Abstract

Standard evaluation procedures, based on field measurements and statistical, hydraulic models, have been developed for assessing irrigation systems performance. However, given the diverse nature of the irrigation methods, it is not possible to use a unique evaluation procedure. Ideally, variables would be measured at every point throughout the field under study, but that is clearly impractical. Instead, measurements are taken of selected samples, or irrigation models are used to predict field-wide distributions of the variables. In this paper, irrigation models for trickle, sprinkler and furrow irrigation are used to assess how well the irrigation performance indicators generated by standard procedures match those generated by whole-field simulations. Six performance indicators were used: distribution uniformity, uniformity coefficient of Christiansen, application efficiency, deep percolation ratio, tail water ratio and requirement efficiency. The analysis was applied to systems typical of cotton crops in Southern Spain. The results show that the procedure used to determine performance indicators in trickle irrigation provides good estimates of the whole field performance. The procedure used in sprinkler irrigation is also acceptable, but yields variable results. Finally, the standard procedure used for furrow irrigation produces biased, highly variable results and overestimates distribution uniformity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Deviations from uniform application under trickle irrigation can be caused by variations in: the pressure along the laterals, the emitters (manufacturing variations), the frequency (and degree) of emitter clogging and the operating times of different irrigation subunits. The factors affecting the distribution of water by a sprinkler irrigation system are nozzle characteristics (size, type, angle and number), system layout (sprinkler spacing along laterals, separation between laterals, height of sprinklers, inclination of the risers and ground slope), pressure distribution, climate (wind-speed and drop evaporation) and management (operating time of each lateral or set of laterals). In furrow irrigation, the infiltrated depth at a given point is a function of opportunity time, wetted perimeter and soil intake characteristics, so its variability along the furrow will depend on the variability of these factors. Other variables, such as slope and roughness, will also have an indirect influence through their effects on the abovementioned factors. Moreover, when considering the entire irrigated field, differences in inflow rate among furrows and variations in application time within each set of furrows will also cause variations in infiltrated depth.

Assessment of the irrigation systems is based on performance indicators that were revisited, updated and standardized by Burt et al. (1997). To calculate the performance indicators, appropriate field measurements and data manipulations are required. Merriam and Keller (1978) compiled standard procedures and guides for evaluating on-farm irrigation systems. Performance indicators obtained following the standard evaluation procedures have been widely used to evaluate irrigation performance at farm and regional scales, and to compare the performance of different irrigation methods (Hanson et al. 1995).

The evaluation of trickle irrigation is based on measurements of pressure at the manifolds serving the laterals and measurements of the volume of water applied to the soil by each emitter of a defined sample of emitters (Merriam and Keller 1978). In sprinkler irrigation evaluations, applied water is sampled at the nodes of a defined grid using catch cans usually placed above the crop canopy. In the evaluation of furrow irrigation, the applied water is measured only at the furrow inlet, and the distribution of water is not derived from measurements of infiltrated water or applied water, but from measurements of opportunity time used to estimate infiltrated water by means of an infiltration function.

Therefore, while the same indicators are used to describe the performance of different irrigation methods, the procedures used to obtain them cannot be the same because of the diverse nature of the irrigation methods. Behind each of these procedures there are statistical and hydraulic models that may not be consistent with each other. Furthermore, after the water infiltrates through the soil surface, it moves within the soil due to horizontal and vertical gradients of water potential (Hart 1972). This phenomenon and the extent of plant roots (Seginer 1979; Cogels 1983) may reduce the application variability (Mateos et al. 1997). The magnitude of this dampening will depend on the scale of variation of the sources of non-uniformity.

All these differences have raised doubts about the ability of standard procedures for evaluating irrigation systems to give accurate assessments of their whole-field performance, and the validity of comparing evaluations of different irrigation methods. This paper presents a simulation analysis of the validity and consistency of methods used to evaluate field irrigation performance.

