Abstract

Rice irrigation-water use was estimated in Mississippi (MS) and Arkansas (AR) in 2003 and 2004. Irrigation inputs were compared on naturally sloping (i.e. contour-levee system) and mechanically graded fields. In MS, rice production consumed, on average, 895 mm water, but irrigation inputs were greatly affected by production system. Contour-levee systems accounted for 35% of the production area and consumed 1,034 mm irrigation. Fields mechanically graded to a consistent slope of approximately 0.1% (i.e. straight-levee systems) consumed 856 mm irrigation and accounted for 60% of the production area. Fields devoid of slope (i.e. zero-grade system) accounted for 5% of the production area and consumed 382 mm irrigation. In AR, contour-levee rice production consumed 789 mm compared to 653 mm with a straight-levee system. Using low pressure, thin wall (9–10 mil) disposable irrigation tubing to deliver water to each paddy independently reduced irrigation inputs by 28% in MS and 11% in AR when compared to a single-point (levee-gate) distribution system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As the amount of water dedicated to irrigation declines, agriculture will have to use less water to meet increased global demands for food and fiber. Thus, water savings through improved irrigation practices are essential to meeting the future water needs of both agriculture and other stakeholders (CAST 1996). Currently, the alluvial aquifer in the rice producing areas of Mississippi (MS) and Arkansas (AR) is declining as the result of water extractions associated with agriculture and aquaculture irrigation. The maximum rate of alluvial aquifer decline is associated with areas of intensive aquaculture and rice production and is approximately 268 mm year−1 in MS and 292 mm year−1 in the Grand Prairie region of Arkansas (Pennington 2005; Young and Sweeny 2005). Furthermore, water extractions from the Memphis/Sparta aquifer, which underlies the alluvial aquifer in the Grand Prairie region of Arkansas, have led to an average year decline of approximately 283 mm. Collectively, this indicates that adoption of water saving irrigation practices are necessary if current rice production levels are to be maintained within these regions.

In the United States, rice (Oryza sativa L.) is unique among agronomic crops because it is grown in flooded paddies where floodwaters are maintained at a constant depth of approximately 80–150 mm throughout much of the growing season. Growing rice in flooded environments results in higher irrigation inputs in rice when compared to other agronomic crops.

US rice producers distribute water within a rice field using several different methods that may affect irrigation inputs. In the mid-southern states, the most widely used method of water distribution is through “levee-gates” or levee spillways. Water is pumped into a single point in the paddy with the highest elevation. To deliver water to the subsequent down-slope paddy, the preceding up-slope paddy must be over-filled to generate runoff over the levee spillway. This cascade of water gradually moves over the entire field. Therefore, producers generally keep the entire rice field completely filled once the permanent flood is established.

Multiple-inlet irrigation is an alternative method of water distribution that is gaining grower acceptance in the mid-southern United States. With multiple-inlet irrigation, disposable low pressure, thin wall (9–10 mil) irrigation tubing, commonly referred to as ‘polypipe’, is connected to the irrigation source and rolled out down-slope over the levees. Irrigation outlets are installed into the tubing to deliver water to each paddy simultaneously. Thus, the up-slope paddies do not have to be over-filled to deliver water to subsequent down-slope paddies. This may increase rainfall-holding capacity and reduce over-pumping and tail-water runoff from irrigated rice fields (Tacker et al. 2002; Vories et al. 2005).

Our survey was designed to determine typical irrigation practices and water consumption associated with these practices for rice produced in AR and MS. Located in these states is an 11,200 km2 area of intense agricultural activity along the lower Mississippi River known as the Mississippi alluvial plain (also referred to as the “Mississippi River delta”). The states along the Mississippi River delta account for more than 75% of the US rice cropped area (USDA-NASS 2004). Furthermore, we hope this manuscript helps researchers and modelers understand how study methodology and irrigation practices can influence irrigation inputs in mid-southern rice production. Collectively, this information can help policy makers and resource managers understand the relationship between rice production and hydrology in the Mississippi River delta.

Methods

Mississippi

A rice irrigation survey was conducted as part of the water-use and aquifer-level monitoring programs of the Yazoo–Mississippi Delta Joint Water Management District (YMD). The survey estimated water use by agriculture (agronomic crops and aquaculture) in the MS counties located in the Mississippi River delta. Four different methods of rice irrigation were compared: (1) contoured-levee + levee-gate (CL + LG), (2) straight-levee + levee-gate (SL + LG), (3) straight-levee + multiple-inlet (SL + MI), and (4) zero-grade (ZG). CL + LG fields had unmodified compound slopes. Levees were serpentine, irregularly spaced, and generally separated by about 60 mm of vertical fall.

