Abstract

New adsorbents, poly(N-(3-dimethylamino)propylmethacrylamide-co-acrylic acid), P(NDAPA-AA), poly(N-(3-dimethylamino)propylmethacrylamide-co-4-acryloylmorpholine), P(NDAPA-AMo), and poly(N-(3-dimethylamino)propylmethacrylamide-co-2-acrylamidoglycolic acid), P(NDAPA-AAg) were obtained by radical polymerization and characterized by Fourier transform infrared spectroscopy and thermogravimetry. The uptake metal ion properties of cadmium(II), zinc(II), lead(II), mercury(II), and chromium(III) were examined by batch-equilibrium technique with respect to the initial pH, temperature, and initial metal ion concentration under competitive and noncompetitive conditions. Maximum adsorption capacity was determined. Acid and basic regeneration was tested in order to restore the adsorbent to initial conditions. Resins P(NDAPA-AA) and P(NDAPA-AMo) showed a great ability to retain Cr(III), whereas P(NDAPA-co-AAg) to retain Hg(II).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the last two decades, the problem of water and wastewater remediation is becoming more important due to the adverse impacts that increased industrial activities have had on the economy and public health. The toxicity ascribed to heavy metals, such as cadmium(II), zinc(II), lead(II), mercury(II), and chromium(III), is due to mechanisms such as the blocking essential functional groups of biomolecules and disrupting the integrity of biomembranes [1, 2]. In order to solve heavy metal pollution, traditional technologies have been used. These include precipitation, filtration, adsorption, chemical reduction, solvent extraction, membrane separation, biological treatment, solid phase extraction (SPE), and finally periodic mesoporous silica (PMOs) etc. may be involved [3–6], where adsorption is particularly useful in metal recovery when the concentration of targeted ions in the solution is minute and when a large volume of solution requires remediation. In this context, chelating resins have received increasing attention because of their outstanding simplicity, high efficiency and low cost during the ion exchange, physical adsorption, and chelation [5–9].

Adsorption properties depend on the adsorbents’ physical and chemical properties, such as type and structure of the functional group introduced into the polymer matrix, the crosslinking degree, and swelling as well as sorption conditions including the solution’s pH, the resin quality, contact time, metal ion concentration, and presence of interfering ions [7–11].

The interaction between the functional group and the metal ion and the diffusion of the metal ion into the adsorbent are crucial factors determining the chelating resin’s capacity to adsorb metal ions [12].

Two methods to synthesize functional polymers that pre-concentrate and remove metal ions are available. The first approach consists in the polymerization of a monomer with a specific active ligand to target metal ions, while the second approach consists in the modification of the polymeric matrix, after the polymerization, by an active and specific ligand to one or more different metal ions [13]. In order to extract, determine, pre-concentrate, and remove some heavy metal ions, a variety of new types of functional resins have been developed and intensively studied [7, 14–22].

The aim of this article is to study the ability of three adsorbents that contain amide, amine, morpholinic, or carboxylic groups as active sites to recover, by batch-equilibrium procedure, metal ions with environmental impact. These three resins contain always one common moiety N-(3-dimethylamino)propylmethacrylamide and it is changed the comonomer as 4-acryloylmorpholine, acrylic acid, and 2-acrylamidoglycolic acid.

Experimental

Reagents

N-(3-dimethylamino)propylmethacrylamide (NDAPA, Aldrich), 4-Acryloylmorpholine (AMo, 97% Aldrich), Acrylic acid (AA, 99% Aldrich), and 2-acrylamidoglycolic acid (AAg, 96% Aldrich) were purified by distillation, N,N′-methylene-bisacrylamide (MBA, 99% Aldrich) and ammonium persulfate (AP, 95% Aldrich) were used without further purification.

The nitrate salts of cadmium(II), zinc(II), lead(II), mercury(II), and chromium(III) (all from Merck) were used. The analytical grade, nitric acid, perchloric acid, hydrochloric acid, sulfuric acid, and sodium hydroxide were purchased from Merck.

Synthesis of the adsorbents

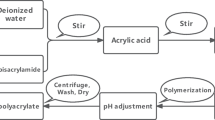

The adsorbents P(NDAPA-AMo), P(NDAPA-AA), and P(NDAPA-AAg) were synthesized by radical polymerization by mixing the corresponding reagents in a polymerization flask as follows:

P(NDAPA-AMo) NDAPA (0.029 mol, 5.0578 g), AMo (0.029 mol, 4.2681 g), MBA (0.00352 mol, 0.5480 g), and AP (0.000293 mol, 0.0685 g), Yield = 54%.

