Abstract

Propionic acid, a widely used food preservative and intermediate in the manufacture of various chemicals, is currently produced from petroleum-based chemicals, raising concerns about its long-term sustainability. A key way to make propionic acid more sustainable is through fermentation of low-cost renewable and inedible sugar sources, such as lignocellulosic biomass. To this end, we utilized the cellulosic hydrolysate of sweet sorghum bagasse (SSB), a residue from a promising biomass source that can be cultivated around the world, for fermentative propionic acid production using Propionibacterium freudenreichii. In serum bottles, SSB hydrolysate supported a higher propionic acid yield than glucose (0.51 vs. 0.44 g/g, respectively), which can be attributed to the presence of additional nutrients in the hydrolysate enhancing propionic acid biosynthesis and the pH buffering capacity of the hydrolysate. Additionally, SSB hydrolysate supported better cell growth kinetics and higher tolerance to product inhibition by P. freudenreichii. The yield was further improved by co-fermenting glycerol, a renewable byproduct of the biodiesel industry, reaching up to 0.59 g/g, whereas volumetric productivity was enhanced by running the fermentation with high cell density inoculum. In the bioreactor, although the yield was slightly lower than in serum bottles (0.45 g/g), higher final concentration and overall productivity of propionic acid were achieved. Compared to glucose (this study) and hydrolysates from other biomass species (literature), use of SSB hydrolysate as a renewable glucose source resulted in comparable or even higher propionic acid yields.

Key points

• Propionic acid yield and cell growth were higher in SSB hydrolysate than glucose.

• The yield was enhanced by co-fermenting SSB hydrolysate and glycerol.

• The productivity was enhanced under high cell density fermentation conditions.

• SSB hydrolysate is equivalent or superior to other reported hydrolysates.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Propionic acid is commonly used in the food industry as preservative and across a wide range of industries as intermediate in the manufacture of polymers, pesticides, perfumes, and pharmaceuticals (Vidra and Németh 2018). The common way to produce propionic acid is via non-sustainable petrochemical routes. However, as societal concerns about greenhouse gas emissions and sustainability intensify, it behooves the chemical industry to transition from traditional fossil resources to renewable ones (Bozell 2008).

Propionibacteria are gram-positive facultative anaerobic bacteria that have been granted GRAS (“generally recognized as safe”) status by the US Food and Drug Administration (Hettinga and Reinbold 1972). They are widely used in the fermentative production of propionic acid (Liu et al. 2012a) and vitamin B12 (Hedayati et al. 2020; Kośmider et al. 2012; Wang et al. 2015a) and in Swiss cheese manufacture for flavor development and appearance (Thierry et al. 2004). Propionic acid fermentation is known to suffer from end-product inhibition and byproduct formation, mainly acetic and succinic acids, which lower the yield and productivity of propionic acid (Jin and Yang 1998). To overcome these limitations, various bioprocessing approaches have been applied (Eş et al. 2017; Liu et al. 2012a; Wang et al. 2014; Wang et al. 2012), including metabolic engineering to enhance the producer strains, but genetic manipulation of propionibacteria has proved to be difficult (Ammar 2013; Ammar et al. 2014; Ammar et al. 2013; Wang et al. 2015b; Wang et al. 2015d; Wei et al. 2016). As a result, propionic acid fermentation is still not economically competitive with petrochemical methods, and hence, further improvements are needed.

Among the approaches employed to reduce the cost of biosynthesis of propionic acid is identifying a low-cost renewable feedstock. Glycerol, an abundant renewable byproduct of the biodiesel industry, has been utilized in propionic acid fermentation (Barbirato et al. 1997; Himmi et al. 2000). The high reductance degree of the glycerol molecule results in higher yield of propionic acid and lower byproduct formation compared to glucose, thus lowering the cost of subsequent downstream processing. However, when used as the sole carbon and energy source in bacterial metabolism, glycerol slows down cellular growth (and hence propionic acid productivity) due to metabolic imbalance, so a combination of sugars is required to maintain high yield and good productivity (Kośmider et al. 2010; Wang and Yang 2013).

An even more abundant and inexpensive source of carbon is lignocellulosic biomass, a renewable resource (Arevalo-Gallegos et al. 2017; Jin et al. 2018). Lignocellulose is a low-cost renewable source of fermentable sugars, mainly glucose, but also xylose and arabinose, which can be microbially converted to value-added products, such as biofuels and organic acids. In this context, there has been increasing interest in producing propionic acid from corncob molasses (Liu et al. 2012b), artichoke (Liang et al. 2012), cassava bagasse (Wang and Yang 2013), and corn stover (Wang et al. 2017) hydrolysates.