SL + LG fields had been graded by earth moving equipment and had nearly zero side-slope. The most common grade on straight-levee fields was about 0.1%, but this varied depending on soil properties prior to leveling. SL + LG fields generally had straight or slightly bending levees that were spaced relatively uniformly at 30–60 mm of fall. These fields were often surrounded by a permanent road-like levee commonly referred to as a “pad.” SL + MI fields used disposable irrigation tubing to simultaneously deliver water to each paddy within a field. In ZG fields, all slopes were removed; hence, the production area was devoid of internal levees but confined by a permanent pad.

Rice irrigation surveys were conducted using a portable ultrasonic single channel flow meter (Model 1010P, Controlotron Corporation) to measure water flow from the irrigation source. During February, March, and April, agricultural fields irrigated with electric wells were identified from the YMD well permit database. The latitude–longitude and electrical meter readings of these wells were recorded. Personnel returned to all identified wells on a weekly basis to further select wells that were specifically dedicated to rice production. These wells with the corresponding production area were selected as water use survey sites. The flow rate, energy consumption rate, area under irrigation, and irrigation method were recorded for all survey sites. The electrical meter serving each well was read on a monthly basis throughout the growing season. Research has shown that seasonal rice water use is varies by rice cultivar and soil type (Pringle 1994). However, for this study, these factors were assumed random across rice irrigation treatments, and their influence was not accounted for in these water use estimates.

Since the purpose of the survey was to monitor irrigation water consumed by crop production, rainfall was not monitored at individual survey sites. However, daily rainfall measurements from NOAA weather stations were obtained throughout the MS survey area (National Climatic Data Center 2005). The irrigation data in MS did not differentiate between water consumption during pre-flood irrigation inputs (i.e. “flushes”) and permanent flood inputs; all irrigation inputs were recorded. Additionally, the survey approach was designed to be unobtrusive and did not influence the agronomic management of rice crops or the water management practices of participating rice producers.

In addition to the rice irrigation survey, a study was conducted in 2004 to determine the percentage of rice area in MS produced using different methods of irrigation. Two hundred wells that were permitted as rice/soybean irrigation wells were selected at random from YMD’s well permit database. The randomly selected wells were ground-inspected during the growing season and the rice irrigation method was recorded. These data allowed for an accurate estimation of the frequency of various irrigation methods.

Arkansas

Rice irrigation water use estimates were recorded as part of the University of Arkansas’ Rice Research Verification Program (RRVP). Established in 1983, this program was designed to verify the profitability of University of Arkansas recommendations in rice fields with less than optimum yields or returns (Branson et al. 2004). RRVP emphasizes management intensity and integrated pest management to maximize returns.

Four different methods of irrigation were compared: (1) CL + LG, (2) contoured-levee + multiple-inlet (CL + MI), (3) SL + LG, and (4) SL + MI. In both 2003 and 2004, ten rice producers across the rice producing region of AR were selected to participate in the RRVP. Each growers participating in the RRVP agreed to pay production expenses, record all production inputs, provide expense data, and implement all University recommendations in a timely manner from planting to harvest on a single specified field.

At each RRVP location, irrigation pumping was recorded with flow meters (McCrometer®) from planting until flood termination. In both years of the survey, rainfall during April and May was sufficient, and none of the fields were flushed with irrigation water prior to establishment of permanent floods.

Statistical analysis

Data were analyzed using mixed model analysis (SAS Institute Inc. 2003). Year and location (well and corresponding rice producing area) effects were considered random. Because water management treatments differed between the MS and AR locations, data from each state were analyzed separately. Data means were separated using least significant difference (0.05).

Results and discussion

Mississippi

Irrigation inputs from 81 sites were surveyed between April 2003 and September 2004 (Table 1). Straight-levees using levee gates (SL–LG) irrigation was the most common rice water management practice with 31 sites, representing 38% of the locations surveyed. SL + LG irrigation was followed by CL + LG irrigation with 24 locations (30%), SL + MI irrigation with 15 locations (19%), and ZG irrigation with 11 locations (14%).

