Abstract

Drip irrigation has the potential to save water and mitigate foliar diseases for processing tomato production in Central Brazil. Four experiments were carried out at Embrapa Vegetables, Brasília, Brazil, to establish irrigation management strategies during vegetative, fruit development, and maturation growth stages of drip-irrigated processing tomato. Soil water tension (SWT) threshold values ranging from 5 to 120 kPa were evaluated. Plants growing under higher water deficit during the vegetative stage showed root systems up to 10 cm deeper than those irrigated more frequently. Maximum fruit yield was reached when irrigations were performed at SWT thresholds of 35, 12, and 15 kPa during vegetative, fruit development, and maturation growth stages, respectively. Total soluble solids content was not affected by irrigation treatments during vegetative and fruit development stages, but increased as SWT increased during fruit maturation growth stage.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Presently, about 80% of the entire Brazilian processing tomato production is located in Central Brazil, because of favorable soil and climatic conditions. Drip irrigation associated with fertigation can increase processing tomato fruit yield and save 30% of irrigation water compared with sprinkle irrigation (Colla et al. 1999; Prieto et al. 1999). Center pivot sprinkler irrigation is the method generally employed in Brazil for processing tomato production. Because drip irrigation applies water directly to the soil, without wetting leaves and fruits, foliar disease, fungicide use, and fruit decomposition are reduced with drip irrigation (Silva et al. 1999).

Although the drip-irrigated area of processing tomato in Brazil has been increasing, it still occupies a small area. In the last 10 years, the area has grown from about 200 to 1,300 ha and currently represents 9% of the total irrigated processing tomato. In general, both lack of coherent information about the advantages of drip irrigation and the absence of irrigation management strategies under Brazilian conditions are important constraints which have limited its expansion. Marouelli et al. (2003) reported that even with higher production costs, the net economic revenue of drip irrigated processing tomatoes is slightly higher than the net revenue under center pivots.

Several studies on sprinkler irrigated processing tomato irrigation have been conducted in Central Brazil (Silva and Marouelli 1999). In the case of sprinkler systems, excess irrigation favors higher incidence of foliar diseases and higher occurrence of decomposed fruit, while deficit irrigation, mainly in the fruit development stage, reduces fruit yield. However, the occurrence of moderate water deficits during the vegetative stage favors deeper rooting and during the maturation growth stage increases the total soluble solids, regardless of the irrigation system used (Marouelli et al. 2004; Johnstone et al. 2005; Machado and Oliveira 2005).

The design of proper irrigation scheduling should avoid detrimental water deficits or excesses and requires information on the effects of water stress during the different crop development stages (Renquist and Reid 2001). Appropriate soil water tension (SWT) threshold values can vary significantly as a function of crop development stage (Marouelli et al. 1991) and are important for the establishment of adequate irrigation schedules. In the Brazilian literature there are no recommendations regarding these thresholds for drip irrigated processing tomato. According to Renquist and Reid (2001), the differential effects of soil–water deficit on tomato fruit yield and quality are complex and poorly defined despite much research worldwide. Irrigation thresholds should be determined for site-specific conditions, because they may be affected by factors such as climate and soil conditions, cultivar, and irrigation system (Martin et al. 1990; Prieto et al. 1999; Shock et al. 2007). For drip irrigation under California conditions, Hartz and Hanson (2005) recommended that until the beginning of fruit maturation growth stage the SWT irrigation thresholds should be in the range of 20–35 kPa and from then on, in the range of 40–50 kPa.

The objective of this work was to establish the parameters of water management for processing tomatoes irrigated by drip systems in Central Brazil, by evaluating the effects of SWT irrigation thresholds during tomato’s vegetative, fruit development and fruit maturation growth stages.

Materials and methods

Four experiments were carried out during the months of May through September, the drier and cooler season of the year, from 2000 throughout 2002, at the experimental fields of Embrapa Vegetables, located in the Federal District of Brazil, in the central region of the country. The experimental site was 997 m above the sea level and was located at 15°56′ south and 48°08′ west. The local climate is classified by Köppen as Cwa-type, humid and hot summers and dry and cold winters, and the soil is a well-drained clayey red Oxysol. Soil–water retention characteristics, for the top 40 cm of the profile, in the range of 5–1,500 kPa, are represented by the adjusted equation θ(ψm) = 23.0 + 14.9/[1 + (0.0576 × ψm)1.7563]0.4301 (van Genuchten 1980), where θ is the volumetric soil moisture content (%) and ψm the soil matric tension (kPa).

