Abstract

Malolactic fermentation (MLF) plays an important role in the production of wine, especially red wines, resulting in microbial stability, deacidification, as well as contributing to the aroma profile. MLF can be influenced by a number of factors. In this study, the influence of pH and ethanol on expression of the structural malolactic enzyme gene (mle) from Lactobacillus plantarum was investigated in a synthetic wine media, as well as in wine using quantitative PCR. Expression of mle was shown to be inducible by the presence of malic acid, with increased expression in the middle of MLF. Expression of mle was also shown to be increased at low pH values and decreased in the presence of ethanol. This indicates the role of MLF in acid tolerance and the negative impact of ethanol on the completion of MLF. The results therefore provide further evidence that L. plantarum should be applied as co-inoculation for MLF where alcohol will initially not have a negative impact on the malic acid degradation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The malolactic fermentation (MLF) is a secondary fermentation responsible for the conversion of l-malic acid to l-lactic acid and CO2. It takes place during or after alcoholic fermentation and is carried out by one or more species of lactic acid bacteria (LAB) [1]. The principal LAB genera involved in MLF are Lactobacillus, Leuconostoc, Oenococcus and Pediococcus [19]. Conversion of l-malic acid to l-lactic acid can occur through three possible enzymatic pathways [15]. The pathway generally utilized by the wine LAB is the direct conversion of malic acid to lactic acid by the enzyme malate decarboxylase, also known as the malolactic enzyme [18]. The reaction requires NAD+ and Mn2+ as co-factors and no free intermediates are produced. The second pathway involves the conversion of l-malic acid to pyruvic acid by the malic enzyme, after which the pyruvic acid is reduced to lactic acid by the l-lactate dehydrogenase. Lactobacillus casei and Enterococcus faecalis both possess the malic enzyme [7]. A third pathway exists in Lactobacillus fermentum [10] and involves the reduction of malate to oxaloacetate by malate dehydrogenase, followed by decarboxylation to pyruvate and reduction to lactic acid [19].

The malolactic enzyme (Mle) has been purified from various species of LAB including Lactobacillus spp., Oenococcus oeni and Lactococcus lactis [2], and the mle genes from several of these species have been sequenced [12, 13, 18]. MLF involves active transport of malic acid into the cell, decarboxylation and transport of lactic acid out of the cell [2]. The three genes involved in the malolactic reaction in O. oeni were sequenced and characterized by Labarre et al. [12, 13]. The mleA gene encodes the structural malolactic enzyme, mleP encodes malate permease and mleR encodes a regulatory protein. The malolactic enzyme (MleA) consists of 542 amino acids. The genes are present in a cluster, with mleA and mleP on the same operon and mleR transcribed in the opposite direction [2].

The most important physiological function of MLF for LAB is the generation of a proton motive force, both to drive ATP synthesis via membrane ATPases [7, 10] and to maintain the intracellular pH [3, 7]. MLF is an important step in the winemaking process as it contributes to the de-acidification of wine, microbial stability and has an influence on the aroma profile.

Oenococcus oeni is the species most commonly responsible for MLF in winemaking. This is due to its high tolerance for ethanol, low pH, low temperature and sulphur dioxide (SO2) [19]. One of the most dominant species of lactobacilli occurring throughout the winemaking process is Lactobacillus plantarum and it is currently being considered as the next generation starter culture for MLF [5]. The first L. plantarum starter culture for MLF was released in 2010 by Lallemand Inc, namely V22®.

