Abstract

Three calcitic marble types often used as cladding material and different in lattice preferred orientation (texture), grain shape preferred orientation, grain size distribution and grain interlocking are investigated to study the combined effect of thermal cycles (day-night) and moisture on the decay of marble, particularly on the bowing phenomenon. Repetitive heating-cooling under dry conditions leads to considerable inelastic residual strain only in the first thermal cycle. The residual strain continuously increases again if water is present, whereby the moisture content after a thermal cycle has a certain impact on the decay rate. The water-enhanced thermal dilatation strongly correlates with the deterioration rate obtained from the laboratory bow test. All applied approaches reveal that the texture in combination with the grain shape preferred orientation control the intensity and anisotropy of marble deterioration, thus, the cutting direction of facade panels has to be considered in terms of durability. On-site analysis from building facades confirm the laboratory results such as the bowing tendency of different marbles, directional dependence, relevance of moisture content during cyclical heating and the loss of strength due to environmental impact.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Durability is an important issue to consider when specifying stones as cladding material for exterior exposure. The use of stone panels as cladding materials for facades has undergone a considerable increase in the last decades. The observed durability problems, for example the most spectacular deterioration feature of some marble slabs is their bowing behaviour, has given a negative image to these material. The bowing, however, is well known from ancient grave stones (Grimm 1994, 1999). The complete replacement of facade panels of some prestigious buildings like the Amoco building in Chicago (Trewitt and Tuchmann 1988), the Finlandia Hall in Helsinki (Ritter 1992) or the Grande Arche de la Defense in Paris (Bouineau and Perrier 1995) all made of some varieties of marble coming from the Carrara area are often cited examples for the existing concerns on the durability of those materials.

Marbles exhibit a large variation in the way they weather including backweathering, micro-karst, breakouts, formation of coloured crusts, biological colonisation, granular disintegration, flaking etc. Chemical mechanisms have received much attention in recent years with a special emphasis on the effects of acid rain or biofilms. These superficial phenomena are occasionally also of penetrative nature. Feddema and Meierding (1987) observed backweathering rates of tombstones in Philadelphia of a magnitude greater than 3.5 mm/100 a in the centre of the city while at the countryside <0.5 mm/100 a was reported. However, the processes of bowing cannot be explained by the chemical weathering or anthropogenically induced acid rain and the development of gypsum in polluted environments. Kessler (1919) found that repeated heating may lead to permanent dilatations due to microfracturing, Bortz and others (1988) and Thomasen and Ewart (1984) concluded that a variation in moisture contents may be responsible for the deformation. Schouenborg and others (2000) found that repeated heating cycling of certain marble types under water saturated conditions leads to an unlimited residual expansion. Logan and others (1993) explained the bowing of marble slabs on the Amoco Building as being due to the anomalous expansion-contraction behaviour of calcite combined with the release of locked residual stresses. Winkler (1996) favoured the role of moisture since continuous rows of ordered water molecules may cause swelling by elongation and stone disruption, but also damage by greater interaction with sulphate in capillaries smaller than 0.1 μm. Jornet and others (2002) and Koch and Siegesmund (2002) compared the technical properties of natural and artificially weathered marble slabs which clearly show a significant reduction of flexural and compressive strength after weathering cycles. The rock fabric which includes grain size, grain aspect ratios, grain boundary morphology, grain shape preferred orientation, lattice preferred orientation (texture) and the microcrack populations was also discussed as a control of marble deterioration (e.g. Widhalm and others 1996, Siegesmund and others 2000, Royer-Carfagni 2000 or Zeisig and others 2002). Weiss and others (2002, 2003) clearly demonstrated on microstructure-based finite-element simulations the control on physical weathering caused by ansiotropic thermal expansion. The progressive loss of cohesion along grain boundaries due to dilatancy may serve as an example for the initial stage of marble bowing. Previously, Rosenholtz and Smith (1949), Sage (1988) and Ondrasina and others (2002) reported length changes of 1 mm/m due to heating and cooling. Thermally treated marbles, which do not return to initial length after cooling or freeze-thaw cycles, can show an inelastic residual stress even as a result of very small temperature changes (e.g. Battaglia and others 1993). However, the damage under dry conditions is restricted to up to four heating-cooling cycles and cannot be used as a general decay mechanism of marbles. Schouenborg and others (2001, 2003) concluded that exposure to heating alone is not sufficient to explain the expansion and bowing of marble cladding, whereas the combination with moisture reproduces realistic conditions on a facade .

To demonstrate the effect of environmental impacts on the bowing of marbles a detailed study on three selected calcitic marbles often used as cladding material was performed. Different approaches were applied for the characterisation of the type and degree of bowing. Therefore, thermal expansion measurements were performed under dry and wet conditions to investigate the combined effect of heating–cooling and moisture on the decay of marbles. Moreover, the bowing potential was also performed in the laboratory by artificial weathering. All the experimental work was done with respect to the rock fabric to quantify the deterioration rate. Finally, the results are discussed with respect to on-site damage analysis.

Materials and Methods

Investigations of the microfabric were done using polished 30 µm-thin sections. In this study, the terms (micro-)fabric and microstructure are used in accordance with Passchier and Trouw (1996) meaning the complete spatial and geometrical configuration of all components a rock consists of including grain size distribution, grain aspect ratio, grain shape preferred orientation, grain boundary morphology, grain boundary geometry, size and orientation of microcracks and lattice preferred orientation. The latter is termed in the sense of material sciences as texture.

A reference-coordinate system was introduced (Fig. 1a) to obtain the anisotropy of the fabric and, thus, its influence on the directional dependence of physical rock properties. For this purpose thin sections were prepared in three orthogonal sections (XY-, XZ-, YZ-planes).

