Abstract

Folic acid is an important biological compound for human disease diagnosis. Traditional detection methods of folic acid are mostly time-consuming or dependent on analytical equipment. Here we demonstrate the rapid and colorimetric detection of folic acid using a novel colorimetric sensor enabled by molecularly imprinted photonic hydrogels, which are prepared by the polymerization of precursor solution in the interstitial voids of the polystyrene colloidal crystal and subsequent removal of colloidal crystal and folic acid molecules. As folic acid is instable under the preparation process of molecularly imprinted photonic hydrogels, we introduce folic acid (imprinted molecule) in the form of supramolecular complex with β-CD units to improve its stability and further create stable molecular recognition sites. The folic acid recognition can be directly transferred into a visually perceptible color change due to the highly ordered macroporous structure. With this novel sensory system, the highly selective, high sensitive (as low as 10–12 M), and rapid response (< 60 s) to folic acid is achieved without the use of instruments.

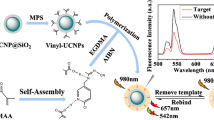

Graphic abstract

A novel folic acid colorimetric sensor enabled by molecularly imprinted photonic hydrogels is successfully prepared.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Folic acid is highly involved in human metabolism, such as cell proliferation, tissue growth and the synthesis of purines and pyrimidines for DNA [1,2,3]. As such, the deficiency of folic acid would lead to severe diseases including birth defects, haemolytic anaemia, myeloproliferative disorders, cardiovascular and cerebrovascular diseases, and certain type of cancer [3,4,5]. Consequently, the monitor of folic acid level in human body is valuable for these disease diagnosis. Until now, the available detection methods mainly include microbiological assay [6], chromatographic methods [7, 8], enzyme protein binding assay [9], and electrochemical sensors [10,11,12,13]. These methods have shown high sensitivity and specificity for the detection of folic acid, but they all have some drawbacks limiting their further application. Microbiological assay is time-consuming (maximum 5 days) and requires elaborate operation. Chromatographic methods involve expensive and large-scale instruments. The kits involved in enzyme protein binding assay have short shelf-life. Electrochemical sensors show high effectiveness and is cost-effective, but the instrument is still required for presenting the assay results. Considering that, a rapid and self-reporting assay approach like a pH test paper without any instruments would be promising for the detection of folic acid.

Recently, a rapid and self-reporting assay approach with high sensitivity and selectivity (termed as molecularly imprinted photonic hydrogels colorimetric sensor) has been proposed based on the combination of molecular imprinting, colloidal crystal and polymer hydrogels [14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34]. In this approach, molecular imprinting allows for the construction of specific molecular-recognition sites, enabling high sensitivity and selectivity toward the imprinted molecules [35,36,37]. Colloidal crystal would bring about periodic lattice spacing (highly ordered and interconnected macropore array), thus enabling fascinating Bragg diffraction and bright structural colors [38,39,40,41,42]. Polymer hydrogels could swell or shrink rapidly in response to physical or chemical stimuli and give rise to volume changes [43,44,45], thus leading to shift of Bragg diffraction peak and a visually perceptible color change (self-reporting signal) if the periodic lattice spacing has been incorporated into polymer hydrogels [46,47,48,49].

So far, a large amount of molecularly imprinted photonic hydrogels colorimetric sensors have been constructed to detect various kinds of molecules, such as amino acid [28, 29] and bisphenol A [30] with relatively small molecular size, tetracycline [15], cholesterol [19] and protein [31] with large molecular size. They could deliver rapid visually perceptible color change upon exposing into the relevant molecule solution with different concentration, thus enabling a rapid and self-reporting assay for target molecules without any instruments. These fascinating work would naturally inspire the colorimetric detection of folic acid based on molecularly imprinted photonic hydrogels. Nevertheless, folic acid colorimetric sensor enabled by molecularly imprinted photonic hydrogels has never been reported, probably due to the difficult imprinting of folic acid—it is hard to acquire specific molecular-recognition sites by the molecular imprinting since folic acid is instable under the synthetic condition (high temperature or UV radiation) of molecularly imprinted photonic hydrogels [10, 11, 50]. Therefore, the prerequisite for successfully constructing folic acid molecularly imprinted photonic hydrogels lies in keeping folic acid stable during the molecular imprinting.