Several factors are known to influence the growth and metabolic activity of LAB, these include pH, ethanol, temperature, SO2, yeast metabolic products and interactions with yeast, as well as phenolic compounds [5, 6, 11, 15, 24]. The pH of wine from cool climates can range from 2.8 to 3.2, whereas pH of wine produced in warm climates can be as high as pH 3.8 [16]. Wines with a pH of 3.4 or higher are less problematic in terms of LAB growth and survival, as well as MLF. pH levels less than 3.2 have been shown to be inhibitory to the survival of O. oeni [7]. Ethanol concentrations in warm climate wines can be as high as 15% v/v, while that of cool climates is generally around 11% v/v. Very high ethanol concentrations can be inhibitory to MLF and for this reason co-inoculation of yeasts and MLF starter cultures is being considered for high ethanol wines [9, 25]. Concentrations of malic acid in grape must are normally 2–5 g/l in cool viticultural regions, while malic acid concentration in warm climates is generally lower than 2 g/l [7]. MLF is therefore especially important for winemaking in cool climates, where grapes may have high levels of malic acid, in order to reduce the total acidity of the wine.

The aim of this study was to investigate the effect of pH, ethanol and malic acid concentration on expression of the structural mle gene of a wine isolated L. plantarum strain and a commercial L. plantarum strain, in both synthetic wine medium and in wine, using quantitative real-time PCR.

Materials and Methods

Strains and Fermentation Culture Conditions

Lactobacillus plantarum strain 113.1 (collection of the Institute for Wine Biotechnology, Stellenbosch University, South Africa) and L. plantarum R1122 (Lallemand, Toulouse, France) were used to investigate the expression of the malolactic enzyme in wine synthetic media and in wine.

The strains were grown in de Man, Rogosa and Sharpe (MRS) broth (Biolab Diagnostics (PTY) Ltd., Wadeville, Gauteng, South Africa) at 30°C for 2 days before being inoculated into adaptation media (MRS 50 g/l, d(−)-fructose 40 g/l, d(+)-glucose 20 g/l, l(−)-malic acid 4 g/l, Tween 80 1 g/l) at pH 4.6 and 6% v/v ethanol. They were grown to 109 cfu/ml in the adaptation media before being inoculated at 107 cfu/ml into the synthetic wine media [23] with 3.5 g/l l-malic acid, or at 108 cfu/ml into Riesling wine (pH 3.5, 12.5% v/v ethanol, l-malic acid, 2.9 g/l). MLF in the synthetic wine media and the wine was carried out at 20°C. Six different fermentation conditions were used for the synthetic wine media; 0% v/v ethanol at pH 3.2 and pH 3.8, 12% v/v ethanol at pH 3.2 and pH 3.8 and 15% v/v ethanol at pH 3.2 and pH 3.8.

Sequencing of mle Genes

The mle structural gene of L. plantarum strains 113.1 and R1122 was amplified by PCR using the following primers, forward (5′-ATG ACA AAA ACT GCA AGT GA-3′) and reverse (5′-CTA TTT GCT GAT GGC CCG GTA-3′). Total DNA was extracted from 5 ml of L. plantarum cultures grown in MRS broth at 30°C overnight, using the guanidium thiocyanate method as described by Pitcher et al. [21] and as modified by Björkroth and Korkeala [4]. The PCR reactions contained 100 ng of template DNA, 200 μM of deoxynucleotide triphosphate (dNTPs), 25 pMol of each primer, 1× Taq polymerase PCR buffer (Genaxxon, Ulm, Germany) and 1.5 U of Taq DNA polymerase (Genaxxon). The PCR products were amplified in 32 cycles of denaturation at 94°C for 1 min, primer annealing at 54°C for 1 min and extension at 72°C for 1.5 min. PCR products were cleaned using the Peqgold cycle pure kit (Peqlab, Erlangen, Germany) and the purified products were sent for sequencing at GATC Biotech (Constance, Germany), using the PCR primers as described above. Forward and reverse sequences were aligned and assembled using DNASTAR, Inc. software. The DNA sequence was translated and the translated amino acid sequence was aligned with other Mle sequences in the GenBank database.

Monitoring of MLF

The concentration of malic acid in the wine synthetic media and wine was determined using an l-malic acid kit (Roche, Mannheim, Germany) at regular intervals to monitor the degradation of malic acid, and samples were also plated out on MRS plates incubated at 30°C for 2 days to monitor bacterial growth. Samples from the synthetic media intended for RNA extraction were taken midway through MLF and when MLF had been completed. Samples from the wine for RNA isolation were taken on day 2 and day 7 of MLF.

