Abstract

We report the synthesis of a novel poly (acrylate-acrylic acid-co-maleic acid) hydrogel by the copolymerization of acrylic acid and maleic acid in aqueous media using N,N′-methylenebisacrylamide (NMBA) as cross linker and ammonium persulfate as initiator. Hydrogels with varying concentration of the cross linker and monomer were prepared and were characterized using Fourier transform IR spectroscopy and thermogravimetry. The mechanical properties of the gel were investigated using tensile strength measurements and the morphology was confirmed with environmental scanning electron microscopy at room temperature. Water absorbency studies of the hydrogels revealed that synthesized hydrogels are responsive towards ionic strength and pH of the swelling medium. Cross link density and tensile strength were found to increase with increase in the NMBA content which was optimized from swelling experiments. Reswelling experiments of the hydrogel revealed that the synthesized hydrogel is a reusable material and it indicates its applicability in the waste water purification.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Synthetic hydrogels, are the cross linked polymers which can absorb large amount of water without dissolving in it. Polymeric hydrogel network may be formed from monomers [1, 2] pre-polymers or existing hydrophilic polymers [3–6]. Polymerization of monomers having hydrophilic groups takes place in the presence of some free radical initiators such as ammonium or potassium persulfate, 2,2′-azobisisobutyronitrile (AIBN) etc. Hennink and van Nostrum [7] reported that the cross linking in a hydrogel can be either physical or chemical in nature and thus can prevent its dissolution in an aqueous environment. In the physically cross linked hydrogel the dissolution is prevented by physical interaction between the chains and the cross linking agents such as N,N′-methylenebisacrylamide, ethylene glycol dimethacrylate, 1,4-butanediol dimethacrylate etc. Softness, smartness and the capacity to store water make the hydrogels unique materials for its wide variety of applications [8–10].

In recent years many research work has been ongoing on to prepare environment responsive hydrogels that undergo swelling and deswelling in response to changes in variables such as temperature, ionic strength and pH. The polymer chains which are close to each other before swelling but in swollen state they separate to some extent and the interaction between them diminishes. The swelling also depends on the amount of cross linker, concentration of the monomers etc. The large swelling was found to be accompanied by poor mechanical strength which can be improved by increasing the cross linking density, but then the swelling behavior is reported [11] to be affected.

The swelling behavior of the hydrogel is known to depend upon its network structure which is described by the molecular weight between the cross links (Mc), corresponding mesh size (ξ), number of elastically effective chains (Ve) etc. Due to the random nature of the polymerization process, only the average values of the Mc—the measure of the degree of cross linking can be calculated. The cross link density (γ) can thus subsequently be calculated from Mc. There are several theories to describe the network parameters of the hydrogels. The earliest theory to describe the network parameters was developed by Flory and Rehner [12] which describes the molecular weight determination between the cross links for the nonionic polymers. Brannon-Peppas and Peppas [13] derived an equation for the ionic contribution of the ionic hydrogels. By combining the approaches, Peppas–Merril equation have used here to determine simultaneously Mc and γ.

More than one-half of the world’s major rivers are being seriously polluted, degraded and thus threatening the health and livelihood of people who depend upon them for irrigation, drinking and industrial water. Major pollutants include heavy metals such as nickel, cadmium, mercury and zinc and the dyes such as methylene blue, malachite green and eosin. Chemical precipitation [14], ion exchange [15] and adsorption using activated carbon [16, 17] were the traditional methods for removal of all these contaminants. Recently there is a growing interest in using polymeric hydrogels for the removal of heavy metal ions and dyes from aqueous solution, because of their selectivity, reusability and high adsorption capacity. The comparatively moderate cost and the ease of preparation make the hydrogels a promising candidature for the above said application. Functional groups within the polymeric matrix produce complex structures which in turn help in binding the environmental pollutants. Removal of cationic dye can be effectively done by gum arabic co polymerized with sodium acrylate and acrylamide hydrogel [18] or chitosan hydrogel beads generated by anionic surfactant gelation [19]. Many grafted copolymeric hydrogels like gelatin with acrylamide [20], starch with acrylic acid/montmorillonite nanocomposites [21] and cellulose with poly(acrylic acid)/attapulgite [22] are also used for purification of waste water. Poly acrylic acid copolymerized with poly acrylamide [23], methacrylamide [24] and itaconic acid [25] were reported to use in dye industry for purification of water.