For the quantification of the lattice preferred orientation (texture) of calcite neutron diffraction was applied. The measurements were carried out at the time-of-flight texture diffractometer at the pulsed reactor IBR-2 of the Frank Laboratory for Neutron Physics of the Joint Institute of Nuclear Research at Dubna, Russia (see Siegesmund and others 2000 for further details). Due to the high penetration depth of neutrons, this method allows to measure relatively large sample volumes even of coarse-grained marbles. In this study, one cylindrical specimen per marble type of 40 mm diameter and 40 mm height was measured. Furthermore, it is possible to calculate the three-dimensional orientation distribution function (ODF; see Dahms and Bunge 1989) which represents the complete statistical description of the texture, allowing the recalculation of the pole figure of any desired lattice direction (hkl). Pole figures are related to the reference system as well (Fig. 1b). To characterise the symmetry of the intensity distribution of the c-axes pole figures the tensor shape T calculated from the pole figure tensor was applied (Jelinek 1981). T=1 corresponds to a single c-axis maximum (perfectly linear; c-axis fibre-type, Leiss and Ullemeyer 1999), and T=-1 to a girdle distribution where the c-axes are uniformly arranged in a plane rotating around one of the a-axes (perfectly planar; a-axis fibre-type).

Thermal expansion was measured by means of a pushrod dilatometer (Fig. 2) in three orthogonal directions coinciding with the directions of maximum, intermediate and minimum dilatation. Up to six cylinders of 50 mm length and 15 mm diameter can be measured simultaneously. In this study, three specimens (X-, Y- and Z-direction) of each marble type were measured per session. The dilatometer consists of three main units: the heating unit, the specimen holder in the climate chamber and the displacement register. The heating-up is done by two copper-plates directly beneath and above the specimens The displacement sensors allow to determine length changes of ±1 µm. Due to a sample length of 50 mm a final residual strain of about 0.02 mm/m could be resolved. Calibration of the dilatometer was done by using quartz glass standards. The temperature was recorded from a sensor directly placed inside of a dummy cylinder made of the same material as the samples.

Scheme of the pushrod dilatometer. Left: a Position of the climate chamber. b Sample cylinder 50 mm in length and 15 mm in diameter. c Temperature sensor. d Quartz glass pushrod. e Displacement sensor. Right: a Water level. b Heat exchanger copper plate. c Quartz glass pushrod. d Displacement sensor. e Sample cylinder. (Strohmeyer 2004)

The thermal behaviour of the marble types was tested in a way that all samples pass through three temperature cycles (Fig. 3). Heating and cooling was performed with a velocity of 0.5 °C/min to ensure thermal equilibration of the specimen and, secondly, to simulate the real conditions at the building (investigations at building facades displayed a maximum temperature increase of 0.3 °C/min at summer days, early morning, facing east). After reaching the destination temperature of each cycle, the temperature was kept at one level until the sample length remained stable. Basis level was room temperature. This operating sequence allowed detection of (a) the thermal dilatation by simulating temperature changes comparable to those observed under natural conditions, (b) the buffering effect of pre-existing microcrack systems due to former thermal degradation or pre-existing microcracks originating from the geological history (e.g. Siegesmund and others 2000, Leiss and Weiss 2000), (c) the effect of the increase of the thermal dilatation coefficient of calcite (Fei 1995) and (d) the influence of intrinsic properties and thermal degradation (see Zeisig and others 2002).

The thermal dilatation coefficient (α in 10-6 K-1) was calculated according to Eq. 1 as

where Δl is the length change of the sample cylinders, l the cylinder length and ΔT the temperature interval. The residual strain (εrs in mm/m) is defined as the ratio between the length change of the sample after cooling down to room temperature Δlrt and the original sample length l (see Eq. 2).

εrs can only be related to one temperature level, in this case to room temperature before and after any temperature cycle. Residual strain, as it is used in this study, means the inelastic strain apart from its geological history which is irreversible and not released during subsequent deformation.

In addition, to detect the anomalous weathering behaviour of marbles the thermal expansion tests were also carried out under a combination of dry and wet conditions. For this purpose the set-up was modified by tilting the specimen holder and the climate chamber by an angle of 25° what enabled to fill the chamber with demineralised water covering half of the sample cylinders surface (Fig. 2). Starting with room temperature eight dry 90 °C cycles were carried out until the increase of the residual strain stopped. Subsequently, at least ten additional wet cycles were performed. One hour before the heating-up of each cycle the climate chamber was filled with water. The destination temperature (90 °C) was kept for 8 h until the sample length remained stable. This happened when all the water in the chamber has been evaporated. For this set-up, one cylindrical sample per direction and marble type was investigated.

Simulating the conditions of marble panels at the building in an extreme way, the bowing potential was tested in the laboratory on marble slabs of 400×100×30 mm in three orthogonal directions X, Y and Z (see Fig. 1a) referring to the direction of the long axes of the slabs. For each marble type three specimens per direction were measured. The specimens were exposed to moisture on one side lying on a mm-thick film of demineralised water, and cyclical heat from a heating pad 3 cm above the slab surfaces on the reverse side. One cycle included a heating period of 5 hours where the surface finally reached 80 °C or 120 °C, respectively, and a cooling period of at least 12 hours so that the duration of one cycle was on average 1 day. Every first to fourth cycle the bowing was measured by means of a measuring bridge with an accuracy of 1 µm/35 cm. A total of 40 cycles was performed (method is following Nordtest Method 2002a).

To determine the loss of strength, measurements of flexural strength were carried out on fresh as well as the artificially weathered slabs from the bow test on samples of 200×50×30 mm (quarters from bow test slabs) in three orthogonal directions in accordance with the standard EN 12372 (1999). An average of seven specimens per direction and marble type was tested.

To quantify the pore space due to thermal microcracking and possible subsequent corrosion, mercury (Hg) porosimetry has been applied. Using a CARLO ERBA-porosimeter (type “Porosimeter 2000”) the pore radii distribution in the range of 0.038 µm until approximately 10 µm (Hg-pressure: <0.1-200 MPa) as well as the porosity were determined at cylinders of 12.5 mm diameter and a length of 40 mm. Because of the very low porosity of marble (nearly all fresh marbles <1 %) at least two measurements per sample were performed. For each measurement a correction of the Hg intrusion volume was done by subtracting the mercury intrusion curve of the blank.