The irrigated area per well (i.e., field size) ranged from 27.3 to 43.2 ha but did not differ across water management treatments (Table 1). These data agree with a similar survey of MS rice producers from 1991 to 1994 which reported an average area of production of 40.5 ha per well (Cooke et al. 1996). Pump capacity also did not differ across water management treatment and ranged from 130 to 138 l min−1 ha−1 (Table 1). These values agree with the 128 l min−1 ha−1 reported by Cooke et al. (1996) in an earlier survey. Because two different dependent variables (i.e. production area per well and pumping capacity) are similar between the Cooke et al. (1996) and our survey, general methodologies were likely similar between studies.

The minimum recommended pump capacity for rice production in MS is 140 l min−1 ha−1 (Miller and Street 2000). Forty-seven of the 81 surveyed sites had pump capacities below the recommended minimum. The pump capacity was below 100 l min−1 ha−1 for approximately 25% of the surveyed sites (data not shown). Rice production with pump capacities less than the recommended minimum is not advised for several reasons. First of all, during exceedingly dry years, with limited pump capacity, it may not be possible to flush or flood the fields fast enough to prevent stand loss or yield reductions as the result of moisture deficits (Miller and Street 2000). Secondly, insufficient pump capacity can delay establishing a complete flood on the entire field beyond the advised window of 4–5 days. Since approximately two-thirds of the seasonal nitrogen is applied as urea immediately prior to flooding the rice (Norman et al. 1997), delayed flood establishment can result in excessive nitrogen loss through ammonia volatilization (Wilson et al. 2001, 1998). This may result in yield reductions because of nitrogen deficiencies in the areas of the fields that are the last to flood (Brandon and Wells 1986). Since multiple-inlet irrigation delivers water to all paddies simultaneously, it is a more efficient method of irrigation distribution (Tacker et al. 2002). Given the limited pumping capacity found in this survey, it may be possible that many MS rice producers could benefit from the improved flooding efficiency with multiple-inlet distribution compared to levee-gate distribution.

Water management treatments greatly influenced irrigation inputs. Rice grown with CL + LG irrigation used an average of 1,034 mm of irrigation water with a standard error (SE) of 55.3 (Table 1). CL + LG irrigation was followed by SL + LG irrigation at 856 mm (SE 51.5), SL + MI irrigation at 619 mm (SE 64.7), and ZG at 382 mm (SE 77.0). Because of the large variations in water inputs within each management treatment, CL + LG and SL + LG were not significantly different. However, water inputs with SL + MI irrigation was statistically lower than CL + LG irrigation, and ZG was statistically lower than CL + LG and SL + LG.

SL + MI irrigation consumed 619 mm of irrigation water, representing a 40% reduction in irrigation compared to CL + LG irrigation and a 28% reduction in irrigation compared to SL + LG irrigation. These data suggest the water saving practices of straight-levee rice production and multiple-inlet irrigation distribution are additive. Including multiple-inlet distribution within rice production systems was shown by Tacker et al. (2002) and Vories et al. (2005) to reduce irrigation inputs by approximately 25%. Furthermore, multiple-inlet distribution can be equally effective within both contour- and straight-levee production systems with minimal equipment and labor adaptations. These two production systems account for 95% of the rice production area in MS. Thus, widespread adoption of the multiple-inlet distribution system could result in significant irrigation water savings on rice.

Zero grade irrigation consumed 382 mm of irrigation water, representing 63, 55, and 38% water saving compared to CL + LG, SL + LG, and SL + MI irrigation systems, respectively. Currently, ZG irrigation accounts for only 5% of the rice production area in the state (Table 3). The percentage of area in ZG irrigation has reached a steady state in MS (Thomas 2005). One of the main reasons for this is that ZG is poorly suited for soybean production (Blaine 2005). Mississippi State University recommends a rice–soybean rotation to avoid the eventual declining yields that are often observed when land is continuously cropped with rice (Miller and Street 2000). In MS, ZG rice production is not expected to significantly increase above the current level (Thomas 2005). Thus, the regional water saving potential with ZG irrigation is low when compared to SL + MI irrigation.

An estimation of the “average” rice irrigation input for the state of MS can be calculated by taking a weighted average of irrigation inputs for CL + LG, SL + LG, and ZG irrigation systems based on the percentage area of production for each irrigation system. If we assume that multiple-inlet distribution use is negligible compared to the total area of rice production in MS, the weighted average for rice irrigation inputs is 895 mm (Table 3).

