Abstract

Optically active, thermosensitive, and amphiphilic polymer brushes, which consist of helical poly(N-propargylamide) main chains and thermosensitive poly(N-isopropylacrylamide) (PNIPAm) side chains, were prepared via a novel methodology combining catalytic polymerization, atom transfer radical polymerization (ATRP), and click chemistry. Helical poly(N-propargylamide) bearing α-bromoisobutyryl pendent groups was synthesized via catalytic polymerization, followed by substituting the –Br moieties with azido groups. Then, alkynyl terminated PNIPAm formed via ATRP was successfully grafted onto the azido functionalized helical polymer backbones via click chemistry, providing the expected polymer brushes. GPC, FT-IR, and 1H-NMR measurements indicated the successful synthesis of the novel amphiphilic polymer brushes. UV–vis and CD spectra evidently demonstrated the helical structures of the polymer backbones and the considerable optical activity of the final brushes. The polymer brushes self-assembled in aqueous solution forming core/shell structured nanoparticles, which were comprised of optically active cores (helical polyacetylenes) and thermosensitive shells (PNIPAm).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Copolymers with unique topologies, for instance linear block, miktoarm star, gradient graft, brush-shaped, hyperbranched, and dendritic architectures, have gained increasing attention [1–3]. Among them, polymer brushes, possessing a high density of side chains covalently attached to the linear backbone [4–6], have been the subject of continually increasing interest because of their unique structures, properties, and potential applications [7–9]. In the past decade, a great deal of investigations have been devoted to the synthesis of polymer brushes majorly via three approaches, “grafting through” [10, 11], “grafting from” [12, 13], and “grafting onto” [14, 15], by a combination of different polymerization mechanisms such as ring-opening polymerization [16], ring-opening metathesis polymerization [17], nitroxide-mediated polymerization [18], atom transfer radical polymerization (ATRP) [19], and reversible addition-fragmentation chain transfer polymerization [20]. However, few polymer brushes derived from optically active polymers have been reported yet, even though the latter are a category of polymers of high interest [21–24]. Our earlier study reported on for the first time a “grafting from” approach to preparing and self-assembly of polymer brushes comprised of helical polyacetylene backbone and poly(N,N-dimethylamino-2-ethyl methacrylate) (PDMAEMA) side chains [25]. Such novel polymer brushes showed remarkable thermosensitivity and in particular optical activity. Nevertheless, the earlier strategy showed a disadvantage in the limited number of the brushes, namely, the number of the grafted chains was small and the length of the grafted chains was short. Accordingly, in the present study we adopted a “grafting onto” approach instead of the earlier “grafting from” one. The newly obtained polymer brushes possessed much higher graft density, also showed optical activities, and underwent self-assemble to form core/shell nanoparticles, as to be discussed in detail below.

Copper-catalyzed azide-alkyne coupling reactions, i.e., “click” chemistry, have been widely utilized as a powerful strategy in preparation of intriguing polymer architectures, due to the excellent functional-group tolerance, high specificity and almost quantitative yields under mild experimental conditions [26–28]. Since Gao and Matyjaszewski [14] reported the synthesis of molecular brushes by the “grafting onto” method via combination of ATRP and click chemistry in 2007, a series of novel polymer brushes have been created [17, 29–39]. However, to the best of our knowledge, a combination of click chemistry with catalytic polymerization has not yet been employed for the synthesis of optically active polymer brushes via “grafting onto” approach.

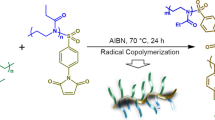

In our previous study, a series of (optically active) helical polymers [40–42] as well as optically active polymeric nanoparticles (including solid nanoparticles [43–45], core/shell nanoparticles [25, 46, 47], solid/hollow multi-layered nanoparticles [48, 49], and hybrid microspheres [50]) have been prepared. Furthermore, optically active polymer brushes were also prepared via a “grafting through” approach [25]. In the present study, we will prepare optically active polymer brushes with relatively high graft density via the “grafting onto” method by the combination of ATRP, catalytic polymerization and click chemistry. The strategy is schematically outlined in Scheme 1.

The strategy for preparing the brushes in Scheme 1 consists of four major steps: (1) Synthesis of alkynyl terminated PNIPAm (to be used as the side chains in polymer brushes) by ATRP to provide one “click” reagent; (2) Synthesis of helical poly(1-co-2) (acting as the helical polymer backbone) by catalytic polymerization; (3) Synthesis of azido functionalized poly(1-co-2) by transformation of the bromide groups to azide groups to provide the other “click” reagent; and (4) Synthesis of the optically active polymer brushes by click reaction. The self-assembly of the amphiphilic polymer brushes was further investigated, clearly demonstrating that the polymer brushes could self-assemble in aqueous solution to form core/shell structured nanoparticles simultaneously possessing optical activities and thermosensitivities. Therefore, the present methodology is of high importance for further designing advanced polymer brushes with intriguing properties and for the practical applications of polymer brushes as chiral materials, smart materials, etc.

