice in the fast pick area (see Bartholdi and Hackman 2014), because it eases the orientation of workers due to a steady storage topology. Alternatively, shared storage assigns each incoming load a new open storage position, resulting in SKUs being spread over multiple locations. Fast pick areas, however, are not directly connected with the receiving area, but replenished from bulk storage whenever a SKU is about to be depleted. Therefore, shared storage’s more economic use of space (see Bartholdi and Hackman 2014) is not relevant in the fast pick area.

-

We assume an equal number of shelves and SKUs, i.e., \(R \cdot C=|J|\), within our problem. If we have more shelves than SKUs in the real world, then shelves can either remain empty (see above) or some SKUs can be assigned to multiple shelves to reduce their replenishment effort. Once we have decided which SKUs should receive how many additional shelves, we can split the selected (real world) SKUs and treat them as separate SKUs with reduced picking frequency within our problem. After having solved our storage assignment problem, all shelves assigned to the split SKUs receive the same real-world SKU they refer to. This simple approach, however, requires that the number of shelves per SKU has already been decided. If deciding on the number of shelves per SKU is integrated into the problem as an additional decision variable, this adds considerable complexity to the problem. We aim at the most basic problem setting here and leave such extensions to future research.

-

Our line picking system is partitioned into disjunct and non-overlapping areas each operated by a separate picker, which is a common choice for the fast pick area of a warehouse Dallari et al. (2009). In the recent years, other operating principles such as the bucket brigade protocol (e.g., see Bartholdi and Hackman 2014) have been introduced. Bucket brigades abstain from fixed zones and flexibly hand over work whenever two pickers meet along the line in order to flexibly adjust the division of labor to workload variations. Without fixed areas, however, a definite (ex-ante) assessment of ergonomic risks of specific pickers is difficult. Thus, for an ergonomic design of workplaces fixed zones seem preferable.

-

Furthermore, we assume that prior planning steps are already finished so that, according to some target performance, SKU-specific workloads (picking frequencies) and the workforce size have been fixed beforehand. In this setting, we aim to minimize and level the ergonomic burden for the given performance level of the system in order to analyze the positive effect on ergonomics by distributing picking work according to an ergonomic objective instead of a performance oriented one as is usually done. Therefore, we do not consider further means of reducing ergonomic stress, e.g., by adding more breaks (Battini et al. 2016a) or using mechanical support tools.

-

We neglect the additional feedback link, that a reduction of ergonomic stress can, in turn, increase the performance, because less stressed workers are able to pick more items. At least in our experience, integrating such effects seems hardly agreeable with the representatives of the trade unions. Furthermore, we are not aware of any ergonomics measuring methods (see below) considering such highly nonlinear feedback links.

-

To keep the problem as basic as possible, we also neglect the impact of an increasing fraction of unproductive travel time if a zone increases. The zones in a fast pick area are fairly small, so that adding a few columns merely increases a zone by a (negligible) few meters.

Eventually, we investigate the computational complexity of our workplace design problem. Even with the most basic ergonomics measurement method, which led us to ESAZ-basic, solving our problem turns out as a complex matter.

Theorem 1

ESAZ-basic is strongly NP-hard.

Proof

See Appendix 2. \(\square \)

3 How to quantify ergonomic risks

There are various competing ergonomics measuring methods, which are, e.g., surveyed by Stanton et al. (2006). Some of them are more elaborate, others are conceived as simple paper-and-pencil methods. Among the methods, which are particularly suitable for order picking workplaces with a high share of manual lifting, are, for example:

-

The variable lifting index based on the revised equation of the National Institute for Occupational Safety and Health, which we refer to as NIOSH-Eq (Waters et al. 1994, 2009),

-

The Leitmerkmalsmethode of the Federal Institute of Occupational Safety and Health (Bundesanstalt für Arbeitsschutz und Arbeitsmedizin 2001),

-

The Static Strength Prediction Program (Chaffin and Erig 1991), and

-

The Liberty Mutual Manual Material Handling Tables (Marras et al. 1992).

Clearly, all the competing methods can only be imperfect measures for the “true” MSD risks, which only materialize after a considerable time lag. Evaluating the methods is beyond our study and remains up to ergonomists.

Throughout our paper, we examine two approaches to measure ergonomic risks. As the representative for the complex scientific methods we decided for NIOSH-Eq, because it is the most widespread and comprehensive one (Waters et al. 1994, 2009). NIOSH-Eq was specifically developed for jobs with highly variable lifts, such as warehouse operations (see Waters et al. 2009, 2016). This methodology is recommended by the Occupational Safety and Health Administration of the US (see the mandatory Appendix D.1 to §1910.900 of the Final Ergonomics Program Standard), by the International Organization for Standardization as a tool for the application of the standard ISO/DIS 11228-1.2 (see Waters et al. 2016), and it was largely adopted by the European norm EN 1005-2. Aspects of NIOSH-Eq were examined and validated in a number of studies (e.g., Waters et al. 1993; Lee et al. 1996; Potvin 1997; Waters et al. 1999; Battevi et al. 2016), see also Elfeituri and Taboun (2002) for discussions on the safety limits and functional forms of the NIOSH-Eq. We refer the reader to Dempsey (2002) for a detailed discussion of the implementation issues of some aspects of the NIOSH-Eq methodology in companies.

From the practitioner’s perspective, however, these scientific methods are quite complex and require plenty effort for collecting the data. From the authors’ experience (mainly stemming from German automotive supply chains), firms rather prefer handy, house-tailored ergonomic measures, which only depend on the SKUs and their storage heights. Such basic ergonomic measures may be computed, for example, based on the energy expenditure as in the Predetermined Motion Energy System of Battini et al. (2016b). Such basic ergonomic measures directly lead to our risk factors \(e_{jr}\), which we apply for ESAZ-basic.

Note that our simplified problem version ESAZ-basic, thus, has two potential fields of application:

-

It can either directly be applied if linear risk measures \(e_{jr}\), e.g., based on the energy expenditure, are utilized, or

-

it may be used as a surrogate objective for approximating the outcome of a more complex measuring method.

In the latter case, ESAZ-basic is applied in order to avoid the complex, often nonlinear objective functions of more sophisticated measuring methods such as NIOSH-Eq. It is part of our computational study to quantify the appropriateness of our surrogate objective. As an alternative, we also customize our solution procedures to directly integrate a complex measuring method. We will further explore the basic trade-off between a simpler model on the one hand and more measuring accuracy on the other hand in our computational study (see Sect. 5.3).

Obviously, the same lifting or lowering tasks constitute different risks of different order pickers, which depend, for instance, on their individual fitness, sex, and body height. A common practice, however, is to plan for representative workers, for example the 90%-percentile worker. On the one hand, in many countries it is prohibited by law to consider individual characteristics of workers in order to avoid discrimination (EN 614-1 2006). On the other hand, staffing workplaces is rather a subsequent decision task, so that individual data may simply not be available during workplace design.