RNA Isolation and Malolactic Gene Expression Using Quantitative Real-Time PCR

Total bacterial RNA from synthetic wine media fermentations was isolated using the nucleic acid extraction protocol by Hoffman and Winston [8] with the following modifications: RNase free water was used where necessary, after adding 1 ml ethanol, nucleic acid was left to precipitate for 30 min and was then spun down for 10 min at 12,000×g. The pellet was then washed with 70% ethanol, dried at room temperature and resuspended in RNase free water.

Total bacterial RNA from wine fermentations was isolated from ca. 1 × 108 cells using the GE RNA Isolation Kit (GE Healthcare, Munich, Germany) and Qiagen RNA protect solution (Qiagen) according to the manufacturer’s instructions. RNA concentration was determined using a NanoDrop ND-1000 spectrophotometer (Peqlab, Erlangen, Germany) at 260 nm. Purity was checked by determining the 260/280 nm ratio and the quality and integrity of the RNA was checked by electrophoresis on a 1.2% denaturing formaldehyde agarose gel. RNA was treated with DNA-free DNAse (Ambion, Darmstadt, Germany) and cDNA was synthesized using the iScript cDNA synthesis kit (Biorad, Munich, Germany) according to manufacturer’s instructions. cDNA was used in quantitative real-time PCR (RT-qPCR) experiments using the iScript One-Step RT-PCR Kit with SYBR Green (BioRad).

For RT-qPCR, the structural malolactic enzyme gene (mle) was amplified with the following degenerate primers, forward (5′-GGG GTG TYM ASG GTG TTG A-3′) and reverse (5′-YTT TTS GTT RTT TGT TCC AGC ATC-3′) and the L. plantarum 16S rRNA housekeeping gene was amplified using the forward (5′-TCA TGA TTT ACA TTT GAG TG-3′) and reverse (5′-GAC CAT GCG GTC CAA GTT GTT-3′) primers. RNA digested with 10 mg/ml RNase at 37°C for 30 min was used to test for DNA contamination. Thermal cycling conditions were as follows: Initial denaturation at 94°C for 2 min, followed by 40 cycles of 94°C for 15 s, 54°C annealing for 20 s and 72°C elongation for 30 s. An additional step starting from 55°C to 94°C was performed to establish a melting curve and verify the specificity of the reaction for each primer pair. RT-qPCR was carried out in a 7500 Real-Time PCR System (Applied Biosystems, Johannesburg, South Africa). Results were analyzed using the comparative critical threshold (ΔΔC T) method [17].

Results

Sequencing of mle Genes

The nucleotide sequences of the malolactic enzyme gene from L. plantarum strains R1122 (accession no. JF421760) and 113.1 (accession no. JF421761) were translated in silico and the protein sequences for strains R1122 and 113.1 were compared to those of L. plantarum JDM1 (accession no. YP_003062506) and WCSF1 (accession no. NP_784797) obtained from the GenBank databank, as shown in Fig. 1. The L. plantarum strain 113.1 Mle protein sequence showed 546 of 547 identical amino acids (99.8%) when compared to the sequence of L. plantarum WCSF1. Thus, the L. plantarum strain WCFS1 possessed a cysteine at position 207, whereas the strains JDM1 and 113.1 had an arginine at this position. The Mle sequences of L. plantarum strains R1122 and JDM1 were 100% identical. The sequences of these two strains furthermore differed from the sequences of strains WCFS1 and 113.1 in that R1122 and JDM1 contained a serine at position 544, while the strains WCFS1 and 113.1 contained an alanine at this position. This is a conserved change, with serine being the hydroxylated version of alanine. The malolactic enzyme consists of 547 amino acids. The theoretical molecular weight and the pI of the different Mle proteins were calculated from the amino acid sequences using the Protean module of Lasergene (version 7) (DNAStar, GATC Biotech, Constance, Germany). The pI values were 4.60 for the Mle of L. plantarum strain WCFS1 and 4.64 for the corresponding proteins from strains JDM1, 113.1 and R1122. The theoretical molecular weights for strains JDM1 and R1122 were identical at 59533.71 Da, while the theoretical molecular weights for the Mle proteins of L. plantarum strains WCFS1 and 113.1 were 59464.67 and 59517.71 Da, respectively.