Methods

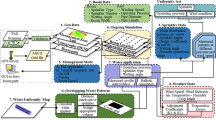

Irrigation models

The trickle irrigation model simulates the pressure and discharge distributions in the system, calculating head losses due to pipe friction using a combination of the Darcy-Weisbach and Blasius equations (Watters and Keller 1978 and p. 523 in Keller and Bliesner 1990), taking into account the emitter-connection-friction loss as an equivalent length of lateral (Keller and Bliesner 1990):

where h f (m) is the pipe friction head loss, S (m) is the spacing between emitter connections along the lateral or between lateral connections along the manifold, q is flow rate (l s−1), D (mm) is the inside diameter of the pipe and f 1 (m) is the emitter or lateral connection loss as an equivalent length of lateral or manifold, respectively. The model first calculates pressure distribution based on a nominal discharge. It then recalculates the emitter flow rate as a function of the pressure head using a discharge equation of the type

where H (m) is the pressure head at the emitter, x (non-dimensional) the discharge exponent and k 1 (l s−1 m–x) the discharge coefficient. The discharge variation due to manufacturing variation and clogging is considered through variations in the discharge coefficient, which is assumed to follow a normal distribution. The calculation of the pressure and discharge distributions is repeated until convergence is achieved. This model is a variation of that published by Solomon (1985). Solomon’s model considered the variations due to manufacture and clogging separately, and also formulated the effect of temperature on the emitter discharge. However, in this study the complexity of the proposed model was considered to be appropriate for the scope of the analysis.

Sprinkler irrigation was simulated with the model developed by the author (Mateos 1998). Sprinkler pressure heads were calculated using the Hazen–Williams equation (as recommended in Keller and Bliesner 1990, p. 134). Then, wind-distorted water distribution patterns of single sprinklers were simulated on the basis of a ballistic trajectory model and a radial water precipitation pattern under wind-free conditions (Fukui et al. 1980). Evaporation was calculated using mass transfer theory, assuming that the drops are spheres of different diameters traveling from the nozzle to the ground. The individual patterns were overlapped according to the system layout and the lateral operation sequence. Finally, precipitation was obtained at the nodes of a 1 m × 1 m square grid.

Open-furrow irrigation was simulated using a kinematic-wave approximation (Cunge et al. 1980), based on the continuity equation and a unique relationship between discharge and cross sectional area at any location in the stream. This relationship was described in the model by Manning’s equation. Infiltration was calculated using a branched equation (Clemmens 1981) modification of the Kostiakov–Lewis equation. Infiltration variability was accounted for by generating families of infiltration curves around the average infiltration curve, assuming that the variability of the generated curves was due to the variability of the final infiltration rate (Oyonarte et al. 2002). Runoff was calculated from the flow simulated through the dowstream boundary of the furrows. Details about the model and the procedure for generating infiltration curves are provided in Oyonarte and Mateos (2002).

Field characteristics, irrigation system layouts and models application

The field used for this analysis is typical of irrigation settlements in Southern Spain, where the land is divided into 12 ha, rectangular lots, each usually further subdivided into two fields. The dimension of the field in this simulation analysis was 264 m × 264 m. The field had a uniform slope of 0.3% in one direction. The three irrigation methods investigated—trickle, stationary sprinkler and open furrow—are used for cotton, a common crop in Southern Spain. The author used the irrigation models to simulate the hydraulics of the typical system layout and management in this region.

When trickle irrigation was simulated, the system was divided into two units, each further subdivided into two subunits. The laterals were spaced 2 m apart, with the emitters at 1-m intervals. The nominal flow rate of the emitters was 2 l h−1. Irrigation was simulated assuming either (case 1) that there were pressure regulators at the inlet of each manifold (and the pressure head was 20 m at the inlet of both irrigation units) or (case 2) the pressure head was 20 and 15 m at the inlet of irrigation units 1 and 2, respectively. The discharge variations due to manufacturing variations and clogging were considered by varying the discharge coefficient. The mean discharge coefficient was 0.3164 l s−1 m0.65 and its coefficient of variation (CVemitter) was varied from 0 to 0.20. The discharge exponent was assumed to be x = 0.65. It was assumed that irrigation was applied daily at an average rate of 7 mm d−1. Units 1 and 2 were irrigated consecutively.

