Abstract

The association of kefir microbiota was observed by electron microscopic examination. Scanning electron microscopic (SEM) observations revealed that kefir grain surface is very rough and the inner portions had scattered irregular holes on its surface. The interior of the grain comprised fibrillar materials which were interpreted as protein, lipid and a soluble polysaccharide, the kefiran complex that surrounds yeast and bacteria in the grain. Yeast was observed more clearly than bacteria on the outer portion of the grain. Transmission electron microscopic (TEM) observations of kefir revealed that the grain comprised a mixed culture of yeast and bacteria growing in close association with each other. Microbiota is dominated by budded and long-flattened yeast cells growing together with lactobacilli and lactococci bacteria. Bacterial cells with rounded ends were also observed in this mixed culture. Kefir grains, kefir suspensions, and kefiran were tested for antimicrobial activities against several bacterial and fungal species. The highest activity was obtained against Streptococcus faecalis KR6 and Fusarium graminearum CZ1. Growth of Aspergillus flavus AH3 producing for aflatoxin B1 for 10 days in broth medium supplemented with varying concentrations of kefir filtrate (%, v/v) showed that sporulation was completely inhibited at the higher concentrations of kefir filtrate (7–10%, v/v). The average values of both mycelial dry weights and aflatoxin B1 were completely inhibited at 10% (v/v). This is the first in vitro study about the antifungal characteristics of kefir against filamentous fungi which was manifested by applying its inhibitory effect on the productivity of aflatoxin B1 by A. flavus AH3.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Kefir is an acid–alcohol fermented milk, originally made in Balkans, Eastern Europe and the Caucasus. It is traditionally produced by inoculating milk with grains of kefir. Kefir grains are irregularly shaped, gelatinous masses varying in size from 1 to 6 mm in diameter. These grains contain a complex flora of lactic acid bacteria (lactobacilli, lactococci, leuconostocs), acetic acid bacteria, and yeast mixture coupled together in a slimy polysaccharide matrix named kefiran, which is the result of the microbial metabolism of milk lactose [23].

Yeast and lactic acid bacteria coexist in a symbiotic association and responsible for an acidic–alcoholic fermentation [21]. Kefir is considered to have a high nutritional, biological, and dietetic value [19], in addition to this the microbes constituting kefir grains produce lactic acid and other biologically active components [17] that increase the storage capability of milk and inhibit the growth of undesirable and pathogenic microbes [19].

Kefir and its exopolysaccharide, kefiran were proved to have antimicrobial activity. Both have been reported to exhibit significant antibiotic activity against both Gram-positive and Gram-negative bacteria [7, 18, 30, 31] and Candida albicans [30].

Mycotoxins are secondary metabolites that are formed during growth of certain fungi and are some of the most potent toxic compounds known to man [4]. The preferred method of controlling the presence of mycotoxins in foods is to prevent their formation, either in the field or during storage [4]. There have been a number of reports of the effects of fermentation on the aflatoxin content of contaminated raw materials [6, 26, 37].

The main objectives of this research were to briefly describe the nature of microbiota constituting kefir grains through an ultrastructural study. The study was extended to focus on the antimicrobial activity of kefir, kefiran, and kefir grains. The particular antifungal activity of the fermented kefir against toxigenic filamentous fungi has not been previously reported. The efficacy of fermented kefir in inhibition of aflatoxin B1 production was also investigated in this article.

Materials and Methods

Activation and Maintenance of Kefir Grains

Kefir grains were obtained from a household in Zagazig (Egypt). In the laboratory, they were propagated in pasteurized skimmed cows’ milk (proteins, 2.8%; fat, 0.2%; carbohydrates, 4.5%) at 30°C for 24 h. The grains were retrieved by sieving, reinoculated into fresh milk, and incubated at the same conditions. This procedure was repeated for 2 or 3 weeks before the grains were considered active and used as starter inoculum [14]. Kefir grains were then kept at 4 and −80°C for short- and long-term storage, respectively [20].

Ultrastructures of Kefir Grain

Scanning Electron Microscopy (SEM)

Fresh kefir grains were fixed in 2.5% glutaraldehyde at 4°C for 24 h and post fixed in 1.0% osmium tetraoxide for 1 h at room temperature [15]. The specimens were then dehydrated with ascending concentrations of acetone, critical point dried, and finally sputter coated with gold and examined on JEOL Scanning Microscope (JSM-T100).