Experimental part

Materials

Monomers M1 and M2 were synthesized and purified according to earlier reports (M1, Ref. [25]; M2, Ref. [51]). Rh-catalyst [(nbd)Rh+B−(C6H5)4] (nbd = norbornadiene) was prepared as reported [52]. The reagents were purchased from Aldrich, unless otherwise noted. N-isopropylacrylamide (NIPAm, TCI) was purified by recrystallization from a mixture of toluene and n-hexane (40/60, v/v) for three times. Copper(Ι) bromide (CuBr) was washed with glacial acetic acid for three times, dried in vacuum at room temperature, and then stored in an amber bottle. Sodium azide (NaN3), N,N,N′,N″,N″-pentamethyldiethylenetriamine (PMDETA, Alfa Aesar) and 1,1,4,7,10,10-hexamethyl triethylenetetramine (HMTETA) were used as received without additional purification. The solvents were purified by distilling under reduced pressure prior to use.

Characterizations

1H-NMR spectra were recorded on a Bruker AV600 spectrometer with CDCl3 as solvent. FT-IR spectra were recorded with a NICOLET NEXUS 670 infrared spectrometer (KBr tablet). UV–vis absorption and circular dichroism (CD) spectra were recorded in chloroform on a Jasco 810 spectropolarimeter. Number-average molecular weights (M n) and molecular weight distributions (PDI, M w/M n) of the polymers were determined by GPC (Waters 515-2410 system) calibrated by using polystyrenes as the standards and THF as the eluent. The morphology of the self-assembly products was observed on a Hitachi H-800 transmission electron microscope (TEM).

Synthesis of alkynyl terminated PNIPAm via ATRP

Alkynyl terminated PNIPAm (see Scheme 1) was synthesized using M1 as ATRP initiator with molar feed ratio [NIPAm]/[M1]/[CuBr]/[HMTETA] of 100/1/1/1.2. ATRP reaction was performed in a 25 mL Schlenk tube equipped with a magnetic stirrer and the typical procedure is described below. Predetermined amounts of CuBr, NIPAm, and HMTETA were added in the tube containing 9 mL of THF/water (1/1, v/v) mixture. The reaction mixture was degassed by three vacuum/nitrogen cycles. Then the initiator (M1, 0.0406 g, 0.2 mmol) was added into the mixture under a dry nitrogen atmosphere. The tube was sealed with a three-way stopcock and the polymerization reaction was allowed to proceed under continuous stirring at 60 °C for 5 h. The reaction was stopped by diluting with THF and the diluted mixture was passed through a neutral aluminum oxide column to remove the catalyst complex. After removing most THF using a rotary evaporator and precipitating the solution in excess anhydrous diethyl ether, the product was collected by filtration and dried under vacuum at room temperature for 24 h. The obtained polymer was characterized by 1H-NMR (CDCl3, 600 MHz, 20 °C), and the related data are as follows: δ 1.1 (g, –NH–CH–(CH 3)2), 1.2–2.2 (c, CO–C(CH 3)2; d, –CH 2–CH–; e, –CH2–CH–), 2.86 (a, CH≡C), 3.85 (b, CH≡C–CH 2 ), 4.0 (f, –NH–CH–(CH3)2), 6.0–6.8 ppm (h, NH).

Synthesis of poly(1-co-2) via catalytic polymerization

Predetermined amounts of M1 and M2 (M1/M2 = 1/4, mol/mol) were copolymerized to provide the helical main chain of the subsequent polymer brushes. The copolymerizations were carried out with [(nbd)Rh+B−(C6H5)4] as catalyst in dry CHCl3 under nitrogen at 30 °C for 5 h with [monomer]0 = 1.0 M (total monomer concentration) and [catalyst] = 0.01 M. After polymerization, the solution was poured into a large amount of n-hexane to precipitate the polymer. The polymer was filtered and washed with acetone to exclude the residual monomer and catalyst, and then dried under reduced pressure.

Synthesis of azido functionalized poly(1-co-2)

For preparing the azido functionalized poly(1-co-2), poly(1-co-2) (0.15 g, containing M1 0.13 mmol) obtained above and NaN3 (0.085 g, 1.3 mmol) were dissolved in 5 mL DMF in a 25 mL Schlenk tube equipped with a magnetic stirrer. The mixture was allowed to react under stirring at room temperature for 24 h. The reaction mixture was diluted with THF and then passed through a neutral aluminum oxide column to remove the sodium salt and excess NaN3. After removing most solvent using a rotary evaporator and precipitating the solution in excess n-hexane, the product was collected by filtration and dried under vacuum at room temperature for 24 h.

Synthesis of poly(1-co-2)-g-PNIPAm via click chemistry

The amphiphilic polymer brushes were prepared by click reaction of alkynyl terminated PNIPAm with the azido functionalized poly(1-co-2). A mixed solution of alkynyl terminated PNIPAm (0.432 g, 0.108 mmol), azido functionalized poly(1-co-2) (0.12 g, containing M1 units 0.108 mmol), and CuBr (0.0311 g, 0.216 mmol) in 5 mL of DMF was degassed by three vacuum/nitrogen cycles. PMDETA (45 μL, 0.216 mmol) was added in the system under nitrogen atmosphere. The reaction was allowed to proceed under continuous stirring at room temperature for 24 h. Then, the reaction mixture was diluted with THF and passed through a neutral aluminum oxide column to remove the catalyst complex. After removing most THF using a rotary evaporator and precipitating the solution in excess n-hexane, the product was collected by filtration and dried under vacuum at room temperature for 24 h. The as-prepared copolymer was characterized by 1H-NMR (CDCl3, 600 MHz, 20 °C), and the relevant data are as follows: δ 1.1 (g, –NH–CH–(CH 3)2), 1.2–2.2 (c, CO–C(CH 3)2; d, –CH 2 –CH–; e, –CH2–CH–), 3.85 (b, CH=C–CH 2 ), 4.0 (f, –NH–CH–(CH3)2), 6.0–6.8 (h, NH), 8.03 ppm (a′, methine protons in 1,2,3-triazole rings).

