Abstract

Tuning the interfacial layers in OPVs should enable reduced resistance and control of the work function of the electrode. We synthesized an amine-functionalized polyfluorene derivative (PF-PDMA) as an interfacial layer for organic photovoltaic cells. We fabricated a conventional device using PF-PDMA as an electron transport layer. P3HT and PC61BM were employed as the active layer to form the bulk heterojunction. The power conversion efficiency of the device fabricated using the interlayer (3.18 %) was higher than that of the device without the interfacial layer (2.36 %).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Over the past few years, organic photovoltaic devices (OPVs) have attracted great interest as alternative energy sources because of their many advantages, which include low processing cost, high flexibility, and light weight. Interfacial layers, such as hole transport layers (HTLs) and electron transport layers (ETLs), are employed between the electrode and active layer to improve the efficiencies of OPVs. The poly(3,4-ethyenedioxylene-thiophene):poly(styrene sulfonic acid) (PEDOT:PSS) is widely used as the HTL, and low work function metals (i.e., Ca, Mg, LiF) are used to form the ETL. However, each layer is weak and unstable with respect to oxidation [1, 2]. Various strategies have been applied to increase the device stability and improve device performance [3–5].

In an attempt to resolve the above problem, alcohol-soluble polyelectrolytes, such as poly[(9,9-bis(3′-(N,N-dimethylamino)propyl)-2,7-fluorene)-alt-2,7-(9,9–dioctylfluorene)] (PFN) and polyethylenimine ethoxylated (PEIE), etc. have been developed as interfacial layers [5–8]. These materials easily form layers on nonpolar organic active layers without damaging the surface because of solvent selectivity. Moreover, they realign the electric fields within a device because of the dipole of the pendant group; this enables control of the vacuum level of the electrode surface to up or down, thus tuning the work function of the metal electrode. In addition, they could reduce the series resistance of organic photovoltaic cells [9].

Some charged ionic conjugated polymers have been reported as interlayers for OPVs [7–9]; however, to improve their solubility, they require some amount of water, which could damage the organic active layer. Therefore, in this study, we designed a fluorine polymer with non-ionic dimethylamine functional groups. We supposed that the hydrophobic polymer backbones faced to active layer and the polar dimethylamine groups faced to metal electrode which would increase the vacuum level of the electrode and the open-circuit voltage of the OPV devices [9]. We synthesized poly[(9,9′-bis(4-(6-N,N-dimethylaminehexyloxy)phenyl)fluorene-2,7-diyl)] (PF-PDMA) as an electron transporting interlayer for organic photovoltaic cells, as shown in Scheme 1, and investigated the effect of this interfacial layer in OPVs.

Experimental details

Measurements

1H NMR was measured by the Varian Mercury Plus 300 MHz. Absorption spectroscopy and cyclic voltammetry (CV) were performed using a JASCO JP/V-570 instrument and CH Instruments Electrochemical Analyzer. The energy level of the polymer was determined in an acetonitrile solution containing 0.1 M tetrabutylammonium tetrafluoroborate (TBABF4) with a supporting electrolyte and a Ag/AgNO3 reference electrode, platinum wire counter electrode, and platinum working electrode. The performance of conventional OPVs was determined using a McScience K201 LAB50 Solar Simulator under AM 1.5 G illumination (100 mW/cm2), and the external quantum efficiency (EQE) was measured using a McScience K3100 EQX.

Materials

Bis(1,5-cyclooctadiene)nickel(0) (Ni(COD)2) was purchased from Strem Chemicals. Silica cells for column chromatography and the fullerene derivative, i.e., [6,6]-phenyl-C61-butylic acid methyl ester (PC61BM), were obtained from EM-index. Poly(3-hexylthiophene-2,5-diyl) (P3HT) as a donor was purchased from Rieke Metals. All other materials were purchased from Aldrich and used without further purification.

Synthesis of polymer

6,6′-(((2,7-Dibromo-9H-fluorene-9,9-diyl)bis(4,1-phenylene))bis(oxy))bis(N,N-dimethylhexan-1-amine) (2)

