Abstract

Campylobacteriosis has become common cause of diarrhea in humans and is associated with Guillain–Barré Syndrome, Reactive Arthritis and Irritable Bowel Syndrome is caused mainly by contaminated food and water intake in which the majority occurs from manipulation, preparation and consumption of poultry meat. The aim of this study was to estimate the prevalence of Campylobacter in chicken carcasses from slaughterhouses located in the states of Parana, Santa Catarina and Rio Grande do Sul in the South of Brazil. The samples were analyzed for Campylobacter enumeration using the ISO method 10272-2 and the species C. jejuni and C. coli, important for public health, were identified through Maldi-TOF mass spectrometry. From July 2017 to July 2018, 816 samples were analyzed, indicating the prevalence of 35.84%, with higher occurrence of C. jejuni (78.47%). No difference in prevalence was observed in relation to the size of the slaughterhouses. However, significant differences were noted among the three states in the southern region of the country, with the lowest prevalence being observed in Parana. The results reinforce the need to advance in the implementation of strategies to control this pathogen in the country, in order to safeguard consumer’s health and contribute for the maintenance of Brazil’s position in the international poultry meat market.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Campylobacteriosis is a disease transmitted by water and food contaminated by thermophilic Campylobacter species, mainly C. jejuni and C. coli. Following an increase in the incidence of this disease observed in the 1980s and 1990s, the number of cases stabilized in the early twenty-first century and is currently among the most important and frequent foodborne diseases worldwide [1]. Campylobacter is most often associated with cases of gastroenteritis, resulting in an acute self-limiting infection, with an incubation period ranging from two to five days, symptomatic period of three to five days, whose clinical manifestation includes abdominal pain, nausea, headache, muscle pain, fever and diarrhea [2, 3]. Although complications from campylobacteriosis are uncommon, they are quite severe. Among these complications are Guillain-Barré Syndrome (GBS), which is an acute neuromuscular paralysis [2].

European Food Safety Authority (EFSA) reported that cases of campylobacteriosis became more frequent than cases of salmonellosis and yersiniosis, reaching 64.8 cases per 100,000 inhabitants in 2017 [4]. In 2010, New Zealand reported that the highest occurrence of campylobacteriosis in the country was in 2006, with a proportion of almost 400 cases per 100,000 inhabitants [5].

Between implicated foods, it is estimated that at least 50% of campylobacteriosis human cases occurring in the Americas are associated with chicken meat [6]. A research conducted in the United States amongst 2007 and 2008 to estimate the prevalence of Campylobacter in broiler carcasses, identified 46% of pathogen-positive carcasses [7]. In Canada, the national prevalence study conducted in 2012 and 2013 identified 27.4% of chicken carcasses contaminated by Campylobacter and 39.0% chicken cuts contaminated with Campylobacter, possibly due to cross-contamination and manipulation while cutting procedures [8]. In 26 EU Member States, plus Norway and Switzerland, the 2008 prevalence baseline identified 75.8% of carcasses contaminated with Campylobacter [9].

Brazil occupies a prominent position in poultry meat production since 2011, is the global leader in exports and is the second largest producer in the world. However, in order to remain an export leader in a highly competitive market, it is necessary to keep in line with microbiological safety requirements. The EU member states are one of the main destinations of Brazilian poultry meat and have a mirror effect on other importing markets, adopted in 2018 Campylobacter microbiological criteria for chicken carcasses [10]. As a result, Brazilian slaughterhouses qualified to export chicken meat to EU must meet their requirements.

In Brazil, the Federal Inspection Service (SIF) of the Ministry of Agriculture, Livestock and Food Supply (MAPA) acts on a risk-based inspection model [11]. Studies on the prevalence of Campylobacter in poultry in Brazil are crucial for future implementation of policies for the management of this microorganism in the country. The present study aimed to estimate the prevalence of Campylobacter spp. in chicken broiler carcasses in slaughterhouses under SIF in the states of Paraná (PR), Rio Grande do Sul (RS) and Santa Catarina (SC).