Transmission Electron Microscopy (TEM)

Kefir grains were fixed in 2.5% glutaraldehyde for 3 h, washed twice with 0.2 M phosphate buffer of pH 7.4 for 30 min, then post fixed in 1.0% osmium tetraoxide [15] for 2 h. After that the grains were washed again with the phosphate buffer for 30 min. All steps of fixation were carried out at 4°C. The grains were then dehydrated in a graded ethanol series (from 50 to 100%), passed in three changes of acetone:ethanol (1:2, 1:1 and 2:0) for 10 min for each and embedded in resin capsule [22]. The capsules containing the samples were sectioned with a diamond knife (Ultramicrotome RMC, USA) into ultrathin sections about 70 nm that were carried out on copper grids and contrasted with uranyl acetate [34] followed by lead citrate [29] for 30 min each. The grids were examined on JEOL-100 CX TEM.

Antimicrobial Activity of Kefir and Kefiran

Microorganisms

Bacterial and fungal species used in the susceptibility test were E. coli ATCC 11229, Klebsiella pneumoniae ATCC 13883, Staphylococcus aureus ATCC 6538, Pseudomonas aeruginosa ATCC 15442, Salmonella typhi ATCC 14028, C. albicans ATCC 10231 were kindly obtained from the National Research Center, Giza, Egypt; Bacillus cereus GST4, Bacillus subtilis BW2 and Streptococcus faecalis KR6 were kindly obtained from the Microbiology Department, Faculty of Medicine, Zagazig University, Egypt. Aspergillus flavus AH3 and Fusarium graminearum CZ1 were isolated from a soil sample cultivated with Trifolium alexandrinum and were identified to the species level according to Moubasher [25] and Domsch et al. [8].

Recovery of Kefiran

The exopolysaccharide, kefiran was recovered from the kefir filtrate according to the method described by Frengova et al. [11], where the filtrate was treated with 17% (v/v) of 80% trichloro-acetic acid solution and centrifuged at 16,000 r.p.m. at 4°C for 30 min. The exopolysaccharide was precipitated by adding three volumes of cold absolute ethanol, and stored overnight at 4°C. The recovered precipitates were redissolved with distilled water and dialyzed against the same solution for 24 h at 4°C to remove the residual of lactose. The amount of kefiran was measured as total sugar according to the phenol–sulfuric acid method [9].

Antimicrobial Assay

Antimicrobial activities of fermented milk kefir, neutralized kefir (fermented kefir filtrate was neutralized with Na2CO3), and purified kefiran were evaluated using the disk diffusion technique as described by Wayne [36]. Cell suspensions of 107 CFU/ml were prepared from either fresh bacterial or yeast cells. Kefir suspensions and purified kefiran extracts were pipetted on to 5-mm diameter paper disks. Amounts used were 0.1 ml of 24 h fermented kefir suspension, neutralized kefir suspension, and purified kefiran at 0.35 and 0.70 mg/ml. The filter paper disks were applied to nutrient or Sabouraud’s-agar surface (25 ml) previously inoculated with 0.1 ml of either bacterial or yeast suspension, respectively. Similarly, the disks were applied to Czapek–Dox’s agar (25 ml) inoculated with 0.2 ml either of A. flavus or F. graminearum conidial spore suspension containing 106 spores per ml from 168 h old cultures. Meanwhile, the kefir grain itself was also tested for its antimicrobial activity. The plates were then refrigerated for 2 h, then the bacterial and yeast inoculated plates were incubated at 35 °C for 24 h. While the fungal inoculated plates were incubated at 28 °C for 7 days. At the end of the mentioned incubation periods, the diameters of inhibition zones formed in all three replicates were measured.

Effect of Milk Kefir on Mycelial Growth and Aflatoxin B1 Formation of A. flavus AH3

Cultivation Conditions

Czapek–Dox’s broth was prepared and sterilized in Erlenmeyer flasks of 250 ml capacity, each containing 50 ml medium. Milk kefir filtrate was prepared after separating the kefir grains from kefir cultures with a sterile aperture sieve (710 μm). The resulting fermented filtrate was then filtered sterilized by passing through a cellulose nitrate membrane (0.45 μm). Different volumes of fermented milk kefir filtrate were added separately to the broth to give the following concentrations: 0, 0.5, 1.0, 2.0, 3.0, 4.0, 5.0, 6.0, 7.0, 8.0, 9.0, and 10% (v/v). The flasks were inoculated with 0.2 ml A. flavus conidial spore suspension containing 106 spores per ml from 168 h old cultures under aseptic conditions and incubated at 28°C for 10 days. The fungal cultures were observed visually at the end of incubation period.

