Abstract

Steroid C25 dehydrogenase (S25DH) from Sterolibacterium denitrificans Chol-1S is a molybdenum oxidoreductase belonging to the so-called ethylbenzene dehydrogenase (EBDH)-like subclass of DMSO reductases capable of the regioselective hydroxylation of cholesterol or cholecalciferol to 25-hydroxy products. Both products are important biologically active molecules: 25-hydroxycholesterol is responsible for a complex regulatory function in the immunological system, while 25-hydroxycholecalciferol (calcifediol) is the activated form of vitamin D3 used in the treatment of rickets and other calcium disorders. Studies revealed that the optimal enzymatic synthesis proceeds in fed-batch reactors under anaerobic conditions, with 6–9 % (w/v) 2-hydroxypropyl-β-cyclodextrin as a solubilizer and 1.25–5 % (v/v) 2-methoxyethanol as an organic co-solvent, both adjusted to the substrate type, and 8–15 mM K3[Fe(CN)6] as an electron acceptor. Such thorough optimization of the reaction conditions resulted in high product concentrations: 0.8 g/L for 25-hydroxycholesterol, 1.4 g/L for calcifediol and 2.2 g/L for 25-hydroxy-3-ketosterols. Although the purification protocol yields approximately 2.3 mg of pure S25DH from 30 g of wet cell mass (specific activity of 14 nmol min−1 mg−1), the non-purified crude extract or enzyme preparation can be readily used for the regioselective hydroxylation of both cholesterol and cholecalciferol. On the other hand, pure S25DH can be efficiently immobilized either on powder or a monolithic silica support functionalized with an organic linker providing NH2 groups for enzyme covalent binding. Although such immobilization reduced the enzyme initial activity more than twofold it extended S25DH catalytic lifetime under working conditions at least 3.5 times.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sterols are ubiquitous compounds in nature that play a range of physiological roles in all living organisms. In mammals, they are mostly used as cell membrane components, hormones, and vitamin D precursors, which leads to their wide application as pharmaceuticals. Therefore, the ability to modify their base structure and to introduce functional groups is of the utmost importance. Although traditional methods of organic chemistry in the synthesis of many steroid drugs have been successfully used with great efficiency, biocatalytic methods (being more selective and environmentally friendly) have recently attracted more attention and have been incorporated into the organic chemist’s toolbox (Brixius-Anderko et al. 2015; Donova 2007; Holland 1992; Riva 1991; Zhang et al. 2014).

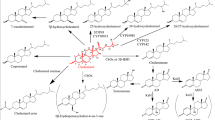

25-hydroxylated derivatives of sterols play an important role in human metabolic control and treatment of associated disorders. 25-hydroxycholesterol (25-OH-Ch) is known to perform a complex regulatory function in the immunological system by (i) controlling the differentiation of monocytes into macrophages, (ii) suppressing the production of IgA by B cells, and (iii) directing the migration of activated B cells to the germinal follicle (Bauman et al. 2009; McDonald and Russell 2010; Reboldi et al. 2014). Thus, 25-OH-Ch is proposed as a drug in diseases associated with IgA overproduction such as Berger disease (Bauman et al. 2009). Calcifediol (25-OH-D3) is an activated form of cholecalciferol (vitamin D3), an important compound introduced into the organism from dietary sources or formed in skin tissue from 7-dehydrocholesterol after sunlight UV irradiation and further activation (regioselective hydroxylation) in liver (Zhu et al. 2013). 25-OH-D3 is the main blood-circulating metabolite responsible for maintaining calcium and phosphate homeostasis. As a drug, calcifediol is much more potent than the parental vitamin D3 and therefore it is used in the treatment of rickets and other calcium disorders (Bischoff-Ferrari et al. 2012; Brandi and Minisola 2013; Jetter et al. 2014).

However, the production of sterols derivatives activated at C25 carbon atom, such as 25-OH-Ch and 25-OH-D3, is challenging, severely limiting research on 25-OH-Ch potential biomedical applications (McDonald and Russell 2010). The chemical syntheses of both compounds require a multi-step approach which poses high time and labor demands on the production and results in relatively low yields of the overall synthetic pathways (6–25 %) (Kurek-Tyrlik et al. 2005; Miyamoto et al. 1986; Ogawa et al. 2009; Riediker and Schwartz 1981; Ryznar et al. 2002; Westover and Covey 2006). The more efficient method of 25-OH-Ch synthesis (yield 60–70 %) requires an expensive starting material such as desmosterol (Zhao et al. 2014). On the other hand, the reported enzymatic methods are much more straightforward and usually involve single hydroxylation step catalyzed by P450 cytochromes (Ban et al. 2014; Yasuda et al. 2013; Yasutake et al. 2013) or a non-heme monooxygenase overproduced in transgenic plants Arabidopsis thaliana and Solanum tuberosum (Beste et al. 2011).

Steroid C25 dehydrogenase (S25DH) from β-proteobacterium Sterolibacterium denitrificans (Chol-1S), a facultative anaerobic microorganism capable of the full mineralization of cholesterol in both aerobic and anaerobic conditions (Tarlera 2003) appears to be another example of a catalyst for the regioselective hydroxylation of sterols and their derivatives. S25DH is a molybdenum enzyme belonging to the so-called ethylbenzene dehydrogenase (EBDH)-like subclass of DMSO reductases (Heider et al. 2016; Hille et al. 2014). It is a heterotrimer (αβγ, 168 ± 12 kDa) containing a bis-pyranopterin-guanine dinucleotides (MGD)-molybdenum cofactor and [4Fe-4S] cluster in the α subunit (108 kDa), four more iron-sulfur clusters in the β subunit (38 kDa) and one heme in the γ subunit (27 kDa) (Dermer and Fuchs 2012).

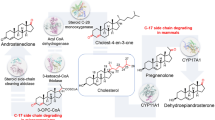

In the cholesterol degradation pathway, S25DH activates a tertiary C25 carbon atom of the cholest-4-en-3-one by introduction of the oxygen atom that originates from a water molecule, finally yielding the 25-hydroxycholest-4-en-3-one ( Chiang et al. 2007, 2008b) (Fig. 1a). Beside its native substrate, S25DH also catalyzes the regioselective hydroxylation of other 3-ketosterols, 3-hydroxysterols (e.g., cholesterol and 7-dehydrocholesterol) and cholecalciferol (Dermer and Fuchs 2012; Warnke et al. 2016) (Fig. 1b). Therefore, the enzyme can be applied in the catalytic synthesis of pharmacologically important molecules such as 25-hydroxycholesterol, 25-hydroxy-7-dehydrocholesterol (hydroxylated pro-vitamin D3, 25-OH-pro-D3), and calcifediol (25-OH-D3) (Dermer and Fuchs 2012; Szaleniec et al. 2015; Warnke et al. 2016).