Material and Methods

Data Collect

The study was carried out in chicken slaughterhouses under SIF, located in the Brazilian states of PR, SC and RS, between July 2017 and July 2018. The sampling plan to estimate the prevalence of Campylobacter spp. in chicken carcasses was calculated based on an expected prevalence of 50%, expected error of 10% and statistical confidence of 95%. The slaughterhouses were classified according to their daily slaughter as small (S) when slaughtering less than 50,000 chickens per day, medium (M) between 50,001 and 100,000 chickens per day, large (L) between 100,001 and 200.00 chickens per day and extra-large (XL) when slaughtering over 200.001 chickens per day. The number of samples was defined considering the number of their classification.

A total of 71 chicken slaughterhouses located in the south of Brazil were sampled. The number of samples foreseen for this study was 776 chicken carcasses, 40 collected in S slaughterhouses, 112 in M, 336 in L and 288 in XL. The sampling of chicken carcasses was performed by the officials of the inspection service at the slaughterhouse. At slaughterhouses classified as S and M a sample was taken every three weeks, at slaughterhouses L and XL a sample was taken every two weeks. The sample at random, considering equal chances for all lots, slaughter lines, days of the week and slaughter shifts. The sample consisted of an entire chicken carcass collected after pre-chilling. For the transport from the slaughterhouse to the laboratory, the samples were kept refrigerated, with temperature between 0 and 8 °C [11]. The modes of transport used were terrestrial, air or both, according to the location of the slaughterhouse.

The analyzes for Campylobacter were performed at the food microbiology unit of the official laboratory (LFDA) located in Porto Alegre (RS), with quality management system accredited [12] and the enumeration was performed according to ISO [13]. At the LFDA, the carcasses were rinsed with 500 mL of buffered peptone water 1%. Aliquots of 1 mL obtained from 100 and 101 dilutions were inoculated onto surface of modified cefoperazone deoxycholate charcoal agar plates (mCCDA), incubated in microaerophilia.

Then, the presumptive colonies were counted and 5 characteristic colonies, from each dilution, were random selected and plated on blood agar, followed by incubation in microaerobic atmosphere. The confirmation of the colonies was made by microscopy with phase contrast observing characteristics of morphology and motility and oxidase testing. Positive colonies were transferred to blood agar and incubated under aerobic conditions at 25 °C for 44 ± 4 h. Reference strains were used for microbiological quality control. Results were reported in carcass colony forming units (CFU/carcass). In plates where there was no growth of colonies the result was reported as < 500 CFU/carcass. For the identification of C. jejuni and C. coli species, isolated and confirmed colonies were submitted to Maldi-TOF mass spectrometry using the direct plating protocol, with triplicates from each colony, considering the identification of the species only for the colonies with score equal to or greater than 2.0 [14]. Spatial analysis of location of the chicken slaughtering slaughterhouses available at SIGSIF system was performed using ArCGIS Desktop® version 10.6.

Statistics Analysis

Descriptive analysis of the data were done using Microsoft® Office Excel® 2010. Prevalence results considering size and location of slaughterhouses were subjected to analysis using the nonparametric test of Kruskal Wallis. Logistic regression analysis was performed to assess the effect of time between sample collection and reception at the LFDA. Statistical analysis was performed using the software Stata® version 14.0 [15]. The prevalence and logistic regression were calculated using survey commands of Stata® version 14.0 using sampling weights base in the number of the total number of slaughterhouses and those sampled, the quantity of production of each slaughterhouse sampled and the number of samples by slaughterhouse sampled, as demonstrated in the formula bellow.

When the prevalence and its confidence interval are estimated using the sample weight, the values have an improved external validity and the estimate is considered more reliable. Prevalence estimates tend to have values slightly higher or lower than simple positivity rates. This is due to the occurrence of positive cases in more frequency in larger establishments (estimates go up) or smaller establishments (estimates go down).

