Abstract

Crystallisation of sodium sulfate solutions by evaporation under controlled climatic conditions has revealed the existence of crystalline hydrated sodium sulfate salts not previously reported. The sodium sulfate phase crystallising and the concentration of the solution at the point of crystallisation depends on the climatic conditions (temperature and evaporation rate). During the rehydration of the anhydrous sodium sulfate phase, thenardite, another previously unreported phase was formed prior to the nucleation of the stable phase, mirabilite Na2SO4 · 10H2O. The addition of organic inhibitors changes both the crystallisation and the rehydration behavior in this system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

It is widely accepted that salt crystallisation is an important cause for the weathering and damage of building stones and that sodium sulfate is one of the most damaging salts for the built cultural heritage (Goudie and Viles 1997). However, the reason that damage from sodium sulfate crystallisation is greater than from other salts remains a subject of continuing debate (Rodriguez-Navarro et al. 2000; Chaterji 2000; Scherer 2000, 2004; Flatt 2002). One reason for this is the complexity of the sodium sulfate system, with two stable phases (thenardite, Na2SO4 and mirabilite, Na2SO4 · 10H2O) and one reported metastable phase, the heptahydrate, Na2SO4 · 7H2O. The equilibrium phase diagram is shown in Fig. 1 from which it is evident that the dissolution of thenardite at temperatures below about 32°C will result in a solution supersaturated with respect to mirabilite. Supersaturation has regularly been invoked as a key issue in salt crystallisation damage, as it provides an excess free energy for nucleation and growth and results in a crystallisation pressure (Correns 1949; Benavente et al. 2004; Steiger 2005a, b) which may be in excess of the tensile strength of most building stone and concrete (Flatt 2002). It follows that the crystallisation pressure increases with the degree of supersaturation (Correns 1949; Steiger 2005a, b).

Phase diagram for sodium sulfate. The solid lines are equilibrium phase boundaries, and the dashed line is the metastable extension of the thenardite-solution boundary and therefore represents solution compositions in metastable equilibrium with thenardite but supersaturated with respect to mirabilite (after Flatt 2002)

Clearly, supersaturation of a solution is defined relative to a specific solid whose solubility must be known. The existence of the metastable heptahydrate is widely referred to in the older chemical literature and in standard textbooks of the time (e.g. Wetmore and LeRoy 1951), but does not rate much attention in the more recent literature on salt damage, as it apparently has not been observed in building stone (Flatt 2002). However, in any supersaturated solution in a system involving more than a single solid phase, metastable phases may be expected to crystallise (Furedi-Milhofer et al. 1990) and the usual acceptance that only thenardite and mirabilite are relevant when considering sodium sulfate crystallisation damage needs to be reconsidered.

One reason for the lack of recognition of metastable sodium sulfate phases in building stone is the difficulty of characterisation. As is evident from Fig. 1, mirabilite will dehydrate to thenardite at low relative humidity at normal ambient temperatures. This dehydration is rapid, as will be discussed later in this paper, as is the dehydration of the heptahydrate. The rehydration of thenardite is much slower, and involves a dissolution and reprecipitation mechanism (Rogriguez-Navarro and Doehne 1999), which is an important conclusion in the light of the once commonly accepted hypothesis that the large molar volume change on hydration is responsible for the build up of stresses and hence crystallisation damage. In a dissolution-reprecipitation process the relative solubilities of parent and product are more important than the molar volume change and in assessing the relative amounts of material dissolved and reprecipitated (Putnis 2002).

The aim of this paper is to present experimental observations of the crystallisation of sodium sulfate, specifically to determine the degree of supersaturation required for nucleation and growth, to determine how the supersaturation depends on factors such as the evaporation rate, and finally to identify which sodium sulfate phase crystallises under which conditions. A further aim is to observe the rehydration of thenardite under controlled climatic conditions and to identify the sequence of hydrated phases which form. The main conclusion of this paper is that the crystallisation behavior of sodium sulfate is much more complex than previously recognised and that this needs to be taken into account when assessing the cause of stone damage.

