Abstract

Several issues of butyric acid production with bacteria through fermentation are presented in this review. The current progress including the utilization of butyric acid, the production strains, the metabolic pathway, and regulation are presented in the paper. Process operation modes such as batch, fed-batch, and continuous fermentation are being discussed. Genetic engineering technologies for microbial strain improvement are also being discussed and fermentation systems have been recommended.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Butyric acid, a 4-carbon short chain fatty acid, is widely used in chemical, food, and pharmaceutical industries. The main application of butyric acid is in the manufacture of cellulose acetate butyrate plastics which is used for textile fiber production. Butyric acid is also used directly as an additive to fibers for heat and sunlight resistance enhancement. Its application in the production of biodegradable polymer β-hydroxybutyrate is currently under investigation. Calcium butyrate has been used in various leather tanning processes. Butyric acid esters have been extensively used as flavors additives to increase fruit-like fragrance in the food industry [1]. Various derivatives of butyric acid are used as vasoconstrictor drugs, in anesthetics as well as for antioxidants. The application of butyric acid in the treatment of hemoglobinopathies, cancer, and gastrointestinal diseases is well known, and several drugs derived from butyric acid have been widely investigated and some formulations are being developed [2–6]. Furthermore, the addition of butyric acid to an acetone–butanol–ethanol (ABE) fermentation process has shown a significant enhancement of bio-butanol yield [7–11].

Nowadays, butyric acid production at industry scale is dominated by chemical synthesis with starting materials derived from crude oil [12]. Chemical synthesis of butyric acid is currently more attractive due to its low production cost and large scale supply. Despite of higher production cost, butyric acid obtained via microbial fermentation is often required for some specific applications [6, 13]. With the decreasing supply of world crude oil, the increasing supply of food industry by-products which can be used for butyric acid production and the increasing consumer demand for organic natural products in food additives, pharmaceutical products, and preservatives, the production of butyric acid through microbial fermentation has generated again a favorable business climate [2, 3, 14, 15].

For example, organic acids produced by fermentation are preferred over chemically synthesized counterpart for food additives and pharmaceutical products [13]. At present, the contradiction between low production and high demands is becoming acute, giving high incentives for increasing the butyric acid production rate via biological processes. Thus, fermentation can play a significant role in the butyrate supplying market [16].

Butyric Acid Production by Fermentation

The history of the butyric acid fermentation began with Pasteur’s discovery. He found that some rod-shaped microbials grew and produced butyric acid in the absence of air, and were inhibited by exposure to air. The butyric-acid fermenting bacteria were extensively studied during the 1880s and the microbials were divided into two groups: those producing mostly butyric acid as final product and those producing mostly butanol as final product. The latter process—called acetone–butanol–ethanol (ABE) fermentation—was one of the oldest known industrial fermentations and was one of the largest biotechnological processes ever known since the First World War until 1960s. On the contrary, the advances for butyric acid production, including strain development and fermentation technology as well as downstream process technology have been extremely slow [16, 17]. This review will try to introduce the developments mainly made in recent 20 years on butyric acid production.

Microbial Strains

There are more than 10 butyrate-producing bacteria species from at least seven genera with butyric acid producing capacity being investigated for potential industry application. All of them are anaerobic microorganisms belonging to the genera Clostridium, Butyrvibrio, Butyribacterium, Eubacterium, Fusobacterium Megasphera, and Sarcina [16–18]. For industrial application, the strains of Clostridium have been used for production of butyric acid and were the mostly studied in the past 20 years (Table 1). Among them, C. butyricum [1, 19–30], C. populeti [31], C. tyobutyricum [12, 32–42], and C. thermobutyricum [43–46] were the focus of these studies. All of these strains are Gram positive, strictly anaerobic, and spore-forming bacteria. The optimal culture temperature is around 30–37°C for C. butyricum, C. populeti as well as C. tyrobutyricum, and 55°C for C. thermobutyrium. The culture pH range for clostridia is from 5.0 to 7.5. The difference in pH of a culture media typically led to different product distribution (proportion changes) between acetate and butyrate. A wide range of carbon source is able to be utilized by clostridia. During the 1980s and 1990s, C. butyricum was the favored organism as the working microbial for the development of fermentation technologies and fermentations combined with simultaneous product recovery. C. butyricum utilizes many carbon sources including hexose, pentose, glycerol, lignocellulose, molasses, potato starch, and cheese-whey permeate. While, C. tyrobutyricum uses only glucose, xylose, and fructose [17, 47]. C. thermobutyricum isolated from horse manure consumes the following sugars: monomeric sugars (glucose, fructose, maltose, xylose, and ribose, but not arabinose, galactose, and mannose); dimeric (cellobiose), oligomeric, polymeric sugars [45].

