Abstract

In the current study, an extracellular cellulase belonging to symbiotic Bacillus subtilis Bc1 of the leopard moth is purified and characterized. The molecular mass of enzyme was 47.8 kDa using SDS-PAGE. The purified enzyme had optimum activity in temperature and pH around 60 °C and 8, respectively. The purified cellulase was introduced as a stable enzyme in a wide variety of temperature (20–80 °C) and pH (4–10) and remained active to more than 74% at 80 °C for 1 h. Moreover, the cellulase extremely was stabled in the presence of metal ions and organic solvents and its activity was increased by acetone (20% v/v), CaCl2 and CoCl2 and inhibited by MnCl2 and NiCl2. The values of enzyme's Km and Vmax were found to be 1.243 mg/mL and 271.3 µg/mL/min, respectively. The purified cellulase hydrolyzed cellulose, avicel and carboxymethyl cellulose (CMC) and the final product of CMC hydrolysis was cellobiose using thin-layer chromatography analysis. Consequently, owing to exo/endoglucanase activity and organic solvent, temperature and pH stability of the purified cellulase belong to B. subtilis BC1, it can be properly employed for various industrial purposes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lignocellulose is the most numerous organic matter of woody plants and dead plant materials containing lignin, cellulose and hemicellulose in its structure [1]. Due to abundance of cellulose and hemicellulose in lignocellulosic biomass, it can be an appropriate candidate to produce bioethanol [2]. Moreover, lignocellulose is known as a major renewable natural resource which cannot be completely decomposed in the environment because of its complex structure [3]. In general, microbial communities are the main producers of enzymes which can efficiently decompose lignocellulosic biomass [4].

Cellulase is one of the most important commercial enzymes that is being largely applied in different areas of industry including: biofuel, food, feed, beverages, paper, textile, pharmaceutical and agriculture [5, 6]. Hence, enzyme characterization and purification of cellulase producing bacteria from different sources with high catalytic activity and stability will be an important objective for many researchers due to importance of this enzyme in industry [7].

In general, xylophagous insects are capable of decomposing wood by producing their endogenous digestive enzymes and their association with fungi, protozoa and other microorganisms. It has been shown that both insect and microorganisms enzymes participate in lignocellulose degradation [8, 9]. Moreover, the genetic diversity of cellulase encoding gene in insect genome is less than that of symbiotic microorganisms. Thus, it does not allow complete cellulose degradation. It seems that microorganism's cellulase plays an important role in providing energy for xylophagous insects [10]. As a result, it seems that insect gut microbiome's enzymes, especially cellulase, are sources of novel enzymes with potential use in biotechnology [11].

The leopard moth, Zeuzera pyrina L. (Lepidoptera: Cossidae), is one of the most destructive wood borer pests. It is widely distributed all over the world and it can affect many tree and shrub species. Mature insects usually oviposit in young tree shoots. However, newly hatched larvae penetrate branches and feed on the wood. Then they gradually attack the larger branches and the trunk and feed themselves for two or three years until they reach maturity [12]. The extreme alkaline pH of the leopard moth midgut (pH range of 10–11) causes severely harsh conditions that leads special microorganism to harbor in it [11]. This way it will establish a new source of cellulolytic bacteria. The present study is designed to isolate cellulolytic bacteria from leopard moth gut and obtain the biochemical characterization of the cellulase enzyme.

Materials and Methods

Bacteria Isolation from Digestive Tract of Leopard Moth

Early larval ages of Zeuzera pyrina were collected from the infected branches of walnut orchards located in the Saman County of the Chaharmahal and Bakhtiari Provinces in the West of Iran. Whole digestive tracts were isolated in sterile conditions under a UV laminar flow hood, and individual gut was transferred to 200 μl sterile PBS (50 mM) buffer pH 7.