Experimental procedures

Crystal growth experiments were carried out in a climate chamber in which the temperature can be controlled from −2 to +60°C (deviation: ±0.1°C). Crystal growth was induced by evaporation of a solution. The evaporation rate was controlled by varying the temperature and humidity inside the chamber, as well as by using different geometries for the holder containing the solution. The humidity inside the chamber was varied by salt solutions in contact with their solid salts, and independently measured using a humidity meter. The temperature and humidity were continuously monitored and data logged during the experiments. For the crystallisation experiments a sodium sulfate solution with concentration of 190 gl−1 Na2SO4 was prepared and filtered through a 0.2 μm filter to remove any suspended particles which might influence the crystallisation. The fluid was pipetted into cylindrical, flat-bottomed sample holders which were machined from PVC and polished. Crystallisation was induced by evaporation, and the weight of the holder and fluid continuously monitored with a sensitive balance to determine the evaporation rate. A CCD camera with a macro-objective recorded the onset of crystal growth. The continuous data logging allowed the point of crystallisation to be related to the weight of the sample from which the solution concentration could be calculated.

As it is well known that nucleation and growth experiments are difficult to reproduce, considerable care was taken to keep experimental conditions identical in each set of experiments. The aim of each experimental run was to determine the concentration in the solution at the point of nucleation of crystals and how this depended on the evaporation rate. To investigate the variables which might influence the results, sample holders were prepared with different volumes and different surface areas. For example, cylindrical sample holders with the same volume (38.5 μl) but with different surface areas (internal diameters of 5, 6 and 7 mm) were used to vary evaporation rates at constant humidity and temperature. Evaporation rates were also measured for sample holders with the same surface areas but with different volumes (deeper cylinders with volumes of 23.7, 47.5 and 71.3 μl). In these latter experiments the rate of change of concentration in the solution is different even when the evaporation rate is the same. Experiments were also tried using sample holders with the same volume and surface area but with a different shape and different material to determine the extent to which surface effects of the sample holder influence crystallisation. The most consistent results were obtained using sample holders with intermediate ratios of surface area:volume i.e. using a fixed fluid volume in holders which were neither too deep (small surface area) nor too shallow (large surface area). Every experiment was repeated at least three times to determine which experimental set-up produced the most consistent results. The results reported here are from sample holders with the same volume and with different surface areas. Changes in the evaporation rate were also induced by increasing the temperature and also by reducing the humidity.

One of the inherent problems with inducing supersaturation by evaporation is the likely presence of concentration gradients in the solution, with higher concentrations at the evaporating surface. The determined solution concentrations at the time when crystallisation begins, are calculated from the weight loss and hence averaged over the whole fluid sample. These calculated concentrations are most probably underestimates of the true supersaturation at the fluid surface, which is normally the site of nucleation of the crystals.

As a control, experiments were repeated under the same climatic conditions for the evaporation of NaCl solution (starting composition 250 gl−1) which has none of the complications of crystallisation of hydrated or metastable phases.

To determine which sodium sulfate phase crystallised from the solution, the crystals were removed from solution as soon as enough was available for analysis by X-ray powder diffraction. The powder patterns were collected with a Philips PW3040 diffractometer with a primary monochromator and Cu Kα1 radiation. In preliminary experiments it was found that unless special precautions are taken to prevent dehydration of the sample during sample preparation and data collection, the phase found in the X-ray diffraction experiments was always thenardite. As the experimental set-up in the diffractometer did not allow humidity control, the crystals grown from solution were only lightly broken up and immediately coated with paraffin oil to slow down any phase changes. Checks were made that showed that the paraffin oil had no chemical interaction with the crystals and does not change the crystal phase. The diffractometry was carried out immediately with a rapid scan rate of 6° 2θ per minute to detect the rapid changes which take place in the sample, even when partially protected from dehydration by the paraffin. The resultant powder patterns are therefore not of high quality with a poor peak/background ratio, but nevertheless, sufficient to identify the main peaks which occur between 15° and 40° 2θ. Each scan was repeated until no further changes took place in the sample. This was typically after about 30–40 min (7–10 scans). In some cases scans were repeated on ‘aged’ samples after 24 h to verify that no further changes took place. In a further set of experiments thenardite was rehydrated in the climate chamber at a temperature of 8°C and humidities of 75, 86 and 97%. Samples were taken from the climate chamber at intervals of 5, 10, 20, 30, 40 and 80 days, immediately encapsulated in paraffin oil and X-ray powder diffraction carried out.