Sweet sorghum is a crop of increasing commercial interest because it can grow in a variety of climates around the world as a source of food and fiber and can withstand drought conditions (Ali et al. 2008; Gnansounou et al. 2005). Sweet sorghum bagasse (SSB) is an agro-industrial lignocellulosic biomass that is currently used as animal feed, soil fertilizer, and combustible fuel for power and heat generation (Dar et al. 2018). Through chemical pretreatment and enzymatic hydrolysis, SSB can be transformed into a valuable source of renewable cellulose- and hemicellulose-derived sugars that can be fermentatively converted to biofuels and bioproducts, such as ethanol (Dar et al. 2018; Sipos et al. 2009), butanol (Cai et al. 2013), and succinic acid (Lo et al. 2020).

In the present study, we report the fermentative production of propionic acid by Propionibacterium freudenreichii using for the first time SSB hydrolysate as a renewable source of glucose. We investigated SSB both as sole carbon source and in combination with glycerol under various fermentation conditions. Overall, fermentation of SSB hydrolysate resulted in similar or better yields compared to glucose and also compared to hydrolysates from other types of biomass, as reported in the literature. The findings establish sweet sorghum, a food and biomass crop commercially cultivated around the world, as a new biomass source for potentially cost-effective and sustainable propionic acid biosynthesis.

Materials and methods

Bacterial strain, media, and cultivation

Propionibacterium freudenreichii DSM 4902 was obtained from Professor ST Yang’s lab. Unless otherwise noted, all experiments were carried out under anaerobic conditions in 120-mL sealed serum bottles at 32 °C without shaking. The serum bottles contained 50 mL of media purged with nitrogen gas to establish and maintain an anaerobic atmosphere and autoclaved at 121 °C for 20 min. Addition of media components to or withdrawal of samples from the bottles was carried out using sterile syringes under aseptic conditions. Bacterial cultures stored at − 80 °C were initially activated on sodium lactate broth (NLB) containing 10 g/L sodium lactate, 10 g/L yeast extract, and 10 g/L trypticase soy broth and using 1% v/v inoculum incubated for 72 h (Ammar et al. 2013). The activated cultures were kept at 4 °C for short-term storage. For fermentation kinetics studies, NLB bottles were inoculated with short-term storage culture using 5% v/v inoculum. Cells were grown for 48 h to an optical density (OD) of approximately 2, and a 5% v/v inoculum of those cultures was used to inoculate bottles with fermentation medium containing 10 g/L yeast extract, 5 g/L trypticase soy broth, 0.25 g/L K2HPO4, 0.05 g/L MnSO4, and the specified amount of carbon source(s). All cultures were started at pH 6.5 and were supplemented with 2% w/v CaCO3 as pH buffer, a common practice in fermentations for production of propionic acid (Ammar et al. 2013). Whenever the OD of the culture had to be monitored, no CaCO3 was added to the fermentation medium as it interfered with spectrophotometry. In high cell density (HCD) fermentations, a large volume of freshly prepared 48-hour NLB culture was collected, centrifuged, and resuspended in NLB medium equivalent to 1/50 and 1/100 of the original volume for the 50× and 100× HCD runs, respectively, and the concentrated culture was subsequently used to inoculate the fermentation medium at 5% v/v. In bioreactor batch fermentations, a 3.5-L New Brunswick BioFlo® benchtop fermentation system was used, equipped with temperature and pH monitoring and control systems (New Brunswick Scientific, Edison, NJ). A working volume of 600 mL was maintained in the fermentor, and anaerobic conditions were established by sparging the medium with nitrogen gas for an hour before adding the inoculum. During fermentation, the temperature was kept at 32 °C, pH was kept at 6.5 using a 5 M NaOH solution, and agitation was kept at 100 rpm. Samples were taken at proper time intervals from the fermentor and analyzed for carbon source(s) consumption and organic acid production.

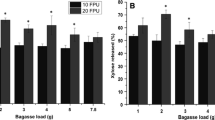

Sweet sorghum bagasse hydrolysate preparation

SSB hydrolysate was prepared under the optimal conditions previously described (Lo et al. 2020). Briefly, SSB was first pretreated using concentrated phosphoric acid under mild conditions (50 °C for 43 min at 130 g/L biomass concentration) with the final pH being adjusted to 5. The pretreated SSB was dried at 60 °C until no further change in dry weight occurred and was then enzymatically hydrolyzed to release its cellulosic glucose. Based on common practices in the literature and on the enzyme manufacturer’s recommendations (Sheet 2010), hydrolysis with Cellic CTec2 cellulase was carried out at 40 Filter Paper Units/g of pretreated SSB using acetic buffer (pH 5.0) in a water bath shaker (50 °C for 72 h at 50 rpm). Afterwards, the liquid phase was separated by centrifugation at 5000 rpm for 10 min (Sorvall RC BIOS Centrifuge, Thermo Electron LED GmbH, Germany) followed by filtration of the separated liquid through a 0.2-μm vacuum filter unit.