Self-assembly of amphiphilic polymer brushes

Self-assembly of the amphiphilic polymer brushes was performed by dissolving the polymer (15 mg) in THF (0.2 mL), followed by a progressive addition (1 drop/10 s) of 1 mL deionized water under vigorous stirring overnight. A complete removal of THF was realized by spontaneous evaporation, and the self-assembly product was then subjected to CD and TEM measurements.

Results and discussion

Synthesis of the amphiphilic polymer brushes

Synthesis of the alkynyl terminated PNIPAm

Our previous study demonstrated that M1 bearing an α-bromoisobutyryl group was an efficient initiator for ATRP [25]. In the present study, M1 was also employed as an initiator for ATRP of NIPAm at 60 °C in the mixture of THF and H2O for 5 h, in the presence of CuBr/HMTETA as catalyst/ligand. This practice provided the alkynyl terminated PNIPAm with suitable molecular weight. The reaction mixture became dark green and viscous as polymerization proceeded. The reaction was terminated by diluting with THF. The diluted mixture was passed through a neutral aluminum oxide column. Then, alkynyl terminated PNIPAm was obtained by reprecipitation from THF in diethyl ether thrice and subjected to the GPC, 1H-NMR, and FT-IR spectroscopy measurements. The corresponding results are presented in Table 1 and Figs. 1a, 2A, 3c, respectively. All these measurements will be discussed in detail later on.

When a “grafting onto” method was employed for preparing polymer brushes, the grafting density may be limited due to the steric hindrance of the pre-formed side chains [14, 53]. Therefore, controlling the length of the side chains is of great importance for preparing polymer brushes. As shown in Scheme 1, PNIPAm was used as the side chains in the designed polymer brushes. The polymerization degree (DP) of PNIPAm was controlled by controlling the ATRP reaction time (5 h) to prepare alkynyl terminated PNIPAm with suitable molecular weight. Herein it should be pointed out that the molecular weight of the PNIPAm should be moderate. A too high molecular weight of the as-prepared PNIPAm will result in a low grafting density of the subsequent polymer brushes due to the steric congestion between the side chains [14]. In contrast, a too low molecular weight of PNIPAm cannot meet the requirement for self-assembly of the polymer brushes. Table 1 indicates that the yield of the alkynyl terminated PNIPAm was 41.5 % and the number average molecular weight (M n) was 4000. The GPC curve of the alkynyl terminated PNIPAm is presented in Fig. 1a. It shows a single peak with narrow polydispersity (M w/M n) around 1.35, which provided clear evidence for the good controllability of the ATRP reaction.

The structure of the alkynyl terminated PNIPAm was further characterized by 1H-NMR and FT-IR spectroscopy measurements. The relevant results are displayed in Figs. 2 and 3. In the 1H-NMR spectra presented in Fig. 2, the signals located at the chemical shifts in the region of 1.2–2.2 ppm (c + d + e) are attributed to the methyl protons (c) derived from M1 and the methylene (d) and methine protons (e) in the polymer chain. Characteristic signals of PNIPAm at δ = 4.0 (f) and 1.1 (g) in Fig. 2A represent the methine and methyl protons on the isopropyl groups, and the integration area ratio of peak f to peak g is approx. 1:6, which identified the structure of PNIPAm. The signal at δ = 2.86 ppm is attributed to the terminal alkynyl proton (a, CH≡C) in the PNIPAm chain. The peak located at chemical shift of 3.85 ppm was associated with the methylene protons (b, CH≡C–CH 2) adjacent to the C≡C triple bond. Furthermore, from the FT-IR spectra shown in Fig. 3c, alkynyl terminated PNIPAm exhibited a typical absorbance at 2,122 cm−1, which is the characteristic absorbance of the C≡C triple bond. The NMR and FT-IR analyses thus lead to such a conclusion that the alkynyl terminated PNIPAm has been successfully synthesized. The alkynyl terminated PNIPAm rendered possibilities to perform click reaction, by which polymer brushes can be expected. This will be discussed in detail later.

Synthesis of azido functionalized poly(1-co-2)

For preparing polymer brushes with helical polymer main chain and optical activities, M2 was employed to carry out catalytic copolymeriztion with M1, yielding the copolymer designated as poly(1-co-2). [(nbd)Rh+B−(C6H5)4], which has been proved to be an efficient catalyst for preparing helical substituted polyacetylenes with high stereoregularity [25, 40–50], was also used as catalyst in this copolymerization system. The relevant polymerization result is presented in Table 1. The poly(1-co-2) could be formed with a moderate molecular weight (M n = 14500, M w/M n = 2.64) and in a quantitatively yield (98.7 %). The corresponding GPC curve of poly(1-co-2) is shown in Fig. 1b.