Sprinkler irrigation was simulated for a stationary system in which only one lateral operated at any given time. The laterals were spaced 15 m apart, and the sprinklers were housed in 1-m tall risers at 15 m intervals along the lateral. The sprinklers were RBR-32HX models with single-leg distribution patterns obtained directly from, and flow- and throw-pressure head relationships derived from, data provided by Tarjuelo et al. (1992):

where q is expressed in l s−1, R is the throw in m and H (the pressure head) is also expressed in m. The sprinkler irrigation model was run to simulate the 18 lateral positions required to cover the whole field. Each irrigation of the whole field was accomplished in 6 days with three 7-h lateral positions per day (from 01:00 to 08:00 am, from 09:00 am to 16:00 pm and from 17:00 to 24:00 pm). Eight irrigations were simulated between mid-May and mid-July, 1994, using actual climatic data recorded at Cordoba, Spain. The evaluations lasted for 7 h, the duration of a lateral position, and were simulated for the central sprinkler of each of the 12 central lateral positions. The average infiltration depth was 48 mm per irrigation. Mean diurnal and nocturnal temperatures during the simulated evaluations were 29.4 and 19.7°C, respectively; mean diurnal and nocturnal relative humidities were 45.7 and 68.8%, respectively; and mean diurnal and nocturnal wind speeds were 2.2 and 0.8 m s−1, respectively.

In furrow irrigation, the 264 furrows were spaced 1 m apart, with a slope of 0.3% and opened at their tails. The water was assumed to be applied by means of a flexible pipe with two perforations per furrow, one being plugged for cutback. The average inflow rate was 1.28 l s−1, with a CV from furrow to furrow of 0.15. Inflow after cutback was 70% of initial flow. The cutback time was 190 min and cut-off time 220 min. The selected inflow rate maximized application efficiency (AE) for the field characteristics. The exponent and coefficient of the average Kostiakov equation (first branch of the infiltration equation used in the furrow model) were a = 0.476 and k = 0.0054 (m3 m−1 min−a), respectively. The assumed average final infiltration rate was 0.00015 m3 m−2 min−1, with a CV of 0.15. The final infiltration rate was assumed to be normally distributed, without spatial structure. Infiltration functions were generated for every 1-m segment of each furrow. The period between irrigations was assumed to be 7 days and the average infiltration depth was 48 mm per irrigation.

The irrigations were scheduled at fixed intervals without an explicit calculation of gross irrigation requirements but assuming for all cases that the applied depth was equal to the required depth.

Evaluation methods

The evaluation procedure for trickle irrigation consisted of determining the discharge of 16 emitters in the most unfavorable irrigation subunit. The emitters were placed in the laterals at the inlet, at the far end, and at points one third and two thirds of the distance along the manifold. Four emitters were selected along each of these laterals: at the inlet, the far end, and at points one third and two thirds of the distance between them. Pressure was determined at the end of each manifold.

As well as determining the discharge and pressure, the distribution uniformity (DU) and the uniformity coefficient of Christiansen (Christiansen 1942) were calculated for the subunit (DUsubunit and UCCsubunit, respectively) and system (DUsys and UCCsys, respectively) as (Merriam and Keller 1978):

where q is the emitter flow, \(\overline {q}\) is the average emitter flow rate, \(\overline{{q_{25\%}}}\) is the average flow rate of the lowest 25% flows, n the number of observations and f is:

with \(\bar{P} \) the average minimum pressure of the system manifolds and \(\overline{{P_{{25\% }} }} \) the average minimum pressure of the 25% of manifolds with lowest pressure.