Screening of Cellulolytic Bacteria

The isolated guts were homogenized and spread on nutrient agar and LB agar plates. The inoculated plates were incubated for 7 days at 27 °C and 37 °C. For screening of cellulolytic bacteria, isolated strains were cultured on solid M-II medium which contained 0.5% (w/v) of CMC [13]. Cellulase activity zones were observed by plate staining with 0.1% (v/v) solution of Congo red for 15 min and de-stained in 1 M NaCl for 20 min [14]. The strains with high clearance zone of cellulase activity were used to determine the biochemical reactions of bacteria including gram staining [15], catalase and oxidase activity tests [16], Tween 80 hydrolysis test, carbohydrate fermentation test (lactose, glucose and maltose) and hydrogen sulfide (H2S) production test [17]. For cellulase activity assay, 0.150 mL of culture broth supernatant was added to 0.250 mL of 50 mM PBS buffer (pH 7.0) containing 1% (w/v) of CMC as substrate. The resulting mixture was incubated at 35 °C for 1 h. The amount of reducing sugar that released during the enzyme activity was determined by the dinitrosalicylic acid (DNS) method [18]. One unit of cellulase activity has been defined as the amount of enzyme which can release 1 μmol of reducing sugar per min under assay conditions.

Identification of Isolated Bacteria

Selected strain's Genomic DNA was extracted by DNA extraction kit (CinnaGen`, Tehran) based on the manufacturer’s instructions. Partial 16S rRNA genes were amplified from genomic DNA using the general primers 27F and 1492R in a Bio-Rad Mycycler Thermal cycler (Hercules, USA) [19]. DNA sequencing was performed at the Bioneer Biotechnology Company (Seoul, South Korea).

Optimization of Bacterial Culture Medium

In this experiment, M-II was used as a basal culture medium and optimization was performed using the single-valued method such that each factor was separately examined in various levels of each test. The factors included nitrogen sources (1% w/v): ammonium chloride, peptone, ammonium sulfate, urea and yeast extract; carbon sources (1% w/v): maltose, lactose, fructose, glucose and sucrose; different values of CMC (0–2% w/v); temperature (20–40 °C); various pH (5.0–10.0); and several amount of inoculums (1–5% v/v).

Purification of Enzyme

The bacteria was grown under optimal conditions for cellulase enzyme production and culture broth was centrifuged at 12,000×g for 20 min at 4 °C. The supernatant was precipitated with 85% (w/v) ammonium sulfate. The overnight resulting precipitations were collected by centrifugation for 20 min at 12,000×g (4 °C). Then, the produced pellet was dissolved in a slight amount of 20 mM Tris–HCl buffer (pH 8.0) and dialyzed against huge amount of the same buffer. For the final purification step of the enzyme, protein loading on a Q-sepharose column which was pre-equilibrated with 20 mM Tris–HCl buffer (pH 8.0). Fractions were collected by washing the column with linear gradient of NaCl (0.1—1 M) in Tris–HCl buffer (pH 8). Then, all of fraction was monitored for protein concentration at 280 nm and cellulase activity. Protein concentration was measured according to the Bradford method using bovine serum albumin as standard protein [20].

Polyacrylamide Gel Electrophoresis and Native Page

The concentrated cellulase fraction was loaded on 12% and 5% (w/v) separating and stacking sodium dodecyl sulfate–polyacrylamide gel (SDS-PAGE), respectively, to measure the molecular weight of the purified enzyme. For zymogram analysis, non-denaturing polyacrylamide gel electrophoresis was done on 12% (w/v) separating gel containing 1% CMC. Electrophoresis resulting gel was washed with Triton 100-X and floated in 20 mM Tris–HCl buffer (pH 8) at 30 °C for 4 h. The cellulase activity band was seen as a clear zone against background by staining the gel with 0.1% Congo red and de-staining it with 1 M NaCl.

pH and Temperature Effect on Cellulase Activity and Stability

Broad-range buffering systems containing 50 mM of each buffer were used: acetate (pH 4.0–6.0), sodium phosphate (pH 7.0–8.0), Tris/HCl (pH 8.0–9.0) and glycine–NaOH (pH 9.0–10.0) to determine the optimum pH for cellulase activity. Moreover, the enzyme reaction mixture without substrates was incubated at different pH buffers systems as above before at 4 °C for 1 h to determine pH stability. Subsequently, enzyme's residual activity was measured at standard conditions.

