Abstract

The electrical conductivity of (Mg0.93Fe0.07)SiO3 ilmenite was measured at temperatures of 500–1,200 K and pressures of 25–35 GPa in a Kawai-type multi-anvil apparatus equipped with sintered diamond anvils. In order to verify the reliability of this study, the electrical conductivity of (Mg0.93Fe0.07)SiO3 perovskite was also measured at temperatures of 500–1,400 K and pressures of 30–35 GPa. The pressure calibration was carried out using in situ X-ray diffraction of MgO as pressure marker. The oxidation conditions of the samples were controlled by the Fe disk. The activation energy at zero pressure and activation volume for ilmenite are 0.82(6) eV and −1.5(2) cm3/mol, respectively. Those for perovskite were 0.5(1) eV and −0.4(4) cm3/mol, respectively, which are in agreement with the experimental results reported previously. It is concluded that ilmenite conductivity has a large pressure dependence in the investigated P–T range.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Electrical conductivity is a physical parameter that can be characterized, along with seismic wave velocities, from measurements at the Earth’s surface. A comparison of geophysical models with mineral properties would provide important constraints for mineralogical and compositional models of the Earth’s mantle. For this reason, the electrical conductivities of the mantle minerals have been measured extensively (Katsura et al. 1998; Li and Jeanloz 1990a, b, 1991; Li et al. 1993; Omura 1991; Omura et al. 1989; Poirier and Peyronneau 1992; Shankland and Duba 1990; Shankland et al. 1993; Xu et al. 1998a, b, 2000; Xu and Shankland 1999).

Although temperature dependence of the electrical conductivity of mantle minerals has been determined precisely, pressure dependence has not been studied in detail. Shankland et al. (1993) measured the electrical conductivity of silicate perovskite at pressures of 1.2 and 40 GPa, and reported a small negative activation volume of −0.26 cm3/mol. Xu et al. (2000) measured the electrical conductivity of olivine at pressures of 4–10 GPa, and showed a positive activation volume of 0.6(6) cm3/mol. Although the electrical conduction mechanisms of both of these minerals are considered to be hopping of small polarons associated with the charge transfer between Fe2+ and Fe3+, their activation volumes have opposite signs. Thus, at present we have no reasonable consensus for the pressure dependence of the electrical conductivity of ferromagnesian minerals. In order to obtain a better understanding of the electrical conductivity of ferromagnesian minerals, we need further studies on the pressure dependence of the electrical conductivity.

In this study, we measured the electrical conductivity of (Mg0.93Fe0.07)SiO3 ilmenite at temperatures of 500–1,200 K at elevated pressures from 25 to 35 GPa in a multi-anvil apparatus. The electrical conductivity of perovskite with the same composition was also measured, to verify the reliability of the experimental method used in the present study, by comparing the results obtained by this method with those of previous studies. Until recently, the effect of pressure on the electrical conductivity of high-pressure minerals was difficult to study using a multi-anvil apparatus because of the limited pressure range. Thanks to the recent technical development of high-pressure generation using sintered diamond anvils (Ito et al. 2005), we can now determine the pressure dependence of the electrical conductivity of high-pressure minerals.

Experimental procedure

The starting material was enstatite with a (Mg0.93Fe0.07)SiO3 composition, which was the same as that used in our previous measurement of the electrical conductivity of silicate perovskite (Katsura et al. 1998). This enstatite was synthesized from Mg, Fe and tetraethylorthosilicate by the sol-gel method. The enstatite powder was compressed to a disk shape, which was sintered at 1,670 K for 1 h with a CO2 and H2 mixed gas with a ratio of 10:1. The oxygen partial pressure is 10−1.9 Pa under these conditions, which is by 2.8 orders higher than the IW buffer and by 0.4 orders lower than the WM and QFM buffers.