To prepare the other precursor for the subsequent click reaction, azido groups should be attached onto the poly(1-co-2). In this study, we carried out the reaction of poly(1-co-2) containing α-bromoisobutyryl groups with sodium azide in DMF at room temperature for 24 h to yield the anticipated “click” reagent. The azido functionalized poly(1-co-2) was purified by passing through a short neutral aluminum oxide column to remove the sodium salt and excess NaN3 and then reprecipitated in excess n-hexane for three times with a quantitative yield of 98.6 %. The GPC result indicated that M n = 15000, M w/M n = 2.66, as illustrated in Table 1. It can be obviously observed in Fig. 1c that the GPC trace of the azido functionalized poly(1-co-2) was monomodal without obvious change, when compared with poly(1-co-2) before the substitution reaction. To further attest to the reaction of poly(1-co-2) with sodium azide, poly(1-co-2) and azido functionalized poly(1-co-2) were subjected to FT-IR spectroscopy measurement. The corresponding spectra were displayed in Fig. 3a, b, respectively. By comparing the two FT-IR spectra, no visible difference can be observed between the two curves except the appearance of characteristic absorbance peak of azido group at 2,113 cm−1. On the basis of the results of GPC and FT-IR measurements, an important conclusion can be drawn that the bromide groups of poly(1-co-2) have successfully converted to azido groups without the degradation of the polymer backbone.

Synthesis of poly(1-co-2)-g-PNIPAm via click chemistry

The azido functionalized poly(1-co-2) underwent reactions with the alkynyl terminated PNIPAm by the “click” reaction via a “grafting onto” method to provide the expected polymer brushes, poly(1-co-2)-g-PNIPAm, as depicted in Scheme 1. We conducted the click chemistry between azido functionalized poly(1-co-2) and alkynyl terminated PNIPAm in the presence of CuBr/PMDETA in DMF at room temperature. After the click reaction, the catalyst was removed from the polymer solution by passing through a neutral alumina column and the resulting polymer brushes were obtained by precipitating in excess n-hexane in a quite high yield (>95 %). Then, the polymer brushes were characterized by GPC, 1H-NMR, and FT-IR. The relevant results are shown in Fig. 1d, 2B, 3d, respectively.

The molecular weight of the poly(1-co-2)-g-PNIPAm was determined by GPC and listed in Table 1. The number-average molecular weight (M n) was 46,600 and the molecular weight distribution (M w/M n) was 1.32. The GPC trace of poly(1-co-2)-g-PNIPAm together with those of its precursors, alkynyl terminated PNIPAm and azido functionalized poly(1-co-2), is presented in Fig. 1. It can be apparently observed that the GPC trace of poly(1-co-2)-g-PNIPAm is unimodal without any trace of the two precursors of the “click” chemistry and clearly shifted to the higher M w region when compared with those of alkynyl terminated PNIPAm and azido functionalized poly(1-co-2). This indicates that the alkynyl terminated PNIPAm and azido functionalized poly(1-co-2) were completely converted to the corresponding polymer brushes, since the alkynyl terminated PNIPAm and azido functionalized poly(1-co-2) were fed in an equimolar ratio.

To further verify the formation of polymer brushes, 1H-NMR and FT-IR spectra of poly(1-co-2)-g-PNIPAm were measured, as presented in Figs. 2B and 3d. From 1H-NMR spectra of poly(1-co-2)-g-PNIPAm, we could discern all characteristic signals of PNIPAm segment. More importantly, proton signal from C≡C triple bond (a, δ = 2.86 ppm) disappearred completely, while a new resonance signal (a′, δ = 8.03 ppm) characteristic of the methine protons in 1,2,3-triazole rings appeared, providing strong evidence for the occurrence of the “click” reaction. Furthermore, when comparing the FT-IR spectra of poly(1-co-2)-g-PNIPAm with those of alkynyl terminated PNIPAm and azido functionalized poly(1-co-2), we can find the most noteworthy change, i.e., the complete disappearance of the absorbance peaks characteristic of the azido and alkynyl groups at about 2,100 cm−1. Based on the above discussions, it can be concluded that the polymer brushes have been successfully synthesized via the “click” grafting onto method.

Optical activity of the amphiphilic polymer brushes

To investigate the optical activities and helical structures of poly(1-co-2) and azido functionalized poly(1-co-2), UV–vis and CD analyses, which have been proved highly effective to determine the secondary structures of helical polyacetylenes [25, 40–50], were employed in this work. Figure 4 shows the UV–vis and CD spectra of the poly(1-co-2) and azido functionalized poly(1-co-2) measured at varied temperatures in chloroform. As can be observed in Fig. 4a, both poly(1-co-2) and azido functionalized poly(1-co-2) showed a strong UV–vis absorption peak around 350 nm. Referring to the series of investigations on helical polyacetylenes [25, 40–50], we can conclude that both poly(1-co-2) and azido functionalized poly(1-co-2) formed helical conformations under the examined conditions. However, the maximum wavelengths of poly(1-co-2) and azido functionalized poly(1-co-2) are a little different. The UV–vis peak of poly(1-co-2) appeared at about 355 nm while the UV–vis peak of azido functionalized poly(1-co-2) appeared at about 350 nm. This probably resulted from the varied effective conjugation length of poly(1-co-2) main chains before azidozation (homopoly-1, λmax, 390 nm; homopoly-2, λmax, 350 nm) and after azidozation (homopoly-N3, λmax, 350 nm; homopoly-2, λmax, 350 nm) since the azidozation of poly(1-co-2) indeed changed the composition of the copolymer poly(1-co-2). In our another study, we found that when homopoly-1 was converted to homopoly-N3, the maximum UV absorption wavelength appeared at 350 nm. (The relevant investigations are currently on-going and we will report them in a separate article.)

