Abstract

A poorly performing industrial water kefir production process consisting of a first fermentation process, a rest period at low temperature, and a second fermentation process was characterized to elucidate the causes of its low water kefir grain growth and instability. The frozen-stored water kefir grain inoculum was thawed and reactivated during three consecutive prefermentations before the water kefir production process was started. Freezing and thawing damaged the water kefir grains irreversibly, as their structure did not restore during the prefermentations nor the production process. The viable counts of the lactic acid bacteria and yeasts on the water kefir grains and in the liquors were as expected, whereas those of the acetic acid bacteria were high, due to the aerobic fermentation conditions. Nevertheless, the fermentations progressed slowly, which was caused by excessive substrate concentrations resulting in a high osmotic stress. Lactobacillus nagelii, Lactobacillus paracasei, Lactobacillus hilgardii, Leuconostoc mesenteroides, Bifidobacterium aquikefiri, Gluconobacter roseus/oxydans, Gluconobacter cerinus, Saccharomyces cerevisiae, and Zygotorulaspora florentina were the most prevalent microorganisms. Lb. hilgardii, the microorganism thought to be responsible for water kefir grain growth, was not found culture-dependently, which could explain the low water kefir grain growth of this industrial process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water kefir is a naturally fermented beverage with health-promoting potential that is produced and drunk at household scale worldwide (Marsh et al. 2013; Pothakos et al. 2016). It is obtained through a 2 to 4-day anaerobic fermentation of a mixture of water, (dried) fruits, and sugar, inoculated with water kefir grains (Gulitz et al. 2011; Laureys and De Vuyst 2014). At the end of a fermentation process, the water kefir grains are separated from the water kefir liquor by sieving and reused for a next water kefir fermentation process through a backslopping procedure. Water kefir grains are brittle, consist of exopolysaccharides, and onto which the water kefir microorganisms are attached (Laureys and De Vuyst 2014; Moinas et al. 1980). Recently, the microbial community dynamics, species diversity, and meta-metabolomics of the water kefir fermentation process have been studied at laboratory scale (Laureys and De Vuyst 2014). It turned out that the key microorganisms during water kefir fermentation are the lactic acid bacteria (LAB) species Lactobacillus paracasei, Lactobacillus hilgardii, and Lactobacillus nagelii and the yeast species Saccharomyces cerevisiae. The end-metabolites of all of them contribute to the flavor of the final water kefir liquor. The viable counts of acetic acid bacteria (AAB) range from neglible (Laureys and De Vuyst 2014) to 8.5 log colony-forming units (CFU) per gram of water kefir grains (Franzetti et al. 1998; Gulitz et al. 2011; Laureys and De Vuyst 2014). Similarly, Bifidobacterium aquikefiri is sometimes present but does not seem to be essential for the water kefir fermentation process. These microorganisms convert sucrose into water kefir grain exopolysaccharides of the glucan-type (Lb. hilgardii), which results in an increase of the water kefir grain mass, next to the end-metabolites ethanol (yeast), carbon dioxide (yeast), lactic acid (LAB, bifidobacteria), glycerol (yeast), acetic acid (LAB, yeast, AAB, and bifidobacteria), mannitol (LAB), and a variety of aroma compounds, among which the esters isoamyl acetate, ethyl hexanoate, ethyl octanoate, and ethyl decanoate (yeast) are the most abundant (Laureys and De Vuyst 2014).

Today, only a few small companies produce water kefir products, which are mostly sold in health stores as health-promoting supplements for human and animal use (Marsh et al. 2014). A major reason for the limited industrial production of water kefir is that the water kefir fermentation process is unstable and yields water kefir beverages of variable quality that do not meet the expectations of contemporary beverage consumers. Another major problem during water kefir fermentation is the low water kefir grain growth, which can prevent successful backslopping of the water kefir grains and upscaling of a water kefir production process.

This study aimed at the investigation of an industrial water kefir fermentation process that suffered from poor water kefir grain growth and instability, to better understand the possible causes behind these two common problems during fermentation, by comparing the data obtained with those of water kefir fermentation processes carried out at laboratory scale previously.