Determination of Mycelial Dry Weights

At the end of the incubation period, the fungal culture flasks were filtered through pre-weighed Whatman no. 1 filter papers, oven dried at 80°C till a constant weight.

Extraction of Aflatoxin B1 from A. flavus AH3 Cultures

This was carried out according to the procedure described by Criseo et al. [5], in which a known volume of the culture filtrate was transferred to a separating funnel, extracted with equal volume of chloroform, shaked for about 30 min, and allowed to stand for 30 min. The chloroform layer was filtered over anhydrous sodium sulfate then evaporated under vacuum till dryness. The resultant dried crude extract was dissolved in methanol and undergone the necessary chromatographic analysis.

Qualitative and Quantitative Determination of Aflatoxin B1

The method of aflatoxin B1 determination was adopted according to Basappa et al. [1] using precoated thin layer chromatographic (TLC) plates with silica gel GF-254. The concentrated extracts and authentic aflatoxin B1 (Sigma Co.) were loaded on to the chromatograms and developed in toluene:ethyl acetate:formic acid (6:3:1, v:v:v). Aflatoxin B1 bands (R f = 0.47) give blue influorescence under short- and long-wave length (254 and 366 nm) ultraviolet light using Min UVIS, DUOUV source for TLC. The fluorescent bands were eluted from the silica gel and rechromatographed with the same conditions for further purification. The fluorescent bands corresponding to the authentic aflatoxin B1 were again scrapped off and eluted with methanol. Aflatoxin B1 was then quantified by ultraviolet spectroscopic analyses performed with a Deuterium UV 21 D Milton Roy spectrophotometer. Aflatoxin B1 absorption was monitored at 363 nm, and the concentration was obtained after recording the optical density against a standard curve.

Statistical Analyses

All experiments were conducted in triplicates. LSD 0.05 and LSD 0.01 were calculated according to Snedecor and Cochran [33]. If the difference between the arithmetical means of data is less than LSD 0.05, the result is non-significant. If the difference is more than LSD 0.05, the result is significant. If the difference is more than LSD 0.01, the result is highly significant.

Results and Discussion

Ultrastructures Studies

SEM Examination

The SEM observations cleared that kefir grain surface is very rough (Fig. 1a). The inner portions had scattered irregular holes on the surface resembling a collection of small craters (Fig. 1a and c). The same SEM observations on the roughness of the Turkish kefir grain were recorded by Güzel-Seydim et al. [13] who reported that the apparent surface roughness may be the result of the procedure used in the preparation of kefir grains for electron microscopy. However, when viewed with the naked eyes, the exterior surface of the grains looked smooth and shiny. The interior of kefir grain comprises unstructured material. These fibrillar materials were interpreted as protein, lipid, and a soluble polysaccharide, the kefiran complex that surrounds yeast and bacteria in the kefir grain (Fig. 1b and c). Hallè et al. [14] showed that the kefir grain matrix is composed of a complex of 13% protein (by dry weight), 24% polysaccharide, along with cellular debris and unknown components. Garrote et al. [12] reported that kefir grains are soft, gelatinous white, composed mostly of proteins and polysaccharides, the kefiran complex that surrounds yeast and bacteria in the grains. It was observed that yeasts can be found more clearly than bacteria on the outer portion of the grain (Fig. 1b and c). Bacteria were hardly observed on the outer surface of the grain, this because they are too embedded in the fibrillar material (kefiran) in the sub-inner portion. The same result was reported by Güzel-Seydim et al. [13] who reported that this is perhaps because yeast is aerobic and more likely to colonize the kefir grain surface. They observed different types of lactobacilli (short, long, and curved), but did not observe lactococci through the grain under SEM. Marshall et al. [23] observed sheet-like structures and scroll-like forms in kefir grains.

