Abstract

Different wound dressings with antibacterial property have been surveyed and one among them is bacterial cellulose (BC). Since the BC does not have antibacterial property, the biologically produced silver nanoparticles (SNPs) were impregnated into the BC. For the BC production, Hestrin–Schramm broth was used. Formation of the BC was proven by enzymatic hydrolysis. For SNPs production, the bacterial supernatant was treated with AgNO3 and formation of SNPs was monitored through spectrophotometer, TEM and XRD. For impregnation of SNPs into the BC, the cleaned membrane was placed in the bacterial supernatant that contained 1 mmol of AgNO3. The antibacterial assay was done for the BC/SNPs. Enzymatic hydrolysis proved the presence of the BC. Spectrophotometer and XRD results showed the formation of SNPs. TEM analysis revealed the presence of SNPs with sizes around 5–100 nm. SEM micrographs showed the impregnation of SNPs into the BC. Antibacterial test exhibited the antibacterial activity of the BC/SNPs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nowadays development of the new wound dressing materials is one of the most attractive areas of researches. Wound dressing materials are produced by different chemical or biological processes and are used for better wound healing [19]. In the past few years, among various procedures of polymer synthesis, the biological one has been used widely because this type of production is simple, and the produced polymer is usually pure. Among different wound dressing materials, bacterial cellulose has a great attraction. Molecular structure of the bacterial cellulose consists of an ultrafine three-dimensional microfibrillar network and has high ability of water maintenance. Moreover, this polymer in its highly swollen status protects the wound against bacteria and many other contaminations. Furthermore, this polymer can preserve the temperature of the wound and can be easily sterilized without any change in its structure [16]. Biological production of cellulose is done by many types of plants and some bacteria. In contrast to plant cellulose, bacterial cellulose (BC) is pure and does not contain any other impurities such as lignin and hemicellulose. This polymer is easily produced by bacteria [3]. Among Gram positive and negative bacterial genera with the ability of cellulose production are Agrobacterium, Aerobacter, Alcaligenes, Achromobacter, Azotobacter, Pseudomonas, Rhizobium, Salmonella, and Sarcina [2]. Furthermore, there are two important genera of acetic acid bacteria, Gluconacetobacter, and Acetobacter, which produce high amount of cellulose membrane with applications in medicinal field. However, bacterial cellulose membrane itself does not have any antibacterial properties and it is one of its deficiencies in the medicinal field [30]. So for better activity of this polymer, development of a new generation of bacterial cellulose with antibacterial property is under research. Successful impregnation of the chemically synthesized silver nanoparticles (SNPs) into the BC membrane was done by some researchers [19, 30]. From ancient times, silver was used as the antibacterial factor. Nowadays SNPs are interested as a potential antibacterial item and are used for curing the multiple-drug-resistant infections [32]. SNPs in contrast to their bulk silver metal have better antibacterial property due to their high specific surface area. It is proved that SNPs act on the bacterial cell by several different patterns such as interacting with DNA, cell membrane [23], thiol groups of enzymes, and some important respiratory proteins [4]. These patterns are not well understood, but several reports are available about the contribution of the size of SNPs on their antibacterial efficiency [25].

Impregnation of the chemically synthesized silver nanoparticles is cheap and simple, but one of its deficiencies is the remaining of some chemical ingredients after completion of the reaction on the surface of the nanoparticles. This impurity usually has some toxic effects if they are used in vivo [28]. This research is focused on the use of cellulose-producing bacteria with the ability of silver nanoparticles production and impregnation of the synthesized silver nanoparticles into the bacterial cellulose membrane. Finally, the antibacterial property of the produced BC/SNPs was evaluated against some pathogenic bacteria.