On another note, supramolecular chemistry has been recognized as a powerful tool in molecular imprinting [36, 37]. The rationale behind is that the strong supramolecular interaction can effectively enhance the interaction between binding sites and target molecules. As a star molecule in supramolecular chemistry, β-cyclodextrins (β-CD) has been incorporated into hydrogel precursor solution for synthesizing molecularly imprinted photonic hydrogels [22, 29], and help to improve their sensing performance. Moreover, β-CD could enhance the stability and aqueous solubility of folic acid by forming supramolecular complex [51,52,53]. By virtue of the improved stability, the imprinting of folic acid would become possible. The hypothesis made herein was that the folic acid molecularly imprinted photonic hydrogels colorimetric sensor would be constructed if each folic acid molecule could exist in the form of supramolecular complex with β-CD during the whole fabrication process.

To explore this possibility, we introduce folic acid (imprinted molecule) in the form of supramolecular complex with β-CD units to the hydrogel precursor solution, instead of simply mixing imprinted molecules and functional monomers in solution. Assisted by this novel motif, folic acid molecularly imprinted photonic hydrogels is prepared by the UV-polymerization of precursor solution in the interstitial of the polystyrene colloidal crystal. After the removal of colloidal crystal and folic acid molecules, a folic acid colorimetric sensor enabled by molecularly imprinted photonic hydrogels is finally fabricated. The morphology of the molecularly imprinted photonic hydrogels at different stages was systematically investigated. Different parameters affecting the fabrication process and sensing properties were studied and optimized in detail. The proposed sensor enables a relatively highly selective, highly sensitive, and rapid colorimetric detection of folic acid without any instruments. Introducing imprinting molecule in the form of supramolecular complex to the hydrogel precursor solution represents an effective and novel strategy for fabricating molecularly imprinted photonic hydrogel sensor.

Experimental

Materials

Folic acid (FA), theophylline, L-glutamic acid, pteroic acid, and β-cyclodextrins (β-CD) were purchased from Aladdin Chemistry Co., Ltd. (China). Acrylamide (AM), maleic anhydride (MAH), N,N-dimethylformamide (DMF), styrene, acrylic acid, ammonium persulfate (APS) and N,N′-methylene bisacrylamide (BIS) were supplied by Sinopharm Chemical Reagent Co., Ltd. (China). 2,2-Diethoxyacetophenone (DEAP) was purchased from TCI (Shanghai) Chemical Industry Development Co., Ltd. β-CD was purified by recrystallization, and then dried under vacuum for 24 h. DMF was treated with active molecular sieve to remove trace water. Styrene and acrylic acid was purified by vacuum distillation. Other chemicals were directly used without further purification. Glass slides (76.2 mm × 24.5 mm × 1 mm) as colloidal crystal supports were well-cleaned using acetone, anhydrous ethanol and distilled water in an ultrasonic bath.

Preparation of polystyrene (PS) colloidal crystal

Polystyrene (PS) colloidal crystal was prepared following our previously reported procedure [22]. Briefly, the monodispersed PS colloids (Fig. S1a) were first synthesized by emulsifier-free emulsion polymerization. Then, the PS colloids self-assembled into colloidal crystal in a simple vertical deposition process. Fig. S1b and Fig. 1b shows that the colloidal crystal delivers highly ordered face-center-cubic close-packed structure. The interstitial between colloids would allow hydrogel precursor solution penetrating into.

Preparation of hydrogel precursor solution

Different from simply mixing imprinted molecules and functional monomers in solution, we prepared hydrogel precursor solution by dissolving folic acid supramolecular complex with β-CD derivatives into acrylamide aqueous solution with BIS as a cross-linker and DEAP as an initiator. The fabrication of supramolecular complex includes two critical steps: (1) β-CD was modified by using maleic anhydride to introduce vinyl carboxylic acid groups (termed as MAH-β-CD), enabling the integration of β-CD units into polyacrylamide hydrogels by simple radical copolymerization [54], and (2) a freeze-drying process was used to prepare folic acid supramolecular complex with MAH-β-CD. The successful preparation of supramolecular complex is demonstrated by the FT-IR spectra and XRD patterns of folic acid, MAH-β-CD, and supramolecular complex (Fig. S2). Additionally, the supramolecular complex shows darker yellow color in comparison with the MAH-β-CD, also indicating the successful fabrication of supramolecular complex.