P(NDAPA-AA) NDAPA (0.029 mol, 5.0554 g), AA (0.029 mol, 2.1246 g), MBA (0.00117 mol, 0.1856 g), and AP (0.00117 mol, 0.2776 g), Yield = 100%.

P(NDAPA-AAg) NDAPA (0.029 mol, 5.0522 g), AAg (0.029 mol, 4.9870 g), MBA (0.00352 mol, 0.5506 g), and AP (0.00117 mol, 0.2760 g), Yield = 100%.

The polymerization mixtures were kept under nitrogen at 60 °C for 4 h (Scheme 1). Then, the adsorbent was removed from the flask, filtered and washed with plenty of water (Type I). The adsorbent was dried under vacuum at 50 °C and then milled and sized by screening. The fraction with mesh size in the range of 180–250 μm was chosen.

Metal ion uptake

The effect of the pH on the metal ion retention properties was studied by batch-equilibrium procedure. These batch metal uptake experiments were carried out using solutions of the following standard metal salts: Cd(NO3)2, Zn(NO3)2, Pb(NO3)2, and Cr(NO3)3, at pH 1, 3, and 5; and Hg(NO3)2 at pH 1 and 2. All the experiments were performed in flasks placed on a Julabo air-batch shaker at 20 °C and 140 rpm. The retention ability for Cd(II), Zn(II), Pb(II), Cr(III), and Hg(II), under noncompetitive and competitive conditions, was determined as a function of the pH. Batches of 50.0 mg adsorbent, together with a mixture of 5.00 mL of metal ion(s) solution, were used. Under noncompetitive conditions, the adsorbent (repeat unit)/metal ion ratio (in mol) is 20:1. Under competitive conditions, solutions were prepared as before but considering the sum total mmol of the metal ions involved while maintaining the adsorbent/metal ions ratio. After a preestablished shaking time, concentration, and temperature, each sample was filtered and washed with deionized water at the corresponding pH. The filtrate was collected into a calibrated 50.0 mL volumetric flask and diluted to volume. The metal ions were determined by atomic absorption spectrometry (AAS).

In order to obtain the maximum adsorption capacity (MAC) for the metal ions, batches of 500.0 mg adsorbent were used together with a mixture of 25.00 mL of 1.00 g/L metal ion solution. After a shaking time of 1 h at 20 °C, each sample was filtered. Then, the batches were reconstituted by adding 25.00 mL of fresh metal ion solution. The process was repeated three times. The last filtration step was followed by a washing step with water at the corresponding pH. Filtrate was collected into calibrated 100.0 mL volumetric flask and diluted to volume with water at the selected pH. The metal ions were determined by AAS.

Time, temperature, and concentration effects on ion retention were performed with all the adsorbents at the optimum retention pH of the corresponding metal ion as described above under noncompetitive conditions. The time effect was studied at 15, 30, 60, and 80 min. Temperature effect was studied at 20, 30, 40, and 50 °C. The concentration effect was studied at adsorbent/metal ion ratios of 20:1; 20:2, and 20:4. Selectivity was determined as described above under competitive conditions by maintaining a constant 20:1 adsorbent/metal ions ratio as pointed before.

Elution of metal ions

Elution studies were performed by using HNO3, HCl, HClO4, and H2SO4 at 1, 2, and 4 mol L−1 each and Na2CO3 at 1 and 2 mol L−1 as eluents. In this context, 50.0 mg of dry adsorbent—loaded at MAC were eluted by shaking with 5.00 mL of eluent for 1 h. Then, the filtrate was collected and analyzed for the corresponding metal ion by AAS.

Measurements

An Atomic Absorption Spectrometer (H. Jürgens and Co. A Unicam Solar M Series) was utilized for determination of metal ions in filtrates and eluates. A Magna Nicolet 550 Spectrometer was used for recording the FTIR spectra of unloaded adsorbents and some loaded adsorbents. An STA-625 Thermoanalyzer recorded the corresponding thermograms of loaded as well as unloaded adsorbents by heating approximately 5 mg of the dry sample at a heating rate of 20 °C/min under a dynamic nitrogen atmosphere.

