Abstract

Phage endolysins have received increased attention in recent times as potential antibacterial agents and the biopreservatives in food production processes. Staphylococcus aureus is one of the most common pathogens in bacterial food poisoning outbreaks. In this study, the endolysin Lysdb, one of the two-component cell lysis cassette of Lactobacillus delbrueckii phage phiLdb, was shown to possess a muramidase domain and catalytic sites with homology to Chalaropsis-type lysozymes. Peptidoglycan hydrolytic bond specificity determination revealed that Lysdb was able to cleave the 6-O-acetylated peptidoglycans present in the cell walls of S. aureus. Turbidity reduction assays demonstrated that Lysdb could effectively lyse the S. aureus live cells under acidic and mesothermal conditions. To further evaluate the ability of Lysdb as a potential antibacterial agent against S. aureus in cheese manufacture, Lactobacillus casei BL23 was engineered to constitutively deliver active Lysdb to challenge S. aureus in lab-scale cheese making from raw milk. Compared with the raw milk, the viable counts of S. aureus were reduced by 105-fold in the cheese inoculated with the engineered L. casei strain during the fermentation process, and the pathogenic bacterial numbers remained at a low level (104 CFU/g) after 6 weeks of ripening at 10 °C. Taken together, all results indicated that the Lysdb has the function as an effective tool for combating S. aureus during cheese manufacture from raw milk.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Phages are the most abundant living entities on Earth and kill 50 % of the bacteria produced every day (Oliveira et al. 2013). Double-stranded DNA phages utilize a two-component cell lysis cassette (endolysin and holin) to collapse the peptidoglycan layer of bacterial cell walls, enabling progeny release and new host infection (Young 2013). Holins are small membrane-spanning proteins that accumulate as oligomers in the cytoplasmic membrane (White et al. 2011). Endolysins are highly evolved enzymes that target bonds within the peptidoglycan (Catalão et al. 2012). There are five major functional types of phage endolysins: muramidase, amidase, peptidase, lytic transglycosylase, and endopeptidase. Muramidases hydrolyze the β-1,4 glycosidic bond between N-acetylmuramic acid and N-acetylglucosamine of the bacterial peptidoglycan (Endersen et al. 2014). Several muramidases belong to a group termed the Chalaropsis-type (Ch-type) lysozymes, including those from Chalaropsis, Streptomyces coelicolor, phages of Streptococcus pneumonia (Cp phages), Lactobacillus spp. phage MV1, and φadh, which display both β-1,4-N-acetyl-muramidase and β-1,4-N,6-O-diacetylmuramidase activity (Pérez-Dorado et al. 2007; Rau et al. 2000). The latter enables endolysin to degrade the cell wall of Staphylococcus aureus (Rau et al. 2000). Some endolysins only act upon the cell walls of several bacterial phylotypes, while some show broad-spectrum antimicrobial activity (Yoong et al. 2004). These properties make endolysins be effective candidates as antibacterial agents that could potentially replace antibiotics to target specific pathogens (Callewaert et al. 2011; Rodríguez-Rubio et al. 2012; Park et al. 2012; Zhang et al. 2012).

S. aureus is the most prevalent food-borne pathogen of traditionally produced cheeses (Fleurot et al. 2014). During cheese production processes, raw milk from mastitic cows, biofilm in the processing plant environment, and healthy human carriers are the probable sources of S. aureus contamination (Walcher et al. 2014). Milk is a good substrate for S. aureus growth, and when S. aureus counts reach approximately 106 CFU/g, this species begin to produce enterotoxin (Gücükoğlu et al. 2012). Therefore, dairy products are a known source of intoxication (De Buyser et al. 2001; Jorgensen et al. 2005). To prevent the growth of S. aureus, several strategies have been employed to eliminate vegetative pathogenic bacteria, including thermal processing and chemical preservatives. While pathogen-free food with minimal processing, fewer chemical preservatives, and high nutritional value becomes an ever-growing demand around the world, which promotes the development of new natural preservatives (Castellano et al. 2015; Tilkens et al. 2015). Accordingly, phage endolysins have drawn increasing interests as novel natural preservatives to treat food-borne S. aureus (Obeso et al. 2008).

Lactic acid bacteria (LAB), widely used in food fermentation, are generally recognized as safe (GRAS) status and chosen to heterologously produce endolysins (Hugenholtz 2008; Morello et al. 2008). Lactococcus lactis has been used to synthesize endolysins Ply511 (N-acetylmuramoyl-l-alanine amidase) and Ply118 (l-alanoyl-d-glutamate peptidase) from Listeria monocytogenes bacteriophages in an effort to develop dairy starter strains with food biopreservation properties (Gaeng et al. 2000). The endolysin LysK from staphylococcal bacteriophage K was expressed in L. lactis as an alternative to Escherichia coli (O’Flaherty et al. 2005). Also, secretion of active Clostridium perfringens endolysin CP25L by Lactobacillus johnsonii FI9785 has been achieved for biocontrol of C. perfringens in the simulative gastrointestinal tract (Gervasi et al. 2014a). Lactobacillus casei is a major non-starter lactic acid strain in cheese making, and also applied as an ideal host for the production of bioactive enzymes in the manufacture of various dairy products (Rochat et al. 2006; Xu and Kong 2013). In this study, an endolysin Lysdb, originating from Lactobacillus delbrueckii phage phiLdb was identified as a Ch-type lysozyme with lytic activity against S. aureus, and this endolysin was constitutively secreted by L. casei BL23 for the biocontrol of S. aureus during cheese manufacture from raw milk.