Materials and Methods

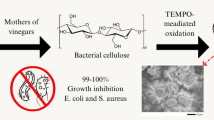

Isolation of Cellulose-Producing Bacteria

Cellulose-producing bacteria were isolated from different food sources such as fruit juices and vinegar. 1 mL of each source was serially diluted by ddH2O and cultured onto the Hestrin–Schramm (HS) agar medium [8]. All plates were incubated at 30 °C for at least 5 days. For BC production, each single colony was transferred into the HS broth medium at 30 °C for 5 days in a static incubator [1].

Identification of Isolated Bacteria

Phenotypic Identification

The BC producing bacteria were identified by various macroscopic and microscopic tests such as colony morphology and Gram reaction, respectively. Other phenotypic tests were performed according to Bergey’s manual of systematic bacteriology [17].

Genotypic Identification

DNA was extracted by the phenol–chloroform extraction method previously described by Katzwinkel-Wladarsch et al. [12]. Polymerase Chain Reaction (PCR) primers that were used in this study amplified partial sequence of the 16S rDNA. These primers were 63F (5′CAGGCCTAACACATGCAAGTC3′) as the forward and 1389R (5′ACGGGCGGTGTGTACAAG3′) as the reverse ones [21]. PCR was performed in the conditions that previously described by Pourali and her colleagues [24, 31]. The optimum annealing temperature was attained by gradient PCR from 57 to 65 °C. After that, obtained PCR products were sequenced in one direction by the forward primer. Resulted DNA sequences were examined on the BLASTn program (http://www.ncbi.nlm.nih.gov/BLAST) available on the National Centre for Biotechnology Information (NCBI).

Purification of BC Membrane

The obtained BC membrane contained the former bacteria with other impurities of the culture medium, so in order to purify the BC membrane, the produced membrane was harvested from top of the broth culture and boiled with 1 % NaOH solution for 2 h and ddH2O for another 2 h. This cycle was repeated three times, and finally the BC membrane was thoroughly washed with ddH2O to achieve its natural pH (around 7) [30].

Enzymatic Hydrolysis of BC Membrane

In order to prove the production of the BC membrane by bacteria, each of the purified polymer was dried and undergone the enzymatic hydrolysis. For this aim, 1 mg of the dried BC membrane was suspended in the enzymatic solution contained 0.05 mL of 0.5 U endoglucanase, 0.05 mL of 0.5 U exoglucanase (Sigma-Aldrich, USA), and 0.2 mL of 0.05 M sodium acetate buffer (pH 5.0). Each vial was incubated at 30 °C, 100 rpm for 24 h [9]. After that, the mixture was filtered and the filtrated solution undergone the Molisch’s (for all carbohydrates detection) and Benedict’s (for reducing sugars detection) tests. In the Molisch’s test, two drops of Molisch’s reagent (α-naphthol dissolved in ethanol) were added to 2 mL of the test solution, and after mixing, 1 mL of concentrated sulphuric acid was added. In this test, all carbohydrates reacted positively with this reagent. In Benedict’s test, 2 mL of Benedict’s reagent (AppliChem, USA) and five drops of the test solution were mixed together and heated for 5 min at 95 °C in a water bath. In this test, the presence of reducing sugars was determined [26].

Biosynthesis of Silver Nanoparticles

All the identified and BC producing strains were tested for SNPs production. For this aim, a loop full of each bacterial single colony was transferred into the 50 mL of Nutrient broth (Merck, Germany) medium and was incubated at 30 °C, 150 rpm for 3 days. After the bacterial growth, each sample was centrifuged at 6,000 rpm for 10 min. Then, 50 mL of the obtained supernatant was filtered through 0.45-µm syringe filter (EMD Millipore, USA) and challenged with 50 µL of the 1 molar silver nitrate solution (Sigma-Aldrich, USA) at a final concentration of 1 mmol. All the flasks were incubated at 37 °C, 200 rpm for 24 h. The negative control was the sterile Nutrient broth medium with 1 mmol final concentration of the silver nitrate solution. This flask was also incubated with the others in the same conditions. Production of SNPs was observed through the color change in the filtrated supernatant from yellow to dark brown. Change in the color of the reaction mixture is due to the surface plasmon resonance (SPR) of conducting electron on the surface of silver nanoparticles [27].