Results and discussion

Synthesis and characterization of the adsorbents

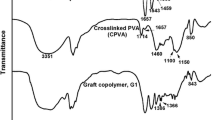

Three water-insoluble adsorbents were synthesized by radical polymerization. Adsorbents were characterized by FT-IR spectroscopy. Table 1 shows the most characteristic absorption bands confirming the polymerization process. Adsorbent compositions were determined from their FT-IR spectra by comparing the areas corresponding to each monomer.

Data of the thermal study under dynamic conditions, shown in Table 2, demonstrate that adsorbents loosed water occluded into the polymer matrix up to 200 °C. By comparison, the adsorbent having the lowest weight loss at 500 °C is P(NDAPA-AAg) possibly because of the lack of carboxylic acid groups, whereas the adsorbents P(NDAPA-AMo) and P(NDAPA-AA) have the highest weight loss probably due to the presence of carboxylic acid groups, as lateral substituent, which decompose by forming CO2.

Metal ion adsorption studies

Effect of pH on the removal of metal ions

This study was carried out in order to compare adsorbent affinity and selectivity for Cd(II), Zn(II), Pb(II), Cr(III), and Hg(II). The polymer surface chemistry as well as the solution chemistry of these metal ions is pH dependent. The amount of absorbed metal ions depends on the species’ stability in solution phase and on the adsorbent’s adsorbing properties. Changes in pH are known to affect the adsorbent’s surface charge, and the adsorbate’s degree of ionization and speciation [24]. Consequently, the dependence of adsorption on adsorbents at different pH for the metal ions was determined (see Figs. 1, 2, 3).

The contact time used was 1 h because all the metal ions achieve the equilibrium close to 30 min, which is considered too short since the reactions occur in heterogeneous media. This fast adsorption equilibrium time takes place probably due to a high complexation rate (i.e. high affinity) between Cd(II), Zn(II), Pb(II), Cr(III), and Hg(II) ions and the functional group anchored in the adsorbent structure.

The effect of pH on the removal of metal ions, except for Hg(II), can be explained with the well-known electrostatic interaction model, namely the ion exchange model [25]. As the pH decreases, the adsorbent’s surface enhances its positive character and the adsorption of cationic species becomes unfavorable. These studies were performed up to pH 5 because above this value the precipitation of the corresponding metal hydroxides starts to occur.

The lower metal ion retention observed at low pH can be explained by taking into account that the nitrogen atom of the amine moieties is protonated at low pH, forming –NH+A−-groups. As the pH increases, enough carboxylic acid groups become available to complex metal ions or to form adducts with positive hydroxo complexes [i.e. Hg(II)]. In this context, the acryloylmorpholine group in P(NPDA-AMo) does not contribute meaningfully to the complex: it does form adducts with the studied metal ions, except for the amine moieties. This would explain the higher retention observed with this adsorbent at the higher pHs (see Fig. 1). On the other hand, when acrylic acid and acrylamidoglycolic acid moieties were incorporated in adsorbents (P(NPDA-AA) and P(NPDA-AAg), a higher retention for Hg(II) was observed at pH 2 (see Figs. 2, 3). This can be explained as due to the increased availability of carboxylate groups at pH 2 than at the lowest pH.

Maximum retention capacity (MRC)

In order to explore the applications of the adsorbents, it is very important to know their adsorption capacity for the metal ions studied. This parameter was determined for each adsorbent by considering only those metal ions with significant retention percentage at optimum pH. Results are summarized in Table 3.

Effect of temperature on adsorption

The temperature has two main effects on the adsorption process. Increasing the temperature is known to improve the rate of the metal ion diffusion due to a reduction in the solution’s viscosity. Additionally, the temperature change modifies the absorbent’s capacity for the particular metal ion [26].

Considering the results of the effect of pH on retention, the combined effect of temperature and pH on metal ions adsorption was investigated by carrying out a series of experiments at different pHs from 20 to 50 °C. Resin P(NDAPA-AMo) shows in Fig. 4 that Cr(III) and Zn(II) retention increases and Pb(II) retention slightly decreases with increasing temperature at pH 5, which might be attributed to a higher stability of the formed complexes at lower temperatures.

On the other hand, resin P(NDAPA-co-AA) shows only an increment of almost 10% in the retention of Cr(III) at 30 °C with respect to the different values observed in the same temperature range. Finally, resin P(NDAPA-co-AAg) shows that the retention of Hg(II) at pH 2 decreases with increasing temperatures, even though a higher temperature could accelerate decomposition of the chelate or the ion exchanger group, which could explain the drop of the adsorption rate. In general terms, the decrease in adsorption at higher temperatures may suggest that the adsorption is a complex process and it could be the result of both chemical and physical processes.