The identification of the crystal phases was based on the X-ray patterns from Nord (1973), Hawthorne and Ferguson (1975) and Mehrotra et al. (1978) for thenardite, Ruben et al. (1961) and Levy and Lisensky (1978) for mirabilite, and Mehrotra et al. (1987) for the heptahydrate. It should be noted that as the phase detection limit of X-ray powder diffraction requires at least 5% of the phase in the sample, there is always the likelihood that minor amounts in a phase mixture may not be detected.

Results

Supersaturation at crystallisation

The results from the experiments presented in this paper are shown in Table 1. In all of the crystallisation experiments carried out at temperatures within the stability field of mirabilite, high concentrations of solution are required, relative to the solubility curve of mirabilite, before any crystallisation takes place (Fig. 2). In experiments at 10 and 20°C the solutions at the point of crystallisation are also significantly supersaturated with respect to the heptahydrate phase. In terms of supersaturation defined as S = C/C 0 (where C is the concentration in the fluid and C 0 is the equilibrium concentration) the average values for S are between 1.1 and 1.5 with respect to the heptahydrate and between 2.6 and 4 with respect to mirabilite. As mentioned in the experimental section, these supersaturations are very likely to be lower estimates. Given the inherent difficulties in reproducing nucleation experiments, the results are self-consistent. The scatter in the determined solution concentrations is also due to the fact that the data are from experiments using both 5 and 7 mm diameter sample holders and hence with different evaporation rates (see next section), to show that in all cases the supersaturation values at these temperatures are high.

At 30°C the concentration at crystallisation is only slightly higher than mirabilite and also approximates to the metastable extension of the solubility curve for thenardite. At 40°C, where thenardite would be expected to crystallise, the solution concentrations when crystallisation begins are lower, and approximate to the solubility curve of thenardite. The fact that the data generally plots just below the solubility curve of thenardite also indicates that the measured concentrations must be an underestimate.

When the crystallisation of NaCl is carried out in the same experimental set-up, at temperatures of 10, 20, 30, and 40°C, the determined solution concentrations at crystallisation are all near the equilibrium solubility line as expected (Fig. 3), demonstrating that the crystallisation experiment produces consistent results.

Concentrations of sodium sulfate solution (dark bars) and sodium chloride solution (stippled bars) at the point of crystallisation, as a function of the evaporation rate. The evaporation rate was progressively decreased at each temperature by using cylindrical fluid containers with three different surface diameters (7, 6, 5 mm from left to right, respectively). The data for the graph is in Table 1

The dependence on the rate of change of supersaturation

Changing the evaporation rate changes the rate at which the system supersaturates, and this in turn should affect the actual supersaturation (termed the threshold supersaturation) at crystallisation. More rapid departures from equilibrium normally result in greater degrees of metastability and hence a greater threshold supersaturation. Figure 3a, b shows results for sodium sulfate crystallisation at 10 and 20°C in cylindrical sample holders with the same volume (38.5 μl) but with decreasing surface area (7, 6 and 5 mm diameter) and decreasing evaporation rate. Contrary to expectation the concentration in the solution at crystallisation increases with decreasing evaporation rate at both temperatures. Under the same conditions, NaCl solution shows a negligible change in the supersaturation as the evaporation rate changes.

To check for possible experimental artifacts, the sodium sulfate crystallisation experiments were repeated at 20°C in identical sample holders at two different humidities, RH11 and RH48. At RH48 the evaporation rate is lower than at RH11, but the concentration at crystallisation is very significantly higher at the lower evaporation rate, confirming the previous, yet unexpected result. As a final check, experiments at RH48 were repeated at 30 and 20°C and again the concentration at crystallisation was higher in the 20°C experiment, where the evaporation rate was lower.

This unusual behavior was not observed in experiments at 30 and 40°C (Fig. 3c, d) where a decrease in evaporation rate results in a decrease in the supersaturation in the fluid when sodium sulfate crystallises.