Optimal temperature of cellulase activity was calculated at different temperatures ranged from 20 to 80 °C, with 10 degree intervals. Thermal stability was studied by incubating the enzyme without substrates at different temperatures from 20 to 80 °C for 1 h. Subsequently, the residual activity of the purified enzyme was determined at standard conditions.

The Effect of Organic Solvents, Metal Ions and Inhibitors on Cellulase Activity

The effect of 2.5, 5, and 10 mM concentration of metal ions/organic solvents/inhibitors which include, FeCl3, CaCl2, MgCl2, KCl, MnCl2, BaCl2, NaCl, CoCl2, ZnCl2, NiCl2, beta mercaptoethanol and ammonium persulfate, 10 and 20% (v/v) concentration of acetone, n-butanol, toluene, diethyl ether, triton, isopropanol, ethanol, methanol and hexane and 0.5 and 1% (v/v) concentration of tween was determined. The effect of sodium dodecyl sulfate (SDS), hydrogen peroxide (H2O2), cetyl trimethylammonium bromide (CTAB) was also measured by adding them to the purified enzyme reaction mixture at 4 °C for 1 h. Subsequently, residual activity was measured in standard enzyme assay conditions. Cellulase activity in the absence of any additives was considered as 100% activity.

Kinetic Parameters

The kinetic parameters (Vmax and Km) of the purified cellulase for CMC as a substrate were measured using the Michaelis–Menten equation. The kinetic constants of cellulase were measured using the GraphPad Prism 6 software.

Substrate Specificity

In this case, 0.250 ml of each substrate solution (1% w/v) including cellulose, Avicel and CMC in 50 mM Tris–HCl buffer (pH 8) was mixed with 0.150 ml of the purified enzyme solution. Then the mixture was incubated at 60 °C for 60 min and finally enzyme activity was determined by the DNS method.

Thin-Layer Chromatography of Enzyme Hydrolysis Products

Enzymatic action of cellulase on CMC substrate at times 6, 12, and 24 h in standard enzyme assay conditions was analyzed using thin-layer chromatography (TLC) with a slight modification [21].

Results

According to the results of the cellulase screening approach on CMC plates, only 4 strains including Ac4, Bc1, Bc8 and Dc4 showed cellulolytic activity from among all purified isolates. The biochemical characteristics and cellulase activity of the isolated strains are shown in Table 1. Strain Bc1 with 0.42 (U/ml) catalytic activity showed the highest cellulase activity and was selected for further analysis.

Sequence Analysis

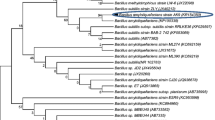

Partial 16S rRNA sequence of isolated strain was deposited in NCBI GenBank database under MN658389 accession number. Based on 16S rRNA sequence analysis and biochemical tests, strain BC1 was identified as Bacillus subtilis with more than 98% homology with Bacillus subtilis subsp. spizizenii.

Culture Optimization for Cellulase Production

Based on the results, it was revealed that 1% (w/v) of maltose, 1% (w/v) of yeast extract, 1.5% (w/v) of CMC, pH 8, 2% (v/v) of inoculums size and temperature of 35 °C are the most effective factors for cellulase producing by B. subtilis BC1 (Table 2).

