Abstract

The electrochemical, structural and photoelectrochemical properties of blend of a low-viscosity IL 1-ethyl 3-methyl imidazolium dicynamide (EMIM DCA, viscosity 17 cP) in poly(vinylidene fluoride-hexafluoropropylene) (PVdF-HFP) are presented in detail. The blending of low-viscous IL provides charge carriers with higher mobility which are significantly observed in ionic conductivity measurement. The incorporation of IL provides more amorphous region within polymer matrix which is known as a beneficial condition for conductivity enhancement and are affirmed by our DSC and XRD measurements. The fabricated supercapacitor with configuration MWCNT/PVdF-HFP +IL/MWCN shows promising results.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ionic liquids (ILs) are proposed as one among known materials playing a dominant role in the emerging electrochemical devices market. Recent research trends prove that ILs are safe, environmentally friend and used as novel electrolytes in popular electrochemical devices available in market [1–3]. Due to its advantageous properties over other popular electrolytes it may be treated as recent hot electrolytes and worldwide IL companies are growing rapidly. In electrochemical devices such as batteries, dye sensitized solar cell (DSSC), actuators, fuel cells, supercapacitors, etc., the IL demand is increasing day by day [4–7]. The selection criteria for IL application in each above-mentioned devices are based on their matching physical and chemical properties. It is well known that ILs are composed of ions only and hence they play a dominant role in conductivity modulation. In supercapacitors the attainable cell voltage depends mainly on the electrolyte breakdown voltage, while the equivalent series resistance (ESR) depends on the electrode nature and electrolyte conductivity. Hence, the choice of good electrolytes plays a dominant role in developing efficient supercapacitor. The most frequent popular electrolytes are based on either aqueous electrolytes or organic solvents. Although aqueous electrolyte shows high conductivity, their narrow cell voltage, low energy density create problem while in other side the organic electrolytes have a higher breakdown voltage, but have also greater resistance than those based on aqueous solution [8, 9].

Ionic liquids (ILs) have attracted a great deal of attention due to their low vapor pressure, nonflammability, high thermal stability, good conductivity albeit the liquid natures at room temperature of most of the ILs are the biggest disadvantage [10, 11]. Therefore, to develop a solid electrolyte, one of the novel methods is to blend these ILs in a suitable polymer electrolyte matrix. It is well documented that the ionic conductivity (σ) of polymer electrolyte is closely related to viscosity (η) by the following equations:

and

where n, q and μ are defined as the number of ionic charge carriers, columbic charge and mobility of the species, respectively. Following these equations, it is clear that the mobility (μ) or ionic conductivity (σ) is inversely proportional to the viscosity (η), and hence low-viscosity IL could be a preferable material to achieve high ionic conductivity.

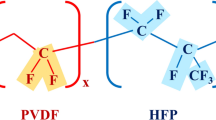

Good efficient electrochemical double-layer supercapacitors (EDLC) have been reported in the literature, choosing various polymer matrixes such as poly(methyl methacrylate) (PMMA), polyacrylonitrile (PAN), poly(vinyl chloride) (PVC), poly(vinyl pyrrolidone) (PVP), poly(ethylene oxide) (PEO) and poly(vinylidene fluoride) (PVDF) or poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP). Among them, poly(vinylidene fluoride-co-hexafluoropropylene) is widely used because of its good mechanical and electrochemical stability with respect to nonaqueous electrolyte and electrode materials [9, 10]. Keeping these things in mind the prime aim of the present communication is to check the role of low-viscosity IL (1 ethyl 3 methylimidazolium dicyanamide, EMIM DCA, viscosity 17 cP) [10] addition into polymer poly(vinylidene fluoride-hexafluoropropylene) (PVdF-HFP) matrix. Fabrication of supercapacitor comprising multiwalled carbon nanotubes (MWCNT) and IL-blent solid polymer electrolyte is presented in detail.