X-ray powder diffraction of crystallised sodium sulfate

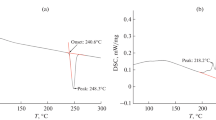

X-ray powder diffraction was carried out on the first crystals to grow at 20°C from a sodium sulfate solution at two different evaporation rates, by using a 7 and a 5 mm diameter sample holder at the same constant RH48. Note that for X-ray diffraction the crystals have been removed from the crystallisation chamber, after coating with paraffin to inhibit dehydration. Nevertheless, there is a possibility that some changes could have occurred in the crystals during sample preparation for X-ray diffraction. Figure 4 shows a series of diffractograms taken at 4-min intervals (the time to scan the 2θ range) of the first crystalline phase to be recovered from the 7 mm sample holder. It is clear that the pattern shows changes in consecutive scans. The first pattern (phase A) has the main peak at 28.9° and minor peaks at 29.4° and 32.5° but no peak at 16.0. With time a new peak appears at 16° with a minor peak at 18.7°. In the final pattern the 16° peak disappears and a new peak at 33.9° establishes the whole pattern as thenardite with the main peaks at 19.0°, 28.0°, 28.9°, 32.1° and 33.8° 2θ. There are no further changes in the pattern and the original clear crystals become white and powdery, indicative of a complete dehydration to thenardite. Although it is likely that the patterns show mixtures of different phases, the appearance of a peak at 16° 2θ, suggests that an original phase A dehydrates via an intermediate phase to thenardite. It is noteworthy that neither phase A nor the intermediate phase can be identified as either mirabilite or the heptahydrate, but that the final product of dehydration is thenardite, indicating that the first formed phases are hydrates of sodium sulfate.

A sequence of X-ray powder diffraction patterns (top to bottom) of crystals removed from a solution crystallising at 20°C, RH 48, in the 7 mm diameter solution container (evaporation rate ∼13 × 10−5 g/min: see Table 1). Each scan takes approximately 4 min and was then repeated through the same 2θ range to show the progressive stages of dehydration. The nature of the initial phase is unknown but the final dehydration product is thenardite

When the experiments are repeated using the 5 mm diameter sample holder, and hence a lower evaporation rate, the first formed crystals have a different diffraction pattern which also evolves in a different way with time (Fig. 5). The first phase to crystallise has dominant peaks at 16°, 16.4°, 32.5° and 32.9° 2θ with minor peaks at 14.8° and 29.4°. In successive scans minor modifications of this pattern are followed by the growth of new peaks indicative of thenardite and the gradual decrease in intensity of original peaks. Again neither the original peaks nor the intermediates can be identified as either mirabilite or the heptahydrate phase, although the final product is thenardite. This indicates that the early-formed crystals are a previously unidentified sodium sulfate hydrate.

A sequence of X-ray powder diffraction patterns (top to bottom) of crystals removed from a solution crystallising at 20°C, RH 48, in the 5 mm diameter solution container (evaporation rate ∼6 × 10−5 g/min: see Table 1). Each scan takes approximately 4 min and was then repeated through the same 2θ range to show the progressive stages of dehydration. The last two scans were taken after 1 and 24 h respectively and show no further changes with time. The nature of the initial phase is unknown but the final dehydration product is thenardite

Although there are similarities in the diffraction patterns from the first formed crystals at two different evaporation rates, the significant differences suggest that the phases are different, and also that they evolve in a different way as dehydration to thenardite proceeds.

Because the use of crystal growth inhibitors has been widely suggested as a possible stone treatment to reduce crystallisation damage, preliminary experiments were also carried out to test whether inhibitors modified the phase which crystallised. Under the same crystal growth conditions in the climate chamber the addition of 20 mM/l of PBTC (Phosphobutane-tricarboxylic-acid) or DTPMP (Di-ethylene-triamine-pentamethylene-phosphonic acid heptasodium salt) resulted in mirabilite as the phase first to crystallise, which then dehydrated to thenardite in the diffractometer. The addition of 20 mM/l of HEDP (hydroxy-ethylene-di-phosphoric-acid) suppressed the crystallisation of any hydrated phase and thenardite crystallised directly from the solution at temperatures where mirabilite is the stable phase. No “unknown phases” formed in the presence of these inhibitors. However, it should be noted that the addition of even small amounts of inhibitor effectively reduces the evaporation rate under the same temperature and humidity conditions in the climate chamber, and this may be a contributing factor determining which phases form.