Scanning electron micrographs (SEM, X 3500) of the inner portion surface of kefir grain. (a): A SEM of the rough surface of kefir grain. The inner portions have scattered irregular holes. (b and c): SEM of the kefiran complex that surrounds yeast (Y) and bacteria (B). Yeast is observed more clearly than bacteria on the outer portion of the grain. 157 × 140 mm (300 × 300 DPI)

TEM Examination

The TEM observations cleared the association of the kefir microbiota. It was found that the kefir grain comprises a mixed culture of yeast and bacteria growing in close association with each other (Fig. 2a). Microbiota is dominated by budded and long-flattened yeast cells (Fig. 2b) growing in close association with lactobacilli (short mono- and diplo- or long strepto-bacilli) and lactococci (mono- and diplo-cocci) (Fig. 2 c, d, and e). The large circular electron-transparent area represents a granule of poly-β-hydroxy-butyrate (PHB) and the smaller, diffuse, transparent areas (gl, Fig. 2 c, d and e) scattered throughout the cytoplasm are glycogen particles. Bacterial cells with rounded ends are also found in this mixed culture (Fig. 2f). Kefir grains were reported to be a mixed culture consists of various yeasts (Kluyveromyces, Candida, Saccharomyces, and Pichia), various lactic acid bacteria of the genus Lactobacillus, Lactococcus, Leuconostoc, and acetic acid bacteria [12, 23]. Our results were similar to those obtained by Lopitz-Otsoa et al. [21] who observed the association of bacteria and yeasts and further reported that yeast and bacteria share a symbiotic relationship, meaning they survive or propagate by sharing their byproducts as an energy source or growth-stimulating source.

Transmission electron micrographs (TEM) of bacteria and yeast of kefir grain (a): A TEM (X 10,000) of bacteria (B) and yeast (Y) growing in close association in kefiran matrix (b): A TEM (X 10,000) of budded yeast cell in kefir mixed culture, (c) and (d): TEM (X 20,000) of lactobacilli and lactococci bacteria in kefir mixed culture (e): A TEM (X 20,000) of lactobacilli bacteria in chains in kefir mixed culture (f): A TEM (X 14,000) of bacterial cells with rounded ends in kefir mixed culture. PHB poly-ß-hydroxy-butyrate inclusion; gl smaller electron-opaque areas believed to contain glycogen. 165 × 217 mm (300 × 300 DPI)

Antimicrobial Activity Studies

In this study, a preliminary test was conducted to elucidate the antibacterial and antifungal effect of milk kefir suspension (0.1 ml of either fermented kefir or neutralized kefir suspension) and purified kefiran (at 0.35 and 0.70 mg/ml) towards some bacteria and fungi by the disk diffusion technique (Table 1). In general, the fermented kefir suspension showed the strongest antibacterial activity against all the tested bacteria. The fermented kefir suspension exhibited significant antibacterial activity compared to that of neutralized kefir suspension and kefiran (at 0.35 and 0.70 mg/ml) against all the tested bacteria except K. pneumoniae ATCC 13883. S. faecalis KR6 followed by S. aureus ATCC 6538 showed the highest response to the antibacterial activity of kefir suspensions and kefiran concentrations. The recorded inhibition zone diameter of S. faecalis KR6 was 15 mm as a result of its response to the effect of the fermented kefir suspension. S. aureus ATCC 6538 and S. typhi ATCC 14028 showed inhibition zones equal to 14 mm as a result of their response to the effect of the fermented kefir suspension. E. coli ATCC 11229 was the least sensitive to the kefir suspensions where the recorded inhibition zones were 11 mm with the fermented kefir suspension and 8.0 mm with the neutralized kefir suspension and showed no response to kefiran concentrations. Similar results were obtained by Rodrigues et al. [30]. They found that Streptococcus pyogenes was the most sensitive microorganism to kefiran followed by S. aureus and Staphylococcus salivarius. Their study indicated that P. aeruginosa and E. coli showed the lowest sensitivity to kefiran.