Metabolic Pathway and Regulation

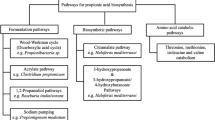

The metabolic pathway of glucose fermentation for butyric acid production with clostridia is illustrated in Fig. 1. Glucose is metabolized to pyruvate via Embden–Meyerhof–Parnas (EMP) pathway and produces two moles of ATP and NADH, respectively. The butyrate-producing clostridia produce butyrate concomitantly with acetate, H2, CO2, and trace lactate and other products. Glucose fermentation by C. butyricum and C. tyrobutyricum follows the stoichiometric equation below:

and C. thermobutyricum fermentation of glucose can be represented by following equation:

The metabolic pathway of the butyrate-producing clostridia [16, 17, 27, 32, 34] 1 EMP pathway and hexose phosphotransferase, 2 pyruvate–ferredoxin oxidoreductase, 3 hydrogenase, 4 acetyl CoA-acetyltransferase, 5 β-hydroxylbutyryl CoA dehydrogenase, 6 crotonase, 7 butyryl CoA dehydrogenase, 8 phosphotransbutyrylase (PTB), 9 butyrate kinase (BK), 10 phosphotransacetylase (PTB), 11 acetate kinase (AK), 12 proposed enzyme butyryl CoA-acetate transferase (for recycling of acetate), 13 NAD-independent lactate dehydrogenase (iLDH)

It is obvious that by-product acetic acid production is a branched pathway when butyric acid is produced in the fermentation. This brings difficulties for the recovery of butyrate in downstream processing. Since one-third of carbon source derived form glucose is removed as CO2, therefore the maximum yield will be only at 0.67 (g/g) for organic acid production. The CO2 gas and reduced ferredoxin FdH2 are the products of the conversion from pyruvate to acetyl-CoA by the enzyme pyruvate:ferredoxin oxidoreductase. Reduced ferredoxin FdH2 is re-oxidized to Fd by hydrogenase which passes the two electrons to hydrogen ions yielding the H2 gas which is a typical by-product of these microorganisms. Lactate is produced by NAD-independent lactate dehydrogenase from pyruvate, and NADH is reoxidized to NAD. In the acetate branch, phosphotransacetylase (PTA) and acetate kinase (AK) are involved in the production of the acid. For butyrate branch, phosphotransbutyrylase (PTB) and butyrate kinase (BK) catalyze the reactions from butyryl-CoA to butyrate.

An additional ATP is formed from butyryl-phosphate and therefore three ATPs for each butyrate are produced from glucose. In the acetate branch, two moles of acetic acid are produced and 2 ATPs are produced from acetyl-P to acetate, so 4 ATPs are formed during the conversion of glucose to two acetic acids. Acetate is the main product especially during the cell growth phase. At the end of the exponential growth, a major metabolic pathway switch took place in the organisms. The organisms slowed down acetate production, and took up excreted acetate and convert it into butyrate [20, 35, 44]. The purpose of recycling in the organism may be related to detoxify the medium by reducing total hydrogen ion concentration, which occurred when one butyrate substituted for two acetates, so the metabolism shifted from more energy producing formation “acetate” (Eq. 3) to less H2-producing butyrate formation (Eq. 4)

Many factors are able to influence the metabolic pathway of a microorganism during fermentation. In the case of butyrate-producing clostridia, the concentrations of glucose, pH, H2 partial pressure, acetate, and butyrate, impact the growth rate, final product concentration and the distribution of products [28, 34, 48]. Excess carbon source often affects osmotic dehydration of microorganisms in a fermentation process. A significant increase in the butyrate/acetate ratio was observed in a glucose-limited culture without sparging nitrogen into fermenter in a butyrate fermentation process with C. butyricum as working microorganism [49].

Different pH value will affect the distribution of produced acids, cell membrane transport behavior, and cell lysis [16]. Relative high pH (e.g. >6.0) is beneficial for cell growth and butyric acid biosynthesis, especially in C. butyricum [19]. Media pH also affects the specific growth rate, butyric acid production rate, and the reducing sugars consumption rate. For C. tyrobutyricum, different pH is able to change the distribution of the metabolic flux. At pH 6.3, the highest butyrate production is produced, compared to that at pH 6.0 and 6.7 [12, 34]. Butyrate production was lower at lower pH, with acetate and lactate as the main acid products at pH 5.0. The metabolic shift from butyrate formation at pH 6.3 to lactate and acetate formation at pH 5.0 is associated with decreased activities of PTB and independent lactate dehydrogenase (iLDH), and increased activities of PTA and LDH [12].