In sprinkler irrigation, catch containers were placed at 1-m intervals along both sides of the lateral line to be evaluated. The containers covered an area corresponding to a sprinkler, i.e., the sector between the two immediately adjacent sprinklers and the outer edge of the wetted area. By overlapping the right- and left-hand catch data, the total catch between adjacent lateral positions was calculated. The distribution uniformity and the uniformity coefficient of Christiansen could then be calculated with Eqs. 5a, b and DUsys and UCCsys were calculated using Eqs. 6a, b with f (Keller and Bliesner 1990)

where P min and \(\overline{P} \) are, respectively, the minimum and average sprinkler pressures in the lateral.

Since DUsys and UCCsys are the final result of the uniformity evaluation, hereafter they will be called DUeval and UCCeval, respectively.

For furrow irrigation, the evaluation procedure adopted for this analysis used the two point method to determine the parameters of the infiltration equation (Walker and Skogerboe 1987). Advance and recession were determined at the furrow tail and at mid-furrow. The advance trajectory was adjusted to a power function and the recession trajectory was adjusted to two straight lines; both passing through the half furrow length (distance, time) point, but the first passing through the head and the second passing through the tail (distance, time) points. The volume balance model with assumed surface and subsurface shapes was then applied to obtain the parameters of the first branch of the infiltration equation. The opportunity time along the furrows under evaluation was obtained from the adjusted advance and recession trajectories. The infiltrated depth along the furrows under evaluation was obtained by entering the opportunity time in the adjusted infiltration equation. DUeval and UCCeval were calculated using Eqs. 5a, b, but substituting flow rate by infiltrated depth estimated at various points along the furrow. Runoff was calculated from the difference between applied and infiltrated water amounts.

The other four performance indicators used in this analysis were: application efficiency (AE), deep percolation ratio (DPR), tail water ratio (TWR) and requirement (storage) efficiency (RE). AE is defined as the fraction of applied water stored in the root zone, DPR and TWR as the fractions of applied water going to percolation and tail water runoff, respectively, and RE as the fraction of the root zone that is filled to field capacity with irrigation water (Zerihum et al. 2001). The numerator of DPR was calculated by cumulating the values of the positive differences between the applied or infiltrated depths and the required depth, obtained during the evaluation processes. TWR was applicable only to furrow irrigation, and it was calculated by dividing the outflow volume by the applied water volume.

The effective distribution of water was obtained by calculating the moving averages of applied or infiltrated water extended to areas of 4 m × 2 m (8 m2) for the trickle system and 3 m × 3 m (9 m2) for the sprinkler and furrow systems. The extent of the moving average was somewhat smaller than the 4 m × 4 m used by Mateos (1998) based on experimental data of Mateos et al. (1997), thus the effective distribution results herein are conservative. Hereafter, field performance indicators calculated from the raw data will be indicated by the subscript “field”, and the field performance indicators calculated from moving averages will be indicated by the subscript “effective”. The subscript “eval” will be kept to name performance indicators result of the simulated evaluations.

Results

Distribution uniformity

Figure 1a depicts both the DU obtained following the evaluation procedure (DUeval) and the whole field distribution uniformity (DUfield, computed from the simulated discharge of every emitter in the field) for the trickle system with pressure regulators at the inlet of each manifold and various emitter discharge variations (CVemitter). The two distribution uniformities were very similar, indicating that the evaluation procedure reproduced the behavior of the system well at the field scale. However, if there were no pressure regulators at the manifold inlets, DUeval was significantly (P<0.001 with the F test) lower than DUfield (Fig. 1b). This overestimation seemed to increase with increases in CVemitter. Similar results were obtained when the uniformity coefficient of Christiansen was analyzed (Table 1).