Experiment I consisted of nine irrigation management treatments resulting from the combination of three levels during two timings: (1) SWT irrigation thresholds (15, 30 and 70 kPa) applied during the vegetative growth stage, and (2) SWT irrigation thresholds (15, 30 and 70 kPa) applied during the fruit development stage. Treatments in experiment II consisted of six SWT irrigation thresholds (6, 10, 15, 30, 60 and 120 kPa) during the vegetative growth stage, and experiment III consisted of six SWT irrigation thresholds (5, 8, 12, 20, 45 and 100 kPa) during the fruit development stage. Four SWT irrigation thresholds (15, 30, 60 and 120 kPa) were evaluated during fruit maturation growth stage in experiment IV. Each experiment was carried out during one growing season. During the nontarget crop growth stages of each experiment, no treatments were applied and irrigations were scheduled uniformly at SWT threshold values of 20 kPa during fruit development stage and 45 kPa during both vegetative and fruit maturation growth stages (Hartz and Hanson 2005).

The vegetative growth stage corresponded to the period between the initial seedling establishment and the beginning of flowering (from the 8th to the 33rd day after the seedling transplant). The fruit development stage started at the end of the vegetative stage and finished at the beginning of the fruit maturation growth stage (from the 34th to the 90th day). In experiment IV, the irrigation treatments were started when 70% of the plants had at least one red fruit and irrigations were ended when 80% of the fruit were red (from the 85th to the 110th day after transplant).

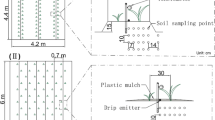

In each experiment, tomato seedlings were planted about 30 days after sowing, at 30 × 120 cm spacing, in pre-irrigated soil with a water content near field capacity in the top 40 cm. Experimental plots (28.8 m2) were situated inside a continuous crop field and included four 6-m long rows. Five-meter long sections of the central two rows of the plot were harvested for yield analysis.

Tomato plants were cultivated during the traditional dry growing season. Seedlings were planted in the second week of May in experiments I and III, in the third week of June in experiment II, and in the second week of April in experiment IV. The objective of applying this strategy was to avoid rainfall during the target growth stage when the treatments were evaluated. Three different tomato hybrid cultivars (AP533, H9498 and H9992Footnote 1) were used in the four experiments because those were the planting material typically cultivated by the growers and available in the market at the time of the experiments.

All treatments were fertilized with 200 kg of N, 300 kg of K2O, 600 kg of P2O5, 100 kg of Ca, 40 kg of Mg, 5 kg of Zn, and 2 kg of B, per hectare. Fertilizer sources included urea, potassium and calcium nitrate, potassium and calcium chloride, phosphate, limestone, magnesium and zinc sulfate, and borax. All phosphorus and micronutrients were applied pre-plant as well as 15% of the nitrogen and potassium, and 70% of the calcium. The remaining nutrients were supplied weekly through fertigation. Pest management followed standard commercial procedures.

A single drip line was placed on the soil surface within 5–10 cm of the crop row. This placement prevented the formation of a water saturated zone near the plant stems and soil-borne diseased. Drip line had emitters spaced 30 cm apart and a flow rate of 4.0 l h−1 m−1.

In the first week after transplanting, irrigations were scheduled on a daily basis for all treatments. Subsequent irrigations were scheduled according to the treatments previously established for each experiment.

In each treatment, SWT irrigation thresholds were evaluated with sensors at depths corresponding to 50% of the effective root system depth, that is, at 10 cm during the vegetative growth stage, at 15 cm in the beginning of the fruit development stage (from the 34th to the 55th day), and at 20 cm from thereon until the irrigations were ceased. SWT was measured using tensiometers for tensions up to 60 kPa and individually calibrated electrical resistance gypsum blocks for tensions above 60 kPa. Sensors were installed in three replicates of each treatment and placed 10 cm from the emitter and the plant. Sensors were read manually up to four times a day, and irrigations were performed when SWT reached values near threshold values established for each treatment.