Enzyme Purification and Molecular Weight Determination

The optimal broth culture supernatant had 6.25 U/mL activity, 1.56 mg/mL protein, 1877.04 U/mL total activity, 469.83 mg total protein and 4 U/mg specific activity. The whole culture medium (500 mL) was precipitated using 85% ammonium sulfate salt and this improved enzyme specific activity to 4.29 U/mg. Subsequently, enzyme specific activity was increased to 10.86 U/mg with 2.72-fold purification in the final purification step of enzyme using Q-sepharose ion-exchange chromatography (Table 3). The molecular weight of purified enzyme on SDS-PAGE is about 47.8 kDa as shown in Fig. 1. Moreover, zymography results of β-1,4-glucanase show a single activity band on native PAGE.

pH and Temperature Effect on Cellulase Activity and Stability

The effect of pH value (4–10) on activity and stability of purified enzyme is shown in Fig. 2a. The results indicated that the highest enzyme activity is observed at pH 8. The results also indicate that enzyme has a broad range of pH stability from 4 to 10 and after treatment at pH values ranging from 4 to 10 it maintains 75% of its own activity.

The optimal temperature for purified cellulase activity was 60 °C as shown in Fig. 2b. The results demonstrated that enzyme was very stable at temperatures between 20 and 60 °C since it maintained 100% of its activity after 60 min of incubation. Moreover, more than 74% of cellulase activity remained at temperatures between 60 and 80 °C.

The Effect of Various Metal Ions, Organic Solvents and Inhibitors on the Enzyme Activity

Purified cellulase enzyme can be completely active in all concentrations of organic solvents as shown in Fig. 3a. The results showed that in the presence of 20% (v/v) of acetone, enzyme activity was increased. Among the metal ions which were evaluated, MnCl2 and NiCl2 decreased enzyme activity, whereas CaCl2 and CoCl2 increased enzyme activity. In addition, FeCl3, KCl, MgCl2, BaCl2, NaCl and ZnCl2 had no significant effect on enzyme activity (Fig. 3b). CTAB and H2O2 completely inhibited enzyme activity as shown in Fig. 3c.

Enzyme Kinetics

Kinetic parameters of the purified cellulase toward CMC were determined according to the Michaelis–Menten plots. Km and Vmax values of the enzyme were found to be 1.243 mg/mL and 271.3 µg/mL/min, respectively.

Substrate Specificity and Thin-Layer Chromatography

The purified cellulase showed the highest activity of 0.77a ± 0.001 (U/mg) in the presence of cellulose as substrate, whereas the enzyme activities toward avicel and CMC were 0.72b ± 0.001 and 0.69c ± 0.002 (U/mg), respectively. Thin-layer chromatography (TLC) results after 12 h and 24 h incubation revealed that cellobiose was the final hydrolytic product of the purified cellulase toward a CMC as substrate (Fig. 4). This indicates exo and endoglucanase activities of the B.subtilis BC1 cellulase.

Discussion

Insects are the most tolerant group of multicellular organisms that live in various conditions along with many microorganisms present in their gut [22]. Among all microorganisms, bacterial population which live in insect guts play a fundamental role in efficient digestion of woody material by producing various cellulolytic and ligninolytic enzymes [11]. Research studies have shown that Proteobacteria and Firmicutes are common phyla in insect gut [23]. Manfredi et al. indicated that Firmicutes and especially Bacillus genus is the prevalent bacteria that degrades cellulose in many insect families in Northwest of Argentina [24]. In the present study, cellulolytic strain B. subtilis BC1 was isolated from the gut of leopard moth and subsequently cellulase enzyme was purified and characterized for the first time. Bacillus sp. belonging to the gram-positive groups firmicutes with cellulolytic activity have also been reported in other lepidopteran insects previously [25, 26]. Furthermore, B. subtilis is a common cellulolytic strain in xylophagous termite gut [27, 28].

The 16S sequence of this strain was highly similar (more than 98% identity) to Bacillus subtilis subsp. spizizenii strain Cpl13 (accession number: MN960275) isolated from Calotropis procera leaf and also with Bacillus halotolerans strain af-M9 (accession number: MN512294) which has been isolated from honey bee gut. On the base of biochemical tests and morphological characters, this strain was identified as Bacillus subtilis.

