Abstract

A simple procedure was developed for the design of low-cost, gravity-fed, drip irrigation single-manifold subunits in hilly areas with laterals to one or both sides of the manifold. The allowable pressure head variation in the manifold and laterals is calculated individually for different pressure zones, and the manifold subunit design is divided into independent processes for laterals and manifold. In the manifold design, a two-stage optimal design method is used. In the first design stage, the pipe cost is minimized and a set of optimal manifold pipe diameters is obtained. In the second design stage, a partial list of available diameters is prepared based on the calculated optimal diameters, and the lengths for available diameters and pressure head of every lateral location along the manifold are calculated. The size of each of the pressure sections is determined according to the pressure head distribution along the manifold. Using the proposed methodology, the minimum manifold pipe cost is obtained, and the target emission uniformity is satisfied for gravity-fed drip irrigation subunits.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The cultivation of fruit trees and other crops can be more profitable in upland hilly areas due to favorable climatic conditions, such as those found in northwest China. However, farmers grow rain-fed crops in these areas with relatively low yields when irrigation water is scarce. Hand-watering of crops, as used on a small scale in some water-scarce upland areas, is perhaps the most efficient water application method, but it requires a huge amount of labor. Drip irrigation can be used instead of hand-watering with minimal water losses and a significant reduction in labor, and it has the potential to increase crop yield (Singh 1978). Also, due to topographical advantages, drip irrigation systems in hilly or mountainous areas can be pressurized by elevation change without the need for pumping. In some gravity-fed drip irrigation systems, there is no energy cost associated with their operation, nor is there a need for pump equipment and power units to drive the pumps, whereas in others, water must be pumped up to a reservoir above the irrigated area.

Different technical aspects of the design of drip irrigation systems have been discussed in detail by Keller and Bliesner (1990) and Bucks and Nakayama (1986). Wu (1997) assessed drip irrigation systems with respect to the relative effects of hydraulic design, emitter manufacturing variation, grouping of emitters, and emitter plugging. The design of multi-diameter and multi-outlet pipes laid on flat or sloping lands has been analyzed by many researchers (e.g., Anwar 1999; Ajai et al. 2000; Jain et al. 2002; Mahar and Singh 2003; Valiantzas 2002; Juana et al. 2004; Yildirim 2007). Procedures for the optimal design and operation of a multiple subunit drip irrigation system on flat ground were developed by Dandy and Hassanli (1996). Ravindra et al. (2008) also developed a design procedure for drip irrigation subunits. Bhatnagar and Srivastava (2003) investigated gravity-fed drip irrigation systems for hilly terraces in which low-pressure emitters were used, but without dividing the irrigated area into subunits with different pressure ranges.

In many drip irrigation systems in hilly or mountainous areas, the manifold runs downhill and laterals are laid along elevation contours. In these systems, emitters should be chosen according to the nominal design pressure that best matches the available pressure at the entrance of each lateral. For instance, emitters designed for a low operating pressure can be used on the upper segments of the manifold, and emitters with a high operating pressure can be used on the lower part of the manifold. Thus, there could be several “pressure sections” (e.g., low, middle, and high pressure sections), consisting of groups of adjacent laterals along the manifold, in which each section would use emitters that are appropriate for the average available pressure in that section.

In this paper, the hydraulic characteristics of different pressure sections along the manifold are analyzed and a design procedure is presented for low-cost, gravity-fed drip irrigation systems that can use pressure-compensating emitters but do not require the use of pressure regulators. The design criteria are such that the target emission uniformity is satisfied in each of the pressure sections and the manifold pipe sizing results in minimal pipe cost. The design procedure considers one or more pressure sections in which potentially different emitters are matched to the pressure range in groups of laterals along the manifold.