Materials and methods

Bacterial strains, plasmids, and growth conditions

The bacterial strains and plasmids used in this study are listed in Table 1. L. delbrueckii subsp. bulgaricus ATCC11842 was kindly provided by Prof. M. van de Guchte and used to propagate the virulent phage phiLdb (van de Guchte et al. 2006; Wang et al. 2010). Lactobacillus was grown in de Man, Rogosa and Sharpe (MRS) broth at 37 °C statically. L. lactis and Enterococcus faecalis were grown in M17 broth (Oxoid, UK) supplemented with 0.5 % (wt/vol) glucose (GM17) at 30 °C statically. Streptococcus thermophilus was grown in M17 broth supplemented with 1 % (wt/vol) lactose at 42 °C statically. E. coli, S. aureus, Bacillus cereus and Salmonella enterica subsp. enterica serovar Braenderup were grown in LB broth at 37 °C aerobically. L. monocytogenes strains were grown in brain heart infusion (BHI) broth at 37 °C aerobically. When appropriate, the following antibiotics were added to the broth or the agar medium: ampicillin (100 μg/mL for E. coli) and chloramphenicol (10 μg/mL for E. coli or 2.5 μg/mL for Lactobacillus).

Identification and cloning of the putative endolysin gene lysdb from phage phiLdb

The endolysin sequence is available in the phage phiLdb complete nucleotide sequence under GenBank accession number KF188410. The conserved domain search was conducted using the NCBI Conserved Domain Database (http://www.ncbi.nlm.nih.gov/Structure/cdd/wrpsb.cgi). Amino acid alignments were performed using ClustalW software. Tertiary structure analysis was conducted using the Swiss Model (http://swissmodel.expasy.org) online server.

Molecular cloning techniques were performed using standard methods (Sambrook and Russell 2001). Taq DNA polymerase, restriction enzymes, T4 DNA polymerase, and T4 DNA ligase were used according to the instructions of the manufacture (TaKaRa, Japan).

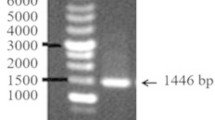

The putative endolysin gene lysdb was PCR amplified from the genomic DNA of phiLdb (Wang et al. 2010) with primers PLysdb-NdeIF (5ʹ-TGACATATGACTAAGTTTGATTTAATGGCTG-3ʹ; the underlined bases indicate an NdeI site) and PLysdb-XhoIR (5ʹ-ATCCTCGAGACTGAATTTACCCCAATAA-3ʹ; the underlined bases indicate an XhoI site). The PCR product was restricted with NdeI/XhoI and cloned into the corresponding sites of the pET-22b(+) vector. The resultant plasmid pELysdb was transformed into chemically competent E. coli BL21 cells, generating the recombinant strain E. coli/pELysdb.

Analysis of the lytic activity of Lysdb

To prepare the purified Lysdb protein, E. coli/pELysdb was grown at 37 °C aerobically to an OD600 of 0.8, and then 0.1 mM isopropyl-β-d-thiogalactopyranoside was added to induce the expression of the His-tagged protein. The His-tagged Lysdb protein was purified by Ni-NTA affinity chromatography. The purified protein was dialyzed against 20 mM sodium phosphate (pH 6.0) and quantified using the Bradford protein assay. The lytic activity of Lysdb against the indicator strains was tested by zymogram as described previously (Wang et al. 2008).

To detect the lytic activity of Lysdb against S. aureus strains ATCC33591 and ATCC27217, exponential cells were collected, washed and resuspended in 20 mM sodium phosphate (pH 6.0) as the live cell substrates. The activity of Lysdb was assessed by turbidity reduction using 10 μg/mL Lysdb in 20 mM sodium phosphate buffer for 100 min. The boiled Lysdb protein in the same buffer was used as the control. The relative lytic activity was calculated using the following equation: 100 × (OD600 of control sample – OD600 of reaction sample)/OD600 of control sample. The lytic activity was determined at temperatures ranging from 4 to 45 °C and over a pH range of 3.0 to 5.0 in 20 mM sodium citrate buffer and pH 6.0 to 8.0 in 20 mM sodium phosphate buffer.