Results and Discussion

Between July 2017 and July 2018, approximately 5.5 billion of poultry were slaughtered in slaughterhouses under SIF were 64% slaughtered in the Southern states of Brazil (34.85% in PR, 15.60% in SC and 14.11% in RS). Despite the expansion of the poultry production chain in the Midwest due to the increased availability of corn and soybeans, that are basis for poultry feeding [16], the South remains the country's leading broiler producer, consolidating an activity that was boosted in these states in the 1970s.

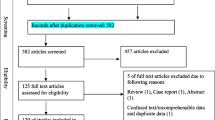

In this study, 816 samples were collected from 70 slaughterhouses, maintaining the proportional distribution of the samples among slaughterhouses according to their size (Table 1). Throughout the study it was observed that eight slaughterhouses had alteration in their size classification, consequently the number of samples were changed. In addition, in one slaughterhouse it was not possible to test for Campylobacter because all chicken samples arrived frozen in the LFDA.

To calculate the prevalence, the sample weight was considered as a function of the number of slaughtered chickens per slaughterhouse during the study period. The prevalence of Campylobacter spp. in chicken carcasses was 35.84% (95% CI 31.94 to 39.93%). The highest occurrence observed was C. jejuni with 78.47% (113/144), followed by C. coli with 9.72% (14/144) and C. coli plus C. jejuni with 7.64% of samples (11/144). In 4.17% (6/144) of the samples it was not possibly to identify the species therefore these results were described as Campylobacter spp. Campylobacter coli and C. jejuni enumeration are shown in Table 2, being 80% (115/144) of the results between 103 and 104 CFU/carcass and no differences were observed between enumeration of C. coli, C. jejuni and C. coli plus C. jejuni (p > 0.05).

The higher occurrence of C. jejuni observed may be considered a concern for public health authorities, as this species is responsible for most campylobacteriosis cases registered in the United Kingdom and the United States, 90% and 95%, respectively [3, 17].

There was no difference in prevalence observed (p > 0.05) in relation to size of the slaughterhouses (Table 3). A significant difference of Campylobacter prevalence (p < 0.05) in the three Brazilian states was observed, PR showed the lowest prevalence 20.74% (95% CI: 16.26 to 26.07) and RS the highest prevalence 63.28% (95% IC 54.50 to 71.25). The probability of positive samples occurring in SC is three times higher compared to PR (odds ratio 3.25) and six times higher in RS compared to PR (odds ratio 6.38).

In 2.58% (21/816) of analyzed samples there was a loss of plates with a dilution of 100 caused by invasive colonies scattering. In these cases, the result obtained only from the 101 dilution plate was expressed as < 5000 CFU/carcass when there was no colony growth.

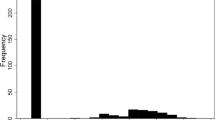

In 63.12% (515/816) of the analyzed samples there was no growth of colonies, being the result expressed as < 500 CFU/carcass. From these samples, it was observed that 61.35% (316/515) were collected in slaughterhouses located in the state of PR. Figure 1 shows the highest occurrence of enumeration results < 500 CFU/carcass in the state of PR, followed by SC and RS. The infectious dose of C. jejuni for humans is low, between 500 and 800 cells [5]. In the present study, approximately 72% of the results obtained were below 1,000 CFU per carcass.

Most slaughtering slaughterhouses are located the countryside, far from airports and with restricted access to ground transportation. Some slaughterhouses from northern of PR, are 1,000 km away from the laboratory. Therefore, these far distances between slaughterhouses and official laboratories associated with the lack of transport infrastructure posed a great challenge for the sample logistics.

Campylobacter is a fastidious, oxygen-sensitive bacteria that may have enumeration results affected especially when samples have been stored for long periods or transported prior to analysis [18]. When subjected to stress conditions, Campylobacter cells adopt as a survival strategy the shape change with loss of multiplication capacity in culture medium, being considered viable and non-cultivable forms [19].