Including multiple-inlet distribution in a contour-levee or straight-levee system can result in a 25% water savings as compared to single-point distribution (Tacker et al. 2002; Vories et al. 2005). If 40% of the rice contour- and straight-levee production area included multiple-inlet distribution, the theoretical average rice irrigation input for MS-grown rice decreases to 807 mm (Table 3). If 80% of the contour- and straight-levee production area includes multiple-inlet distribution, the theoretical average rice irrigation input equals 720 mm. As stated earlier, widespread adoption of multiple-inlet distribution has the potential to greatly reduce irrigation inputs in MS-grown rice.

It may of interest to compare this recent rice water use survey to an earlier survey conducted by Cooke et al. (1996). Least square means analysis of Cooke et al. (1996) data indicated that CL + LG irrigation consumed 803 mm (SE 45.8) of irrigation water. Given the larger number of CL + LG observations (60 locations) in the Cooks et al. survey compared to our more resent survey (24 locations), the amount of variation between the two studies is very similar.

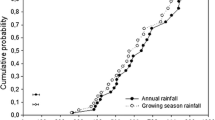

In our survey, rice grown with SL + LG irrigation received 856 mm irrigation (Table 1). This represents a 17% saving compared to CL + LG irrigation. Least square means analysis of Cooke et al. (1996) data indicated that rice grown with SL + LG irrigation consumed 725 mm (SE 41.6) of irrigation water. Given the larger number of SL + LG observations (94 locations) in the Cooks et al. survey compared to our more resent survey (31 locations), the amount of variation between the two studies is very similar. Interestingly, CL + LG irrigation inputs increased by 267 mm (35%) between the two surveys, while the SL + LG irrigation inputs increased by 118 mm (16%). The difference in irrigation inputs between this survey and the one conducted by Cooke et al. (1996) cannot be explained by variations in the amount of growing-season rainfall between the two survey periods. From May through August, the cumulative rainfall in the Mississippi Delta during the Cooke et al. (1996) survey was 487 mm compared to 470 mm in this survey (Table 2). Furthermore, the average pump capacity between the Cooke et al. (1996) survey and this survey was within 2–8% of each other. Since the amount of rainfall (Table 2) and pump capacity varied by less than 10% from the Cooke et al. (1996) survey, the variables of growing-season rainfall and irrigation pump capacity do not explain the different estimates between the two surveys. However, some survey methodology, land modifications, and agronomic practices may have differed between the two surveys.

One possible explanation for higher irrigation inputs in the later survey compared to the survey by Cooke et al. (1996) may be related to pre-flood irrigation inputs. It is not clear whether the Cooke et al. (1996) survey included water consumed during repeated irrigations (i.e. ‘flushing’) prior to permanent flood establishment. However, the later survey was designed to record inputs related to pre-flood flushing. Since each flush consumes 50–100 mm of water, this can greatly influence the total irrigation inputs during rice production. The potential difference in pre-flood irrigation inputs between the two surveys may explain why irrigation inputs were higher in the later survey compared to the earlier survey.

An additional factor that may have influenced the higher irrigation inputs for CL + LG irrigation in our survey compared to Cooke et al. (1996) is that, currently, a greater proportion of rice fields are in a straight-levee system than in a contour-levee system compared to when the surveys were conducted by Cooke et al. (1996). During the mid- and late-1990s, the amount of rice production area in MS that was converted from a contoured-levee system to a straight-levee system greatly increased (Street 2005).

We could not find data citing the percentage of rice production area in different irrigation systems during the time period of the Cooke et al. (1996) survey. However, in 2004, 60% of the rice production area in MS was in some type of straight-levee system compared to 35 and 5% for contour-levee and zero-grade systems, respectively (Table 3). The cost of precision land-forming fields is directly related to the amount of soil that has to be moved during the grading operation (Laughlin and Mehrle 1996). Therefore, it is reasonable to assume, that the since the survey by Cooke et al. (1996), fields that remain in a contour-levee system are the least cost effective to convert to a straight-levee system due to their relatively steep slopes that would require significant soil movement. Thus, the 35% of the rice production area that currently remains in a contoured irrigation system is possibly more difficult to irrigate than the contoured-levee fields sampled in the Cooke et al. (1996) survey because of steep, compound slopes and shallow, course soil types. The increased conversion of rice fields to a straight-levee system since the earlier survey may explain why the most recent survey found that contour-levee rice production consumed 35% more water than in the Cooke et al. (1996) survey, but straight-levee rice only consumed 16% more in the latest survey when compared to the survey done by Cooke et al. (1996).