In the CD spectra in Fig. 4b, both poly(1-co-2) and azido functionalized poly(1-co-2) showed intense CD signals at the positions almost completely correspond to the UV–vis absorption peaks (Fig. 4a), reflecting that both the copolymers were optically active. Moreover, the intensities of the UV–vis and CD peaks of azido functionalized poly(1-co-2) exhibited only a slight decrease when compared with those of the poly(1-co-2). This was also in good agreement with the GPC results. Also can be observed in Fig. 4a, b is that when UV–vis and CD spectra were measured at varied temperatures, the strengths of the UV–vis absorptions and CD signals of both copolymers almost keep unchanged upon increasing temperature from 20 up to 60 °C, indicating that both the copolymers possessed highly stable preferential helical screw sense. Based on the above discussions, it can be reasonably concluded that both poly(1-co-2) and azido functionalized poly(1-co-2) formed stable helical conformations and exhibited strong optical activities, and the azido functionalization of poly(1-co-2) did not affect the secondary structure of the copolymer backbones.

The UV–vis and CD spectra of the polymer brushes, poly(1-co-2)-g-PNIPAm, measured at varied temperatures in chloroform were presented in Fig. 5. As can be seen in Fig. 5a, there was a UV–vis absorption peak at around 340 nm, which revealed that poly(1-co-2)-g-PNIPAm maintained the helical structure of the polymer main chain. More importantly, an obvious CD signal at 340 nm can be clearly observed in Fig. 5b, significantly demonstrating that the polymer brushes formed helical conformations and furthermore indicating that poly(1-co-2)-g-PNIPAm was also optically active. However, the intensities of UV–vis absorption peaks and CD signals of the poly(1-co-2)-g-PNIPAm were somewhat lower than those of the azido functionalized poly(1-co-2) before “click” reaction. This phenomenon was similar with our earlier study on amphiphilic polymer brushes based on helical polyacetylenes [25] and it should be derived from the decrease of helical polymer content after the incorporation of PNIPAm side chains. In addition, when compared the UV–vis and CD spectra of the poly(1-co-2)-g-PNIPAm with those of the azido functionalized poly(1-co-2), a blue shift was observed after the incorporation of PNIPAm side chains. This also occurred in the earlier reported polymer brushes [25] and substituted polyacetylene emulsions (nanoparticles) [43–49]. This should be attributed to the more packed polymer backbone and shorter effective conjugated length owing to the incorporation of the pendent PNIPAm chains. More importantly, the spectra measured at different temperatures were almost the same in terms of their profiles and intensities either in the UV–vis spectra or in the CD spectra, demonstrating the high thermostability of the helical structure and optical activity of the polymer brushes prepared via “click” chemistry. Kuhn dissymmetry factors [54] (g-value, in Table 1) of the poly(1-co-2), azido functionalized poly(1-co-2), and poly(1-co-2)-g-PNIPAm were calculated and listed together in Table 1 for a clearly comparison. We found that all the g-values were about –3.10 × 10−3 with little difference, even after the azido functionalization reaction and especially even after the “click” reaction, demonstrating that the helical structures of the copolymers and the polymer brushes were stable regardless of the incorporation of PNIPAm side chains.

Self-assembly of the amphiphilic polymer brushes

It is well known that PNIPAm is a hydrophilic and particularly thermosensitive polymer, which undergoes phase transition at its lower critical solution temperature (LCST, approx. 32 °C) [55]. PNIPAm is soluble in cold water while it becomes insoluble as the solution temperature exceeds its LCST. The present polymer brushes prepared via “grafting onto” method is comprised of hydrophobic helical poly(N-propargylamides) main chain and hydrophilic PNIPAm side chains, so the poly(1-co-2)-g-PNIPAm should exhibit amphiphilicity and self-assemble in suitable solvents. We carried out the self-assembly of the poly(1-co-2)-g-PNIPAm in THF/water by using the method similar with our previous report [25]. To study the structure of the self-assembly aggregates of poly(1-co-2)-g-PNIPAm polymer brushes in aqueous solution, TEM observation was conducted at temperatures below and above LCST of PNIPAm (25 and 50 °C, in this work).