Steroid C25 dehydrogenase characterization. a 25-hydroxycholest-4-en-3one synthesis scheme presenting substrate hydroxylation with simultaneous enzyme reduction (S25DHred) and further enzyme re-oxidation (S25DHox) by one of the artificial electron acceptors. b S25DH substrates chemical structures divided to 3-ketosterols, 3-hydroxysterols and others

In this work, we present extensive studies on the engineering of reaction medium, the optimization of the biocatalyst formulation and the simplified aerobic purification procedure of steroid C25 dehydrogenase from S. denitrificans. To apply S25DH for hydroxylation of sterols, cholecalciferol, or ergocalciferol (Fig. 1b), the following obstacles had to be overcome: (i) the low solubility of hydrophobic reagents in aqueous medium, (ii) the sensitivity of S25DH to oxygen, (iii) the high cost of enzyme purification, (iv) the low hydroxylation rate of 3-hydroxysterols (such as cholesterol) compared to 3-ketosterols (such as cholest-4-en-3-one), and (v) the limitation of the reaction conversion by the availability of enzyme re-oxidant. Here, we provide the results of a stepwise optimization of the reaction conditions that addresses these issues. Moreover, to demonstrate a real application potential of S25DH, we conducted the syntheses of 25-OH-Ch and 25-OH-D3 in fed-batch reactors using either pure enzyme or enzyme preparation. The syntheses of 25-hydroxy 3-ketosterols were carried out in fed-batch reactors systems using either the homogenous or immobilized enzyme. We also tested a plug flow reactor thus broadening the scope of reaction systems and introducing a possibility of switching from a batch process to a continuous one.

Methods

Materials and bacterial strain

All chemicals of analytical grade were purchased from Sigma-Aldrich (Poland), Avantor Performance Materials (Poland), GE Healthcare (USA) or Carbosynth Ltd. (UK). Cholest-1,4-dien-3-one was synthesized according to Barton’s protocol (Iida et al. 1988) (melting point: 99–101 °C, lit. 97–100 °C (Czarny et al. 1977)), while cholesteryl succinate Tris salt was prepared according to Bildziukevich’s protocol (Bildziukevich et al. 2013) (melting point of acid: 174–176 °C, lit. 176–177 °C (Carvalho et al. 2010)). S. denitrificans Chol-1S (DSMZ 13999) was purchased from the Deutsche Sammlung fur Mikroorganismen und Zellkulturen GmbH (Braunschweig, Germany).

Cultivation of bacteria

Sterolibacterium denitrificans was grown on cholesterol as a sole carbon source at 30 °C under anoxic, denitrifying conditions as previously described (Chiang et al. 2008b; Tarlera 2003). Large-scale fermenter cultures (100–150 L) were conducted according to a previously described procedure (Chiang et al. 2007) with the automatic measurement of pH and supplementation of 1 M sulfuric acid. The fermentations were conducted in the facility of the Department of Biotechnology and Food Microbiology, University of Life Sciences in Poznan, Poland. Cells were harvested by centrifugation during the exponential growth phase at an optical density of 0.8–1.0 and stored at −80 °C.

Aerobic enzyme purification

The S25DH was purified from S. denitrificans according to a modified protocol (Dermer and Fuchs 2012) under aerobic conditions. Briefly, the procedure comprised four steps: (i) cell extract solubilization, (ii) ion-exchange separation on DEAE-Sepharose, (iii) ion-exchange separation on Q-Sepharose, and (iv) affinity separation on Reactive Red 120 (see Table S1). The active pool after (i) is referred to as “crude enzyme,” after (ii) as “enzyme preparation,” and after (iv) as “pure enzyme.” Details of the purification procedure were provided in the Supplementary Material.

Enzyme immobilization

The immobilization of pure S25DH was conducted on four types of support: (i) Granocel and commercial cellulose; (ii) mesostructured cellular foam (MCF), SBA15, and SBA15-ultra (Santa Barbara Amorphous) silica powder carriers with amino groups; (iii) Eupergit® C; and (iv) silica monoliths with amino groups (see Table S2 for BET surface characterization). Briefly, the immobilization procedure advanced along the following steps: (i) carrier activation (if needed), (ii) rinsing of the activator, (iii) binding of S25DH in the presence of a protective re-oxidant (K3[Fe(CN)6]), and (iv) end-capping of the still-free active surface groups with Tris. All eluates were collected and analyzed for the presence of the unbound protein and S25DH activity. The amount of protein bound to a carrier was calculated as the difference between the amount of the protein used for the immobilization and the amount of unbound protein. The initial activity of the immobilized biocatalysts was determined in an HPLC assay for the first 3 h of reaction in the batch system. The activity recovery (AR) was calculated as a ratio of the specific activities [mU/mg of enzyme] measured for the immobilized and the free enzyme. A description of the carrier syntheses and functionalizations, as well as a detailed description of the protein immobilization protocols, were provided in the Supplementary Material.

S25DH activity assay

The standard reaction assay was prepared in a 0.4-mL sample probe containing 280 mM KH2PO4/K2HPO4 pH 7.0 buffer, 12.5 mM K3[Fe(CN)6] as an electron acceptor, 8 % (w/v) 2-hydroxypropyl-β-cyclodextrin (HBC) as a solubilizer, 1.25 % (v/v) 2-methoxyethanol (EGME) as an organic co-solvent and substrate stock solution, containing app. 0.25 g/L of sterol substrate (C3-ketone, C3-alcohol, C3-ester, or cholecalciferol) and S25DH (in an amount differing depending on the substrate type and the purity of the enzyme). The reactions were carried out under anaerobic conditions at 30 °C in a thermoblock shaker at 800 rpm. As in each reaction cycle two equivalent protons are released to the reaction medium, the elevated concentration of the buffer (i.e., 280 mM) was used in order to maintain a stable pH during the prolonged reaction runs (up to 1 month).

The tests with immobilized S25DH were conducted at a 10-fold higher scale (4 mL), where 0.5 mL of the immobilized enzyme suspension was used as a catalyst.

UV-Vis detection of activity

The activity was measured spectrophotometrically at 290 nm, 30 °C in a 0.4-mL quartz cuvette with 200 μM ferrocenium tetrafluoroborate (Δε = 6218.9 M−1 cm−1) as an electron acceptor. The initial substrate concentration was 0.25 g/L, and the pure enzyme concentration was 0.625 μg/mL. The tests were conducted in triplicate. The assay was used in the optimization of reaction conditions for cholest-4-en-3-one, where the HBC content was tested in the range of 8–20 % (w/v) and EGME in the range of 1.25–10 % (v/v).