Compound 1 [10] was synthesized using a previously reported method. 2,7-Dibromo-9,9-bis(4-(6-bromohexyloxy)phenyl)-9H-fluorene (1; 1.66 g, 2.0 mmol) was dissolved in dry tetrahydrofuran (THF; 5.0 mL) and dimethylamine (2 M THF solution, 12.9 mL, 25.8 mmol) was added dropwise to the solution. After 1 h; the solution was then left to react for 24 h at room temperature. When the reaction was complete, the solvent was removed. The residue was dissolved in 0.1 M sodium hydroxide solution (0.5 mL) and chloroform (5 mL). After stirring for 30 min, the solvent was removed under reduced pressure and the residue was purified by silica gel column chromatography to give a yellow viscous liquid. 1H NMR (300 MHz, CDCl3): δ 7.6 (d, 2H), 7.5 (dd, 4H), 7.0 (d, 4H), 6.7 (d, 4H), 3.9 (t, 4H), 2.3 (t, 4H), 2.2 (s, 12H), 1.7 (m, 4H), ~1.3–1.5 (m, 12H). 13C NMR (300 MHz, CDCl3): δ 158.2, 153.7, 137.8, 136.3, 130.7, 129.3, 129.0 121.8, 121.6, 114.3, 67.9, 64.4, 31.8, 29.4, 29.3, 26.1, 22.7, 14.2.

PF-PDMA

Polymer PF-PDMA was synthesized from the corresponding monomers via Yamamoto coupling in an argon atmosphere. 6,6′-(4,4′-(2,7-Dibromo-9H-fluorene-9,9-diyl)bis(4,1-phenylene))bis(oxy)bis(N,N-dimethylhexan-1-amine) (2; 0.6 g, 0.8 mmol), Ni(COD)2 (0.34 g, 1.25 mmol), and 2,2′-dipyridyl (0.21 g, 1.32 mmol) were dissolved in a toluene/dimethylformamide mixed solvent (1:1; 10 mL). After stirring for 30 min, 1,5-cyclooctadiene (0.2 mL) was added to the flask. The mixture was then left to react at 80 °C for 36 h. To complete the synthesis, bromobenzene was added as an end-capping reagent. The synthesized polymer was purified by recrystallization from ether, column chromatography, and Soxhlet extraction with methanol for 1 day to remove any remaining impurities.

Fabrication of OPVs

ITO glass was cleaned with acetone and 2-propanol and then treated with UV-ozone. A 40 nm thick layer of PEDOT:PSS (Clevios P) was spin-coated onto the ITO glass, which was then baked at 140 °C for 15 min in air. The substrate was transferred to a glove box for spin coating the BHJ active layer to thickness of 100 nm. The solution for applying the active layer was prepared by overnight dissolution in dichlorobenzene (o-DCB) with P3HT:PC61BM (1.0:0.7 w/w ratio, polymer concentration of 15 mg/mL). After 2 h of drying, a solution of PF-PDMA in ethanol (1 mg/mL) was spin-casted at 2000 rpm for 30 s and annealed at 100 °C for 10 min. Last, an Al metal cathode (120 nm) was applied by thermal evaporation (Active area: 0.09 cm2).

Results and discussion

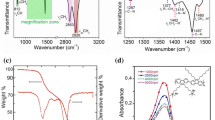

Optical and electrochemical properties of the synthesized polymer

The normalized absorption spectrum is plotted in Fig. 1. The maximum absorption wavelengths of the solution and film states were 308 and 312 nm, respectively. The optical band-gap was calculated by measuring the onset wavelength of the absorption spectrum of the polymer film using the following equation: E optg = 1240/λ edge. The measured onset absorption wavelength of the polymer film was 330 nm, which corresponds to optical band-gap energy (E optg ) of 3.76 eV. The energy level of the highest occupied molecular orbital (HOMO) was determined via CV in solution, and the lowest unoccupied molecular orbital (LUMO) was measured from the HOMO energy level and optical band gap energy. The measured optical properties of the polymer are summarized in Table 1.

Performance of the OPVs

The synthesized polymer, i.e., PF-PDMA, was used as an interfacial layer in organic photovoltaic cells. The OPVs were fabricated with the following structure: ITO/PEDOT:PSS/P3HT:PC61BM/PF-PDMA/Al. For comparison, an OPV device without an interfacial layer (ITO/PEDOT:PSS/P3HT:PC61BM/Al) was also fabricated and characterized as a reference device.

The current density–voltage curve (J–V curve) and external quantum efficiency (EQE) values of the fabricated devices are plotted in Fig. 2. The device fabricated using PF-PDMA showed better performances at all values than the reference device: The open-circuit voltage (V OC) increased from 0.50 to 0.61 V, the short circuit current density (J SC) increased from 9.23 to 9.45 mA/cm2, and the fill factor (FF) increased from 0.51 to 0.55 with the addition of the interfacial layer. The shunt resistance of the device fabricated using the interfacial layer increased while the series resistance of the device decreased relative to those of the reference device. Therefore, the overall power-conversion efficiency (PCE) of the device with PF-PDMA was higher (3.18 %) than that of the reference device (2.36 %). The performances of the fabricated OPV devices are summarized in Table 2.