Determination of the peptidoglycan hydrolytic bond specificity of Lysdb

Peptidoglycan extraction from an exponentially growing culture of S. aureus ATCC33591 and determination of hydrolytic bond specificity were performed according to the protocol described by Atrih et al. (1999). The peptidoglycan (3 mg) was incubated with 500 μg purified Lysdb protein in a final volume of 500 μL (20 mM sodium citrate buffer, pH 4.0) overnight at 37 °C. Peptidoglycan cleavage site determination was carried out by reverse-phase high-performance liquid chromatography (RP-HPLC) and mass spectrometry (MS). Samples were applied to an XBridge BEH300 C18 reverse-phase column (150 × 4.6 mm; Waters, USA) with a flow rate of 1.0 mL/min. The column was equilibrated at 45 °C with solvent A. Separation of the reduced muropeptides was effected with a gradient of 0 to 100 % solvent B over 100 min. Solvent A was 40 mM sodium phosphate (pH 4.5); solvent B was 40 mM sodium phosphate (pH 4.0) containing 20 % methanol. The column effluent was monitored by the A202.

Constitutive secretion of Lysdb in L. casei BL23

A constitutive secretory vector was constructed to deliver Lysdb in L. casei BL23 according to following method. The lysdb gene was PCR amplified from the genomic DNA of phiLdb with the primers PLysdb-NsiIF (5ʹ-GCTATGCATCGACTAAGTTTGATTTAAT-3ʹ; the underlined bases indicate NsiI site) and PLysdb-EcoRIR (5ʹ-ACGAATTCCTAGTGGTGGTGGTGGTGGTGACTGAATTTACCCCAA-3ʹ; the underlined bases indicate EcoRI site, and the bases in italics indicate His-tag codons). The plasmid pSec:Nuc, containing Usp45 signal peptide fused to the staphylococcal nuclease gene (nuc) mature moiety under the control of the nisin-inducible promoter PnisA (Enouf et al. 2001). was digested by NsiI/EcoRI to remove the nuc gene. Then, the NsiI/EcoRI Lysdb fragment was inserted into the compatible sites of pSec:Nuc, yielding the recombinant plasmid pSLysdb. To obtain the plasmid pBLysdb, the nisin-inducible promoter PnisA of plasmid pSLysdb was replaced by the constitutive promoter B6 (Guo et al. 2012). To generate the plasmid pB6, the lysdb gene in plasmid pBLysdb was excised by NsiI/EcoRI, and the linearized vector was blunt ended by T4 DNA polymerase and self-ligated by T4 DNA ligase. The plasmids pBLysdb and pB6 were electrotransformed into L. casei BL23 competent cells (Thompson and Collins 1996). The recombinant strains L. casei BL/pBLysdb and L. casei BL/pB6 were selected in MRS agar supplemented with 2.5 μg/mL chloramphenicol.

The overnight culture of L. casei BL/pBLysdb was diluted 100-fold in fresh MRS broth supplemented with 2.5 μg/mL chloramphenicol and grown at 37 °C. Cell growth was monitored by changes in turbidity over 12 h, and the culture was sampled every 2 h. The culture supernatant was recovered by centrifugation at 10,000×g for 10 min at 4 °C and filtered through a 0.22-μm membrane to obtain the secretory protein fraction. Lysdb secreted with the signal peptide Usp45 in the secretory protein fraction was directly detected by Western blot analysis using antibodies to the His-tag (Novagen, USA), and its lytic activity was analyzed by the agar diffusion method on agar containing autoclaved S. aureus ATCC33591 cells.

Challenging S. aureus during cheese manufacture from raw milk

A lab-scale model cheese-making trial (Xu and Kong 2013) was adopted to test the delivery of Lysdb for challenging S. aureus. Pasteurized milk inoculated with approximately 104 colony forming units (CFU)/mL of S. aureus ATCC33591 cells was used as the raw milk. Overnight cultures of L. lactis CCTCCAB20102111 and L. casei BL/pBLysdb were diluted 100-fold in raw milk. After incubation at 35 °C for 90 min, 0.001 % rennent (1400 IMCU/g; CHR-Hansen, Denmark) was added, followed by another 55 min incubation at 35 °C. Then, the curd was cut and stirred. The incubation temperature was increased by 1 °C every 5 min until the final temperature reached 38.5 °C. The whey was drained when the pH reached 4.5 (360 min). Salt was added to the curd at a concentration of 2.5 %. Ripening was conducted at 10 °C for 6 weeks. The number of viable S. aureus was assessed by counting the colonies formed in the curd juice over 360 min and in the cheese over 6 weeks. The raw milk inoculated with L. lactis CCTCCAB20102111 and L. casei BL/pB6 and with L. lactis CCTCCAB20102111 and L. casei BL/pBLysdb were set as the control cheese and the experimental cheese, respectively.