HPLC detection of activity

The reagent concentrations in the reactors were monitored over time by the collection of 10-μL samples. The reactions were stopped by the addition of the sample to 10 μL of isopropanol and 1 μL of a saturated solution of FeSO4. The precipitated enzyme and electron acceptor were centrifuged (25,000g, 15 min), and the sample was transferred to a glass vial for LC-MS analysis. Samples were analyzed with RP-HPLC-DAD-MS on an Ascentis® Express RP-Amide column (2.7 μm, 7.5 cm × 4.6 mm, 1 mL/min) using the gradient method 55–98 % acetonitrile/H2O/10 mM NH4CH3COO (DAD/(+)-ESI-MS) for C3-ketones and cholecalciferol and 95–98 % acetonitrile/H2O/0.01 % HCOOH for C3-alcohols and esters (DAD/(+)-APCI-MS). The quantitative analysis was conducted with a DAD detector (240 nm for cholest-4-en-3-one and cholest-1,4-dine-3-one, 265 nm for cholecalciferol and ergocalciferol, 280 nm for 7-dehydrocholesterol, and 205 nm for cholesterol and cholesteryl succinate). The hydroxylation of the product was confirmed by MS spectroscopy (Table S4) by the detection of the characteristic quasi-molecular signals corresponding to the masses of the product [M + H]+ or [M + K]+ higher by 16 m/z than the respective quasi-molecular signals of the substrate or characteristic of product fragmentation signals (e.g., [M + H − H2O]+).

Reactor systems (batch, fed-batch, plug flow)

Optimization of the reactor conditions for cholecalciferol and cholesterol were carried out under anaerobic conditions in 20 and 2 mL volumes, respectively. The reactor contents comprised the enzyme preparation (15.5 and 1.15 mL, respectively; C = 1.01 mg/mL, specific activity (SA) = 1.34 mU/mg) as a catalyst and reaction buffer, 12.5 mM K3[Fe(CN)6] and varied amounts of EGME with substrate (1.25–5 % (v/v), substrate stock concentration: 20.2 g/L for cholecalciferol, 12.8 g/L for cholesterol) and HBC (1–12 % (w/v) for cholecalciferol, 4–16 % (w/v) for cholesterol). Increased amounts of EGME (1.25, 2.5, and 5 % (v/v)) resulted in increased loadings of cholecalciferol (0.25, 0.5, and 1 g/L, respectively) or cholesterol (0.16, 0.32, and 0.64 g/L, respectively).

The 12 different reactions (four tests with replicates) with cholecalciferol were carried out in glass bottles fitted with magnetic stirring bars (500 rpm) at 25–30 °C. The 12 different reactions (6 reactors with replicates) with cholesterol were carried out in 2-mL probes in a thermoblock (800 rpm, 30 °C). The average volume activity (VA) for each reactor was calculated from the first 24 or 15.5 h of the reaction (for cholesterol or cholecalciferol, respectively) and presented as the 3D contour plots in STATISTICAv10 (StatSoft) using a distance-weighted least squares fitting for non-linear interpolation (Neter et al. 1985).

In fed-batch mode, the substrate and electron acceptor were supplemented by the addition of substrate in EGME (20 g/L stock solution) or K3[Fe(CN)6] (1 M stock solution) whenever an HPLC analysis showed a low level of the substrate (<0.05 g/L) or a UV-Vis measurement (Abs 420 nm, ε = 1040 M−1 cm−1) showed a low concentration of the re-oxidant.

Reactors with electrochemical recovery of re-oxidant

The reactions with the electrochemical recovery of the re-oxidant were carried out in anaerobic conditions in batch reactors fitted with an electrochemical system, as previously described (Tataruch et al. 2014).

Plug flow reactor

The reactions in 1.5-mL monolithic silica plug flow reactors (Szymanska et al. 2013) were conducted in anaerobic conditions using cholest-1,4-dien-3-one (0.23 g/L) as a substrate in 280 mM buffer K2HPO4/KH2PO4 pH 7.0 containing 8 % (w/v) HBC, 1.25 % (v/v) EGME, and 12.5 mM K3[Fe(CN)6]. Next, 10 mL of the reaction mixture was pumped through the reactor at a 0.1 mL/min flow rate. The reagent concentrations were determined by HPLC at the end of the reactor. After each pass through the reactor, the reaction mixture was collected for the next pass. Altogether, the reactor was tested across 7 days time with six passages of the reaction mixture.

Product separation

The reaction mixtures were extracted with ethyl acetate (3 × 0.25 of reaction medium volume). The combined extracts were washed with saturated KClaq, dried over anhydrous magnesium sulfate and evaporated under reduced pressure. The obtained residue was purified using column chromatography on silica with ethyl acetate: hexane (1:1).

Results

Low solubility of hydrophobic substrates in aqueous medium

The composition of the reaction mixture was optimized to achieve the highest possible hydroxylation rate of sterols and their derivatives by S25DH with simultaneous minimization of the required HBC and organic solvent content. The total replacement of HBC in sterol solubilization was reported as difficult (Dermer and Fuchs 2012; Warnke et al. 2016). Indeed, the employment of other solubilizers, such as N-dodecyl-D-beta-maltoside (DDM), CHAPS (3-[(3-cholamidopropyl)dimethylammonio]-1-propanosulfonian) or saponins resulted in a significant decrease in product conversion (data not shown). As β-cyclodextrin was reported to be a better sterol solubilizer than the α- and γ-forms (Seung-Kwon et al. 2002), we compared three different β-cyclodextrin derivatives, i.e., 2-hydroxypropyl-, methyl-, and unmodified β-cyclodextrin. The HBC proved to be the best solubilizer, as the reaction in methyl-β-cyclodextrin proceeded two times slower for cholest-4-en-3-one (both reactors with 8 % (w/v) solubilizer content), while the reaction with unmodified β-cyclodextrin proceeded four times slower for cholest-4-en-3-one and 2.5 times slower for cholecalciferol (reactor with saturated 2 % (w/v) solubilizer content compared with 8 % (w/v) HBC). Despite the slower initial activity observed for methyl-β-cyclodextrin with respect to HBC, in both reactions the final conversion reached 100 % (after 5 vs. 12 h, respectively for 2-propyl- and methyl-β-cyclodextrin) (Fig. S1 of Supplementary Material). Meanwhile, the conversion in reactors with unmodified β-cyclodextrin reached only 5–8 % (Fig. S2 of Supplementary Material).

Despite the presence of solubilizer a small content of organic solvent (at least 1 %) for introduction of sterol into the reaction mixture is always required. The previously established S25DH assay was based on 20 % (w/v) HBC and 1.25 % (v/v) 1,4-dioxane (Dermer and Fuchs 2012). We tested S25DH activity with UV-Vis assay in other organic solvents for compatibility with S25DH such as tert-butanol, 2-propanol, methanol, ethanol, 1,2-propanodiol and 2-methoxyethanol (ethylene glycol monomethyl ether (EGME)) (data not shown). Above all, EGME proved to be the most efficient substitute of 1,4-dioxane. We determined S25DH initial activity in cholest-4-en-3-one hydroxylation (constant substrate concentration) with different HBC and EGME content (Fig. 2a). Hence, S25DH reaction rate turned out to be dependent on the sterol solubility in the reaction medium (lower range of HBC/EGME concentration) and putative substrate sequestration by the multiple-HBC complexes (Yamamoto et al. 2005) (upper HBC range) together with the detrimental influence of the organic solvent on the enzyme activity (EGME upper range). Notably, in the presence of EGME, the content of HBC could be reduced from 20 % (w/v) to 8 % (w/v) without cholest-4-en-3-one precipitation from the solution. This, in turn, increased the observed initial S25DH activity threefold (reaction with 8 % (w/v) HBC and 1.25 % (v/v) EGME compared to the assay with 20 % (w/v) HBC and 1.25 % (v/v) 1,4-dioxane). Reaction mixture with 8 % (w/v) HBC and 1.25 % (v/v) EGME was found as the most favorable for hydroxylation of cholest-4-en-3-one, although the enzyme tolerated EGME levels up to 5 % (v/v).