With respect to the tested fungi, the results showed that kefir suspensions and kefiran did not have any effect against C. albicans ATCC 10231. However, F. graminearum CZ1 was responded strongly to the inhibitory effect of kefir suspensions and kefiran at 0.70 mg/ml (Table 1). The fermented kefir suspension was found to have highly significant antifungal activity against F. graminearum CZ1 compared to that of neutralized kefir suspension and kefiran (at 0.35 and 0.70 mg/ml). The results further showed that the growth of A. flavus AH3 was not affected by kefir suspensions and kefiran concentrations; however, its sporulation was clearly inhibited. The antifungal activity of kefir suspensions and kefiran was reported against C. albicans; however, no reports have not yet been studied on their antifungal activity against filamentous fungi. Many lactobacilli are capable of producing a wide range of antimicrobial compounds, including organic acids (lactic and acetic acids), carbon dioxide, hydrogen peroxide, ethanol, diacetyl, and peptides (bacteriocins) that may be beneficial not only in the reduction of food-borne pathogens and spoilage bacteria during food production and storage, but also in the treatment and prevention of gastrointestinal disorders and vaginal infections [3, 16, 24]. Kefir is claimed to act against Salmonella, Helicobacter, Shigella, Staphylococcus [7, 30, 31], Enterobacter aerogenes, Proteus vulgaris, and B. subtilis [18]. The results presented in Table 1 also revealed that the whole kefir grains had a weak inhibitory effect on the growth of S. faecalis KR6, P. aeruginosa ATCC 15442, S. typhi ATCC 14028, B. subtilis BW2, K. pneumoniae ATCC 13883, and F. graminearum CZ1. In the same connection, Schneedorf and Anfiteatro [31] and Serot et al. [32] reported that fresh kefir grains were found to have antibacterial activity but did not show any effect on the growth of C. albicans and S. cerevisiae. The antimicrobial activity of several isolated strains from kefir grains also has been reported [7, 31]. Kefir grains are composed mostly of proteins and polysaccharides in which the complex microflora that produce lactic acid and other biologically active components are enclosed [17].

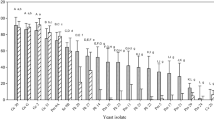

Efficacy of Fermented Milk Kefir in Inhibition of the Mycelial and Sporulative Growth and Aflatoxin B1 Formation of A. flavus AH3

The effect of Czapek–Dox’s broth supplemented with varying concentrations of milk kefir filtrate (%, v/v) on mycelial dry weights, spore production and aflatoxin B1 formation by A. flavus AH3 after 10 days of incubation, was summarized in Table 2. Sporulation was intense at the lower concentrations of kefir filtrate (0.5 to 2%, v/v), became slight to very slight at the concentrations (3 to 6%, v/v) and completely inhibited at the higher concentrations (7–10%, v/v). It was also obvious that the increase in the concentrations of kefir filtrate (concentrations higher than 0.5%) caused a high significant decrease in the average values of both mycelial dry weights and aflatoxin B1 compared with the average value of the control culture (free from fermented kefir filtrate). This reduction reached a complete inhibition in both parameters at 10% of kefir filtrate. At 0.5% of kefir filtrate, mycelial dry weight production was high significantly reduced by 33.3% compared with production at control culture. At the same concentration of kefir filtrate, aflatoxin B1 production was significantly reduced by 14.9% compared with production at control culture filtrate. The mycelial dry weights and aflatoxin B1 amounts produced in the presence of 9% of kefir filtrate were approximately 18.77 and 13.90%, respectively, of those produced in the control culture filtrate after 10 days of incubation. Aflatoxins are a worldwide important problem in public health, agriculture, and economics. Aflatoxin B1 has been demonstrated in animals to be the most potent liver carcinogen [28]. Kefir is an acidic and mildly alcoholic fermented dairy product that is believed to have functional properties [10]. The microorganisms contained within the kefir grains typically produce lactic acid and antibiotics; such products inhibit the proliferation of both spoilage and pathogenic microorganisms [10]. Nout [26] and Westby et al. [37] summarized the effect of fermentation on aflatoxin B1 production. They reported that during food fermentations, the cyclopentanone moiety of aflatoxin B1 was reduced which results in aflatoxicol A and in the presence of organic acids, aflatoxicol A is irreversibly converted into the stereo-isomer aflatoxicol B which is about 18 times less toxic than aflatoxin B1. Under the conditions created in lactic acid fermentation (pH ≤ 4.0), aflatoxin B1 is readily converted to aflatoxin B2a which is also less toxic. Lactic acid fermentation was used in reduction of the extent of aflatoxin B1 in different contaminated raw materials as mentioned by Blanco et al. [2] and Dada and Muller [6]. Onilude et al. [27] found that Lactobacillus plantarum was able to inhibit the vegetative and sporulative growth of all the aflatoxin producing aspergilli. Antifungal activities by a L. casei strain that inhibited both the growth and the aflatoxins production of A. parasiticus have been reported [35]. Hydrogen peroxide is another metabolite produced by some lactic acid bacteria as antimicrobial compound [38].