Materials and methods

Water kefir prefermentation and fermentation processes

The water kefir prefermentation and fermentation processes were carried out in a small Belgian company that produces water kefir. In the company, the water kefir grain inoculum was stored at −20 °C. To start a water kefir production process, the water kefir grains were thawed and reactivated through a series of three consecutive water kefir prefermentations. These were performed in a plastic fermentation vessel covered with a muslin cloth, which allowed aerobic fermentation conditions. Hereto, 5.0 kg of thawed water kefir grains was initially added to 6.0 l of demineralized water, supplemented with 1.5 kg of sucrose and 0.3 kg of dried figs, and fermented at 21 °C for 4 days. Then, a backslopping practice was applied, whereby the water kefir grains were separated from the water kefir liquor by sieving and recultivated in fresh medium under the same conditions as mentioned above. The activated water kefir grain mass thus obtained was used to start the actual water kefir production process, which consisted of a first water kefir fermentation process (further referred to as K1), a rest period at low temperature (further referred to as the KR period), and a second water kefir fermentation process (futher referred to as the K2 process). The rest period between two subsequent fermentation processes was applied to adjust the production output to the demand for water kefir liquor. These processes were carried out in a plastic fermentation vessel covered with a muslin cloth, as mentioned above. The K1 process was started by adding 5.0 kg of activated water kefir grains from the third prefermentation to a mixture of 15.0 l of demineralized water, 5.0 kg of sucrose, and 1.0 kg of figs. This mixture was fermented at 21 °C for 3 days, after which the water kefir grains were separated from the liquor by sieving and used as inoculum for the KR period. Hereto, 5.0 kg of water kefir grains from the K1 process was added to a mixture of 6.0 l of demineralized water and 1.5 kg of sugar. This mixture was hold at 8 °C for 5 days, after which the water kefir grains were separated from the liquor by sieving and used as inoculum for the K2 process. The K2 process was performed as described above for the K1 process. Samples were taken in triplicate (representing three technical replicates) during the K1 and K2 processes after 0, 1, 2, and 3 days of fermentation and during the KR period after 1 and 5 days. No water kefir grains were available at the start of the K1 process (day 0).

pH and water kefir grain mass determinations

The pH of the water kefir liquors was measured with a SenTix 41 glass electrode (WTW GmbH, Weilheim, Germany). The water kefir grains were separated from the water kefir liquors by sieving to determine their wet mass at the end of each (pre)fermentation process, as described previously (Laureys and De Vuyst 2014). The water kefir grain growth was defined as the increase of the water kefir grain wet mass at the time of sampling compared with that at the start of the fermentation, divided by the water kefir grain wet mass at the start of the fermentation, and expressed as percentage (%, m/m). Also, the water kefir grains were assessed visually throughout the production process by comparison with those from the household water kefir fermentation process maintained by a private person described previously (Laureys and De Vuyst 2014).

Microbial enumerations

To enumerate the microorganisms, decimal dilutions of the water kefir liquors and water kefir grain suspensions were prepared and plated on different selective agar media, as described previously (Laureys and De Vuyst 2014). Presumptive LAB were enumerated on de Man-Rogosa-Sharpe (MRS) agar medium supplemented with cycloheximide (final concentration of 0.1 g l−1; Sigma-Aldrich, Saint Louis, MO, USA); presumptive yeasts were enumerated on yeast extract-peptone-dextrose (YPD) agar medium supplemented with chloramphenicol (final concentration of 0.1 g l−1; Sigma-Aldrich), and presumptive AAB were enumerated on modified deoxycholate-mannitol-sorbitol (mDMS) agar medium (Papalexandratou et al. 2013) supplemented with cycloheximide (final concentration of 0.1 g l−1; Sigma-Aldrich). The MRS, YPD, and mDMS agar media were incubated at 30 °C for 6 days. Colony enumerations were expressed as log CFU per milliliter of water kefir liquor or per gram of water kefir grains.

Culture-dependent microbial species diversity and community dynamic analyses

The culture-dependent microbial diversity and community dynamics in the water kefir liquors and on the water kefir grains were assessed after 3 days of fermentation for the K1 and K2 processes, and after 5 days of fermentation for the KR period. Hereto, 10 to 20% of the total number of colonies on the MRS, mDMS, and YPD agar media with 30 to 300 colonies were picked up and purified on the appropriate agar media. Purified isolates were cultured in the appropriate liquid media to obtain cell pellets for DNA extraction. DNA from LAB was obtained after treatment of the cell pellets with mutanolysin, lysozyme, and proteinase K; DNA from AAB was obtained after treatment of the cell pellets with lysozyme and proteinase K, and DNA from yeasts was obtained after treatment of the cell pellets with lyticase and proteinase K, as described previously (Laureys and De Vuyst 2014). The DNA obtained was further purified with a Nucleospin 96 tissue kit (Macherey-Nagel, Düren, Germany), according to the instructions of the manufacturer. The purified bacterial and yeast DNA was further diluted to 50 ng μl−1 and subjected to (GTG)5-PCR and M13-PCR fingerprinting, respectively (Laureys and De Vuyst 2014). The fingerprint patterns obtained were clustered numerically with Bionumerics version 5 software (Applied Maths, Sint-Martens-Latem, Belgium). Representative isolates within each cluster were identified by gene sequencing. For LAB and AAB, the primer pair pA/pH was used to amplify and sequence part of the 16S ribosomal RNA (rRNA) gene (Edwards et al. 1989). For yeasts, the primer pair LR0R/LR3 was used to amplify and sequence part of the large subunit (LSU) of the 26S rRNA gene (Vilgalys and Hester 1990) and the primer pair ITS1/ITS4 was used to amplify and sequence the internal transcribed spacer (ITS) region (White et al. 1990). The type strains with sequences most similar to the sequenced fragments (expressed as % identity) were determined with the BLAST algorithm (Altschul et al. 1990) and the GenBank database (http://blast.ncbi.nlm.nih.gov/). The accession numbers of their sequences are reported.