Analytical methods

Cell density was determined by measuring the optical density (OD) of the culture at 600 nm in 1.5-mL cuvettes (1-cm light path length) using a DU 730 UV/Vis spectrophotometer (Beckman Coulter, Germany). The pH was determined using an Orion 3-Star Benchtop pH Meter (Thermo Scientific, Singapore). The concentrations of sugars (glucose and glycerol) and organic acids in the fermentation media were determined via high-performance liquid chromatography (HPLC) with an organic acid column (Bio-Rad Aminex HPX-87H). Before analysis, all fermentation samples were centrifuged at 10,000 rpm and 10 °C for 10 min using an Eppendorf 5430 R centrifuge (Eppendorf, Hamburg, Germany). The supernatant was then filtered using a 0.2-μm syringe filter. Filtrates were analyzed on UltiMate 3000 Ultra HPLC (Thermo Scientific, Waltham, MA) equipped with a refractive index detector. The HPLC was operated with 5 mM H2SO4 as mobile phase at 0.6 mL/min flow rate and column and detector temperature of 50 °C. The resulting chromatograms were analyzed and processed using the Chromeleon 7.2.6 Chromatography Data System HPLC software (Lo et al. 2020).

Statistical analysis and yield and productivity calculation

All experiments were carried out at least in duplicate to check reproducibility, and the mean and standard deviation (SD) values were determined using Microsoft Excel’s built-in statistical tools for data analysis. The yield was calculated by dividing the mass of propionic acid produced by the respective mass of sugar consumed over a period of time and was expressed in g/g units. The volumetric productivity was calculated by dividing the concentration of propionic acid reached at the end of a period of time by the amount of time that elapsed to reach that concentration and was expressed in g/L/h units.

Results

Fermentation of SSB hydrolysate in serum bottles

First, we compared fermentative production of propionic acid from SSB hydrolysate to production from glucose in serum bottles (Fig. 1). In the presence of CaCO3 as pH buffer, SSB hydrolysate produced 9.9 g/L of propionate at a yield and productivity of 0.51 g/g and 0.080 g/L/h, respectively, thus exceeding the performance of glucose, which produced 8.5 g/L of propionate at a yield and productivity of 0.44 g/g and 0.070 g/L/h, respectively. Acetic acid was also produced with the propionate/acetate (P/A) ratio being higher in SSB (2.95) compared to glucose (2.49). On the other hand, the sugar consumption rate was similar (0.158 g/L/h) in SSB hydrolysate and glucose.

Next, we repeated the experiment in the absence of CaCO3 to compare the growth of propionibacteria on SSB vs. glucose without pH buffering. As expected, fermentation kinetics became slower in both SSB (Fig. 2a) and glucose (Fig. 2b) in terms of sugar consumption and propionate production rate due to insufficient pH buffering during the fermentation. Interestingly, sugar consumption and propionate production were still significantly faster in SSB. Likewise, cells grew faster and to a higher OD in SSB than in glucose (Fig. 2d).

Fermentation of glucose vs. SSB hydrolysate by P. freudenreichii in the absence of CaCO3. (a) Glucose; (b) SSB hydrolysate (50% v/v); (c) glucose supplemented with cellulase buffer (acetate buffer, pH 5). Panel (d) compiles the time progression of cell growth (OD) and culture pH during fermentations (a), (b), and (c)

Effect of cellulase buffer

To assess whether the cellulase buffer (acetate buffer, pH 5) that was carried over with SSB (by way of its production) contributes to the enhanced performance of P. freudenreichii in SSB in the absence of CaCO3, we supplemented the glucose medium with an amount of acetate buffer equivalent to that present in SSB hydrolysate (Fig. 2c). Again, the pH dropped to lower levels in glucose compared to SSB, but the presence of acetate buffer lessened the pH drop in the glucose medium, especially towards the end of the fermentation, when the pH was comparable to that in SSB (Fig. 2d). However, cell growth and propionic acid productivity on glucose with acetate buffer (Fig. 2c) did not change significantly compared to glucose without buffer (Fig. 2a).

Tolerance to propionic acid

To investigate whether SSB hydrolysate affects the tolerance of P. freudenreichii to propionate, given that feedback inhibition has been documented in the literature, we spiked the fermentation medium with increasing concentrations of propionic acid (0, 5, 10, 15, and 20 g/L) added at the beginning of fermentation with the starting pH set at 6.5. The OD was then monitored and compared, as shown in Fig. 3. In glucose, increasing the initial propionic acid concentration resulted in lower cell growth rate and final OD. Slower growth rate was also observed in SSB, but the negative effect was significantly less pronounced than in glucose. Actually, at 15 and 20 g/L of propionic acid addition, the final OD of the SSB culture was only slightly less than the final OD of the control (0 g/L).