The high pressures and high temperatures were generated using a Kawai-type multi-anvil apparatus with a DIA-type guide block system installed at ISEI, Okayama University (AMAGAEL). We used sintered-diamond second-stage anvils with an edge length of 14.0 mm. The anvil truncation was 2.0 mm. The generated pressures were calibrated by in situ X-ray diffraction with the MgO pressure scale (Matsui et al. 2000) using a similar high P–T apparatus installed at the synchrotron radiation facility SPring-8 [SPEED-Mk.II, (Katsura et al. 2004)]. As mentioned later, the conductivity measurements were conducted at press loads of 4, 6 and 8 MN, in which the sample pressures were estimated to be 25, 30 and 34 GPa at 300 K, respectively. The sample pressure changes by changing the sample temperature. Heating the sample from 500 to 1,200 K increases the sample pressure by 1 GPa. The reproducibility of the pressure generation is considered to be within 1 GPa, from our experience of in situ X-ray diffraction experiments using sintered diamond in a multi-anvil apparatus.

The furnace assembly for the electrical conductivity measurement is shown schematically in Fig. 1. The disk-shaped sample with a thickness of 0.2 mm was sandwiched between Fe disks. The Fe disks were set to keep the oxidation state of the sample on the iron-wustite (IW) buffer during the experiment. The sample was heated using a pair of Re disk heaters. The sample temperature was measured using a W97Re3–W75Re25 thermocouple, which was inserted in parallel with the disk heaters. Because of the small furnace size, there could be 10% of temperature variation in the sample. One of the Fe disks was electrically connected to the Re heater through a Mo rod. The other disk was in direct contact with the thermocouple. We conducted insulation tests for the assembly. We found that the insulation resistance is more than 106 Ω at ambient temperature, and decrease to around 105 Ω at temperatures to 1,400 K. The insulation resistance is more than 1 order of magnitude higher than the sample resistance.

The measurement circuit is shown in Fig. 2. The probe current, I probe, was applied to the sample using one side of the thermocouple and the heater through the anvil and guide block, which serve as electrodes. The alternative voltage on the sample, V sample, was measured using the other side of the thermocouple and the heater as electrodes. The sample was connected with the reference resistance (R ref) and the function generator in series. The function generator generated sinusoidal signals, whose frequency and amplitude were 10 mHz and 5 V, respectively. The magnitude of the reference resistance was 100 kΩ in this study. The I probe was measured from the alternative voltage applied on the reference resistance, V ref. Thus, the impedance of the sample, Z sample was obtained by R ref and the complex ratio of V sample to V ref as:

The sample resistance, R sample, was estimated from the sample impedance by assuming a parallel circuit with a capacitance, C, as

where ω is the angular frequency of the signal. Note that the heating and electrical conductivity measurement systems share the circuit between the heater and guide block. The frequency of the signal of the electrical conductivity measurement is 10 mHz, which is much lower than that of the heating current, I heating (60 Hz). The noise from the heating circuit was removed from the signal of the electrical conductivity measurement by averaging the signals for 1/60 s. The relative errors in the present resistance measurement are very small and on the order of 10−5.

Electric circuit of electrical conductivity measurement at high pressures and temperatures in a multi-anvil apparatus. The sample is connected with the reference resistance and function generator in series. The function generator generates a sinusoidal signal with a frequency of 10 mHz to flow the probe current (I probe)

We conducted two runs to measure the electrical conductivity, using the following procedures. In the first run, the sample was compressed to the press load of 4 MN, and heated to 1,200 K. Under these conditions, the sample should be transformed from enstatite to ilmenite. The formation of ilmenite at this temperature was confirmed in a separate run. After the ilmenite synthesis, the sample temperature was decreased to 500 K in steps of 100 K, measuring the electrical conductivity at each step. After the measurement at 4 MN, the sample was compressed to a press load of 6 MN, and heated to 1,200 K. The electrical conductivity was measured according to the same procedure as for 4 MN. The sample was then further compressed to a press load 8 MN. The conductivity was measured by the same procedure as for 4 and 6 MN.