Culture-independent microbial species diversity and community dynamic analyses

The culture-independent species diversity and community dynamics of the water kefir grains were determined after 0, 1, 2, and 3 days of fermentation for the K1 process, after 1 and 5 days for the KR period, and after 1, 2, and 3 days for the K2 process. Hereto, 10 ml of water kefir grain suspensions was centrifuged (7200×g, 20 min, 4 °C), and the supernatants were removed. DNA from the pellets of the water kefir grain suspensions was obtained after treatment with lyticase, mutanolysin, lysozyme, and proteinase K, as described previously (Laureys and De Vuyst 2014). The DNA extracts were further purified with a Nucleospin food kit (Macherey-Nagel) according to the instructions of the manufacturer and diluted to approximately 50 ng μl−1. The microbial community profiles were obtained by amplifying selected genomic fragments in the total DNA with the universal prokaryotic primer pair 357f-GC/518r (V3) (Ercolini et al. 2001), the LAB-specific primer pair LAC1/LAC2-GC (LAC) (Garcia-Armisen et al. 2010), the Bifidobacterium-specific primer pair bif164f/bif662r-GC (Bif) (Satokari et al. 2001), and the universal eukaryotic primer pair NL1-GC/LS2 (Yeast) (Cocolin et al. 2000) and separating the PCR amplicons in a 6% (v/v) polyacrylamide gel through denaturing gradient gel electrophoresis (DGGE), as described previously (Garcia-Armisen et al. 2010; Papalexandratou et al. 2011). The denaturing gradients of the gels were, from top to bottom, 45–60% for the V3 and the yeast primer pairs, 40–55% for the LAC primer pair, and 45–55% for the Bif primer pair. Selected bands of the community profiles were cut from the gels, amplified with their respective primer pairs (without GC clamp), and sequenced for microbial identification. The type strains with sequences most similar to the sequenced fragments (expressed as % identity) were determined as described above. The accession numbers of their sequences are reported.

Substrate consumption and metabolite production analyses

Cell-free supernatants were obtained after centrifugation (7200×g, 20 min, 4 °C) of the sieved water kefir liquors and used for substrate and metabolite analyses. All samples (except for the analysis of the aroma compounds) were vortexed, centrifuged (21,000×g, 20 min, 4 °C), and filtered (0.2-μm pore size Whatman filters; GE Healthcare Life Sciences, Bucks, UK) before they were injected into the column. Quantifications were performed with external calibration curves with standards prepared in the same way as the samples.

The concentrations of sucrose, fructose, and glucose were measured through high-performance anion exchange chromatography with pulsed amperometric detection (HPAEC-PAD) with a Dionex chromatograph (Dionex, Sunnyvale, CA, USA) equipped with a Carbopac™ PA10 column (Dionex) coupled to a pulsed amperometric detector (Dionex), as described previously (Laureys and De Vuyst 2014). Therefore, 100 μl of cell-free supernatant was added to 400 μl of ultrapure water, after which 50 μl of this dilution was added to 950 μl of sample preparation solution [500 μl of acetonitrile, 449.5 μl of ultrapure water, and 0.5 μl of 50 g l−1 rhamnose solution (internal standard; Sigma-Aldrich)]. These samples were treated as described above, injected (10 μl) into the column, and eluted as described previously (Janssens et al. 2012).