Evaluated (DUeval), field (DUfield) and effective (DUeffective) distribution uniformities versus coefficient of variation of the emitters (CVemitter) in the trickle irrigation system: a assuming that there were pressure regulators at the inlet of the irrigation subunits, and b assuming that there were no pressure regulators. The error bars indicate two times the standard deviation

In the case of sprinkler irrigation, DUeval values obtained for each of the 12 lateral positions of each of the 8 irrigations are presented in Fig. 2. DUeval ranged from 0.755 to 0.872, the variation being mainly due to differences in the prevailing wind conditions. The average DUeval and DUfield values were 0.826 and 0.813, respectively (note that DUfield also accounts for edge effects, thus its value should always be slightly smaller than average DUeval). Therefore the evaluation procedure did not show a great bias, but yielded variable results depending on the time of evaluation. Similar results were obtained when UCCeval and UCCfield (Table 1) were compared.

DUeval values resulting from the evaluation of each of the 264 furrows of the furrow irrigated field ranged from 0.716 to 0.962, with an average of 0.922 (Fig. 3). In contrast, the DU of single furrow irrigations (which were simulated with the furrow irrigation model considering that both the wetted perimeter and the infiltration characteristics of the soil are variable) ranged from 0.431 to 0.708, with an average of 0.649 (Fig. 3), and DUfield was 0.571. Therefore, the furrow irrigation evaluation procedure greatly overestimated the whole field DU and the same conclusion was obtained when comparing UCCeval and UCCfield (Table 1). Moreover, the evaluation results varied greatly from furrow to furrow, so it would be necessary to evaluate a large number of furrows to obtain statistically valid results.

Effective DU under trickle irrigation showed patterns similar to those of field DU (Fig. 1), but the effect of emitter variation was markedly reduced. For instance, for CVemitter = 0, field and effective (DUeffective) distribution uniformities were practically equal, while for CVemitter = 0.20, DUeffective was 0.125 larger than DUfield. Under sprinkler irrigation, DUeffective was about 0.013 larger than DUfield (Fig. 2). Finally, under furrow irrigation, DUeffective (Fig. 3) was 0.061 larger than DUfield (Fig. 3).

Application efficiency

The AE followed trends similar to those of the DU. For trickle irrigation with pressure regulators at the inlet of each manifold, the AE obtained according to the evaluation procedure (AEeval) and the whole field application efficiency (AEfield) decreased with increasing CVemitter in a very similar manner (Fig. 4). In the case presented here, AEeval and AEfield were 0.99 for CVemitter = 0 and 0.92 for CVemitter = 0.20, while the effective application efficiency (AEeffective) was 0.99 and 0.96 for CVemitter = 0 and CVemitter = 0.20, respectively. These changes in application efficiencies corresponded to greater changes in field and effective distribution uniformities (from 0.99 to 0.75 and from 0.98 to 0.87, respectively). Note that AE is determined by the DU and both the required and applied depths, which in this analysis were assumed to be equal. Therefore, the correspondence between AE and DU would change if a different ratio between applied and required depths was assumed.

Evaluated (AEeval), field (AEfield) and effective (AEeffective) application efficiencies versus coefficient of variation of the emitters (CVemitter) in the trickle irrigation system with pressure regulators at the inlet of the irrigation subunits. The error bars indicate two times the standard deviation

AE was calculated by integrating the applied depth below the required depth and dividing by the applied volume. The integration was extended to every point for computing AEfield and to the 16 measuring points of the most unfavorable irrigation subunit for computing AEeval. Therefore, in the absence of pressure regulators at the manifold inlets, AEeval was between 0.01 and 0.04 greater than AEfield (data not shown), because the applied depth in the subunit with the lower pressure head was lower than the field-averaged applied depth.

In the case of sprinkler irrigation, the AEeval obtained for each of the 96 (12 laterals per irrigation times 8 irrigations) evaluations (Fig. 5) ranged from 0.908 to 0.961, thus it took values greater than DUeval and varied less than DUeval. AEeval averaged for each of the 12 lateral evaluations in each irrigation was around 0.008 and 0.003 greater than AEfield and AEeffective, respectively, of the corresponding irrigations, for the same reasons that DUeval was greater than DUfield and DUeffective.