Preparation of folic acid colorimetric sensors enabled by molecularly imprinted photonic hydrogels

The prepared hydrogel precursor solution was infiltrated into the interstitial of colloidal crystal by using a capillary-attraction-induced method and then was polymerized in an ice bath by irradiation at 254 nm for 2 h to obtain molecularly imprinted photonic hydrogels adhered onto glass slide. Afterwards, molecularly imprinted photonic hydrogels exfoliated automatically by immersing into deionized water. The exfoliated hydrogels were immersed in dimethylbenzene to fully etch the PS colloids, and subsequently incubated in methanol/acetic acid (8/2, v/v) until no obvious UV–Vis absorbance in eluent (Fig. S3), thus indicating effective removal of folic acid molecules. Finally, folic acid colorimetric sensor (termed as Sensor I) enabled by free-standing molecularly imprinted photonic hydrogels was fabricated by rinsing with methanol and neutral phosphate buffer. Two reference sensors were synthesized with the same method, but using different precursor solution: Sensor II, also known as non-molecularly imprinted photonic hydrogels, was based on the precursor in the absence of folic acid; Sensor III was based on the precursor by simply mixing folic acid and functional monomers.

Characterization

Morphologies of colloidal crystal and photonic hydrogels were observed by field emission scanning electron microscopy (SEM, Hitachi, S-4800). The X-ray diffraction patterns of folic acid and supramolecular complex with β-CD were collected by X-ray diffractometer (XRD, D8 Advance, Bruker) with Cu Kα radiation (λ = 1.5418 Å). UV–Vis spectra of the eluent were recorded by using a TU-1901 UV–Vis spectrophotometer. The sensing properties of the prepared sensors were checked by exposure to folic acid buffer one after another from low to high concentrations. After final testing, the sensor was soaked again in a methanol/acetic acid (8/2, v/v) solution and then purged thoroughly with neutral phosphate buffer to recover the blank state for the next detection. The Bragg diffraction wavelength shift of sensors upon exposing into folic acid solution can be used to evaluate the sensor performance and was recorded by a miniature fiber optic spectrometer (FLA 4000 + , China). The corresponding color change was obtained by using a common digital camera under a daylight lamp.

Results and discussion

Fabrication of folic acid colorimetric sensor

In this work, the folic acid colorimetric sensor was enabled by free-standing molecularly imprinted photonic hydrogels. Figure 1a shows a conventional three-step approach employed for the fabrication of molecularly imprinted photonic hydrogels:

Step I the self-assembly of polystyrene (PS) colloids into colloidal crystal (Fig. 1a–i). Monodispersed PS colloids with a diameter of ~ 200 nm (Fig. S1a) were used to form purple colloidal crystal on glass slide (Fig. S1c). PS colloidal crystal with face-center-cubic close-packed structure (Fig. 1b) was used as template to create highly ordered periodic structure, and the interstitial space was used for accommodating the hydrogel precursor.

Step II the infiltration and polymerization of hydrogel precursor (Fig. 1a-ii). For the effective infiltration of precursor, a “sandwich structure” was firstly obtained by covering PS colloidal crystal templates with a quartz glass plate and immobilizing tightly. Based on this structure, the precursors could infiltrate the interstitial of PS colloidal crystal templates by capillary-attraction-induced force. Through polymerization, PS colloidal crystal was readily immobilized into polymer hydrogels (Fig. 1c). The hydrogel can be readily exfoliated from the glass slides by immersing in deionized water before step III. The exfoliated hydrogel would overcome the constraint on swelling by substrate, thus enhancing the sensitivity of the molecularly imprinted photonic hydrogels.

Step III the removal of PS colloids and imprinted folic acid molecules (Fig. 1a-iii). The removal of PS colloids yielded 3D highly ordered and interconnected macroporous arrays with a thin hydrogel wall (~ 50 nm in thickness, Fig. 1d), thus imparting the polymer hydrogels with fascinating Bragg diffraction and bright structural color (Fig. S4). The removal of the folic acid molecules imparts the specific molecular-recognition sites that are complementary to the folic acid molecules in both shape and functionality in the thin hydrogel wall. The presence of macropores and thin hydrogel wall is beneficial for mass transport in hydrogel, enabling easier accessibility to specific molecular-recognition sites and rapid swell or shrinkage in response to analytes.

