Abstract

It is evermore imperative to develop green processes and products due to the environmental and health problems facing modern society. Thus, the aims of this study were as follows: to use HPLC–MS to identify and quantify the phenolic compounds in Amazon Curcuma longa L. starch; to develop a bioactive starch film and to characterise its phenolic compounds (HPLC–MS) and antioxidant capacity (DPPH, ABTS and ORAC), as well its thickness and granular structure (SEM), mechanical (tensile strength and elongation at break) and colour (CIE-lab scale: L*, a*, b*) properties. HPLC–MS revealed eight major phenolic compounds in the C. longa starch and six in its film. The starch and the film from C. longa had high levels of antioxidant capacity, 65–92% (as measured by DPPH and ABTS). Furthermore, C. longa exhibited a smooth structural surface and strong resistance to tensile force, as well as maintaining its elasticity as measured by mechanical assays (tensile strength and elongation at break). Based on the obtained results a novel biodegradable starch film was obtained applying a single matrix, the Amazon Curcuma longa L. starch.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There is a growing need to develop packaging materials, such as films and coatings, from renewable matrices or industrial wastes [1, 2]. This is driven by the surge in productive economic processes and the need to preserve the environment and to consume less processed foods. Biodegradable starch packaging, which can also act as antioxidants and antimicrobials, serves these interests by lowering the levels of additives incorporated in foods to preserve them [3, 4]. Starch is a well-known, renewable raw material that presents significant technological features including gelling, whitening, thickening and emulsifying. These properties make it one of the most used base materials and the most investigated in terms of the development of biodegradable films [2, 5,6,7,8].

With established applications in a variety of industrial fields (food, pharmaceuticals, textiles, paper and chemicals), starch is mainly composed of two glucose polymers, one of which is linear (amylose) and the other is branched (amylopectin), which are linked by α-1,4 and α-1,6 connections at branched points. It is the amylose molecule that is responsible for the formation of vigorous and flexible films [9, 10]. Amylose has a molecular weight of ≅ 105–106 and composes the amorphous and the single helical conformation of starch granules [6]. However, amylopectin has a molecular weight of ≅ 107–109 and its branches form clusters of double helices that aggregate into crystallites in starch granules [6]. Due to factors such as their botanical source, growing conditions, granule size and shape and amylose and amylopectin ratio, native starches have different properties. Therefore, it is essential to study and investigate non-conventional starch sources [5, 10].

Curcuma longa L. belongs to the Zingiberaceae family genus and it has been extensively investigated as a medicinal and pigment source. Popularly known as turmeric, this rhizome originates in South Asia and has more than 100 catalogued species [11]. The Curcuma rhizome is widely cultivated and easily obtained: India is the main producer and consumer [12]. Brazil has an impressive cultivation of turmeric in the centre-west that corresponds to 26% of the production of the state of Goiás, demonstrating the potential to supply the demands of the internal market [13]. Moreover, its cultivation stimulates the economic growth of rural families in the northeast region of Brazil [13]. The main use of the powdered rhizome of Curcuma is to extract oleoresin for pigments known as curcuminoids (curcumin; desmethoxycurcumin and bisdemethoxycurcumin) [1, 13, 14]. India has 78% of the global turmeric market and pharmaceutical applications account for over 52%. The quest for natural colourants in food and beverages has increased the demand for Curcuma longa L. [15]. According to Van Hung and Vo [11], the pigment only accounts for 2–8% of the powdered rhizome: its starch content is a residue that represents 78–85% of the initial matter and it has no commercial value [16]. C. longa rhizome starch represents an attractive low-cost renewable base material for bioplastics [16]. Apart from its important phenolic compounds, which impart antioxidant, antibacterial and anticancer properties, another advantage of C. longa rhizome starch in relation to developing starch films is its apparent amylose content of 48% [11, 12].

Considering that starch, which is a major component in turmeric rhizomes, has been poorly investigated regarding its application as an active film, this study focused on characterising the phenolic compounds of Amazon turmeric starch (Curcuma longa L.), its antioxidant capacity (DPPH, ABTS, ORAC) and its application as a naturally active starch film. The film was also investigated for its structural and mechanical properties.

Materials and methods

Samples

The native turmeric rhizomes (Curcuma longa L.) were harvested in the crop area of Aripuanã city, Mato Grosso, in the Amazon region of Brazil (10°10′00″S/59°27′34″W). The starch was extracted as described in a previous study [5]. The starch film was prepared according to the procedure described by Pauli et al. [17]. Commercial corn starch was used as a control sample. The samples were coded as follows: a—corn starch, b—corn starch film, c—native turmeric starch and d—turmeric starch film.