The concentrations of acetic acid and D-lactic acid and L-lactic acid were measured through high-performance liquid chromatography with ultraviolet detection (HPLC-UV) with a Waters chromatograph (Waters, Milford, MA, USA) equipped with a Shodex ORpak CRX 853 column (Showa Denko, Tokyo, Japan) coupled to an UV detector operating at 253 nm (Waters). Therefore, 250 μl of cell-free supernatant was added to a mixture of 500 μl of acetonitrile and 250 μl of ultrapure water. These samples were treated as described above, injected (30 μl) into the column, and eluted with 10% acetonitrile and 90% 1 mM CuSO4.

The concentrations of glycerol and mannitol were measured through HPAEC-PAD with the same Dionex chromatograph as mentioned above but equipped with a Carbopac™ MA1 column (Dionex), as described previously (Laureys and De Vuyst 2014).

The concentrations of ethanol were measured through gas chromatography with flame ionization detection (GC-FID) with a Focus gas chromatograph (Interscience, Breda, The Netherlands) equipped with a Stabilwax-DA column (Restek, Bellefonte, PA, USA) coupled to a flame ionization detector (Interscience), as described previously (Laureys and De Vuyst 2014).

The volatile aroma compounds in the headspace of the water kefir liquors were determined through static headspace gas chromatography with mass spectrometry (SH-GC-MS) detection by means of an Agilent 6890 chromatograph equipped with a DB-WAXetr column coupled to an Agilent 5973N mass spectrometer (Agilent Technologies, Santa Clara, CA, USA), as described previously (Laureys and De Vuyst 2014).

Results

Water kefir grain mass and pH

The water kefir grains used to start the industrial water kefir production process described in the present study were small, and their structure was damaged when compared to water kefir grains from a household water kefir fermentation process (Fig. 1). The water kefir grain wet mass remained stable at 5.0 kg during all prefermentations, the K1 process, the KR period, and the K2 process. Thus, the water kefir grain growth was nihil during all these fermentation periods.

During the first 2 days of the K1 and K2 processes, the pH decreased fast from 5.88 ± 0.05 to 3.76 ± 0.03, followed by a slower decrease until pH 3.54 ± 0.03 after 3 days of fermentation (Fig. 2b). During the KR period, the pH decreased slower and reached values of 4.6 ± 0.01 and 3.30 ± 0.01 after 1 and 5 days of fermentation, respectively.

pH, substrate consumption, and metabolite production as a function of time during an industrial water kefir production process consisting of a first water kefir fermentation process K1, a rest period KR, and a second water kefir fermentation process K2. a Sucrose (triangles), glucose (squares), and fructose (diamonds). b pH (circles), ethanol (squares), and lactic acid (triangles). c Glycerol (diamonds), mannitol (squares), and acetic acid (circles). d Isoamyl alcohol (circles), 2-methyl-1-propanol (squares), and ethyl acetate (diamonds)

Microbial enumerations

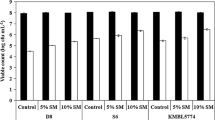

The viable counts of the LAB, AAB, and yeasts on the water kefir grains remained stable throughout the K1 process, the KR period, and the K2 process, at levels of 7.7 ± 0.5, 5.2 ± 0.5, and 7.1 ± 0.4 log CFU g−1, respectively. In the water kefir liquors, these LAB, AAB, and yeast viable counts remained more or less stable as well, at levels of 7.1 ± 0.3, 5.2 ± 0.4, and 6.1 ± 0.3 log CFU ml−1, respectively. The averages of the ratios of the viable counts of the LAB to those of the yeasts were 4.0 ± 1.9 on the water kefir grains and 11.0 ± 2.6 in the water kefir liquors. The ratios of the viable counts on the water kefir grains to those in the water kefir liquors were 3.3 ± 2.6, 1.4 ± 4.4, and 9.6 ± 2.2 for the LAB, AAB, and yeasts, respectively.

Culture-dependent microbial species diversity and community dynamics

The culture-dependent microbial species diversity and community dynamics in the water kefir liquors were more or less similar to those on the water kefir grains (Fig. 3). Furthermore, they remained more or less stable during the K1 process, the KR period, and the K2 process.