The prerequisite for constructing molecularly imprinted photonic hydrogels with high specificity lies in the formation of specific molecular-recognition sites during the molecular imprinting. However, it is hard to acquire specific molecular-recognition sites for folic acid by the molecular imprinting since folic acid is instable under the synthetic condition of high temperature or UV radiation [10, 11, 50] In order to keep folic acid stable during the molecular imprinting, β-cyclodextrins (β-CD) units are incorporated to form supramolecular complex with folic acid. To achieve this design, we proposed a novel process for the preparation of hydrogel precursor solution by dissolving folic acid supramolecular complex with MAH-β-CD into acrylamide aqueous solution, instead of simply mixing imprinted molecules and functional monomers in solution.

In this work, multiple interactions including (1) supramolecular interaction between hydrophobic cavities of β-CD units and pteridine group of folic acid, and (2) hydrogen binding between amino group of acrylamide monomer and carboxylic groups of folic acid, play a vital role in the construction of specific molecular-recognition sites. The possible establishment process is shown schematically in Fig. 2. The removal of imprinted molecules folic acid from polymer matrix yields specific molecular-recognition sites which would not only deliver strong interaction with folic acid, but are topographically complementary in shape and size.

The specific molecular-recognition sites in polymer matrix arise from the removal of imprinted molecules in supramolecular complex. In our case, adding more supramolecular complex would yield a sensor with increased number of recognition sites, thus improving the sensing performance. Fig. S5a, b and c shows the sensing performance of sensors fabricated by using different contents of supramolecular complex upon exposing into folic acid buffer one after another from low to high concentrations (Pure buffer, 10–12 M, 10–11 M, 10–10 M, 10–9 M, 10–8 M, and 10–7 M). For a better comparison, the Bragg diffraction peak shift (Δλ) of sensors at different concentration of folic acid is plotted in Fig. S5d. With the increment of supramolecular complex from 0.3 to 1 mmol, the maximum redshift increases from 61 to 132 nm when immersed in folic acid buffer of 10–7 M, indicating the enhanced sensing performance. Although increasing the supramolecular complex content could greatly improve the sensing performance of sensors, it is impossible to infinitely increase the supramolecular complex content because too much β-CD units in precursor impede the formation of polymer hydrogels. Additionally, the sensor based on the hydrogel precursor with 1 mmol supramolecular complex could deliver obviously visually perceptible color change with the shift of Bragg diffraction peak from 502 to 634 nm. Therefore, the supramolecular complex content was fixed at 1 mmol.

As the shift of Bragg diffraction peak is tightly related with the swelling or shrinkage of photonic hydrogels, the degree of crosslinking would be a critical parameter for the construction of molecularly imprinted photonic hydrogels. Therefore, different ratio of cross-linker to acrylamide (2, 4, and 6%) was further explored. Fig. S6 compares the sensing performance of sensors fabricated by using different contents of cross-linker upon exposing into folic acid buffer one after another from low to high concentrations (Pure buffer, 10–12 M, 10–11 M, 10–10 M, 10–9 M, 10–8 M, and 10–7 M). With higher amounts of cross-linker, the photonic hydrogels deliver higher crosslinking degree. This would lead to contradictory phenomenon: (1) the integrity of 3D ordered macroporous structure and delicate recognition sites would be well maintained, enhancing the specific recognition capability, and (2) the swelling and shrinkage capability of the photonic hydrogels would be weakened, decreasing the Bragg diffraction shifts upon exposure to the target analytes (84 nm at 6% vs. 132 nm at 4%). In contrast, a lower content of cross-linker (2%) cannot create stable recognition sites in photonic hydrogels, deteriorating the adsorption of target analytes and thus leading to small Bragg diffraction shifts (94 nm). To strike a balance between stable recognition sites and good swelling/shrinkage capability, the ratio of cross-linker to acrylamide was selected as 4%.

Sensing properties of the sensor

Based on the optimized recipe, folic acid colorimetric sensor (Sensor I) enabled by molecularly imprinted photonic hydrogels was successfully fabricated. The sensing properties were checked by exposure to folic acid buffer one after another from low to high concentrations (Pure buffer, 10–12 M, 10–11 M, 10–10 M, 10–9 M, 10–8 M, and 10–7 M). All measurements are repeated for three times. Figure 3a shows the sensing performance of Sensor I. The Bragg diffraction peak of the sensor in folic acid buffer of 10–7 M redshifted 132 nm in comparison with that of original sensor in buffer (Fig. 3d). The color changes that accompany the Bragg diffraction peak shift are visually evident (Fig. 3e). Even upon exposure to 10–12 M folic acid in phosphate buffer, the diffraction peak of sensor shifted from 502 to 519 nm, and it delivers an obviously color change. From this point of view, this sensor delivers detection limits of as low as 10–12 M for folic acid.