Effect of SSB hydrolysate strength

In all previous experiments, each serum bottle contained 50 mL of medium prepared using 25 mL of SSB hydrolysate to a final glucose content of 23 ± 2 g/L; hence, hydrolysate was used at a 50% strength (v/v). In addition to cellulosic glucose, SSB hydrolysate by nature contains several additional known and unknown components that could be inhibitory to propionibacteria at certain concentrations. To assess such a potential inhibitory effect, we investigated the use of high-strength SSB hydrolysate (75% and 100%) during fermentation, while maintaining the concentration of medium nutrients fixed, as described in the “Materials and methods” section. As shown in Fig. 4, increasing SSB hydrolysate strength actually resulted in higher final propionate concentrations of 10.5 and 11.5 g/L at 75% and 100% SSB strength, respectively, compared to 8.0 g/L at 50% strength. On the other hand, increasing the SSB strength slowed down the cell growth rate during the first 48 hours, which could be attributed to a longer lag phase needed for cells to adapt to the higher concentration of hydrolysate components. Nevertheless, after 72 hours, the 75% and 100% strength cultures significantly outgrew the 50% strength culture with maximum OD values of 19.2, 23.8, and 23.8 in the 50%, 75%, and 100% cultures, respectively.

Effect of SSB hydrolysate strength on propionic acid production by P. freudenreichii. Fermentations were conducted in the absence of CaCO3 in fermentation media containing SSB hydrolysate at (a) 50% v/v; (b) 75% v/v; (c) 100% v/v. Panel (d) compiles the time progression of cell growth (OD) during fermentations (a), (b), and (c)

Effect of fermentation medium supplementation

In search of why SSB hydrolysate outperforms glucose, we examined whether SSB hydrolysate on its own can support propionic acid biosynthesis without the nutrients of the fermentation medium, namely yeast extract, trypticase soy broth, K2HPO4, and MnSO4. As illustrated in Fig. 5, using plain SSB hydrolysate resulted in virtually no sugar consumption. Similarly, cell growth was very limited. When SSB hydrolysate was partially supplemented with nutrients at 25% and 50% of their standard amounts typically used in the fermentation medium, glucose consumption, propionate concentration, and cell growth improved proportionally to the level of nutrient supplementation. However, the fermentation performance was not as robust as when using medium nutrients at full strength.

Effect of fermentation medium supplementation on propionic acid production by P. freudenreichii. Fermentations of full-strength SSB hydrolysate (100% v/v) were conducted in the absence of CaCO3 with fermentation medium provided at (a) 0; (b) 25%; (c) 50%; (d) 100% of full supplementation. Panel (e) compiles the time progression of cell growth (OD) during fermentations (a), (b), (c), and (d)

Fermentation of SSB hydrolysate-glycerol mixtures with high cell density inoculum

In order to further enhance propionic acid yield, we supplemented SSB hydrolysate with varying amounts of glycerol at SSB hydrolysate (glucose equivalents)/glycerol mass ratios of 2:1, 1:1, and 1:2, while maintaining the total carbon source (glycerol + SSB glucose) concentration at about 30 g/L. Overall, as the glycerol inclusion rate increased, so did both the propionate yield and the P/A ratio. Propionate yields of 0.54, 0.57, and 0.59 g/g and P/A ratios of 4.72, 5.07, and 8.42 were achieved at 2:1, 1:1, and 1:2 SSB/glycerol mass ratios, respectively. On the other hand, the volumetric productivity of propionic acid did not really change at the various ratios (0.098, 0.098, and 0.099 g/L/h at 2:1, 1:1, and 1:2 SSB/glycerol mass ratios, respectively). It should be noted, however, that SSB hydrolysate fermentation was much faster than fermentation of glycerol, when the latter was the sole carbon source (data not shown).

Striving to achieve higher propionic acid productivity along with higher yield and P/A ratio, we repeated the SSB-glycerol fermentations in serum bottles, but this time under high cell density (HCD) conditions (Liu et al. 2016; Stowers et al. 2014; Wang et al. 2015c), which were achieved by utilizing inoculum with cell density (OD) equal to 50× and 100× the regular starting OD (Fig. 6). At 50× and 100× HCD, the fermentation reached its peak in just 72 and 48 h, respectively, compared to 96 to 144 h at regular inoculum density. At 50× HCD, propionate productivities of 0.190, 0.194, and 0.174 g/L/h were achieved at 2:1, 1:1, and 1:2 SSB/glycerol mass ratios, respectively, compared to 0.098 to 0.099 g/L/h in regular fermentation. At 100× HCD, propionate productivities further increased to 0.247, 0.257, and 0.238 g/L/h at 2:1, 1:1, and 1:2 SSB/glycerol mass ratios, respectively.