In the second run, the measurements were conducted at 4 and 6 MN in the same way as for the first run, in order to confirm the reproducibility of the measurement. After the measurements under these conditions, the sample was heated to 1,400 K at 6 MN so that perovskite was formed from the ilmenite. The electrical conductivity of perovskite was measured at 6 and 8 MN at decreasing temperatures from 1,400 to 500 K with 100 K steps.

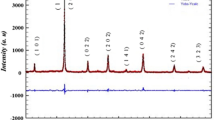

After recovery, a cross-section of the sample was taken, and the phase present was identified using a micro-focused X-ray diffractometer. The sample textures were observed using an electron microscope to confirm absence of other phases, such as metallic and oxide phases and no reaction of the sample with the surrounding material. Although Fe3+ and H+ should affect on the conductivity, the amounts of these components were not measured mainly because of the small sample size for Mossbauer and IR spectroscopies, respectively. However, note that the amounts of Fe3+ in the samples were minimized by coexisting with the Fe disks.

The sample dimensions were measured using an electron microscope. By assuming that the sample volumes were changed isotropically at high pressures and temperatures, the dimensions were corrected using the equations of state of ilmenite (Wang et al. 2004) and perovskite (Fiquet et al. 1998). The errors in dimension are about 10 μm. The electrical conductivity of the sample was calculated from the sample resistance and corrected dimensions.

Results

The logarithmic conductivity of (Mg0.93Fe0.07)SiO3 perovskite at each press load is plotted against the reciprocal temperature in Fig. 3. The logarithmic conductivity of perovskite linearly increases with decreasing reciprocal temperature. The conductivity of perovskite increases with increasing pressure. The rates are 0.08 and 0.05 (log10S/m)/GPa at 500 and 1,200 K, respectively. The slope of the logarithmic the conductivity against the reciprocal temperature decreases with increasing pressure with a small rate; the slopes are −0.182 and −0.176 (log10S/m)K at 6 and 8 MN, respectively.

Experimental results for (Mg0.93Fe0.07)SiO3 perovskite. The red and green triangles denote the results at press loads of 6 and 8 MN, respectively. The numbers denote the sample pressures at 500 and 1,400 K at each press load. The solid line denotes the conductivity of perovskite at 23 GPa given by Katsura et al. (1998). The dotted line denotes the extrapolation of the conductivity of perovskite in the present study to 23 GPa. The dot-dashed lines denote the conductivity of perovskite at 1.2 and 40 GPa given by Shankland et al. (1993 )

The logarithmic conductivity of (Mg0.93Fe0.07)SiO3 ilmenite at each press load is plotted against reciprocal temperature in Fig. 4. The results at 4 and 6 MN are in reasonable agreement between these separate runs. The maximum differences between these two runs are only 0.2 and 0.05 log units at 500 and 1,200 K, respectively. The logarithmic conductivity linearly increases with decreasing reciprocal temperature as in the case of perovskite. The conductivity increases with increasing pressure at constant temperature. As is in the case of perovskite, the slope decreases with increasing pressure. Note that the decreasing rate of the slope for ilmenite is much larger than that for perovskite. The slopes are −0.23, −0.20, and −0.16 (log10S/m)K at press loads of 4, 6 and 8 MN, respectively.

Experimental results for (Mg0.93Fe0.07)SiO3 ilmenite. The triangles and circles denote the results from the first and second runs, respectively. The blue, red and green symbols denote the results at press loads of 4, 6 and 8 MN, respectively. The numbers denote the sample pressures at 500 and 1,200 K at each press load

Discussion

Because of the linearity of the logarithmic conductivity against the reciprocal temperature, we can express the electrical conductivity of ilmenite and perovskite, σ, using Arrhenius’s formula:

where σ 0 is the electrical conductivity at the infinitely high temperature (so-called pre-exponential factor), and H a is an activation enthalpy. Since the slope of the logarithmic conductivity against the reciprocal temperature becomes smaller with increasing pressure, the pressure dependence of the activation enthalpy could be expressed as a linear function of pressure, P, using the activation volume, V a:

where E a is the activation energy at zero pressure. Since the extrapolations of conductivity at different pressures to infinite temperature seem to converge to one value, the pre-exponential factor is assumed to be constant under the present experimental conditions.