In butyrate-producing strains, PTA, AK, PTB, BK, iLDH, and LDH are the main enzymes relevant to acetate, butyrate, and lactate production. Their product distribution is affected by media pH significantly. AK and BK in the direction of acyl phosphate formation were not significantly affected by the pH between 5.0 and 7.0. However, in the acyl-phosphate-forming direction, the activity of PTA increased while PTB decreased with increasing the pH [12].

It has also been reported that under a low partial pressure of H2, the acetate/butyrate ratio increased with the decreasing of H2 partial pressure, accompanied by an increase of ATP yield during butyric acid production fermentation by C. butyricum [20].

Acetic acid, the main by-product from butyrate-producing clostridia, will be taken up by the microorganism and converted to butyrate in a typical fermentation process. The addition of acetate in the medium enhances the consumption of glucose, leads to faster cell growth, and increases the final biomass and butyrate concentration [43, 44, 46].

Butyrate-producing metabolic pathway is inhibited by its end product-butyrate. Undissociated butyric acid passes through the bacterial membrane and dissociates inside the cell. It affects the transmembrane pH gradient and decreases the amount of energy available for biomass growth [16, 50]. This problem could not be solved by common fermentation designs such as operation mode. On-line separation or in situ product removal is proposed to address such problem and to enhance the performance of butyric acid production in clostridia by fermentation. Especially, extraction and pertraction are suggested to be the most suitable methods [38, 51–55].

Fermentation Approaches

Batch and fed-batch technology are widely used in the laboratory (Table 1) for butyrate production. It was observed that supply of glucose via fed-batch mode increased the productivity of butyrate production by C. tyrobutyricum fermentation. The ratio of butyrate to acetate (selectivity) was affected by biomass growth rate. At high growth rates, both acetate and butyrate were produced, whereas in glucose-limited fed-batch cultures, acetate (which accumulated at high growth rates) was recycled and converted to butyrate [35]. This recycling process (probably involving a CoA transferase; Fig. 1 [dashed lines]) provides no direct energetic advantage for re-utilization of acetate.

Historically, continuous culture techniques have not been widely used in laboratory scale. In laboratory, these techniques have been used increasingly for studying the growth and physiology of microorganisms [16, 37, 43]. Continuous cultivation is a method of prolonging the exponential phase of an organism in batch culture, whilst maintaining an environment that has less fluctuation in nutrients and cell number (biomass) [56].

Cell density is a critical guideline for the fermentation productivity evaluation. Therefore, immobilized cell bioreactor has several advantages: first and foremost, high cell density could be achieved in immobilized cell systems and could lead to an increased production efficiency. The increased efficiency includes improved reaction rates and simplified product separation. Second, the structure of bioreactor may be relatively simple. When the fermentation is finished, the bacteria could be easily separated from the media fluid, making the downstream process simple and less cost. Furthermore, immobilized cell bioreactor could improve reactor productivity [57, 58].

Fluidized-bed bioreactor, packed-bed bioreactor [59], and crossflow membrane system are the most popular immobilized cell bioreactors employed for various applications. Recently, because of their low cost, high void volume, high mechanical strength, high specific surface area, and high permeability, fibrous materials have been developed for cell immobilization [39]. A fibrous-bed bioreactor (FBB) which is actually a packed-bed with immobilized cells in the fibrous matrix packed in the reactor has been successfully used to produce butyric acid and several other organic acids (lactic acid, acetic acid, and propionic acid). The reactor productivity, final product yield, and concentration were significantly improved comparing to other configuration of the bioreactors [37–39, 42, 60–62]. The advantages of the FBB include efficient and continuous operation without repeated inoculations, elimination of cell lag phase, good long-term stability, and easier downstream processing. These advantages could be attributed to the high viable cell density maintained in the bioreactor [39, 60].

The conventional anaerobic production of butyrate faces several operation problems, such as excess carbon source, down-stream processing, and the inhibitory effect of end-products. Therefore, the fed-batch fermentation process which is combined with online separation or in situ product isolation is recommended.

Genetic Engineering Aspect

Conventional butyric acid fermentation process is not yet economically competitive because not only butyric acid is produced at a relatively low concentration, low yield as well as low productivity, but also acetic acid is produced as a by-product in the process which reduces butyrate yield and increases product recovery and purification costs. To improve the economics of the fermentation process, it is desirable to increase butyrate production while reducing acetate production, which also reduces the product separation cost [41, 42], or to enhance butyrate tolerance of strains, or to achieve both of them [16, 17, 63].