Visible Spectral Analysis

In order to prove the bio-production of SNPs, all the color changing filtrated supernatants were analyzed through visible spectrophotometer from 300 to 700 nm wavelengths. The filtrated supernatant without silver nitrate solution was used as a blank [7].

Transmission Electron Microscope (TEM)

Average size and morphology of the extracellular-produced SNPs were determined using Ziess Leo 910 transmission electron microscope operating at 80 kV accelerating voltage and Gatan SC1000 camera [11].

X-ray Diffraction Analysis (XRD)

Freeze-dried filtrated supernatants that contained SNPs were analyzed by Philips automatic X-ray diffractometer with Philips PW 1830 X-ray generator. The diffracted intensities for each sample were recorded from 30° to 80° 2θ angles [27].

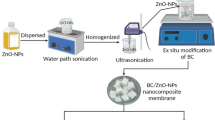

Impregnation of the Bacterial Cellulose Membrane with Biologically Produced Silver Nanoparticles

Each filtrated supernatant was challenged with the silver nitrate solution at the final concentration of 1 mmol. Before incubation, the purified BC membrane was added to each flask. The negative control that contained filtrated supernatant and purified BC membrane without silver nitrate solution was incubated with the others. After that, all the flasks were incubated at 37 °C, 200 rpm for 24 h. Finally, in order to remove excess of the silver nitrate solution, all the color changed BC membranes were washed three times with ddH2O.

Scanning Electron Microscope (SEM)

Micrographs of the freeze–dried BC membrane before and after exposure to the silver nitrate solution were obtained. Each sample was coated with a thin layer of gold and images were taken by Leo VP 1450 scanning electron microscope operating at 15 kV at a magnification of 20 to 300,000× [30].

Antibacterial Assay

An antibacterial test was done on some Gram positive and negative pathogenic bacteria that were obtained from Persian Type Culture Collection (PTCC). Gram positive bacteria were Staphylococcus aureus (PTCC 1113) and Bacillus cereus (PTCC 1015), and Gram negative ones were Escherichia coli (PTCC 1330) and Pseudomonas aeruginosa (PTCC 1310). Each of the bacteria was cultured in the Muller–Hinton broth (Merck, Germany) medium and was incubated at 37 °C, 200 rpm for 24 h. After that each of the pathogenic bacteria was full streaked onto the Mueller–Hinton agar (Merck, Germany) medium and two identical pieces of the cellulose membrane (8 mm in diameter), one with and the other one without SNPs were placed on each culture. All plates were incubated at 37 °C for 24 h. Finally, clear inhibition zones were measured [13, 20].

Results

Isolation of Cellulose-Producing Bacteria

In total 32 different bacterial colonies with ability of the BC membrane production were isolated from the food sources especially from vinegar. Five of them with higher ability of the BC membrane production were identified by the phenotypic and genotypic tests and examined for the silver nanoparticles biosynthesis.

Identification of Isolated Bacteria

Phenotypic Identification

Phenotypic identification revealed that all the strains were Gram negative and no spore forming bacteria that belonged to Pseudomonas, Achromobacter, and Gluconacetobacter genera.

Genotypic Identification

Concentration of the extracted DNA was measured by spectrophotometer and adjusted to 30–35 ng/µL for better PCR performing. Concentrations of the forward and reveres primers were 200 ng/µL and 410 ng/µL, respectively. Results from gradient PCR indicated that the optimum annealing temperature was 59 °C. Obtained PCR products were sequenced in one direction by the 63F primer, and resulted DNA sequences were examined on the BLASTn program. Sequencing results for these five strains are shown in Table 1. As the results show, two strains that were identified by phenotypic method could not identified by genotypic one.