The amounts of water to be applied were determined according to the rate of soil moisture depletion (Keller and Bliesner 1990), considering a SWT at field capacity of 6 kPa, taking into account 35% of the wetted area and employing the adjusted van Genuchten equation. The low SWT at field capacity is due to the strong aggregation of the Brazilian Oxisols, usually attributed to the presence of high contents of aluminum and iron oxides (Muggler et al. 1999). For treatments with SWT irrigation threshold below 10 kPa, water depths were determined as the product of reference crop evapotranspiration and crop coefficient (% canopy cover × 1.1). Daily reference crop evapotranspiration was estimated using data from a weather station localized near to the experimental sites, using FAO Penman-Monteith method (Allen et al. 1998). For adjusting the amount of applied water, sensors were placed about 5 cm below the limit of the effective crop rooting depth. At that depth, the SWT was maintained between 15 and 25 kPa, 1 day after irrigation.

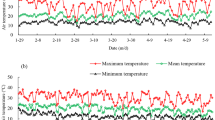

The average climatic conditions during the vegetative growth stage in experiments I and II, fruit development stage in experiments I and III, and fruit maturation growth stage in experiment IV were, respectively, air temperature: 22.4, 22.8, and 23.6°C; relative humidity: 54, 55, and 51%; solar global radiation: 18.9, 19.3, and 18.4 MJ m−2day−1; wind speed: 1.2, 1.3, and 1.0 m s−1; cumulative rainfall: 0, 4 and 1 mm, and class A pan evaporation: 6.9, 6.4, and 5.9 mm day−1. Corresponding reference grass crop evapotranspiration based on pan evaporation were 4.8, 5.1, and 5.7 mm dia−1. Cumulative rainfall during the entire growth period of experiments I, II, III, and IV was 149, 240, 188, and 48 mm, respectively.

Fruits were harvested manually when the proportion of red fruit reached about 95%. The evaluation variables for the treatments in all experiments were the depth of applied water, effective rooting depth, final plant stand, biomass production, proportion of red fruit, marketable fruit yield, average fruit mass, number of fruits per plant, proportion of decomposed fruits, total soluble solids content and yield, and titrable acidity.

Plant vegetative biomass production was determined by weighing the mass of plant canopy, except the fruit, dried in a ventilated oven at 60°C. The proportion of red fruit at harvest was determined by the relationship between the mass of red (includes orange) fruit and the sum of masses of red and green fruit. Only red, disease-free fruits were considered for yield, average fruit mass, and number of fruit per plant. Titrable acidity and soluble solids content were determined from homogenized samples of 15 fruits per plot according to Moretti et al. (1998). Effective root system depth, containing about 80% of the root mass, was evaluated in two replicates after the harvest of experiment II by the method of the reticulate profile (Atkinson and Mackie-Dawson 1991).

All experiments used a randomized-block design with four replicates in experiments I, II and III and six replicates in experiment IV. Data from each experiment were analyzed using analysis of variance procedures. Treatments with significant differences (P < 0.05) were further analyzed using linear regression using the method of the orthogonal polynomials. Since the levels of the SWT irrigation threshold in kPa were not equally spaced, a logarithmic transformation was used. Student’s t was used for testing hypotheses about equality of two population regression coefficients (Zar 1999).

Results and discussion

Similarly to the results of Marouelli et al. (1991), there was no significant interaction (P > 0.05) among factors for the evaluated variables in experiment I. This allowed the factors “water tension during vegetative growth stage” and “water tension during fruit development stage” to be analyzed separately. Although experiments I and II were carried out in different years using different tomato cultivars, the variance analysis of experiments I and II (“water tension during vegetative growth stage” factor) showed that the relationship between the larger and the smaller residual mean square of the evaluated variables were smaller than seven; that is, the residuals’ mean square of both experiments are homogeneous (Gomes 1991). This allowed the data to be analyzed all together. The same trends were observed among experiments I and III during the fruit development stage.

Effect of SWT during vegetative growth stage

The amount of water applied each year during the vegetative growth stage in experiments I and II ranged from 46 to 136 mm, depending upon the treatment. During the other stages 204 mm was applied to all treatments.