In addition to the porosity determined by Hg porosimetry the volume of the pore space of samples under fresh and artificially weathered conditions was measured on an average of nine samples of 200×50×30 mm for each marble type by a standard weighting method (water absorption).

Results

Microfabric

Three different types of calcitic marble have been investigated: They are from Switzerland (CH), Portugal (PO) and Italy (IT), and are frequently used as cladding material over the past years and at present. They show similarities as well as differences in their fabric elements which are summarized in Table 1.

Sample CH is a medium to coarse grained, strongly decorated marble. The foliation is clearly visible due to greyish or brownish straight cm-wide veins, light grey elongated clouds and long lenses of coarser grains in cm- up to dm-scale.

Microscopically, calcite grains show a seriate grain size distribution (nomenclature according to Passchier and Trouw 1996) ranging from 0.4 to 5 mm at an average of 1.5 mm (Fig. 4a). Interlobate grains predominantly show curved, less often straight grain boundaries where subgrains and bulging often occur. More evidence of crystal-plastic deformation is presented by undulose extinction and frequent deformation twins which are sometimes bent. Grains have a moderate shape-preferred orientation parallel to the foliation (Fig. 4a). Accessory muscovite (size: 0.2 to 0.5 mm) and quartz (size about 0.2 mm) appear between calcite grains or as calcite inclusions. Isolated elongated aggregates (size up to 2 mm) are observable containing quartz and mica.

The Portuguese marble (PO) is of a medium grey homogeneous colour. The foliation is straight and macroscopically clearly defined by a distinct grain boundary preferred orientation. Up to dm-long healed cracks <1 mm in width run more or less parallel through the marble with cm-separation from each other.

The seriate grain size distribution reaches from 0.1 to 1.5 mm with an average of about 0.2 mm (Fig. 4b). Grain boundaries are mostly curved or irregular, rarely straight. Undulose extinction as well as subgrains are often observed what suggests dynamic recrystallization as the dominant mechanism of deformation. The shape-preferred orientation defining a continuous foliation is moderate in Y-direction as observed in YZ-sections, and strong in X-direction, visible in XY- and in XZ-sections (Fig. 4b). Thus, the grains are elongated in X- and flattened in Z-direction forming a LS tectonite in the sense of Passchier and Trouw (1996). Thin sections perpendicular to the foliation show cm-long, intergranular narrow cracks subparallel to the foliation up to 50 µm thick filled with fine grained calcite. Sometimes the cracks branch out. Along the cracks aggregates of up to 1 mm occur filled with a matrix of fine grain size presumably consisting of chlorite, calcite and quartz.

The matrix of the Italian marble (IT) is light white, intersected by a network of grey mm-thick veins without any preferred orientation. Thus, no clearly developed foliation is observable.

In thin sections the marble shows a nearly equigranular-polygonal (granoblastic) foam structure with straight grain boundaries and 120° triple-point junctions (Fig. 4c). The grain size is averaged 0.3 mm and ranges closely between 0.1 and 0.6 mm. Undulose extinction or subgrains are not observable. The long-axes of the slightly elongated grains are preferably oriented in Z-direction, visible in XZ- and YZ-thin sections (Fig. 4c).

Texture

All three samples show nearly similar textures with respect to their symmetry. They can all be described as the c-axis fibre type with a weak tendency to form a intermediate fibre-type (e.g. Leiss and Ullemeyer 1999). All textures are characterised by a single intensity maximum of the c-axes (006)-poles) normal to the foliation or the XY-plane, respectively (Z-direction), which is slightly elongated along a girdle around the XY-plane (Fig. 5). The (110) poles are arranged on a great circle around the (006) pole density maximum. The crystallographic a-axes corresponding to the (110) poles are oriented within the XY-plane. All samples show a weak a-axes maximum in X-direction which is normal to the corresponding weak great circle distribution of the c-axes (YZ-plane). The maximum intensities of (006) poles of 2.7 mrd (multiples of random distribution) of CH and 3.0 mrd of PO indicate strong textures (Fig. 5a, b), whereas the (006) pole density maximum of IT (1.3 mrd) is weak (Fig. 5c).

Calcite texture (lattice preferred orientation) of the marbles investigated: c-axis (006) (left) and a-axis [110] (right) pole figures of a Switzerland marble (CH), b Portuguese marble (PO), c Italian marble (IT). Isolines in multiples of random distribution (mrd); the maximum is indicated by a filled circle and quantified at the lower right of any pole figure in mrd; Schmidt-net; lower hemisphere

Evidence for the similarity of the pole figure symmetry gives the tensor shape T. The samples cover only a small range between 0.26 (IT) and 0.41 (PO) indicating a moderately pronounced cluster-like shape of the c-axes intensity distribution.

Thermal dilatation

The thermal dilatation as a function of temperature basically shows the following characteristics (Fig. 6): During the first cycle (20–60–20 °C; Fig. 3) the slope increases successively until the destination temperature is reached. In the second cycle (20–90–20 °C) the slope appears relatively straight (cycle 2a) up to the maximum temperature of the first cycle, followed by a sudden increase at 60 °C and again a successive increase afterwards up to 90 °C (cycle 2b). The thermal dilatation coefficient α which is defined by the gradient of the slope (see Eqs. (1) and (2)) changes with an increase in thermal degradation or microcracking, respectively, and might also be related to the buffering of pre-existing microcracks (Zeisig and others 2002).

Thermal dilatation (ε) as a function of temperature, given in three orthogonal directions: a Switzerland marble (CH), b Portuguese marble (PO) and c Italian marble (IT). d Specific example for the PO marble in Z-direction illustrating typical thermal behaviour. The course of the expansion curves is indicated by arrows and numbers corresponding with Fig. 3. For further explanation see text. incr. increase of temperature; decr. decrease of temperature

All samples generally exhibit a pronounced increase of residual strain after cooling down of each cycle which is highest after the first 90 °C-cycle (cycle 2) and very low after repetition of 90 °C (cycle 3).