Culture-dependent species diversity of the water kefir liquors and water kefir grains of an industrial water kefir production process consisting of a first fermentation process (K1), a rest period (KR), and a second fermentation process (K2). The closest relatives to the sequenced fragments are given. a MRS agar media isolates: Lactobacillus paracasei (99% identity, accession no. AP012541) (1), Lactobacillus nagelii (99% identity, accession no. NR112754) (2), Leuconostoc mesenteroides (99% identity, accession no. LC071839) (3), Lactobacillus satsumensis (99% identity, accession no. NR028658) (4), Gluconobacter cerinus (99% identity, accession no. NR118192) (5), Gluconobacter roseus/oxydans (99% identity, accession no. NR041049/NR026118) (6), and Acetobacter orientalis (98% identity, accession no. NR113852) (7). b mDMS agar media isolates: Lb . paracasei (99% identity, accession no. AP012541) (1), G. roseus/oxydans (99% identity, accession no. NR041049/NR026118) (2), Gluconobacter cerinus (99% identity, accession no. NR118192) (3), Acetobacter okinawensis (99% identity, accession no. NR113546) (4), and A. orientalis (98% identity, accession no. NR113852) (5). c YG agar media isolates: Saccharomyces cerevisiae [LSU (99% identity, accession no. KC881066) and ITS (100% identity, accession no. KC881067)] (1), Zygotorulaspora florentina [LSU (100% identity, accession no. U72165) and ITS (100% identity, accession no. AY046168)] (2), Dekkera anomala [LSU (99% identity, accession no. AY969052) and ITS (99% identity, accession no. AF043510)] (3), Candida boidinii [LSU (99% identity, accession no. JQ689009) and ITS (100% identity, accession no. KM384039)] (4), Pichia membranifaciens [LSU (99% identity, accession no. NG042444) and ITS (100% identity, accession no. NR111195)] (5), and Wickerhamomyces anomalus [LSU (100% identity, accession no. U74592) and ITS (99% identity, accession no. NR111210)] (6)

The main LAB species recovered from the MRS agar media (Fig. 3a) were Lb. paracasei, Lb. nagelii, and Leuconostoc mesenteroides. Additionally, Lactobacillus satsumensis was found in the water kefir liquors of the K1 process and the KR period. The main AAB species recovered from the mDMS agar media (Fig. 3b) were Gluconobacter roseus/oxydans and Gluconobacter cerinus, besides low abundances of Acetobacter okinawensis and Acetobacter orientalis. The main yeast species recovered from the YG agar media (Fig. 3c) were S. cerevisiae, Zygotorulaspora florentina, Dekkera anomala, and Candida boidinii, next to low abundances of Pichia membranifaciens and Wickerhamomyces anomalus.

Culture-independent species diversity and community dynamics

The main bands in the rRNA-PCR-DGGE community profiles obtained with the V3 primer pair for the water kefir grains were attributed to Lb. paracasei, Lb. hilgardii/diolivorans, Lb. nagelii, L. mesenteroides, B. aquikefiri, and the taxon Acetobacteraceae (Fig. 4). However, the relative intensities of the bands attributed to Lb. hilgardii/diolivorans and L. mesenteroides decreased, whereas those of the bands attributed to Lb. nagelii and B. aquikefiri increased over the K1 process, the KR period, and the K2 process. The relative intensities of the bands attributed to Lb. paracasei remained stable over these three periods. The results for the LAB were confirmed by the rRNA-PCR-DGGE community profiles obtained with the LAC primer pair. The presence of B. aquikefiri (100% identity, accession no. LN849254) was confirmed by the rRNA-PCR-DGGE community profiles obtained with the Bif primer pair. The only band in the rRNA-PCR-DGGE community profiles obtained with the Yeast primer pair was attributed to S. cerevisiae. Its relative intensity remained stable over the three periods.

PCR-DGGE community profiles of the water kefir grains of an industrial water kefir production process consisting of a first fermentation process (K1), a rest period (KR), and a second fermentation process (K2), obtained with the V3 primer pair. The numbers indicate the bands that have been sequenced: Lactobacillus nagelii/ghanensis (99% identity, accession no. NR112754/NR043896) (1), Bifidobacterium aquikefiri (100% identity, accession no. LN849254) (2), Lactobacillus hilgardii/diolivorans (100% identity; accession no. LC064898/NR037004) (3), Lactobacillus paracasei/casei/zeae/rhamnosus (99% identity, accession no. AP012541/AP012544/NR037122/JQ580982) (4), Leuconostoc mesenteroides/pseudomesenteroides (99% identity, accession no. LC071839/LC096220) (5), and Acetobacteraceae (100% identity) (6)