In the case of furrow irrigation, AE was determined by the runoff amount and the percolation due to infiltration non-uniformity. Therefore, the large difference between DUfield and DUeval corresponded to a difference between AEfield (and AEeffective) and average AEeval of about 0.09 (Fig. 6), indicating that the evaluation procedure considerably overestimated whole field application efficiency. Moreover, as also observed for the DU, the variation of AE from furrow to furrow was very large.

Deep percolation ratio, requirement efficiency and tail water ratio

The DPR and one minus the RE were very similar for both the trickle and sprinkler systems, since the irrigation strategy involved applying a water depth equal to the required depth. The evaluation and field results were very close for trickle irrigation, but for sprinkler irrigation DPRfield was slightly greater than DPReval and REfield was slightly smaller than REeval, and for furrow irrigation the field values diverged considerably from the evaluation values (Table 2). Field and effective values did not differ greatly for any of the irrigation methods (Table 2). The difference between the field and effective values was about 0.01 for sprinkler and furrow irrigation and about 0.04 for trickle irrigation at the highest CVemitter values.

Since the models assumed that trickle and sprinkler irrigation did not produce runoff, the TWR applied only to furrow irrigation. This ratio is independent of both the redistribution of water in the soil profile and the extent of the plant roots, thus the field and effective values of the TWR were the same (Table 2). The simulated evaluation and field TWRs took very similar values because the main difference in the procedures used to obtain them was that the former ignored and the latter took into account the variability of the soil intake characteristics and wetted perimeter, which had very little effect on the runoff generation (Table 2).

Discussion

The evaluation of furrow irrigation produced biased and highly variable results. The overestimation of DU (Fig. 7a) and AE (Fig. 7b) for furrow irrigation prevents comparison of its performance results with sprinkler and trickle irrigation. The DUeval and AEeval of trickle irrigation and sprinkler systems provided acceptable estimations of DUfield and AEeval, respectively, and thus they were comparable (Fig. 7). However, two further points should be noted. First, the range of variation of DUeval resulting from the evaluation of sprinkler irrigation systems indicated that evaluating a single lateral during a single irrigation may not yield statistically valid results. Thus, field evaluations need to be repeated in several laterals to ensure that average DUeval approaches DUfield. Second, the underestimation of DUfield in the absence of pressure regulators indicates that the f factor in Eq. 7 overestimated the effect of the pressure variation among manifolds in the trickle system, while the f factor in Eq. 8 captured the pressure variation among the sprinklers well.

Given Eq. 7’s inability to generate accurate estimates of global DU from subunit uniformity parameters, more appropriate procedures for such extrapolations should be developed. Clemmens and Solomon (1997) presented methods for estimating global DU based on a combination of uniformity components by means of basic statistical relationships. However, a complicating factor in such analyses is that uniformity has often been expressed merely in terms of the ratio of two average depths; the numerator being the average of the extreme values of the distribution—often the low quarter, although the low half (Christiansen 1942) has been widely used for sprinkler irrigation—and the denominator the average of all values. In addition to knowing the mean and standard deviation of each uniformity component, a coefficient that depends on the statistical distribution of that component is required. The writer feels that shifting from DU to the more statistically meaningful concept of CV would facilitate the combination of sources of non-uniformity. In fact, emitter manufacturing variability is already expressed in terms of CV. The expression 1 − CV, proposed by Wilcox and Swailes (1947), would be a convenient choice for expressing irrigation uniformity and would be easier to compute in electronic spreadsheets than DU. The following example illustrates the use of this expression to compute field uniformity.