Design assumptions

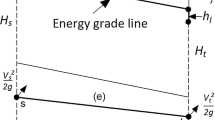

For the proposed design procedure, a single drip irrigation subunit consisting of a manifold running downhill along a constant, uniform slope from a water supply tank feeds water to laterals on both sides of the manifold. The laterals are uniformly spaced along the manifold, and emitters are uniformly spaced along the laterals. In the design, the manifold pipe may have several different pipe diameters to accommodate lateral inlet pressure requirements and to minimize the cost of the pipe. The laterals are assumed to be laid along elevation contours and the manifold runs downhill. According to the proposed design procedure, the water pressure in the manifold will increase monotonically in the downhill direction, provided the ground slope is sufficiently steep. Many different emitter designs could be used, but for practicality the manifold subunit may be divided into only 1–4 pressure sections, each with only one type of emitter. Appropriate emitters are chosen according to the allowable head range in each of the pressure sections. Therefore, the design pressure at each emitter is matched to the pressure at the entrance of each lateral. An example of the steady-state pressure change along a manifold and laterals (with laterals to only one side) is illustrated in Fig. 1.

Uniformity analysis of a gravity-fed drip irrigation system subunit

To achieve the desired water distribution uniformity, the minimum emitter discharge in the different pressure sections can be related as follows (Keller and Bliesner 1990):

where N p is minimum number of emitters from which each plant receives water; q ai is the average emitter discharge in the ith pressure section; q ni is the minimum emitter discharge in the ith pressure section; CVmi is the emitter coefficient of manufacturing variation in the ith pressure section; and E u is the target irrigation uniformity (fraction).

Equation 1 assumes a normal distribution of emitter discharges, which is generally true when the E u is greater than about 85%. For system design purposes, the average emitter discharge is set equal to the desired emitter discharge. The head-discharge relationship for emitters is assumed to take the following general form:

where q is the emitter discharge (m3/h); K d and x are empirical parameters; and H is the pressure head (m) in the lateral at the emitter location. Equation 2 is valid within a given range of pressure heads, depending on the emitter design.

The minimum emitter pressure in different pressure sections can be expressed as:

where x i is the emitter discharge exponent in the ith pressure section; H ai is the average emitter pressure head in the ith pressure section (m); and H ni is the minimum emitter pressure head in the ith pressure section (m). The allowable pressure head variation in different pressure sections can be calculated as follows (Keller and Bliesner 1990):

where ∆H si is the allowable pressure head variation in the ith pressure section (m).

The allowable pressure head variation in a pressure section is the sum of the pressure head variations in the laterals and manifold:

where ∆H smi is the allowable manifold pressure head variation in the ith pressure section (m) and ∆H sLi is the allowable lateral pressure head variation in the ith pressure section (m).

Alternatively, Eq. 5 can be expressed as:

where μ i is a number between 0 and 1, referred to herein as a distribution coefficient. Thus, ∆H smi = μ i ∆H si and ∆H sLi = (1 − μ i )∆H si.

Then, the maximum allowable pressure head in the ith pressure section can be calculated as:

And, the manifold pressure head in different sections should satisfy the following condition:

where H m(i−1) is the allowable pressure head at the downhill end of the manifold in the (i − 1)th pressure section (m); μ i is the distribution coefficient of the manifold pressure head variation in the ith pressure section (m); and ΔH i,(i−1) is the inlet pressure head difference from last (downstream) lateral in the (i − 1)th pressure section to the first lateral in the ith pressure section. In general, because the distance between laterals is small compared to the length of the manifold in each pressure section, ∆H i,(i−1) is of small magnitude and can be omitted from Eq. 8. Also, the distribution uniformity is greater when omitting ∆H i,(i−1) than when including it, so the omission of this term makes the design somewhat more conservative. Thus, μ i can be calculated from Eq. 8 as:

where H mi is the maximum allowable pressure head in the ith pressure section.