Expression of the mle Gene in Synthetic Media

Expression of mle was investigated both under the least stressful and the harshest fermentation conditions, i.e. pH 3.8 without ethanol and pH 3.2 with 15% ethanol, respectively, in the middle and at the end of MLF (when all malic acid had been consumed, as shown in Fig. 2), for both L. plantarum 113.1 and L. plantarum R1122 strains, with the end of MLF being the reference condition.

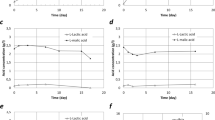

For both conditions and for both strains, expression in the middle of MLF, when malic acid concentration was approximately 1.75 g/l, was higher than when compared to the end of MLF, when all of the malic acid had been consumed (Fig. 3).

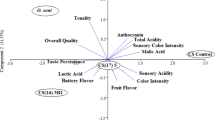

The two conditions (pH 3.8 without ethanol and pH 3.2 with 15% v/v ethanol) were also compared to each other, with pH 3.2 with 15% v/v ethanol being the reference condition, and it was found that expression of the mle gene was lower at pH 3.8 without ethanol (Fig. 4). This trend was observed for both strains in the middle of MLF and at the end.

The experiment was repeated for L. plantarum R1122 under the conditions of pH 3.2 with 0% v/v ethanol, pH 3.2 and pH 3.8 with 12% v/v ethanol and pH 3.2 and pH 3.8 with 15% v/v ethanol. A similar trend was revealed for relative expression of mle in the middle of MLF compared with expression at the end of MLF. The conditions pH 3.8 with 12% v/v ethanol and pH 3.2 and 3.8 with 15% v/v ethanol showed at least a twofold increased expression in the middle of MLF (Fig. 5) when compared to the end of the MLF.

Relative expression between all six fermentation conditions was compared, and for this the condition pH 3.2 and 0% v/v ethanol served as the control condition, against which the other five were compared. Relative mle gene expression was decreased for all fermentation conditions in both the middle and the end of MLF (Fig. 6) when compared to the control condition. Although the expression does not strictly correlate with the rate of MLF (Fig. 2), the condition where MLF took the longest to complete (pH 3.8 with 15% v/v ethanol) correlates with the lowest gene expression.

MLF and mle Expression in Wine

Lactobacillus plantarum strain R1122 completed MLF within 2 days in the wine, while L. plantarum 113.1 took longer as malic acid was completely degraded when measured again at day 7 (Fig. 7).

The relative expression of the mle gene was almost four-fold higher on day 2 for L.plantarum strain 113.1, and almost 25-fold for L. plantarum R1122, when compared to expression levels of this gene the end of MLF (day 7), when all the malic acid had been consumed (Fig. 8).