Suppose the trickle irrigation system is being used without pressure regulators and CVemitter = 0.15. The evaluation of the most unfavorable subunit (with manifold pressure head H = 15 m) yields \(\overline{q} = 1.86\,{\rm l}\,{\rm s}^{- 1}, \overline{{q_{25\% }}} = 1.51\,{\rm l}\,{\rm s}^{- 1}, {\rm DU}_{\rm subunit} = 0.816, f = {\left( {{15} / {17.5}} \right)}^{{0.65}} = 0.9047,\) and DUeval = 0.816 × 0.9047 = 0.738, quite different from DUfield = 0.780. Now, in terms of CV: 1−CVsubunit = 0.851. For the subunits with H = 20 m, average emitter flow rate can be estimated as \(\overline{{{{q}}_{{{{20}}}} }} = \overline{{{{q}}_{{{{15}}}} }} /{\left( {{20}/{15}} \right)}^{{0.65}} = 2.24\,{{ {\rm l\,s}}}^{{ - {{1}}}}.\) If we assume that CV is not significantly different from subunit to subunit, then 1 − CVeval is \(1 - {{\left( {{\sqrt {2{\left( {{\rm CV}_{{\rm sub-unit}} } \right)}^{2} {\left( {\overline{{q_{{15}} }} + \overline{{q_{{20}} }} } \right)}^{2} + {\left( {\overline{{q_{{15}} }} - \overline{{q_{{20}} }} } \right)}^{2} } }} \right)}} / {{\left( {\overline{{q_{{15}} }} + \overline{{q_{{20}} }} } \right)}} = 0.824,\) which is very close to 0.821, the value of 1−CVfield.

Furthermore, use of 1 − CV would facilitate the treatment of other relationships of interest for scheduling irrigations, such as the relationships between uniformity, AE and the ratio of applied to required water depths (Wu 1988; Anyoji and Wu 1994). 1 − CV would be equivalent to the DU calculated as the ratio between the extreme and average values of the distribution with a fraction of total area with smallest depth approximately equal to 0.38, which is between the low quarter and the low half distribution uniformities.

The comparison between effective and field distribution uniformities indicated that different scales of variation were involved. For very low values of CVemitter, the DU in trickle irrigation was mostly governed by pressure head differences, which are of large scale. The evaluation of furrow irrigation considered opportunity time as the only source of variation, which is also a large scale variation. Consequently, in these two cases, effective and field distribution uniformities took very similar values. However, the estimation of DUfield for furrow irrigation took account of variations in soil intake characteristics at 1 m intervals (small scale variation). Similarly, trickle irrigation with moderate or high CVemitter values also exhibited relevant variation at small scales. Consequently, in both cases, effective and field distribution uniformities diverged. Finally, the situation in sprinkler irrigation was intermediate in this respect, since pressure head differences represent a large scale, and wind-distorted sprinkler distribution patterns an intermediate scale, source of variation. Therefore, there was divergence between effective and field distribution uniformities in sprinkler irrigation but the divergence was not great.

Conclusions

This study demonstrates the value of irrigation simulation models for analyzing irrigation performance and evaluation procedures. The results show that the procedure used to determine performance indicators in trickle irrigation yields good estimates of the whole field performance, provided there are no pressure variations among subunits. To overcome shortcomings in the evaluation procedure if there are such variations, the writer suggests that global DU estimates should be based on a combination of uniformity components and a uniformity indicator based on the CV of applied water volumes.

The evaluation procedure used in sprinkler irrigation is also acceptable, but it needs to be applied along several laterals, to account for the effects of climatic variations. The evaluation of furrow irrigation produced biased, highly variable results and overestimated DU, preventing comparison of this performance indicator with corresponding figures for sprinkler and trickle irrigation systems.

The comparison between effective and field distribution showed the effect of scales of variation of the water distribution. All three irrigation methods have large-scale sources of non-uniformity (variations of pressure in trickle and sprinkler systems and of opportunity time in furrow systems). Trickle and furrow systems also exhibited small scale sources of variation, including variations in emitter discharge and soil intake characteristics, respectively. Sprinkler systems also had an intermediate scale source of variation; their wind-distorted sprinkler distribution patterns. The weaker the influence of the small-scale sources of variation, the closer the field and effective performance indicators.