Purification of BC Membrane

Purification of BC membrane was successfully done. Figure 4a shows the BC membrane after purification. Results showed that several rounds of washing and boiling did not induce any changes in the appearance, consistency, and stiffness of the BC gels.

Enzymatic Hydrolysis of BC Membranes

Results for all the enzymatic hydrolysis products showed that after adding of Molisch’s reagent and sulphuric acid into the enzymatic filtrates, red rings appear at the junction of the two liquids that indicated the presence of the carbohydrates in the solutions. In Benedict’s test, after adding of Benedict’s reagent, formation of the orange color indicated the presence of the reducing sugars in the enzymatic filtrates.

Biosynthesis of Silver Nanoparticles

The ability of the SNPs production in the identified BC producing strains was examined. In this step, the filtrated supernatants of Pseudomonas luteola, Pseudomonas sp., and Achromobacter sp. were changed from yellow to dark brown color which indicated the formation of the SNPs.

Visible Spectral Analysis

The obtained visible spectra for the color changed filtrated supernatants proved formation of the SNPs in the solutions. The results indicated that the filtrated supernatants had maximum absorption peaks around 410–450 nm attributed to the surface plasmon resonance band (SPR) of the silver nanoparticles.

Figure 1 shows visible absorption spectra of the filtrated supernatant of all the three identified strains.

Transmission Electron Microscope (TEM)

TEM analysis revealed that the SNPs were spherical in their shapes and their average sizes were around 10–100 nm. Figure 2 shows the TEM images of all the three identified strains.

X-ray Diffraction Analysis (XRD)

XRD results showed the presence of the sharp Bragg peaks at 2θ values of 38.17°, 44.32°, 64.46°, and 77.39°. Obtained patterns proved the presence of the elemental silver in the bacterial filtrated supernatants. Figure 3 indicated the XRD result that was obtained from the filtrated supernatant containing SNPs of P. luteola.

Impregnation of the Bacterial Cellulose Membrane with Biologically Produced Silver Nanoparticles

Production of the BC membrane containing SNPs was successfully done. Results showed that after exposure of the purified BC membranes to the filtrated supernatants that contained a silver nitrate solution at a 1 mmol final concentration, the color of the BC membranes was shifted from pale yellow to dark brown indicated the formation of SNPs in their structures. The BC membranes in the negative controls preserved their yellow color after incubation time. Figure 4 shows the BC membrane before and after the impregnation of SNPs.

Scanning Electron Microscope (SEM)

SEM micrographs of the all three washed and freeze-dried BC membrane before and after impregnation of the SNPs are shown in the Fig. 5. As the results show, in contrast to the control, after impregnation of the SNPs into the BC membranes, SNPs covered the BC surfaces.

Antibacterial Assay

Antibacterial tests indicated that unlike the pure BC membrane, the ones which contained the SNPs had antibacterial activity against both of the Gram positive and negative tested bacteria. The pure BC membranes without SNPs did not have antibacterial activity against all the tested bacterial strains. The results of this assay are shown in Table 2.

Discussion

It is proven that for better wound healing the use of the moist environment is very effective. In recent years, some active wound dressings were introduced. Basically these materials are in the form of gels and hydrogels with water maintenance property. This characteristic will moisture and accelerate the healing of the wounds. One of the wound dressing hydrogels is the bacterial cellulose membrane that has high water maintenance activity with an ultrafine three-dimensional microfibrillar structure and can be sterilized by high temperatures. However, this component itself does not have any antibacterial property to prevent wound infection. So in order to improving the antibacterial effect of the BC membrane, silver nanoparticles (SNPs) or other antibacterial agents were embedded into the BC structure [19].