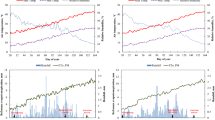

The maximum tomato effective root system depth, evaluated at the end of the crop season in experiment II, had a linear response to the log of SWT (Fig. 1a). Treatments with a larger soil–water deficit during the vegetative growth stage had deeper roots than those irrigated more often. According to Lopes et al. (2006), plants with deeper root system, besides absorbing nutrients more efficiently, tolerate less frequent irrigation during subsequent growth stages, and are less prone to soil-borne disease.

The Student’s t test indicated that the relative responses to the levels of water tension threshold in the vegetative growth stage in experiments I and II were similar. Since the population regression curves in each experiment did not show different slopes, aggregate regression equations were adjusted for the variables that were significantly affected by SWT during the vegetative growth stage.

Fruit harvest was conducted 116 and 112 days after transplant for experiment I and II, respectively. The proportion of red fruit averaged 94.3%, and was not significantly affected by SWT. Therefore, the duration of the plant phenological cycle was not affected by SWT during vegetative growth stage, consistent with the results reported by Prieto et al. (1999).

Plant stand during the vegetative growth stage had a quadratic response to the log of SWT (Fig. 1a). The maximum number of plants per unit of area occurred at the SWT of 19 kPa [log(kPa) = 1.28]. The SWT of 120 kPa [log(kPa) = 2.08] reduced plant stands, probably due to water deficits early in the vegetative growth stage when the new plants were not well-established. The reduction in stand due to lower SWT may have been due to soil-borne diseases favored by the maintenance of high moisture content near to plant stem (Lopes and Avila 2005).

Plant vegetative biomass production decreased linearly with the increase of the log of soil water deficit (Fig. 1b). In the 120 kPa treatment, a 23% biomass reduction occurred due to both stand reduction and smaller plant growth.

Based on the adjusted response function, the maximum marketable fruit yield was obtained for the SWT irrigation threshold of 35 kPa [log(kPa) = 1.54] (Fig. 1b). Under these experimental conditions, this SWT corresponded to an irrigation interval of 4–5 days during vegetative growth stage. These results are in agreement with Hartz and Hanson (2005), who recommended a SWT irrigation threshold in the range of 25–35 kPa for irrigation management in clay soils. The lowest yield was associated with a SWT of 120 kPa, with a reduction of 18% in comparison to the maximum yield.

According to the present work, the largest root system development was associated with moderate SWT during vegetative growth stage, in contrast to grower’s beliefs, and did not result in increased fruit yield. Therefore, the deficit management strategy used in tomato sprinkler-irrigated fields that helps to minimize foliar diseases was not advantageous under drip irrigation.

Individual fruit mass averaging 78 g and number of marketable fruits averaging 59.9 fruits per plant were not affected by the SWT treatments. Yield variations from SWT irrigation thresholds during vegetative growth stage were predominantly due to the effects of on plant stand. For processing tomatoes irrigated by sprinkler systems, Marouelli et al. (1991) showed that water deficit during the vegetative growth stage did not affect fruit mass, but decreased the number of fruits per plant. That can be attributed to the difference between the irrigation systems employed in each situation and to the fact that the plants were submitted to water tensions up to 460 kPa by Marouelli et al. (1991), compared to a maximum of 120 kPa in the present study.

Furthermore, none of the evaluated fruit quality variables were affected by the SWT treatments. The average rate of decomposed fruit was 3.4%, the average titrable acidity was 0.31% of citric acid, and the total content of soluble solids averaged 4.4%. The nonsignificant effect of SWT treatments on the quality variables was expected since they were applied only during vegetative growth stage, before effective fruit set, development, and maturation. Since the soluble solids content was not affected by the treatments, the soluble solids yield can be interpreted as a direct function of the marketable fruit yield, that is, it was also maximized for the SWT irrigation threshold of 35 kPa during vegetative growth stage.

Effect of SWT during fruit development stage

The average net water depth applied during the fruit development stage in experiments I and III ranged from 118 to 192 mm, depending upon the treatment. During the other stages a depth of 155 mm was applied uniformly to all treatments.

The regressions in experiment I and III for the levels of SWT evaluated during fruit development stage did not have statistically different slopes. Therefore, an aggregate regression equation was adjusted for each variable that was affected significantly by SWT.

Fruits were harvested at 116 and 121 days after transplant for experiments I and III, respectively. The proportion of red fruit averaged 95% for all treatments; consequently, the crop development cycle was not significantly affected by SWT irrigation thresholds evaluated during fruit development stage. These results are consistent with those of Prieto et al. (1999) who did not observe variations in the rate of fruit maturation as a function of different irrigation regimes.