Fermentation of SSB hydrolysate-glycerol mixtures by P. freudenreichii using high cell density (HCD) inoculum. Fermentation was conducted in the presence of CaCO3 at SSB hydrolysate (glucose equivalents)-to-glycerol mass ratios of (a, b) 2:1; (c, d) 1:1; (e, f) 1:2 using inoculum of 50× and 100× the regular inoculum density, as indicated

Fermentation of SSB hydrolysate in a bioreactor

To check the scalability of SSB hydrolysate fermentation for propionic acid production, we conducted batch fermentations in a bioreactor using 100% strength SSB hydrolysate supplemented with fermentation medium nutrients at a controlled pH of 6.5. As seen in Fig. 7, after a lag phase of 24 h, the culture started to consume SSB glucose, and grow and produce propionic acid. After 132 h, the propionibacteria consumed nearly 49 g of glucose and produced nearly 22 g of propionate resulting in a yield of 0.45 g/g, a volumetric productivity of 0.168 g/L/h, and a P/A ratio of 4.58 with no succinate formation. As with serum bottle batches, xylose in the SSB hydrolysate was not consumed during the fermentation.

Discussion

The better fermentation performance of P. freudenreichii in SSB hydrolysate than in glucose may be due to the pH buffering capacity provided by the cellulase buffer (acetate buffer, pH 5) that is present in the SSB hydrolysate (Lo et al. 2020). However, when glucose medium was supplemented with the same buffer at the same strength, there was no noticeable improvement (Fig. 2a, 2c), leading to the conclusion that the buffering capacity of SSB hydrolysate may be one, but not the sole, reason for the hydrolysate’s better performance. A previous report on P. acidipropionici fermentation in corn meal hydrolysate showed higher propionate yield compared to sugars, which was presumably related to additional nutrients present in the corn meal hydrolysate (Huang et al. 2002). This could also be the case in the present study with SSB hydrolysate, which may contain additional nutrients that enhance propionic acid biosynthesis. Indeed, when SSB hydrolysate was supplied to the fermentation media at higher strength, propionic acid yield and cell growth improved considerably (Fig. 4). Still, SSB hydrolysate had to be supplemented with rich medium nutrients for a successful fermentation (Fig. 5) in agreement with previous reports that propionic acid biosynthesis requires vitamins and other nutrients present in yeast extract (Hettinga and Reinbold 1972; Ramsay et al. 1998). This can be explained by the presence of biotin and other vitamins in yeast extract, which are co-factors for key propionic acid biosynthesis enzymes of the Wood-Werkman metabolic cycle (Falentin et al. 2010; Piwowarek et al. 2018).

Moreover, SSB hydrolysate was also associated with better tolerance of the propionibacteria to the end product, propionic acid, as seen in Fig. 3. Considering that product feedback inhibition is a key limiting factor to propionic acid production (Jin and Yang 1998), SSB hydrolysate seems to offer a productivity advantage for large-scale deployment of the fermentation. The few existing literature reports on the use of biomass hydrolysates for propionic acid production, summarized in Table 1, indicate that P. freudenreichii co-fermented cassava bagasse hydrolysate and crude glycerol at a yield of 0.57 g/g (Wang and Yang 2013) that is comparable to our 0.54–0.59 g/g. Similar yields are reported for P. acidipropionici in poplar hydrolysate (Ramsay et al. 1998), corn meal starch (Huang et al. 2002), wheat flour (Kagliwal et al. 2013), and corn mash (Stowers et al. 2014). On the other hand, lower yields were reported for P. acidipropionici in Jerusalem artichoke hydrolysate (0.38–0.48 g/g) (Liang et al. 2012), sugarcane bagasse hydrolysate (0.29 and 0.37 g/g) (Zhu et al. 2012), and corn stover hydrolysate (0.44–0.50 g/g) (Wang et al. 2017). Overall, SSB hydrolysate is as good as or superior to those reported from other biomass feedstocks.

We have previously reported the glucan and xylan content of SSB to be 34.8 ± 0.8 g and 23.6 ± 1.2 g per 100 g SSB, respectively (Lo et al. 2020). In that study, under optimal pretreatment conditions, 32.75 g of glucose per 100 g SSB was released, which corresponded to 85% of the glucose content of SSB. Therefore, the propionate yield achieved in the present study (0.51 g/g) could be further enhanced, if all SSB glucose were released during pretreatment. At the same time, no sugar degradation products (furfural and hydroxymethyl furfural) were detected in the SSB hydrolysate, providing an inhibitor-free environment for propionibacteria growth and propionic acid biosynthesis. Hence, the combination of high carbohydrate content in the SSB (~ 60%) and absence of metabolic inhibitors in the hydrolysate make SSB a promising feedstock for propionic acid fermentation.