Effect of contact time on adsorption

For those metal ions appreciably retained at optimum pH, contact time effect on retention was studied from 15 to 80 min. Results are shown in Fig. 5. As seen, resin P(NDAPA-co-AMo) retained Cr(III) achieving a maximum capacity, within 15 min, which was not varied with an increasing time. On the other hand, retention of Pb(II) increased around 10% at 60 min with regard to the retention at 30 min. Resin P(NDAPA-co-AAg) shows that retention of Hg(II) increases in a little extent with time. Finally, resin P(NDAPA-co-AA) shows a higher retention of Cr(III) within 15 min which slightly increases with time.

Effect of resin/metal ion ratio on adsorption

The effect of the resin/metal ion ratio on adsorption was evaluated at 20:1, 20:2, and 20:4 ratios. Results are summarized in Fig. 6. As can be observed in all the cases, metal ion uptake increases as the resin/metal ion ratio decreases, where Cr(III) is the metal ion most retained by resin P(NDAPA-co-AMo). Clearly in all the cases, the uptake was below the resin’s maximum retention capacity.

Elution behavior

Attempts were carried out to desorb the adsorbed metal ions from the loaded adsorbents at optimum pH, using HCl, HClO4, HNO3, H2SO4, and Na2CO3 at different concentrations. The results are shown in Tables 4 and 5. The best performance was achieved with 4 mol L−1 HNO3 to recover Cr(III) and Hg(II).

Selectivity studies

In order to verify if the synthesized P(NDAPA-co-AMo) can be useful for selective separation of heavy metal ions, selectivity studies were performed under competitive conditions for the ternary mixture of Cr(III), Zn(II), and Pb(II). Adsorption performed batch-wise from solutions containing these three metal ions shows that this resin offers high selectivity toward these heavy metal ions as can be seen in Table 6. At low pH there is a competition of protons with metal as cations. At higher pH as at pH 5 almost all the amine groups are deprotonated and carboxylic acid are as carboxylate and coordinate through the free electrons with the corresponding metal ion and carboxylic acid are as carboxylate favoring the polymer ligand–metal ion complex. Nevertheless, there is not experimental evidences to that, it is possible suggest that the more important groups to remove metal ions are the amino and carboxylic acid groups.

Conclusions

Three cross-linked adsorbents were synthesized by radical solution polymerization. The adsorption was solution-pH dependent and the highest removal for the selected metal ions occurred at pH 5 except for Hg(II) at pH 2. Adsorption equilibrium was mostly achieved in approximately 15 min. P(NDAPA-co-AMo) showed high retention for Cr(III) and Zn(II) and P(NDAPA-co-AA) just for Cr(III). On the other hand, P(NDAPA-co-AAg) showed an important retention only for Hg(II). Acid was used to regenerate the spent adsorbent, and 4 mol L−1 HNO3 was the eluent that best recovered the resin loaded with Cr(III) and Hg(II).

References

Nriagu JO, Pacyna JM (1988) Quantitaive assessment of worldwide contamination of air, water and soils by trace-metals. Nature 333:134–139

Bayramoglu G, Arica MY (2005) Ethylenediamine grafted poly(glycidylmethacrylate-co-methylmethacrylate) adsorbent for removal of chromate anions. Sep Purif Technol 45:192–199

Lee MS, Ahn JG, Ahn JW (2005) A novel amine-shielded surface cross-linking of chitosan hydrogel beads for enhanced metal adsorption performance. Ind Eng Chem Res 44:6692–6700

Starvin AM, Prasada Rao T (2004) Removal and recovery of mercury(II) from hazardous wastes using 1-(2-thiazolylazo)-2-naphtol functionalized activated carbon as solid phase extractant. J Hazard Mater 113:75–79

Chandra D, Yokoi T, Tatsumi T, Bhaumik A (2007) Highly luminescent organic-inorganic hybrid mesoporous silicas containing tunable chemosensor inside the pore wall. Chem Mater 19:5347–5354

Chandra D, Kumar Das S, Bhaumik A (2010) A fluorophore grafted 2D-hexagonal mesoporous organosilica: excellent ion exchanger for the removal of heavy metal ions from wastewater. Micropor Mesopor Mater 128:34