Acrylic acid, the simplest unsaturated carboxylic acid, is commercially valued as it readily combines with themselves or with other monomers to form homopolymers or copolymers for various applications including hydrogel synthesis. In aqueous medium poly acrylic acid loses protons, acquires negative charge and can thus act as a polyelectrolyte. Presence of ionic groups makes polyelectrolyte hydrogels sensitive to pH, ionic strength and temperature [26–28]. Copolymerization of hydrophobic monomers with hydrophilic groups of other monomers results in hydrogels of high mechanical strength [29]. Acrylic acid based hydrogel interpenetrated with polyacrylamide, poly vinyl alcohol (PVA) and polyethylene glycol (PEG) were reported [11, 23, 30] in literature as examples for improved water absorbency and mechanical strength. By manipulating the hydrophilic segment in the hydrogel and the degree of cross linking, hydrogel may be tailored to exhibit specific properties [31]. The effective removal of chromium using hydrogels produced by the copolymerization of acrylamide with maleic acid is reported in the literature [32]. Here the chromium adsorption mechanism might be through hydrogen bond between –O atom on chromate and –H atom on carboxylic group and amide group of polymeric matrix.

Thus it was planned to produce a polymeric matrix having water retention qualities to trap pollutant molecules. Accordingly, we prepared poly (acrylic acid) (PAA) and a series of poly (acrylate-acrylic acid-co-maleic acid) (PAAAM) hydrogels. Since the adsorption of contaminants on the hydrogel system depends upon the cross link density, monomer composition etc. it is essential to carry out the swelling experiments of prepared hydrogels in various media and find out the optimal condition and composition of hydrogel for the concerned applications. In this work we have studied the structure, thermal properties, mechanical properties, swelling and deswelling of the hydrogels in detail.

Experimental

Materials and reagents

The monomer acrylic acid (AA), co-monomer maleic acid (MA), initiator ammonium persulfate (APS) and cross linker N,N′-methylenebisacrylamide (NMBA) of analytical grade were purchased from Hi Media, Mumbai, India. The chemical structures of these materials were as given in Scheme 1. They were used as received without any further purification. Acrylic acid was neutralized to a desired degree using KOH (Spectrum chemicals, India) and all the solutions were prepared in double distilled water. Sodium chloride (NaCl), Calcium chloride (CaCl2) Aluminium chloride (AlCl3), Hydrochloric acid (HCl) and NaOH, used for swelling studies, were from Merck, India.

Preparation of PAA and PAAAM hydrogels

The PAA hydrogel was synthesized by the polymerization of AA in presence of initiator APS and cross linker NMBA. For this NMBA (0.25 mol%) and APS (0.8 mol%) were dissolved in 4 mL double distilled water. After the addition of AA (1 mL), the solution was placed in one end sealed poly (vinyl chloride) straws of 0.3 cm diameter and 20 cm length. The straws were kept in an electric oven at 60 °C for 2h. Hydrogels were formed and the straws were taken out from the oven, cooled to room temperature. The hydrogels were taken out from the straw and cut into small cylindrical pieces and put in double distilled water for 5–6h in order to remove the unreacted species. The water was replaced by every 30 min. Then the hydrogel was dried at 40 °C till they attained constant weight. The hydrogels formed was highly transparent, very soft, elastic and cylindrical in shape. The PAAAM hydrogels were also prepared by the same procedure. Here we varied the concentration of MA, NMBA and the extend neutralization of AA in order to determine the effect of these factors on the properties of the hydrogel. The MA concentration varied from 0.0014 to 0.004 mol, NMBA from 0.1 to 0.25 mol% and the neutralization of AA is from 0 to 50 %. The composition of PAAAM hydrogel is shown in Table 1. The minimum amount of cross linker for the formation of PAAAM hydrogel is optimized to be 0.1 mol%, below which it is not formed.

Characterization

FTIR spectra of the PAA and PAAAM hydrogels were recorded by FTIR spectrometer (model, Thermo Nicolet, avatar 370) with ATR accessory.