Final plant stand averaged 2.65 plants per square meter and was not significantly affected by irrigation treatments during fruit development stage, consistent with Marouelli et al. (1991). Plant vegetative biomass production was linearly reduced with the log of SWT (Fig. 2a). Plants submitted to a SWT of 100 kPa [log(kPa) = 2.00] had a biomass reduction of 17% compared to low SWT (5–12 kPa).

Number of marketable fruits per plant was linearly reduced as SWT increased (Fig. 2a). This reduction may be explained by smaller plant growth, higher flower drop and abortion of small fruit as the plants were submitted to drier conditions during the short period between the end of the flowering and the beginning of the fructification (Marouelli et al. 1991; Prieto et al. 1999).

The average marketable fruit mass showed a quadratic response to the log of SWT and was maximized for SWT of 11 kPa [log(kPa) = 1.04] (Fig. 2b). Fruit mass reduction, even under moderate soil–water deficit conditions during fruit development stage, was also observed by Colla et al. (1999). Very frequent irrigations from the adoption of low SWT irrigation threshold such as 5 kPa may have caused a lack of soil aeration in the root zone and nutrient leaching.

Marketable fruit yield had a quadratic response to SWT irrigation threshold and it was maximized at 12 kPa [log(kPa) = 1.08] (Fig. 2b), which corresponded to a 1-day irrigation interval during fruit development stage. Based on the evaluated production variables, it was observed that yield differences, as affected by the treatments, may be attributed to both the number of fruits per plant and the fruit mass, since plant stand did not change.

For California conditions, Hartz and Hanson (2005) recommended that irrigations should be performed at a SWT between 20 and 35 kPa, which are considerably higher than the value obtained in the present study. Nevertheless, such large differences may occur because the magnitude of that parameter is affected, among other factors, by soil and climatic conditions and the position of the sensor in relation to the plant and the emitter (Martin et al. 1990; Hartz and Hanson 2005).

Fruit decomposition showed a linear and negative response to the log of SWT (Fig. 2c). In accordance with the observations recorded by Machado and Oliveira (2005), the highest rate of decomposed fruit occurred in the plots more frequently irrigated. That was mainly due to the longer time the fruit remained in contact with the wet soil surface and the higher development of the foliage, which most likely favored a more humid environment within the plant canopy. Humid conditions favor fungi and bacteria diseases such as those caused by Rhizoctonia solani and Erwinia spp. that occur mainly in fruits which have direct contact with the soil and/or due to wounds caused by insects (Lopes and Avila 2005).

The soluble solids content averaged 4.8% and was not affected by SWT irrigation threshold during fruit development stage. Consequently, soluble solid yield had a response similar to that of the fruit yield, that is, it was maximized at the SWT irrigation threshold of 12 kPa. According to Lowengart-Aycicegi et al. (1999), the water regime has little effect on the soluble solid content during fruit development stage, but it is decisive from the beginning of the fruit maturation growth stage. The titrable acidity increased linearly as the log of SWT increased (Fig. 2c). Such response is consistent with the findings of Colla et al. (1999) who observed that water supply restrictions during either fruit development or maturation growth stages promote significant increase in fruit acidity.

Effect of SWT during fruit maturation growth stage

Before the beginning of the SWT treatments, a water depth of 232 mm had been applied uniformly to all the tomato plants. During fruit maturation growth stage the SWT treatments resulted in total irrigations ranging from 45 to 128 mm, according to treatment.

Fruits were harvested 117 days after transplanting and the proportion of red fruit increased linearly as the log of SWT increased (Fig. 3a), indicating that the irrigation threshold affected the length of crop development cycle as opposing to what was observed in the other crop growth stages.

The plant final stand averaged 2.56 plants per square meter and the dry mass of the canopy averaged 2.64 Mg ha−1, but neither was significantly influenced by the SWT treatments (P > 0.05). The drip irrigation system did not wet the plants and so irrigation-induced disease problems were not observed on either plant stands or vegetative growth at the end of the crop growth cycle.