Reaction medium optimization for cholest-4-en-3-one. a Initial volume activity VAinit of S25DH as a function of HBC and EGME contents. In all tests, the substrate concentration was 0.25 g/L. b Progress curves for cholest-4-en-3-one (squares) to 25-OH-product (circles) conversions for reaction mixture with 1.25 % (v/v) 1,4-dioxane (black, solid line) and EGME (blue, dashed line). In both experiments, the other conditions, including the amount of S25DH enzyme (SA 15 mU/mg), were identical

Subsequently, the selected optimal medium conditions utilizing EGME was compared to previously described conditions utilizing 1,4-dioxane in the experiment employing two parallel reactors with the same enzyme and initial cholest-4-en-3-one concentrations (Fig. 2b). Again, the change of solubilizer content and organic co-solvent type resulted in a significantly higher conversion rate after 4 h of reaction, i.e., 31 % for reactor with EGME and 18 % for reactor with 1,4-dioxane. Moreover, a better dissolution of the substrate was achieved in reactor with EGME (respectively, 0.3 and 0.25 g/L), despite the same substrate concentration in the organic stock solutions.

As the substrates of interest differ in hydrophobicity (log P for cholesterol 8.7, cholest-4-en-3-one 8.4 and cholecalciferol 7.9 – XLogP, PubChem DataBase), the HBC and EGME content in the S25DH reaction mixture were optimized individually for each substrate. Furthermore, as the reported apparent K m values for S25DH are relatively high (in the range of 0.4–0.8 mM) (Warnke et al. 2016), the increased substrate loading of the reactors has a significant impact on the observed reaction rate. Therefore, the increased EGME content was combined with the increase of substrate concentration. The optimal reaction conditions were determined using the average volume activity (VA) from the first 24 or 15.5 h of cholesterol or cholecalciferol hydroxylation in batch reactors.

For cholecalciferol (Fig. 3a), the optimum reaction medium conditions were found to be 6–8 % (w/v) HBC and 5 % (v/v) EGME while for cholesterol (Fig. 3b): 6–9 % (w/v) HBC and 2.5 % (v/v) EGME. Initial substrate concentrations reached 0.52 g/L for cholecalciferol and 0.32 g/L for cholesterol, respectively.

Aerobic vs. anaerobic atmosphere

The enzymes of the EBDH class, including S25DH, were reported to be oxygen sensitive, especially in their reduced state (Dermer and Fuchs 2012; Szaleniec et al. 2007; Tataruch et al. 2014). Despite some contradicting reports (Warnke et al. 2016), we decided to assess the influence of an oxygen-containing atmosphere on the long-term performance of the S25DH catalyst. Two 8-mL batch reactors were prepared for the hydroxylation of 7-dehydrocholesterol: one under aerobic conditions and the other in a glove box (97 % N2/3 % H2) (Fig. 4, Fig. S3). The final product concentration in aerobic reactor reached 0.05 g/L and the enzyme was inactivated (no further change in product concentration) after approximately 48 h. Meanwhile, under anaerobic conditions, 0.15 g/L of product was reached, and the enzyme remained active for at least 150 h. A similar effect was observed for the immobilized S25DH (Fig. 4 circles), where after an initial period of an identical reaction rate (app. 24 h), the enzyme working under aerobic atmosphere lost most of its activity within 96 h, while the enzyme under anaerobic atmosphere remained active after 480 h of continuous processing. It should be underlined that in each case, the reaction progress was not limited by substrate availability, as the initial concentration of 7-dehydrocholesterol was in the range of 0.29–0.36 g/L (Fig. S3 of Supplementary Material), and the K3[Fe(CN)6] was replenished whenever it reached a low level.

Influence of oxygen-containing atmosphere on S25DH activity. Progress curves of 7-dehydrocholesterol conversions conducted in aerobic (filled symbols) and anaerobic (empty symbols) conditions for homogenous (squares, solid black line SA 0.5 mU/mg) and immobilized (SBA15-AEAPTS) pure enzyme (blue circles, dashed line SA 0.1 mU/mg)

Purity of S25DH

Two protocols for the S25DH purification described in the literature are composed of multiple steps (Dermer and Fuchs 2012; Warnke et al. 2016). However, recently it was suggested that the conversions of cholecalciferol and 7-dehydrocholesterol can be achieved with a crude enzyme preparation as a catalyst (Warnke et al. 2016). We studied three different types of S25DH: (i) crude enzyme, (ii) enzyme preparation (eluate of diethylaminoethanol (DEAE)-Sepharose column), and (iii) pure enzyme (three chromatographic steps (DEAE-Sepharose, Q-Sepharose, Reactive Red 120). Notably, the enzyme types (i) and (ii) contained cholest-4-en-3-one-Δ1-dehydrogenase (AcmB), the FAD-enzyme that in the presence of S25DH re-oxidants catalyzes oxidative dehydrogenation of 3-ketosteroids and 3-ketosterols (Chiang et al. 2008a). Nevertheless, AcmB is unable to dehydrogenate 3-hydroxy substrates such as: cholesterol, 7-dehydrocholesterol and cholecalciferol. Therefore, less pure enzyme preparations (i and ii) can be applied for the hydroxylation of 3-hydroxysterols with high conversion and selectivity (Fig. S4 Supplementary Material). Significantly, enzyme preparation (ii) is a more preferable form of a catalyst than (i) due to a lower content of other redox proteins. Such protein impurities in the enzyme preparation (ii) and especially in (i) consume re-oxidization agents ([Fe(cp)2]BF4 or K3[Fe(CN6]) in the redox side reactions. As a result, in order to avoid decreasing the reaction rate and limiting the yield by low content of re-oxidization agent, a frequent replenishment of the re-oxidant (preferably better soluble K3[Fe(CN)6]) or the application of an electrochemical recovery system is required.