The products of butyrate-producing clostridia include butyrate, acetate, CO2, and H2 from carbohydrate. To increase butyrate production, modern genetic methods are being applied to the butyrate-producing strains aimed to delete the acetate-producing pathway. The mutants of C. tyrobutyricum with either pta- or ak- enzyme production capability were constructed. As compared with the wild type, higher final butyrate concentration and higher yield were achieved. It was obvious that more carbon and energy fluxes flowed into the butyrate-producing branch pathway resulting in higher butyrate production in the mutants. Additionally, better tolerance to product inhibition of the mutants was obtained. Increased hydrogen production was achieved by the ack-deleted mutant. However, because of significant reduction of AK and PTA activities in the mutants, less ATP was produced from the acetate-producing (PTA-AK) pathway, which can generate more ATP per mole of glucose metabolized than the butyrate-producing (PTB-BK) pathway does. The trade off is, however, the mutants suffered from a slower biomass growth rate. Unfortunately, the acetate production of the mutants did not decrease much [32, 39, 41, 42]. A possible reaction catalyzed by CoA transferase (Dashed Lines) to produce acetate in the absence of PTA and AK was proposed (Fig. 1), in which CoA transferase catalyzes the formation of acetate from acetyl-CoA. This enzyme has been found in some other clostridia bacteria [64].

End product inhibition is one of the key factors limiting the butyric acid production by fermentation. To avoid or reduce the inhibitory effect, traditional methods were applied to enhance the butyrate tolerance of Clostridium thermobutyricum from 150 to 350 mM by simultaneous product removal [44]. The other approach is to apply genetic engineering technology by overexpression some genes. For example, butanol-producing strains with either spo0A or groESL overexpression imparted increased tolerance and prolonged metabolism in response to butanol stress [65–68]. Using the similar technology, we believe that, butyrate tolerance of butyrate-producing strains can also be enhanced. Of course, the premise of strain development depends on the advance on genome research of butyrate-producing strains.

Future Research

Today, butyric acid produced by chemical synthesis dominates the production in industry. However, since it is widely utilized for human consumption in food additives, pharmaceutical products, and preservatives, “natural sources” of butyric acid is in consumers’ high demand. Thus butyric acid produced by microbe fermentation will have high potential to supplement the market. The prospect of future challenge of the fermentation technology will depend upon increasing butyrate tolerance of clostridia strains and decreasing cost of culture media material.

Regardless of how wonderful the prospect of decreasing acetate production and increasing butyrate tolerance is, much still remains to be done. Compared with other aspects, very few researches have focused on the research in enzymology and physiology of butyrate-producing strains, which we believe will be the hotspot in the near future.

Lignocellulosic materials have the potential to serve as a cost-effective source of raw material for the production of liquid fuel, including bioethanol and biobutanol, and various organic chemicals. Production for these materials is potentially sustainable and conversion to a fuel can be expected to meliorate many of the problems associated with consumption of petroleum-based fuels. The main obstacle to utilization of lignocellulosic feedstocks for fuel production is cost, which are dominated by the expense of hydrolyzing cellulose to monomer and dimer sugars [69, 70].

Since the cost of fermentation substrate has great influence on the cost of butyric acid produced by fermentation, the use of other renewable and economically feasible substrates such as agricultural waste has being investigated. Feedstock cost is an important issue in the economics of butyric acid production by fermentation, so the use of cellulose-rich wastes has the potential to significantly improve overall production cost. Introduction of cellulose-derived butyric acid into the market will most likely enhance process development of utilizing cellulose-rich wastes [71–74]. The benefits of such development may lead to revolutionize clostridia fermentation which can be summarized as follows.

First, clostridial co-culture of C. thermocellum and C. thermobutyricum was suggested by the authors that the mixed culture can integrate the four steps listed below into a single step: the production of saccharolytic enzymes (cellulases and hemicellulases); the hydrolysis of carbohydrate components from pretreated biomass into sugars; the fermentation of hexose (six carbon member) sugars (glucose, mannose and galactose); and the fermentation of pentose (five carbon member) sugars (xylose and arabinose). The integrated step was named consolidated bioprocessing (CBP) [75–80]. C. thermocellum is capable of producing cellulase and hemicellulase, utilizing the hexoses but not the pentose sugars generated from cellulose and hemicellulose. At the same time, C. thermobutyricum ferments pentose and hexose, more quickly than C. thermocellum, to butyric acid. In this mixed culture, the cost of cellulase production is significantly reduced or avoided, and C. thermobutyricum is able to consume glucose and cellobiose more quickly than C. thermocellum does. Glucose and cellobiose are the inhibitors to the cellulase excreted by C. thermocellum [72].