Discussion

Comparison of the most stressful condition (pH 3.2 and 15% v/v ethanol) and the mildest condition (pH 3.8 and 0% v/v ethanol) indicated that gene expression was decreased under the mildest condition (Fig. 4). This would suggest that stress conditions enhance mle expression; however, it was not possible to determine whether the ethanol or the low pH was responsible for this effect. To determine this, further experiments on the remaining five conditions (pH 3.2 without ethanol, pH 3.2 and 3.8 with 12% v/v ethanol and pH 3.2 and 3.8 with 15% v/v ethanol) showed that the pH 3.2 without ethanol condition resulted in the highest level of mle gene expression, with increasing ethanol concentrations resulting in a decrease in mle gene expression (Fig. 6). However, mle gene expression at the pH 3.8 conditions was always lower than at the corresponding pH 3.2 condition. It therefore appears that ethanol has a negative influence on mle gene expression, while low pH has a positive influence, despite the fact that both ethanol and low pH have been described as having a negative effect on the growth and metabolic activity of LAB [6, 15, 20, 22, 24]. A study by Beltramo et al. [3] on the stress response of O. oeni in a wine-like medium showed that acidic pH (pH 3.5 compared to pH 5.3) resulted in increased mle expression, which correlates with our findings. This increase in mle expression in acidic medium could be linked to the fact that MLF plays a role in the regulation of the intracellular pH, giving the LAB a biological advantage under acid stress conditions. Lemme et al. [14] also reported that the mle genes from Streptococcus mutans are under the control of acid inducible promoters, indicating that they play a role in the early acid stress response. In the study by Beltramo et al. [3], the presence of ethanol also increased mle gene expression, although the temperature differed between the experiments, and this could also have an influence on the gene expression levels.

The malolactic enzyme has been reported as being inducible by l-malic acid [18] and Arthurs and Lloyd [1] showed addition of l-malic acid resulted in increased malolactic activity for Lactobacillus collinoides. The results of this study support these findings. Comparison of the relative expression levels of the mle gene at the two different time-points indicates the correlation between malic acid concentration and gene expression levels. This trend is seen in the synthetic wine media, where mle expression at the end of MLF is much lower than in the middle and this was also observed for the wine.

MLF is known to be influenced by a large number of factors, and this study has given an indication of the effect of pH, ethanol and malic acid concentration at the gene expression level. Presence of malic acid, as previously described, results in an increase in mle expression. This could be of practical relevance in that it might mean that MLF may not proceed to completion in wines with very low levels of malic acid. Low pH levels seem to increase expression of mle, while increased ethanol concentration seems to decrease the mle gene expression. It has already been established that MLF is hampered by high ethanol concentrations [6, 24] and the decrease in the mle gene expression could be one of the reasons for this.

In conclusion, the results further support the strategy of co-inoculation of L. plantarum for MLF, as the MLF is most affected by ethanol. As the fermentation proceeds, the increasing ethanol concentrations and increasing pH thus lead to a decrease in mle gene expression. Inoculation with L. plantarum starter culture at the end of the alcoholic fermentation would thus probably lead to an inefficient malic acid removal. The mle gene would, however, be most active under low ethanol conditions at the beginning of the fermentation, and probably lead to more efficient malic acid consumption when co-inoculated with the yeasts early in the fermentation.

References

Arthurs CE, Lloyd D (1999) Kinetics, stereospecificity, and expression of the malolactic enzyme. Appl Environ Microbiol 65:3360–3363

Bartowsky EJ (2005) Oenococcus oeni and malolactic fermentation—moving into the molecular arena. Aust J Grape Wine Res 11:174–187

Beltramo C, Desroche N, Tourdot-Maréchal R et al (2006) Real-time PCR for characterizing the stress response of Oenococcus oeni in a wine-like medium. Res Microbiol 157:267–274

Björkroth J, Korkeala H (1996) Evaluation of Lactobacillus sake contamination in vacuum-packaged sliced cooked meat products by ribotyping. J Food Prot 59:398–401

du Toit M, Engelbrecht L, Lerm E, Krieger-Weber S (2010) Lactobacillus: the next generation of malolactic fermentation starter cultures—an overview. Food Bioprocess Technol. doi:10.1007/s11947-010-0448-8

Gockawiak H, Henschke PA (2003) Interaction of pH, ethanol concentration and wine matrix on induction of malolactic fermentation with commercial ‘direct inoculation’ starter cultures. Aust J Grape Wine Res 9:200–209

Henick-Kling T (1993) Malolactic fermentation. In: Fleet GH (ed) Wine microbiology and biotechnology. Harwood Academic Publishers, Chur, Switzerland, pp 289–326