In detail, the thermal expansion coefficients α of sample CH and PO show a distinct directional dependence, whereas the thermal dilatation of IT is more or less isotropic (see Fig. 6, 7). It can be observed that within a single marble the degree of thermal expansion is linked to the c-axes density at a certain direction (see Fig. 1b, 5). The higher the (006) pole density the steeper the slope and vice versa. Consequently, the IT marble with a weak c-axes maximum of 1.32 mrd displays nearly no directional differences. The residual strain as an indicator of thermal degradation exhibits a pronounced directional dependence as well which is connected to the anisotropy of α for the samples CH and PO. In contrast the residual strain of IT is also anisotropic although α is directionally independent (see Fig. 6c).

The thermal dilatation coefficient from cycle 2a and 2b is compared (Fig. 7) to quantify the impact of thermal degradation and, again, to reveal the anisotropy of α. In general, all α-values of individual directions of cycle 2b are higher than those in cycle 2a. While for sample CH a small range and for sample PO a wide range of α coincide, the difference between the two cycles for IT is very pronounced what means a strong degradation due to thermal treatment. The directional dependent variation of α (height of bars in Fig. 7) increases from cycle 2a to 2b in sample CH and especially in sample PO, the small variation for IT remains stable.

Hygric dilatation

A detectable expansion due to hygric dilatation could be found for none of the three investigated marbles. This observation is in accordance with the findings from other authors. Poschlod (1990) for example measured the expansion of marbles from Carrara and Laas by immersion in water for one day. Values of 0.006 and 0.012 mm/m range under the detection limit of 0.020 mm/m.

Water-enhanced thermal dilatation

Repeating temperature cycles under dry conditions produces a strong increase of irreversible residual strain, but only for the first cycle (Fig. 8). The increase of progressive residual strain ends between the second (CH) and the fifth cycle (IT). Under wet conditions the marbles show a much more different expansion behaviour. They start to expand continuously. This increase of water-enhanced residual strain after ten further temperature cycles is relatively low for the CH marble (0.25–0.59 mm/m) and little higher for PO marble (0.27–0.76 mm/m). IT marble shows the highest residual strain between 0.80 and 1.28 mm/m. A high directional dependence can be observed for all samples (Fig. 8). In the Z-direction, PO marble exhibits a three times higher total expansion after ten wet cycles than in X-direction where the length nearly remains stable after a few cycles. The directional dependence for the IT marble is less pronounced.

Progressive increase of residual strain of the marbles investigated as a function of the number of heating cycles under dry (cycle 1 to 8) and wet (cycle 8 to 18) conditions: a Switzerland marble (CH), b Portuguese marble (PO), c Italian marble (IT). The colours of the curves indicate different directions of the sample reference system

The amount of residual strain under dry conditions does not necessarily correlate directly with the amount of residual strain after a few wet cycles as can be seen for CH and PO marble in Z-direction (Fig. 8a, b). Sample PO starts at a lower level (0.20 mm/m after one dry cycle) in comparison to CH (0.33 mm/m), however, the total length change is opposite after ten wet temperature cycles for PO (0.76 mm/m) and CH (0.59 mm/m).

Bowing potential

All marble types start to bow in a convex way except for PO marble which initially bows concave (Fig. 9). The deterioration rate detected in the bow test differs between marble types and directions. For CH marble, the slabs show a slow but continuous bowing which is also directional dependent: 0.27±0.07 mm/m for slabs cut parallel to the Z-direction and 0.14±0.05 mm/m in X-direction after 40 cycles. For PO marble, slabs cut in X-direction nearly stop to bow after 10 cycles, whereas slabs in Z-direction a three times higher bowing after 40 cycles (0.36±0.05 mm/m in Z-, 0.12±0.04 mm/m in X-direction) can be observed. IT marble deteriorates rapidly from the beginning and displays a severe bowing after 40 cycles which is higher in X-direction (0.60±0.03 mm/m) than in Z-direction (0.43±0.10 mm/m).

Bowing of marble slabs versus number of heating cycles: a Switzerland marble (CH), b Portuguese marble (PO), c Italian marble (IT). Each curve represents the mean bowing trend of three slabs of 400×100×30 mm in dimension. The colours of the curves are related to the cut-directions displayed in the cube sketch. The coloured rectangles represent the test pieces. X, Y and Z indicate the long axes of the test specimens. Positive values mean convex bowing, negative ones concave bowing

Since the same orientations were used as for the thermal dilatation test (long axes of test specimens are identical oriented and termed) it is clearly documented that the results from the bow test are connected with the results from the thermal expansion under wet conditions (see Fig. 8). The bowing tendencies of different marble types and directions are identical to the residual strain curves when the effect of moisture is involved. Correlating the end values of Fig. 8 after 18 cycles and Fig. 9 after 40 cycles (CH, PO and IT each in X- and Z-direction) a correlation coefficient of R=0.99 can be found.

Flexural strength

The flexural strength shows a distinct directional dependence for all three marble types (Fig. 10). Comparing different directions of the same type and under same conditions (fresh or weathered), the value differences vary between 38 % for the Switzerland marble and 71 % for the Portuguese marble, where the flexural strength in X-direction is even three times higher than in Z-direction. In accordance with observations from many other authors (e.g. Jornet and others 2000, 2002) flexural strength decreases significantly under artificial weathering. The strongest loss of strength can be observed for the Italian marble in Z-direction with a reduction of 58 % after 40 heating cycles. The weakest one reveals sample CH decreasing only 17 % in Z-direction.

Flexural strength of marble slabs fresh and after 40 heating cycles in the bow test. The colours of the curves indicate different directions of the sample reference system which are equivalent to the direction of tensile stress in the specimens during the flexural strength test. The standard deviations are indicated by error bars

It seems that the thermal degradation in the bow test is connected to the initial flexural strength as well as to the resistance to loss of strength due to artificial weathering (compare with Fig. 9). Generally, the bowing potential is high when the resulting flexural strength after the bow test is low and vice versa. Accordingly, IT marble in X-direction with the most pronounced bowing behaviour (0.60±0.03 mm/m) exhibits the lowest flexural strength after 40 cycles (2.7±0.5 MPa), whereas PO marble in X-direction displays very little bowing (0.12±0.04 mm/m) and consequently the highest strength (13.0±1.2 MPa; Fig. 9 and 10).