Second, in order to achieve cellulolytic ability for butyrate-producing strains while maintaining excellent butyric acid production capability, the recombinant technology to develop a cellulolytic organism is suggested, especially for Clostridium thermobutyricum due to its culture temperature similar to the temperature at which cellulase is most active. The butyrate-producing strains that can also hydrolyze cellulose will effectively reduce the over all process cost.

Since a major characteristic of butyrate fermentation is the simultaneous production of both butyric and acetic acids, the identification of specific control points in the bacterium that will allow selective butyric acid formation is crucial for the eventual successful of a commercial process.

Conclusion

Chemical synthesis of butyric acid dominates the production of this organic acid used in industry, while in food and pharmaceutical industries, fermentation production of such acid will play an important role in meeting the demands. Using traditional fermentation and process integration methods or genetic engineering technology to modify the microbial strains will enhance the butyrate tolerance and the butyrate production performance of the target strains. Advances in processing technology can also lead to improve butyric acid yield and productivity, which can eventually ameliorate the economics and efficiency of fermentation process. The application of lignocellulosic materials as a substrate will also reduce the raw material cost and over all production cost. All of these can make the butyric acid fermentation process more attractive and competitive comparing to that from petrochemical process.

References

Zigová J, Šturdík E, Vandák D, Schlosser S (1999) Butyric acid production by Clostridium butyricum with integrated extraction and pertraction. Process Biochem 34:835–843

Chen Z-X, Breitman TR (1994) Tributyrin: a prodrug of butyric acid for potential clinical application in differentiation therapy. Cancer Res 54:3494–3499

Ada Rephaeli RZAN (2000) Prodrugs of butyric acid from bench to bedside: Synthetic design, mechanisms of action, and clinical applications. Drug Dev Res 50:379–391

Collier-Hyams LS, Sitaraman S, Neish A (2006) Butyric acid, a physiologic bacterial fermentation product, represses epithelial inflammatory signaling via changes in Cul-1 neddylation. In: digestive disease week meeting/107th annual meeting of the American-Gastroenterlogical-Association. Los Angeles, CA, W B Saunders Co-Elsevier Inc., pp A491–A491

Blank-Porat D, Gruss-Fischer T, Tarasenko N, Malik Z, Nudelman A, Rephaeli A (2007) The anticancer prodrugs of butyric acid AN-7 and AN-9, possess antiangiogenic properties. Cancer Lett 256:39–48

Hamer HM, Jonkers D, Venema K, Vanhoutvin S, Troost FJ, Brummer R-J (2008) Review article: the role of butyrate on colonic function. Aliment Pharmacol Ther 27:104–119

Soni BK, Jain MK (1997) Influence of pH on butyrate uptake and solvent fermentation by a mutant strain of Clostridium acetobutylicum. Bioprocess Eng 17:329–334

Huang WC, Ramey DE, Yang ST (2003) Continuous production of butanol by Clostridium acetobutylicum immobilized in a fibrous bed bioreactor. In: 25th symposium on biotechnology for fuels and chemicals. Breckenridge, CO, Humana Press Inc., pp 887–898

Huang WC, Ramey DE, Yang ST (2004) Continuous production of butanol by Clostridium acetobutylicum immobilized in a fibrous bed bioreactor. Appl Biochem Biotechnol 113:887–898

Lee S-M, Cho MO, Park CH, Chung Y-C, Kim JH, Sang B-I, Um Y (2008) Continuous butanol production using suspended and immobilized Clostridium beijerinckii NCIMB 8052 with supplementary butyrate. Energy Fuels 22:3459–3464

Yang S (2009) Preparing butanol comprises providing feedstock having carbohydrate source; fermenting the carbohydrate source with butyric-acid producing bacteria to give butyric acid and hydrogen; and hydrogenating butyric acid with catalyst. Univ Ohio State

Zhu Y, Yang S-T (2004) Effect of pH on metabolic pathway shift in fermentation of xylose by Clostridium tyrobutyricum. J Biotechnol 110:143–157

Sutton JD, Dhanoa MS, Morant SV, France J, Napper DJ, Schuller E (2003) Rates of production of acetate, propionate, and butyrate in the rumen of lactating dairy cows given normal and low-roughage diets. J Dairy Sci 86:3620–3633