Substrate consumption and metabolite production profiles

The total residual carbohydrate concentrations at the start of the K1 and K2 processes were 234 ± 2 and 222 ± 1 g l−1, respectively, and those at the end of these processes were 221 ± 3 and 228 ± 2 g l−1, respectively (Fig. 2). Those in the KR period were 152 ± 1 and 148 ± 1 g l−1 after 1 and 5 days of fermentation, respectively. Sucrose remained the main carbohydrate during the K1 process, the KR period, and the K2 process. The sucrose consumption and metabolite production was slower at the start of the K2 process than at that of the K1 process. The main metabolites produced during the K1 process, the KR period, and the K2 process were ethanol, lactic acid, glycerol, mannitol, and acetic acid. Mannitol production started slowly but increased as the fructose concentration increased upon progress of the water kefir fermentation process. The ethanol concentrations at the end of the K1 process, the KR period, and the K2 process were 3.28 ± 0.02, 2.14 ± 0.05, and 4.35 ± 0.01 g l−1, respectively, and the lactic acid concentrations were 1.20 ± 0.01, 0.74 ± 0.01, and 1.48 ± 0.01 g l−1, respectively. The only aroma compounds found in the water kefir liquors were ethyl acetate, isoamyl alcohol, and 2-methyl-1-propanol. The production profiles of these aroma compounds paralleled that of ethanol (Fig. 2).

Discussion

This study dealt with the analysis of an industrial water kefir fermentation process suffering from poor water kefir grain growth and instability. The water kefir grain inoculum used by the company was stored frozen at −20 °C, and after thawing, three prefermentations were performed to reactivate the water kefir grains. This was followed by the actual water kefir production process that consisted of a first water kefir fermentation process (K1), a rest period carried out at a lower temperature than the fermentation temperature (KR), and a second water kefir fermentation process (K2). The water kefir grain growth remained zero throughout all prefermentations and fermentation processes. This might have been caused by freezing and thawing of the water kefir grains. Indeed, visual inspection of the water kefir grains used for the production process revealed that their structure was damaged compared with water kefir grains from a household water kefir fermentation process. Furthermore, there were no signs that the damage to the water kefir grains restored over the course of the prefermentations or the water kefir production process. This was in line with literature data that indicate that freezing and thawing damages water kefir grains irreversibly, after which they do not recover their original structure nor do they display water kefir grain growth even not after six backslopping steps (Gulitz 2013). Water kefir grains contain around 86% (m/m) water (Laureys and De Vuyst 2014), and the growth of ice crystals during a freezing process may damage the polysaccharide structure of the water kefir grains and/or the cell envelope of the water kefir microorganisms. This damage might have been to such an extent that the microbial communities do not function properly anymore, causing sluggish water kefir fermentation. Quick freezing of fresh viable water kefir grains in liquid nitrogen followed by a freeze-drying process is a more suitable technique for their storage (Gulitz 2013).

During the water kefir production process studied, the pH decreased as expected (from pH 5.0–6.0 to pH 3.4–3.6 after 3 days of fermentation). However, the concentrations of lactic acid and acetic acid were only approximately 1.2 and 0.4 g l−1, respectively, whereas they are commonly around 3.0 and 1.0 g l−1, respectively (Laureys and De Vuyst 2014). The low pH values at these low lactic acid and acetic acid concentrations were probably caused by the use of demineralized water during the industrial water kefir production process. Demineralization of water removes most salts, whereby the buffer capacity (hardness) of the water decreases and hence causing a larger pH decrease than normal for a certain level of acid production. During the rest period, the pH decreased even toward 3.3, and such low pH values are associated with low water kefir grain growth (Laureys and De Vuyst, unpublished data).

Low water kefir grain growth has been associated with high viable counts on the water kefir grains (Laureys and De Vuyst, unpublished data). The viable counts of the LAB and yeasts on the water kefir grains of the water kefir production process of the present study were slightly lower than those reported in the literature (Laureys and De Vuyst 2014). Nevertheless, the ratios of the viable counts of the LAB to those of the yeasts (in the water kefir liquors and on the water kefir grains) and the ratios of the viable counts on the water kefir grains to those in the water kefir liquors (for the LAB and yeasts) were in line with previous results (Laureys and De Vuyst 2014). The aerobic fermentation conditions during the industrial water kefir production process studied explained the high viable counts of AAB in the water kefir liquors and on the water kefir grains. However, the effect of oxygen on the characteristics of water kefir fermentation has not been studied yet. Thus, it cannot be excluded that oxygen may have an influence on the LAB and/or yeasts during water kefir fermentation.