Marble degradation and pore space

All investigated marble types show a unimodal pore size distribution (Fig. 11) which is not connected with the grain size (see Table 1). Under fresh conditions fine grained IT marble shows the largest pore space (porosity: 0.83 %) with a pore radii maximum between 0.2 and 0.6 µm, whereas coarse grained CH marble displays a lower porosity (0.33 %) with a smaller pore radii maximum around 0.1 µm. Fresh PO marble has a very low porosity (0.18 % or even 0.05 % by standard weighting method; Table 2). After 40 bow test cycles with destination temperatures of 80 °C the pore space increase is less pronounced, while after 40 cycles up to 120 °C the increase is much stronger for all marbles (Fig. 11). The maximum of pore radii generally shifts to larger pore sizes.

Discussion

Bowing of calcitic marble panels is to be considered as coming along with irreversible expansion of the stone forced by the impact of temperature changes and moisture (Kessler 1919, Rosenholtz and Smith 1949, Thomasen and Ewart 1984, Bortz and others 1988, Widhalm and others 1996). It is commonly assumed that the deformation of marbles originates from a combined effect of intrinsic (mineral content and microfabric, such as lattice preferred orientation, grain shape preferred orientation, grain interlocking, grain size distribution, microcracks, etc.) and extrinsic parameters (climatic conditions, influenced by local climate, point of compass, height above ground, building physics, kind of ventilation, etc.).

Since it is well known that the rock fabric is one factor which controls the deterioration of marble (Siegesmund and others 2000, Zeisig and others 2002) it is the question what influence does fabric parameters have on the bowing phenomenon. Strong textured CH and PO marble show a clear correlation between the c-axis preferred orientation and the direction of maximum deterioration observed in all experimental results. Both the maximum of dilatancy, residual strain, progressive residual strain under wet conditions and bowing are each linked to the c-axis maximum (Fig. 6,8,9), due to the extremely anisotropic thermal behaviour of calcite. The coefficient of thermal dilatation (α.) is 26×10-6 K-1 parallel to the crystallographic c-axis and -6x10-6 K-1 perpendicular to it, i.e. parallel to the a-axes (Kleber 1990). The total anisotropy for a monomineralic aggregate has to be between an isotropic situation (random orientation of all crystals) and a situation of maximum anisotropy where all the crystals have the same crystallographic orientation which corresponds to the single crystal anisotropy. Consequently, the anomalous expansion-contraction behaviour may produce a crack porosity as a function of the c-axes preferred orientation in combination with the grain shape preferred orientation as it was shown by Ruedrich and others (2002).

For samples CH and PO, the texture effect may be supported by the grain shape preferred orientation or the preferred grain boundary orientation, respectively. Thermally induced microcracks mostly occur along grain boundaries depending on the degree of grain interlocking (Royer-Carfagni 1999, Weiss and others 2002, 2003). However, grain boundaries represent zones of weaker cohesion with a fracture resistance energy smaller than inside the grain. The ability to generate intergranular cracks in a certain direction should be proportional to the numbers of grain boundaries per length unit. In sample CH and PO, a higher frequency of grain boundaries occur parallel to the Z-direction (perpendicular to the foliation), which coincides with the c-axis maximum and the direction of maximum deterioration (compare with Fig. 4a,b).

In contrast, sample IT yielding a weak c-axis intensity maximum exhibits a preferred orientation of the grain long axes in Z-direction which leads to lower grain boundary frequency parallel to this direction. As a result, IT marble shows in Z-direction the lowest deformation in the expansion test under dry and wet conditions as well as in the bow test (Fig. 6c, 8c, 9c). The directional dependence of the thermal expansion is less pronounced due to the weak texture (Fig. 6c, 7). In conclusion, both parameters together the texture as well as the grain shape preferred orientation mutually influence the anisotropy of marble degradation.

Fitting to the above mentioned model the flexural strength in different directions of a certain marble type is reciprocal to the frequency of grain boundaries (Fig. 4,10). The anisotropy of flexural strength remains constant even after the bow test which may be controlled by thermally induced microcracks along grain boundaries.

The grain size of the marble is regarded as a less important factor for marble degradation. Tschegg and others (1999) assume that this is attributed to the fact that larger grain sizes on the one hand leads to a stronger deterioration along grain boundaries, on the other hand the total grain boundary area per volume decreases. Zeisig and others (2002) demonstrated in a large collection of different marble types that marbles with a large grain size exhibit the same deterioration rate as marbles with smaller grain sizes. Again, those findings are confirmed by this study, for example sample CH and PO differ extremely in grain sizes (Table 1), but they show comparable deterioration rates (Fig. 6,7,8,9). Comparing samples PO and IT which are similar in grain size, the deterioration rates are completely different. However, the directional dependence of thermal degradation has a much larger effect.

The irregularity of grain boundaries plays an important role according to numerous authors (e.g. Barsotelli and others 1998, Royer-Carfagni 2000, Zeisig and others 2002). Indeed, smooth grain boundaries of sample IT are connected with a strong deterioration rate. However, Zeisig and others (2002) found that the grain boundary morphology, i.e. the irregularity of grain boundaries does not play such an important role as it was previously assessed. Calcitic marbles with interlobate fabrics as well as such with polygonal fabrics may show a comparable residual strain after thermal treatment.

Moisture is considered as to be a key parameter concerning the bowing phenomenon (Schouenborg and others 2001, 2003) and can lead to unlimited residual expansion of certain marble types (tested up to 250 cycles, Grelk personal communications 2003). Bucher (1956) mentioned that the bending of marble slabs is reported only from countries with abundant rainfall. Winkler (1996) points out the importance of moisture in the bowing process. Many authors (e.g. Sage 1988) could demonstrate that the increase of residual strain stops after few heating cycles if moisture is absent. To discuss these effects more detailed measurements of progressive residual strain of the Italian marble were performed on four specimens under slightly different conditions (Fig. 12). Eight dry cycles up to 90 °C were followed by 25 additional wet cycles altogether, whereby the first six wet cycles were carried out in a way that at the end of a heating cycles the samples in the climate chamber remained slightly humid still in contact with water. In the following 19 cycles the samples were run until totally dry. The findings from this approach are: (1) The progressive residual strain indeed proceeds continuously; the increase is constant even after 25 cycles under wet conditions. (2) The moisture content after a heating cycle apparently influences the intensity of marble degradation. The strain versus cycles curve (Fig. 12) tends to get flat as long as water is still available after cooling down. As soon as samples totally dry up after each heating cycle the durable marble expansion accelerates again.