X-ray powder diffraction of the hydration of thenardite

In all rehydration experiments with thenardite, the first hydrated phase to form could be clearly identified as the heptahydrate which coexisted with thenardite. At longer hydration times, a new phase S appears which coexists with both the heptahydrate and thenardite. The heptahydrate disappears from the diffraction pattern when mirabilite forms which then coexists with both the new phase S and a little thenardite. Finally, mirabilite is the only phase present. At 8°C, the whole hydration sequence takes up to 20 days at 97% RH, 30–40 days at 86% RH and 70–80 days at 75% RH.

Further experiments were carried out to try to isolate the unknown phase S. Figure 6 shows the diffraction pattern of virtually pure phase S. The peaks cannot be assigned as mixtures of any other known hydrated sodium sulfate phases, nor do they correspond to the unknown phase described in the crystallisation experiments. Given that this phase appears consistently during hydration experiments at these conditions, and that a virtually pure phase can be identified at some stage in the hydration sequence, it has been termed Selmaite, for ease of reference. Table 2 shows the list of 2θ values and the relative intensities of the peaks for Selmaite. Only 2θ values up to 45° are given as beyond that value the peaks are ill defined it becomes uncertain whether they belong to this phase.

X-ray powder diffraction pattern of a new phase formed during the hydration of thenardite at 8°C. This phase, termed “Selmaite” is formed at all three relative humidities investigated (75, 86 and 97%). See Table 2 for listing of the peaks

The programme TREOR (Werner et al. 1985) which is a trial and error routine for indexing unknown powder patterns returned the following crystallographic data for Selmaite: Monoclinic, a = 7.6 Å, b = 11.6 Å, c = 6.9 Å, β = 102.7 Å.

Preliminary experiments were carried out to determine the effect of the presence of crystallisation inhibitors on the hydration of thenardite. To introduce the inhibitors the thenardite was crystallised at temperatures between 40 and 45°C from a solution which contained 20 mM/l of either PBTC, DTPMP or HEDP. The crystals were removed from the solution, dried and then introduced into the climate chamber at 8°C and 97% RH, 86% RH and 75% RH. While the first two inhibitors did not affect the phase sequence which formed on hydration (i.e. the hydration sequence was similar to that described above), thenardite which had been crystallised in the presence of HEDP only formed the heptahydrate on hydration. HEDP appears to inhibit the formation of mirabilite (note that in the crystal growth experiments at 20°C, the addition of HEDP also inhibited the formation of any hydrated phase and thenardite crystallised directly.)

Discussion

The first significant observation from these experiments is that nucleation of mirabilite from an evaporating sodium sulfate solution is difficult and does not occur directly, even at high supersaturation values. On the other hand, at the temperatures where thenardite is the only stable phase (see Fig. 1), thenardite nucleates and grows at low supersaturation values. One reason for this difference in behavior between mirabilite and thenardite may be an activation enthalpy effect and that, at the higher temperatures where thernadite is stable, rates of nucleation and growth will be faster. However, it may also be that hydrated phases are inherently more difficult to nucleate due to an activation entropy effect with the complexity of assembling 40 water molecules into the large unit cell of mirabilite (cell volume 1,460.3 Å3) (Levy and Lisensky 1978), leading to a low pre-exponential factor in the equation for nucleation rate. The structure of thenardite is much simpler, has a unit cell volume of ∼700 Å3 and contains no water molecules and may be therefore easier to nucleate.