The possibility of interference of the time factor between the sample collection, the receipt and the beginning of the analysis was evaluated. Campylobacter enumeration (CFU/carcass) by State is shown in Table 4, and Table 5 presents the number of samples according to the time between collection and receipt in the LFDA, in days, and the frequency of samples with Campylobacter count, being observed difference (p < 0.05) between samples with 3 or more days between collection and receipt compared to samples that took up to 2 days to reach the laboratory. Samples collected in slaughterhouses located in PR took longer to reach the LFDA compared to those collected in RS, possibly due to the greater distances between the slaughterhouses and LFDA (Fig. 2).

The location of the slaughter slaughterhouses and the Euclidean distances to LFDA are show in Fig. 3. Most north slaughterhouses of RS are within 250 km away from the LFDA, while slaughterhouses located in the north of PR are 1000 km away from the LFDA. The great distances and the lack of logistic infrastructure [20] contributed to longer periods between collection and reception of samples at the laboratory. However, 83.5% of the samples were analyzed within 72 h, similar to the 80-h limit established for the prevalence study conducted by EFSA in 2008 [21].

The logistic regression analysis indicated that there could be difference in detection of Campylobacter depending on the time period between the sample collection and arrival at the laboratory. In samples that took 3 or more days to arrive to the LFDA was two time less likely to detect Campylobacter (odds ratio 0.4577) compared to those arriving within 2 days. Therefore, the next statistic analysis considered only samples that arrived at the LFDA within 2 days totalizing 398 samples, 113 from PR, 111 from SC and 154 from RS.

The observed prevalence of the 398 samples was 40.77% (95% CI 33.94 to 47.98). The significant difference (p < 0.05) remained between the prevalence results observed in the three Brazilian states, with the lowest prevalence observed in PR with 24.25% (95% CI 15.66 to 35.56) and the highest prevalence in RS with 64.91% (CI 95% 55.23 to 73.50) (Table 6). The probability of positive samples occurring was almost three times higher in the state of SC compared to PR (odds ratio 2.94) and six times higher in RS compared to PR (odds ratio 6.06). The Campylobacter enumeration results for the three states considering only samples that arrived at the LFDA in 2 days (n = 398) (Fig. 4).

In the USA a Campylobacter baseline study was conducted in 2007 and 2008 [7] and samples were transported at temperatures between 0 and 10 °C, reaching the laboratory within 24 h after collection. In New Zealand, to assess the performance of the slaughterhouses with the Campylobacter microbiological criterion the samples should reach the laboratory within 24 h after collection, with a temperature below 10 °C [22].

In the European prevalence study, the 80-h limit period between collection and reception was adopted as the criterion for receiving the sample at the laboratory. The delay between sample collection and laboratory analysis increased the chance of detection of Campylobacter in chicken samples [21]. The (EU) Regulation 2017/1495, adopted after the EFSA prevalence study, set a limit of maximum 48 h between sample collection and laboratory analysis and a temperature of 1 to 8 °C for samples storage and transport [10].

It is important to define a timeout period between sample collection and laboratory analysis as a procedure in program to control Campylobacter. Maintenance of the sample at refrigerated temperature is justified by the evidence that freezing appears to have an effect on Campylobacter inactivation, reducing the level of contamination in frozen chicken. Samples of skinned chicken cuts showed a reduction of 1 log10 after 24 h of freezing at − 22 °C [23] and a reduction of up to 1.5 log10 in frozen chicken meat [24]. It was demonstrated [25] that despite a reduction of up to 2 log10 after three weeks of freezing at − 10 °C, in most chicken carcasses evaluated it was still possible to detect Campylobacter even after 120 days of freezing.

The risk associated with refrigerated meat with average contamination of 4.5 log10 CFU is approximately the same as frozen meat with average contamination of 5.25 log10 CFU [26]. Freezing has been one of the measures taken in countries with Denmark, Iceland, Norway and New Zealand to minimize the risk of Campylobacter contamination in chicken meat [22, 24].