In the following, we explain the methodology of NIOSH-Eq (Sect. 3.1) and, finally, propose a linear surrogate objective for NIOSH-Eq in Sect. 3.2.

3.1 Ergonomic risk measurement method NIOSH-Eq

NIOSH-Eq, which is explained in greater detail in (Waters et al. 1994, 2016), is a comprehensive methodology that takes the interdependencies between the most important risk factors into account. It is specifically designed for workplaces where lifting and lowering is one of the major activities. NIOSH-Eq estimates ergonomic risks by computing a so-called lifting index LI. We start with a brief description of \(LI_j(\Omega )\) for handling a single SKU j. After that we show, how to compute the aggregated risk \(LI(\Omega , \Theta _z)\) of an order picking workplace z (with columns \(\Theta _z\)) where order pickers have to handle many SKUs. The computation of \(LI_j(\Omega )\) is often referred to as the revised NIOSH equation in the ergonomics literature, and \(LI(\Omega , \Theta _z)\) is called the variable lifting index (Waters et al. 1994, 2016).

Let \(h_j\) be the height (measured in cm) of the row/shelf SKU j is assigned to in storage assignment \(\Omega \). Then, the lifting index \(LI_j(\Omega )\) for j is calculated as follows [in order to ease presentation, we define the multipliers as the reciprocals of the original ones in Waters et al. (1994)]:

The first multiplier relates the actual weight of item j (\(w_j\), in kg) to a weight limit of 23 kg. This value has been determined in ergonomic studies as the maximal weight that can be lifted under ideal lifting conditions without (relevant) ergonomic risk (Waters et al. 1994). However, the actual material handling conditions for an item j in a warehouse are usually less favorable than the ideal ones. This is taken into account by a set of M risk factor multipliers \(RFM_m(j) \ge 1\) (\(m=1,\ldots ,M)\). Examples are the vertical multiplier, which depends on the height \(h_j\) of the shelf where item j is located, the distance multiplier, which is the difference between \(h_j\) and the height of the conveyor belt where j is dropped, and the frequency multiplier (see below). A value \(LI_j(\Omega ) \le 1\) indicates that there is no ergonomic risk. This is true for items with a weight of up to 23 kg under ideal conditions and items with lower weights that compensate for worse lifting conditions. If \(LI_j(\Omega ) > 1\), then the combination of weight and lifting conditions is considered to be risky and ergonomic risk increases as \(LI_j(\Omega )\) increases.

For a matter of convenience, we subsume all multipliers of \(LI_j\) except for the frequency multiplier (but including the weight ratio) into a height-dependent parameter \(\sigma _j(h_j)\). The frequency multiplier, which we denote as \(F(\cdot )\), depends (in a nonlinear manner) on the number of picks \(\phi _j\). This is depicted in Fig. 2, which is derived from Table 5 in Waters et al. (1994) by computing the reciprocals of the frequency multipliers (interpolated if necessary) given for an 8-h shift.

An order picking workplace has to handle more than a single SKU, so that we have to compute an overall lifting index \(LI(\Omega , \Theta _z)\) for a complete workplace (or zone z) that specifies the general function f in formula (1). We describe the so-called variable lifting index of Waters et al. (2016), which specifically addresses the conditions of order picking workplaces.

Each zone z constitutes a workplace which has to pick the assigned SKUs \(j \in J_z=\{j\,|\,(j,r,c)\in \Omega , c\in \Theta _z \}\) from height \(h_j\) of the shelf (r, c) to which SKU j is assigned in \(\Omega \). Now, for each examined zone z, we have to aggregate all SKUs \(j \in J_z\) into six categories \(g=1,\ldots ,6\) according to the distribution of their parameters \(\sigma _j(h_j)\). For this, the range between the minimal value \(\underline{\sigma }_z=\min \{\sigma _j(h_j)\,|\,j \in J_z \}\) and the maximal value \(\bar{\sigma }_z=\max \{\sigma _j(h_j)\,|\,j \in J_z \}\) is divided into six intervals. Waters et al. (2016) recommend a division either into six equal intervals or into six (possibly unequal) intervals according to percentiles of the distribution of the height-dependent parameters \(\sigma _j(h_j)\). We use the first approach throughout the paper. All the SKUs of zone z belonging to the same category g (collected in set \(J_z(g)\)) are then unified to a single task, so that we have a single virtual task per category. For a matter of differentiation, we indicate category-specific parameters with capital letters. We compute the frequency of picks for a category g in zone z as the total number of order picks of the corresponding SKUs as follows: \(\Phi _{gz}=\sum _{j \in J_z(g)}{\phi _j}\). If category g contains a SKU with the maximal height-dependent parameter \(\bar{\sigma }_z\), then we set \(\Sigma _{g}:=\bar{\sigma }_z\) for the aggregated height-dependent parameter of category g. Otherwise, the value of \(\Sigma _{g}\) is computed as the mean of the height-dependent parameters \(\sigma _j(h_j)\) for the SKUs \(j \in J_z(g)\).

Recall that frequency multiplier \(F(\cdot )\) is nonlinear in the number of lifts. Instead of simply computing \(LI(\Omega , \Theta _z)\) by taking the sum of each category’s lifting index, dynamics are taken into account when calculating the variable lifting index \(LI(\Omega , \Theta _z)\) as follows:

Equation (4) depends on the succession of the categories, i.e., their numbering. Waters et al. (2016) propose two renumbering procedures in their examples. The categories can be renumbered either according to non-increasing \(\Sigma _g\) or according to risks measured by surrogate indices as \(\Sigma _g \cdot F\left( \Phi _{gz} \right) \). In this article, we use the first approach, because the second one may lead to inconsistencies (lower lift frequency may lead to higher variable lifting index).

Example: Consider a zone z with seven SKUs (\(J_z=\{1,\ldots ,7\}\)) and height-dependent parameters \(\sigma _j(h_j)\) in the current assignment as provided in Table 3. The observed range of the height-dependent parameters for this zone is \([\underline{\sigma }_z,\bar{\sigma }_z]=[0.2,2.6]\). We divide this range into six equal intervals that determine the categories (see Table 4). Category 6 contains SKU 6 and SKU 7, so that \(\Sigma _6:=\frac{0.4+0.2}{2}=0.3\) and \(\Phi _{6}=0.1+0.1=0.2\). The rest of the categories contains one SKU each. The categories are already numbered according to non-increasing \(\Sigma _g\). We compute the variable lifting index as \(LI=2.6\times 1.180+2\times (1.215-1.180)+1.6\times (1.253-1.215)+1.4\times (2.564-1.253)+0.8\times (2.703-2.564)+0.3\times (2.860-2.703)=5.1925 \approx 5.20\) (rounding to the next multiple of 0.05 gives sufficient preciseness).