Under conditions where nucleation is difficult, metastable phases would be expected to form, and this is the case in the experiments described here. Although our experiments were carried out over a limited range of evaporation rates and temperature conditions, the number of new hydrated sodium sulfate phases observed suggests a richness of metastable phase behavior which has previously not been reported. Similarly, the hydration of thenardite at 8°C also produces a well-defined new metastable phase, Selmaite, which has also not been previously documented. Hydration of thenardite is a kinetically slow process, even at high relative humidity, a fact which has also been noted by previous authors (Charola and Weber 1992; Knacke and von Erdberg 1975; Steiger et al. 2000). This may be due to the difficulty of nucleation of the hydrated salts from a solution which is saturated with respect to thenardite.

The observation that, under the conditions where mirabilite is the stable phase, the concentration of sodium sulfate in solution at the point of crystallisation increases as when the evaporation rate decreases is contrary to expectation for crystal growth of a specific phase. This behavior seems to suggest that for nucleation of hydrated salts of sodium sulfate there is an inverse relationship between the rate of change of supersaturation R β and the threshold value of supersaturation at the point of crystallisation (β th), whereas a direct relationship would be expected, given by R β = K(β th)m where K and m are constants (Nyvlt 1983; Putnis et al. 1995). Thenardite as well as sodium chloride crystallisation is consistent with this expected relationship.

An explanation for the anomalous crystallisation behavior within the stability field of hydrated sodium sulfate most probably lies in the fact that under different conditions, different hydrated sodium sulfate phases are the first formed crystals. Thus the data cannot be interpreted as an inverse relation between supersaturation rate and the threshold supersaturation at the point of nucleation, because supersaturation can only be defined relative to the phase which is crystallised. At a high evaporation rate a more metastable and hence more soluble phase would be expected to crystallise compared to the phase crystallising at a lower evaporation rate. If the supersaturation required to nucleate the more soluble phase is less than that required to nucleate a less soluble phase, then the observed relationship between evaporation rate and solution concentration at nucleation can be explained.

The likely influence of the evaporation rate on the phase crystallising may also explain the observation in Table 1, that at highest evaporation rates crystallisation takes place at a lower Na2SO4 fluid concentration. This may not mean a lower supersaturation, if the phase crystallising at lower evaporation rate has a different hydration state.

Without any further data on the nature of the metastable sodium sulfate hydrates, especially on their solubilities, it is not possible to relate the measured concentration values to a supersaturation value, nor to attempt to relate supersaturation to crystallisation pressure. A sequence of crystallising phases could follow the Ostwald step rule, whereby at high supersaturations relative to the stable phase, a sequence of metastable phases with relatively small activation energies form as an alternative to the direct nucleation of the stable phase. In such a case the supersaturation of the fluid relative to each metastable phase need not be high.

It is clear that to fully understand the crystallisation behavior of sodium sulfate experiments are needed in which the nature of the phases crystallising under different conditions can be monitored in situ. Suitable crystallisation cells could be set up either in synchrotron X-ray or neutron diffraction beam line and time-resolved diffraction studies carried out, similar in principle to those described by Meller et al. (2004). Thermogravimetric measurements under controlled humidity conditions will be required to accurately determine the hydration states. Only when we have a better understanding of sodium sulfate crystallisation in an unconstrained fluid medium can we progress to a study of sodium sulfate crystallisation in porous building materials.

References

Benavente D, Garcia del Cura MA, Garcia-Guinea J, Sanchez-Moral S, Ordonez S (2004) Role of pore structure in salt crystallisation in unsaturated porous stone. J Cryst Growth 260:532–544

Charola AE, Weber J (1992) The hydration and deterioration mechanism of sodium sulfate. In: Delagado Rodrigues J, Henriques F, Telmo Jeremias F (eds) 7th International congress on deterioration and conservation of stone. Laboratório Nacional de Engenharia Civil, Lisbon, pp 581–590

Chaterji S (2000) A discussion of the paper “Crystallisation in pores” by G.W. Scherer. Cem Concr Res 30:669–671

Correns CW (1949) Growth and dissolution of crystals under linear pressure. Discuss Faraday Soc 5:267–271

Flatt RJ (2002) Salt damage in porous materials: how high supersaturations are generated. J Cryst Growth 242:435–454

Füredi-Milhofer H, Babic-Ivancic V, Brecevic L, Filipovic-Vincekovic N, Kralj D, Komunjer L, Markovic M, Skrtic D (1990) Factors influencing nucleation from solutions of supersaturated to different crystal hydrates. Colloids Surf 48:219–230