Lateral hydraulic calculations

The proposed design procedure can be applied in two ways: (1) for a specified lateral diameter, calculate the maximum allowable lateral length or (2) for a specified lateral length, calculate the minimum allowable lateral diameter. This is to accommodate practical considerations in which only a few different lengths will fit the size and shape of the irrigated area, depending on the pipe layout, and there are usually only three or four available lateral pipe diameters on the market. Because the laterals are laid along elevation contours, the ground slope along the lateral is equal to zero. Thus, the lateral friction loss for a given pipe diameter can be calculated as:

where H fLi is the lateral friction loss in the ith pressure section (m), which can also be calculated as:

where K is a coefficient to account for local hydraulic losses at each emitter (K ≥ 1); f is a constant equal to 84,000 s2/m; ξ1 and ξ2 depend on the friction loss equation (ξ1 = 1.75 and ξ2 = 4.75 for the Blasius equation); S e is the emitter spacing along the lateral (m); Q L(i,j) is the lateral discharge at the jth emitter in the ith pressure section (m3/h); D Li is the lateral inside diameter in the ith pressure section (mm); and (N e )i is the calculated number of emitters along a lateral in the ith pressure section.

For practicality, the design procedure assumes that the same diameter is used for all laterals in a pressure section, but different pressure sections can each have a different lateral diameter. In the design procedure, the smallest available lateral pipe diameter is chosen such that the target E u is satisfied in each of the pressure sections. Of course, for laterals running uphill or on level ground, the largest available pipe diameter will give the best pressure uniformity.

The number of emitters per lateral and lateral length is determined according to the process shown in Fig. 2, based on Eq. 11, when the lateral diameter is specified. Then, the maximum allowable lateral length in a given pressure section can be calculated as:

where (L Li) a is the maximum allowable lateral length (m). This maximum lateral length can be compared to different subunit layout alternatives and the most appropriate of them can be selected.

Manifold hydraulic design

The manifold pressure head needs to increase in the downhill direction in a gravity-fed drip irrigation system because the elevation decreases along the manifold. Most currently available long-path turbulent flow emitters and pressure-compensating emitters require an operating water pressure head of 5 m or more for best performance. Additional pressure head is required to overcome the friction losses in different components of the system. Thus, the average hydraulic gradient in each pressure section is less than or equal to the ground slope along the manifold. The maximum head in each pressure section is assumed to be at the lowest (downstream) point in the manifold within that pressure section, which is true when the manifold slope is sufficiently steep and the pipe diameter is not too small. The allowable manifold friction loss can be calculated as follows:

where (H fm) a is the allowable manifold friction loss (m); J m is the ground slope (assumed constant) along the manifold pipe (J m > 0 for downhill slopes); L m is the total manifold length (m); and H m0 is the pressure head at the uphill end of the manifold (m); \( H_{{m,N_{a} }} \) is the pressure head at the downhill end of the manifold (m).

The manifold design process consists of two stages, as described in the following paragraphs. The first stage calculates the exact required manifold pipe inside diameters, and the second stage selects the most appropriate diameters from a list of available pipe diameters.

Stage I: optimal pipe diameters

When the decision variable is taken as a combination of pipe diameters, the pipe objective function is to minimize the manifold pipe cost and can be written as follows (Zhu et al. 2005; Holzapfel 1990):

where W is the total manifold pipe cost ($); D j is the diameter of the jth manifold pipe segment (m); S L is the uniform lateral spacing (m); N L is the total number of laterals along the manifold (Fig. 3); and,

where C is pipe material price ($/kg); γ p is pipe material density (kg/m3); σ is pipe allowable tensile stress (kN/m2); γ w is water bulk density (9.8 kN/m3); t is pipe useful life (year); and H lt is the allowable pipe operating pressure head (m).

The actual manifold friction loss is set equal to the allowable loss:

where Q j is the discharge of the jth pipe segment (m3/h). A supplemental function can be written as follows:

where Z(D 1, D 2,…, D NL) is the supplemental function and λ is a sufficiently large number (typically λ > 1010). When λ is a very large number, the solution to the original function (Eq. 14) is equal to the supplemental function, and the term in parentheses should be zero according to Eq. 16.