Results

Bioinformatic analysis of a putative endolysin Lysdb from phage phiLdb

A putative endolysin lysdb gene (orf 58) was identified in the L. delbrueckii phage phiLdb genome (accession number KF188410) by comparative genomic analysis, and the deduced amino acid sequence (906 amino acids) showed 97 to 99 % identity to the endolysins from L. delbrueckii phage LL-Ku, c5, Ld3, Ld17, and Ld25A. The Lysdb contains a conserved Glyco_hydro_25 domain at the N-terminus and a bacterial SH3 domain at the C-terminus. Tertiary structure prediction showed that the N-terminal domain of Lysdb has a β/α barrel fold, similar to the Ch-type lysozyme from Streptomyces cellosyl (data not shown). Sequence alignment of the N-terminal domain of Lysdb with four Ch-type lysozymes revealed Lysdb also contains three putative catalytic active sites (Asp9, Asp104, and Glu106), suggesting that Lysdb is a member of Ch-type lysozymes that possess both β-1,4-N-acetyl-muramidase and β-1,4-N,6-O-diacetylmuramidase activity (Fig. 1).

Sequence alignment of the N-terminal domain of Lysdb with Ch-type lysozymes from the fungus Chalaropsis, Streptomyces cellosyl, Streptomyces erythraeu, and Xylella fastidiosa (Rau et al. 2000). Sequence conservation is represented by light gray (conserved residues in three sequences), dark gray (conserved residues in four sequences), or black (equivalent residues in all sequences). Conserved catalytic active residues are indicated by frames

Lytic activity of Lysdb against two S. aureus strains

For analysis of the lytic activity, Lysdb was overexpressed in E. coli BL/pELysdb and purified by Ni-NTA affinity chromatography. Purified Lysdb (10 μg/mL) was added to the suspension of S. aureus strains ATCC33591 and ATCC27217 (OD600 = 1.0). After 10 min treatment at 35 °C, the cell densities of both strains began to decrease and dropped rapidly as the treatment time prolonged. At the time point of 100 min, the OD600 of the two cell suspensions reduced by 62.1 and 60.2 %, whereas the control groups decreased by 9.4 and 8.1 %, indicating that most S. aureus cells were lysed by the action of Lysdb (Fig. 2a).

Characterization of the lytic activity of Lysdb against two S. aureus strains. a Lytic activity of Lysdb against two S. aureus strains at 35 °C over 100 min. Filled squares, S. aureus ATCC33591 plus 10 μg/mL boiled Lysdb protein; empty squares, S. aureus ATCC33591 plus 10 μg/mL Lysdb protein; filled circles, S. aureus ATCC27217 plus 10 μg/mL boiled Lysdb protein; empty circles, S. aureus ATCC27217 plus 10 μg/mL Lysdb protein. b, c Influence of temperature and pH on the lytic activity of Lysdb against two S. aureus strains. Results are the averages of triplicate experiments

To optimize the lytic conditions of Lysdb, its lytic activity was tested at various temperatures and pH values. As shown in Fig. 2b, the optimal temperature for lytic activity was 35~40 °C, while the activity decreased sharply when the temperature fell below 35 °C. The lytic activity was also pH dependent, with an optimal pH value of 4 (Fig. 2c). These properties of Lysdb were consistent with the growth conditions of L. delbrueckii which was grown at the acidic and mesothermal conditions.

Peptidoglycan hydrolytic bond specificity of Lysdb

To further confirm the lytic activity of Lysdb against S. aureus, the peptidoglycan of the cell walls was extracted from S. aureus ATCC33591 cells and digested with purified Lysdb under optimal conditions. Muropeptides fragments were separated by RP-HPLC, and the molecular masses of the muropeptides were determined by LC-MS, generating ions with an m/z of 1008.7 and 2075.4. As shown in Fig. 3, the primary fragments of peaks 1 and 2 correspond to the disaccharide hexapeptide GlcNAc-MurNAc-(l-Ala-d-iGln-l-Lys-(Gly)2-d-Ala) and disaccharide tetrapeptide disaccharide nonapeptide GlcNAc-MurNAc-(l-Ala-d-iGln-l-Lys-d-Ala)-(l-Ala-d-iGln-l-Lys-(Gly)5-d-Ala)-MurNAc-GlcNac. This result demonstrated that Lysdb exhibits β-1,4-N,6-O-diacetylmuramidase activity, capable of cleaving the 6-O-acetylated peptidoglycans present in the cell walls of S. aureus.

Constitutive delivery of active Lysdb in L. casei BL23

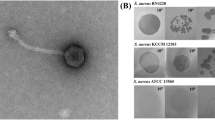

To evaluate the antibacterial activity of Lysdb during cheese making from raw milk, L. casei BL23, a non-starter culture of cheese was adopted to heterologously deliver Lysdb with signal peptide Usp45. A scheme illustrating the construction of engineered L. casei BL/pBLysdb was shown in Fig. 4a. As a result, no obvious difference in growth was observed between the engineered strain L. casei BL/pBLysdb and the control strain L. casei BL/pB6 (Fig. 4b), indicating that the expression of Lysdb did not result in the death of host cells and the level of secretory Lysdb increased gradually during the culture time (Fig. 4c). Moreover, the supernatant of L. casei BL/pBLysdb produced obvious clearing zones against the autoclaved S. aureus cells, while no clearing zone was observed in the control group (L. casei BL/pB6) (Fig. 4d), indicating that active Lysdb was successfully delivered into the supernatant by L. casei BL/pBLysdb.