The differences of the two devices originated from the dipole character of the interfacial layer between the metal electrode and organic contact. The dipoles increased the built-in potential and redistributed the electric fields in the devices. Therefore, the vacuum level of the metal electrode increased and the work function of the electrode could be tuned. Thus, the V OC of the device increased as a result of the presence of this interfacial layer. In addition, dipoles enhanced the extraction of electrons from the acceptor surface and reduced hole electron recombination in active layer. Moreover, the PF-PDMA interlayer could reduce the series resistance between the electrode and organic film [9, 11–13].

Conclusion

In this study, we synthesized non-ionic polyfluorene derivatives with amine functional groups in the side chain. The synthesized polymer was employed as the electron transporting interfacial layer in OPVs. The open circuit voltages, short circuit currents, and fill factors of the device fabricated using the interfacial layer were higher than those of the reference device without an interfacial layer.

References

De Jong MP, Van IJzendoorn LJ, De Voigt MJA (2000) Stability of the interface between indium-tin-oxide and poly(3,4-ethylenedioxythiophene)/poly(styrenesulfonate) in polymer light-emitting diodes. Appl Phys Lett 77(14):2255–2257

Kawano K, Pacios R, Poplavskyy D, Nelson J, Bradley DDC, Durrant JR (2006) Degradation of organic solar cells due to air exposure. Sol Energy Mater Sol Cells 90(20):3520–3530

Sun Y, Welch GC, Leong WL, Takacs CJ, Bazan GC, Heeger AJ (2012) Solution-processed small-molecule solar cells with 6.7 % efficiency. Nat Mater 11(1):44–48

Kim JY, Lee K, Coates NE, Moses D, Nguyen T-Q, Dante M, Heeger AJ (2007) Efficient tandem polymer solar cells fabricated by all-solution processing. Science 317(5835):222–225

He Z, Zhong C, Su S, Xu M, Wu H, Cao Y (2012) Enhanced power-conversion efficiency in polymer solar cells using an inverted device structure. Nat Photonics 6(9):591–595

Zhou Y, Fuentes-Hernandez C, Shim J, Meyer J, Giordano AJ, Li H, Winget P, Papadopoulos T, Cheun H, Kim J, Fenoll M, Dindar A, Haske W, Najafabadi E, Khan TM, Sojoudi H, Barlow S, Graham S, Brédas J-L, Marder SR, Kahn A, Kippelen B (2012) A universal method to produce low–work function electrodes for organic electronics. Science 336(6079):327–332

Hoven C, Yang R, Garcia A, Heeger AJ, Nguyen T-Q, Bazan GC (2007) Ion motion in conjugated polyelectrolyte electron transporting layers. J Am Chem Soc 129(36):10976–10977

Seo JH, Gutacker A, Sun Y, Wu H, Huang F, Cao Y, Scherf U, Heeger AJ, Bazan GC (2011) Improved high-efficiency organic solar cells via incorporation of a conjugated polyelectrolyte inter layer. J Am Chem Soc 133(22):8416–8419

Lee W, Seo JH, Woo HY (2013) Conjugated polyelectrolytes: a new class of semiconducting material for organic electronic devices. Polymer 54(19):5104–5121

Lee J-H, Hwang D-H (2003) Alkoxyphenyl-substituted polyfluorene: a stable blue-light-emitting polymer with good solution processability. Chem Commun 22:2836–2837

Goh C, Scully SR, McGehee MD (2007) Effects of molecular interface modification in hybrid organic-inorganic photovoltaic cells. J Appl Phys 101(11):114503

Xu X, Cai W, Chen J, Cao Y (2011) Conjugated polyelectrolytes and neutral polymers with poly(2,7-carbazole) backbone: synthesis, characterization, and photovoltaic application. J Polym Sci, Part A: Polym Chem 49(5):1263–1272

Xu X, Zhu Y, Zhang L, Sun J, Jun Huang, Chen J, Cao Y (2012) Hydrophilic poly(triphenylamines) with phosphonate groups on the side chains: synthesis and photovoltaic applications. J Mater Chem 22:4329–4336

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) Grant funded by the Korea government (MSIP) through GCRC-SOP (No. 2011-0030013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, J.B., Kim, JH. & Hwang, DH. Fluorene-based conjugated polymer as an interfacial layer for organic photovoltaic cells. Polym. Bull. 73, 2393–2399 (2016). https://doi.org/10.1007/s00289-016-1625-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-016-1625-3