The results of this study showed that the molecular mass of purified cellulase is 47.8 kDa that is close to the molecular mass of another cellulase reported from B. subtilis strain that is 46 kDa [29]. B. subtilis YJ1 and B. subtilis UMC7 have shown different hydrolysis bands corresponding to 32.5 kDa and 56 kDa [27, 30].

In the current study, the results of optimal pH for purified cellulase activity (pH 8) was completely similar to β1,4-glucanases isolated from gut bacteria of other insects.[26, 31, 32]. It should be mentioned that optimal pH for enzyme activity of some strains such as B. pumilus MGB05 and B. subtilis UMC7 isolated from silk worm midgut and termite Macrotermes malaccensis gut, respectively, is less than 8 [25, 27]. Since purified cellulase activity can be recovered after exposure to a wide range of pH values (4 to 10), this enzyme can possibly be applied in different industrial applications.

The results showed that cellulase of B. subtilis isolated from gut of leopard moth has an optimum temperature activity at 60 °C that is similar to those reported for other cellulase from B. subtilis [27, 30, 33]. As reported, the purified cellulase was stable in a wide range of temperatures. Thereby, this enzyme can be employed as a heat-resistant enzyme in many industrial applications, particularly in bioethanol production.

Moreover, it was observed that the cellulase of B. subtilis BC1 is completely stable in the presence of all organic solvents tested in the present research study and some organic solvents such as acetone (20% v/v) even enhance enzyme activity. Organic solvent tolerant cellulases have many industrial applications such as bioremediation of carbohydrate-polluted salt marshes and treatment of industrial waste water contaminated with organic solvents [34]. Enzyme activity enhanced by organic solvents might be due to residues of carried-over non-polar hydrophobic solvents which provide an interface and thus keep the enzyme in an open conformation which results in stimulated activation [35]. Thus, organic solvent stability of the purified cellulase indicates that this enzyme can be used in the industry under harsh conditions.

In current study, cellulase retained 79.9, 121.0, and 28.04% activity in the presence of Tween 20 (1%v/v), Triton X-100 (20% v/v) (non-ionic surfactant) and SDS (anionic surfactant), respectively. Alkalophilic cellulase from B. halodurans CAS 1 in contrast to cellulase from B.subtilis BC1 of the leopard moth had more and low tolerance to SDS and Triton X-100 (84.33% and 68%), respectively [34]. It seems that purified cellulase is non-ionic surfactant tolerant enzyme and it can be used in detergent industry dealing with cellulases.

Purified cellulase activity has been stimulated with Ca2+ and most frequently similar results have been reported for Bacillus strains [34, 36,37,38]. The presence of Ca2+ ions may enhance the substrate binding affinity of the enzyme by stabilizing the conformation of the catalytic site [27]. Based on the results obtained in this study the purified cellulose activity is inhibited by Mn2+ and Ni2+ and stimulated with Co2+. Gaur and Tiwari reported that cellulase activity from Bacillus vallismortis RG-07 was slightly inhibited by Ni2+, whereas it was severely inhibited in the presence of Mn2+ [37]. Annamalai et al. indicated that Mn2+ can enhance but Co2+ inhibits cellulase activity from Bacillus halodurans CAS 1 [34]. Similarly, Co2+ had also inhibitory effect on cellulase activity from Bacillus sp. AC-1 [39].

The purified cellulase significantly exhibited high activity toward cellulose, avicel and CMC. Therefore, this enzyme was able to efficiently hydrolyze both amorphous cellulose (CMC and cellulose) and crystalline cellulose (avicel) by simultaneous assistance of exo and endoglucanases activity [40]. Annamalai et al. isolated cellulase which had only endoglucanase activity and did not hydrolyze cellulose and avicel, while cellulase from yak rumen metagenome and Thermobifida halotolerans YIM 90,462 exhibited both endo and exoglucanase activities and a broad substrate specificity [41, 42]. In general, the enzyme which was introduced in this study has high affinity toward crystalline cellulose that can be a very strong candidate for efficient saccharification of lignocellulosic biomass.