Thermal analysis of the PAA and PAAAM hydrogel were done by thermo gravimetric analyzer (2960 SDT V2.2B). 7.07 mg of sample were placed in platinum cups and analyzed over the temperature range of 25–1,000 °C at the rate of 10 °C/min in nitrogen atmosphere at the rate of 100 ml/min.

Tensile strength of the hydrogel with dimensions of 100 mm × 1 mm × 1 mm and with varying amount of cross linker were determined at 25 °C with a Universal Testing Machine -Instron 3345 with cross head speed 10 mm/min and grip distance 40 mm.

The swollen sample was examined by Environmental scanning electron microscopy (ESEM) FEI Quanta 200, The Netherlands. ESEM maintains the structure of the swollen gel in its most natural form throughout the measurement. The crosslink density and average molecular weight between the crosslinks were determined using an electronic densimeter MD-300S (ALFA MIRAGE) with a resolution of 0.001 g/cm3.

Swelling studies

The synthesized hydrogels (≈0.03 g) were immersed in 20 mL of double distilled water at room temperature (25 °C) for 2 days to reach the swelling equilibrium and is wiped out with filter paper. After weighing the swollen gels, the SR (swelling ratio, g/g) of the hydrogels were calculated using Eq. (1) [32–34]

Where W2 and W1 were the mass of the swollen and the dried gel in grams.

For studying the swelling behaviour of the hydrogels at different pHs, the medium were prepared from standard aqueous HCl (pH 1) and NaOH (pH 14) solutions. These solutions were diluted with distilled water to reach the desired acidic and basic pH.

Network parameter determination

The molecular weight between the cross links Mc, was calculated from the swelling data Eq. (2) as discussed by Pappas and Merill [35]

Here, ρp is the density of hydrogel, Vs is the molar volume of solvent (18 cm3/mol), Φ is the volume fraction of the gel, Φ = \(\frac{{V_{p} }}{{V_{p} + V_{s} }}\)

χ is the polymer–solvent interaction parameter, which is equal to 0.495 for poly acrylic acid–water system [36].

Thus the cross link density, γ, was calculated as

where M0 is the molar mass of the repeating units which can be determined as [37, 38]

where, mAA and mMA are the masses of AA and MA respectively in gram and MAA and MMA are the molar masses of AA and MA in g/mol, respectively.

The number of elastically effective chains induced in a perfect network per unit volume, Ve of the gel was calculated as

where NA is the Avogadro’s number. The hydrogel mesh size was then calculated using equation

Here, Cn is the Flory characteristic ratio (=6.7 for poly acrylic acid) [39].

Results and discussion

Preparation

The polymerization reaction for the formation of PAAAM hydrogel is shown in Scheme 2. In the first step, the thermally dissociating initiator, i.e., APS is decomposed under heating (60 °C) to produce sulfate anion-radicals. These radicals initiate the copolymerization of AA and MA. Crosslinking occurred in the presence of the cross linker, NMBA.

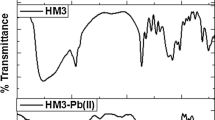

Fourier transform IR spectra

FTIR spectra of PAA and N4 hydrogels were shown in Fig. 1. The bands at 2,500–3,500 cm−1 represents the stretching of O–H bonds of AA and MA present in the hydrogels. It is observed that the –OH peaks in the N4 is much more intense than that of PAA hydrogel, which may be due to the presence of more –OH groups in the latter. The observed band at 1,705 cm−1 in the prepared hydrogels is due to the C=O bonds of carboxylic groups whereas the peak at 1,638, 1,630 cm−1 in PA and N4 respectively are attributed to the C=O stretching frequency of amide groups present in NMBA, the cross linker. Similarly the absorption peaks at 1,402, 1,406 cm−1 in PA and N4 respectively due to the stretching of C–N bond present in NMBA and the peaks noted at 1,000–1,200 cm−1 is due to the C–O stretching and O–H bending of the carboxylic group present in the hydrogels.

Thermal properties

Figure 2 shows the TGA for the PAA and N4 hydrogel as a function of weight loss against temperature. No weight loss was noticed up to 150 °C for the PAA gel, but a sharp weight loss was noticed at 170 °C, indicating the decomposition of the hydrogel back bone. The sharp weight loss for N4 sample was observed at 264 °C accounts to the increased thermal stability of N4 over the other.