To demonstrate that the diffraction peak shift is induced by the well-designed molecular recognition sites, we also performed control experiment by preparing non-molecularly imprinted photonic hydrogels (termed as Sensor II) with the same method, but in the absence of folic acid. Figure 3b shows the sensing performance of Sensor II. As clearly shown in Fig. 3d, the Bragg diffraction peak only shifted slightly upon exposure to 10−7 M folic acid buffer probably due to some nonspecific adsorption, and the Bragg diffraction peak shift of non-molecularly imprinted photonic hydrogels is relatively stable in three cyclic measurements. The clear difference in Bragg diffraction peak shift between Sensor I and Sensor II indicates that the molecular recognition sites created by molecular imprinting are responsible for the good sensing properties of proposed sensor.

In order to further emphasize the significance of our design (introducing folic acid in the form of supramolecular complex to the hydrogel precursor solution, instead of simply mixing imprinted molecules and functional monomers in solution), we also compared the sensing properties of Sensor III based on the precursor by simply mixing folic acid and functional monomers. Figure 3c shows the sensing performance of Sensor III. The peak of Sensor III soaked in 10–7 M folic acid redshifted 72 nm (Fig. 3d), which is lower than that of Sensor I (132 nm). This may be due to that the smaller number of molecular recognition sites is created using precursor prepared by simply mixing of imprinted molecules and functional monomers. During mixing process, not all folic acid can form supramolecular complex with β-CD units, leading to partial degradation of folic acid upon UV irradiation and thus decreased number of molecular recognition sites. The results described above clearly indicate that adding folic acid supramolecular complex with β-CD units to the hydrogel precursor solution could ensure the stable existence of folic acid during the polymerization process and the formation of molecular recognition sites by the removal of folic acid.

Selectivity of the sensor

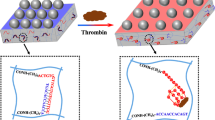

The demonstrated Bragg diffraction peak shift upon exposure in folic acid buffer indicates that the fabricated sensors could respond to folic acid and that the recognition process is accompanied by visually perceptible color change (Fig. 3). Further, the selectivity and sensing specificity of sensor were evaluated by using pteroic acid, theophylline, and L-glutamic acid as the reference compounds, which are structurally related to that of folic acid (Fig. 4a). Figure 4b shows the observed Bragg diffraction peak shift upon exposure of the sensor to 10−7 M solution each of folic acid, pteroic acid, theophylline, and L-glutamic acid. In comparison with folic acid, these structurally related compounds only induce relatively smaller Bragg diffraction peak shift under the same measurement conditions. The slight shift is believed to be caused by the less non-specific adsorption of molecularly recognition sites. In contrast, much more folic acid can be adsorbed into hydrogel matrix due to the complementary shape, size, and interaction sites with the molecularly recognition sites, causing the larger swelling of the hydrogels and thereby inducing the larger shift of the Bragg diffraction peak. Although the sensor did not show absolutely sensing specificity to folic acid, the most pronounced shift for sensing of folic acid indicates that the sensor is able to efficiently discriminate these structurally related compounds.

a Chemical structures of folic acid, pteroic acid, theophylline, and L-glutamic acid. b Observed changes in Bragg diffraction peak shift of the sensor upon the binding of competing molecules: demonstrating the relative selectivity of the sensor toward folic acid. c Schematic illustration of the folic acid binding into molecular recognition sites and swelling the hydrogel

According to the above results, we proposed the sensing mechanism of the sensor: the formed molecular recognition sites within the thin hydrogel wall would adsorb folic acid specifically due to the complementary shape, size and interaction sites (Fig. 4c), thus inducing the formation of concentration gradient of folic acid between hydrogel matrix and solution. To offset the concentration gradient, more water would penetrate into the hydrogel matrix and swell the hydrogel (this is similar as a cell swelling process when solute concentration in intracellular fluid is higher than that in extracellular fluid), causing the shift of the Bragg diffraction peak and visually perceptible color change.