References

Anyoji H, Wu IP (1994) Normal distribution water application for drip irrigation schedules. Trans ASAE 37:159–164

Burt CM, Clemmens AJ, Strelkoff TS, Solomon KH, Bliesner RD, Hardy LA, Howell TA, Eisenhauer DE (1997) Irrigation performance measures: efficiency and uniformity. J Irrig Drain Eng 123:423–442

Christiansen JE (1942) Irrigation by sprinkling. Univ Calif Berkeley Agric Exp Sta Bull 670

Clemmens AJ (1981) Evaluation of infiltration measurements for border irrigation. Agric Water Manage 3:251–267

Clemmens AJ, Solomon KH (1997) Estimation of global irrigation distribution uniformity. J Irrig Drain Div Eng 123:454–461

Cogels OG (1983) An irrigation system uniformity function relating the effective uniformity of water application to the scale of influence of the plant root zones. Irrig Sci 4:289–299

Cunge JA, Holly FM, Verwey A (1980) Practical aspects of computational river hydraulics. Pitman Publishing, London, p 420

Fukui Y, Nakanishi K, Okamura S (1980) Computer evaluation of sprinkler irrigation uniformity. Irrig Sci 2:23–32

Hanson B, Bowers W, Davidoff B, Kasapligil D, Carvajal A, Bendixen W (1995) Field performance of microirrigation systems. Microirrigation for a changing world: conserving resources/preserving the environment. In: Proceedings of the 5th international microirrigation congress, FL, USA

Hart WE (1972) Subsurface distribution of nonuniformly applied surface waters. Trans ASAE 15:656–661, 666

Keller J, Bliesner RD (1990) Sprinkler and trickle irrigation. Chapman & Hall, New York NY, p 652

Mateos L (1998) Assessing whole-field uniformity of stationary sprinkler irrigation systems. Irrig Sci 18:73–81

Mateos L, Mantovani EC, Villalobos FJ (1997) Cotton response to non-uniformity of conventional sprinkler irrigation. Irrig Sci 17:47–52

Merriam JL, Keller J (1978) Farm irrigation system evaluation: a guide for management, 3rd edn. Utah State University, Logan, p 285

Oyonarte NA, Mateos L (2002) Accounting for soil variability in the evaluation of furrow irrigation. Trans ASAE 45:85–94

Oyonarte NA, Mateos L, Palomo MJ (2002) Infiltration variability in furrow irrigation. J Irrig Drain Eng 128:26–33

Seginer I (1979) Irrigation uniformity related to horizontal extent of root zone: a computation study. Irrig Sci 1:89–96

Solomon KH (1985) Global uniformity of trickle irrigation systems. Trans ASAE 28:1151–1158

Tarjuelo JM, Valiente M, Lozoya J (1992) Working conditions of sprinkler to optimize application of water. J Irrig Drain Eng 118:895–913

Walker WR, Skogerboe GV (1987) Surface irrigation. Theory and practice. Prentice-Hall, Englewood Cliffs, p 386

Watters GZ, Keller J (1978) Trickle irrigation tubing hydraulics. ASAE technical paper no 78-2015

Wilcox JC, Swailes GE (1947) Uniformity of water distribution by some undertree orchard sprinklers. Sci Agric 127:565–583

Wu IP (1988) Linearized water application function for drip irrigation schedules. Trans ASAE 31:1743–1749

Zerihum D, Sanchez CA, Farrell-Poe KL (2001) Analysis and design of furrow irrigation systems. J Irrig Drain Eng 127:161–169

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by S. Ortega-Farias

Rights and permissions

About this article

Cite this article

Mateos, L. A simulation study of comparison of the evaluation procedures for three irrigation methods. Irrig Sci 25, 75–83 (2006). https://doi.org/10.1007/s00271-006-0036-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00271-006-0036-x