Interestingly, co-fermentation of SSB hydrolysate with glycerol boosted the propionic acid yield from 0.49 g/g (no glycerol) to as high as 0.59 g/g and the P/A ratio from 2.95 (no glycerol) to as high as 8.42 at a SSB/glycerol mass ratio of 1:2, in agreement with previous reports (Barbirato et al. 1997; Himmi et al. 2000) that can be attributed to glycerol and propionic acid having the same degree of reductance of 4.7 compared to 4.0 for glucose. As a result, when glycerol is used as carbon/energy source in propionic acid fermentation, the redox potential remains balanced, thus suppressing synthesis of additional metabolites. Hence, propionate becomes in essence the only product in the SSB fermentation broth. In contrast, when glucose is the carbon/energy source, the less reduced acetate (along with small amounts of succinate) is also produced to achieve redox balance in the fermentation, leading to a lower P/A ratio (Barbirato et al. 1997; Himmi et al. 2000; Kośmider et al. 2010; Wang and Yang 2013) and necessitating significant downstream processing to purify propionic acid. Given the production of significant amounts of glycerol by the burgeoning biodiesel industry, its fermentative conversion to propionic acid represents a value-added opportunity.

It should be noted that SSB glucose and glycerol were co-utilized during fermentation (Fig. 6) in agreement with previous such reports (Liu et al. 2011; Wang et al. 2015b; Wang et al. 2015d; Wang and Yang 2013). Moreover, high cell density (HCD) inoculum at 50× doubled the productivity of the SSB-glycerol fermentation compared to regular cell density inoculum and 100× HCD further increased productivity in agreement with previous reports (Liu et al. 2016; Stowers et al. 2014; Wang et al. 2015c). Based on Fig. 6, a 1:1 SSB/glycerol mass ratio led to the highest propionic acid productivity under both regular and HCD conditions, whereas a 1:2 SSB/glycerol ratio led to the highest yield of propionic acid, although a significant portion of glycerol was not consumed by the end of the fermentation. A previous work reported a 1:2 mass ratio as the best one with cassava bagasse hydrolysate (Wang and Yang 2013).

As expected, the kinetic parameters of fermentation in the bioreactor (Fig. 7) were generally superior to those in serum bottles, most likely as a result of tight pH control and better mass transfer in the fermentor. At a constant pH of 6.5 in the bioreactor, most of the produced propionic acid is in the dissociated form, whereas as pH drops to 5 or lower in serum bottles, propionic acid is mostly present in the undissociated form, which is more toxic to propionibacteria (Jin and Yang 1998). The higher P/A ratio and lack of succinate formation in the bioreactor fermentation of SSB hydrolysate present a major advantage from a commercialization perspective, as low byproduct formation reduces the cost of downstream processing for propionic acid purification.

In conclusion, we successfully demonstrated that sweet sorghum bagasse hydrolysate can be fermented effectively by P. freudenreichii serving as a source of renewable cellulosic glucose for propionic acid production. The propionibacterium grew better, yielded more propionic acid, and was less sensitive to product inhibition in SSB hydrolysate fermentation compared to glucose fermentation. Productivity was further enhanced by co-fermenting SSB hydrolysate and glycerol and by using a high cell density inoculum. The process looks promising and scalable, but further optimization is required to lower the cost of biobased propionic acid through a combination of bioprocess design (Liang et al. 2012; Suwannakham and Yang 2005) and genetic engineering (Ammar 2013; Ammar et al. 2014; Wang et al. 2015b; Wang et al. 2015d; Wei et al. 2016).

Availability of data and material

All data generated or analyzed during this study are included in the published article

References

Ali M, Rajewski J, Baenziger P, Gill K, Eskridge K, Dweikat I (2008) Assessment of genetic diversity and relationship among a collection of US sweet sorghum germplasm by SSR markers. Mol Breed 21(4):497–509

Ammar EM (2013) Metabolic engineering of propionibacteria for enhanced propionic acid and n-propanol fermentative production. Doctoral Thesis, The Ohio State University

Ammar EM, Jin Y, Wang Z, Yang S-T (2014) Metabolic engineering of Propionibacterium freudenreichii: effect of expressing phosphoenolpyruvate carboxylase on propionic acid production. Appl Microbiol Biotechnol 98(18):7761–7772

Ammar EM, Wang Z, Yang S-T (2013) Metabolic engineering of Propionibacterium freudenreichii for n-propanol production. Appl Microbiol Biotechnol 97(10):4677–4690

Arevalo-Gallegos A, Ahmad Z, Asgher M, Parra-Saldivar R, Iqbal HM (2017) Lignocellulose: a sustainable material to produce value-added products with a zero waste approach—a review. Int J Biol Macromol 99:308–318

Barbirato F, Chedaille D, Bories A (1997) Propionic acid fermentation from glycerol: comparison with conventional substrates. Appl Microbiol Biotechnol 47(4):441–446

Bozell JJ (2008) Feedstocks for the future – biorefinery production of chemicals from renewable carbon. Clean Soil Air Water 36(8):641–647