Rapid response and recoverability of the sensor

The 3D highly ordered and interconnected macroporous arrays of the sensor not only enable visually perceptible color, but endow the rapid mass transport from bulk solution to recognition sites during the binding process of target analytes. On the other hand, the created recognition sites are situated either at the surface or in proximity to the surfaces of the thin hydrogel wall, which is also favorable for rapid binding to recognition sites. Figure 5a shows that the sensor exhibited a very fast response (the response process was completed within 60 s). Similarly, the responded sensor can be easily recovered by using methanol/acetic acid for the extraction of rebinding molecules. Figure 5b exhibits the diffraction peak changes over six cycles, indicating good recoverability of the sensor.

Conclusions

In summary, a novel folic acid colorimetric sensor enabled by molecularly imprinted photonic hydrogels was successfully developed by introducing folic acid (imprinted molecule) in the form of supramolecular complex with β-CD units to the hydrogel precursor solution. Benefited from the protection effect of β-CD, folic acid is stable during the polymerization process, and thus the specific molecular recognition sites are created by the removal of folic acid. Owing to the complementary shape, size and interaction sites with well-designed molecular recognition sites, the demonstrated sensor delivers high selectivity, sensitivity, and rapid response to folic acid. More importantly, the response can be directly readable by the visually perceptible color change. This work provides a new avenue for the successful imprinting of molecules that may decompose during the molecularly imprinting.

References

Apodaca DC, Pernites RB, Ponnapati RR, Del Mundo FR, Advincula RC (2011) Electropolymerized Molecularly Imprinted Polymer Films of a Bis-Terthiophene Dendron: Folic Acid Quartz Crystal Microbalance Sensing. ACS appl mater interfaces 3:191–203

Hussain M, Iqbal N, Lieberzeit PA (2013) Acidic and basic polymers for molecularly imprinted folic acid sensors—QCM studies with thin films and nanoparticles. Sensors and Actuators B: Chemical 176:1090–1095

Gupta K, Pandey A, Gangopadhyay AN, Prasad S, Singh TB, Khanna HD, Upadhyaya VD (2008) Estimation and correlation of serum folic acid levels in spina bifida babies and their mothers. J Pediatr Neurosci 3:134–137

Prasad BB, Tiwari MP, Madhuri R, Sharma PS (2010) Development of a highly sensitive and selective hyphenated technique (molecularly imprinted micro-solid phase extraction fiber–molecularly imprinted polymer fiber sensor) for ultratrace analysis of folic acid. Anal Chim Acta 662:14–22

Ashraf MJ, Cook JR, Rothberg MB (2008) Clinical Utility of Folic Acid Testing for Patients with Anemia or Dementia. J gen intern med 23:824–826

Wallock LM, Tamura T, Mayr CA, Johnston KE, Ames BN, Jacob RA (2001) Fertil Steril 75:252–259

Leporati A, Catellani D, Suman M, Andreoli R, Manini P, Niessen WMA (2005) Anal Chim Acta 531:87–95

Brusač E, Jeličić ML, Amidžić Klarić D, Nigović B, Turk N, Klarić I, Mornar A (2019) Pharmacokinetic profiling and simultaneous determination of thiopurine immunosuppressants and folic acid by chromatographic methods. Molecules 24(19):3469

Arcot J, Shrestha AK, Gusanov U (2002) Enzyme protein binding assay for determining folic acid in fortified cereal foods and stability of folic acid under different extraction conditions. Food Control 13:245–252

Prasad BB, Madhuri R, Tiwari MP, Sharma PS (2010) Electrochemical sensor for folic acid based on a hyperbranched molecularly imprinted polymer-immobilized sol–gel-modified pencil graphite electrode. Sensors and Actuators B: Chemical 146:321–330

Karimian N, Zavar MHA, Chamsaz M, Turner APF, Tiwari A (2013) On/off-switchable electrochemical folic acid sensor based on molecularly imprinted polymer electrode. Electrochem Commun 36:92–95

Ruiyi L, Tinling P, Hongxia C, Jinsong S, Zaijun L (2020) Electrochemical detection of cancer cells in human blood using folic acid and glutamic acid-functionalized graphene quantum dot-palladium@gold as redox probe with excellent electrocatalytic activity and target recognition. Sensors and ActuatorsB: Chemical 309:127709

Hussain S, Zaidi SA, Vikraman D, Kim H-S, Jung J (2019) Facile preparation of molybdenum carbide (Mo2C) nanoparticles and its effective utilization in electrochemical sensing of folic acid via imprinting. Biosens Bioelectron 140:111330