Constitutive delivery of active Lysdb by L. casei BL/pBLysdb. a A scheme showing the construction of vector pBLysdb for the secretion of Lysdb in L. casei BL/pBLysdb, as well as the control plasmid pB6. The black line represents the pSec:Nuc backbone. To construct the plasmid pBLysdb, the nisin-inducible promoter PnisA and the nuc gene of the pSec:Nuc were replaced by the constitutive promoter B6 and the lysdb gene. To construct the plasmid pB6, the lysdb gene of pBLysdb was deleted. b Growth curves of the control strain L. casei BL/pB6 and the engineered strain L. casei/pBLysdb in MRS broth. c Analysis of Lysdb in the culture supernatant of L. casei BL/pB6 (a) and L. casei BL/pBLysdb (b) by Western blot analysis. d Lytic activity of the culture supernatant of L. casei BL/pB6 (a) and L. casei BL/pBLysdb (b) against autoclaved S. aureus ATCC33591. In (c) and (d), the numbers represent the samples taken at the time points: 0, 2, 4, 6, 8, 10, and 12 h

Challenging S. aureus during cheese manufacture from raw milk

Cheese is the most complex among the fermented dairy products, and S. aureus is a common contaminant of cheese. To evaluate the potential of the delivered Lysdb as an antibacterial agent in cheese making, a lab-scale model cheese was built up using L. lactis CCTCCAB20102111 and L. casei BL/pBLysdb as the starters to challenge 4.0 × 104 CFU/mL S. aureus ATCC33591 in the raw milk. As shown in Fig. 5a, after 360 min fermentation, the pH values of the experimental cheese were similar to those of the control cheese, suggesting that the model cheese worked effectively. The viable counts of S. aureus ATCC33591 in the raw milk drastically increased and reached 1.7 × 109 CFU/mL after 360 min fermentation (Fig. 5b). For the control cheese group, high S. aureus counts appeared at 270 min with 2.5 × 107 CFU/mL and remained constant until the end of fermentation. For the experimental cheese, the viable S. aureus counts increased gradually to 1.6 × 106 CFU/mL in the first 210 min, while reduced to 1.0 × 104 CFU/mL at the time point of 360 min, indicating that the delivered Lysdb effectively inhibited the growth of S. aureus. During cheese ripening at 10 °C, the viable counts of strain ATCC33591 in the raw milk and control cheese remained at a high level of 2.0 × 109 and 3.9 × 107 CFU/g, respectively, while the counts in the experimental cheese dropped continuously over time, reaching 2.7 × 103 CFU/g after 6 weeks (Fig. 5c). These results indicated that the delivery of endolysin Lysdb by the engineered L. casei strain combated S. aureus efficiently during cheese manufacture from raw milk.

Combat of S. aureus ATCC33591 using endolysin Lysdb delivered by L. casei BL/pBLysdb in raw milk model cheese. a pH profile of the model cheese. b Viability of S. aureus ATCC33591 during cheese fermentation. Filled squares, the raw milk; filled circles, the control cheese (the raw milk inoculated with L. lactis CCTCCAB20102111 and L. casei BL/pB6); filled triangles, the experimental cheese (the raw milk inoculated with L. lactis CCTCCAB20102111 and L. casei BL/pBLysdb). c Viability of S. aureus ATCC33591 during cheese ripening. Black bar, the raw milk; gray bar, the control cheese; white bar, the experimental cheese. Results are the averages of triplicate experiments

Lytic spectrum of endolysin Lysdb

To further investigate the lytic spectrum of Lysdb as an antibacterial agent, several lactic acid bacteria commonly used in cheese making and 3-food spoilage bacteria were tested to determine their sensitivity to Lysdb. As shown in Fig. 6, Lysdb exhibited lytic activity against L. delbrueckii ATCC11842, Lactobacillus plantarum WCFS1, Lactobacillus brevis ATCC367, and E. faecalis ATCC14506, whereas no lytic activity was observed against L. casei BL23, L. lactis subsp. lactis bv. diacetylactis CCTCCAB20102111, and S. thermophilus CGMCC 7.179. Moreover, besides two S. aureus strains, food spoilage organisms L. monocytogenes ATCC19114 and Salmonella Braenderup H9812 were also sensitive to Lysdb, indicating the potential of Lysdb as a biopreservative in food processes. L. casei and L. lactis are important starters and adjunct strains in cheese manufacture, and their resistance to the lytic action of Lysdb facilitates the application of this endolysin as an effective tool for combating S. aureus during cheese manufacture. It is known that efficient lysis requires that the C-terminus binds to its cell wall substrate (Fischetti 2008). In the case of Lysdb, its C-terminus may not be able to combine with the cell wall of L. casei BL23 and L. lactis CCTCCAB20102111, leading to their resistance to the lytic action of Lysdb.