Because the design variable is the pipe diameter, the objective function (Eq. 17) is minimized when the derivative ∂Z/∂D j is equal to zero. The following equation is obtained by differentiating Eq. 17:

whereby λ is defined as:

in which λ is the same for every pipe segment. Thus, from Eq. 19,

whereby,

and,

Substituting Eq. 22 into Eq. 16, the following equation is obtained:

Finally, the diameter of the jth manifold pipe segment can be calculated as:

Stage II: selecting from available manifold diameters

Stage I of the design procedure results in the calculation of exact manifold pipe diameters based on an optimization process as described earlier, but the final design must take into account only those pipe diameters that are commercially available in the required range of sizes. The enumeration method is applied in Stage II after first compiling a list of N d different available manifold pipe diameters based on the results from Stage I of the design procedure. Minimization of the annual operating cost is taken as the objection function for selecting from among the list of available pipe diameters, where the pipe diameter is a decision variable.

The minimum cost of the jth manifold pipe segment was expressed by Pleban and Shacham (1984) and Zhu et al. (2005):

where H fm(j,k) is the friction loss of the jth pipe segment using the kth diameter (m); E is energy cost ($/kWh); and T is the total annual irrigation system operation time (h). The friction loss in the jth pipe segment with the kth pipe diameter can be calculated as follows:

where D j,k is the kth diameter of the jth pipe segment (mm).

The minimal cost from the first to the jth pipe segment can be expressed as follows:

where min W(j) is the minimal cost from the first to the jth pipe segment; W(j − 1) is the minimal cost from the first to the (j − 1)th pipe segment; J is the number of pipe segments, from 1 to N L (Fig. 3); W i,k is the cost of the jth pipe segment with the kth diameter; min {W i,k} is the minimum cost of the jth pipe segment with the optimal available diameter; and N d is the number of available diameters. Equation 25 is subject to the following condition:

where N L is the number of lateral along the manifold.

Required manifold inlet pressure head

Some emitters may have zero discharge if the manifold inlet pressure head is insufficient to meet the minimum emitter operating pressure at all locations along the lateral. Zhu et al. (2009) demonstrated that the minimum emitter operating pressure is affected by field micro-topography, which describes small surface elevation irregularities along a lateral. Due to these irregularities, the actual elevations of some emitters are higher than the assumed elevations, resulting in relatively low pressures. The field roughness height is defined as the difference between the elevation of an assumed uniform (sloping or level) ground surface and the actual elevation of a given emitter. Thus, when the manifold inlet pressure head is insufficient, the discharge at some emitters might be zero.

Zhang and Wu (2005) and Zhu et al. (2009) developed the following formula using Taylor binomials:

where q zv is the discharge variation rate caused by field micro-topography; x is as defined in Eq. 2; ∆Z is the maximum ground roughness height difference (m); and H a is the required average emitter pressure head (m). The discharge variation rate caused by micro-topography decreases with increasing average pressure head at the emitters, and with decreasing surface roughness height. However, this discharge variation is usually neglected in conventional drip irrigation system designs, and it has been suggested (Zhang and Wu 2005) that q zv is negligible when it is less than 0.05.

The required minimum manifold inlet pressure head is (Keller and Bliesner 1990):

where (H m0)min is the required minimum manifold inlet pressure head (m).

Design procedure

The design procedure, which was presented in detail earlier, can be summarized in the following steps:

-

Step 1: emitter hydraulic calculations

-

1.

Apply Eq. 1 to determine the nominal emitter flow rates according to the design parameters;

-

2.

Apply Eq. 3 to calculate the minimum emitter heads in each of the pressure sections;

-

3.

Apply Eq. 4 to determine the allowable head variation in each of the pressure sections;

-

4.

Apply Eq. 7 to obtain the maximum allowable head in each pressure section; and

-

5.

Apply Eq. 9 to calculate the distribution coefficients, μ i , for each pressure section.

-

1.

-

Step 2: lateral hydraulic calculations

-

6.

Apply Eq. 10 to calculate the lateral friction loss in each pressure section;

-

7.

Apply Eq. 11 to calculate the lateral friction losses in a different way, and equating the results to the respective values from Eq. 10; and

-

8.

Apply Eq. 12 to determine the maximum allowable lateral length in each pressure section.

-

6.

-

Step 3: manifold hydraulic calculations

-

9.

Apply Eq. 13 to calculate the allowable manifold friction loss;

-

10.