Hu X, An Q, Li G, Tao S, Liu J (2006) Imprinted Photonic Polymers for Chiral Recognition. Angew Chem Int Ed 45:8145–8148

Wang L-Q, Lin F-Y, Yu L-P (2012) A molecularly imprinted photonic polymer sensor with high selectivity for tetracyclines analysis in food. Analyst 137:3502–3509

Wu Z, Tao CA, Lin C, Shen D, Li G (2008) Label-Free Colorimetric Detection of Trace Atrazine in Aqueous Solution by Using Molecularly Imprinted Photonic Polymers. Chem-A Eur J 14:11358–11368

Wang Y-F, Fan J, Meng Z-H, Xue M, Qiu L-L (2019) Fabrication of an antibiotic-sensitive 2D-molecularly imprinted photonic crystal. Anal Methods 11:2875–2879

Hu X, Li G, Li M, Huang J, Li Y, Gao Y, Zhang Y (2008) Ultrasensitive Specific Stimulant Assay Based on Molecularly Imprinted Photonic Hydrogels. Adv Funct Mater 18:575–583

Li J, Zhang Z, Xu S, Chen L, Zhou N, Xiong H, Peng H (2011) Label-free colorimetric detection of trace cholesterol based on molecularly imprinted photonic hydrogels. J Mater Chem 21:19267–19274

Xu D, Zhu W, Wang C, Tian T, Cui J, Li J, Wang H, Li G (2014) Molecularly Imprinted Photonic Polymers as Sensing Elements for the Creation of Cross-Reactive Sensor Arrays. Chem-A Eur J 20:16620–16625

Zhou C, Wang T, Liu J, Guo C, Peng Y, Bai J, Liu M, Dong J, Gao N, Ning B (2012) Molecularly imprinted photonic polymer as an optical sensor to detect chloramphenicol. Analyst 137:4469–4474

Yang Z, Shi D, Chen M, Liu S (2015) Free-standing molecularly imprinted photonic hydrogels based on β-cyclodextrin for the visual detection of 1-tryptophan. Anal Methods 7:8352–8359

Chen W, Meng Z, Xue M, Shea KJ (2016) Molecular imprinted photonic crystal for sensing of biomolecules. Molecular Imprinting 4:1–12

Chen Q, Shi W, Cheng M, Liao S, Zhou J, Wu Z (2018) Molecularly imprinted photonic hydrogel sensor for optical detection of L-histidine. Microchim Acta 185:55

Moirangthem M, Arts R, Merkx M, Schenning APHJ (2016) An Optical Sensor Based on a Photonic Polymer Film to Detect Calcium in Serum. Adv Funct Mater 26:1154–1160

Qiu X, Chen W, Luo Y, Wang Y, Wang Y, Guo H (2020) Highly sensitive α-amanitin sensor based on molecularly imprinted photonic crystals. Anal Chim Acta 1093:142–149

Wang P, Sun X, Su X, Wang T (2016) Advancements of molecularly imprinted polymers in the food safety field. Analyst 141:3540–3553

Zhang Y, Pan Z, Yuan Y, Sun Z, Ma J, Huang G, Xing F, Gao J (2013) Molecularly imprinted photonic crystals for the direct label-free distinguishing of l-proline and d-proline. Phys Chem Chem Phys 15:17250–17256

Liu X-Y, Fang H-X, Yu L-P (2013) Molecularly imprinted photonic polymer based on β-cyclodextrin for amino acid sensing. Talanta 116:283–289

Griffete N, Frederich H, Maître A, Ravaine S, Chehimi MM, Mangeney C (2012) Inverse Opals of Molecularly Imprinted Hydrogels for the Detection of Bisphenol A and pH Sensing. Langmuir 28:1005–1012

Hu X, Li G, Huang J, Zhang D, Qiu Y (2007) Construction of Self-Reporting Specific Chemical Sensors with High Sensitivity. Adv Mater 19:4327–4332

Li L, Lin Z, Huang Z, Peng A (2019) Rapid detection of sulfaguanidine in fish by using a photonic crystal molecularly imprinted polymer. Food Chem 281:57–62

Lu W, Dong X, Qiu L, Yan Z, Meng Z, Xue M, He X, Liu X (2017) Colorimetric sensor arrays based on pattern recognition for the detection of nitroaromatic molecules. J hazardous mate 326:130–137