Chemicals and solvents

HPLC grade methanol, hexane and ethyl acetate were obtained from Fisher Scientific Company (Ottawa, ON, Canada). Folin–Ciocalteu reagent, 2,2-diphenyl-1-picrylhydrazyl (DPPH); (2,2′-azino-bis (3-ethylbenzothiazoline-6-sulfonic acid) diammonium salt (ABTS); 6-hydroxy-2,5,7,8-tetramethylchromane-2-carboxylic acid (Trolox); fluorescein and the phenolic compound standards (4-hydroxybenzaldehyde; vanillin; p-coumaric acid and ferulic acid) were purchased from Sigma-Aldrich Company (St. Louis, MO, USA).

Characterization methods

The methods, items 2.3.1–2.3.5 and 2.4, were performed for all samples (Corn starch and film; Turmeric starch and film). The analyses described in item 2.3.5–2.3.8 were realized only for the corn and turmeric starch films.

Physicochemical analyses

The total starch content of the turmeric sample studied was quantified following the methodology described by Jiang et al. [18]. The moisture content was determined by desiccation at 105 °C (oven); total proteins by the Kjeldahl method; total lipids by exhaustive extraction with petroleum ether in Soxhlet apparatus; and fixed mineral residue by incineration in a muffle at 550 °C using the AOAC [19] protocols 930.15, 990.03, 920.39 and 942.05, respectively. The total carbohydrate content was obtained by difference to 100%.

Extraction of free and bound phenolic fractions

The turmeric and corn starch films were lyophilised and ground to obtain a powder. Extracts of free and bound phenolic fractions from the starch films powder and of the turmeric and corn starch were obtained according to the methodology described by the authors [20] with some modifications. For the free fraction, 100 mg of each sample (in triplicate) was extracted twice with 80% acidified methanol (1% HCl) and sonicated for 1 h at room temperature prior to centrifugation at 1000 rpm for 10 min. The supernatants were combined and dried under nitrogen at 38 °C and then reconstituted with 300 µL of 50% methanol. For the bound fraction, 50 mg of each sample (in triplicate) was weighed in 5 mL glass tubes. Then, 2 mL of 4 M NaOH was added and the mixture was left in the refrigerator overnight. The samples were then acidified to pH 1.0 with 6 M HCl (≅ 1 mL), vortexed and centrifuged at 10,000 rpm at 4 °C. The supernatant was collected and the remaining sample was washed with 500 µL of pure H2O, vortexed and centrifuged. The supernatants were pooled together and extracted with 2 mL ethyl acetate. The ethyl acetate fraction was dried under nitrogen at 35 °C and reconstituted with 300 µL of 50% aqueous methanol. After the reconstitution, the samples were filtered through a syringe filter (0.22 µm, HV Millipore, DuraPore). The extracts were stored at − 20 °C until the moment of analysis.

Total phenolic content (TPC)

The TPC was obtained using the Folin–Ciocalteu colorimetric method described by Singleton and Rossi [21], with some modifications. An appropriately diluted sample (20 µL) was added to 150 µL of tenfold freshly diluted Folin–Ciocalteu reagent in a microplate. Then 150 µL of sodium carbonate solution (75 g/L) was added and the samples were kept in the dark for 1 h at room temperature. The absorbance was measured at 725 nm in an Epoch Microplate spectrophotometer (Synergy-BIOTEK, USA): ferulic acid was used as the standard. The results were expressed as µM of ferulic acid equivalents (FAE) per milligram of the samples (dry weight basis).

Antioxidant capacity assays

The DPPH radical scavenging activity and ABTS radical scavenging activity were performed in 96-well microplates and read (6× for each sample) in an Epoch Microplate spectrophotometer (Synergy-BIOTEK, EUA).

DPPH radical scavenging activity

The DPPH assay was carried out according to the method of Brand-Williams et al. [22]. Briefly, 10 µL of the sample extracts or standards was added to 190 µL of DPPH radical solution (60 µmol/L), which was freshly made in methanol. After 30 min incubation in the dark at room temperature the absorbance was obtained at 515 nm. The DPPH· radical scavenging activity was obtained as % DPPH = [(DPPH absorbance − sample absorbance)/DPPH absorbance] × 100. The DPPH radical scavenging activity of the sample extracts was expressed as µM of Trolox equivalents (TE) per milligram of the sample (dry weight basis) using a standard curve of Trolox ranging from 100 to 700 µM.