Hydroxylation of different substrates

S25DH performance in a real reactor system with different substrates was never systematically surveyed before. The reported initial apparent specific activity of S25DH was 5–10 times higher in the hydroxylation of 3-ketosterols compared to that of 3-hydroxysterols (Dermer and Fuchs 2012). A series of small 0.4-mL tests in batch mode was studied with pure S25DH (Table 1 and Fig. S5 of Supplementary Material). The catalyst amount was adjusted to the reported initial activity of the substrate, i.e., lower for very active 3-keto substrates, higher for 3-hydroxy substrates. During the long reaction time, a gradual inactivation of the enzyme was observed. For 3-ketosterols, 90 % of the substrate conversion was reached in 4 h, while in the case of cholecalciferol such conversion was obtained after 2 days. For cholesterol and 7-dehydrocholesterol, the 90 % conversion was not obtained, as the enzyme was deactivated before reaching such a conversion.

Therefore, higher yields of 25-hydroxy-3-hydroxysterol were obtained by adding more of the catalyst into the reactor, e.g., doubling the amount of enzyme in the reactors with cholesterol resulted in an increase of conversion from 35 to 67 % (first part of the fed-batch reactor Fig. S6a, b). Interestingly, although the substitution of cholesterol by its succinate ester allowed a much higher loading of the batch reactor (0.92 g/L instead of 0.26 g/L), which resulted in a high yield of the product (0.5 g/L), the reaction proceeded significantly slower than in the case of cholesterol (Table 1, Fig. S6e, f of Supplementary Material). The identity of S25DH products was confirmed by LC-MS and NMR (Table S4, Fig. S10–13 of Supplementary Material) and was consistent with that to reported before (Chiang et al. 2007; Warnke et al. 2016).

Electrochemical recovery of S25DH re-oxidant

During the reaction, S25DH is reduced by a sterol substrate and then re-oxidized by an artificial electron acceptor (K3[Fe(CN)6] or [Fe(cp)2]BF4). The preliminary tests with [Fe(cp)2]BF4 indicated its interaction with a substrate solubilizer, HBC. This phenomenon was confirmed by cyclic voltammetry experiments, which showed a gradual shift of the ferrocenium potential in the HBC solution toward more positive value and a decrease of the observed current (data not shown). As no such effect was observed for K3[Fe(CN)6], it was used in the subsequent tests. The reactor experiments revealed efficient substrate hydroxylation in a broad range of K3[Fe(CN)6] concentrations (1–15 mM). However, an increase of the re-oxidant concentration above 100 mM had a detrimental effect on the S25DH activity.

To provide a steady concentration of K3[Fe(CN)6], we employed an electrochemical reactor (Fig. 5) with cholesterol as a substrate and crude enzyme as a catalyst, i.e., a low-cost catalyst that, due to the side reactions with other redox proteins, consumes more re-oxidant. Initially, at sustained high concentration of K3[Fe(CN)6], the conversion in the electrochemical reactor proceeded faster than in the control reactor without electrochemical recovery. However, after approximately 48 h, the hydroxylation rate in the electrochemical reactor decreased, and the enzyme had become inactive after 100 h. Meanwhile, the enzyme in the control reactor was able to catalyze the hydroxylation of cholesterol for 700 h, despite the gradual loss of its activity. A similar effect was observed for pure enzyme hydroxylating cholest-4-en-3-one, as well as for the hydroxylation of ethylbenzene by immobilized EBDH (data not shown).

Immobilization of S25DH

The activity of immobilized enzyme preparations was evaluated for different supports in batch reactors with cholest-1,4-dien-3-one as a substrate (Table 2). As a reference, homogenous S25DH with an initial activity corresponding to that used for preparation of the immobilized catalyst (8.04 mU) was used. In each case, 0.5 mL of the settled immobilized catalyst was suspended in 3.5 mL of the reaction mixture and placed in a thermostated reactor at 30 °C in an anaerobic atmosphere. The reaction progress was monitored by HPLC for 2 weeks (Fig. S9 of Supplementary Material). The highest activity recovery (% of immobilized specific activity, AR) was observed for mesostructured cellular foam (MCF) and Santa Barbara Amorphous (SBA-15) silica supports both functionalized with 2-aminoethyl-3-aminopropyltrimethoxysilane (AEAPTS; 45 and 30 %), followed by SBA-ultra supports functionalized with 3-aminopropyltrimethoxysilane (APTES) and 3-aminopropyltriethoxysilane (APTMS) (13–14 %). The lowest ARs were detected for S25DH immobilized on cellulose carriers (1–2 %) and Eupergit® C (0.3 %). In order to test the influence of the functionalization linker, further experiments were conducted employing AEAPTS or APTES as linkers on SBA-ultra carriers with pure enzyme (SA 4.67 mU/mg) (Table S3 Supplementary Material). For both carriers functionalized by a longer (AEAPTS) or a shorter (APTES) linker, similar values of protein loading as well as initial activity and AR were obtained. Thus, under experimental conditions the influence of the linker was not observed.

S25DH hydroxylation applications

Synthesis of 25-OH-Ch

The synthesis of 25-OH-Ch in a fed-batch reactor (25 °C, 8 % (w/v) HBC; 1.25–3.75 % (v/v) EGME; 0.12 mL of pure enzyme SA 14 mU/mg, anaerobic atmosphere) resulted in an app. 0.8 g/L product concentration after 500 h of reaction (Fig. S6 of Supplementary Material) and conversion of 40–60 %. The conversion and subsequent downstream processing can be further optimized by decreasing the substrate addition at the later stage of the reaction.

Synthesis of 25-OH-D3

The synthesis of 25-OH-D3 in a fed-batch reactor was carried out in two parallel 20-mL glass reactors (25 °C, 8 % (w/v) HBC and 5 % (v/v) EGME, initial substrate concentration of 1.2 g/L, anaerobic atmosphere) with enzyme preparation as a catalyst (15 mL, SA 1.34 mU/mg). After 162 h of reaction (Fig. S7 of Supplementary Material), the product concentration reached 1.4 g/L with conversion of 99 %. The product, 25-OH-D3, was isolated (see “Methods”) with 70 % yield (40 mg, melting point = 81–83 °C, lit. 81–83 °C (Campbell et al. 1969)) and analyzed by NMR (Fig. 6 and Figs. S11–S13 of Supplementary Material).

Synthesis of 3-ketosterols

The synthesis of 25-hydroxycholest-4-en-3-one was carried out in a 0.4 mL fed-batch reactor (30 °C, 8 % (w/v) HBC and 1.25–6.25 % (v/v) EGME, 0.02 mL of pure enzyme SA 14 mU/mg, anaerobic atmosphere) for 120 h, yielding a 1.64 g/L product concentration (>99 % conversion) (Fig. S8 of Supplementary Material). Similarly, the synthesis of 25-hydroxycholest-1,4-dien-3-one was carried out in two 400-h experiments (Fig. S9 of Supplementary Material), using pure (8.04 mU) or immobilized S25DH (3.6 mU) at 25 °C. The reactor with pure enzyme reached the product concentration of 2.21 g/L, while the reactor with immobilized enzyme reached 1.74 g/L (conversions 82 %). The same reaction carried out in a plug flow reactor under anaerobic atmosphere resulted in 7.5 % conversion during the first pass (100 min), followed by 6.7 % conversion during the second and third passes (second day of the reaction), and 4.5–5 % during the fourth to sixth passes (third and seventh day of the reaction). The final cumulative conversion was 33.5 % (0.16 g/L) and the catalyst exhibited 50 % of its initial activity after 7 days of discontinuous work (intermediate storage of catalyst under anaerobic conditions at 10 °C).