Progressive increase of residual strain of the IT marble as a function of the number of heating cycles under dry (cycle 1 to 8) and wet (cycle 8 to 33) conditions. From cycle 8 to 14 the samples remain humid, from cycle 14 on samples run dry after each cycle. The colours of the curves indicate different directions of the sample reference system

This observation cannot be explained sufficiently by the theory of Winkler (1996) that oriented molecule layers (thickness of 2–3 nm) in capillaries <0.1 µm may cause swelling by elongation and stone disruption. As a result he concludes that panels start to bow outwards if the sun and high humidity exposes the panel from the outside only, and inward if moisture is available behind the panel in a closed cavity where the relative humidity can remain near 100 %. On-site analyses (Koch and Siegesmund 2002) show opposite bowing behaviour where ventilated panels display mainly concave bowing (inwards), thus, the theory does not adequately explain the process which determines concave and convex bowing behaviour.

Poschlod (1990) claimed that oriented water from the STERN-layer (equivalent layer of ordered water in the sense of Winkler 1996) releases the stone not before temperatures of 140 up to 350 °C. According to him even the GOUY-CHAPMAN-layer presenting the transition zone between oriented water and ordinary pore water keeps the water molecules until temperatures of 100 to 140 °C. As a consequence, such molecule layers, once assimilated from the stone, do not release the stone again under normal climatic conditions and are permanently present anyway. Thus, capillary condensation cannot be responsible for stone decay by moisture expansion. How finally moisture combined with temperature cycles (day-night) causes disruption of marble is still unclear.

To evaluate the results from the laboratory work for practical relevance the findings were compared with on-site damage analysis from buildings (Nordtest Method 2002b). In particular, examples from the marble cladding of two buildings are introduced.

- (1):

-

The Oeconomicum building in Goettingen, built in 1966, is cladded with panels of the same type of Switzerland marble as used in the lab tests (128×67×3 cm; open joints without sealant; ventilated; fixed with a kerf on a continuous rail at the bottom and by a ledge at the top; Koch and Siegesmund 2002). On the north facade the different rock structures macroscopically visible on the panel surfaces are a result of the marble slabs being cut in different directions. The bowing is comparable for panels of the same block-cut direction, and is different when the cutting direction with respect to any metamorphic layering, foliation or macroscopic fold changes. The degree of bowing of panels is associated with the orientation of these macroscopically visible fabric elements of the marble since all other influencing factors are relatively constant (dimension, exposition, microclimate, building physics). It varies between no bowing up to 11.5 mm/m within the same panel row. The directional dependent bowing curves of sample CH (Fig. 9a) confirm these qualitative observations.

Examining the effect of bowing on mechanical properties, the decrease of flexural strength in the laboratory bow test reveals an exponential trend (Fig. 13a) showing a strong strength reduction in the weakly bowed slabs and a less pronounced decrease in the strongly bowed slabs. The same trend is observed in nine removed panels of Switzerland marble from different facades representing a broad variation of bowing (Fig. 13b,c). Both the flexural strength as well as the breaking load at dowel hole (EN 13364 1999) display identical characteristics of the strength versus bowing relationship.

Mechanical properties versus bowing. The regression curves are indicated by solid lines. The standard deviations are indicated by error bars. a Flexural strength of specimens from different marble types and directions in the bow test as a function of the bowing. b Flexural strength of nine facade panels of Switzerland marble cladding versus bowing of the panels, given in two different directions each parallel to the panel edges. c Breaking load of dowel hole of nine facade panels of Switzerland marble cladding as a function of the bowing of those panels

- (2):

-

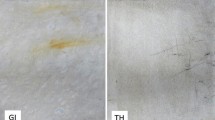

The Goettingen State and University Library, built in 1991, is clad with panels of Italian marble (same type as in the lab test) of different width, same thickness (4 cm) and mostly of same height (104 cm), characterised by open joints without sealant, ventilation gap on the rear and fixing by vertical or horizontal stainless steel dowels. Most panels show a distinct convex bowing (Fig. 14a). On-site measurements performed in 2000 for a representative number of 262 slabs reveal an increase of the bowing intensity from bottom to top observed on all facades (Fig. 14b). The reason for it might be explained by the effect of different moisture content after thermal impact as described above (Fig. 12). The crucial influence factor which causes the bowing differences is supposed to be the average wind velocity and herewith connected the drying up which increases from bottom to top. The result is a significant higher bowing in the uppermost row (maximum height above ground: 14.2 m) on an average of 6.5 mm/m in contrast to the lowermost rows on an average around 2 mm/m. The same observation can be made at the Oeconomicum Building where the lowermost parts of each facade generally show the lowest degree of bowing (Koch and Siegesmund 2002). Water from rain which is forced against the masonry by the wind may additionally intensify the wind effect leading to a different moisture content as well.