ABTS radical scavenging activity

For the ABTS assay, the methodology described by Re et al. [23] was followed, with minor modifications. Stock solutions of 7 mmol/L ABTS solution and 2.45 mmol/L of potassium persulfate solution were prepared. The working solution was mixed with 3 mL of each stock solution and allowed to react for 16 h at room temperature in the dark. The solution was then diluted by mixing 4.0–4.5 mL of ABTS radical cation solution with 250 mL of distilled water to obtain an absorbance of 0.70 at 725 nm. The ABTS·+ radical scavenging activity was calculated as % discolourisation = [(ABTS absorbance − sample absorbance)/ABTS absorbance] × 100. The results were compared with a Trolox standard curve and expressed in µM of Trolox equivalents (TE) per milligram of the sample (dry weight basis).

Oxygen radical absorbance capacity (ORAC)

The ORAC assay was performed to quantify the peroxyl radical-scavenging activity of the samples; it was based on the procedure described by Qiu et al. [24]. The solutions were automatically transferred plate to plate with a Precision 2000 automated microplate pipetting system (BIO-TEK Instruments, Inc., Winooski, VT). Subsequently, a FLx 800 microplate fluorescence reader (Bio-Tek Instruments, Inc., Winooski, VT) was used to obtain an excitation wavelength of 485/20 nm and an emission wavelength of 528/20 nm; it was programmed to record the fluorescence every minute for 50 min after the addition of AAPH. The curve of the fluorescence decay was integrated using KC4 3.0 software. Each sample was measured three times and the results were expressed as µM of Trolox equivalents (TE) per milligram of the sample (dry weight basis).

HPLC–DAD–Q-TOF–MS analysis of phenolic compounds

The HPLC–MS analysis of phenolic compounds was conducted using an HPLC (Waters 2695) machine equipped with a photodiode array detector (PDA) (Waters 996) and autosampler (717 plus, Waters), coupled with a quadrupole time-of-flight mass spectrometer (Q-TOF MS), as described by Chen et al. [25], with minor modifications. The analytical column was a 150 mm × 4.6 mm, Gemini 5 µm C18 110A column (Phenomenex, Torrance, California, USA). The mobile phase consisted of: A (0.1% acetic acid in water) and B (0.1% acetic acid in methanol). The HPLC separation conditions were 35 °C column temperature, 1.0 mL/min flow rate and 10 µL injection volume. A 70-min gradient was used as follows: 0–11 min, 9–14% B; 11–14 min, 14–15% B; 14–17 min, 15% B; 17–24 min, 15–16.5% B; 24–28 min, 16.5–19% B; 28–30 min, 19–25% B; 30–36 min, 25–26% B; 36–38 min, 26–28% B; 38–41 min, 28–35% B; 41–46 min, 35–40% B; 46–48 min, 40–48% B; 48–53 min, 48–53% B; 53–65 min, 53–70% B; 65–66 min, 70–9% B; 66–70 min, 9% B. The phenolic compounds were detected at a wavelength of 280 and 320 nm. The identification was performed by comparing the retention time and spectral matching with external standards, which was confirmed by Q-TOF–MS. The Q-TOF–MS was calibrated using sodium iodide for the negative mode through the mass range of 100–1000. A resolution of 5000 was achieved. Full mass spectra were recorded in negative mode by using a capillary voltage of 900 kV and a cone voltage of 15 V. The flow rates of the desolvation gas (N2) and cone gas (He) were 900 and 50 L/h, respectively. The desolvation gas temperature and the ion source temperature were set at 250 and 120 °C, respectively. The MS/MS spectra were acquired by using a collision energy of 33 V.

Thickness

The film thickness was determined at 15 random positions using a digital micrometer, using a sensitivity of 0.001 mm (Mitutoyo-Absolute DIGIMATIC, Japan).

Glass transition

The glass transition temperature (Tg) of the films was determined using a differential scanning calorimeter (DSC Q200, TA Instruments) [26].