Pouillart PR (1998) Role of butyric acid and its derivatives in the treatment of colorectal cancer and hemoglobinopathies. Life Sci 63:1739–1760

Williams EA, Coxhead JM, Mathers JC (2003) Anti-cancer effects of butyrate: use of micro-array technology to investigate mechanisms. Proc Nutr Soc 62:107–115

Zigová J, Šturdík E (2000) Advances in biotechnological production of butyric acid. J Ind Microbiol Biotechnol 24:153–160

Rogers P, Chen J-S, Zidwick MJ (2006) Organic acid and solvent production. In: The Prokaryotes. Springer New York, pp 511–755

Hofstad T (2006) The genus Fusobacterium. In: The Prokaryotes. Springer New York, pp 1016–1027

He GQ, Kong Q, Chen QH, Ruan H (2005) Batch and fed-batch production of butyric acid by Clostridium butyricum ZJUCB. J Zhejiang Univ Sci 6B:1076–1080

van Andel J, Zoutberg G, Crabbendam P, Breure A (1985) Glucose fermentation by Clostridium butyricum grown under a self generated gas atmosphere in chemostat culture. Appl Microbiol Biotechnol 23:21–26

Vandák D, Telgarský M, Šturdík E (1995) Influence of growth factor supplements on butyric acid production from sucrose by Clostridium butyricum. Folia Micrbiol 40:669–672

Vandak D, Tomaska M, Zigova J, Sturdik E (1995) Effect of growth supplements and whey pretreatment on butyric-acid production by Clostridium butyricum. World J Microbiol Biotechnol 11:363

Abbad-Andaloussi S, Durr C, Raval G, Petitdemange H (1996) Carbon and electron flow in Clostridium butyricum grown in chemostat culture on glycerol and on glucose. Microbiology (UK) 142:1149–1158

Zeng AP (1996) Pathway and kinetic analysis of 1, 3-propanediol production from glycerol fermentation by Clostridium butyricum. Bioprocess Eng 14:169–175

Zhu HG, Miyake J, Asada Y (1996) Hydrogen production from tofu wastewater by Rhodobacter sphaeroides and Clostridium butyricum in rest culture. Recycling Resource 5–6:443–446

Takahashi M, Taguchi H, Yamaguchi H, Osaki T, Kamiya S (2000) Studies of the effect of Clostridium butyricum on Helicobacter pylori in several test models including gnotobiotic mice. J Med Microbiol 49:635–642

Saint-Amans S, Girbal L, Andrade J, Ahrens K, Soucaille P (2001) Regulation of carbon and electron flow in Clostridium butyricum VPI 3266 grown on glucose-glycerol mixtures. J Bacteriol 183:1748–1754

Kong Q, He GQ, Chen F, Ruan H (2006) Studies on a kinetic model for butyric acid bioproduction by Clostridium butyricum. Lett Appl Microbiol 43:71–77

Wang X, Monis PT, Saint CP, Jin B (2009) Biochemical kinetics of fermentative hydrogen production by Clostridium butyricum W5. Int J Hydrogen Energy 34:791–798

Wang XY, Jin B (2009) Process optimization of biological hydrogen production from molasses by a newly isolated Clostridium butyricum W5. J Biosci Bioeng 107:138–144

Patel GB, Agnew BJ (1988) Growth and butyric acid production by Clostridium populeti. Arch Microbiol 150:267–271

Liu X, Zhu Y, Yang ST (2006) Construction and characterization of ack deleted mutant of Clostridium tyrobutyricum for enhanced butyric acid and hydrogen production. Biotechnol Prog 22:1265–1275

Fayolle F, Marchal R, Ballerini D (1990) Effect of controlled substrate feeding on butyric acid production by Clostridium tyrobutyricum. J Ind Microbiol Biotechnol 6:179–183

Jo JH, Lee DS, Park JM (2008) The effects of pH on carbon material and energy balances in hydrogen-producing Clostridium tyrobutyricum JM1. Bioresour Technol 99:8485–8491

Michel-Savin D, Marchal R, Vandecasteele JP (1990) Control of the selectivity of butyric acid production and improvement of fermentation performance with Clostridium tyrobutyricum. Appl Microbiol Biotechnol 32:387–392

Huchet V, Thuault D, Bourgeois CM, Iir (1999) Modelling of the growth of Clostridium tyrobutyricum in semi-hard cheese, Cost 914- Predictive Microbiology Applied to Chilled Food Preservation: 224–228