3.2 Approximating the NIOSH-Eq objective function

There is a strong tendency in practice to simplify complex risk measurement methods for the sake of intuitiveness and organizational convenience. In our computational experiments, we show that we can indeed achieve good results for the general ESAZ problem by iteratively solving ESAZ-basic with approximate ergonomic parameters \(e_{jr}\).

Although there is no direct transformation of NIOSH-Eq into a linear form, we can construct surrogate \(e_{jr}\) values, which preserve the ranking of workplaces in terms of ergonomic risks fairly well. Different kinds of approximations are possible, and we examined several ones in our pretests. We found that already the simple approximation of setting \(e_{jr}:=\sigma _{jr} + \epsilon _j\) leads to very good results, where \(\sigma _{jr}\) is the height-dependent risk multiplier for item j being assigned to row r. The parameter \(\epsilon _j\) is a small randomly generated distortion which is used to simulate the (unknown) linearization failure. For example, this approximation is slightly better performing than the more intuitive approximation \(e_{jr}:=\sigma _{jr}\cdot \phi _j + \epsilon _j\), presumably because the influence of \(\phi _j\) changes drastically depending on the cumulative frequency of the preceding categories (cf. Fig. 2) and, hence, depending on the number of columns in the current zone.

The derived objective function \(E^\prime (\Omega ,\Theta )\) based on our simple approximation \(e_{jr}:=\sigma _{jr} + \epsilon _j\) comes rather close to a monotonic transformation of the true function \(E(\Omega ,\Theta )\) based on NIOSH-Eq as shown by the experiments in Sect. 5.3. In Sect. 4.4, we describe corresponding adaptations of solution procedures for ESAZ-basic based on this approximation.

4 Algorithms

This section is dedicated to deriving upper and lower bounds for ESAZ-basic. Specifically, we introduce two construction heuristics (Sect. 4.1), a tabu search approach (Sect. 4.2), and two lower bound arguments (Sect. 4.3). Finally, we show how to adapt these concepts to the general ESAZ (Sect. 4.4).

4.1 Construction heuristics

Our two construction heuristics aim at quickly deriving a first start solution. To do so, we decompose the solution process into two stages. First, we assign SKUs to the rows of our gravity flow rack without determining a specific column or zone. Then, we successively assign SKUs (and the rows they are already assigned to) to zones (and, thus, columns). By varying the assignment processes of the latter stage, we differentiate two construction heuristics, namely the critical row (CR) heuristic and the equal zones (EZ) heuristic.

Both of them start with assigning SKUs to rows in stage one. As the (surrogate) objective for this stage we aim to minimize the total ergonomic workload, because the lower the total load, the easier seems reducing the maximum ergonomic load per zone in the successive stage. Given variables \(y_{jr}\), which define whether SKU j is assigned to row r (\(y_{jr}=1\)) or not (\(y_{jr}=0\)), the decision task of the first stage can be defined as a linear program consisting of objective function (5) subject to constraints (6) to (8).

subject to:

Objective function (5) minimizes the total ergonomic workload. Constraints (6) ensure that each row cannot store more SKUs than there are columns available and (7) takes care that each SKU is stored in some row. Finally, (8) defines the domain of the variables. As the problem turns out being equivalent to the well-known linear transportation problem (TP, e.g., see Burkhard and Zimmermann 2012) and the right-hand sides of (6) as well as (7) are integer, there is no need to define variables \(y_{jr}\) as binary variables. TP is quickly solvable in polynomial time (Kleinschmidt and Schannath 1995), so that the assignment of SKUs to rows can efficiently be derived.

Example (cont.): Solving transportation problem TP for our example of Table 1 delivers a solution value of \(\Upsilon (Y)=1330\) with SKUs 2, 3, 4, 9, and 10 being assigned to row \(r=1\), SKUs 6, 8, 11, 13, and 14 to row \(r=2\), and SKUs 1, 5, 7, 12, and 15 to row \(r=3\).

From now on, we treat the SKU-to-row assignment found at stage 1 as fixed. The assignment is handed over to the second stage and we, first, describe the procedure of the CR heuristic.

CR heuristic First, we sort the SKUs per row in non-increasing order of their ergonomic stress factors \(e_{jr}\). We, then, successively consider the rows and assign the sorted items consecutively to the zone with the currently lowest cumulative ergonomic load. The first row in this procedure requires special attention, because this row decides on the number of columns each zone consists of. To avoid an exceedingly unbalanced distribution of columns among zones, we identify the critical row \(r^*\) as follows:

Thus, \(r^*\) is the row with the lowest spread between maximum and minimum ergonomic stress (ties are broken arbitrarily). Critical row \(r^*\) starts the assignment process. All SKUs belonging to row \(r^*\) are successively assigned to the zone, which currently has the lowest cumulative ergonomic load of those items already assigned among the zones still having an empty column available. We start with Z empty zones and—after having processed the critical row—we fix the number of columns per zone achieved. The remaining rows are considered in non-decreasing order of \(\rho _r\). Again, we successively assign the sorted SKUs to the zone with the currently lowest cumulative ergonomic load (among all zones still having an empty column available).

Example (cont.): We receive the solution of TP defined above and the resulting SKU-to-row assignment as input. The critical row is \(r^*=2\) (with smallest spread \(230/105=2.19\)), so that we, first, have to place the SKUs assigned to this row. Ordering them according to non-increasing \(e_{jr}\) leads to an assignment sequence 8, 13, 6, 11, and 14. Afterward, we have zone 1, 2, and 3 consisting of one, two, and two columns, respectively. Given these fixed columns per zone, we go on with assigning row 3 and then row 1, which finally leads us to the solution depicted in Table 5 using the notation specified in the legend. The maximum ergonomic load is \(E^\prime =457\).

The EZ heuristic also starts with solving TP in the first stage. The resulting SKU-to-row assignment is handed over to stage two. Here, we start with distributing the number of columns per zone as evenly as possible. We receive \((C \bmod Z)\) large zones with \((\lfloor \frac{C}{Z}\rfloor +1)\) columns and \([Z- (C \bmod Z)]\) small zones each containing \(\lfloor \frac{C}{Z}\rfloor \) columns. Again, we sort the SKUs per row in non-increasing order of their ergonomic stress and start their successive assignment in the small zones. They receive the high-risk SKUs, first, to counterbalance their lower number of columns. Therefore, we consecutively consider the rows in index order and assign the first \([Z- (C \bmod Z)]\times \lfloor \frac{C}{Z}\rfloor \) SKUs of the current row’s sequence to the small zones. Again, we assign the current item to the small zone currently having the lowest cumulative ergonomic load among all small zones still having an empty column available. Once all shelves of the small zones are fully loaded with SKUs, we skip to the large zones where we repeat the successive assignment with the remaining SKUs in the same manner.