Previous studies were focused on the production of BC membranes that contained the chemically produced SNPs [19, 30]. Although this method is simple and cheap, but remaining of the chemical procedures on the surface layer of the SNPs and BC membrane usually have some toxic effects. So the use of these types of BC/SNPs has some limitation in the medicinal field [28]. There are also some available reports dealing with the toxic effects of the organic reagents that are applied for synthesis of SNPs on environment. These reports caused the new approach of the green method for nanoparticles and BC synthesis. In this technique, some species of bacteria are used as the small factories for bio-reduction of metal ions into nanoparticles and for production of BC membranes [6].

On this basis, present research is focused on identification of bacteria with the ability of production of both BC membranes and SNPs. In this approach, by the use of biological method of SNPs production, the produced BC/SNPs membrane is pure and does not have any toxic effects regarding to the previous data [14, 15]. For this aim, production of BC and SNPs were performed by some bacterial species in the static and shaker incubators, respectively. After that in order to impregnation of SNPs into BC membrane, the BC membrane was purified and used as a thick layer for impregnation of SNPs. In the first step of this research, 32 different BC producing bacteria were isolated and five of them with the highest production activity were identified. Molecular identification revealed that three of these bacteria belonged to Pseudomonas and Achromobacter genera. Also two of the phenotypic identified bacteria that belonged to the Gluconacetobacter genus were not identified by the molecular method, and they were reported as unknown bacteria.

Purification and enzymatic hydrolysis of BC membrane proved the presence of the thick cellulose membrane on the surface layer of the bacterial culture. Results showed that all the identified bacteria could produce SNPs in their filtrated culture supernatant. The results from spectrophotometer, TEM and XRD analysis, proved the formation of SNPs. As Fig. 1 showed, in contrast to the controls that no absorption peaks were obtained, there were peaks at 410–450 nm corresponding to the presence of the SNPs in the reaction mixtures due to the surface plasmon resonance (SPR) of the SNPs [10]. The TEM images (Fig. 2) showed that SNPs were nearly spherical in their shapes, and the average sizes of them were 5–50 nm. These small sizes are very important for the entrance of the SNPs in the compact structure of the BC membrane. There is available data about the effects of the sizes of nanoparticles on their antibacterial efficiency. Ruparelia et al. [25] in 2011 showed that smaller nanoparticles have better antibacterial activity due to their higher surface area and can penetrate and interact easily with the bacterial cell walls. El-Rafie et al. [5] in 2012 have reported that by the use of smaller SNPs, around 5–10 nm, excellent antibacterial effects were obtained. They showed that smaller sizes of the SNPs are important for their penetration into the molecular structure of wound dressings. They also reported that although SNPs have chemical and physical bonding with the structure of the wound dressing, they do not bind strongly with it. So on the wound, SNPs release slowly and do their antibacterial activity. Figure 5 showed the SEM results of the control and BC membranes containing SNPs. Results from this step showed that the SNPs are attached to the BC structures.

Antibacterial patterns showed that all the SNPs/BC membranes had better antibacterial properties against Gram negative bacteria. Although some available data emphasized the importance of the bacterial cell wall and the Gram reaction in the antibacterial effect of the SNPs [22], this property probably is due to the strain specificity and is not depend on the structure of the bacterial cell wall [25].

It has been shown that bio-reduction of the SNPs happens by certain enzymatic and non-enzymatic process. In the enzymatic one, it is proven that different enzymes are involved in the transporting of the electrons from especial electron donors such as NADH to the silver ions as the electron acceptors [31]. While in the non-enzymatic process, it is shown that some especial functional groups of the organic materials such as carboxyls, amides, aldehydes, and ketones that are in the amino acid residues or in the surface of the cell walls are involved in the non-enzymatic bio-reduction of the silver nanoparticles [19]. It is also proven that some polymers such as chitosan, that is an amine group rich polymer and BC, a hydroxyl group rich membrane, are the other candidates for this non-enzymatic bio-production [6]. So these sites act by attaching the silver ions for non-enzymatic bio-production process [30]. In the present study, impregnation of SNPs into the BC membrane was performed on the basis of the enzymatic and non-enzymatic bio-reduction. For this aim, after purification of the produced BC membrane, the membrane was placed in the filtrated culture supernatant that contained silver nitrate solution. The cleaned membrane was used as an anchoring site for attaching the silver ions, and the filtrated supernatant was used as a reducing agent. Results showed that impregnation of SNPs into the BC membrane was successfully performed and the antibacterial tests revealed that unlike the purified BC membrane, the BC/SNPs had antibacterial activity. It is also reported that the BC membrane itself has functional groups including hydroxyls, ethers, and carboxyls that the cations such as Ag+ were bound to it by the electrostatic interactions [19]. So, the enzymes in the filtrated culture supernatant and the functional groups of the BC membrane are involved in the impregnation of SNPs into the BC membrane.