Concluding Remarks

In summary, the kefir grain ultrastructure study demonstrated that its surface is very rough and the inner portions had scattered irregular holes and the interior of the grain comprised fibrillar materials of protein, lipid, and a soluble polysaccharide, the kefiran complex that surrounds yeast and bacteria in the grain. The SEM observations revealed that yeasts were observed more clearly than bacteria on the outer portion of the grain. The TEM observations showed that the microbiota of kefir grain were dominated by budded and long-flattened yeast cells growing in close association with lactobacilli and lactococci bacteria. Also, bacterial cells with rounded ends were also observed in this mixed culture. Regarding to the antimicrobial study, kefir suspension, kefiran, and kefir grains showed antibacterial activity against some unicellular bacterial species and new antifungal activity against filamentous fungal species. Furthermore, kefir showed a good efficacy in inhibiting spore formation and aflatoxin B1 production of A. flavus. Therefore, kefir is not only being a probiotic agent but also appears to have promise as safe alternative natural food preservative offering a protection against intoxication from aflatoxin B1.

References

Basappa SC, Sreenivasamurthy V, Parpia HA (1970) Aflatoxin and kojic acid production by resting cells of Asergillus flavus Link. J Gen Microbiol 61:81–86

Blanco JL, Carrion BA, Liria N, Diaz S, Garcia ME, Dominguz L, Suarez G (1993) Behavior of aflatoxins during manufacture and storage of yoghurt. Milchwissenschaft 48:385–387

Bonadè A, Murelli F, Vescovo M, Scolari G (2001) Partial characterization of a bacteriocin produced by Lactobacillus helveticus. Lett Appl Microbiol 33:153–158

Coker RD (1995) Controlling mycotoxins in oilseeds and oilseed cakes. Chem Ind 7:260–264

Criseo G, Bagnara A, Bisignano G (2001) Differentiation of aflatoxin-producing and non-producing strains of Aspergillus flavus group. Lett Appl Microbiol 33:291–295

Dada LO, Muller HG (1983) The fate of aflatoxin B1 in the production of Ogi, Nigerian fermented sorghum porridge. J Cereal Sci 1:63–70

Diniz RO, Garla LK, Schneedorf JM, Carvalho JCT (2003) Study of anti-inflammatory activity of Tibetan mushroom, a symbiotic culture of bacteria and fungi encapsulated into a polysaccharide matrix. Pharmacol Res 47(1):49–52

Domsch KH, Gaws W, Anderson TH (1980) Compendium of soil fungi. vol 1. Academic press, London

Dubois M, Gilles K, Hamilton J, Robers PA, Smith F (1956) Colometric method for determination of sugars and related substances. Anal Chem 28(2):350–356

Farnworth ER (2006) Kefir—a complex probiotic. Food Sci Technol Bull Funct Foods 2:1–17

Frengova GI, Simova ED, Beshkova DM, Simov ZI (2002) Exopolysaccharides produced by lactic acid bacteria of kefir grains. Z Naturforsch C 57(9-10):805–810

Garrote GL, Abraham AG, De Antoni GL (1997) Preservation of kefir grains, a comparative study. Lebensm Wiss Technol 30:77–84

Güzel-Seydim Z, Wyffels JT, Seydim AC, Greene AK (2005) Turkish kefir and kefir grains: microbial enumeration and electron microscopic observation. Int J Dairy Technol 58(1):25–29

Hallé C, Leroi F, Dousset X, Pidoux M (1994) Les kéfirs: des associations bactéries-levures. In: de Roissart H, Luquet FM (eds) Bactéries lactiques, vol 2. Lorica, Uriage, pp 169–182 (in French)

Harley MM, Fergusen IK (1990) The role of SEM in pollen morphology and plant systematic. In: Claugher D (ed) Scanning electron microscope in taxonomy and functional morphology. Systematics association special, vol 41. Clarendon Press, Oxford, pp 45–68

Jamuna M, Jeevaratnam K (2004) Isolation and characterization of lactobacilli from some traditional fermented foods and evaluation of the bacteriocins. J Gen Appl Microbiol 50:79–90