By fitting the experimental data of perovskite to Eqs. 3 and 4, σ 0, E a, and V a are determined:

-

σ 0 = 6(2) S/m

-

E a = 0.5(1) eV

-

V a = −0.4(4) cm3/mol.

The activation enthalpy of perovskite ranges from 0.34 to 0.36 eV under the investigated P–T conditions. Because of the limited pressure range, the activation volume has a large error. Nevertheless, it is clear that the activation volume of perovskite has a small negative value.

The σ 0, E a, and V a for ilminete are determined:

-

σ 0 = 15(5) S/m

-

E a = 0.82(6) eV

-

V a = −1.5(2) cm3/mol.

Thus, ilmenite has a very large negative activation volume. The activation enthalpy of ilmenite ranges from 0.30 to 0.46 eV under the investigated P–T conditions.

The parameters obtained both for ilmenite and perovskite in this study have significantly large errors. The errors from the resistance measurement are small. The main error source is the temperature variation in the sample. The second error source is the limited precision of pressure estimation. For more precise measurement, the homogeneous temperature distribution and precise pressure measurement are required.

The conductivity obtained for perovskite in this study is slightly higher than that of our previous measurements (Katsura et al. 1998) in a similar temperature range. The slopes of the Arrhenius plots obtained in this study are slightly smaller than that obtained previously. These differences can be explained by the differences in the experimental pressures. The conductivity was measured at pressures from 30 to 35 GPa in this study, whereas nominally at 23 GPa by Katsura et al. (1998). Extrapolation of the present data to 23 GPa indicates that the present results agree with those of Katsura et al. (1998). The small difference in the absolute values between these two studies could be explained by errors in measurements of the sample dimensions.

Xu et al. (1998a) and the high-temperature measurement of Katsura et al. (1998) showed much higher activation enthalpies than the present study. This discrepancy can be attributed to the change in activation enthalpy at different temperature regimes of perovskite, which was discussed by Katsura et al. (1998).

The present experimental results are in general agreement with those of Shankland et al. (1993). For example, the difference in conductivity values between the present study and Shankland et al. (1993) is only 0.2 log units at 30 GPa. Although the activation volume obtained in this study has a large error (−0.4(4) cm3/mol), it essentially agrees with that given by Shankland et al. (1993) (−0.26(3) cm3/mol). These facts guarantee our measurements, suggesting the reliability of conclusion that ilmenite has a large negative activation volume.

The present study is the first to provide data on the electrical conductivity of (Mg,Fe)SiO3 ilmenite. The electrical conductivity of ilmenite has a positive pressure dependence, namely, a negative activation volume. The dominant conduction mechanism of ferromagnesian silicates is usually considered to be the hopping of a hole between Fe2+ and Fe3+. As mentioned before, the activation volume of (Mg,Fe)SiO3 perovskite also has a negative activation volume. Fe-rich olivine, magnesiowustite and FeTiO3 ilmenite also have negative activation volumes (Dobson and Brodholt 2000; Omura et al. 1989; Zhang et al. 2006). In contrast, all reports on the electrical conductivity of Mg-rich olivine have shown positive activation volumes (Dai et al. 2006; Omura et al. 1989; Xu et al. 2000). We could conclude that the electrical conductivities of ferromagnesian minerals generally have a negative activation volume, but Mg-rich olivine is an exception.