Deng J, Chen S, Chen J, Ding H, Deng D, Xie Z (2018) Self-Reporting Colorimetric Analysis of Drug Release by Molecular Imprinted Structural Color Contact Lens. ACS appl mater interface 10:34611–34617

Chen L, Wang X, Lu W, Wu X, Li J (2016) Molecular imprinting: perspectives and applications. Chem Soc Rev 45:2137–2211

Dickert FL, Hayden O (1999) Molecular imprinting in chemical sensing. TrAC, Trends Anal Chem 18:192–199

M. Komiyama, T. Takeuchi, T. Mukawa, H. Asanuma (2003) Molecular imprinting. Wiely, Mörlenbach, Germany

Vukusic P, Sambles JR (2003) Photonic structures in biology. Nature 424:852–855

Stein A, Wilson BE, Rudisill SG (2013) Design and functionality of colloidal-crystal-templated materials—chemical applications of inverse opals. Chem Soc Rev 42:2763–2803

Waterhouse GIN, Waterland MR (2007) Opal and inverse opal photonic crystals: Fabrication and characterization. Polyhedron 26:356–368

Zhang J, Wang L, Lamont DN, Velankar SS, Asher SA (2012) Fabrication of Large-Area Two-Dimensional Colloidal Crystals. Angew Chem 51:6117–6120

Zhang J, Wang L, Chao X, Velankar SS, Asher SA (2013) Vertical spreading of two-dimensional crystalline colloidal arrays. J Mater Chem C 1:6099–6102

Buenger D, Topuz F, Groll J (2012) Hydrogels in sensing applications. Prog Polym Sci 37:1678–1719

Tavakoli J, Tang Y (2017) Hydrogel Based Sensors for Biomedical Applications: An Updated Review. Polymers 9:364

Mohammadinejad R, Maleki H, Larrañeta E, Fajardo AR, Nik AB, Shavandi A, Sheikhi A, Ghorbanpour M, Farokhi M, Govindh P (2019) Status and future scope of plant-based green hydrogels in biomedical engineering. Appl Mater Today 16:213–246

Fenzl C, Hirsch T, Wolfbeis OS (2014) Photonic Crystals for Chemical Sensing and Biosensing. Angew Chem Int Ed 53:3318–3335

Smith NL, Hong Z, Asher SA (2014) Responsive ionic liquid–polymer 2D photonic crystal gas sensors. Analyst 139:6379–6386

Cai Z, Zhang JT, Xue F, Hong Z, Punihaole D, Asher SA (2014) 2D Photonic Crystal Protein Hydrogel Coulometer for Sensing Serum Albumin Ligand Binding. Anal Chem 86:4840–4847

Cai Z, Sasmal A, Liu X, Asher SA (2017) Responsive Photonic Crystal Carbohydrate Hydrogel Sensor Materials for Selective and Sensitive Lectin Protein Detection. ACS Sensors 2:1474–1481

Arcot J, Shrestha A (2005) Trends in Food Science & Technology. Trends Food Sci Technol 16:253–266

Ceborska M, Zimnicka M, Pietrzak M, Troć A, Koźbiał M, Lipkowski J (2012) Structural diversity in native cyclodextrins/folic acid complexes – from [2]-rotaxane to exclusion compound. Org biomol chem 10:5186–5188

Ceborska M, Zimnicka M, Wszelaka-Rylik M, Troć A (2016) Characterization of folic acid/native cyclodextrins host–guest complexes in solution. J Mol Struct 1109:114–118

Brewster ME, Loftsson T (2007) Cyclodextrins as pharmaceutical solubilizers. Adv drug deliv rev 59:645–666

Liu Y-Y, Fan X-D (2002) Synthesis and characterization of pH- and temperature-sensitive hydrogel of N-isopropylacrylamide/cyclodextrin based copolymer. Polymer 43:4997–5003

Acknowledgements

This work was funded by the National Nature Science Foundation of China (Grant No.21571084), National First-Class Discipline Program of Light Industry Technology and Engineering (LIFE2018-19), MOE & SAFEA for the 111 Project (B13025), Scientific Research Starting Foundation for PhD (BT2015-01), and the Union of Industry-Study-Research in Jiangsu (BY2020441).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yang, Z., Gong, F., Yu, Z. et al. Highly sensitive folic acid colorimetric sensor enabled by free-standing molecularly imprinted photonic hydrogels. Polym. Bull. 79, 1857–1871 (2022). https://doi.org/10.1007/s00289-021-03584-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03584-2