Discussion

Optimization of reaction conditions

The low solubility of steroids in aqueous medium is a known problem in their biotransformation that limits the yield of such processes (Rao et al. 2013). However, the reactor loading can be increased by the addition of steroid solubilizers, such as 2-hydroxypropyl-β-cyclodextrin (HBC) together with organic co-solvent, which additionally enables an easy introduction of the substrate to the reaction medium. Comparative tests of differently functionalized β-cyclodextrins showed that HBC is especially efficient in the solubilization of sterols, followed by methyl-β-cyclodextrin. The unmodified β-cyclodextrin proved to be very inefficient in that process and limited the conversion. A thorough investigation of the influence of HBC on the observed activity showed that both too low and too high contents of cyclodextrin were detrimental to the reaction rate. The low HBC content results in the low solubility of the substrate and its subsequent precipitation from the reaction medium. On the other hand, a high content of HBC is most probably associated with substrate sequestration by cyclodextrins forming tubular supramolecular structures. This effectively decreases the substrate concentration available to the enzyme (Decaprio et al. 1992; Williams et al. 1998). As a consequence, for more hydrophilic compounds (e.g., cholecalciferol), a lower concentration of the expensive HBC can be used (6 % instead of 8 % (w/v)). The optimal EGME content is also bracketed by low sterol concentrations for low levels of EGME in the reaction mixture and enzyme deactivation due to exposure to high concentrations of denaturizing organic solvent. The tests conducted at the constant concentration of cholest-4-en-3-one indicated, that a low concentration of EGME is optimal for the initial rate of the enzyme. However, the increased EGME concentration not only allows the introduction of higher doses of sterol substrates but also seems to stabilize the high concentration of sterol in the water/HBC medium. As a result the optimal productivity of the reactor can be achieved at higher contents of the EGME due to elevated concentration of the sterol substrate (Fig. 7).

The optimization showed that S25DH performs best under anaerobic conditions. The long-term exposure to aerobic conditions during the reaction results in the significantly faster deactivation of the catalysts. The optimal concentration of the K3[Fe(CN)6] re-oxidant is in the range of 10–15 mM, where a concentration of approximately 1 mM results in the kinetic limitation of the re-oxidation process, and approximately 100 mM in the inactivation of the enzyme (possibly due to too high redox potential). Surprisingly, the introduction of the electrochemical re-oxidation of K4[Fe(CN)6] by a Pt electrode present in the batch reactor resulted in a decrease in the enzyme activity and lower productivity after initially better performance (associated with a high and steady concentration of the re-oxidant). The effect was observed both for homogenous and immobilized biocatalyst, and we have been yet unable to explain this effect, which seems to be characteristic of the EBDH-like class of enzymes. Nevertheless, the potential use of electrochemical recovery in the plug flow system (in the form of an electrochemical flow cell) seems to be an attractive alternative to increase the economic feasibility of the process.

The covalent immobilization of S25DH on a solid support resulted in a significant loss of activity (50–80 %). Although the carrier survey was not very systematic, and many factors could influence the biocatalyst activity after immobilization, one can draw two conclusions from these experiments: (i) cellulose-based carriers behave significantly worse than those functionalized with hydrophobic linker silica supports and (ii) morphology of the silica support is significantly influencing the observed activity of the immobilized biocatalyst. Although these effects require further study, it is possible that the membrane-associated S25DH could retain more of its activity when immobilized on a more hydrophobic surface (i.e., silica functionalized with hydrophobic linker) (Schilke and Kelly 2008). Interestingly, despite the significant decrease of the observed initial activity for the immobilized enzyme (45 % of activity for homogenous enzyme either due to mass transfer limitations or over-binding by covalent linker), the immobilized catalyst performed comparably to the homogenous catalyst. This may suggest that for the immobilized enzyme, the deactivation process is indeed slower, which evens the performance over long-term use (up to months). Additionally, taking into account the simplified downstream processing of the reaction medium, the potential application of the immobilized S25DH enzyme in industrial practice seems to be promising (DiCosimo et al. 2013).

S25DH as a catalyst for the synthesis of 25-hydroxysterols and calcifediol

S25DH has been proven to be an efficient catalyst, especially in the hydroxylation of 3-ketosterols and cholecalciferol. The observed reaction rates were 5–10 times higher for 3-ketosterols compared to 3-hydroxysterols (e.g., cholesterol, 7-dehydrocholesterol or cholesterol succinate), and as a result, a higher yield could be obtained in the synthesis of 25-hydroxy-3-ketosterols (up to 1.5 g/L compared to 0.8 g/L). Therefore, in the synthesis of 25-hydroxycholesterol, we propose chemoenzymatic approach with one enzymatic step: synthesis of 25-hydroxycholest-4-en-3-one from cholest-4-en-3-one and a further chemical isomerization and reduction step afterwards. Interestingly, cholecalciferol is a very good substrate for S25DH, despite the fact that it chemically resembles 3-hydroxysterols. Moreover, S25DH activity in the hydroxylation of ergocalciferol was detected (Table 1). Unfortunately, the reaction rates for ergocalciferol were very low, most probably due to the steric hindrance introduced by the additional methyl group close to the hydroxylation site. A higher solubility of cholecalciferol (compared to other sterols) in aqueous medium seems to result in better saturation of the enzyme active site, resulting in a higher observed hydroxylation rate. To our best knowledge, the use of S25DH for the synthesis of calcifediol yields the highest concentration of the product that has been obtained with biotechnological methods (Fujii et al. 2009; Kang et al. 2006, 2015; Sasaki et al. 1992). The highest product concentration of 0.57 g/L was reported for Rhodococcus erythropolis cells containing a recombinant vitamin D3 hydroxylase from Pseudonocardia autotrophica (Yasutake et al. 2013). In our approach, we were able to reach 1.4 g/L, while experiments with other substrates demonstrated the possibility of going even above 2.0 g/L. The use of isolated enzyme instead of cells also enables the use of less physiological conditions (such as the presence of organic co-solvents) as well as an easy shift from a batch system to flow reactors. In summary, S25DH is an interesting biocatalyst and can be efficiently used in the fine chemical and pharmaceutical industries.