Experimental

IL-blent solid polymer electrolyte films were prepared as follows. PVDF-HFP (average molecular weight M w = 400,000, Aldrich, USA) was dissolved in acetone by continuous stirring (~5 h) at 60 °C. The desired amount of low-viscosity IL (EMIM DCA; Sigma-Aldrich, USA) was then mixed in PVDF-HFP polymer electrolyte solutions. The viscous polymer solutions with and without IL were poured into glass petri dishes and dried under room ambient condition. These free-standing polymer electrolyte films were later dried in a vacuum. The room temperature bulk electrical conductivity, electrochemical stability and supercapacitor performance were carried out with the help of a computer-controlled CHI instrument (CH Instrument, USA) with a frequency range between 10 mHz and 100 kHz. The X-ray diffraction (XRD) patterns were recorded using an X-ray diffractometer (Rigaku D/max-2500) at a scan rate of 50 min−1. The differential scanning calorimetry (DSC) was performed using a TA instrument (MDSC 2910) at 50 °C min−1 in a nitrogen gas atmosphere with a sample weight of ~5 mg in the temperature range 120–190 °C while thermogravimetry analysis (TGA) measurement was carried out using a Perkin-Elmer Pyris-1 analyzer with a heating rate of 10 °C min−1 at a temperature range between 20 and 400 °C.

Multiwalled carbon nanotube (MWCNT) powder was purchased from Sigma-Aldrich., USA. For electrode fabrication fixed amount of MWCNTs, acetylene black, and poly(vinylidene fluoride-hexafluoropropylene) (PVDF-HFP) as binder [70:10:20 (w/w)] was mixed with mortar and pestle. Acetone was used as medium to form slurry which was coated on the graphite sheets having dimension 1 × 1 cm2. Finally the prepared electrodes were vacuum-dried overnight at ~100 °C before fabricating EDLC cell.

Good efficient EDLC was fabricated by sandwiching solid polymer electrolyte (SPE) between two symmetric MWCNT electrodes. The 1 × 1 cm2 graphite sheet has been used as a current collector.

Results and discussions

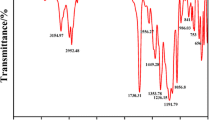

The electrical conductivities (σ) of solid polymer electrolyte films with and without IL were measured and conductivity variation is shown in Fig. 1.

The conductivity of pure PVDF-HFP was in the range of 1.20 × 10−6 S cm−1 while for IL it was 25 × 10−3 S cm−1. It was clear from the figure that with increasing amounts of IL (EMIM DCA), the ionic conductivity (σ) of the films is found to increase, attain a maximum and then decrease. The maximum conductivity was obtained at 250 weight % IL concentration with a conductivity (σ) value of 3.42 × 10−3 S cm−1. The free-standing PVDF-HFP + 250 weight % IL–polymer electrolyte photograph is shown in Fig. 2. It was noticed that after 250 weight % IL concentration, the IL came out from the PVDF-HFP matrix.

Taking account of Eqs. 1 and 2, it was clear that the conductivity enhancement till 250 wt% could be due to more numbers of free charge carriers (n) or high mobility of ions. Interestingly, using Eq. 2, it is well established that ionic conductivity (σ) is inversely proportional to viscosity (η) and hence low viscosity leads to an increase in mobility or ionic conductivity [12–14]. The dispersal of low-viscosity IL (EMIMDCA) could fulfill both the requirements stated above. Adding of low-viscosity IL could provide free charge carriers since it composed of ions only while in other side it produces a less viscous matrix within the gel matrix by suppressing crystallinity (as observed in XRD, DSC) and hence easy movement of ions, which results in an overall improvement in ionic conductivity while suppressing the ionic conductivity, in the later part, was attributed to the aggregation of charge carriers [15]. Figure 3 shows the recorded XRD patterns of the pure PVDF-HFP and PVDF-HFP + 250 weight % EMIM DCA solid polymer electrolyte films. It was clear that pure PVDF-HFP polymer matrix shows well-defined peaks at 2ϴ = 18.3°, 20°, 26.6° and 39° with a hollow at the base indicating the semi-crystalline nature (Fig. 3a). With the blending of low-viscosity IL, the intensity of the PVDF-HFP polymer matrix peaks decreases drastically (Fig. 3b). Additionally the peaks of the polymer electrolyte films (Fig. 3b) become broader and weaker in intensity compared with the patterns of the film without IL. The decreasing crystallinity can result in more amorphous areas of the polymer matrix and enhanced ionic conductivity of polymer electrolyte films. This is a well-known ideal condition for ionic conductivity enhancement [15].