Example (cont.): For our example (see Table 1), the EZ heuristic determines \((5 \bmod 3)=2\) large zones and a single small zone. Given the solution of TP, we start with row \(r=1\) and assign its “riskiest” SKU \(j=2\) with \(e_{21}=156\) to small zone 1. In our example, zone 1 contains only a single column, so that we switch to row 2. This results in the following storage assignment for small zone 1: SKUs 2, 8, and 1 are assigned to the single column in rows 1, 2 and 3, respectively. Afterward, we skip to large zones 2 and 3 and assign the remaining SKUs. The resulting solution is depicted in Table 6. The maximum ergonomic load is \(E^\prime =449\).

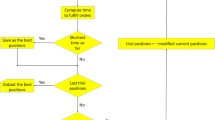

4.2 Tabu search

Tabu search is a well-established meta-heuristic, which has been introduced by Glover (1986). Since then, it has found widespread application in innumerable combinatorial optimization problems. As the basic procedure of tabu search is general operations research knowledge, we only refer the interested reader to one of the tutorial papers, e.g., (Glover 1990). We only elaborate on our main customization steps for adapting tabu search to ESAZ-basic.

We decided for tabu search, because it is a very flexible approach that can be easily integrated into the software of warehouse operators. Tabu search is able to deal with possible additional restrictions and can be easily extended to the case of the general ESAZ. Moreover, it contains a simple and powerful means to avoid cycling of the search and also to enforce diversification, the tabu list. Beyond the standard tabu search, we intensify the search by applying local re-optimization procedures.

Initial solution We start with some initial solution, e.g., by taking the better one of our two construction heuristics (see Sect. 4.1). Afterward, we apply our local re-optimization procedures-1 and -2 (see below) to re-assign SKUs between zones and between rows of the same zone. We set the resulting solution to be the current solution s and the incumbent solution \(s^{*}\).

Neighborhood definition We define the column having the lowest total ergonomic risk in a given zone as a zone’s low risk column. We receive a neighbor of the current solution s by shifting a low risk column from a zone with the highest ergonomic load to any other zone with lower load. Consider our example of Table 1 and, e.g., the feasible solution provided in Table 5. Zone 2 is the one having the highest ergonomic load and in this zone SKUs 9 (with \(e_{9,1}=57\)), 14 (\(e_{14,2}=105\)), and 7 (\(e_{7,3}=18\)) have the lowest ergonomic risk factors in rows 1, 2, and 3, respectively. Thus, SKUs 9, 14, and 7 build the low risk column, which is to be moved to another zone. In our example, we obtain two neighbors: by shifting the low risk column to zone 1 and zone 3 we receive a maximum ergonomic load of \(E^\prime =612\) and \(E^\prime =621\), respectively.

Note that there are up to \(\frac{Z^2}{4}\) neighborhood moves in the defined neighborhood (in case of \(\frac{Z}{2}\) zones with the highest ergonomic load and a distinct low risk column defined per zone). Among all neighbors of s, which got accepted by our tabu list procedure, we take one with smallest objective value as the candidate solution \(s^\prime \). In one iteration of tabu search (given the current solution s), we find a candidate solution \(s^\prime \) and add it to the tabu list. Then, we apply the local re-optimization procedures-1 and -2 and set the resulting solution to be the new current one s. We also update the incumbent solution \(s^{*}\), if s has a lower objective value.

Tabu list The tabu list is the (recency-based) memory of the algorithm. It decides whether or not neighbors of the incumbent solution are acceptable as a candidate solution. We apply a simple probabilistic tabu list management (reactive tabu search, see Battiti and Tecchiolli 1994), where a neighboring solution s is accepted at probability P(s), which is inversely proportional to the number of times nv this specific solution already has been visited. We set \(P(s)=\frac{1}{nv+3}\) for \(nv \ge 1\) (not yet visited solutions are selected with certainty). For instance, if solution s has already been visited once, its probability of being selected a second time is only \(P(s)=25\%\).

Whenever we add a solution to the tabu list, we only save the SKU-to-zone assignment of this solution and increase nv by one for this assignment. This seems to outperform more detailed data structures, because a specific SKU-to-column assignment within the same zone has no influence on the objective value. Moreover, for a given set of SKUs assigned to a zone, we can easily place SKUs (locally) optimal into rows with our local re-optimization procedure-2 (see below).

With the help of local re-optimization procedure-1, we improve candidate solution \(s^\prime \) by swapping SKUs between two zones. Note that an improved objective value can only be achieved, if one of the two zones has the maximal ergonomic load. The SKU pairs (i, j) are examined in a systematic manner based on their numbering starting with pair (1, 2). We perform first-fit search, i.e., we immediately accept a solution after an improving swap as a new candidate solution. We perform swaps until no improving move exists. Observe that by periodically re-assigning SKUs to their most suitable row (by local re-optimization procedure-2), we are likely to get the most improving swaps by considering SKUs of the same row (but belonging to different zones). Therefore, we perform two runs of our procedure: In the first run, we only consider swaps of items in the same row, in the second run we only consider swaps of items located in different rows.

Swaps result in changes of SKU-to-zone assignment, so that we have to add the visited solutions to the tabu list (but we do not prohibit any improving swaps). This way, we prevent the unlikely event of cycling where multiple column shifts return us to already examined solutions.

Local re-optimization procedure-2 is executed each time after re-optimization procedure-1 has been completed. For each zone, we re-assign SKUs to their most suitable row. This is achieved, by finding a (locally) optimal assignment of SKUs to rows in each zone by solving a transportation problem, which is restricted to the columns and the SKUs of the considered zone (see Sect. 4.1).

Termination criterion Finally, we terminate tabu search when the objective value of the incumbent solution equals the lower bound (see Sect. 4.3) or when we have not been able to improve the incumbent solution \(s^{*}\) for a predefined number of iterations.

4.3 Lower bound procedures

We also derive two lower bound arguments, which help us to benchmark our heuristics if optimal solutions are not available.

\(\textit{LB}_{\mathbf{1}}\). Our first bound is based on the consideration that the maximum load per zone at least amounts to the minimum total ergonomic load \(\Upsilon ^*(Y)\) determined by TP (see Sect. 4.1) equally shared among all zones. Thus, \(LB_1\) amounts to

Note that if all ergonomic stress factors \(e_{jr}\) have integer values, we can round up \(LB_1\) to the next integer.

Example (cont.): For our example of Table 1, we receive \(LB_1=\lceil \frac{1330}{3}\rceil =444\).

\(\textit{LB}_{\mathbf{2}}\). Whenever it is not possible that each zone receives the same number of columns, it is often one of the large zones with an extra column, which constitutes the bottleneck. Therefore, our second bounding argument \(LB_2\), which applies a reasoning for parallel machine scheduling by Haouari et al. (2006), successively explores the best assignments (with lowest possible ergonomic load) for the k (largest) zones with \(k\in \{1, \ldots ,Z-1\}\). If \(k\le C \bmod Z\), then the k largest zones at least contain a total of \(C_k^{*}=(\lfloor \frac{C}{Z}\rfloor +1) \cdot k\) columns (cf. Sect. 4.1). Otherwise, they cover at least \(C_k^{*}=C-\lfloor \frac{C}{Z}\rfloor \cdot (Z-k)\) columns.