Tensile strength (TS) and elongation at break (EB)

The mechanical properties were determined according to the D882-91 method [27]. The parameters of tensile strength (TS, MPa) and elongation at break (EB, %) were analysed in a TA.XT Plus texture analyser (Texture Technologies Corp., Hamilton, Canada). The method previously described by [28] was used, with some modifications. The films (8.2 × 8.2 cm) were fixed in the rig probe (TA-108N, Large Film Extensibility) and a 1/2″ dial ball cylindrical probe (TA-18) was used to penetrate the films at a speed of 0.8 mm/s. Ten samples were tested in this analysis.

Colour analysis

The colour determinations were performed with a Konica Minolta colorimeter (model CM-3500d, Minolta, CO., Japan) using the 0.3-cm aperture port, dual 18-element silicon photodiode array and a wedge-shaped continuous interference filter to record the CIELAB space. The method was followed as described in the literature [29, 30].

Statistical analysis

The results were presented as mean ± standard deviation (SD) of triplicated determinations. The data were analysed by ANOVA using SAS statistical software (version 9.3, SAS Institute Inc., Cary, NC, USA). Duncan’s multiple range tests were used to evaluate the significant difference between the means. The significance level was defined at p < 0.05.

Results and discussion

The proximal composition presented by the turmeric starch sample studied was as follows: lipids 0.47%; proteins 1.70%; ashes 2.17%; moisture 16.45%; starch content 57.98%; total carbohydrates content 21.23%.

Similar result for total starch content (56%) was found by literature [31] that isolated the starch from commercial turmeric powder (Karnataka, India), and lower values, ranging from 45.24 to 48.48%, were reported by Sajitha and Sasikumar [32] that studied four different species of turmeric.

Total phenolic content (TPC)

Phenolic compounds are widely distributed in nature; more than 8000 have been identified and the list keeps growing. They have been extensively studied due to their potential uses in relation to human health (in pharmaceuticals and food processing), as antioxidants, and as a chronic disease-preventing agent [25, 33, 34]. The free and bound phenolic fractions of the control samples (a—commercial corn starch, b—commercial corn starch film) and of the C. longa native starch and its derivate film (samples c and d, respectively) were investigated and the results are presented in Table 1.

Phenolics were not detected for the control samples, corn starch (a) and corn starch film (b). The turmeric starch (c) had 187 µM FAE/mg, and the turmeric starch film (d) also presented a high total phenolic content (113 µM FAE/mg) even after being held for 3 min at 90 °C for gelatinisation, thereby demonstrating stability to heat. In contrast to a recent study by [11] regarding starches from two varieties of turmeric rhizomes (Curcuma longa and Curcuma caesia from Lam Dong, Vietnam), the Amazon C. longa turmeric starch (sample c) showed TPC concentration ≅ 71 × higher (961.26 mg/g starch) than the Vietnamese C. longa turmeric starch (13.4 mg/g starch). The differences between the two aforementioned cultivars are likely to have been due to the growing conditions, climate and harvesting method, as well as the procedures and/or reagents used in the analysis. The evaluation of phenolic content and antioxidant activity are important parameters that can help to establish quality parameters and market price [12].

The bound phenolics showed higher potential physiological functions, including antioxidant capacity and bioavailability [35]. Bound phenolics are covalently bound to carbohydrates and the cellular wall structural components of plants [25]. Table 1 shows that the highest amount of bound phenolics was found for sample d and its relationship to the free phenolic fraction could be attributed to the protecting action of the starch granule structure during gel formation for the starch film.

Antioxidant capacity

In the present study, ORAC, DPPH and ABTS assays were performed to evaluate the antioxidant capacity activity of the sample extracts (Table 1). DPPH and ABTS assays are based on the colour reducing properties of the DPPH· and ABTS·+ radicals, respectively, by electron transfer, while ORAC is based on hydrogen atom transfer [25, 36]. No antioxidant activity was detected in the control samples (a and b) in all of the assays that were performed.

The bound fractions of samples c and d showed stronger antioxidant activity in all the antioxidant tests. The C. longa starch and its starch film phenolic content presented the highest antioxidant capacity by transferring electrons (DPPH· and ABTS·+) rather than H atoms (ORAC). Nonetheless, the antioxidant capacity of the C. longa starch was only slightly affected by heat treatment, as previously shown by [37] regarding turmeric root (C. longa—India) extracts. Generally, films that present significant levels of phenolic compounds, as well as antioxidant capacity, are those to which commercial antioxidants (natural or synthetic), plant extracts and essential oils (among others) have been added following the gelatinisation of the starch or the heating of the polymeric solution [3, 4, 7, 8, 38,39,40,41,42].