Cai D, Zhang T, Zheng J, Chang Z, Wang Z, P-y Q, Tan T-w (2013) Biobutanol from sweet sorghum bagasse hydrolysate by a hybrid pervaporation process. Bioresour Technol 145:97–102

Dar RA, Dar EA, Kaur A, Phutela UG (2018) Sweet sorghum-a promising alternative feedstock for biofuel production. Renew Sust Energ Rev 82:4070–4090

Eş I, Khaneghah AM, Hashemi SMB, Koubaa M (2017) Current advances in biological production of propionic acid. Biotechnol Lett 39(5):635–645

Falentin H, Deutsch S-M, Jan G, Loux V, Thierry A, Parayre S, Maillard M-B, Dherbecourt J, Cousin FJ, Jardin J (2010) The complete genome of Propionibacterium freudenreichii CIRM-BIA1T, a hardy Actinobacterium with food and probiotic applications. PLoS One 5(7):e11748

Gnansounou E, Dauriat A, Wyman C (2005) Refining sweet sorghum to ethanol and sugar: economic trade-offs in the context of North China. Bioresour Technol 96(9):985–1002

Hedayati R, Hosseini M, Najafpour GD (2020) Optimization of semi-anaerobic vitamin B12 (cyanocobalamin) production from rice bran oil using Propionibacterium freudenreichii PTCC1674. Biocatal Agric Biotechnol 23:101444

Hettinga D, Reinbold G (1972) The propionic-acid bacteria-a review: I. Growth J Milk Food Technol 35(5):295–301

Himmi E, Bories A, Boussaid A, Hassani L (2000) Propionic acid fermentation of glycerol and glucose by Propionibacterium acidipropionici and Propionibacterium freudenreichii ssp. shermanii. Appl Microbiol Biotechnol 53(4):435–440

Huang YL, Wu Z, Zhang L, Cheung CM, Yang S-T (2002) Production of carboxylic acids from hydrolyzed corn meal by immobilized cell fermentation in a fibrous-bed bioreactor. Bioresour Technol 82(1):51–59

Jin Q, Yang L, Poe N, Huang H (2018) Integrated processing of plant-derived waste to produce value-added products based on the biorefinery concept. Trends Food Sci Technol 74:119–131

Jin Z, Yang S-T (1998) Extractive fermentation for enhanced propionic acid production from lactose by Propionibacterium acidipropionici. Biotechnol Prog 14(3):457–465

Kagliwal LD, Survase SA, Singhal RS, Granström T (2013) Wheat flour based propionic acid fermentation: An economic approach. Bioresour Technol 129:694–699

Kośmider A, Białas W, Kubiak P, Drożdżyńska A, Czaczyk K (2012) Vitamin B12 production from crude glycerol by Propionibacterium freudenreichii ssp. shermanii: optimization of medium composition through statistical experimental designs. Bioresour Technol 105:128–133

Kośmider A, Drożdżyńska A, Blaszka K, Leja K, Czaczyk K (2010) Propionic acid production by Propionibacterium freudenreichii ssp. shermanii using industrial wastes: crude glycerol and whey lactose. Pol J Environ Stud 19(6):1249–1253

Liang Z-X, Li L, Li S, Cai Y-H, Yang S-T, Wang J-F (2012) Enhanced propionic acid production from Jerusalem artichoke hydrolysate by immobilized Propionibacterium acidipropionici in a fibrous-bed bioreactor. Bioprocess Biosyst Eng 35(6):915–921

Liu L, Zhu Y, Li J, Wang M, Lee P, Du G, Chen J (2012a) Microbial production of propionic acid from propionibacteria: current state, challenges and perspectives. Crit Rev Biotechnol 32(4):374–381

Liu Y, Zhang Y-G, Zhang R-B, Zhang F, Zhu J (2011) Glycerol/glucose co-fermentation: one more proficient process to produce propionic acid by Propionibacterium acidipropionici. Curr Microbiol 62(1):152–158

Liu Z, Ge Y, Xu J, Gao C, Ma C, Xu P (2016) Efficient production of propionic acid through high density culture with recycling cells of Propionibacterium acidipropionici. Bioresour Technol 216:856–861

Liu Z, Ma C, Gao C, Xu P (2012b) Efficient utilization of hemicellulose hydrolysate for propionic acid production using Propionibacterium acidipropionici. Bioresour Technol 114:711–714

Lo E, Brabo-Catala L, Dogaris I, Ammar EM, Philippidis GP (2020) Biochemical conversion of sweet sorghum bagasse to succinic acid. J Biosci Bioeng 129(1):104–109

Piwowarek K, Lipińska E, Hać-Szymańczuk E, Kieliszek M, Ścibisz I (2018) Propionibacterium spp.—source of propionic acid, vitamin B12, and other metabolites important for the industry. Appl Microbiol Biotechnol 102(2):515–538