Fig. 14a,b Deterioration of facade panels of the State and University Library in Goettingen. a Bowing of facade panels. b Average bowing of facade panels as a function of height above ground, given as row number. The bottom line of lowermost row 1 is equivalent to a level of 0.6 m; uppermost row 13 equals an altitude of 13.2 m. The distance from one to the next row is 1.05 m. The line indicates the trend of the row bowing averages of the whole building (at least 10 panels per data point). Row averages of north, east, south and west facade are additionally indicated by different marks (at least 3 panels per data point)

To check whether the bow test applied for the laboratory studies reflects the real conditions on the facade the results displayed in Fig. 9a+c are compared with the deterioration rate from the two buildings which are subjected to the same climatic conditions (distance of less than 100 m to each other). After 9 years the average bowing on the University Library (Italian marble) obtained from 262 measurements is 4.34 mm/m resulting in a bowing rate of 0.48 mm/m per year. On the Oeconomicum Building (Switzerland marble) the average bowing 35 years after construction calculated from 1556 measurements is 5.55 mm/m, what means a rate of 0.16 mm/m per year. This represents a difference in the deterioration rate of both claddings of factor 3. In comparison, the average bowing of the IT marble after 40 cycles in the bow test is 0.52 mm/m, for the CH marble it is 0.17 mm/m (in consideration that Z-direction is unrealised on the Oeconomicum Building). Again, the bowing rate of the Italian marble is three times higher than for the Switzerland marble confirming the reliability of the bow test. Such testing could act as a useful tool for architects, building owners and consultants to chose the proper marble type for the specific application as building veneer. Moreover, this method could be a valuable aid when predicting the service life of marble cladding and the risks associated with failure. However, these are first results and more and extensive investigations are necessary to allow the extrapolation of laboratory results to the facade considering the complexity of all influencing factors.

Conclusion

To contain the effect of temperature and moisture on marble decay three calcitic marbles were investigated. They are different in their microstructure (lattice preferred orientation, grain shape preferred orientation, average grain size, grain size distribution, grain interlocking). Based on the present study the following conclusions can be drawn:

-

1.

The lattice preferred orientation is one parameter which clearly controls the intensity of marble deterioration and in particular the degree of bowing of marble slabs. The direction of maximum deterioration is linked to the orientation of the c-axes maximum. The grain shape preferred orientation influences the anisotropy of marble deterioration as well, whereby both parameters lattice and grain shape preferred orientation usually complement one another. Solely depending on the block-cut direction the amount of deterioration can vary up to factor 3. As a consequence, the microfabric of a rock and its influence on the cutting direction of facade panels has to be considered when the bowing potential and the loss in strength are discussed in terms of risk analysis.

-

2.

In accordance with findings from the literature the irreversible residual strain of marble under cyclical heating decreases rapidly after the first cycle under dry conditions. The residual strain increases continuously if water is present. This progressive increase of residual strain strongly correlates with the bowing potential obtained from the laboratory bow tests which reveals a close connection between expansion and bowing.

-

3.

The moisture content after a heating cycle has an impact on the strain rate of the Italian marble. The strain rate is highest when samples totally run dry after each cycle. This may explain why on facades the average bowing of marble panels increases from bottom to top since a rising wind velocity causes a stronger dehydration.

-

4.

Investigations from buildings suggest that the laboratory bow test is an applicable method to simulate the bowing behaviour under real conditions. The bowing trend of different marbles, the exponential strength versus bowing relationship as well as differences in the degree of bowing due to different cutting directions are confirmed by findings from on-site building analysis.

The conclusions of this paper are still under discussion within the TEAM project (see below), awaiting the final conclusions after evaluation of all test results.

References

Barsotelli M, Fratini F, Giorgetti G, Manganelli Del Fa C, Molli G (1998) Microfabric and alteration in Carrara marble: a preliminary study. Scinece and Technology for Cultural Heritage 7(2): 115–126

Battaglia S, Franzini M, Mango F (1993) High sensitivity apparatus for measuring linear thermal expansion: preliminary results on the response of marbles. Il Nuovo Cimento 16:453–461

Bortz SA, Erlin B, Monk CB (1988) Some filed problems with thin veneer building stones. In: Donaldson B (ed) New Stone Technology, Design and Construction for Exterior Wall Systems. American Society for Testing and Materials, Philadelphia, pp 11–31

Bouineau A, Perrier R (1995) La décohésion granulaire, maladie des revêtements de façades en marbre. Mines et Carrières—Industrie Minérale Août-Septembre 147:32–35

Bucher WH (1956) Role of gravity in orogenesis. Bulletin of the Geological Society of America 67:1295–1318

Dahms M, Bunge HJ (1989) The iterative series-expansion method for quantitative texture analysis, I. General Outline. Journal of Applied Crystallography 22:439–447

EN 13364 (1999) Natural stone test methods—Determination of the breaking load at dowel hole. European Committee for Standardization, Brussels

EN 12372 (1999) Natural stone test methods—Determination of flexural strength under concentrated load. Beuth, Berlin

Feddema JJ, Meierding TC (1987) Marble weathering and air pollution in Philadelphia. Atmospheric Environment 21:143–157

Fei Y (1995) Thermal Expansion. In: Ahrens T J (ed) Mineral Physics and Crystallography. American Geophysical Union, Washington, pp 29–44

Grimm WD (1994) “...zum Steinerweichen” - Verformung von Marmorplatten auf alten Friedhoefen. Naturstein 10/94:52–57

Grimm WD (1999) Beobachtungen und Ueberlegungen zur Verformung von Marmorobjekten durch Gefuegeauflockerung. Z dt geol Ges 150:195–236

Jelinek V (1981) Characterization of the magnetic fabric of rocks. Tectonophysics 79:63–67

Jornet A, Rück P (2000) Bowing of Carrara marble slabs: A case study. Proceedings of “Quarry—Laboratory—Monument” International Congress Pavia 2000 1:355–360

Jornet A, Teruzzi T, Rück P (2002) Bowing of Carrara marble slabs: comparison between natural and artificial weathering. In: Prikryl R, Viles HA (eds) Understanding and managing of stone decay (SWAPNET 2001). Karolinum Press, Prague, pp 161–170

Kessler DW (1919) Physical and chemical test of the commercial marbles of the United States. Government Printing Office, Washington DC

Kleber W (1990) Einführung in die Kristallographie, VEB Verlag Technik, Berlin

Koch A, Siegesmund S (2002) Bowing of marble panels: On-site damage analysis from the Oeconomicum Building at Goettingen (Germany). In: Siegesmund S, Weiss T, Vollbrecht A (eds) Natural Stone, Weathering Phenomena, Conservation Strategies and Case Studies. Geological Society, London, pp 299–314