Apply Eq. 24 to determine the exact diameter of each manifold pipe segment (Stage I);

-

11.

Apply Eqs. 25–28 to select from the available diameters for each manifold pipe segment (Stage II); and

-

12.

Apply Eqs. 29 and 30 to calculate the required manifold inlet pressure head.

-

9.

-

Step 4: pressure unit divisions

-

13.

Calculate the pressure head at each lateral inlet along the manifold, and find the pressure head of the lateral inlet that matches the maximum allowable head in each pressure section, as determined in Step 1 of this design procedure.

-

13.

Sample drip system designs

Consider an example design of a gravity-fed pipe drip irrigation subunit where the data and calculation steps are shown in Table 1. A 100-m long manifold has 25 laterals equally spaced at S l = 4 m, whereby the laterals are only to one side of the manifold. The maximum difference in field roughness height along lateral is 0.2 m. The ground slope along the manifold is J m = 0.2 and the emitter spacing is 0.3 m. For this sample design, the number of pressure sections is specified as N a = 3, the manifold inlet pressure head is H m0 = 4 m, and the target emission uniformity is E u = 0.8. The desired average emitter discharge of the three pressure sections is equal to 0.003 m3/h, and the average emitter pressure heads in the same three sections are 5, 8, and 10 m, respectively, from uphill to downhill. The emitter manufacturing variation coefficient of the three pressure areas is equal to 0.07. The maximum roughness height difference (∆Z) along the lateral is 0.2 m.

The minimum desired emitter discharge (q n1, q n2, and q n3) of the three pressure sections is 0.0025 m3/h. The minimum emitter pressure heads of three pressure sections (H n1, H n2, and H n3) are equal to 3.64, 5.82, and 7.28 m, respectively. The discharge variation rate caused by micro-topography (q zv) is 0.027. The head variations in the three pressure sections are ∆H s1 = 4.61 m, ∆H s2 = 5.43 m, and ∆H s3 = 6.80 m, respectively. The maximum emitter pressure heads of the three pressure sections (H m1, H m2, and H m3) are equal to 7.03, 11.3, and 14.1 m, respectively. Finally, the distribution coefficients of manifold pressure head variation of the three pressure sections (μ1, μ2, and μ3) are equal to 0.89, 0.77, and 0.41, respectively.

According to Eqs. 10–12, the maximum allowable lateral lengths in the different pressure sections are 51.9, 54.9, and 51.6 m for 20-, 16-, and 12-mm pipe diameters, respectively, from uphill to downhill. The lateral pipe diameters are selected such that the target E u is satisfied, while minimizing the cost of the lateral pipe. A lateral length of 51 m was used in this sample design, so the number of emitters per lateral is 170. The required minimum manifold inlet pressure head is 4.00 m and the calculated manifold inlet pressure head is 3.98 m, thereby satisfying the design requirement. In order to validate the rationality of emitter operating pressure head in pressure section one, q zv = 0.02 was calculated using Eq. 29, which is small enough and will not significantly influence the irrigation uniformity.

Using Eq. 13, an allowable manifold friction loss of 9.93 m is calculated for the given manifold inlet pressure head of 4 m, outlet pressure head of 14.1 m, and elevation difference of 20 m. Using Eq. 24, the optimal diameter of each pipe segment was obtained for the allowable manifold friction loss. As shown in Table 2, the calculated manifold diameter changed from 18.3 to 42.1 mm. Therefore, in Stage II of the design procedure, three nominal diameters (50, 40, and 25 mm, respectively) were selected. Then, the suitable length of pipe segment of the manifold for each of the three nominal diameters was calculated. The manifold pipe segment lengths for the 50, 40, and 25 mm diameters are 20, 40, and 40 m, respectively. The total friction loss along the manifold is 10.2 m, which, when compared to allowable friction loss of 9.93 m, is only a 1.7% difference. The head at each lateral location along the manifold (H mj) is shown in Table 2, where the actual E u is calculated from Eqs. 1 and 3 by calculating q ni for each pressure section, then solving for E u .