Morphological study

Figure 3 shows the morphology of the sample by ESEM image. The structure verifies the porous structure of the hydrogel, which is believed to be an important factor for its applications. The hydrophilic character of the hydrogel helps them to swell when immersed in an aqueous solution. In the swollen stage, hydrogel contains relaxed chains which in turn help in widening the space within the polymer network. So, when the hydrogel sample is in contact with water, the relaxed space of the hydrogel helps in the ease of movement of molecules into the hydrogel network. Thus the pollutants could move into the hydrogel network along with water through the porous structure. The structure of PAAAM hydrogel as noted in Fig. 3 suggests its utility as a better adsorbent of the contaminants present in effluents.

Swelling properties of hydrogels

Effect of maleic acid, MA

In order to investigate the effect of MA on swelling behavior, the hydrogels having various amounts of monomer dicarboxylic acid in the range of 0.0014–0.004 mol were synthesized. The equilibrium water uptakes of these hydrogels were determined at pH 1 and 7 at room temperature. Results are depicted in the Fig. 4. At these two pHs, the hydrogels show different swelling behavior. At pH 1, when increase the [MA], the swelling ratio of the hydrogel didn’t change considerably as the pka value of AA (4.25) and MA (pka 1 = 1.85 and pka 2 = 6.06) [40] are above the pH of the swelling media. So the carboxylic groups in the hydrogel are in undissociated form. But at pH 7, the swelling ratio of the hydrogel increased with the increase in the amount of MA up to the [MA] = 0.0025 mol and then it begin to decrease with the further rise in [MA]. The SR of the hydrogel is found to increase with lower amounts of MA in the matrix, is attributed to the pH of swelling medium i.e., above the pka values of AA and MA. But at higher [MA] the undissociated carboxylic acid have a screening effect and thus prevent the movement of the solvent into the hydrogel.

Effect of cross linker

One of the most important characteristic structural parameter determining the network of the hydrogel is Mc, the average molar mass between cross links and is directly related to cross link density, γ. The diffusion of water or other solvents and solute into the hydrogel depends upon factors like mesh size and cross link density. The PAAAM hydrogel samples with 0.1, 0.15, 0.2 and 0.25 mol% of NMBA samples were therefore immersed in double distilled water at room temperature (25 °C) and swellings were determined (Table 2). It is seen that the cross link density, γ increases with decrease of Mc, between cross links where as the mesh size decreases with increase of γ. The tensile strength of the hydrogels increases with increase of NMBA. Maximum tensile strength obtained for the hydrogel having NMBA amount of 0.25 mol% of the total monomers. Amount of NMBA used cannot be increased beyond 0.25 %, as the gel cannot be shaped beyond and therefore maximum [NMBA] optimized as 0.25 %.

The equilibrium swelling behavior of PAAAM hydrogels was investigated as a function of cross linker amount in the hydrogel at a fixed temperature (25 °C) (Fig. 5). The swelling ratio is found to decrease with addition of cross linker, NMBA. The three dimensional network might have been changed as the cross linking in the hydrogel increases. Thus it was assumed that a reduction in space for accommodating the penetrating water molecules by the gel occurred as reflected by the decrease in the swelling ratio. This could be the reason for the formation of a less flexible structure beyond 0.25 mol% NMBA. The highest SR was obtained for sample having 0.1 mol% NMBA (100.9 g/g) which got reduced to 81.19 g/g when the cross linker increased from 0.1 to 0.25 mol%.

Effect of neutralization

The hydrogels were neutralized by KOH solution (20, 40 and 50 %) and beyond which they were found to lose their texture due to the presence of more ionized –COO− groups. So K3 sample was taken as the optimized sample composition of the PAAAM.