There are some reports about the effects of the biopolymers containing SNPs on the exposed wound. But in all cases, silver nanoparticles were produced by chemical method. Wiegand et al. [29] in 2009, have studied on the antibacterial and anti inflammatory properties of alginate containing SNPs in chronic wounds. They reported that incorporation of SNPs into alginate gel increased antibacterial and antioxidant activities and improved the binding affinity for elastase and some other proinflammatory cytokines. So, the produced polymer had better wound healing activity. Moreover, Leaper in [18], reported that SNPs dressings reduce infections of open wounds and act as good barriers against cross contaminations. So, further studies are needed for assaying the impact of the BC containing biologically produced SNPs on open wounds.

Conclusions

This was the first report of the impregnation of the biologically produced SNPs into BC membrane due to the selection of bacteria with the ability of production of both SNPs and BC membranes. All the BC containing SNPs had antibacterial property by after washing with ddH2O. So, additional studies are needed on screening of the microorganisms with these two abilities.

References

Carreira P, Mendes JAS, Trovatti E et al (2011) Utilization of residues from agro-forest industries in the production of high value bacterial cellulose. Bioresour Technol 102:7354–7360

Chawla PR, Bajaj IB, Shrikant A et al (2009) Microbial cellulose: fermentative production and applications. Food Technol Biotechnol 47(2):107–124

Cheng K, Catchmark JM, Demirci A (2011) Effects of CMC addition on bacterial cellulose production in a biofilm reactor and its paper sheets analysis. Biomacromolecules 12:730–736

Cho KH, Park JE, Osaka T et al (2005) The study of antimicrobial activity and preservative effects of nanosilver ingredient. Electrochim Acta 51:956–960

El-Rafie MH, Shaheen TI, Mohamed AA et al (2012) Bio-synthesis and applications of silver nanoparticles onto cotton fabrics. Carbohydr Polym 90:915–920

Faramarzi MA, Forootanfar H (2011) Biosynthesis and characterization of gold nanoparticles produced by laccase from Paraconiothyrium variabile. Colloid Surf B 87:23–27

Gericke M, Pinches A (2006) Biological synthesis of metal nanoparticles. Hydrometallurgy 83:132–140

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum II. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58:345–352

Ito F, Amano Y, Nozaki K et al (2004) Hydrolysis of water-soluble and water-insoluble cellulosic substrates by endo-, B-1,4-glucanase from Acetobacter xylinum. Appl Glyeosei 51:297–301

Kasthuri J, Veerapandian S, Rajendiran N (2009) Biological synthesis of silver and gold nanoparticles using apiin as reducing agent. Colloid Surf B 68:55–60

Kathiresan K, Manivannan S, Nabeel MA et al (2009) Studies on silver nanoparticles synthesized by a marine fungus, Penicillium fellutanum isolated from coastal mangrove sediment. Colloid Surf B 71:133–137

Katzwinkel-Wladarsch S, Lieb M, Helse W et al (1996) Direct amplification and species determination of microsporidian DNA from stool specimen. Trop Med Int Health 1:373–378