Figure 4 shows the typical DSC thermograms of the PVDF-HFP polymer and PVDF-HFP solid polymer electrolyte blend with low-viscosity IL.

The exothermic peak observed in the temperature range 140–150 °C was (Fig. 4a) ascribed to the melting point of PVDF-HFP [12].

The relative percentage of crystallinity (χ) of PVDF-HFP and PVDF-HFP blend solid polymer electrolyte films was calculated using the following equation

where ΔH m is the melting enthalpy obtained from the DSC results. ΔH 0 is the melting enthalpy of 100 % crystalline PVDF-HFP which was assumed to be 104.7 J g−1 [12, 16].

The evaluated values of the melting temperature (T m), melting enthalpy (ΔH m) and relative percentage of crystallinity (χ) are listed in Table 1.

It was clear from the table and Fig. 4b that the value of melting temperature of PVDF-HFP film was found to decrease with IL mixing. It has also been observed that the melting endotherm was broadened after incorporation of the IL. Both the reduced melting temperature and the broadening of the melting endotherm supported our findings, which we have already discussed in the previous sections.

Thermal stability of the solid polymer electrolyte films with and without IL was carried out using TGA measurement and plots are shown in Fig. 5.

It is in literature that pure PVDF-HFP matrix shows high thermal decomposition temperature at around 400 °C, and incorporation of IL with polymer electrolyte lowered decomposition temperature [12, 14]. However, we could not observe significant lowering temperature phenomenon in our ionic liquid–polymer electrolyte system.

The electrochemical stability window (ESW) of IL-blent solid polymer electrolyte film was carried out using cyclic voltammetry with symmetrical stainless steel electrodes. Figure 6 shows the typical cyclic voltammograms of PVdF-HFP + 250 wt% IL film, recorded at the scan rate of 5 mV s−1. The ESW of IL-blent solid ionogel electrolyte has been observed from −1. 2 to +2.3 V, which was found to be higher as compared to that for the pure IL-based electrolyte [17].

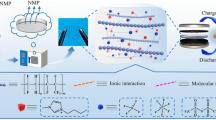

The EDLC having configuration MWCNT//PVDF-HFP + 250 wt% IL//MWCNT was fabricated and characterized using impedance spectroscopy and cyclic voltammetry techniques. The photograph of sandwich supercapacitor comprising electrodes and electrolyte is shown in Fig. 7. Due to the beneficial nature of sticky polymer–IL electrolyte we do not need any other sticking materials externally.

Figure 8 shows the typical complex impedance spectra of fabricated supercapacitor. The MWCNT electrode materials with the IL-based solid polymer electrolyte shows capacitive behavior reflected by the steep rising behavior of the impedance plots in the lower frequency range observed in complex impedance spectroscopy. The various electrical parameters of EDLC were calculated at 10 mHz frequency and values are shown in Table 2.

Cyclic voltammetry (CV) is performed to explain the nature of charge storage at the individual interfaces in the anodic and cathodic regions. Figure 9 shows typical cyclic voltammograms of capacitor (mentioned above) in the potential range −0.8 to 0.8 V at 100 mV/s scan rate. The EDLC supercapacitor using symmetrical electrode and IL-blent solid polymer electrolyte shows specific capacitance of 21 F g−1 which was matched well by our conductivity measurement.