The equilibrium swelling behavior of PAAAM hydrogels as a function of neutralization of AA and its time were investigated at fixed temperature (25 °C) (Fig. 6). SR is found to increase gradually with time to its equilibrium. This is because of the gradual diffusion of water molecules into the hydrogel net work and complete filling or occupation of the pre-existing or dynamically formed spaces between the polymeric chains. The swelling ratio is fast at the beginning and becomes slower towards equilibrium. At equilibrium the polymer chains move apart due to the attachment of water molecules in between the spaces of the chains. Thus the sample having 50 % neutralization showed the highest swelling ratio indicating an increase in COO−/COOH groups in the hydrogels due to neutralisation and thus enhanced hydrophilic nature of the hydrogel.

pH-responsive swelling studies

To study the pH sensitivity, the hydrogel samples were immersed in aqueous medium at room temperature and predetermined pH between 2 and 13. The swelling behavior of PAAAM hydrogel showed that it has a strong dependence on the environmental pH. The swelling was found to increase with increase of pH from 2–7 (Fig. 7) which could be due to the presence of carboxylic and carboxylate groups present on the hydrogel. Maximum swelling was observed up to pH 7 due to the complete dissociation of the acid group present in AA and MA. The dramatic increase in the swelling from pH 2.0–7.0 could be explained using the pka value of these acids as 4.25 and 6.07 respectively. When pH increases, the surface of hydrogel will be covered by –COO− groups which will cause the “charge screening effect” of excess Na+ of the swelling media. Ionic strength of the medium when increased was found to decrease the swelling of the gel consequently. The sharp decrease beyond pH 7 may be explained by the competition between the screening effect of the counter ions and the shielding effect of the carboxylate ions [41].

Effect of salt and ionic strength on swelling

Electrical neutrality for the synthesized hydrogel is balanced by the potassium ions of the neutralizing medium, which will give an ionic concentration difference inside and outside the gel in an aqueous medium. Thus the variation of SR at different salt solutions (Fig. 8) points to the facts that SR will be less in salt solutions than in distilled water and the ionic strength of environment affects the swelling of the hydrogels. Swelling ratios of hydrogel were found to decrease in NaCl, CaCl2 and AlCl3 solutions with increased ionic strength (0.001–0.009 M) of the salt solution. This can be due to the osmotic pressure developed due to the difference in mobile ion concentration between the gel and the aqueous solution. It is observed that at a fixed concentration of salt solutions the SR was in the order NaCl > CaCl2 > AlCl3 indicate the dependence of SR on the valency of the added ion. This dramatic decrease of water absorbency in multivalent cationic solutions could be related to the complexing ability of carboxylate groups (both inter and intra) and thus causes an increase in crosslinking density [42].

Reswelling of the hydrogel

The hydrogel when added to double distilled water, it absorbs water and swell. This swollen hydrogel when added in 0.01 M NaCl solution it starts to shrink (deswelling) due to the difference in the concentration of free ions inside and outside of the gel. Thus the deswelled hydrogel will swell again if it is made into contact with double distilled water. The results were so interesting that even after reswelling three or four times they retained their capacity as depicted in Fig. 9 indicating the effectiveness and reusability of the synthesized PAAAM hydrogel for technical applications, especially in sewage water purification.

Conclusions

The hydrogels prepared by the copolymerization of acrylic acid and maleic acid could have wide practical applications which includes industrial waste water treatment. Cross link density and tensile strength of the hydrogel increased with increase in the amount of cross linker but its corresponding swelling value decreased. Amount of cross linker used is thus optimized to 0.25 mol%.The synthesized intelligent hydrogel showed environmental responsive swelling behavior—a noticeable property. The hydrogel possessed good hydrophilic property due to the presence of acrylic acid and maleic acid and also have high mechanical strength. The MA concentration also optimized from the swelling experiments at different pH of the medium. MA incorporation in the hydrogel increased the thermal strength and water absorption capacity of the gel. The reswelling experiment was confirming the reuse of the hydrogel. All these make this hydrogel acceptable for potential usage in water treatment processes.

References

Valles E, Durando D, Katime I, Mendizábal E, Puig JE (2000) Equilibrium swelling and mechanical properties of hydrogels of acrylamide and itaconic acid or its esters. Polym Bull 44:109–114

Karadag E, Saraydin D (2002) Swelling studies of super water retainer acrylamide/crotonic acid hydrogels cross linked by trimethylolpropane triacrylate and 1,4-butanediol dimethacrylate. Polym Bull 48:299–307

Barralet JE, Wang L, Lawson M, Triffitt JT, Cooper PR, Shelton RM (2005) Comparison of bone marrow cell growth on 2D and 3D alginate hydrogels. J Mater Sci Mater Med 16:515–519