From Tables 1 and 2, it is seen that the first pressure section is from the first to the fifth lateral (from the uphill end of the manifold), in which the manifold pressure ranges from 4.00 to 6.88 m because the required pressure head of manifold in the first pressure section is from 4.00 to 7.03 m. The second pressure section is from the sixth to the fourteenth lateral in which the manifold pressure ranges from 7.18 to 11.0 m, and the required pressure head of manifold in the second pressure section is from 7.03 to 11.3 m. The third pressure section is from the fifteenth to the twenty-fifth lateral in which the manifold pressure ranges from 11.6 to 13.8 m, and the required pressure head of manifold in the third pressure section is from 11.3 to 14.1 m. The design results are shown in Fig. 4, and it is seen in Table 2 that the actual E u values are approximately equal (0.80) or greater than (0.85) the target E u of 0.83.

Alternative designs

The number of pressure sections selected for a given design depends on the availability of emitters on the market, engineering judgment, manifold slope, and manifold inlet pressure. In the earlier mentioned design example, if there were only one or two pressure sections, different manifold design results would be obtained, as shown in Tables 3 and 4. When N a equals 1, the emitter is the same as that used in the first pressure section of the earlier mentioned example with three pressure sections. The maximum allowable lateral length is 51.9 m, and this was rounded down to 51.0 m. The maximum allowable friction loss along the manifold is equal to 17.0 m. From Table 4, it is seen that the manifold pressure ranges from 4.00 to 6.86 m (from the first to the twenty-fifth lateral), and the required manifold pressure head in the first pressure section is from 4.00 to 7.03 m. The actual E u value of this pressure section is approximately 0.80, which is equal to the target E u . The design results for the manifold subunit are shown in Fig. 5.

When N a is equal to 2, the allowable friction loss along the manifold is equal to 12.7 m. From Table 4, it is seen that the first pressure section is from the first to the sixteenth lateral (from the uphill end of the manifold), in which the manifold pressure ranges from 4.00 to 6.94 m because the required manifold pressure head in the first pressure section is from 4.00 to 7.03 m. The second pressure section is from the seventeenth to the twenty-fifth lateral in which the manifold pressure ranges from 7.38 to 11.2 m, and the required manifold pressure head in the second pressure section is from 7.03 to 11.3 m. It is seen in Table 4 that the actual E u values of the two pressure sections are approximately equal to 0.80 and 0.88, respectively, satisfying the target E u of 0.80. The design results for this manifold subunit are shown in Fig. 6.

It is seen that all three design alternatives presented here for the sample system meet the target E u of 0.80. However, based on manifold and lateral pipe diameter differences, the alternative with three pressure sections is less expensive than the one with two pressure sections, which is cheaper than that with only one pressure sections. When the pipe allowable pressure of 200 kPa is selected, the pipes (including manifold and laterals) cost are $333.5, $341.2, and $459, respectively, for three, two, and one pressure sections. Thus, with multiple pressure sections, the cost of the system can be reduced while still meeting the target emission uniformity. In addition, the emitter discharge variation generated by micro-topography, q zv, equal to 0.020, 0.013, and 0.010 when the emitter operating pressure is 5, 8, and 10 m, respectively, decreases with increasing emitter operating pressure.

In the sample designs, the emitter discharge variation generated by micro-topography was neglected because a relatively high emitter operating pressure was chosen. However, if a low emitter operating pressure were selected, q zv can be more than the allowable discharge variation and the target uniformity will not be attained.

Summary and conclusions

A simple gravity-fed drip irrigation system design procedure was developed for low-cost, single-manifold subunits with multiple pressure sections in mountainous areas, optionally using pressure- compensating emitters, but without the use of pressure regulators. The design procedure is based on two optimization stages for optimizing manifold pipe diameters and satisfying the target emission uniformity. In the first stage, pipe cost minimization is used as the objective function, and pipe diameter is used as a decision variable. In the second stage, commercially available pipe diameters are selected, and the length of each available diameter and pressure head at each lateral location along the manifold are determined. The length of the pressure sections is determined according to pressure head distribution in the manifold and the required pressure head of the different pressure sections. Using the proposed methodology, not only is the minimum manifold pipe cost obtained, but the target emission uniformity can also be satisfied. The design procedure can be applied in a spreadsheet application on a personal computer. Although this design procedure has the advantages of potentially lower hardware cost and higher uniformity than traditional design approaches for gravity-fed drip irrigation systems, it also has the disadvantage of a somewhat more complex installation and less convenient maintenance due to the different pressure sections.