The TEM images of the self-assembled products from poly(1-co-2)-g-PNIPAm at 25 °C (Fig. 6a) and at 50 °C (Fig. 6c) together with the magnified TEM images at 25 °C (Fig. 6b) and at 50 °C (Fig. 6d) were presented in Fig. 6. Core/shell structured nanoparticles are apparently observed in both cases at 25 and 50 °C, and both the shells can be obviously distinguished from the cores. The average diameters of the core/shell nanoparticles were estimated by counting at least 20 core/shell nanoparticles in different TEM images of a same sample. The diameter of the core/shell nanoparticles formed at 25 °C was calculated to be about 660 nm, with a core of about 390 nm and a shell of about 135 nm. On the other hand, the diameter of the core/shell nanoparticles formed at 50 °C was calculated to be about 460 nm, with a core of about 370 nm and a shell of about 45 nm. Comparing the diameter of the core/shell nanoparticles formed at 25 °C with that of the core/shell nanoparticles formed at 50 °C, we can easily found that the diameter of the core/shell nanoparticles decreased when the temperature increased to a high value exceeded LCST of PNIPAm, and furthermore, the diameter of the shell decreased dramatically while the diameter of the core changed slightly. It can be hence concluded that the decrease of the diameter was resulted from the decrease of the diameter in the PNIPAm shell, and the core/shell nanoparticles formed were thermosensitive. This conclusion can be further proved to be correct by observation of photographs of the corresponding self-assembled systems at 25 and at 50 °C (the insets in Fig. 6b, d). It can be clearly seen that the self-assemblies of poly(1-co-2)-g-PNIPAm at 25 °C was transparent while the self-assemblies at 50 °C became completely opaque, indicating that the self-assembly core/shell nanoparticles were thermoresponsive.

TEM images of the self-assembled core/shell nanoparticles from poly(1-co-2)-g-PNIPAm (a) at 25 °C and (c) at 50 °C with a concentration of 15 mg/mL in THF/water. b and d present the magnified TEM images of the areas are indicated by the white squares in a and c, respectively. The insets present the corresponding self-assembled systems at 25 °C (in b) and at 50 °C (in d)

To further investigate the optical activity and thermosensitivity of the self-assemblies of poly(1-co-2)-g-PNIPAm, we measured their UV–vis and CD spectra at varied temperatures. The results were presented in Fig. 7. When the spectra were measured at temperatures lower than the LCST of PNIPAm (20 and 30 °C), the spectra were found to be quite similar with those measured in chloroform (Fig. 5). UV–vis absorption peaks and CD signals at around 340 nm can be observed in Fig. 7, and the spectra almost changed little regardless of the temperature, clearly demonstrating that the stable helical structure remained in the core/shell nanoparticles which also showed optical activities originating from the helical conformation of the polymer main chain. However, when the temperatures increased to higher values than the LCST of PNIPAm (40 and 50 °C), the self-assemblies turned opaque and the UV–vis and CD spectra cannot be measured clearly. As shown in Fig. 7, the UV–vis spectra at 40 and 50 °C were almost straight lines and the corresponding CD spectra were ruleless, also provided evidence that the self-assemblies of poly(1-co-2)-g-PNIPAm were thermosensitive.

Conclusions

To sum up, thermosensitive and amphiphilic polymer brushes based on helical polyacetylenes, poly(1-co-2)-g-PNIPAm, have been synthesized by means of ATRP, catalytic polymerization and click chemistry via a “grafting onto” method. It can be concluded that the obtained polymer brushes showed considerable optical activities, which derived from the helical structure of the polymer main chain, according to the UV–vis and CD spectroscopy measurements. Furthermore, the polymer brushes can self-assemble in aqueous solution to form core/shell structured nanoparticles consisting of optically active poly(N-propargylamide) cores and thermosensitive PNIPAm shells. Thus, the polymer brushes and the core/shell nanoparticles are believed to find potential applications in chiral materials and smart materials, and furthermore have a great potential in applications for gene/drug delivery, controlled release, etc.

References

Hadjichristidis N, Iatroua H, Pitsikalisa M, Maysb J (2006) Macromolecular architectures by living and controlling/living polymerizations. Prog Polym Sci 31:1068–1132

Hadjichristidis N, Iatrou H, Pitsikalis M, Pispas S, Avgeropoulos A (2005) Linear and non-linear triblock terpolymers. Synthesis, self-assembly in selective solvents and in bulk. Prog Polym Sci 30:725–782

Sheiko SS, Sumerlin BS, Matyjaszewski K (2008) Cylindrical molecular brushes: synthesis, characterization, and properties. Prog Polym Sci 33:759–785

Bhattacharya A, Misra BN (2004) Grafting: a versatile means to modify polymers Techniques, factors and applications. Prog Polym Sci 29:767–814

Xu Y, Bolisetty S, Ballauff M, Müller AHE (2009) Switching the morphologies of cylindrical polycation brushes by ionic and supramolecular inclusion complexes. J Am Chem Soc 131:1640–1641

Li C, Gunari N, Fischer K, Janshoff A, Schmidt M (2004) New perspectives for the design of molecular actuators: thermally induced collapse of single macromolecules from cylindrical brushes to spheres. Angew Chem Int Ed 43:1101–1104

Sheiko SS, Möller M (2001) Visualization of macromolecules—a first step to manipulation and controlled response. Chem Rev 101:4099–4123

Tsukahara Y, Namba S, Iwasa J, Nakano Y, Kaeriyama K, Takahashi M (2001) Bulk properties of poly(macromonomer)s of increased backbone and branch lengths. Macromolecules 34:2624–2629

Sheiko SS, Prokhorova SA, Beers KL, Matyjaszewski K, Potemkin II, Khokhlov AR, Möller M (2001) Single molecule rod-globule phase transition for brush molecules at a flat interface. Macromolecules 34:8354–8360