Leiss B, Ullemeyer K (1999) Texture characterisation of carbonate rocks and some implications for the modeling of physical anisotropies, derived from idealized texture types. Z dt geol Ges 150/2:259–274

Leiss B, Weiss T (2000) Fabric anisotropy and its influence on physical weathering of different types of Carrara marbles. Journal of Structural Geology 22:1737–1745

Logan JM, Hadedt M, Lehnert D, Denton M (1993) A case study of the properties of marble as building veneer. International Journal of Rock Mechanics, Mining Sciences and Geomechanics 30:1531–1537

Nordtest Method NT BUILD 499 (2002a) Cladding Panels: Test for Bowing. Nordtest project 1443–99/1

Nordtest Method NT BUILD 500 (2002b) Cladding Panels: Field Method for Measurement of Bowing. Nordtest project 1443–99/2

Ondrasina J, Kirchner D, Siegesmund S (2002) Freeze-thaw cycles and their influence on marble deterioration: a long-term experiment. In: Siegesmund S, Weiss T, Vollbrecht A (eds) Natural Stone, Weathering Phenomena, Conservation Strategies and Case Studies. Geological Society, London, pp 9–18

Passchier CW, Trouw RAJ (1996) Microtectonics, Springer, Berlin Heidelberg New York

Poschlod K (1990) Das Wasser im Porenraum kristalliner Naturwerksteine und sein Einfluss auf die Verwitterung. Münchner geowissenschaftliche Abhandlungen : Reihe B, Allgemeine und angewandte Geologie 7:1-62

Ritter H (1992) Die Marmorplatten sind falsch dimensioniert. Stein H.1/1992:18–19

Rosenholtz JL, Smith DT (1949) Linear thermal expansion of calcite, var. Iceland spar, and Yule Marble. The American Mineralogist 34:846–854

Royer-Carfagni G (1999) On the thermal degradation of marble. International Journal of Rock Mechanics and Mining Sciences 36:119–126

Royer-Carfagni G (2000) Some considerations on the warping of marble facades: The example of Alvar Aaltos Finland Hall in Helsinki. Construction and Building Materials 13(18): 449–457

Ruedrich J, Weiss T, Siegesmund, S (2002) Thermal behaviour of weathered and consolidated marbles. In: Siegesmund S, Weiss T, Vollbrecht A (eds) Natural Stone, Weathering Phenomena, Conservation Strategies and Case Studies. Geological Society, London, pp 255–271

Sage JD (1988) Thermal microfracturing of marble. In: Marinos PG, Koukis GC (eds) Engineering Geology of Ancient Works, Monuments and Historical Sites. Balkema, Rotterdam, pp 1013–1018

Schouenborg B, Grelk B, Brundin JA, Alnaes L: Buktningsprovning av marmor för fasadbeklädning. NORDTEST-projekt 1443–99: SP Rapport 2000 28:1-31. http://www.sp.se/building/team/PDF/Rapport%20final.pdf

Schouenborg B, Alnaes L, Brundin JA, Grelk B, Blasi P (2001) Testing and Assessment of Marble and Limestone (TEAM). Proceedings of the fourth annual workshop of EUROTHEN 2001

Schouenborg B, Grelk B, Alnaes L, Brundin JA, Blasi P, Yates T, Marini P, Tschegg E, Unterweger R, Tokarz B, Koch A, Bengtsson T, Mladenovic A, Goralczyk S (2003) TEAM—Testing and Assessment of Marble and Limestone Cladding. International Symposium on Industrial Minerals and Building Stones 2003, Istanbul

Siegesmund S, Ullemeyer K, Weiss T, Tschegg EK (2000) Physical weathering of marbles caused by anisotropic thermal expansion. International Journal of Earth Sciences 89:170–182

Strohmeyer D (2004) Naturwerksteine: Gefuege und gesteinstechnische Eigenschaften. Doctoral thesis, University of Goettingen

Thomasen SE, Ewart CS (1984) Durability of thin-set marble. Third International Conference on Durability of Building Materials and Components 313–323

Trewitt TJ, Tuchmann J (1988) Amoco may replace marble on Chicago headquarters. ENR March: 11–12

Tschegg EK, Widhalm C, Eppensteiner W (1999) Ursachen mangelnder Formbeständigkeit von Marmorplatten. Z dt geol Ges 150/2:283–297

Weiss T, Siegesmund S, Fuller ER (2002) Thermal stresses and microcracking in calcite and dolomite marbles via finite element modelling. In: Siegesmund S, Weiss T, Vollbrecht A (eds) Natural Stone, Weathering Phenomena, Conservation Strategies and Case Studies. Geological Society, London, pp 65–80

Weiss T, Siegesmund S, Fuller ER (2003) Directional dependence of thermal degradation in marble: A finite element approach. Building and Environment 38:1251–1260

Widhalm C, Tschegg E, Eppensteiner W (1996) Anisotropic thermal expansion causes deformation of marble cladding. Journal of Performance of Constructed Facilities 10:5-10

Winkler EM (1996) Technical note: properties of marble as building veneer. International Journal of Rock Mechanics, Mineral Science and Geomechanics 33(2): 215–218

Zeisig A, Siegesmund S, Weiss T (2002) Thermal expansion and its control on the durability of marbles. In: Siegesmund S, Weiss T, Vollbrecht A (eds) Natural Stone, Weathering Phenomena, Conservation Strategies and Case Studies. Geological Society, London, pp 65–80

Acknowledgements

The authors would like to thank the European Commission for financial support in the frame of the European research project “Testing and Assessment of Marble and Limestone” (Contract no. G5RD-CT-2000–00233). The co-operation with the project partners is gratefully acknowledged. The authors are deeply grateful for the careful and constructive review by J. Logan and A. Jornet.

Author information

Authors and Affiliations

Corresponding author

Additional information

Special Issue: Stone decay hazards

Rights and permissions

About this article

Cite this article

Koch, A., Siegesmund, S. The combined effect of moisture and temperature on the anomalous expansion behaviour of marble. Env Geol 46, 350–363 (2004). https://doi.org/10.1007/s00254-004-1037-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00254-004-1037-9