Conclusions

Low-viscosity IL (EMIM DCA) was dissolved in the PVDF-HFP polymer electrolyte matrix. Incorporation of low-viscosity IL shows dual beneficial behavior in polymer matrix. It provided additional charge carriers as it composed of ions only while in other side; it reduced the crystallinity of host polymer and hence increased the ionic conductivity. The crystallinity suppression was confirmed by XRD, DSC measurements. The maximum ionic conductivity of PVDF-HFP + 250 wt% IL was found to be 3.42 × 10−3 S cm−1. The fabricated supercapacitor showing high performance (22 mF cm−2) further affirmed that these IL-blent solid polymer electrolytes seem novel candidates for supercapacitor.

References

Ohno H (ed) (2005) Electrochemical aspects of ionic liquids. VCH Interscience, New Jersey

Wasserscheid P, Welton T (2007) Ionic liquids in synthesis. Wiley

Wilkis JS, Zaworotko MJ (1992) Air and water stable 1-ethyl-3-methylimidazolium based ionic liquids. J Chem Soc Chem Commun 23:965

Thinh NT, Yang YS, Oh IK (2009) Adaptive neuro-fuzzy control of ionic polymer metal composite actuators. Smart Mater Struct 18:065016

Scott MP, Rahman M, Brazel CS (2003) Application of ionic liquids as low-volatility plasticizers of PMMA. Euro Polym J 39:1947

Kepler RG, Anderson RA (1978) Piezoelectricity and pyroelectricity in polyvinylidene fluoride. J Appl Phys 49:4490

Wang TT, Herbert JM, Glass AM (1988) The applications of ferroelectric polymers. Chapman and Hall, London

Khare V, Ruby C, Sonkaria S, Taubert A (2012) A green and sustainable nanotechnology: role of ionic liquids. Int J Precis Eng Manuf. 13:1207

Pandey GP, Kumar Y, Hashmi SA (2010) Ionic liquid incorporated polymer electrolytes for supercapacitor application. Ind J Chem 49A:743

MacFarlane DR, Forsyth SA, Golding J, Deacon GB (2002) Ionic liquids based on imidazolium, ammonium and pyrrolidinium salts of the dicyanamide anion. Green Chem 4:444

Aschenbrenner O, Supasitmongkol S, Taylor M, Styring P (2009) Measurement of vapour pressures of ionic liquids and other low vapour pressure solvents. Green Chem 11:1217

Rudhziah S, Mohamed NS, Ahmad A (2013) Conductivity and structural studies of poly(vinylidene fluoride cohexafluoropropylene)/polyethyl methacrylate blend with ammonium triflate. Int J Electrochem Sci 8:421

Benz M, Euler WB, Gregory OJ (2002) The role of solution phase water on the deposition of thin films of poly(vinylidene fluoride). Macromolecules 35:2682

Liew CW, Ong YS, Lim JY, Lim CS, Teoh KH, Ramesh S (2013) Effect of ionic liquid on semi–crystalline poly(vinylidene fluoride–co–hexafluoropropylene) solid copolymer electrolytes. Int J Electrochem Sci 8:7779

Lalia BS, Sekhon SS (2006) Polymer electrolytes containing ionic liquids with acidic counteranion (DMRImH2PO4, R = ethyl, butyl and octyl). Chem Phys Lett 425:294

Preechatiwong W, Schultz JM (1996) Electrical conductivity of poly(ethylene oxide)-alkali metal salt systems and effects of mixed salts and mixed molecular weights. Polymer 37:5109

Yoshida Y, Muroi K, Otsuka A, Saito G, Takahashi M, Yoko TY (2004) 1-Ethyl-3- methylimidazolium based ionic liquids containing cyano groups: synthesis, characterization, and crystal structure. Inorg Chem 43:1458

Acknowledgments

We are thankful to Prof. Einar Halvorsen for valuable discussion. This work was supported by the ENERGIX, the research council of Norway.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, P.K., Sabin, K.C. & Chen, X. Ionic liquid–solid polymer electrolyte blends for supercapacitor applications. Polym. Bull. 73, 255–263 (2016). https://doi.org/10.1007/s00289-015-1484-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-015-1484-3