For each value \(k\in \{1, \ldots ,Z-1\}\), we calculate the lowest total ergonomic load for the columns that are (at least) contained in the k zones. We compute the lowest ergonomic risks by solving an instance of TP, divide the resulting minimum total load by the number of zones k and take the maximum over all \(k=1,\ldots ,(Z-1) \), which finally leads us to \(LB_2\).

For a specific value k, the corresponding TP instance \(\Delta (k)\) is derived as follows: Each of the original rows \(r=1,\ldots ,R\) gets a column capacity of \(C_k^{*}\) and the original stress factors \(e_{jr}\) are used. An additional virtual row \(r=R+1\) is given the remaining capacity \(|J|-R\cdot C_k^{*}\) of the entire shelf and the stress factors \(e_{j,R+1}=0\) for all SKUs \(j \in J\). The virtual row is intended to receive all remaining SKUs that exceed the capacity of the k zones at no ergonomic cost. Optimizing \(\Delta (k)\) leads to the total ergonomic load \(\Upsilon (\Delta (k))\), so that

Example (cont.): For our example with \(C=5\) columns and \(Z=3\) zones, we have \(k\in \{1,2\}\). For \(k=1\), we consider the single largest zone with at least \(C_1^{*}=(\lfloor \frac{5}{3}\rfloor +1) \cdot 1 = 2\) columns used as the capacity of the rows \(r=1,2,3\). The additional virtual row \(r=4\) gets the remaining \(15-3\cdot 2 = 9\) columns (SKUs). The minimal total ergonomic load determined by TP is \(\Upsilon (\Delta (1))=195\). The \(k=2\) largest zones together have at least \((\lfloor \frac{5}{3}\rfloor +1) \cdot 2 = 4\) columns such that the virtual row gets the \(15 - 3 \cdot 4 = 3\) remaining columns leading to \(\Upsilon (\Delta (2))=804\). Thus, we have \(LB_2=\max \{195,\frac{804}{2}\}=402\).

4.4 Adaptions for solving the general ESAZ

Alternatively to solving surrogate problem ESAZ-basic, the general ESAZ can directly be tackled. This, however, requires an adaption of our solution procedures, which is elaborated in the following.

CR and EZ A straightforward approach to apply our construction heuristics CR and EZ for the general ESAZ is to repeatedly solve ESAZ-basic instances with approximated ergonomic parameters \(e_{jr}\) as described in Sect. 3.2. Preliminary computational tests have shown that the following procedure leads to reasonable results. In the first iteration, we set \(\epsilon _j:=0\) for all SKUs j. In four further iterations, we randomly generate values for \(\epsilon _j\) from the uniform distribution U[0; 0.25]. We evaluate the five constructed solutions with the NIOSH-Eq and take the best one as the output of the procedure.

Our tabu search procedure can directly be applied to the general ESAZ after a minor modification of local re-optimization procedure-2. To do so, we solve the transportation problem TP with approximate ergonomic parameters \(e_{jr}\) five times, once with \(\epsilon _j:=0\) and four times with parameters \(\epsilon _j\) randomly generated from the uniform distribution U[0; 0.25] as described above. We evaluate the constructed solutions with NIOSH-Eq and return the best one. Note that the local re-optimization procedure-2 does not guarantee a locally optimal solution in this case, but it is fast and shows a good performance in our computational experiments nonetheless.

5 Computational study

This section elaborates on our computational tests, where we examine two ergonomic risk measurement approaches: ESAZ-basic, which applies approximate risk measures \(e_{jr}\), and the NIOSH-Eq-based risk measurement leading to the general ESAZ. As there is no established testbed available we, first, describe our generation of test instances (Sect. 5.1). Then, we examine the performance of our solution algorithms in case of linear risk measures \(e_{jr}\) (Sect.5.2) and for the risk measurement with NIOSH-Eq (Sect. 5.3). Furthermore, we evaluate what ergonomic burden threatens if ergonomics aspects are neglected and only performance is considered during workplace design. We also investigate whether our suggestion to solve ESAZ by an iterative application of ESAZ-basic with a linear surrogate objective leads to high-quality solutions, if actually more elaborate measuring methods such as NIOSH-Eq are available. Finally, we address managerial aspects such as appropriate rack layouts and team sizes in Sect. 5.4.

5.1 Instance generation and performance measurement

Our two different approaches of how to quantify ergonomic risks have different levels of detail and, therefore, require separate procedures for data generation. This results in two data sets. The one with the linear risk measures \(e_{jr}\) is dubbed basic data set (abbreviated BDS) and the NIOSH data set (or NDS) considers risk measures according to NIOSH-Eq. Both data sets rely on the same layout of the picking area, but require different ergonomic parameters.

Layout of the picking area Having in mind an order picking setting from a German automotive producer, where parts are picked to supply the final assembly line, we set the number of zones Z and columns C to \(Z=25\) and \(C=150\), respectively. This makes \(\frac{150}{25}=6\) columns (on average) per order picker. Note that, later on, we also vary these values and investigate their impact separately in Sect. 5.4.

In our computational experiments, we presuppose situations with medium or high ergonomic risks. To do so, we randomly generate 50 instances for each of the following four settings: \(R=5\) or \(R=9\) shelf rows per column and either medium or high ergonomic risks. In total, we receive \(50\times 4=200\) instances in each of the two data sets, BDS and NDS.

Ergonomic parameters for BDS During several visits of warehouses (especially in the German automotive industry) the authors have observed that firms often measure ergonomic risks in points. For example, 50 points and higher may indicate a level of high ergonomic risk. Recall that ergonomic points \(e_{jr}\) depend on the height of the row r where SKU j is placed. Mimicking the situation in practice, we presuppose that ergonomic points increase by about 25% when SKUs are moved from a golden-zone row to the highest row. Therefore, we generate ergonomic parameters \(e_{jr}\) in two steps. First, ergonomic points for the most convenient golden-zone row \(r_{mid}\) are drawn from a uniform distribution \(U[0;e_{r_{mid}}^{max}]\). Afterward, to get ergonomic points \(e_{jr}\) of SKU j for row r, its basic points for \(r_{mid}\) are corrected by a row-dependent multiplier varying from 1 to 1.25, which increases in steps of equal size from \(r_{mid}\) to the topmost and bottommost row. We set \(e_{r_{mid}}^{max}=25\) for the case of medium ergonomic risks and \(e_{r_{mid}}^{max}=50\) for the case of high ergonomic risks.