Kaufmann K (1997) Kefir rediscovered. Alive Book, Burnahy

Kwon CS, Park MY, Cho JS, Choi ST, Chang DS (2003) Identification of effective microorganisms from kefir fermented milk. Food Sci Biotechnol 12:476–479

Libudzisz Z, Piatkiewicz A (1990) Kefir production in Poland. Dairy Ind Int 55:31–33

Liu J-R, Lin C-W (2000) Production of kefir from soymilk with or without added glucose, lactose or sucrose. J Food Sci 65:716–719

Lopitz-Otsoa F, Rementeria A, Elguezabal N, Garaizar J (2006) Kefir: a symbiotic yeasts-bacteria community with alleged healthy capabilities. Rev Iberoam Micol 23(2):67–74

Luft JH (1961) Improvements in epoxy resin embedding methods. J Biophys Biochem Cytol 9:409–414

Marshall VM, Cole WM, Brooker BE (1984) Observations on the structure of kefir grain and the distribution of the microflora. J Appl Bacteriol 57:491–497

Messens W, De Vuyst L (2002) Inhibitory substances produced by Lactobacilli isolated from sourdoughs-a review. Int J Food Microbiol 72:31–43

Moubasher AH (1993) Soil fungi in Qatar and other Arab countries. The Centre for Scientific and Applied Research, Doha

Nout MJR (1994) Fermented foods and food safety. Food Res Int 27:291–298

Onilude AA, Fagade OE, Bello MM, Fadahunsi IF (2005) Inhibition of aflatoxin- producing aspergilli by lactic acid bacteria isolated from indigenously fermented cereal gruels. Afr J Biotechnol 4(12):1404–1408

Pitt JI (2000) Toxigenic fungi: which are important? Med Mycol 38(Suppl 1):17–22

Reynolds ES (1963) The use of lead citrate at high pH as an electron opaque stain in electron microscopy. J Cell Biol 17:207–212

Rodrigues KL, Caputo LRG, Carvalho JCT, Evangelista J, Schneedorf JM (2005) Antimicrobial and healing activity of kefir and kefiran extract. Int J Antimicrob Agents 25:404–408

Schneedorf JM, Anfiteatro D (2004) Fitoterapicos anti-inflamatorios by Carvalho, JCT. Quefir, um probiotico produzido por microorganismos encapsulados e inflamacao. Chap 33, pp 443–462

Serot T, Dousset X, Zucca J, Torcatis N (1990) Mise en évidence et purification partielle de substances antibacteriennes produites par Leuconostoc mesenteroides et Lactobacillus plantarum isoles de grains de kéfyr. Microbiol Aliments Nutr 8:71–76

Snedecor GW, Cochran WG (1967) Statistical methods. The Iowa State University Press, Ames

Sptempack JG, Ward RT (1964) An improved staining method for electron microscopy. J Cell Biol 22:679–701

Vanne L, Kleemola T, Haikara A (2000) Screening of the antifungal effects of lactic acid bacteria against toxigenic Penicillium and Aspergillus strains in http://www.vtt./bel/2000microbiology/antifungalattributesoflacticacidbacteria./

Wayne PA (2002) Performance standards for antimicrobial disk susceptibility test. Approved standard M2-A6. 6th edn. National Committee for Clinical Laboratory Standards (NCCLS), Wayne

Westby A, Reilly A, Bainbridge Z (1997) Review of the effect of fermentation on naturally occurring toxins. Food Control 8(5/6):329–339

Yüksekdag ZN, Beyatli Y, Aslim B (2004) Determination of some characteristics coccoid forms of lactic acid bacteria isolated from Turkish kefir with natural probiotic. Lebensm Wiss Technol 37:663–667

Acknowledgments

We thank the technicians of the Central Laboratory of Electron Microscope, Faculty of Science, Zagazig University, Egypt for performance of the processing steps of SEM and TEM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ismaiel, A.A., Ghaly, M.F. & El-Naggar, A.K. Milk Kefir: Ultrastructure, Antimicrobial Activity and Efficacy on Aflatoxin B1 Production by Aspergillus flavus . Curr Microbiol 62, 1602–1609 (2011). https://doi.org/10.1007/s00284-011-9901-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-011-9901-9