Ramsay J, Hassan M-CA, Ramsay B (1998) Biological conversion of hemicellulose to propionic acid. Enzym Microb Technol 22(4):292–295

Sheet FEA (2010) CELLIC Ctec and Htec2—Enzymes for hydrolysis of lignocellulosic materials. Novozymes A/S, Luna (2010-01668) 01

Sipos B, Réczey J, Somorai Z, Kádár Z, Dienes D, Réczey K (2009) Sweet sorghum as feedstock for ethanol production: enzymatic hydrolysis of steam-pretreated bagasse. Appl Biochem Biotechnol 153(1-3):151–162

Stowers CC, Cox BM, Rodriguez BA (2014) Development of an industrializable fermentation process for propionic acid production. J Ind Microbiol Biotechnol 41(5):837–852

Suwannakham S, Yang S-T (2005) Enhanced propionic acid fermentation by Propionibacterium acidipropionici mutant obtained by adaptation in a fibrous-bed bioreactor. Biotechnol Bioeng 91(3):325–337

Thierry A, Maillard M-B, Hervé C, Richoux R, Lortal S (2004) Varied volatile compounds are produced by Propionibacterium freudenreichii in Emmental cheese. Food Chem 87(3):439–446

Vidra A, Németh Á (2018) Bio-produced propionic acid: a review. Period Polytech Chem Eng 62(1):57–67

Wang P, Jiao Y, Liu S (2014) Novel fermentation process strengthening strategy for production of propionic acid and vitamin B12 by Propionibacterium freudenreichii. J Ind Microbiol Biotechnol 41(12):1811–1815

Wang P, Wang Y, Liu Y, Shi H, Su Z (2012) Novel in situ product removal technique for simultaneous production of propionic acid and vitamin B12 by expanded bed adsorption bioreactor. Bioresour Technol 104:652–659

Wang P, Zhang Z, Jiao Y, Liu S, Wang Y (2015a) Improved propionic acid and 5, 6-dimethylbenzimidazole control strategy for vitamin B12 fermentation by Propionibacterium freudenreichii. J Biotechnol 193:123–129

Wang X, Salvachúa D, i Nogué VS, Michener WE, Bratis AD, Dorgan JR, Beckham GT (2017) Propionic acid production from corn stover hydrolysate by Propionibacterium acidipropionici. Biotechnol Biofuels 10(1):200

Wang Z, Ammar EM, Zhang A, Wang L, Lin M, Yang S-T (2015b) Engineering Propionibacterium freudenreichii subsp. shermanii for enhanced propionic acid fermentation: effects of overexpressing propionyl-CoA: succinate CoA transferase. Metab Eng 27:46–56

Wang Z, Jin Y, Yang S-T (2015c) High cell density propionic acid fermentation with an acid tolerant strain of Propionibacterium acidipropionici. Biotechnol Bioeng 112(3):502–511

Wang Z, Lin M, Wang L, Ammar EM, Yang S-T (2015d) Metabolic engineering of Propionibacterium freudenreichii subsp. shermanii for enhanced propionic acid fermentation: effects of overexpressing three biotin-dependent carboxylases. Process Biochem 50(2):194–204

Wang Z, Yang S-T (2013) Propionic acid production in glycerol/glucose co-fermentation by Propionibacterium freudenreichii subsp. shermanii. Bioresour Technol 137:116–123

Wei P, Lin M, Wang Z, Fu H, Yang H, Jiang W, Yang S-T (2016) Metabolic engineering of Propionibacterium freudenreichii subsp. shermanii for xylose fermentation. Bioresour Technol 219:91–97

Zhu L, Wei P, Cai J, Zhu X, Wang Z, Huang L, Xu Z (2012) Improving the productivity of propionic acid with FBB-immobilized cells of an adapted acid-tolerant Propionibacterium acidipropionici. Bioresour Technol 112:248–253

Acknowledgments

We thank Prof. ST Yang for kindly providing the P. freudenreichii strain.

Funding

This work was supported by the Patel College of Global Sustainability at the University of South Florida.

Author information

Authors and Affiliations

Contributions

EMA conceived the idea, designed and conducted experiments, analyzed data, and wrote the manuscript. JM conducted experiments, helped with data analysis, and wrote the introduction section. LB-C conducted experiments, helped with data analysis, and participated in manuscript editing and revision. GPP conceived the idea, designed experiments, analyzed data, and wrote, edited and revised the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Ethics approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Code availability

Not applicable

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ammar, E.M., Martin, J., Brabo-Catala, L. et al. Propionic acid production by Propionibacterium freudenreichii using sweet sorghum bagasse hydrolysate. Appl Microbiol Biotechnol 104, 9619–9629 (2020). https://doi.org/10.1007/s00253-020-10953-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-020-10953-w