Arkansas

A total of 20 sites participated in the University of Arkansas RRVP during 2003 and 2004. CL + LG and SL + LG were studied on five locations each (Table 4). CL + MI irrigation was studied on four sites, and SL + MI irrigation was on six sites. The area irrigated per well ranged from 9.8 to 33.4 ha (Table 4). Pump capacity in the AR study was much higher than in the MS survey and ranged from 151.0 to 281.9 l min−1 ha−1 (Table 4). All pump capacities within the AR study exceeded the recommended minimum pump capacity of 140 l min−1 ha−1, suggesting that farmers participating in the Arkansas RRVP may not accurately represent the range of actual production variables. This is to be expected given the stated objectives of the RRVP. Irrigation inputs in the AR study ranged from 583 to 789 mm (Table 4). Irrigation treatments did not differ statistically because of the limited sample size and large variability. CL + LG consumed 789 mm irrigation as compared to 1,034 mm irrigation in the MS survey. Additionally, SL + LG irrigation consumed 653 mm irrigation in the AR study compared to 856 mm irrigation in the MS survey.

The differences in pump capacities and overall irrigation inputs between the AR and MS studies are probably the result of these two studies having dissimilar objectives and methodologies. The MS survey attempted to estimate the water consumed by rice production without altering water management practices or agronomic inputs. The University of Arkansas RRVP focused on management intensity and integrated pest management to maximize economic returns to the producers. As a result, the sample of growers in AR was not as large as that in the MS survey where growers were randomly selected. The growers participating in the AR study were identified as willing participants who agreed to alter crop management from their normal practices in an effort to increase net returns. Thus, AR growers and scientists were likely more conscientious about limiting over-pumping than survey participants in MS. The smaller, selective sampling in the AR survey means that the participating growers may have been less representative of the practices of most rice growers than the larger, randomly selected sample in the MS survey.

In summary, when comparing different methodologies estimating rice irrigation inputs, having a large number of unobtrusive observations, as in the MS survey, may provide a more accurate estimate of rice irrigation inputs than methods that use a more limited number of observations while focusing on grower agronomic efficiency. A large random survey is especially beneficial when trying to understand how different agronomic variables (soil type, tillage, practice, irrigation distribution method, etc.) may affect total irrigation inputs.

Even though the study methodology differed in MS and AR, several conclusions hold true across both studies. “Typical” seasonal rice irrigation inputs of 760–900 mm are within the observed results of both studies. The data support the conclusion that both straight-levee rice production and multiple-inlet irrigation result in water savings compared to production practices that use neither. Additionally, some degree of the water savings achieved with each of the practices appears to be additive when the practices are combined.

Grower adoption of water saving irrigation practices is successfully occurring in AR and MS. Where natural slopes and soil depths are favorable, widespread adoption of straight-levee rice production has occurred. Adoption as been stimulated by the Natural Resources Conservation Service’s (NRCS) cost share programs that provide willing landowners the opportunity to offset the costs of land improvements such as precision leveling, underground water delivery, and permanent exterior levees (pads).

Furthermore, producers perceive that these ‘permanent’ improvements increase many aspects of production efficiency (Laughlin and Mehrle 1996). With straight-levee rice production, growers can use more ground equipment to apply fertilizer and pesticides instead of being forced to make the applications by air in a contour-levee system. Ground application is less expensive and often producers already own equipment to make these applications instead of contracting with aerial applicators. Additionally, with permanent pads, hand-labor is not required to physically join (butt) interior levees to exterior levees. This greatly reduces seasonal on-farm labor requirements in rice production and reduces the number of levee breaches that complicate rice production during seasonally intense rainfall that is common to this region of the United States.

District (local) NRCS commissioners decide designation of approved NRCS cost share practices and the amount of the cost share payment for each practice. Within the previous two years, many NRCS districts in MS have approved cost share programs that cover most of the material and labor costs associated with multiple-inlet irrigation. This policy has encouraged growers to experiment with multiple-inlet irrigation and learn the system with minimal capital expenditures. It appears that the more progressive rice producers prefer multiple-inlet irrigation and the adoption of this practice is being expedited by word-of-mouth testimonial.