The results of TLC Analysis showed that cellobiose is a final hydrolyze product of purified cellulase on CMC as substrate. This confirms the exoglucanase activity of the purified enzyme. Exoglucanases has a key role in the solubilization of cellulose which results in crystalline cellulose degradation in both complexed and non-complexed cellulolytic systems [43]. Wu et al. showed that beta-1,4-glucanase from B. subtilis BS‑5 produces a mixture of cellotetraose, cellotriose and cellobiose as the final products of CMC hydrolysis [43]. In other Bacillus strains isolated from rosaceae branch borer beetles and termites, the main product of CMC hydrolysis is cellobiose [13, 38].

In conclusion, a novel cellulase has been purified from B. subtilis BC1 of the leopard moth gut bacteria in this research study for the first time. This enzyme exhibited high thermostability, acidic and alkaline tolerance and organic solvent compatibility that make it an appropriate option for biotechnological processes and industrial applications. Since B. subtilis BC1 cellulase is an alkaline enzyme, it seems that future studies should be focused on studying amino acid sequence of the enzyme to better understand the activity mechanism of enzyme at high pH and also determination of 3D-structure of enzyme for further biotechnological approaches. Moreover, designing of a tailored-made enzyme to stable under extreme industrial conditions.

Abbreviations

- CMC:

-

Carboxymethyl cellulose

- CTAB:

-

Cetyl trimethylammonium bromide

- DNS:

-

Dinitrosalicylic acid

- NCBI:

-

National center for biotechnology information

- PCR:

-

Polymerase chain reaction

- SDS-PAGE:

-

Sodium dodecyl sulfate–polyacrylamide gel

- TLC:

-

Thin-layer chromatography

References

Ohkuma M (2003) Termite symbiotic systems: efficient bio-recycling of lignocellulose. Appl Microbiol Biotechnol 61(1):1–9

Sindhu R, Binod P, Pandey A (2016) Biological pretreatment of lignocellulosic biomass–An overview. Bioresour Technol 199:76–82

Zhou H, Guo W, Xu B, Teng Z, Tao D, Lou Y, Gao Y (2017) Screening and identification of lignin-degrading bacteria in termite gut and the construction of LiP-expressing recombinant Lactococcus lactis. Microb Pathog 112:63–69

Cortes-Tolalpa L, Salles JF, van Elsas JD (2017) Bacterial synergism in lignocellulose biomass degradation—Complementary roles of degraders as influenced by complexity of the carbon source. Front Microbiol 8:1628

Knowles J, Lehtovaara P, Teeri T (1987) Cellulase families and their genes. Trends Biotechnol 5(9):255–261

Singh R, Kumar M, Mittal A, Mehta PK (2016) Microbial cellulases in industrial applications. Ann appl Biosci 3(4):23–29

Trivedi N, Reddy C, Lali A (2016) Marine microbes as a potential source of cellulolytic enzymes. Advances in food and nutrition research. Elsevier, Amsterdam, pp 27–41

Engel P, Moran NA (2013) The gut microbiota of insects–diversity in structure and function. Fems Microbiol Rev 37(5):699–735

Tartar A, Wheeler MM, Zhou X, Coy MR, Boucias DG, Scharf ME (2009) Parallel metatranscriptome analyses of host and symbiont gene expression in the gut of the termite Reticulitermes flavipes. Biotechnol Biofuels 2(1):25

Lo N, Tokuda G, Watanabe H (2010) Evolution and function of endogenous termite cellulases. Biology of termites: a modern synthesis. Springer, New York, pp 51–67

Prasad RK, Chatterjee S, Sharma S, Mazumder PB, Vairale MG, Raju PS (2018) Insect gut bacteria and their potential application in degradation of lignocellulosic biomass: a review. Bioremediation: applications for environmental protection and management. Springer, New York, pp 277–299