Hadjichristidis N, Pitsikalis M, Iatrou H, Pispas S (2003) The strength of the macromonomer strategy for complex macromolecular architecture: molecular characterization, properties and Applications of polymacromonomers. Macromol Rapid Commun 24:979–1013

Neugebauer D, Zhang Y, Pakula T, Sheiko SS, Matyjaszewski K (2003) Densely-grafted and double-grafted PEO brushes via ATRP. A route to soft elastomers. Macromolecules 36:6746–6755

Fu GD, Phua SJ, Kang ET, Neoh KG (2005) Tadpole-shaped amphiphilic block-graft copolymers prepared via consecutive atom transfer radical polymerization. Macromolecules 38:2612–2619

Börner HG, Beers K, Matyjaszewski K, Sheiko SS, Möller M (2001) Synthesis of molecular brushes with block copolymer side chains using atom transfer radical polymerization. Macromolecules 34:4375–4383

Gao H, Matyjaszewski K (2007) Synthesis of molecular brushes by “grafting onto” method: combination of ATRP and click reactions. J Am Chem Soc 129:6633–6639

Ranjan R, Brittain WJ (2007) Combination of living radical polymerization and click chemistry for surface modification. Macromolecules 40:6217–6223

Cheng C, Khoshdel E, Wooley KL (2006) Facile one-pot synthesis of brush polymers through Tandem catalysis using Grubbs’ catalyst for both ring-opening metathesis and atom transfer radical polymerizations. Nano Lett 6:1741–1746

Dag A, Sahin H, Durmaz H, Hizal G, Tunca U (2011) Block-brush copolymer via ROMP and sequential double click reaction strategy. J Polym Sci, Part A: Polym Chem 49:886–892

Cheng C, Qi K, Khoshdel E, Wooley KL (2006) Tandem synthesis of core-shell brush copolymers and their transformation to peripherally cross-linked and hollowed nanostructures. J Am Chem Soc 128:6808–6809

Gu L, Shen Z, Zhang S, Lu GL, Zhang XH, Huang XY (2007) Novel amphiphilic centipede-like copolymer bearing polyacrylate backbone and poly(ethylene glycol) and polystyrene side chains. Macromolecules 40:4486–4493

Cheng ZP, Zhu XL, Fu GD, Kang ET, Neoh KG (2005) Dual-brush-type amphiphilic triblock copolymer with intact epoxide functional groups from consecutive RAFT polymerizations and ATRP. Macromolecules 38(7):187–7192

Zhang W, Shiotsuki M, Masuda T (2007) A helical poly(macromonomer) consisting of a polyacetylene main chain and polystyrene side chains. Macromol Rapid Commun 28:1115–1121

Maeda K, Kamiya N, Yashima E (2004) Poly(phenylacetylene)s bearing a peptide pendant: helical conformational changes of the polymer backbone stimulated by the pendant conformational change. Chem Eur J 10:4000–4010

Percec V, Aqad E, Peterca M, Rudick JG, Lemon L, Ronda JC, De BB, Heiney PA, Meijer EW (2006) Steric communication of chiral information observed in dendronized polyacetylenes. J Am Chem Soc 128:16365–16372

Bakandritsos A, Bouropoulos N, Zboril R, Iliopoulos K, Boukos N, Chatzikyriakos G, Couris S (2008) Optically active spherical polyelectrolyte brushes with a nanocrystalline magnetic core. Adv Funct Mater 18:1694–1706

Ding L, Huang YY, Zhang YY, Deng JP, Yang WT (2011) Optically active amphiphilic polymer brushes based on helical polyacetylenes: preparation and self-assembly into core/shell particles. Macromolecules 44:736–743

Kolb HC, Finn MG, Sharpless KB (2001) Click chemistry: diverse chemical function from a few good reactions. Angew Chem Int Ed 40:2004–2021

Lutz JF (2007) 1,3-Dipolar cycloadditions of azides and alkynes: a universal ligation tool in polymer and materials science. Angew Chem Int Ed 46:1018–1025

Lodge TP (2009) A virtual issue of Macromolecules: “Click chemistry in macromolecular science”. Macromolecules 42:3827–3829

Bertoldo M, Zampano G, Terra F, Villari V, Castelvetro V (2011) Amphiphilic amylose-g-poly(meth)acrylate copolymers through “Click” onto grafting method. Biomacromolecules 12:388–398

Yin J, Ge ZS, Liu H, Liu SY (2009) Synthesis of amphiphilic copolymer brushes possessing alternating poly(methyl methacrylate) and poly(N-isopropylacrylamide) grafts via a combination of ATRP and click chemistry. J Polym Sci, Part A: Polym Chem 47:2608–2619

Bao HQ, Li L, Gan HL, Ping Y, Li J, Ravi P (2010) Thermo- and pH-responsive association behavior of dual hydrophilic graft chitosan terpolymer synthesized via ATRP and click chemistry. Macromolecules 43:5679–5687

Xu N, Wang R, Du FS, Li ZC (2009) Synthesis of amphiphilic biodegradable glycocopolymers based on poly(ε-caprolactone) by ring-opening polymerization and click chemistry. J Polym Sci, Part A: Polym Chem 47:3583–3594

Yuan YY, Du Q, Wang YC, Wang J (2010) One-pot synthesis of amphiphilic centipede-like brush copolymers via combination of ring-opening polymerization and “click” chemistry. Macromolecules 43:1739–1746