Ergonomic parameters for NDS For the risk measurement with NIOSH-Eq, we have to generate the number of lifts \(\phi _j\) and height-dependent ergonomic parameters \(\sigma _{jr}\) for each SKU j (and each row r). Typically, only a few SKUs are picked very frequently and the majority of SKUs is less frequented. This corresponds to a skewed distribution of the number of lifts with the mean higher than the mode. We draw the number of lifts from a beta distribution with a mean of 0.1 lifts/min and a mode of 0.05 lifts/min (i.e., \(\alpha =1.8\) and \(\beta =16.2\)). With \(\frac{150 columns \cdot 5 rows }{25 zones }=30\) and \(\frac{150\cdot 9}{25}=54\) items on average per zone, this makes \(30 \cdot 0.1=3\) and \(54 \cdot 0.1=5.4\) lifts/min on average, respectively. This corresponds to a common situation in practice as is described in (Marras et al. 2010; Bartholdi and Hackman 2014).

We randomly draw parameters \(\sigma _{jr_{mid}}\) from a uniform distribution U[0; 1.25] for the setting with medium ergonomic risks and from U[0; 2.5] for the setting with high ergonomic risks. We assume rows of equal height. The lowest row has the gripping height of 15 cm and the highest row has the gripping height of 135 cm. The height-dependent parameter \(\sigma _{jr}\) increases by about 36% if SKU j is moved from a golden-zone row to the lowest/or the highest row.

Performance indicators In the following sections, we define the average performance as the average deviation from the optimal solution. We have solved all the instances of BDS to optimality, because the computed lower bound LB1 equaled to the objective value of the best found solution in each case (see Sect. 5.2).

For the NDS data set, because of the complex aggregation and sorting procedures involved in the computation of the NIOSH-Eq indices (see Sect. 3.1) as well as because of the nonlinearity of the frequency multiplier, lower bounds are of rather poor quality. Therefore, we report the average performance (UB), which is the average relative deviation from the best known upper bound and supplement this measure with further analysis.

First of all, to benchmark our procedures for NDS, we compare results of the designed algorithms with randomly generated solutions. To do so, we have divided the rack into equally sized zones and have generated 5 solutions by randomly assigning SKUs to shelves. The best of these solutions is returned and we dub this procedure Random5. We use this approach to simulate a manual planning process were a limited number of solutions (workplace designs) is examined by an ergonomist and the one with best ergonomic performance is chosen. This is intended to show the optimization potential of a computerized algorithm versus the manual ergonomic planning which is typical in practice.

Secondly, for NDS, we also examine the case when SKUs are assigned solely based on picking frequency, which is one of the most widespread performance indicators, i.e., \(e_{jr}\) are replaced by \(\phi _j\) in ESAZ-basic. We dub the results of the approach based on the picking frequency as Performance-based. Balancing the picking frequency among zones is a widespread managerial routine and a common way of modeling in the literature (see, e.g., Rouwenhorst et al. 2000; Koster et al. 2007; Gu et al. 2007, 2010).

We have implemented our algorithms in Visual Basic.NET and all computational experiments have been performed on a personal computer with i7-4770 processor of 3.40 GHz and 16 GB RAM. We have solved the MIP model for ESAZ-basic (see Appendix 1) with standard solver IBM ILOG CPLEX Optimizer 12.6.0.0 (dubbed CPLEX).

5.2 Computational performance: ESAZ-basic

In this section, we analyze the performance of our solution approaches for basic data set BDS and our ESAZ-basic setting. Table 7 lists the average performance of all solution procedures and the number of instances solved to optimality. From these results, the following conclusions can be drawn:

-

Within the given runtime of 1800 s, CPLEX was not able to find an optimal solution for any of the instances. However, the average gap of 1.5% is very low. Also, CPLEX’s lower bounds are rather strong. They equal the optimum in 85% of all instances and are never more than 0.2% away from optimum. When evaluating the performance of CPLEX, it has to be noticed that the instances are rather large (750 and 1350 items, respectively). In preliminary tests with smaller instances of 80 SKUs (\(R=4\) rows and \(C=20\) columns), CPLEX solved most instances to optimality in <1 min, although it was not able to solve a few instances within half an hour time limit.

-

As the standard solver is not able to deliver optimal solutions, we have to fall back on our lower bound procedures. Although it is possible to construct artificial instances with arbitrary bad performance of LB1, in the randomly generated instances of our experiment, LB1 always equaled the optimal objective function value. Such behavior is in line with observations for similar optimization problems such as job rotation scheduling (see Otto and Scholl (2012)) and maybe connected to our data generation procedure, where the ratio \(\frac{e_{jr}}{e_{jr^{\prime }}}\) is constant for all SKUs \(j\in J\) for given rows \(r,r^{\prime }\in \{1,\ldots ,R\}\) and \(e_{jr^{\prime }}\ne 0\). This guess is confirmed by a pretest on a data set of 25 instances with nine rows, 150 columns, 25 zones and ergonomic parameters \(e_{jr}\) drawn independently from a uniform distribution U[500; 1000] for each row r and SKU j. Here, LB1 is never equal to the optimal objective value and it is slightly outperformed by LB2 which increases the lower bound by 0.5% on average. Overall, LB2 is especially effective in case of ergonomic risks being very unevenly distributed among SKUs. However, as risks are distributed uniformly in our BDS-instances (see Sect. 5.1), there is no need to apply the computationally more expensive LB2.

-

Our construction heuristics EZ and CR are computed in fractions of a second and still find solutions of very good quality. The average performance of EZ and CR over all instances is 0.1% and the gap was never larger than 0.5% from the optimum.

-

Tabu search is also very effective in solving ESAZ-basic. It found an optimal solution for all tested instances, while taking just 0.43 s on average (including the time for computing LB1 and the initial solution). Note that we have limited the number of consecutive non-improving iterations to 25. Furthermore, due to the above results we have omitted LB2 in our tabu search procedure.

It can be concluded that our procedures are able to quickly derive high-quality solutions for ESAZ-basic.

5.3 Computational performance for the general ESAZ

In this section, we consider the general ESAZ problem with ergonomic risks measured according to NIOSH-Eq. The results of the algorithms on data set NDS are summarized in Table 8. Unfortunately, the nonlinear aggregation of ergonomic risks hinders an implementation in CPLEX, so that average performance is only measured by the gap from the best upper bound (UB) solution.

For the procedures directly tackling the general ESAZ, the following conclusions can be drawn:

-

Our tabu search procedure has always found the best solution among the compared algorithms for any instance. Note that, again, we have limited the number of non-improving iterations to 25. For more than 40% of the instances, the best solutions are found within the first five iterations and for about 94% of instances within the first 25 iterations. Overall, tabu search took about 15 min per instance on average and required a maximal computation time of 49 min for one of the instances, so that the run time is significantly longer than in case of ESAZ-basic (see Sect. 5.2).