Salari E, Karimi J, Sadeghi-Nameghi H, Hosseini M (2015) Efficacy of two entomopathogenic nematodes Heterorhabditis bacteriophora and Steinernema carpocapsae for control of the leopard moth borer Zeuzera pyrina (Lepidoptera: Cossidae) larvae under laboratory conditions. Biocontrol Sci Technol 25(3):260–275

Hatefi A, Makhdoumi A, Asoodeh A, Mirshamsi O (2017) Characterization of a bi-functional cellulase produced by a gut bacterial resident of Rosaceae branch borer beetle, Osphranteria coerulescens (Coleoptera: Cerambycidae). Int J Biol Macromol 103:158–164

Wood PJ, Erfle JD, Teather RM (1988) Use of complex formation between Congo Red and polysaccharides in detection and assay of polysaccharide hydrolases. Methods Enzymol 160:59–74

Murray R (1994) Determinative and cytological light microscopy. Methods for general and molecular bacteriology. American Society for Microbiology, Washington, DC, pp 7–20

Wood WA, Krieg NR (1989) Methods for general and molecular bacteriology. ASM Press, Washington DC

Garrity GM (2012) Bergey's manual of systematic bacteriology volume one: the archaea and the deeply branching and phototrophic bacteria. Springer, New York

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428

Lane DJ, Pace B, Olsen GJ, Stahl DA, Sogin ML, Pace NR (1985) Rapid determination of 16S ribosomal RNA sequences for phylogenetic analyses. Proc Natl Acad Sci 82(20):6955–6959

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72(1–2):248–254

Zhang Z, Xie J, Zhang F, Linhardt RJ (2007) Thin layer chromatography for the analysis of glycosaminoglycan oligosaccharides. Anal Biochem 371(1):118

Bourtzis K, Miller TA (2003) Insect symbiosis. CRC Press, Boca Raton

Yun J-H, Roh SW, Whon TW, Jung M-J, Kim M-S, Park D-S, Yoon C, Nam Y-D, Kim Y-J, Choi J-H (2014) Insect gut bacterial diversity determined by environmental habitat, diet, developmental stage, and phylogeny of host. Appl Environ Microbiol 80(17):5254–5264

Manfredi AP, Perotti NI, Martínez MA (2015) Cellulose degrading bacteria isolated from industrial samples and the gut of native insects from Northwest of Argentina. J Basic Microbiol 55(12):1384–1393

Bhuyan PM, Sandilya SP, Nath PK, Gandotra S, Subramanian S, Kardong D, Gogoi DK (2018) Optimization and characterization of extracellular cellulase produced by Bacillus pumilus MGB05 isolated from midgut of muga silkworm (Antheraea assamensis Helfer). J Asia-Pac Entomol 21(4):1171–1181

Prem Anand AA, Vennison SJ, Sankar SG, Gilwax Prabhu DI, Vasan PT, Raghuraman T, Jerome Geoffrey C, Vendan SE (2010) Isolation and characterization of bacteria from the gut of Bombyx mori that degrade cellulose, xylan, pectin and starch and their impact on digestion. J Insect Sci 10(1):107

Wei KSC, Teoh TC, Koshy P, Salmah I, Zainudin A (2015) Cloning, expression and characterization of the endoglucanase gene from Bacillus subtilis UMC7 isolated from the gut of the indigenous termite Macrotermes malaccensis in Escherichia coli. Eletron J Biotechnol 18(2):103–109

Ratnadewi AAI, Santoso AB, Sulistyaningsih E, Handayani W (2016) Application of cassava peel and waste as raw materials for xylooligosaccharide production using endoxylanase from Bacillus subtilis of soil termite abdomen. Procedia Chem 18:31–38. https://doi.org/10.1016/j.proche.2016.01.007