Discussion

Despite advances in modern technologies, the food industry is continuously challenged with the threat of pathogenic and spoilage contamination. Because of the overuse of antibiotics, together with the addition of chemical preservatives, the development of new methods for controlling microbial contamination in the food industry is urgently needed (Endersen et al. 2014). Phage endolysins are considered feasible antibacterial agents for combating food spoilage (Callewaert et al. 2011). Sequence analysis showed that endolysin Lysdb contains a catalytic domain similar to that of the Ch-type lysozyme at the N-terminus, which is able to cleave the 6-O-acetylated peptidoglycans present in the cell wall of S. aureus. Our experimental data also approved the lytic activity of endolysin Lysdb against S. aureus, demonstrating the degradation of 6-O-acetylated peptidoglycans in S. aureus cell walls by hydrolytic bond specificity assays (Fig. 3). These results confirmed the Lysdb was a member of Ch-type lysozymes. It is reported that the Ch-type lysozymes display a broad antimicrobial spectrum, even inhibited the growth of several lactic acid bacteria including L. delbrueckii, L. brevis, L. lactis, and E. faecalis (Rau et al. 2000). The lytic spectrum of Lysdb was in accordance with that of Ch-type lysozyme. Lysdb also lysed the food spoilage bacteria (Fig. 6), suggesting Lysdb could be further developed as a biopreservative in food processes.

Commonly, endolysins are applied as an exogenous supplement (Rodríguez-Rubio et al. 2015). Therefore, mass production of endolysin is needed. However, the formation of inclusion bodies, the subsequent purification process and the bacterial endotoxin make it a challenge to produce active and food-safe endolysin from E. coli cells in large quantities (Fischetti 2010). Fortunately, Lysdb could not lyse L. lactis CCTCCAB20102111 and L. casei BL23 (Fig. 6). L. casei is one of the most prominent non-starter lactic acid bacterial (NSLAB) species found in ripening Cheddar cheese (Settanni and Moschetti 2010). Therefore, we chose L. casei as the host cell for the delivery of Lysdb under a modified NICE system.

To evaluate the availability of Lysdb as an antibacterial agent, a lab-scale model cheese was conducted using the engineered L. casei BL/pBLysdb and L. lactis CCTCCAB20102111 as starters as described previously (Xu and Kong 2013). Our results indicated that L. casei BL/pBLysdb was able to kill S. aureus in situ, with the final viable count of S. aureus reduced by 105-fold compared with the raw milk at the end of fermentation. Interestingly, the final survival of S. aureus in the control cheese (L. lactis and L. casei BL/pB6) was also 102-fold lower than that in the raw milk, indicating that the acidic environment also inhibited the growth of S. aureus to a certain extent. Other reports have also demonstrated that the production of lactic acid by lactobacilli is an important natural antimicrobial (Gervasi et al. 2014b; Lebeer et al. 2008).

Phage endolysins are supposed to be one-use enzymes with a short half-life (Fischetti 2008). Therefore, the use of a protein as a preservative might raise a question about long-term control in the food industry, because the growth of S. aureus was hard to standstill, even though the initial viable counts were undetectable (Delbes et al. 2006; Mayer et al. 2012). In our model cheese, the viable numbers of S. aureus continuously decreased and remained at a low level of 104 CFU/g at the end of 6 weeks’ cheese ripening, indicating that the Lysdb delivered by L. casei was effective throughout the ripening processes. Therefore, the use of engineered endolysin-delivering L. casei strain might facilitate the long-term biocontrol of S. aureus during cheese manufacture from raw milk.

In conclusion, the results presented in this study clearly showed that the Lactobacillus phage endolysin Lysdb possesses a muramidase domain similar to Ch-type lysozymes, which was able to lyse the live cells of S. aureus, as well as other food-borne spoilage bacteria. Active Lysdb delivered by the food grade host L. casei could efficiently combat S. aureus contamination during cheese making from raw milk. Taken together, the results indicated that Lysdb had the potential to be developed as an effective tool to treat spoilage bacteria during food production processes.

References

Atrih A, Bacher G, Allmaier G, Williamson MP, Foster SJ (1999) Analysis of peptidoglycan structure from vegetative cells of Bacillus subtilis 168 and role of PBP 5 in peptidoglycan maturation. J Bacteriol 181:3956–3966

Callewaert L, Walmagh M, Michiels CW, Lavigne R (2011) Food applications of bacterial cell wall hydrolases. Curr Opin Biotechnol 22:164–171

Castellano P, Aristoy MC, Sentandreu MA, Vignolo G, Toldrá F (2015) Lactobacillus sakei CRL1862 improves safety and protein hydrolysis in meat systems. J Appl Microbiol 113:1407–1416

Catalão MJ, Gil F, Moniz-Pereira J, São-José C, Pimentel M (2012) Diversity in bacterial lysis systems: bacteriophages show the way. FEMS Microbiol Rev 37:554–571

De Buyser ML, Dufour B, Maire M, Lafarge V (2001) Implication of milk and milk products in food-borne diseases in France and in different industrialised countries. Int J Food Microbiol 67:1–17