Although the sign of the activation volume for ilmenite obtained in this study is the same as those of most ferromagnesian minerals, its absolute value is unexpectedly high. Goddat et al. (1999) claimed that the activation energy for the hopping of a small polaron should be on the order of magnitude of the difference in volumes between Fe3+ and Fe2+, which is equal to −0.23 cm3/mol. The activation volume of ilmenite conductivity obtained here is 6 times larger than this expected value. One might consider this to be due to experimental errors in the present study. However, the large activation volume obtained here for ilmenite is highly convincing, for the following reasons. First, synthesis of ilmenite from the starting material of enstatite in the same run with the electrical conductivity measurement should exclude the effect of the sample compaction on the conductivity. If we load a sample in a high-pressure cell, the sample should contain pores and cracks, which decrease the sample apparent conductivity. If we compress it to high pressure, the apparent conductivity should largely increase because of close of pores and cracks. However, if the sample is heated to cause the phase transition, the internal structure of the sample should be rearranged so that the pores and cracks disappear. Second, the reproducibility of the pressure effect of the ilmenite conductivity was demonstrated by the two separate runs. Third, the conductivity of perovskite measured in the same run as that for ilmenite agrees with the values obtained in previous studies.

At present, we do not have a persuasive explanation for the high negative activation volume for the hopping conduction of ilmenite. It is very difficult to consider the operation of any other conduction mechanism in ilmenite. Proton conduction could be the dominant conduction mechanism at relatively low temperatures. For example, Yoshino et al. (2006) have shown that olivine contains a small amount of hydrogen at high pressures even if no water is doped initially, and that the proton conduction is a dominant conduction mechanism below 900 K. A small amount of water could have been contained in our ilmenite. However, proton conduction should have a positive activation volume because it is ionic conduction. Therefore, the large negative activation volume cannot be attributed to proton conduction.

One point that we have to consider is that the measurement was conducted out of the stability field of ilmenite. The ilmenite was formed from the starting material at 26 GPa and 1,200 K. These conditions should be in the stability field of perovskite, not ilmenite (Ono et al. 2001). The ilmenite should be formed due to kinetic reasons. The ilmenite survived during the measurements, whose conditions are far above the stability field of ilmenite, also due to kinetic reasons. The metastability may cause distortion of the electric structure of ilmenite, which may lower the activation enthalpy of the hopping. The large decrease in activation enthalpy might be a precursor of high-pressure amorphization. However, this hypothesis has no supporting evidence and theory. In order to understand the electrical conductivity mechanism of ferromagnesian minerals, more studies of electrical conductivity measurements obtained under elevated pressures at high temperatures are required. Theoretical studies are also required.

References

Dai LD, Li HP, Liu CG, Cui TD, Shan SM, Yang CJ, Liu QY, Deng HM (2006) Experimental measurement of the electrical conductivity of single crystal olivine at high temperature and high pressure under different oxygen fugacities. Progress Nat Sci 16:387–393

Dobson DP, Brodholt JP (2000) The electrical conductivity of the lower mantle phase magnesiowustite at high temperatures and pressures. J Geophys Res 105:531–538

Fiquet G, Andrault D, Dewaele A, Charpin T, Kunz M, Hauesermann D (1998) P-V-T equation of state of MgSiO3 perovskite. Phys Earth Planet Int 105:21–31

Goddat A, Peyronneau J, Poirier JP (1999) Dependence on pressure of conduction by hopping of small polarons in minerals of the Earth’s lower mantle. Phys Chem Mineral 27:81–87

Ito E, Katsura T, Aizawa Y, Kawabe K, Yokoshi S, Kubo A, Nozawa A, Funakoshi K (2005) High-pressure generation in the Kawai-type apparatus equipped with sintered diamond anvils: application to the wurtzite-rocksalt transformation in GaN, In: Chen J, Wang Y, Duffy TS, Shen G, Dobrzhinetskaya LF (eds) Advances in high-pressure technology for geophysical applications. Elsevier, Amsterdam, pp 451–460

Katsura T, Sato K, Ito E (1998) Electrical conductivity of silicate perovskite at lower-mantle conditions. Nature 395:493–495

Katsura T, Funakoshi K, Kubo A, Nishiyama N, Tange Y, Sueda Y, Kubo T, Utsumi W (2004) A large-volume high-pressure and high-temperature apparatus for in situ X-ray observation, ‘SPEED-Mk.II’. Phys Earth Planet Int 143–44:497–506

Li X, Jeanloz R (1990a) High pressure–temperature electrical conductivity of magnesiowuestite as a function of iron oxide concentration. J Geophys Res 95:21609–21612