Siu-Rodas Y, de los Angeles Calixto-Romo M, Guillén-Navarro K, Sánchez JE, Zamora-Briseño JA, Amaya-Delgado L (2018) Bacillus subtilis with endocellulase and exocellulase activities isolated in the thermophilic phase from composting with coffee residues. Rev Argent Microbiol 50(3):234–243

Yin L-J, Lin H-H, Xiao Z-R (2010) Purification and characterization of a cellulase from Bacillus subtilis YJ1. J Mar Sci Techol 18(3):466–471

Nimchua T, Thongaram T, Uengwetwanit T, Pongpattanakitshote S, Eurwilaichitr L (2012) Metagenomic analysis of novel lignocellulose-degrading enzymes from higher termite guts inhabiting microbes. J Microbiol Biotechnol 22(4):462–469

Fagbohunka B, Okonji R, Adenike AZ (2016) Purification and characterization of cellulase from termite Ametermes eveuncifer (Silverstri) soldiers. Int J Biol 9(1):1

Zi-Zhong T, Zhen-Fang W, Hui C, Xin L, Xue-yi H, Qi W (2013) Characterization of novel EGs reconstructed from Bacillus subtilis endoglucanase. Appl Biochem Biotechol 169(6):1764–1773

Annamalai N, Rajeswari MV, Elayaraja S, Balasubramanian T (2013) Thermostable, haloalkaline cellulase from Bacillus halodurans CAS 1 by conversion of lignocellulosic wastes. Carbohyd Polym 94(1):409–415

Zaks A, Klibanov AM (1988) Enzymatic catalysis in nonaqueous solvents. J Biol Chem 263(7):3194–3201

Zafar M, Ahmed S, Khan MIM, Jamil A (2014) Recombinant expression and characterization of a novel endoglucanase from Bacillus subtilis in Escherichia coli. Mol Biol Rep 41(5):3295–3302

Gaur R, Tiwari S (2015) Isolation, production, purification and characterization of an organic-solvent-thermostable alkalophilic cellulase from Bacillus vallismortis RG-07. BMC Biotechnol 15(1):19

Javaheri-Kermani M, Asoodeh A (2019) A novel beta-1, 4 glucanase produced by symbiotic Bacillus sp. CF96 isolated from termite (Anacanthotermes). Int J Biol Macromol 131:752–759

Li Y-H, Ding M, Wang J, Xu G-j, Zhao F (2006) A novel thermoacidophilic endoglucanase, Ba-EGA, from a new cellulose-degrading bacterium, Bacillus sp. AC-1. Appl Microbiol Biotechnol 70(4):430–436

Han SJ, Yoo YJ, Kang HS (1995) Characterization of a bifunctional cellulase and its structural gene The cel gene of Bacillus sp. D04 has exo-and endoglucanase activity. J Biol Chem 270(43):26012–26019

Bao L, Huang Q, Chang L, Zhou J, Lu H (2011) Screening and characterization of a cellulase with endocellulase and exocellulase activity from yak rumen metagenome. J Mol Catal B 73(1–4):104–110

Zhang F, Zhang X-M, Yin Y-R, Li W-J (2015) Cloning, expression and characterization of a novel GH5 exo/endoglucanase of Thermobifida halotolerans YIM 90462T by genome mining. J Biosci Bioeng 120(6):644–649

Wu B, Zheng S, Pedroso MM, Guddat LW, Chang S, He B, Schenk G (2018) Processivity and enzymatic mechanism of a multifunctional family 5 endoglucanase from Bacillus subtilis BS-5 with potential applications in the saccharification of cellulosic substrates. Biotechnol Biofuels 11(1):20

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dehghanikhah, F., Shakarami, J. & Asoodeh, A. Purification and Biochemical Characterization of Alkalophilic Cellulase from the Symbiotic Bacillus subtilis BC1 of the Leopard Moth, Zeuzera pyrina (L.) (Lepidoptera: Cossidae). Curr Microbiol 77, 1254–1261 (2020). https://doi.org/10.1007/s00284-020-01938-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-020-01938-z