The antioxidant capacity (DPPH expressed as % radical scavenging/mg of samples) (Table 1) of the total phenolics (free plus bound fractions) obtained for sample c—C. longa native starch, was 19% higher than reported for the same cultivar in a recent study [11] and it only reduced by 6.0% after gelatinisation (sample d). As stated earlier, differences can be attributed to the climate and cultivation of the samples, as well as the reagents and methods used. For sample d (C. longa starch film), the DPPH radical scavenging was 15% higher than the film developed with turmeric (C. longa L.) dye solvent extraction residue [1] and ≅ 97% (when DPPH results were converted to µM of TE/mg of film) higher than cassava starch-based film with different added concentrations of commercial ethanolic propolis extract [38]. Moreover, a recent study [43] obtained a maximum of 55% ABTS antioxidant activity for gelatin-based films with added Curcuma ethanol extract (200 g CEE/100 of the film). The bound fraction of the film obtained in the present study (sample d), which was solely from native C. longa starch, reached 92.5% and surpassed the gelatin-based film. Using a single matrix to produce bioactive films such as C. longa starch represents an economic use of time and resources because the process is simplified. The total phenolic content analysis showed a high correlation with antioxidant activities (ORAC; DPPH; ABTS; r = 1), which was principally related to the bound phenolic fraction for both starch (sample c) and film (sample d) (Fig. 1).

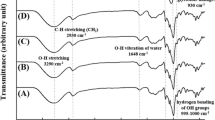

HPLC–MS analysis of phenolic compounds

The free and bound extracts were subjected to HPLC–MS: four of the eight major phenolic compounds/peaks were successfully identified and quantified for samples c (Curcuma longa L. native starch) and d (Curcuma longa L. starch film). Based on their retention times, absorbance spectra and MS data, which are presented in Table 2 and Fig. 2 (supplementary data can be observed in the MS spectra of compounds 2–8), the compounds were identified and their concentration was obtained. The remaining four compounds (peaks 5–8) were characterised and expressed as ferulic acid equivalents. No phenolic compounds were detected in samples a (corn starch) and b (corn starch film), which was in agreement with the TPC results.

The corresponding chromatograms (Fig. 2) are shown at 280 nm to better visualise compounds (1) and (2), 4-hydroxybenzaldehyde and vanillin, respectively. Although they presented absorbance units (AU), slightly higher than compound (4)—ferulic acid (sample c), Table 2 confirms that ferulic acid was the predominant compound identified in the bound fractions of sample c (6695 µg/g starch) and sample d (5446 µg/g film). Contrariwise, p-coumaric acid (141.7 µg/g starch; 92.4 µg/g film) was predominant for the free fraction compound (3), followed by compound (4) (101.6 µg/g starch; 68.3 µg/g film). In contrast with the present study, a recent study [11] focused on determining the curcumin content of the ethanolic extracts from Vietnamese C. longa and C. caesia starches using HPLC: the aforementioned study found curcumin to be the major phenolic compound, with values of 9600 and 15 µg/g, respectively. No other phenolic compound was reported to have been identified in that study. In comparison to the starches studied in the literature, the Amazon C. longa native starch (sample c) exhibited different phenolic compounds, which persisted even after the heat treatment to obtain its derivative film (sample d) and showed a different antioxidant mode of action, as presented by the antioxidant assays performed.

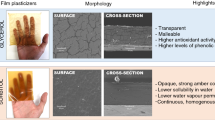

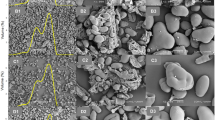

Thickness and SEM analysis

The thickness of the C. longa starch film (sample d) was significantly different from sample b (control sample—corn starch film). The difference of 0.05 mm can be attributed to the size of the starch granule, as determined by the electron microscope in the form of the micrograph (Fig. 3—samples a and c) presented in Table 3. According to Lim and Jane [44], starch film thickness is strongly correlated to starch granule size: the smaller the starch granules the thicker the film, as was found in the present study. Different thicknesses were found by the authors [14, 43], who developed gelatin-based films with C. longa extracts with thicknesses ranging from 0.05 to 0.08 mm. These differences were attributed to the different base materials used to obtain the films. The SEM micrographs in the present study show that the C. longa film (sample d) had a smooth surface compared to the control film made from corn starch (sample b), which presented a rougher surface, with waves affecting its thickness. The homogeneous matrix shown by sample d is a quality indicator of its integrity [9] and better mechanical properties were anticipated, as presented (TS—tensile strength, Table 3) in the mechanical analysis.