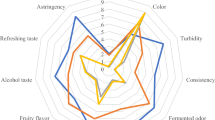

Despite the inoculation of the fermentations with high amounts of water kefir grains that contained more or less normal viable counts of water kefir microorganisms, the water kefir fermentation processes of the present study progressed slowly compared to those described in the literature (Gulitz et al. 2011; Laureys and De Vuyst 2014). Indeed, only a small part of the sucrose was converted into glucose, fructose, exopolysaccharides, and metabolites. This can be explained by the high carbohydrate concentrations used during the industrial fermentation process studied, which may have caused substrate inhibition or excessive osmotic pressure both preventing a normal functioning of the water kefir microbiota (D’Amore et al. 1988), among which exopolysaccharide production (Hehre 1946). The lag phase at the start of the K2 process was probably caused by prolonged fermentation at 8 °C during the preceding rest period. An apparent increase of the total residual carbohydrate concentration during the K2 process could be explained by the diffusion of carbohydrates from the dried figs into the water, as dried figs contain around 48% (m/m) carbohydrates (release 26, http://ndb.nal.usda.gov/). Glucose seemed to be the preferred substrate for metabolite production during fermentation, because its concentrations increased slower compared to those of fructose, indicating faster consumption of glucose than fructose. The sole aroma compounds found in the water kefir liquors were isoamyl alcohol, 2-methyl-1-propanol, and ethyl acetate. The esters ethyl hexanoate, ethyl octanoate, ethyl decanoate, and isoamyl acetate, which might be responsible for the fruity aroma of water kefir beverages, were not found in the water kefir liquors produced by the industrial water kefir production process studied.

The key microorganisms prevailing during water kefir fermentation, namely Lb. paracasei, Lb. nagelii, and S. cerevisiae, were present throughout the whole industrial water kefir production process studied, as revealed by both culture-dependent and culture-independent species diversity analyses (Laureys and De Vuyst, unpublished data). In contrast, the key microorganism Lb. hilgardii, which is thought to be responsible for water kefir grain growth, was only found through culture-independent analyses, whereby its relative abundances decreased over the course of the production process. Hence, in contrast with the cells of the other key microorganisms, those of Lb. hilgardii might have been damaged by the freezing and thawing process, compromising the viability of this LAB species during water kefir fermentation, as has been shown before (Gulitz 2013). Apart from these key microorganisms, L. mesenteroides, B. aquikefiri, G. roseus/oxydans, G. cerinus, and Z. florentinus were present, which have all been found in water kefir fermentations before (Gulitz et al. 2011, 2013; Gulitz 2013; Laureys and De Vuyst 2014; Pidoux 1989). The relative abundances of the bifidobacterial species increased as a function of time, confirming that this microorganism is not sensitive to oxygen or acidic stress (Laureys et al. 2016).

In conclusion, the industrial water kefir production process studied performed poorly. The structure of the industrial water kefir grains that were frozen and thawed was damaged in comparison with that of the grains of a household water kefir fermentation process. The substrate concentrations were very high in comparison with those of common water kefir fermentation processes. Only a small part of the substrate was converted into metabolites and water kefir grain wet mass. Demineralized water should be supplemented with a buffer to avoid excessive acidic stress during water kefir fermentation. Prolonged fermentation at low temperature during a rest period should also be avoided, as this resulted in a lag phase during the subsequent water kefir fermentation process.

References

Altschul SF, Gish W, Miller W, Myers EW, Lipman DJ (1990) Basic local alignment search tool. J Mol Biol 215:403–410

Cocolin L, Bisson LF, Mills DA (2000) Direct profiling of the yeast dynamics in wine fermentations. FEMS Microbiol Lett 189:81–87

D’Amore T, Panchal CJ, Russeil I, Stewart GG (1988) Osmotic pressure effects and intracellular accumulation of ethanol in yeast during fermentation. J Ind Microbiol Biotechnol 2:365–372

Edwards U, Rogall T, Blocker H, Emde M, Bottger EC (1989) Isolation and direct complete nucleotide determination of entire genes—characterization of a gene coding for 16S-ribosomal RNA. Nucleic Acids Res 17:7843–7853

Ercolini D, Moschetti G, Blaiotta G, Coppola S (2001) Behavior of variable V3 region from 16S rDNA of lactic acid bacteria in denaturing gradient gel electrophoresis. Curr Microbiol 42:199–202

Franzetti L, Galli A, Pagani MA, De Noni I (1998) Microbiological and chemical investigations on “sugar kefir” drink. Ann Microbiol Enzimol 48:67–80

Garcia-Armisen T, Papalexandratou Z, Hendryckx H, Camu N, Vrancken G, De Vuyst L, Cornelis P (2010) Diversity of the total bacterial community associated with Ghanaian and Brazilian cocoa bean fermentation samples as revealed by a 16S rRNA gene clone library. Appl Microbiol Biotechnol 87:2281–2292