References

Ajai S, Singh RP, Mahar PS (2000) Optimal design of tapered micro irrigation sub main manifolds. J Irrig Drain Div ASCE 122(2):371–374

Anwar AA (1999) Factor G for pipelines with equally spaced multiple outlets and outflows. J Irrig Drain Eng ASCE 125(1):34–38

Bhatnagar VK, Srivastava RC (2003) Gravity-fed drip irrigation system for hilly terraces of the northwest Himalayas. Irrig Sci 21:151–157

Bucks DA, Nakayama FS (1986) Trickle irrigation for crop production: design, operation and management. Elsevier, New York, 383 pp

Dandy GC, Hassanli AM (1996) Optimum design and operation of multiple subunit drip irrigation systems. J Irrig Drain Eng ASCE 122(5):265–275

Holzapfel EA (1990) Drip irrigation nonlinear optimization model. J Irrig Drain Eng ASCE 116(4):196–479

Jain SK, Singh KK, Singh RP (2002) Microirrigation lateral design using lateral discharge equation. J Irrig Drain Eng ASCE 128(2):125–128

Juana L, Losada A, Rodriguez L, Sánchez R (2004) Analytical relationships for designing rectangular drip irrigation units. J Irrig Drain Eng ASCE 130(1):47–59

Keller J, Bliesner RD (1990) Sprinkler and trickle irrigation. AVI, Van Nostrand Reinhold, New York

Mahar PS, Singh RP (2003) Computing inlet pressure head of multi-outlet pipeline. ASCE J Irrig Drain Eng 129(6):464–467

Pleban S, Shacham D (1984) Minimizing capital costs of multi-outlet pipelines. J Irrig Drain Eng ASCE 110(2):165–178

Ravindra VK, Singh RP, Mahar PS (2008) Optimal design of pressurized irrigation subunit. J Irrig Drain Eng ASCE 134(2):137–146

Singh SD (1978) Effects of planting configurations on water use and economics of drip irrigation systems. Agron J 70:951–954

Valiantzas JD (2002) Continuous outflow variation along irrigation laterals: effect of the number of outlets”. J Irrig Drain Eng ASCE 128(1):34–42

Wu IP (1997) An assessment of hydraulic design of micro-irrigation systems. Agric Water Manag 32:275–284

Yildirim G (2007) Analytical relationships for designing multiple outlet pipelines. J Irrig Drain Eng ASCE 133(2):140–155

Zhang GX, Wu PT (2005) Determination of the design working head of an emitter. Trans Chin Soc Agric Eng 21(9):21–22

Zhu DL, Wu PT, Niu WQ (2005) Sprinkle and micro irrigation submain manifold design by two stages optimal method. Hydr J China 36(5):608–612

Zhu DL, Wu PT, Merkley GP (2009) Drip irrigation lateral design procedure based on emission uniformity and field micro-topography variation. Irrig Drain 59:1–12

Acknowledgments

This study was supported by the Project of the Structure Optimal Design of Rainwater Collection Equipment (2006BAD09B01), the Project of a Study on Water Saving Technology of Fruit Trees in Hilly area (2007BAD88B05), the Project of a Study on Oasis Water Saving Technology in Arid Area (2007BAD3808-02-02), and the 111 Project (No.111-2-16).

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by J. Ayars.

Rights and permissions

About this article

Cite this article

Wu, P.T., Zhu, D.L. & Wang, J. Gravity-fed drip irrigation design procedure for a single-manifold subunit. Irrig Sci 28, 359–369 (2010). https://doi.org/10.1007/s00271-009-0196-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00271-009-0196-6