The intestinal microbiota plays an important role in the development of potentially pathogenic microorganisms by competitive exclusion or by stimulating immune system defenses. It is unclear how this microbiota may influence Campylobacter colonization in the intestine of birds [27].

Previous study at Brazil was conducted in two distinct periods (August/2011 to February/2012 and September/2015 to February/2016) in slaughterhouses of the largest poultry slaughtering company. An occurrence of 13.1 and 6.8% of Campylobacter jejuni was observed in the first and second periods, respectively [28]. Additionally, to the fact that these slaughterhouses exported products to the European Union and were already implementing controls for Campylobacter to meet the new requirements announced by EU.

The prevalence and microbial load of Campylobacter observed in poultry farms were associated with the prevalence and microbial load identified in slaughterhouses [29]. Thus, it is expected that measures to reduce this pathogen at the primary chain reflect in reduction of contamination in slaughterhouses. However, these authors suggested that before adopting stringent biosafety protocols to reduce the occurrence of Campylobacter in farms, more information on the real impact and benefit of such measures should be available [29].

It is possible to reduce between 44 and 95% the occurrence of human campylobacteriosis associated with chicken meat if there is a reduction of one to two logarithmic cycles in the concentration of this bacterium in the intestinal content of poultry [30]. Control measures based on good hygiene practices, generally supported by empirical scientific knowledge and experience, and risk-based measures defined from scientific knowledge [31]. These measures apply from the primary production chain (hatcheries, broiler farms) to the chicken slaughtering and processing industries. Control measures at the primary chain include biosecurity, including restricting access to facilities and birds; cleaning and disinfection of materials, equipment and installations; sanitary void; quality control of water and feed; frequent collection and proper disposal of dead birds [31].

The use of screens to eliminate or prevent mosquito proliferation seemed to reduce the occurrence of Campylobacter in the farm from 51.4 to 15.4% and the bird health status regarding Campylobacter is also important as it allows to schedule slaughter of positive lots in order to reduce the risk of cross-contamination. At slaughterhouses most control measures aim to prevent and reduce faecal contamination, including the use of chemical or physical carcass decontamination methods [31].

Campylobacter counts in chicken carcasses after cooling were associated with short transport and waiting period of the birds until slaughter, the high occurrence of gastrointestinal viscera rupture and the high Campylobacter count in the cecal content [32]. However, slaughterhouses with poor infrastructure and older technology might have higher Campylobacter reduction potentials by implementing modern equipment and up to date washing systems [33].

In Benin, was showed a contamination rate of Campylobacter in the chicken samples of 32.8% and that there is a real risk of poisoning among consumers of chicken meat. Also, the isolated Campylobacter strains are multidrug-resistant, which poses a problem in selecting Campylobacter strains in chicken farms, where antibiotics are used in an anarchic manner [34]. In Lithuania, it was observed occurrence of Campylobacter spp. in faecal samples was higher among crows (39.2%) than pigeons (30.0%), (P < 0.05) from parks and other public places. Wild birds and other environmental sources may contribute to the burden of illness as well [35].

Conclusions

Prevalence of Campylobacter spp. in chicken carcasses was 35.84%. No difference in prevalence was observed in relation to size of the slaughterhouses. Significant difference of Campylobacter prevalence in the states was observed.