Zhao X, Harris JM (1998) Novel degradable poly (ethylene glycol) hydrogels for controlled release of protein. J Pharm Sci 87:1450–1458

Myung D, Koh W et al (2007) Design and fabrication of an artificial cornea based on a photo lithographically patterned hydrogel construct. Biomed Microdevices 9:911–922

Sun G, Zhang XZ, Chu CC (2007) Formulation and characterization of chitosan-based hydrogel films having both temperature and pH sensitivity. J Mater Sci Mater Med 18:1563–1577

Hennink WE, van Nostrum CF (2002) Novel crosslinking methods to design hydrogels. Adv Drug Deliv Rev 54:13–36

Don TM, Huang ML, Chiu AC, Kuo KH, Chiu WY, Chiu LH (2008) Preparation of thermo-responsive acrylic hydrogels useful for the application in transdermal drug delivery systems. Mater Chem Phys 107:266–273

Drury JL, Mooney DJ (2003) Hydrogels for tissue engineering: scaffold design variables and applications. Biomaterials 24:4337–4351

Carvalho HWP, Batista APL, Hammer P, Luz GHP, Ramalho TC (2010) Removal of metal ions from aqueous solution by chelating polymeric hydrogel. Environ Chem Lett 8:343–348

Micic M, Suljovrijic E (2013) Network parameters and biocompatibility of p(2-hydroxyethyl methacrylate/itaconic acid/oligo(ethylene glycol) acrylate) dual-responsive hydrogels. Eur Polym J 49:3223–3233

Caykara T (2004) Effect of maleic acid content on network structure and swelling properties of poly (n-isopropyl acrylamide-co-maleic acid) polyelectrolyte hydrogels. J Appl Polym Sci 93:763–769

Peppas LB, Peppas NA (1991) Equilibrium swelling behaviour of pH-sensitive Hydrogels. Chem Eng Sci 46:715–722

Kurniawan TA, Chan GYS, Lo WH, Babel S (2006) Physico–chemical treatment techniques for wastewater laden with heavy metals. Chem Eng J 118:83–98

Dabrowski A, Hubicki Z, Podkoscienly P, Robens E (2004) Selective removal of the heavy metal ions from waters and industrial wastewaters by ion-exchange method. Chemosphere 56:91–106

Kadirvelu K, Thamaraiselvi K, Namasivayam C (2001) Removal of heavy metals from industrial wastewaters by adsorption onto activated carbon prepared from an agricultural solid waste. Bioresour Technol 76:63–65

Bhattacharyya D, Cheng CYR (1987) Activated carbon adsorption of heavy metal chelates from single and multicomponent systems. Environ Progr Sustain Energy 6:110–118

Paulino AT, Guilherme MR, Reis AV, Campese GM, Muniz EC, Nozaki J (2006) Removal of methylene blue dye from an aqueous media using superabsorbent hydrogel supported on modified polysaccharide. J Colloid Interface Sci 301:55–62

Chatterjeea S, Chatterjeea T, Limb SR, Woo SH (2010) Adsorption of a cationic dye, methylene blue, on to chitosan hydrogel beads generated by anionic surfactant gelation. Environ Technol 32:1503–1514

Chauhan GS, Kumar S, Kumari A, Sharma R (2003) Study on the synthesis, characterization, and sorption of some metal ions on gelatin-and acrylamide-based hydrogels. J Appl Polym Sci 90:3856–3871

Guclu G, Ebru Al, Emik S, Iyim TB, Ozgumus S, Ozyurek M (2010) Removal of Cu2+ and Pb2+ ions from aqueous solutions by starch-graft-acrylic acid/montmorillonite superabsorbent nanocomposite hydrogels. Polym Bull 65:333–346

Liu Y, Wang W, Wang A (2010) Adsorption of lead ions from aqueous solution by using carboxymethyl cellulose-g-poly (acrylic acid)/attapulgite hydrogel composites. Desalination 259:258–264

Li W, Zhao H, Teasdale PR, John R, Zhang S (2002) Synthesis and characterization of a polyacrylamide–polyacrylic acid copolymer hydrogel for environmental analysis of Cu and Cd. React Funct Polym 52:31–41