Zhu Y, Wu ZT, Yang ST (2002) Butyric acid production from acid hydrolysate of corn fibre by Clostridium tyrobutyricum in a fibrous-bed bioreactor. Process Biochem 38:657–666

Zetang Wu S-TY (2003) Extractive fermentation for butyric acid production from glucose by Clostridium tyrobutyricum. Biotechnol Bioeng 82:93–102

Zhu Y (2003) Enhanced butyric acid fermentation by Clostridium tyrobutyricum immobilized in a fibrous-bed bioreactor. In: Department of Chemical Engineering. The Ohio State University. 31–57

Zhu Y, Yang ST (2003) Adaptation of Clostridium tyrobutyricum for enhanced tolerance to butyric acid in a fibrous-bed bioreactor. Biotechnol Prog 19:365–372

Zhu Y, Liu X, Yang ST (2005) Construction and characterization of pta gene-deleted mutant of Clostridium tyrobutyricum for enhanced butyric acid fermentation. Biotechnol Bioeng 90:154–166

Liu X, Zhu Y, Yang S-T (2006) Butyric acid and hydrogen production by Clostridium tyrobutyricum ATCC 25755 and mutants. Enzyme Microb Technol 38:521–528

Canganella F, Wiegel J (2000) Continuous cultivation of Clostridium thermobutyricum in a rotary fermentor system. J Ind Microbiol Biotechnol 24:7–13

Canganella F, Kuk S-U, Morgan H, Wiegel J (2002) Clostridium thermobutyricum: growth studies and stimulation of butyrate formation by acetate supplementation. Microbiol Res 157:149–156

Wiegel J, Kuk S-U, Kohring GW (1989) Clostridium thermobutyricum sp. nov., a moderate thermophile isolated from a cellulolytic culture, that produces butyrate as the major product. Int J Syst Bacteriol 39:199–204

Zhang C-H, Ma Y-J, Yang F-X, Liu W, Zhang Y-D (2009) Optimization of medium composition for butyric acid production by Clostridium thermobutyricum using response surface methodology. Bioresour Technol 100:4284–4288

Matijasic BB, Rajsp MK, Perko B, Rogelj I (2007) Inhibition of Clostridium tyrobutyricum in cheese by Lactobacillus gasseri. Int Dairy J 17:157–166

Rodriguez J, Kleerebezem R, Lema JM, van Loosdrecht MCM (2006) Modeling product formation in anaerobic mixed culture fermentations. Biotechnol Bioeng 93:592–606

Saint-Amans S, Soucaille P (1995) Carbon and electron flow in Clostridium butyricum grown in chemostat culture on glucose-glycerol mixtures. Biotechnol Lett 17:211–216

Henderson PJF (1971) Ion transport by energy-conserving biological membranes. Annu Rev Microbiol 25:393–428

Nuchnoi P, Izawa I, Nishio N, Nagai S (1987) Extractive acidogenic fermentation by a supported liquid membrane. J Ferment Technol 65:699–702

Evans PJ, Wang HY (1990) Effects of extractive fermentation on butyric acid production by Clostridium acetobutylicum. Appl Microbiol Biotechnol 32:393–397

Zigova J, Vandak D, Schlosser S, Sturdik E (1996) Extraction equilibria of butyric acid with organic solvents. Sep Sci Technol 31:2671–2684

Sabolova E, Schlosser S, Martak J (2001) Liquid–liquid equilibria of butyric acid in water plus solvent systems with trioctylamine as extractant. J Chem Eng Data 46:735–745

Martak J, Schlosser S (2008) Liquid–liquid equilibria of butyric acid for solvents containing a phosphonium ionic liquid. Chem Pap 62:42–50

Michel-Savin D, Marchal R, Vandecasteele JP (1990) Butyrate production in continuous culture of Clostridium tyrobutyricum: effect of end-product inhibition. Appl Microbiol Biotechnol 33:127–131

Tanaka A, Nakajima H (1990) Application of immobilized growing cells. In: Bioprocesses and applied enzymology. Springer Berlin/Heidelberg, pp 97–131

Iqbal M, Saeed A (2005) Novel method for cell immobilization and its application for production of organic acid. Lett Appl Microbiol 40:178–182

Chen F, Feng X, Li S, Oyang P, Xu H (2009) Application of bagasse as immobilization material in immobilized fiber bed reactor for producing organic acid, such as propanoic acid, lactic acid, butyric acid, and succinic acid, by fermentation. Univ Nanjing Polytechnic