Han DH, Tong X, Zhao Y (2011) One-pot synthesis of brush diblock copolymers through simultaneous ATRP and clicking coupling. Macromolecules 44:5531–5536

Sun JP, Hu JW, Liu GJ, Xiao DS, He GP, Lu RF (2011) Efficient synthesis of well-defined amphiphilic cylindrical brushes polymer with high grafting density: interfacial “click” chemistry approach. J Polym Sci, Part A: Polym Chem 49:1282–1288

Fan XS, Wang GW, Huang JL (2011) Synthesis of macrocyclic molecular brushes with amphiphilic block copolymers as side chains. J Polym Sci, Part A: Polym Chem 49:1361–1367

Engler AC, Lee H, Hammond PT (2009) Highly efficient “grafting onto” a polypeptide backbone using click chemistry. Angew Chem Int Ed 48:9334–9338

Ostaci RV, Damiron D, Grohens Y, Léger L, Drockenmuller E (2010) Click chemistry grafting of Poly(ethylene glycol) brushes to alkyne-functionalized pseudobrushes. Langmuir 26:1304–1310

Gao C, Zheng X (2009) Facile synthesis and self-assembly of multihetero-arm hyperbranched polymer brushes. Soft Matter 5:4788–4796

Ding L, Jiao XF, Deng JP, Zhao WG, Yang WT (2009) Catalytic polymerizations of hydrophobic, substituted, acetylene monomers in an aqueous medium by using a monomer/hydroxypropyl-β-cyclodextrin inclusion complex. Macromol Rapid Commun 30:120–125

Zhang ZG, Deng JP, Zhao WG, Wang JM, Yang WT (2007) Synthesis of optically active poly(N-propargylsulfamides) with helical conformation. J Polym Sci, Part A: Polym Chem 45:500–508

Deng JP, Luo XF, Zhao WG, Yang WT (2008) A novel type of optically active helical polymers: synthesis and characterization of poly(N-propargylureas). J Polym Sci, Part A: Polym Chem 46:4112–4121

Luo XF, Deng JP, Yang WT (2011) Helix-sense-selective polymerizations of achiral substituted acetylenes in chiral micelles. Angew Chem Int Ed 50:4909–4912

Luo XF, Li L, Deng JP, Guo TT, Yang WT (2010) Asymmetric catalytic emulsion polymerization in chiral micelles. Chem Commun 46:2745–2747

Deng JP, Chen B, Luo XF, Yang WT (2009) Synthesis of nano-latex particles of optically active helical substituted polyacetylenes via catalytic microemulsion polymerization in aqueous systems. Macromolecules 42:933–938

Chen B, Deng JP, Liu XQ, Yang WT (2010) Novel category of optically active core/shell nanoparticles: the core consisting of a helical-substituted polyacetylene and the shell consisting of a vinyl polymer. Macromolecules 43:3177–3182

Luo XF, Liu XQ, Chen B, Deng JP, Yang WT (2010) Optically active composite nanoparticles with chemical bonds between core and shell. J Polym Sci, Part A: Polym Chem 48:5611–5617

Chen B, Deng JP, Yang WT (2011) Hollow two-layered chiral nanoparticles consisting of optically active helical polymer/silica: preparation and application for enantioselective crystallization. Adv Funct Mater 21:2345–2350

Chen B, Deng JP, Tong LY, Yang WT (2010) Optically active helical polyacetylene@silica hybrid organic-inorganic core/shell nanoparticles: preparation and application for enantioselective crystallization. Macromolecules 43:9613–9619

Zhou K, Tong LY, Deng JP, Yang WT (2010) Hollow polymeric microspheres grafted with optically active helical polymer chains: preparation and their chiral recognition ability. J Mater Chem 20:781–789

Tabei J, Nomura R, Masuda T (2002) Conformational study of poly(N-propargylamides) having bulky pendant groups. Macromolecules 35:5405–5409

Schrock RR, Osborn JA (1970) π-Bonded complexes of the tetraphenylborate ion with Rhodium(I) and Iridium(I). Inorg Chem 9:2339–2343

Lian XM, Wu DX, Song XH, Zhao HY (2010) Synthesis and self-assembly of amphiphilic asymmetric macromolecular brushes. Macromolecules 43:7434–7445

Fujiki M (2001) Optically active polysilylenes: state-of-the-art chiroptical polymers. Macromol Rapid Commun 22:539–563

Yoshida R, Uchida K, Kaneko Y, Sakai K, Kikuchi A, Sakurai Y, Okano T (1995) Comb-type grafted hydrogels with rapid de-swelling response to temperature changes. Nature 374:240–242

Acknowledgments

This work was financially supported by the “National Natural Science Foundation of China” (21174010, 20974007), the “Fundamental Research Funds for the Central Universities” (ZZ1117), and the “Major Project for Polymer Chemistry and Physics Subject Construction from Beijing Municipal Education Commission (BMEC)”.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ding, L., Chen, C., Deng, J. et al. Optically active thermosensitive amphiphilic polymer brushes based on helical polyacetylene: preparation through “click” onto grafting method and self-assembly. Polym. Bull. 69, 1023–1040 (2012). https://doi.org/10.1007/s00289-012-0790-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-012-0790-2