Glass transition

An important parameter that can corroborate the performance of starch films (in addition to mechanical, storage and shelf life properties) is the glass transition temperature (Tg) [6]. The moment that the amorphous regions of a polymer changes from the “glassy” to a “rubber” state (the softening point) is related to the Tg temperature. This moment, when coatings and films are more permeable to water vapour and oxygen, can cause the deterioration of diverse products. The glass transition temperatures of the control film (sample b—corn starch film) and the C. longa starch film (sample d) are shown in Table 3. The Tg temperature of sample d did not differ from the control sample. Both had temperatures (≅ 48 °C) that were considered as efficient to provide stability during storage and transportation [10, 45]. In comparison, the C. longa starch film (sample d) showed a higher Tg temperature and was more stable than films developed from other starches (corn 35.12 °C, cassava 42.42 °C and yam 39.26 °C) [46]. These differences can be attributed to the starch source, growing conditions and method of analysis (Fig. 4).

Mechanical properties

The mechanical characteristics of the corn starch control film (sample b) and the C. longa starch film (sample d) are shown in Table 3. It is desirable for polymeric films such as starch films to demonstrate high elongation at break (%) values since they are related to their flexibility and degradability [6]. Moreover, the EB is mainly affected by the tensile strength (TS). Films with increased TS show poor EB results [43]. However, the C. longa starch film (sample d) showed a higher tensile strength (85.8 MPa) than the control sample (sample b), and no difference was obtained for the EB (22.0% sample b; 22.6% sample d) parameter. Hence, the C. longa starch film had better resistance to tensile strength and, therefore, good flexibility for handling. Young’s modulus results were slightly different between the analysed samples. Bitencourt et al. [43] obtained a maximum TS (MPa) of 35.1 and EB (%) of 36.5 for gelatin-based films with added curcuma ethanol extracts. Kalaycıoğlu et al. [47] produced chitosan films with incorporated turmeric extract (from commercial C. longa powder) that showed TS of 47.9 MPa and EB of 6.2%. Comparing the current literature on different films, using C. longa starch to obtain bioactive films is more advantageous because it uses a single matrix, which can provide enhanced mechanical properties and antioxidant activity, as demonstrated in this study.

Colour analysis

Colour is a critical attribute for food products: it defines quality (freshness, maturity and desirability) and acts as a barrier to the oxidation of lipids by light [5, 43]. A CIE-lab scale was used to assess the degree of lightness (L*), in which 0 represents black to 100, which represents whiteness; redness (+ a*) or greenness (− a*); and yellowness (+ b*) or blueness (− b*) of the film samples b and d, as shown in Table 3. As was visually perceived, and was also confirmed by the values obtained in the colour analysis, the C. longa starch film (sample d—Fig. 1) had a reddish yellow colour (+ a*—21.9; + b*—50.7). This colouration can be attributed to the presence of the curcuminoid pigments of the C. longa rhizome, which were carried along during the starch extraction. The pigments persisted after the gelatinisation process to obtain the film, thereby corroborating with the report by Bitencourt et al. [43] that active films have natural pigments which can be expressed as coloured compounds.

Conclusions

The application of turmeric starch as a bioactive film provides a use for curcumin extraction residue (starch) as a reasonable alternative to synthetic plastics, which contribute to the accumulation of waste in the environment. Using HPLC–MS it was possible to identify and quantify four phenolic compounds from the Curcuma longa L. starch, which were also present in the film. It was verified that the starch and the film’s total phenolic content (TPC) were significantly high when compared to the literature and that they exhibited excellent antioxidant capacity, principally by donating or stabilising ions (DPPH and ABTS). The C. longa starch film showed a smooth and homogenous surface (observed in the SEM micrograph), a high glass transition temperature, strong resistance to tension and desirable extensibility, as well as a strong tendency to red and yellow colouration. Based on these findings, a single application of the starch from Curcuma longa L. resulted in a functional film that could provide efficient protection against microbial growth and oxidative deterioration in food products.