Gulitz A, Stadie J, Ehrmann MA, Ludwig W, Vogel RF (2013) Comparative phylobiomic analysis of the bacterial community of water kefir by 16S rRNA gene amplicon sequencing and ARDRA analysis. J Appl Microbiol 114:1082–1091

Gulitz A, Stadie J, Wenning M, Ehrmann MA, Vogel RF (2011) The microbial diversity of water kefir. Int J Food Microbiol 151:284–288

Gulitz AJ (2013) Analysis of the diversity of water kefir microbiota by culture-dependent and -independent approaches. Dissertation, Technischen Universität Munchen

Hehre EJ (1946) Studies on the enzymatic synthesis of dextran from sucrose. J Biol Chem 163:221–233

Janssens M, Myter N, De Vuyst L, Leroy F (2012) Species diversity and metabolic impact of the microbiota are low in spontaneously acidified Belgian sausages with an added starter culture of Staphylococcus carnosus. Food Microbiol 29:167–177

Laureys D, Cnockaert M, De Vuyst L, Vandamme P (2016) Bifidobacterium aquikefiri sp. nov. isolated from water kefir. Int J Syst Evol Microbiol 66:1281–1286

Laureys D, De Vuyst L (2014) Microbial species diversity, community dynamics, and metabolite kinetics of water kefir fermentation. Appl Environ Microbiol 80:2564–2572

Marsh AJ, Hill C, Ross RP, Cotter PD (2014) Fermented beverages with health-promoting potential: past and future perspectives. Trends Food Sci Technol 38:113–124

Marsh AJ, O’Sullivan O, Hill C, Ross RP, Cotter PD (2013) Sequence-based analysis of the microbial composition of water kefir from multiple sources. FEMS Microbiol Lett 348:79–85

Moinas M, Horisberger M, Bauer H (1980) The structural organization of the Tibi grain as revealed by light, scanning and transmission microscopy. Arch Microbiol 128:157–161

Papalexandratou Z, Falony G, Romanens E, Jimenez JC, Amores F, Daniel HM, De Vuyst L (2011) Species diversity, community dynamics, and metabolite kinetics of the microbiota associated with traditional Ecuadorian spontaneous cocoa bean fermentations. Appl Environ Microbiol 77:7698–7714

Papalexandratou Z, Lefeber T, Bahrim B, Lee OS, Daniel HM, De Vuyst L (2013) Hanseniaspora opuntiae, Saccharomyces cerevisiae, Lactobacillus fermentum, and Acetobacter pasteurianus predominate during well-performed Malaysian cocoa bean box fermentations, underlining the importance of these microbial species for a successful cocoa bean fermentation process. Food Microbiol 35:73–85

Pidoux M (1989) The microbial flora of sugary kefir grain (the gingerbeer plant): biosynthesis of the grain from Lactobacillus hilgardii producing a polysaccharide gel. J Appl Microbiol 5:223–238

Pothakos V, Illeghems K, Laureys D, Spitaels F, Vandamme P, De Vuyst L (2016) Acetic acid bacteria in fermented food and beverage ecosystems. In: Matsushita K, Toyama H, Tonouchi N, Okamoto-Kainuma A (eds) Acetic acid bacteria: ecology and physiology. Springer, Tokyo, pp 73–100

Satokari RM, Vaughan EE, Akkermans ADL, Saarela M, de Vos WM (2001) Bifidobacterial diversity in human feces detected by genus-specific PCR and denaturing gradient gel electrophoresis. Appl Environ Microbiol 67:504–513

Vilgalys R, Hester M (1990) Rapid genetic identification and mapping of enzymatically amplified ribosomal DNA from several Cryptococcus species. J Bacteriol 172:4238–4246

White T, Buns T, Lee S, Taylor J (1990) Amplification and direct sequencing of fungal ribosomal RNA genes for phylogenetics. In: Innis N, Gelfand D, Snisky J, White T (eds) PCR protocols: a guide to methods and applications. Academic Press, NY, pp 315–322

Acknowledgements

The authors acknowledge their financial support of the Research Council of the Vrije Universiteit Brussel (SRP, IRP, and IOF projects), the Hercules Foundation, the Research Foundation-Flanders (FWO-Vlaanderen), and the KMO-portefeuille (Agentschap Ondernemen). DL was the recipient of a PhD fellowship of the Vrije Universiteit Brussel.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This paper does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Laureys, D., Van Jean, A., Dumont, J. et al. Investigation of the instability and low water kefir grain growth during an industrial water kefir fermentation process. Appl Microbiol Biotechnol 101, 2811–2819 (2017). https://doi.org/10.1007/s00253-016-8084-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-016-8084-5