-

Next, we consider a random assignment with Random5 (see Sect. 5.1). Ergonomic risks of the solutions found with Random5 are significantly higher (36–42% higher) than those achieved with our methodology, with a maximum gap of 46%. Thus, a sophisticated optimization procedure seems inevitable.

-

The performance-based procedure Performance-based shows results similar to the random assignments because of unfavorable assignments of SKUs to rows. In the worst case, the gap is 51% from the best known solution, i.e., the maximal ergonomic risk can be considerably reduced by our methodology. Since, in practice planners take not only the picking frequency into account, but also tend to assign heavy and bulky items to the middle rows, we expect this gap to be more moderate in majority of firms. However, estimation of ergonomic risks, as in our methodology, will enable managers to evaluate the trade-offs in ergonomic risks more carefully.

As an intermediate result, it seems best to apply tabu search for solving the general ESAZ. However, the rather long run-times and the complex risk measurement of NIOSH-Eq may suggest a simpler approach. Our recommendation elaborated in Sect. 3.2 is a linear approximation of NIOSH-Eq. First, we examine whether our proxy is a good approximation of the original function. Specifically, we examine whether the original NIOSH-Eq objective function and our linear approximation rank workplaces in a similar way. To do so, we generate a random solution with equally sized zones for each of the 200 NDS instances. Then, we evaluate all zones both by the NIOSH-Eq function and our linear approximation with parameter \(\epsilon _j:=0\). Finally, we compute Spearman’s rank correlation coefficient showing the similarity in rankings of the zones constructed by the NIOSH-Eq and by our approximate ergonomic function. A correlation coefficient of 1 (−1) shows that the two functions are a monotonically non-decreasing (non-increasing) transformation of each other while a correlation coefficient of 0 signifies that the values of the two functions are independent from each other. As we can see from Table 8, the suggested approximation function reproduces the ranking of the NIOSH-Eq rather well (i.e., the correlation coefficient is 0.44–0.51). Note that one simple approach to increase the predictive power of our approach is to iteratively apply approximate ESAZ-basic with different parameters for \(\epsilon _j\) (see Sect. 3.2).

Furthermore, we examine the performance of CR-Approx and EZ-Approx with approximate risk measures \(e_{jr}\) (see Sect. 3.2) and also apply our tabu search algorithm with these approximate linear ergonomic measures. From Table 8, we can see that these approximations perform fairly well and gaps are approximately halved compared to Performance-based. Both simple heuristics, CR-Approx and EZ-Approx, perform better than Random5 for all the examined instances. Tabu-Approx shows similar results to CR-Approx, and EZ-Approx. Observe that for some instances the solution of Tabu-Approx may be worse than that of the heuristics, because Tabu-Approx relies on the approximated objective function. The worst case gap of Tabu-Approx, CR-Approx and EZ-Approx never exceeds 29%.

Thus, it can be concluded that if ergonomic risks are to be measured according to NIOSH-Eq, then directly tackling the NIOSH-Eq objective with tabu search seems the best choice. The price to be paid are quite long computation times. If this is not acceptable, then we recommend using approximate measures of ergonomic risks of a favorable assignment of SKUs to rows. Recall, however, that NIOSH-Eq is only an approximation of the true ergonomic risks by itself. Thus, evaluating which measurement function is indeed best suited to anticipate the actual ergonomic burden of different workplaces seems to be an important task for future research.

5.4 Managerial aspects

This section addresses managerial aspects of workplace design. Specifically, we explore the impact of the rack layout and the team size (i.e., the number of zones) on ergonomic risks. Note that for quantifying the ergonomic impact we apply the NIOSH-Eq measure throughout these experiments.

Rack layout To save space and to reduce unproductive walking time, installing higher racks with many rows and just a few columns is advantageous. From an ergonomics perspective, however, such a workplace design increases ergonomic risks, because more products have to be picked from inconvenient shelves.

To explore the impact of the rack layout on the ergonomic burden, the following experiment has been executed. We generate 20 NDS instances with high ergonomic risks (see Sect. 5.1) and 1350 SKUs. For each instance, we determine the lowest ergonomic risk level by solving the instance with tabu search for 1 row and 1350 columns. This value determines the 100% level in Fig. 3. Then, the deviation of all other potential rack layouts can be calculated (also by applying tabu search). Specifically, we place the 1350 SKUs in racks with 1, 3, 5, 7, 9, 11, and 12 rows as well as 1350, 450, 270, 193, 150, 123, and 113 columns, respectively. Whenever there are more shelves than SKUs (i.e., \(R\cdot C > 1350\)), we fill up our SKU set with dummy SKUs with \(\phi _j=0\) and \(\sigma _{jr}=0\). All rows are assumed to be equal in height (15 cm) and we place the middle row in the golden zone at height 75 cm. The only exceptions are racks with 11 and with 12 rows. Here, we equally spread the rows from 15 to 165 cm and from 7.5 to 172.5 cm, respectively.

Naturally, the ergonomic risks reach their lowest level if all the SKUs are located in the golden-zone level (\(R=1\)). For this rack layout, tabu search and the performance-based approach show quite similar results. Tabu search leads to slightly better zoning decisions with about 12% reduction in ergonomic risks by taking the nonlinear effect of the number of picks (due to the frequency multipliers) into account. With a growing number of rows and more rows at inconvenient height, the performance-based approach leads to a rapid increase in ergonomic risks. In case of 12 rows, for instance, the risks are about 1.4 times higher than for a single-row rack. Interestingly, tabu search is able to keep ergonomic risks low even for high racks with many rows, provided that some light and handy SKUs are present. Indeed, ergonomic risks of a workplace change only slightly if a light and handy item is moved from the golden zone to an inconvenient row.

Number of workplaces A straightforward, but costly, method to reduce ergonomic risks is to apply additional order pickers, so that the same ergonomic load is distributed among a larger workforce. In terms of our problem, this is equivalent to increasing the number of zones Z. We generate 20 NDS instances with high ergonomic risks, nine shelf rows and set the number of zones to 5, 10, 15, 20, 25, 30, 35, 40, 45, 50, 75, and 150. Again, our reference (i.e., 100%) is the lowest ergonomic risk level, which is achieved by tabu search for 150 zones. Figure. 4 depicts the average performance of the performance-based procedure and tabu search depending on varying numbers of zones. As expected, the performance-based approach leads to significantly higher risks, namely to an increase of 20–50%, than our tabu search procedure. Another important finding is that the positive effect of additional workers (and zones) quickly diminishes. Applying 15 instead of 5 workers leads to a remarkable reduction of the maximum ergonomic load. From 20 workers onward only moderate reductions are achievable. This is good news for warehouse managers: Already just a few additional workers (and, thus, moderate additional labor costs) can considerably reduce ergonomic risks.