References

Maniglia BC, Domingos JR, de Paula RL, Tapia-Blácido DR (2014) Development of bioactive edible film from turmeric dye solvent extraction residue. LWT Food Sci Technol 56:269–277

Gutiérrez TJ, Alvarez VA (2017) Cellulosic materials as natural fillers in starch-containing matrix-based films: a review. Polym Bull 74:2401–2430

Talón E, Trifkovic KT, Nedovic VA et al (2017) Antioxidant edible films based on chitosan and starch containing polyphenols from thyme extracts. Carbohydr Polym 157:1153–1161

Salgado PR, Ortiz CM, Musso YS et al (2015) Edible films and coatings containing bioactives. Curr Opin Food Sci 5:86–92

Hornung PS, Ávila S, Lazzarotto M et al (2017) Enhancement of the functional properties of Dioscoreaceas native starches: mixture as a green modification process. Thermochim Acta 649:31–40

Li M, Xie F, Hasjim J et al (2015) Establishing whether the structural feature controlling the mechanical properties of starch films is molecular or crystalline. Carbohydr Polym 117:262–270

Piñeros-Hernandez D, Medina-Jaramillo C, López-Córdoba A, Goyanes S (2017) Edible cassava starch films carrying rosemary antioxidant extracts for potential use as active food packaging. Food Hydrocoll 63:488–495

Shah U, Naqash F, Gani A, Masoodi FA (2016) Art and science behind modified starch edible films and coatings: a review. Compr Rev Food Sci Food Saf 15:568–580

Mali S, Grossmann MVE, Garcia MA et al (2002) Microstructural characterization of yam starch films. Carbohydr Polym 50:379–386

Jiménez A, Fabra MJ, Talens P, Chiralt A (2012) Edible and biodegradable starch films: a review. Food Bioprocess Technol 5:2058–2076

Van Hung P, Vo TND (2017) Structure, physicochemical characteristics, and functional properties of starches isolated from yellow (Curcuma longa) and black (Curcuma caesia) turmeric rhizomes. Starch Stärke 69:1600285

Anubala S, Sekar R, Nagaiah K (2014) Development and validation of an analytical method for the separation and determination of major bioactive curcuminoids in Curcuma longa rhizomes and herbal products using non-aqueous capillary electrophoresis. Talanta 123:10–17

Berni RF, Chaves FCM, Pinheiro JB, Vaz APA (2014) Produção de açafrão em função de acessos e do peso de rizomas-semente. Rev Bras Plantas Med 16:765–770

Musso YS, Salgado PR, Mauri AN (2016) Smart edible films based on gelatin and curcumin. Food Hydrocoll 66:8–15

Global Market Insights (2016) Curcumin market size by application (food, pharmaceutical, cosmetics), industry analysis report, regional outlook, growth potential, price trend, competitive market share and forecast, 2016–2024. http://www.gminsights.com/industry-analysis/curcumin-market. Accessed 05 Oct 2017

Nguyen CM, Nguyen TN, Choi GJ et al (2014) Acid hydrolysis of Curcuma longa residue for ethanol and lactic acid fermentation. Bioresour Technol 151:227–235

Pauli RB, Quast LB, Demiate IM, Sakanaka LS (2011) Production and characterization of oxidized cassava starch (Manihot esculenta Crantz) biodegradable films. Starch/Staerke 63:595–603

Jiang H, Jane J, Acevedo D et al (2010) Variations in starch physicochemical properties from a generation-means analysis study using amylomaize V and VII parents. J Agric Food Chem 58:5633–5639

AOAC (2000) American Association of Official Analytical Chemists. Official methods of analysis of The American Association of Official Analytical Chemists, 17th edn. AOAC, Gaithersburg

Zhang H, Shao Y, Bao J, Beta T (2015) Phenolic compounds and antioxidant properties of breeding lines between the white and black rice. Food Chem 172:630–639

Singleton VL, Rossi JR (1965) Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Vitic 16:144–158

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT Food Sci Technol 28:25–30

Re R, Pellegrini N, Proteggente A et al (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med 26:1231–1237

Qiu Y, Liu Q, Beta T (2010) Antioxidant properties of commercial wild rice and analysis of soluble and insoluble phenolic acids. Food Chem 121:140–147

Chen Z, Yu L, Wang X et al (2016) Changes of phenolic profiles and antioxidant activity in canaryseed (Phalaris canariensis L.) during germination. Food Chem 194:608–618

Luchese CL, Frick JM, Patzer VL et al (2015) Synthesis and characterization of biofilms using native and modified pinhão starch. Food Hydrocoll 45:203–210