Goudie AS, Viles H (1997) Salt weathering hazards. Wiley, Chichester, 241 p

Hawthorne FC, Ferguson RB (1975) Anhydrous sulfates. I: Refinement of the crystal structure of celestite with an appendix on the structure of thenardite. Can Mineral 13:181–187

Knacke O, von Erdberg R (1975) The crystallisation pressure of sodium sulfate decahydrate. Ber Bunsen Ges 79:653–657

Levy HA, Lisensky GC (1978) Crystal structures of sodium sulfate decahydrate (Glauber’s salt) and sodium tetraborate decahydrate (Borax) redetermination by neutron diffraction. Acta Cryst B 34:3502–3510

Mehrotra BN, Hahn T, Eysel W, Röpke H, Illguth A (1978) Crystal chemistry of compounds with thenardite structure. Neues Jahrb Mineral Monatsh 408–421

Mehrotra B (1987) Acta Cryst., A43: 119 JCPDS 2002 Card 40–0727

Meller N, Hall C, Jupe AC, Colston SL, Jacques SDM, Barnes P, Phipps J (2004) The paste hydration of brownmillerite with and without gypsum: a time resolved synchrotron diffraction study at 30, 70, 100 and 150 °C. J Mater Chem 14:428–435

Nord AG (1973) Refinement of the crystal structure of thenardite, Na2SO4 (V). Acta Chem Scand 27:814–822

Nyvlt J (1983) Induction period of nucleation and metastable zone width. Collect Czech Chem Commun 48:1977–1983

Putnis A (2002) Mineral replacement reactions: from macroscopic observations to microscopic mechanisms. Mineral Mag 66:689–708

Putnis A, Prieto M, Fernandez-Diaz L (1995) Fluid supersaturation and crystallisation in porous media. Geol Mag 132(1):1–13

Rodriguez-Navarro C, Doehne E (1999) Salt weathering: influence of evaporation rate, supersaturation and crystallisation pattern. Earth Surf Process Landf 24:191–209

Rodriguez-Navarro C, Doehne E, Sebastian E (2000) How does sodium sulfate crystallize? Implications for the decay and testing of building materials. Cem Concr Res 30:1527–1534

Ruben HW, Templeton DH, Rosenstein RD, Olovsson I (1961) Crystal structure and entropy of sodium sulfate decahydrate. J Am Chem Soc 83:820–824

Scherer GW (2000) Reply to the discussion by S. Chatterji of the paper “Crystallisation in pores”. Cem Concr Res 30:673–675

Scherer GW (2004) Stress from crystallization of salt. Cem Concr Res 34:1613–1624

Steiger M, Beyer R, Dorn J, Zeunert A (2000) Data compilation and experimental determinations. In: Price C (ed) An expert chemical model for determining the environmental conditions needed to prevent salt damage in porous materials (contract no. ENV4-CT95–0135). EU research report no. 11

Steiger M (2005a) Crystal growth in porous materials—I: The crystallization pressure of large crystals. J Cryst Growth 282:455–469

Steiger M (2005b) Crystal growth in porous materials—II: Influence of crystal size on the crystallization pressure. J Cryst Growth 282:470–481

Werner P-E, Eriksson L, Westdahl M (1985) TREOR, a semi-exhaistive trial-and-error powder indexing program for all symmetries. J Appl Cryst 18:367–370

Wetmore FEW, LeRoy DJ (1951) Principles of phase equilibria. McGraw-Hill Book Company, New York, p 200

Acknowledgment

This work is funded through an EU STREP project (Contract SSP1-CT-2003–501571-SALTCONTROL). We thank J. Schumacher and R. Thewes for the construction of the climate chamber for the crystallisation experiments, A. Breit and V. Rapelius for technical help and P. Schmid-Beurmann for running the TREOR program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Genkinger, S., Putnis, A. Crystallisation of sodium sulfate: supersaturation and metastable phases. Environ Geol 52, 329–337 (2007). https://doi.org/10.1007/s00254-006-0565-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00254-006-0565-x