References

Ban JG, Kim HB, Lee MJ, Anbu P, Kim ES (2014) Identification of a vitamin D3-specific hydroxylase genes through actinomycetes genome mining. J Ind Microbiol Biotechnol 41(2):265–273. doi:10.1007/s10295-013-1336-9

Bauman DR, Bitmansour AD, McDonald JG, Thompson BM, Liang GS, Russell DW (2009) 25-hydroxycholesterol secreted by macrophages in response to toll-like receptor activation suppresses immunoglobulin a production. Proc Natl Acad Sci U S A 106(39):16764–16769. doi:10.1073/pnas.0909142106

Beste L, Nahar N, Dalman K, Fujioka S, Jonsson L, Dutta PC, Sitbon F (2011) Synthesis of hydroxylated sterols in transgenic Arabidopsis plants alters growth and steroid metabolism. Plant Physiol 157(1):426–440. doi:10.1104/pp.110.171199

Bildziukevich U, Rarova L, Saman D, Havlicek L, Drasar P, Wimmer Z (2013) Amides derived from heteroaromatic amines and selected steryl hemiesters. Steroids 78(14):1347–1352

Bischoff-Ferrari HA, Dawson-Hughes B, Stöcklin E, Sidelnikov E, Willett WC, Edel JO, Stähelin HB, Wolfram S, Jetter A, Schwager J, Henschkowski J, von Eckardstein A, Egli A (2012) Oral supplementation with 25(OH)D3 versus vitamin D3: effects on 25(OH)D levels, lower extremity function, blood pressure, and markers of innate immunity. J Bone Miner Res 27(1):160–169. doi:10.1002/jbmr.551

Brandi ML, Minisola S (2013) Calcidiol [25(OH)D3]: from diagnostic marker to therapeutical agent. Curr Med Res Opin 29(11):1565–1572. doi:10.1185/03007995.2013.838549

Brixius-Anderko S, Schiffer L, Hannemann F, Janocha B, Bernhardt R (2015) A CYP21A2 based whole-cell system in Escherichia coli for the biotechnological production of premedrol. Microb Cell Factories 14:135. doi:10.1186/s12934-015-0333-2

Campbell JA, Squires DM, Babcock JC (1969) Synthesis of 25-hydroxycholecalciferol biologically effective metabolite of vitamin D3. Steroids 13(5):567–577

Carvalho JF, Silva MM, Moreira JN, Simoes S, Sa e Melo ML (2010) Sterols as anticancer agents: synthesis of ring-B oxygenated steroids, cytotoxic profile, and comprehensive SAR analysis. J Med Chem 53(21):7632–7638. doi:10.1021/jm1007769

Chiang YR, Ismail W, Muller M, Fuchs G (2007) Initial steps in the anoxic metabolism of cholesterol by the denitrifying Sterolibacterium denitrificans. J Biol Chem 282(18):13240–13249. doi:10.1074/jbc.M610963200

Chiang YR, Ismail W, Gallien S, Heintz D, Van Dorsselaer A, Fuchs G (2008a) Cholest-4-en-3-one-Delta(1)-dehydrogenase, a flavoprotein catalyzing the second step in anoxic cholesterol metabolism. Appl Environ Microbiol 74(1):107–113

Chiang YR, Ismail W, Heintz D, Schaeffer C, Van Dorsselaer A, Fuchs G (2008b) Study of anoxic and oxic cholesterol metabolism by Sterolibacterium denitrificans. J Bacteriol 190(3):905–914. doi:10.1128/jb.01525-07

Czarny MR, Nelson JA, Spencer TA (1977) Synthesis of 4-Spiro[Cyclopropanecholestan-3beta-Ol. J Org Chem 42(17):2941–2944. doi:10.1021/jo00437a041

Decaprio J, Yun J, Javitt NB (1992) Bile-acid and sterol solubilization in 2-hydroxypropyl-Beta-cyclodextrin. J Lipid Res 33(3):441–443

Dermer J, Fuchs G (2012) Molybdoenzyme that catalyzes the anaerobic hydroxylation of a tertiary carbon atom in the side chain of cholesterol. J Biol Chem 287(44):36905–36916

DiCosimo R, McAuliffe J, Poulose AJ, Bohlmann G (2013) Industrial use of immobilized enzymes. Chem Soc Rev 42(15):6437–6474. doi:10.1039/C3CS35506C

Donova MV (2007) Transformation of steroids by actinobacteria: a review. Appl Biochem Micro 43(1):1–14. doi:10.1134/S0003683807010012

Fujii T, Fujii Y, Machida K, Ochiai A, Ito M (2009) Efficient biotransformations using Escherichia coli with tolC acrAB mutations expressing cytochrome P450 genes. Biosci Biotechnol Biochem 73(4):805–810. doi:10.1271/bbb.80627

Heider J, Szaleniec M, Sünwoldt K, Boll M (2016) Ethylbenzene dehydrogenase and related molybdenum enzymes involved in oxygen-independent alkyl chain hydroxylation. J Mol Microbiol Biotechnol 26(1–3):45–62

Hille R, Hall J, Basu P (2014) The mononuclear molybdenum enzymes. Chem Rev 114(7):3963–4038. doi:10.1021/cr400443z

Holland HL (1992) Organic synthesis with oxidative enzymes. Wiley-VCH, New York

Iida T, Shinohara T, Goto J, Nambara T, Chang FC (1988) A facile one-step synthesis of delta-1,4-3-keto bile-acid esters by iodoxybenzene and benzeneselenic anhydride. J Lipid Res 29(8):1097–1101

Jetter A, Egli A, Dawson-Hughes B, Staehelin HB, Stoecklin E, Goessl R, Henschkowski J, Bischoff-Ferrari HA (2014) Pharmacokinetics of oral vitamin D(3) and calcifediol. Bone 59:14–19

Kang D-J, Lee H-S, Park J-T, Bang JS, Hong S-K, Kim T-Y (2006) Optimization of culture conditions for the bioconversion of vitamin D3 to 1α,25-dihydroxyvitamin D3 using Pseudonocardia autotrophica ID 9302. Biotechnol Bioproc E 11(5):408–413. doi:10.1007/bf02932307

Kang DJ, Im JH, Kang JH, Kim KH (2015) Bioconversion of vitamin D3 to calcifediol by using resting cells of Pseudonocardia sp. Biotechnol Lett 37(9):1895–1904. doi:10.1007/s10529-015-1862-9

Kurek-Tyrlik A, Michalak K, Wicha J (2005) Synthesis of 17-epi-calcitriol from a common androstane derivative, involving the ring B photochemical opening and the intermediate triene ozonolysis. J Org Chem 70(21):8513–8521. doi:10.1021/jo051357u

McDonald JG, Russell DW (2010) Editorial: 25-hydroxycholesterol: a new life in immunology. J Leukoc Biol 88(6):1071–1072. doi:10.1189/jlb.0710418

Miyamoto K, Kubodera N, Murayama E, Ochi K, Mori T, Matsunaga I (1986) Synthetic studies on vitamin-D analogs .6. A new synthesis of 25-hydroxycholesterol from lithocholic acid. Synthetic Commun 16(5):513–521. doi:10.1080/00397918608078765

Neter J, Wasserman W, Kutner MH (1985) Applied linear statistical models: regression, analysis of variance, and experimental designs. Irwin, Homewood, IL