6 Conclusion

This paper treats the workplace design in the fast pick area of warehouses. SKUs are to be assigned to shelves and the rack is to be partitioned into zones, such that the maximum ergonomic burden among a given workforce is minimized. We formalize the resulting optimization problem and provide suited algorithms for two important cases. For simple ergonomic measures that are often applied in practical applications we treat the ESAZ-basic problem and the general ESAZ covers more complex measurement methods for ergonomic risks such as NIOSH-Eq. Our computational investigations of these two problem settings reveal the following insights for warehouse managers:

-

Neglecting ergonomics and only focusing on economic aspects leads to considerably higher ergonomic risks of the workforce.

-

A simple approximation of complex measurement methods such as NIOSH-Eq already leads to a significant reduction of ergonomic risks and is a reasonable alternative if a good-quality solution has to be received quickly. If computation time is a non-issue, directly tackling a more complex method seems favorable.

-

A sophisticated optimization approach can achieve a good workplace design even in cases of unfavorable rack layouts, i.e., plenty of only uncomfortably reachable shelf rows. By carefully assigning heavy and frequently picked SKUs to the golden zone (and lighter items to inconvenient higher and lower racks) a fair sharing of the ergonomic burden among the workforce can still be reached.

-

The positive impact of additional workers (zones) quickly diminishes. Already just a few additional workers can considerably reduce the ergonomic risks of each worker, whereas this effect becomes negligible if the workforce is already large.

In this paper, we compare the results of our solution approaches with a planning solely based on picking frequency. Future research should also examine ergonomic risks at workplaces planned according to picking time, which is another important performance indicator. Picking time, which is calculated, for example, with the Methods-time measurement (MTM) method (Bokranz and Landau 2006; Longo and Mirabelli 2009), takes some ergonomic aspects into account. For example, the picking time of heavy SKUs is usually higher than that of lighter ones. However, because time measurement methods only estimate the ergonomic aspects relevant for the picking duration, they may not be able to eliminate ergonomic risks and may even result in workplaces with quite high ergonomic risks (cf. Otto and Scholl 2011; Battini et al. 2016b). In particular, the MTM Association recommends supplementing the time measurement with the measurement of ergonomic risks to design workplaces with acceptable physical loads (see www.dmtm.com, Schaub et al. 2004; Walch et al. 2009; Caragnano and Lavatelli 2012). A future study should investigate ergonomic risks of workplace design according to picking times for typical load distributions and layouts of warehouses.

Furthermore, future research should answer the question for the right ergonomics measurement method, which is also suitable for optimization procedures and computer-aided planning processes. Many ergonomics methods, including NIOSH-Eq, are designed to evaluate already existing workplaces by human planners. In the first place, they aim to be straightforward (sometimes at the cost of consistency) and, unavoidably, apply a rough risk estimation only. In a computer-aided planning process, a more rigorous methodology is easily implementable. Once a widely accepted method is available further exact and heuristic solution procedures can be developed. This way, even better workplace designs for the aging workforce of future generations should be obtainable.

References

Bartholdi JJ, Hackman ST (2014) Warehouse & distribution science: Release 0.96. The Supply Chain and Logistics Institute, Georgia Institute of Technology, Atlanta, USA

Battevi N, Pandolfi M, Cortinovis I (2016) Variable lifting index for manual-lifting risk assessment: a preliminary validation study. Hum Factors 58(5):712–725

Battini D, Calzavara M, Otto A, Sgarbossa F (2016a) The integrated assembly line balancing and parts feeding problem with ergonomics considerations. In: 8th IFAC conference on manufacturing modelling, management, and control, 49:191–196

Battini D, Delorme X, Dolgui A, Persona A, Sgarbossa F (2016b) Ergonomics in assembly line balancing based on energy expenditure: a multi-objective model. Int J Prod Res 54:824–845

Battini D, Glock CH, Grosse EH, Persona A, Sgarbossa F (2016c) Human energy expenditure in order picking storage assignment: a bi-objective method. Comput Ind Eng 94:147–157

Battiti R, Tecchiolli G (1994) The reactive tabu search. ORSA J Comput 6(2):126–140

Bautista J, Batalla C, Alfaro R (2013) Incorporating ergonomics factors into the tsalbp. Advances in production management systems. Compet Manuf Innov Prod Serv 397:413–420

Bokranz R, Landau K (2006) Produktivitätsmanagement von Arbeitssystemen. Schäffer-Poeschel Verlag, Stuttgart

Boysen N, Emde S, Hoeck M, Kauderer M (2015) Part logistics in the automotive industry: decision problems, literature review and research agenda. Eur J Oper Res 242(1):107–120

Buckle P, Devereux J (1999) Work-related neck and upper limb musculoskeletal disorders. European Agency for Safety and Health at Work, EU-OSHA, Bilbao

Bundesanstalt für Arbeitsschutz und Arbeitsmedizin (2001) Handlungsanleitung zur Beurteilung der Arbeitsbedingungen beim Heben und Tragen/ beim Ziehen und Schieben von Lasten. Druckhaus Schmergow, Schmergow

Bureau of Labor Statistics (2009) Nonfatal occupational injuries and illnesses requiring days away from work. Economic News Release, 24th November

Bureau of Labor Statistics (2014) Employer-reported workplace injuries and illnesses – 2013. Economic News Release, 24th November

Burkhard RE, Zimmermann UT (2012) Einführung in die mathematische Optimierung. Springer, Berlin

Caragnano G, Lavatelli I (2012) Ergo-mtm model: an integrated approach to set working times based upon standardized working performance and controlled biomechanical load. Work 41:4422–4427

Carnahan BJ, Norman BA, Redfern MS (2001) Incorporating physical demand criteria into assembly line balancing. IIE Trans 33:875–887

Carnahan BJ, Redfern MS, Norman B (2000) Designing safe job rotation schedules using optimization and heuristic search. Ergonomics 43:543–560

Chaffin DB, Erig M (1991) Three-dimensional biomechanical static strength prediction model sensitivity to postural and anthropometric inaccuracies. IIE Trans 23:215–227

Costa AM, Miralles C (2009) Job rotation in assembly line employing disabled workers. Int J Prod Econ 120:625–632

Dallari F, Marchet G, Melacini M (2009) Design of order picking system. Int J Adv Manuf Technol 42:1–12

de Koster R, Le-Duc T, Roodbergen KJ (2007) Design and control of warehouse order picking: a literature review. Eur J Oper Res 182:481–501

de Koster RB, Le-Duc T, Zaerpour N (2012) Determining the number of zones in a pick-and-sort order picking system. Int J Prod Res 50:757–771

Dempsey PG (2002) Usability of the revised niosh lifting equation. Ergonomics 45(12):817–828

Drury GC, Roberts DP, Hangsen R, Bayman JR (1983) Evaluation of palletizing aid. Appl Ergon 14:242–246

Elfeituri FE, Taboun SM (2002) An evaluation of the NIOSH lifting equation: a psychophysical and biomechanical investigation. Int J Occup Saf Ergon 8(2):243–258