ASTM (1996) Standard test methods for tensile properties of thin plastic sheeting, D882-91, 1996th edn. ASTM, Philadelphia

Galdeano MC, Wilhelm AE, Mali S, Grossmann MVE (2013) Influence of thickness on properties of plasticized oat starch films. Braz Arch Biol Technol 56:637–644

ASTM E313-05 (2005) Standard practice for calculating yellowness and whiteness indices from instrumentally measured color coordinates. ASTM International, West Conshohocken

Robertson AR (1977) The CIE 1976 color-difference formulae. Color Res Appl 2:7–11

Kuttigounder D, Lingamallu JR, Bhattacharya S (2011) Turmeric powder and starch: selected physical, physicochemical, and microstructural properties. J Food Sci 76:C1284–C1291

Sajitha PK, Sasikumar B (2015) Qualitative and quantitative variation in starch from four species of Curcuma. Cytologia (Tokyo) 80:45–50

Cheynier V (2012) Phenolic compounds: from plants to foods. Phytochem Rev 11:153–177

Lordêlo M, Silva C, Costa RS et al (2010) Compostos fenólicos, carotenóides e atividade antioxidante em produtos vegetais. Ciências Agrárias 31:669–682

Acosta-Estrada BA, Gutiérrez-Uribe JA, Serna-Saldívar SO (2014) Bound phenolics in foods, a review. Food Chem 152:46–55

Ragaee S, Abdel-Aal ESM, Noaman M (2006) Antioxidant activity and nutrient composition of selected cereals for food use. Food Chem 98:32–38

Selvam R, Subramanian L, Gayathri R, Angayarkanni N (1995) The anti-oxidant activity of turmeric (Curcuma longa). J Ethnopharmacol 47:59–67

Araújo GKP, Souza SJ, Silva MV et al (2015) Physical, antimicrobial and antioxidant properties of starch-based film containing ethanolic propolis extract. Int J Food Sci Technol 50:2080–2087

López D, Márquez A, Gutiérrez-Cutiño M et al (2017) Edible film with antioxidant capacity based on salmon gelatin and boldine. LWT Food Sci Technol 77:160–169

Jiménez A, Fabra MJ, Talens P, Chiralt A (2013) Physical properties and antioxidant capacity of starch-sodium caseinate films containing lipids. J Food Eng 116:695–702

Ciannamea EM, Stefani PM, Ruseckaite RA (2016) Properties and antioxidant activity of soy protein concentrate films incorporated with red grape extract processed by casting and compression molding. LWT Food Sci Technol 74:353–362

Arabestani A, Kadivar M, Shahedi M et al (2016) Characterization and antioxidant activity of bitter vetch protein-based films containing pomegranate juice. LWT Food Sci Technol 74:77–83

Bitencourt CM, Fávaro-Trindade CS, Sobral PJA, Carvalho RA (2014) Gelatin-based films additivated with curcuma ethanol extract: antioxidant activity and physical properties of films. Food Hydrocoll 40:145–152

Lim S-T, Jane J-L (1992) Effect of starch granule size on physical properties of starch-filled polyethylene film. Biotechnol Prog 8:51–57

Arvanitoyannis I, Biliaderis CG (1998) Physical properties of polyol-plasticized edible films made from sodium caseinate and soluble starch blends. Food Chem 62:333–342

Mali S, Grossmann MVE, García MA et al (2006) Effects of controlled storage on thermal, mechanical and barrier properties of plasticized films from different starch sources. J Food Eng 75:453–460

Kalaycıoğlu Z, Torlak E, Akın-Evingür G et al (2017) Antimicrobial and physical properties of chitosan films incorporated with turmeric extract. Int J Biol Macromol 101:882–888

Acknowledgements

The authors gratefully acknowledge the support of the Government of Canada through the Emerging Leaders of the Americas Program (ELAP) for the financial resources provided and CAPES-Brazil. Equipment used for HPLC-LC analysis of phenolic compounds and ORAC assay was generously funded by the Canada Foundation for Innovation (New Opportunities Fund and Leaders Opportunities Fund). The authors also acknowledge the technical assistance provided by Alison Ser of the Department of Food and Human Nutritional Science.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hornung, P.S., Masisi, K., Malunga, L.N. et al. Natural bioactive starch film from Amazon turmeric (Curcuma longa L.). Polym. Bull. 75, 4735–4752 (2018). https://doi.org/10.1007/s00289-018-2285-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-018-2285-2