Future research will focus on alternative flood management practices that may allow producers to capture more of the 280 mm of rainfall that occur throughout the period when rice is traditionally flooded. This may result in decreased water inputs and reduced non-point source pollution runoff from rice fields.

References

Blaine AM (2005) Personal communication. Extension soybean specialist. Mississippi State University, Mississippi State

Brandon DM, Wells BR (1986) Improving nitrogen fertilizer in mechanized rice culture. In: DeDatta SK, Patrick WH (eds) Nitrogen economy of flooded rice soils. Martinus Nijhoff Publ. Co., Dordrecht, pp 161–170

Branson J, Wilson C, Runsick S, Windham T, Marshall J (2004) University of Arkansas Rice Research Verification Program. Available at http://www.aragriculture.org/cropsoilwtr/rice/Verification/2004/RRVP04.pdf (verified 15 Nov. 2005)

Cooke FT, Caillavet DF, Walker JC (1996) Rice water use and cost in the Mississippi Delta. Bull. 1039. MS Agri. and Forestry Exp. Stn., Mississippi State

Council for Agricultural Science and Technology (1996) Future of Irrigated Agriculture, Task Force Report No. 127, Ames

Laughlin DH, Mehrle RK (1996) Straight versus contour levee rice production practices in Mississippi. Bull. 1063. MS Agri. and Forestry Exp. Stn., Mississippi State

Miller TC, Street JE (2000) Mississippi’s Rice Growers Guide. Pub. 2255. MS Agri. and Forestry Exp. Stn., Mississippi State

National Climatic Data Center (2005) Available at http://www.ncdc.noaa.gov/oa/ncdc.html (Verified 15 Nov. 2005)

Norman RJ, Wilson CE, Slaton NA, Gravois DA, Moldenhauer KAK (1997) Grain yield response of new rice cultivars/varieties to nitrogen fertilization. In: Norman RJ, Johnson TH (eds) B.R. Wells rice research studies 1996, Ser. 456. University of Arkansas Agri. Exp. Stn. Res., pp 125–129

Pennington DA (2005) YMD Joint Water Management District Annual Report 2004. Available on-line at http://www.ymd.org/annualreports.htm (Verified 11 Apr. 2005)

Pringle HC (1994) Minimum water requirements for rice grown in the mid-south. Technical Completion Report Project Number G2028–06, Year 3. Water Resources Research Institute. Mississippi State University. Miss State

SAS Institute Inc (2003) SAS 9.1 Qualification Tools User’s Guide. SAS Institute Inc., Cary

Street JE (2005) Personal communication. Former Extension Rice Specialist. Mississippi State University, Mississippi State

Tacker P, Vories E, Kratz D (2002) Rice irrigation water management for water, labor, and cost savings. In: Norman RJ, Meullenet JF (eds) B.R. Wells rice research studies 2001, Ser. 495. Univ. of Arkansas Agri. Exp. Stn. Res., pp 219–223

Thomas J (2005) Personal communication. Extension agricultural engineer. Mississippi State Univ, Mississippi State

USDA National Agricultural Statistics Service (2004) 2002 Census of Agriculture. USDA agriculture, vol 1, Part 51, 424p. Available on-line at http://www.nass.usda.gov/census/census02/volume1/us/USVolume104.pdf (Verified 15 Nov. 2005)

Vories ED, Tacker PL, Hogan R (2005) Multiple-inlet approach to reduce water requirements for rice production. Am Soc Agri Eng 21:611–616

Wilson CE, Bollich PK, Norman RJ (1998) Nitrogen application timing effects on nitrogen efficiency of dry-seeded rice. Soil Sci Soc Am J 62:959–964

Wilson C, Slaton N, Norman R, Miller D (2001) Efficient use of fertilizer. In: Slaton N (ed) Rice production handbook. University of Arkansas Cooperative Extension Service. Little Rock

Young JR, Sweeny JR (2005) Arkansas ground water and management report for 2004. Available on-line at http://www.aswcc.arkansas.gov/Draft%20for%20’04–’05.pdf (Verified 11 Apr. 2006)

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by A. Kassam

Rights and permissions

About this article

Cite this article

Smith, M.C., Massey, J.H., Branson, J. et al. Water use estimates for various rice production systems in Mississippi and Arkansas. Irrig Sci 25, 141–147 (2007). https://doi.org/10.1007/s00271-006-0041-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00271-006-0041-0