Marketable fruit yield, number of fruits per plant, and average fruit mass were reduced linearly as the log of SWT increased during fruit maturation growth stage (Fig. 3a, b). These reductions may be attributed to a higher soil water deficit to which the plants were submitted. Thus, the differences in fruit yield were directly related to the variations in the number of fruits per plant and fruit size. For the conditions of this study, SWT irrigation thresholds which maximized fruit yield (15 kPa) corresponded to a daily irrigation frequency during fruit maturation growth stage.

The reduced number of marketable fruits per plant with greater SWT (greater irrigation deficit) during fruit maturation growth stage can be explained by the facts that: (1) treatments began when only about 30% of the plants had at least one red fruit and, therefore, a significant number of small green fruits did not enlarge under drier conditions; and (2) small, red pear-shaped fruit (Ø < 2 cm) were not harvested, consistent with commercial practices.

The results obtained in this study differ from those normally observed in processing tomato irrigated by center pivot sprinkler irrigation systems in Brazil (Silva and Marouelli 1999), where fruit yield is generally reduced as irrigation frequency increases during fruit maturation growth stage. This can be explained by the fact that high frequency sprinkler irrigation favors great incidence of foliar disease and decomposed fruit (Lopes and Ávila 2005). In the present work, decomposed fruits averaged 1.4% and was not affected by irrigation treatments during fruit maturation growth stage. These results are consistent with the findings of Johnstone et al. (2005) who reported that deficit irrigation during the fruit maturation growth stage resulted in substantial yield loss in drip-irrigated processing tomato.

Total soluble solids increased linearly as the log of SWT increased (Fig. 3c). That is in accordance with Cahn et al. (2002) and Johnstone et al. (2005) who reported that moderate and controlled water deficit during the beginning of the fruit maturation growth stage is crucial for high soluble solids content. On the other hand, soluble solids yield averaged 5.87 Mg ha−1 and was not significantly affected by the treatments, which can be explained by the fact that the fruit yield and the soluble solids content showed a negative correlation. Fruit yield and soluble solids content response to SWT obtained in this work are in agreement with Hartz and Hanson (2005) who reported that moderate SWT (40–50 kPa) promotes an increase in soluble solids content and a slight reduction in fruit yield.

Similarly to Colla et al. (1999) and Marouelli et al. (2004), it was observed that a linear increment in the titrable acidity with increasing water deficits (Fig. 3c). Thus, greater SWT (less frequent irrigations) during the fruit development and maturation growth stages favor fruit with higher acidity content.

Conclusions

Maximum fruit yields were associated with SWT irrigation thresholds of 35, 12 and 15 kPa, during the vegetative growth, fruit development and fruit maturation growth stages, respectively. Under the experimental conditions, maximum fruit yield was associated with the adoption of average irrigation interval ranging from 4 to 5 days during the vegetative growth stage and 1 day during the remaining crop growth stages.

Processing tomato plants submitted to higher SWT (hence less frequently) during vegetative growth stage had deeper root systems than those ones irrigated at low SWT (and more frequently). Higher SWT during the beginning of the vegetative growth stage also reduced yield, due to plant stand reductions.

Fruit soluble solids content was not affected by the SWT irrigation threshold during vegetative growth or fruit development stages, but increased at higher SWT irrigation thresholds (higher soil–water deficits) during fruit maturation growth stage. Total soluble solids yield responses to SWT during vegetative growth and fruit development stages were similar to fruit yield responses, but soluble solids yield was not affected by SWT between 15 and 120 kPa during fruit maturation growth stage.

Notes

The mentioning of trade names does not imply in endorsement by the authors or Embrapa.

References

Allen RG, Pereira LS, Raes D, Smith M (1998) Crop evapotranspiration: guidelines for computing crop water requirements. FAO, Rome, 328 pp. (Irrigation and Drainage Papers, 56)

Atkinson D, Mackie-Dawson LA (1991) Root growth: methods of measurement. In: Smith KA (ed) Mullins CE soil analysis. Marcel Dekker, New York, pp 447–509

Cahn M, Hanson B, Hartz T, Herrero E (2002) Optimizing fruit quality & yield grown under drip irrigation. California Tomato Grower 45:7–9

Colla G, Casa R, Locascio B, Saccardo F, Temperini O, Leoni C (1999) Responses of processing tomato to water regime and fertilization in Central Italy. Acta Hortic 487:531–535