References

Wagenaar JA, French NP, Havelaar AH (2013) Preventing Campylobacter at the source: why is it so difficult? Clin Infect Dis 57:1600–1606

WHO/FAO World Health Organization/Food and Agriculture Organization (2013) The global view of campylobacteriosis: report of an expert consultation. Utrecht

Pitkanen T, Hanninen ML (2017) Members of the family Campylobacteraceae: Campylobacter jejuni, Campylobacter coli. In: Rose JB, Jiménez-Cisneros B (eds) Global water pathogens project. Michigan State University, E. Lansing, MI, UNESCO

EFSA European Food Safety Authority and European Centre For Disease Prevention and Control (ECDC) (2018) The European union summary report on trends and sources of zoonoses, zoonotic agents and food-borne outbreaks in 2017. EFSA J 16:5077

Epps SVR, Harvey RB, Hume ME et al (2013) Review foodborne Campylobacter: infections, metabolism, pathogenesis and reservoirs. Int J Environ Res Public Health 10:6292–6304

Hoffmann S, Devleesschauwer B, Aspinall W et al (2017) Attribution of global foodborne disease to specific foods: findings from a World Health Organization structured expert elicitation. PLoS ONE 12:e0183641

USDA/FSIS United States Department of Agriculture, Food Safety and Inspection Service (2008) The nationwide microbiological baseline data collection program: young chicken survey. July 2007–2008

Canada (2016) Canadian Food Inspection Agency (CFIA). National microbiological baseline stud y in broiler chicken. December 2012–2013

EFSA European Food Safety Authority (2010) Analysis of the baseline survey on the prevalence of Campylobacter in broiler batches and of Campylobacter and Salmonella on broiler carcasses in the EU, 2008, Part A: Campylobacter and Salmonella prevalence estimates. EFSA J 8:1503

European Union (EU) (2017) Commission regulation (EC) 2017/1495 of 23 August 2017 amending regulation (EU) 2073/2005 as regards Campylobacter in broiler carcasses. Official Journal of European Union

Brasil (2017) Ministério da Agricultura, Pecuária e Abastecimento. Norma Interna DIPOA/SDA n 2, de 12 de junho de 2017. Estabelece o programa exploratório para pesquisa e estimativa de Campylobacter spp em carcaças de frangos. Boletim de Pessoal, Brasília

ISO International Standards Organization (2017) 17025 General requirements for the competence of testing and calibration laboratories. International Standard ISO, Geneva

ISO International Standards Organization (2017) 10272-2 Microbiology of the food chain—horizontal method for the detection and enumeration of Campylobacter spp. Part 2: Colony count technique. International Standard—ISO. Geneva

Rodrigues CS, Armendaris PM (2018) Avaliação de amostras de carcaças de frango para presença e prevalência de Campylobacter nos SIFs do Brasil. Fundação APINCO de Ciência e Tecnologia Avícolas (FACTA). http://www.facta.org.br/salmonella2018/anais/view/home/. Accessed Apr 17 2019

StataCorp (2015) Stata statistical software: release 14. College Station, Texas

Rodrigues WOP, Garcia RG, Naas IA et al (2014) Evolução da avicultura de corte no Brasil. Enciclopédia Biosfera, Centro Científico Conhecer 10:1666–1684

Sheppard SK, Maiden MCJ (2015) The evolution of Campylobacter jejuni and Campylobacter coli. Cold Spring Harb Perspect Biol 7:a018119

Seliwiorstow T, Zutter L, Houf K et al (2016) Comparative performance of isolation methods using Preston broth, Bolton broth and their modifications for the detection of Campylobacter spp from naturally contaminated fresh and frozen raw poultry meat. Int J Food Microbiol 234:60–64

Melo RT (2012) Fatores de patogenicidade e potencial risco à saúde em Campylobacter spp. isoladas em carcaças de frango. Dissertation, Federal University of Uberaba

Lobo A (2018) Desempenho logístico: Brasil sofre com falta de infraestrutura. ILOS Especialistas em Logística e Supply Chain. http://www.ilos.com.br/web/lpi-o-brasil-continua-sofrendo-com-a-infraestrutura/. Accessed May 14 2019

EFSA European Food Safety Authority (2010) Analysis of the baseline survey on the prevalence of Campylobacter in broiler batches and of Campylobacter and Salmonella on broiler carcasses in the EU, 2008, Part B: Analysis of factors associated with Campylobacter colonization of broiler batches and with Campylobacter contamination of broiler carcasses; and investigation of the culture method diagnostic characteristics used to analyse broiler carcass samples. EFSA J 8:1522