Delbes C, Alomar J, Chougui N, Martin JF, Montel MC (2006) Staphylococcus aureus growth and enterotoxin production during the manufacture of uncooked, semihard cheese from cows raw milk. J Food Prot 69:2161–2167

Endersen L, O’Mahony J, Hill C, Ross RP, McAuliffe O, Coffey A (2014) Phage therapy in the food industry. Annu Rev Food Sci T 5:327–349

Enouf V, Langella P, Commissaire J, Cohen J, Corthier G (2001) Bovine rotavirus nonstructural protein 4 produced by Lactococcus lactis is antigenic and immunogenic. Appl Environ Microbiol 67:1423–1428

Fischetti VA (2008) Bacteriophage lysins as effective antibacterials. Curr Opin Microbiol 11:393–400

Fischetti VA (2010) Bacteriophage endolysins: a novel anti-infective to control Gram-positive pathogens. Int J Med Microbiol 300:357–362

Fleurot I, Aigle M, Fleurot R, Darrigo C, Hennekinne JA, Gruss A, Borezée-Durant E, Delacroix-Buchet A (2014) Following pathogen development and gene expression in a food ecosystem: the case of a Staphylococcus aureus isolated in cheese. Appl Environ Microbiol 80:5106–5115

Gaeng S, Scherer S, Neve H, Loessner MJ (2000) Gene cloning and expression and secretion of Listeria monocytogens bacteriophage-lytic enzymes in Lactococcus lactis. Appl Environ Microbiol 66:2951–2958

Gervasi T, Horn N, Wegmann U, Dugo G, Narbad A, Mayer MJ (2014a) Expression and delivery of an endolysin to combat Clostridium perfringens. Appl Microbiol Biotechnol 98:2495–2505

Gervasi T, Lo Gurto R, Minniti E, Narbad A, Mayer MJ (2014b) Application of Lactobacillus johnsonii expressing phage endolysin for control of Clostridium perfringens. Lett Appl Microbiol 59:355–361

Gücükoğlu A, Kevenk O, Uyanik T, Cadirci Ő, Terzi G, Alisarli M (2012) Detection of enterotoxigenic Staphylococcus aureus in raw milk and dairy products by multiplex PCR. J Food Sci 77:620–623

Guo T, Kong J, Zhang L, Zhang C, Hu S (2012) Fine tuning of the lactate and diacetyl production through promoter engineering in Lactococcus lactis. PLoS One 7(4):e36296

Hazebrouck S, Pothelune L, Azevedo V, Corthier G, Wal JM, Langella P (2007) Efficient production and secretion of bovine beta-lactoglobulin by Lactobacillus casei. Microb Cell Factories 6:12

Hugenholtz J (2008) The lactic acid bacterium as a cell factory for food ingredient production. Int Dairy J 18:466–475

Jorgensen HJ, Mork T, Hogasen HR, Rovik LM (2005) Enterotoxigenic Staphylococcus aureus in bulk milk in Norway. J Appl Microbiol 99:158–167

Lebeer S, Vanderleyden J, De Keersmaecker SC (2008) Genes and molecules of lactobacilli supporting probiotic action. Microbiol Mol Biol Rev 72:728–764

Mayer MJ, Gasson MJ, Narbad A (2012) Genomic sequence of bacteriophage ATCC 8074-B1 and activity of its endolysin and engineered variants against Clostridium sporogenes. Appl Environ Microbiol 78:3685–3692

Morello E, Bermúdez-Humarán LG, Llull D, Solé V, Miraglio N, Langella P, Poquet I (2008) Lactococcus lactis, an efficient cell factory for recombinant protein production and secretion. J Mol Microbiol Biotechnol 14:48–58

Obeso JM, Martínez B, Rodríguez A, García P (2008) Lytic activity of the recombinant staphylococcal bacteriophage φH5 endolysin active against Staphylococcus aureus in milk. Int J Food Microbiol 128:212–218

O’Flaherty S, Coffey A, Meaney W, Fitzgerald GF, Ross RP (2005) The recombinant phage lysin LysK has a broad spectrum of lytic activity against clinically relevant staphylococci, including methicillin-resistant Staphylococcus aureus. J Bacteriol 187:7161–7164

Oliveira H, Melo LD, Santos SB, Nóbrega FL, Ferreira EC, Cerca N, Azeredo J, Kluskens LD (2013) Molecular aspects and comparative genomics of bacteriophage endolysins. J Virol 87:4558–4570

Park J, Yun J, Lim J-A, Kang D-H, Ryu S (2012) Characterization of an endolysin, LysBPS13, from a Bacillus cereus bacteriophage. FEMS Microbiol Lett 332:76–83

Pérez-Dorado I, Campillo NE, Monterroso B, Hesek D, Lee M, Páez JA, García JL, Mobashery S, Menéndez M, Hermoso JA (2007) Elucidation of the molecular recognition of bacteria cell wall by modular pneumococcal phage endolysin CPL-1. J Biol Chem 282:24990–24999