Gomes FP (1991) Análise de grupos de experimentos In: Gomes FP (ed) Curso de estatística experimental. Nobel, Piracicaba, pp 168–197

Hartz T, Hanson B (2005) Drip irrigation and fertigation management of processing tomato. Vegetable research and information center, University of California, Davis, p 9

Keller J, Bliesner RD (1990) Sprinkle and trickle irrigation. VanNostrand Reinhold, New York, p 652

Johnstone PR, Hartz TK, LeStrange M, Nunez JJ, Miyao EM (2005) Managing fruit soluble solids with late-season deficit irrigation in drip-irrigated processing tomato production. HortScience 40:1857–1861

Lopes CA, Ávila AC (2005) Doenças do tomateiro. Embrapa Hortaliças, Brasília, p 151

Lopes CA, Marouelli WA, Café Filho AC (2006) Associação da irrigação com doenças de hortaliças. Rev An Pat Plant 14:151–179

Lowengart-Aycicegi A, Manor H, Krieger R, Gera G (1999) Effects of irrigation scheduling on drip-irrigated processing tomatoes. Acta Hortic 487:513–518

Machado RMA, Oliveira MRG (2005) Tomato root distribution, yield and fruit quality under different subsurface drip irrigation regimes and depths. Irrig Sci 24:15–24

Marouelli WA, Sant’Ana RR, Silva WLC, Moretti CL, Vilela NJ (2003) Avaliação técnica e econômica do espaçamento de gotejadores em tomateiro para processamento cultivado em fileiras simples e duplas. Hort Bras 21:202–206

Marouelli WA, Silva HR, Oliveira CAS (1991) Produção de tomate industrial sob diferentes regimes de umidade no solo. Pesq Agrop Bras 26:1531–1537

Marouelli WA, Silva WLC, Moretti CL (2004) Production, quality and water use efficiency of processing tomato as affected by the final irrigation timing. Hort Bras 22:225–230

Martin DL, Stegman EC, Fereres E (1990) Irrigation scheduling principles. In: Hoffman GJ, Howell TA, Solomon KH (eds) Management of farm irrigation systems. ASAE, St. Joseph, pp 155–203

Moretti CL, Sargent SA, Huber DJ, Calbo AG, Puschmann R (1998) Chemical composition and physical properties of pericarp, locule and placental tissues of tomatoes with internal bruising. J Am Soc Hort Sci 123:656–660

Muggler CC, van Griethuysen C, Buurman P, Pape T (1999) Aggregation, organic matter, and iron oxide morphology in Oxisols from Minas Gerais, Brazil. Soil Sci 164:759–770

Prieto MH, López J, Ballesteros R (1999) Influence of irrigation system and strategy of the agronomic and quality parameters of the processing tomatoes in Extremadura. Acta Hort 487:575–579

Renquist AR, Reid JB (2001) Processing tomato fruit quality: influence of soil water deficits at flowering and ripening. Aust J Agric Res 52:793–799

Shock CC, Pereira AB, Hanson BR, Cahn MD (2007) Vegetable irrigation. In: Lescano R, Sojka R (eds) Irrigation of agricultural crops, vol 30, 2nd edn. Agron Monogr. ASA, CSSA, and SSSA, Madison, pp 535–606

Silva WLC, Giordano LB, Marouelli WA, Fontes RR, Gornat B (1999) Response of six processing tomatoes cultivars to subsurface drip fertigation. Acta Hort 487:569–573

Silva WLC, Marouelli WA (1999) State of the art of irrigation research on processing tomatoes in Brazil. Acta Hort 487:487–491

van Genuchten MT (1980) A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci Soc Am J 44:288–291

Zar JH (1999) Biostatistical analysis. Prentice Hall, Upper Saddle River, p 663

Acknowledgments

The authors thank Rain Bird do Brasil Ltda. and Unilever BestFoods do Brasil Ltda. for providing irrigation equipment and tomato seedlings, and Dr. Clinton C. Shock for the manuscript revision.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by S. Raine.

Rights and permissions

About this article

Cite this article

Marouelli, W. ., Silva, W. .C. Water tension thresholds for processing tomatoes under drip irrigation in Central Brazil. Irrig Sci 25, 411–418 (2007). https://doi.org/10.1007/s00271-006-0056-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00271-006-0056-6