Li X, Jeanloz R (1990b) Laboratory studies of the electrical conductivity of silicate perovskites at high pressures and temperatures. J Geophys Res 95:5067–5078

Li X, Jeanloz R (1991) Effect iron content on the electrical conductivity of perovskite and magnesiowuestite assemblages at lower mantle conditions. J Geophys Res 96:6113–6120

Li X, Ming LC, Manghnani MH, Wang Y, Jeanloz R (1993) Pressure dependence of the electrical conductivity of (Mg0.9Fe0.1)SiO3 perovskite. J Geophys Res 98:501–508

Matsui M, Parker SC, Leslie M (2000) The MD simulation of the equation of state of MgO: application as a pressure calibration standard at high temperature and high pressure. Am Mineral 85:312–316

Omura K (1991) Change of electrical conductivity of olivine associated with the olivine-spinel transition. Phys Earth Planet Int 65:292–307

Omura K, Kurita K, Kumazawa M (1989) Experimental study of pressure dependence of electrical conductivity of olivine at high temperatures. Phys Earth Planet Int 57:291–303

Ono S, Katsura T, Ito E, Kanzaki M, Yoneda A, Walter MJ, Urakawa S, Utsumi W, Funakoshi W (2001) In situ observation of ilmenite–perovskite phase transition in MgSiO3 using synchrotron radiation. Geophys Res Lett 28:835–838

Poirier J-P, Peyronneau J (1992) Experimental determination of the electrical conductivity of the material of the Earth’s lower mantle. In: Syono Y, Manghani MH (eds) High pressure research: application to earth and planetary sciences, Geophysics Monograph No. 67. American Geophysical Union, Washington, pp 77–87

Shankland TJ, Duba AG (1990) Standard electrical conductivity of isotropic, homogeneous olivine in the temperature range 1200°–1500°C. Geophys J Int 103:25–31

Shankland TJ, Peyronneau J, JP Poirier (1993) Electrical conductivity of the Earth’s lower mantle. Nature 366:453–455

Wang YB, Uchida T, Zhang JZ, Rivers ML, Sutton SR (2004) Thermal equation of state of akimotoite MgSiO3 and effects of the akimotoite-garnet transformation on seismic structure near the 660 km discontinuity. Phys Earth Planet Int 143–144:57–80

Xu YS, Shankland TJ (1999) Electrical conductivity of orthopyroxene and its high pressure phases. Geophys Res Lett 26:2645–2648

Xu YS, McCammon C, Poe BT (1998a) The effect of alumina on the electrical conductivity of silicate perovskite. Science 282:922–924

Xu YS, Poe BT, Shankland TJ, Rubie DC (1998b) Electrical conductivity of olivine, wadsleyite, and ringwoodite under upper-mantle conditions. Science 280:1415–1418

Xu YS, Shankland TJ, Duba AG (2000) Pressure effect on electrical conductivity of mantle olivine. Phys Earth Planet Int 118:149–161

Yoshino T, Matsuzaki T, Yamashita S, Katsura T (2006) Electrical conductivity of single-crystal hydrous olivine: assessment of water in the upper mantle. Nature 443:973–976

Zhang BH, Katsura T, Shatskiy A, Matsuzaki T, Wu XP (2006) Electrical conductivity of FeTiO3 ilmenite at high temperature and high pressure. Phys Rev B 73:134104

Acknowledgments

The synchrotron radiation experiments were performed at the BL04B1 in the SPring-8 with the approval of the Japan Synchrotron Radiation Research Institute (JASRI) (proposal: 2004A0367-ND2b-np, 2004B0498-ND2-np). This research was supported by the 21st century COE program of the Japan Society for the Promotion of Science.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Katsura, T., Yokoshi, S., Kawabe, K. et al. Pressure dependence of electrical conductivity of (Mg,Fe)SiO3 ilmenite. Phys Chem Minerals 34, 249–255 (2007). https://doi.org/10.1007/s00269-007-0143-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00269-007-0143-0