Ogawa S, Kakiyama G, Muto A, Hosoda A, Mitamura K, Ikegawa S, Hofmann AF, Iida T (2009) A facile synthesis of C-24 and C-25 oxysterols by in situ generated ethyl(trifluoroxymethyl)dioxirane. Steroids 74(1):81–87. doi:10.1016/j.steroids.2008.09.015

Rao SM, Thakkar K, Pawar K (2013) Microbial transformation of steroids: current trends in cortical side chain cleavage. Quest 1:16–20

Reboldi A, Dang EV, McDonald JG, Liang GS, Russell DW, Cyster JG (2014) 25-Hydroxycholesterol suppresses interleukin-1-driven inflammation downstream of type I interferon. Science 345(6197):679–684. doi:10.1126/science.1254790

Riediker M, Schwartz J (1981) A new synthesis of 25-hydroxycholesterol. Tetrahedron Lett 22(46):4655–4658. doi:10.1016/S0040-4039(01)83005-7

Riva S (1991) Enzymatic modification of steroids., vol 1. Marcel Dekker, Inc., New York

Ryznar T, Krupa M, Kutner A (2002) Syntheses of vitamin D metabolites and analogs. Retrospect and prospects. Przem Chem 81(5):300–310

Sasaki J, Miyazaki A, Saito M, Adachi T, Mizoue K, Hanada K, Omura S (1992) Transformation of vitamin-D3 to 1-alpha, 25-dihydroxyvitamin-D3 via 25-hydroxyvitamin-D3 using Amycolata sp. strains. Appl Microbiol Biotechnol 38(2):152–157

Schilke KF, Kelly C (2008) Activation of immobilized lipase in non-aqueous systems by hydrophobic POIY-DL-tryptophan tethers. Biotechnol Bioeng 101(1):9–18. doi:10.1002/bit.21870

Seung-Kwon, N, Myung-Kuk, K, Won-Tae, Y, Kyung-Moon, P, Sang-Ok, P (2002) Method for preparation of androst-4-ene-3,17-dione and androsta-1,4-diene-3,17-dione. PCT/KR2002/000876

Szaleniec M, Hagel C, Menke M, Nowak P, Witko M, Heider J (2007) Kinetics and mechanism of oxygen-independent hydrocarbon hydroxylation by ethylbenzene dehydrogenase. Biochemistry 46(25):7637–7646. doi:10.1021/bi700633c

Szaleniec, M, Rugor, A, Dudzik, A, Tataruch, M, Szymańska, K, Jarzębski, A (2015) [Method of obtaining 25-hydroxylated sterol derivatives, including 25-hydroxy-7-dehydrocholesterol]. Poland

Szymanska K, Pudlo W, Mrowiec-Bialon J, Czardybon A, Kocurek J, Jarzebski AB (2013) Immobilization of invertase on silica monoliths with hierarchical pore structure to obtain continuous flow enzymatic microreactors of high performance. Micropor Mesopor Mat 170:75–82

Tarlera S (2003) Sterolibacterium denitrificans gen. Nov., sp. nov., a novel cholesterol-oxidizing, denitrifying member of the Proteobacteria. Int J Syst Evol Microbiol 53(4):1085–1091. doi:10.1099/ijs.0.02039-0

Tataruch M, Heider J, Bryjak J, Nowak P, Knack D, Czerniak A, Liesiene J, Szaleniec M (2014) Suitability of the hydrocarbon-hydroxylating molybdenum-enzyme ethylbenzene dehydrogenase for industrial chiral alcohol production. J Biotechnol 192:400–409. doi:10.1016/j.jbiotec.2014.06.021

Warnke M, Jung T, Dermer J, Hipp K, Jehmlich N, von Bergen M, Ferlaino S, Fries A, Müller M, Boll M (2016) 25-hydroxyvitamin D3 synthesis by enzymatic steroid side-chain hydroxylation with water. Angew Chem Int Ed Engl 55(5):1881–1884. doi:10.1002/ange.201510331

Westover EJ, Covey DF (2006) Synthesis of ent-25-hydroxycholesterol. Steroids 71(6):484–488. doi:10.1016/j.steroids.2006.01.007

Williams RO, Mahaguna V, Sriwongjanya M (1998) Characterization of an inclusion complex of cholesterol and hydroxypropyl-beta-cyclodextrin. Eur J Pharm Biopharm 46(3):355–360. doi:10.1016/S0939-6411(98)00033-2

Yamamoto S, Kurihara H, Mutoh T, Xing XH, Unno H (2005) Cholesterol recovery from inclusion complex of beta-cyclodextrin and cholesterol by aeration at elevated temperatures. Biochem Eng J 22(3):197–205

Yasuda K, Endo M, Ikushiro S, Kamakura M, Ohta M, Sakaki T (2013) UV-dependent production of 25-hydroxyvitamin D2 in the recombinant yeast cells expressing human CYP2R1. Biochem Biophys Res Commun 434(2):311–315. doi:10.1016/j.bbrc.2013.02.124

Yasutake Y, Nishioka T, Imoto N, Tamura T (2013) A single mutation at the ferredoxin binding site of P450 Vdh enables efficient biocatalytic production of 25-hydroxyvitamin D(3. Chembiochem 14(17):2284–2291. doi:10.1002/cbic.201300386

Zhang D, Zhang R, Zhang J, Chen L, Zhao C, Dong W, Zhao Q, Wu Q, Zhu D (2014) Engineering a hydroxysteroid dehydrogenase to improve its soluble expression for the asymmetric reduction of cortisone to 11β-hydrocortisone. Appl Microbiol Biotechnol 98(21):8879–8886. doi:10.1007/s00253-014-5967-1

Zhao Q, Ji L, Qian GP, Liu JG, Wang ZQ, WP Y, Chen XZ (2014) Investigation on the synthesis of 25-hydroxycholesterol. Steroids 85:1–5. doi:10.1016/j.steroids.2014.02.002

Zhu JG, Ochalek JT, Kaufmann M, Jones G, Deluca HF (2013) CYP2R1 is a major, but not exclusive, contributor to 25-hydroxyvitamin D production in vivo. Proc Natl Acad Sci U S A 110(39):15650–15655. doi:10.1073/pnas.1315006110

Acknowledgments

The authors acknowledge the financial support of the Polish institutions of the National Center of Research and Development (grant project: LIDER/33/147/L-3/11/NCBR) and the National Center of Science (grant SONATA UMO-2012/05/D/ST4/00277).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare no conflict of interests.

Human and animal rights and informed consent

This article does not contain any studies with human participants or animals performed by any of the authors.

Electronic Supplementary Materials

ESM 1

(DOCX 1.85 mb)

Rights and permissions

About this article

Cite this article

Rugor, A., Tataruch, M., Staroń, J. et al. Regioselective hydroxylation of cholecalciferol, cholesterol and other sterol derivatives by steroid C25 dehydrogenase. Appl Microbiol Biotechnol 101, 1163–1174 (2017). https://doi.org/10.1007/s00253-016-7880-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-016-7880-2