Lee J, Castle M, Duncan G et al (2015) Example of a microbiological criterion (MC) for verifying the performance of a food safety control system: Campylobacter performance target at end of processing of broiler chickens. Food Control 58:23–28

Sampers I, Habib I, Zutter L et al (2010) Survival of Campylobacter spp in poultry meat preparations subject to freezing, refrigeration, minor salt concentration and heat treatment. Int J Food Microbiol 137:147–153

Rosenquist H, Sommer HM, Nielsen NL et al (2006) The effect of slaughter operations on the contamination of chicken carcasses with thermotolerant Campylobacter. Int J Food Microbiol 108:226–232

Sandberg M, Hofshagen M, Ostensvik O et al (2005) Survival of Campylobacter on frozen broiler carcasses as a function of time. J Food Prot 68:1600–1605

WHO/FAO World Health Organization/Food and Agriculture Organization (2009) Risk assessment of Campylobacter spp. in broiler chickens: interpretative summary. Microbiological Risk Assessment Series No 11. Geneva

Han Z, Willer T, Li L et al (2017) Influence of the gut microbiota composition on Campylobacter jejuni colonization in chickens. Infect Immun 85:e00380-e417

Melo RT, Grazziotin AL, Júnior-Valadares EC et al (2019) Evolution of Campylobacter jejuni of poultry origin in Brazil. Food Microbiol 82:489–496

Berghaus RD, Thayer SG, Law BF et al (2013) Enumeration of Salmonella and Campylobacter spp in environmental farm samples and processing plant carcass rinses from commercial broiler chicken flocks. Appl Environ Microbiol 79:4106–4114

Nauta M, Johannessen G, Adame LL et al (2016) The effect of reducing numbers of Campylobacter in broiler intestines on human health risk. Microb Risk Anal 1–2:68–77

CAC Codex Alimentarius Commission (2011) Guidelines for the control of Campylobacter and Salmonella in chicken meat. CAC/GL 78/2011

Seliwiorstow T, Baré J, Berkvens D et al (2016) Identification of risk factors for Campylobacter contamination levels on broiler carcasses during the slaughter process. Int J Food Microbiol 226:26–32

Lehner Y, Reich F, Klein G (2014) Influence of process parameter on Campylobacter spp. counts on poultry meat in a slaughterhouse environment. Curr Microbiol 69:240–244. https://doi.org/10.1007/s00284-014-0575-y

Kouglenou SD, Agbankpe AJ, Dougnon V, Djeuda AD, Deguenon E, Hidjo M, Baba-Moussa L, Bankole H (2020) Prevalence and susceptibility to antibiotics from Campylobacter jejuni and Campylobacter coli isolated from chicken meat in southern Benin. West Africa BMC Res Notes 13:305. https://doi.org/10.1186/s13104-020-05150-x

Ramonaitė S, Novoslavskij A, Zakarienė G, Aksomaitienė J, Malakauskas M (2015) High prevalence and genetic diversity of Campylobacter jejuni in wild crows and pigeons. Curr Microbiol 71:559–565. https://doi.org/10.1007/s00284-015-0881-z

Acknowledgments

To Coordination for the Improvement of Higher Education Personnel (CAPES) and to the Ministry of Agriculture, Livestock and Food Supply (MAPA) (Process No. 21000.055750/2018-26). The author CB de Melo is a Research Productivity Fellow (PQ) from the National Council for Scientific and Technological Development—Brazil (CNPq).

Author information

Authors and Affiliations

Contributions

The authors contributed equally to the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rodrigues, C.S., Armendaris, P.M., de Sá, C.V.G.C. et al. Prevalence of Campylobacter spp. in Chicken Carcasses in Slaughterhouses from South of Brazil. Curr Microbiol 78, 2242–2250 (2021). https://doi.org/10.1007/s00284-021-02478-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-021-02478-w