Rau A, Hogg T, Marquardt R, Hilgenfeld R (2000) A new lysozyme fold. Crystal structure of the muramidase from Streptomyces coelicolor at 1.65 Å resolution. J Biol Chem 276:31994–31999

Rochat T, Gratadoux JJ, Gruss A, Corthier G, Maguin E, Langella P, van de Guchte M (2006) Production of a heterologous nonheme catalase by Lactobacillus casei: an efficient tool for removal of H2O2 and protection of Lactobacillus bulgaricus from oxidative stress in milk. Appl Environ Microbiol 72:5143–5149

Rodríguez-Rubio L, Martínez B, Rodríguez A, Donovan DM, García P (2012) Enhanced staphylolytic activity of the staphlococcus aureus bacteriophage vB_SauS-phiIPLA88 HydH5 virion-associated peptidoglygan hydrolase: fusions, deletions, and synergy with LysH5. Appl Environ Microbiol 78:2241–2248

Rodríguez-Rubio L, Gutiérrez D, Donovan DM, Martínez B, Rodríguez A, García P (2015) Phage lytic proteins: biotechnological applications beyond clinical antimicrobials. Crit Rev Biotechnol 0:1–11

Sambrook J, Russell D (2001) Molecular cloning: a laboratory manual, vol 1–3. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, New York

Settanni L, Moschetti G (2010) Non-starter lactic acid bacteria used to improve cheese quality and provide health benefits. Food Microbiol 27:691–697

Thompson K, Collins MA (1996) Improvement in electroporation efficiency for Lactobacillus plantarum by the inclusion of high concentrations of glycine in the growth medium. J Micro Methods 26:73–79

Tilkens B, King AM, Glass KA, Sinderlar JJ (2015) Validating the inhibition of Staphylococcus aureus in shelf-stable, ready-to-eat snack sausages with varying combinations of pH and water activity. J Food Prot 78:1215–1220

van de Guchte M, Penaud S, Grimaldi C, Barbe V, Bryson K, Nicolas P, Robert C, Oztas S, Mangenot S, Couloux A, Loux V, Dervyn R, Bossy R, Bolotin A, Batto J-M, Walunas T, Gibrat J-F, Bessières P, Weissenbach J, Ehrlich SD, Maguin E (2006) The complete genome sequence of Lactobacillus bulgaricus reveals extensive and ongoing reductive evolution. Proc Natl Acad Sci U S A 103:9274–9279

Walcher G, Gonano M, Kümmel J, Barker GC, Lebl K, Bereuter O, Ehling-Schulz M, Wagner M, Stessl B (2014) Staphylocuccus aureus reservoirs during traditional Austrian raw milk cheese production. J Dairy Res 81:462–470

Wang S, Kong J, Zhang X (2008) Identification and characterization of the two-component cell lysis cassette encoded by temperate bacteriophage φPYB5 of Lactobacillus fermentum. J Appl Microbiol 105:1939–1944

Wang S, Kong J, Gao C, Guo T, Liu X (2010) Isolation and characterization of a novel virulent phage (phiLdb) of Lactobacillus delbrueckii. Int J Food Microbiol 137:22–27

White R, Chiba S, Pang T, Dewey JS, Savva CG, Holzenburg A, Pogliano K, Young R (2011) Holin triggering in real time. Proc Natl Acad Sci U S A 108:798–803

Xu Y, Kong J (2013) Construction and potential application of controlled autolytic systems for Lactobacillus casei in cheese manufacture. J Food Prot 76:1187–1193

Yoong P, Schuch R, Nelson D, Fischetti VA (2004) Identification of a broadly active phage lytic enzyme with lethal activity against antibiotic-resistant Enterococcus faecalis and Enterococcus faecium. J Bacteriol 186:4808–4812

Young R (2013) Phage lysis: do we have the hole story yet? Curr Opin Microbiol 16:790–797

Zhang H, Bao H, Billington C, Hudson JA, Wang R (2012) Isolation and lytic activity of the Listeria bacteriophage endolysin LysZ5 against Listeria monocytogenes in soya milk. Food Microbiol 31:133–136

Acknowledgments

We would like to thank M. van de Guchte, S. Hazebrouck, and N. Galleron for the kindness of providing L. delbrueckii subsp. bulgaricus ATCC11842, L. casei BL23, and pSec:Nuc vector, respectively. This work was supported by grants from the National Natural Science Foundation of China (grant no. 31271905), Hi-tech Research and Development Program of China (no. 2011AA100902), and the Fundamental Research Funds of Shandong University (no. 2014GN024).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Human and animal rights and informed consent

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Guo, T., Xin, Y., Zhang, C. et al. The potential of the endolysin Lysdb from Lactobacillus delbrueckii phage for combating Staphylococcus aureus during cheese manufacture from raw milk. Appl Microbiol Biotechnol 100, 3545–3554 (2016). https://doi.org/10.1007/s00253-015-7185-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-015-7185-x