Cavus S, Gurdag G, Sozgen K, Ali Gurkaynak M (2008) The preparation and characterization of poly (acrylic acid-co-methacrylamide) gel and its use in the non-competitive heavy metal removal. Polym Adv Technol 20:165–172

Rodríguez E, Katime I (2003) Behaviour of acrylic acid–itaconic acid hydrogels in swelling, shrinking, and uptakes of some metal ions from aqueous solution. J Appl Polym Sci 90:530–536

Park TG (1999) Temperature modulated protein release from pH/temperature sensitive hydrogels. Biomaterials 20:517–521

Brazel CS, Peppas NA (1995) Synthesis and characterization of thermo- and chemo mechanically responsive poly (N-isopropylacrylamide-co-methacrylic acid) hydrogels. Macromolecules 28:8016–8020

Sakiyama T, Takata H, Kikuchi M, Nakanishi K (1999) Polyelectrolyte complex gel with high pH-sensitivity prepared from dextran sulphate and chitosan. J Appl Polym Sci 73:2227–2233

Sun QX, Li Q, Lin J, Wu J (2009) Preparation of porous polyacrylate/poly (ethylene glycol) interpenetrating network hydrogel and simplification of Flory theory. J Mater Sci 44:3712–3718

Hernandez R, Lopez D, Mijangos C (2006) Preparation and characterization of polyacrylic acid-poly (vinyl alcohol)-based interpenetrating hydrogels. J Appl Polym Sci 102:5789–5794

Malik PK (2004) Dye removal from wastewater using activated carbon developed from sawdust: adsorption equilibrium and kinetics. J Hazard Mater B113:81–88

Bajpai SK, Johnson S (2005) Poly (acrylamide-co-maleic acid) hydrogels for removal of Cr(VI) from aqueous solutions, part 1: synthesis and swelling characterization. J Appl Polym Sci 100:2759–2760

Pourjavadi A, Salimi H (2008) New protein-based hydrogel with super absorbing properties: effect of monomer ratio on swelling behaviour and kinetics. Ind Eng Chem Res 47:9206–9213

Wasim Ali S, Zaidi SAR (2005) Synthesis of copolymeric acrylamide/potassium acrylate hydrogels blended with poly (vinyl alcohol): effect of crosslinking and the amount of poly (vinyl alcohol) on swelling behaviour. J Appl Polym Sci 98:1927–1931

Peppas NA, Merrill EW (1977) Cross linked poly (vinyl alcohol) hydrogel as swollen elastic networks. J Appl Polym Sci 21:1763–1770

Elliott JE, Macdonald M et al (2004) Structure and swelling of poly (acrylic acid) hydrogels: effect of pH and ionic strength and dilution on the cross linked polymer structure. Polymer 45:1503–15010

Bajpai SK, Johnson S (2006) Poly (acrylamide-co-maleic acid) hydrogels for removal of Cr(VI) from aqueous solutions, Part I, synthesis and swelling characterisation. J Appl Polym Sci 100:2759–2769

Bajpai S, Pal Singh S (2006) Analysis of swelling behaviour of poly (methacrylamide-co-methacrylic acid) hydrogels and effect of synthesis conditions on water uptake. React Funct Polym 66:431–440

Peppas NA, Wright SL (1996) Solute diffusion in poly (vinyl alcohol)/poly (acrylic acid) interpenetrating networks. Macromolecules 29:8798–8804

Lide DR (ed) (1994) Analytical chemistry. In: CRC Handbook of Chemistry and Physics, 75th edn. CRC Press, New York, pp 8.45–8.46

Pourrjavadi A, Samadi M, Ghasemazadeh H (2008) Fast swelling super absorbent hydrogels from poly (2-hydroxy ethyl acrylate-co-sodium acrylate) grafted on starch. Starch/starke 60:79–86

Cavus S, Gurdag G (2009) Noncompetitively removal of heavy metal ions from aqueous solutions by poly[2-(acrylamide)-2-methyl-1-propanesulfonic acid-co-itaconic acid] hydrogel. Ind Eng Chem Res 48:2652–2658

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Souda, P., Sreejith, L. Environmental sensitive hydrogel for purification of waste water: part 1: synthesis and characterization. Polym. Bull. 71, 839–854 (2014). https://doi.org/10.1007/s00289-014-1097-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-014-1097-2