Kim JS (2007) Antimicrobial effects of silver nanoparticles. Nanomedicine 3:95–101

Kim J, Kwon S, Ostler E (2009) Antimicrobial effects of silver nanoparticles. J Biol Eng 3:20–29

Kiruba Daniel SCG, Tharmaraj V, Anitha Sironmani T et al (2010) Toxicity and immunological activity of silver nanoparticles. Appl Clay Sci 48:547–551

Klemm D, Schumann D, Udhardt U et al (2001) Bacterial synthesized cellulose-artificial blood vessels for microsurgery. Prog Polym Sci 26(9):1561–1603

Krieg NR, Holt JG (1984) Bergey’s manual of systematic bacteriology, 9th edn. Williams & Wilkins, Baltimore

Leaper DJ (2006) Silver dressings: their role in wound management. Int Wound J 3(4):282–294

Maneerung T, Tokura S, Rujiravanit R (2008) Impregnation of silver nanoparticles into bacterial cellulose for antimicrobial wound dressing. Carbohydr Polym 72:43–51

Nanda A, Saravanan M, Hil MP (2009) Biosynthesis of silver nanoparticles from Staphylococcus aureus and its antimicrobial activity against MRSA and MRSE. Nanomed Nanotechnol 5:452–456

Osborn AM, Moore ERB, Timmis KN (2000) An evaluation of terminal-restriction fragment length polymorphism (T-RFLP) analysis for the study of microbial community structure and dynamics. Environ Microbiol 2:39–50

Panacek A, Kvıtek L, Prucek R et al (2006) Silver colloid nanoparticles: synthesis, characterization, and their antibacterial activity. J Phys Chem B 110:16248–16253

Percival SL, Bowler PG, Russell D (2005) Bacterial resistance to silver in wound care. J Hosp Infect 60:1–7

Pourali P, Baserisalehi M, Afsharnezhad S et al (2013) The effect of temperature on antibacterial activity of biosynthesized silver nanoparticles. Biometals 26:189–196

Ruparelia JP, Chatterjee AK, Duttagupta SP et al (2011) Strain specificity in antimicrobial activity of silver and copper nanoparticles. Free Radic Biol Med 363:481–489

Sadasivam S, Balasubramanian T (1985) Practical manual (undergraduate). Tamil Nadu Agricultural University, Coimbatore

Sadhasivam S, Shanmugam P, Yun K (2010) Biosynthesis of silver nanoparticles by Streptomyces hygroscopicus and antimicrobial activity against medically important pathogenic microorganisms. Colloid Surf B 81(1):358–362

Thakkar KN, Mhatre SS, Parikh RY (2010) Biological synthesis of metallic nanoparticles. Nanomed Nanotechnol 6:257–262

Wiegand C, Heinze T, Hipler UC (2009) Comparative in vitro study on cytotoxicity, antimicrobial activity, and binding capacity for pathophysiological factors in chronic wounds of alginate and silver-containing alginate. Wound Repair Regen 17:511–521

Yang G, Xie J, Hong F et al (2012) Antimicrobial activity of silver nanoparticle impregnated bacterial cellulose membrane: effect of fermentation carbon sources of bacterial cellulose. Carbohydr Polym 87:839–845

Zhang H, Li Q, Lu Y et al (2005) Biosorption and bioreduction of diamine silver complex by Corynebacterium. J Chem Technol Biotechnol 80:285–290

Zhou Y, Kong Y, Kundu S et al (2012) Antibacterial activities of gold and silver nanoparticles against Escherichia coli and bacillus Calmette-Guérin. J Nanobiotechnol 10:19–25

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pourali, P., Yahyaei, B., Ajoudanifar, H. et al. Impregnation of the Bacterial Cellulose Membrane with Biologically Produced Silver Nanoparticles. Curr Microbiol 69, 785–793 (2014). https://doi.org/10.1007/s00284-014-0655-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-014-0655-z