Jing X, Liu F, Yang X, Ling P, Li L, Long C, Li A (2009) Adsorption performances and mechanisms of the newly synthesized N,N'-di(carboymethyl)dithiocarbamate chelating resin toward divalent heavy metal ions from aqueous media. J Hazard Mater 167:589–596

Moyers EM, Fritz JS (1976) Separation of metal ions using a hexylthioglycolate resin. Anal Chem 48:1117–1120

Chen YY, Chen XW (1988) Synthesis of functional resins containing heterocyclic rings and their sorption properties for noble metal ions. J Macromol Sci Chem A25:1443–1454

Polakovicova J, Medved J, Stresko V, Kubokova J, Celkova A (1996) Spectrographic determination of gold in geological material after preconcentration on spheron thiol. Anal Chim Acta 320:145

Shah R, Devi S (1998) Chelating resin containing s-bonded dithizone for the separation of copper(II), nickel(II) and zinc(II). Talanta 45:1089–1096

Ji C, Qu R, Sun C, Wang C, Xu Q, Sun Y, Li C, Guo S (2007) Macroporous chelating resins incorporating heterocyclic functional groups via hydrophilic PEG spacer arms. I. Synthesis and characterization. J Appl Polym Sci 103:3220–3227

Kavakli C, Malci S, Tuncel SA, Salih B (2006) Selective adsorption and recovery of precious metal ions from geological samples by 1,5,9,13-tetrathiacyclohexadecane-3,11-diol anchored poly(p-CMS-DVB) microbeds. React Funct Polym 66:275

Drutsa R, Gutsanu V, Rusu V (2006) Sorption of CMID-containing cations on strongly basic anion exchangers. J Appl Polym Sci 102:3978–3982

Sun C, Qu R, Ji C, Wang Q, Wang C, Sun Y, Cheng GA (2006) A chelating resin containing S, N and O atoms: synthesis and adsorption properties for Hg(II). Eur Polym J 42:188–194

Dinu MV, Dragan ES (2008) Heavy metals adsorption on some iminodiacetate chelating resins as a function of the adsorption parameters. React Funct Polym 68:1346–1354

Zhang Y, Qu R, Sun C, Chen H, Wang C, Ji C, Yin P, Sun Y, Zhang H, Niu Y (2009) Comparison of synthesis of chelating resin silica-gel-supported diethylenetriamine and its removal properties for transition metal ions. J Hazard Mater 163:127–135

Dinu MV, Dragan ES, Trochimczuk AW (2009) Sorption of Pb(II), Cd(II) and Zn(II) by iminodiacetate chelating resins in non-competitive and competitive conditions. Desalination 249:374–379

Rivas BL, Villegas S, Ruf B, Perič IM (2007) Removal of metal ions with impact on the environment by water-insoluble functional copolymers: synthesis and metal ion uptake properties. J Chil Chem Soc 52:1164–1168

Rivas BL, Muñoz C (2007) Removal of environmentally impacting metal ions using functional resin poly(4-styrene sulfonate-co-4-vinylpyridine): synthesis and metal ion retention properties. J Appl Polym Sci 104:1769–1774

Rivas BL, Villegas S (2004) Water-insoluble polymers with ability to remove metal ions. J Appl Polym Sci 91:3679–3685

Rivas BL, Muñoz C (2009) Synthesis and metal ion adsorption properties of poly(4-sodium styrene sulfonate-co-acrylic acid) resin. J Appl Polym Sci 114:1587–1592

Silverstein RM, Webster FX, Kiemle David (2005) Spectrometric identification of organic compounds, 7th edn. Wiley, New York, pp 120–124

Elliot HA, Huang CP (1981) Adsorption characteristics of some Cu(II) complexes on aluminosilicates. Water Res 15:849–855

Bullock JI, Tuck DG (1965) Some oxyanion complexes of mercury(II). J Chem Soc 1877

Dogan M, Turhan Y, Alkan M, Namli H, Turan P, Demirbas O (2008) Functionalized sepiolite for heavy metal ions adsorption. Desalination 230:248–268

Acknowledgments

The authors thank FONDECYT (Grant No 1070542), Anillo ACT 130, and CIPA for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rivas, B.L., Perič, I.M. & Villegas, S. Synthesis and metal ion uptake properties of water-insoluble functional copolymers: removal of metal ions with environmental impact. Polym. Bull. 65, 917–928 (2010). https://doi.org/10.1007/s00289-010-0304-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-010-0304-z