Jiang L, Wang J, Liang S, Wang X, Cen P, Xu Z (2008) Production of butyric acid from glucose and xylose with immobilized cells of Clostridium tyrobutyricum in a fibrous-bed bioreactor. Appl Biochem Biotechnol

Jiang L, Wang J, Liang S, Wang X, Cen P, Xu Z (2009) Butyric acid fermentation in a fibrous bed bioreactor with immobilized Clostridium tyrobutyricum from cane molasses. Bioresour Technol 100:3403–3409

Huang YL, Wu Z, Zhang L, Ming Cheung C, Yang S-T (2002) Production of carboxylic acids from hydrolyzed corn meal by immobilized cell fermentation in a fibrous-bed bioreactor. Bioresour Technol 82:51–59

Liu XG, Yang ST (2005) Metabolic engineering of Clostridium tyrobutyricum for butyric acid fermentation, Abstracts of Papers of the American Chemical Society 229: 070-BIOT

Papoutsakis ET Meyer CL (1985) Equations and calculations of product yields and preferred pathways for butanediol and mixed-acid fermentations. Biotechnol Bioeng 27:50–66

Dürre P, Bohringer M, Nakotte S, Schaffer S, Thormann K, Zickner B (2002) Transcriptional regulation of solventogenesis in Clostridium acetobutylicum. J Mol Microbiol Biotechnol 4:295–300

Alsaker KV, Spitzer TR, Papoutsakis ET (2004) Transcriptional analysis of spo0A overexpression in Clostridium acetobutylicum and its effect on the cell’s response to butanol stress. J Bacteriol 186:1959–1971

Tomas CA, Beamish J, Papoutsakis ET (2004) Transcriptional analysis of butanol stress and tolerance in Clostridium acetobutylicum. J Bacteriol 186:2006–2018

Papoutsakis ET (2008) Engineering solventogenic clostridia. Curr Opin Biotechnol 19:420–429

Hendriks A, Zeeman G (2009) Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour Technol 100:10–18

Mtui GYS (2009) Recent advances in pretreatment of lignocellulosic wastes and production of value added products. Afr J Biotechnol 8:1398–1415

Chandra R, Bura R, Mabee W, Berlin A, Pan X, Saddler J (2007) Substrate pretreatment: the key to effective enzymatic hydrolysis of lignocellulosics? In: Biofuels. Springer-Verlag Berlin, Berlin, pp 67–93

Turner P, Mamo G, Karlsson EN (2007) Potential and utilization of thermophiles and thermostable enzymes in biorefining. Microb Cell Fact 6:23

van Zyl WH, Lynd LR, den Haan R McBride JE (2007) Consolidated bioprocessing for bioethanol production using Saccharomyces cerevisiae. In: Biofuels. Springer-Verlag Berlin, Berlin, pp 205-235

Ding SY, Xu Q, Crowley M, Zeng Y, Nimlos M, Lamed R et al (2008) A biophysical perspective on the cellulosome: new opportunities for biomass conversion. Curr Opin Biotechnol 19:218–227

Demain AL, Newcomb M, Wu JHD (2005) Cellulase, clostridia, and ethanol. Microbiol Mol Biol Rev 69:124–154

Lynd LR, van Zyl WH, McBride JE, Laser M (2005) Consolidated bioprocessing of cellulosic biomass: an update. Curr Opin Biotechnol 16:577–583

Blumer-Schuette SE, Kataeva I, Westpheling J, Adams MWW, Kelly RM (2008) Extremely thermophilic microorganisms for biomass conversion: status and prospects. Curr Opin Biotechnol 19:210–217

Fu N, Peiris P (2008) Co-fermentation of a mixture of glucose and xylose to ethanol by Zymomonas mobilis and Pachysolen tannophilus. World J Microbiol Biotechnol 24:1091–1097

Lin C-Y, Hung W-C (2008) Enhancement of fermentative hydrogen/ethanol production from cellulose using mixed anaerobic cultures. Int J Hydrogen Energy 33:3660–3667

Nakamura N, Yamada R, Katahira S, Tanaka T, Fukuda H, Kondo A (2008) Effective xylose/cellobiose co-fermentation and ethanol production by xylose-assimilating S. cerevisiae via expression of [beta]-glucosidase on its cell surface. Enzyme Microb Technol 43:233–236

Acknowledgment

This project was financed by the Key Research Programs of Shandong Province, P. R. China, under contract 2007GG2QT07006.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, C., Yang, H., Yang, F. et al. Current Progress on Butyric Acid Production by Fermentation. Curr Microbiol 59, 656–663 (2009). https://doi.org/10.1007/s00284-009-9491-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-009-9491-y