Hoffman CS, Winston F (1987) A ten-minute DNA preparation from yeast efficiently releases autonomous plasmids for transformation of Escherichia coli. Gene 57:267–272

Jussier D, Morneau AD, Mira de Ordũna R (2006) Effect of simultaneous inoculation with yeast and bacteria on fermentation kinetics and key wine parameters of cool-climate Chardonnay. Appl Environ Microbiol 72:221–227

Konings WN (2002) The cell membrane and the struggle for life of lactic acid bacteria. Antonie van Leeuwenhoek 82:3–27

Kunkee RE (1991) Some roles of malic acid in the malolactic fermentation in wine making. FEMS Microbiol Lett 88:55–72

Labarre C, Divies C, Guzzo J (1996) Genetic organization of the mle locus and identification of a mleR-like gene from Leuconostoc oenos. Appl Environ Microbiol 62:4493–4498

Labarre C, Guzzo J, Cavin JF et al (1996) Cloning and characterization of the genes encoding the malolactic enzyme and the malate permease of Leuconostoc oenos. Appl Environ Microbiol 62:1274–1282

Lemme A, Sztajer H, Wagner-Döber I (2010) Characterization of mleR, a positive regulator of malolactic fermentation and part of the acid tolerance response in Streptococcus mutans. BMC Microbiol 10:280–1471

Lerm E, Engelbrecht L, du Toit M (2010) Malolactic fermentation: the ABC’s of MLF. S Afr J Enol Vitic 31:186–212

Liu SQ (2002) Malolactic fermentation in wine—beyond deacidification. J Appl Microbiol 92:589–601

Livak KJ, Schmittgen TD (2001) Analysis of relative gene expression data using real-time quantitative PCR and the 2−ΔΔCT method. Methods 25:402–408

Lonvaud-Funel A (1995) Microbiology of the malolactic fermentation: molecular aspects. FEMS Microbiol Lett 126:209–214

Lonvaud-Funel A (1999) Lactic acid bacteria in the quality improvement and depreciation of wine. Antonie van Leeuwenhoek 76:317–331

Nel HA, Bauer R, Vandamme EJ et al (2001) Growth optimization of Pediococcus damnosus NCFB 1832 and the influence of pH and nutrients on the production of pediocin PD-1. J Appl Microbiol 91:1131–1138

Pitcher DG, Saunders NA, Owen RJ (1989) Rapid extraction of bacterial genomic DNA with guanidium thiocyanate. Lett Appl Microbiol 8:151–156

Rojo-Bezares B, Saenz Y, Navarro L et al (2007) Coculture-inducible bacteriocin activity of Lactobacillus plantarum strain J23 isolated from grape must. Food Microbiol 24:482–491

Ugliano M, Genovese A, Moio L (2003) Hydrolysis of wine aroma precursors during malolactic fermentation with four commercial starter cultures of Oenococcus oeni. J Agric Food Chem 51:5073–5078

Vaillant H, Formisyn P, Gerbaux V (1995) Malolactic fermentation of wine: study of the influence of some physiochemical factors by experimental design assays. J Appl Bacteriol 79:640–650

Zapparoli G, Tosi E, Azzolini et al (2009) Bacterial inoculation strategies for the achievement of malolactic fermentation in high-alcohol wines. S Afr J Enol Vitic 30:49–55

Acknowledgments

The authors gratefully acknowledge the financial support of Lallemand Inc., Winetech, NRF and THRIP, as well as the German Federal Ministry of Education and Research for sponsoring a research stay of Bronwen Miller at the MRI in Karlsruhe.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miller, B.J., Franz, C.M.A.P., Cho, GS. et al. Expression of the Malolactic Enzyme Gene (mle) from Lactobacillus plantarum Under Winemaking Conditions. Curr Microbiol 62, 1682–1688 (2011). https://doi.org/10.1007/s00284-011-9914-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-011-9914-4