Abstract

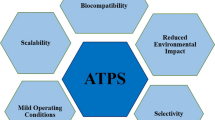

Nowadays, there is an increasing demand to establish new feasible, efficient downstream processing (DSP) techniques in biotechnology and related fields. Although several conventional DSP technologies have been widely employed, they are usually expensive and time-consuming and often provide only low recovery yields. Hence, the DSP is one major bottleneck for the commercialization of biological products. In this context, polyethylene glycol (PEG)–salt aqueous two-phase systems (ATPS) represent a promising, efficient liquid–liquid extraction technology for the DSP of various biomolecules, such as proteins and enzymes. Furthermore, ATPS can overcome the limitations of traditional DSP techniques and have gained importance for applications in several fields of biotechnology due to versatile advantages over conventional DSP methods, such as biocompatibility, technical simplicity, and easy scale-up potential. In the present review, various practical applications of PEG–salt ATPS are presented to highlight their feasibility to operate as an attractive and versatile liquid–liquid extraction technology for the DSP of proteins and enzymes, thus facilitating the approach of new researchers to this technique. Thereby, single- and multi-stage extraction, several process integration methods, as well as large-scale extraction and purification of proteins regarding technical aspects, scale-up, recycling of process chemicals, and economic aspects are discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nowadays, a wide variety of biomolecules and several specialized biotechnological products are required in different biochemical and biotechnological industries, such as the cosmetic, food, and pharmaceutical industry, and the demand for these products is continuously increasing (Pavlou and Reichert 2004; van Winssen et al. 2014a, b). Thereby, the downstream processing (DSP) regarding recovery and purification of biomolecules is often representing a major bottleneck of the whole production process in terms of complexity and high cost, which can make up more than 70 % of the total DSP product cost (Belter et al. 1988; Naganagouda and Mulimani 2008; Raja et al. 2011). This process is complicated due to product sensitivities toward organic solvents, pH values, or high temperatures, severe regulatory laws for final product quality, many unspecified impurities, and comparatively low product concentrations (Nfor et al. 2008; van Winssen et al. 2014a, b). In order to develop an economically feasible concentration and purification process, some factors have to be considered, viz., recovery, compatibility, selectivity, and throughput (Naganagouda and Mulimani 2008). Since current DSP strategies become often expensive owing to drawbacks inherently related to these factors and are limited by product loss or irreversible deactivation of target products, there has been a growing interest in the development of feasible, efficient, stable, selective, and economical DSP unit operations for the separation and purification of proteins and enzymes (Naganagouda and Mulimani 2008; van Winssen et al. 2014b). In this context, the application of aqueous two-phase systems (ATPS) or aqueous two-phase extraction (ATPE) is representing a promising unit operation for the DSP of sensitive biomolecules and biotechnological products (Aguilar et al. 2006; van Winssen et al. 2014b).

In general, practical strategies are required for the development and design of ATPE processes or their extraction stages for primary recovery and purification of biological products using ATPS in order to overcome the poor understanding of the molecular mechanism governing the partitioning behavior of solute in ATPS (Benavides and Rito-Palomares 2008; Rito-Palomares 2004). Traditionally, ATPE processes are developed by empirically established operating conditions for each extraction stage, at which the required time for the design of these ATPE stages can be effectively reduced by practical strategies (Rito-Palomares 2004). A practical approach employed for predicting the development and design of ATPE processes for the recovery of biomolecules using polyethylene glycol (PEG)–salt ATPS is represented in Fig. 1, providing general rules for an initial establishing of the preliminary ATPE process conditions (Rito-Palomares 2004). This proposed practical approach can be divided into four main stages, viz., (1) initial physicochemical characterization of the feedstock, (2) selection of the ATPS type, (3) selection of system parameters, and (4) evaluation of the influence of process parameters upon recovery/purity (Benavides and Rito-Palomares 2008). For an initial characterization of physicochemical product properties involved in the feedstock (i.e., product and major contaminants, molecular weight (MW), isoelectric point (pI), hydrophobic character), it is recommended to use experimental determinations and/or reported information (Benavides and Rito-Palomares 2008). Once the feedstock has been characterized, a suitable ATPS type (polymer–salt, polymer–polymer, or ATPS formed with alternative components) has to be selected to be used in the process considering the desired partitioning of target biomolecules (Benavides and Rito-Palomares 2008). In this context, the selection of polymer–salt ATPS has been preferred due to low-cost of the phase-forming components, at which PEG–phosphate ATPS are most widely exploited in this field (Rito-Palomares 2004). Afterwards, the system parameters (PEG MW, tie-line length (TLL), volume ratio (V R), and pH) are preselected and evaluated upon the recovery of target products according to the essential corresponding phase diagram and physicochemical properties of the product in order to define the operating ATPE process conditions, finally achieving a selective partitioning (Benavides and Rito-Palomares 2008). If the recovery of the target product is not acceptable or low after an evaluation of the system parameters, the ATPS type has to be changed (Benavides and Rito-Palomares 2008). On the other hand, if the recovery is acceptable or high enough, the influence of process parameters (i.e., sample loading, addition of neutral salts or other chemicals, consecutive ATPE stages, system geometry, recycling of chemicals, biomass concentration), upon product recovery/purity has to be evaluated for further improving, thus optimizing the performance of the recovery process by ATPE (Benavides and Rito-Palomares 2008).

Practical approach for the development and design of ATPE processes for the recovery of biomolecules using PEG–salt ATPS, adapted from Benavides and Rito-Palomares (2008)

ATPE has been used since the mid-1950s as a mild bioseparation technique covering a wide range of applications in cell biology, biochemistry, and biotechnology (Albertsson 1986). In this context, ATPS have been efficiently used for separating various proteins and enzymes and gained an increasing interest of different industries for the recovery and purification of high valuable products (Azevedo et al. 2009b; Benavides and Rito-Palomares 2008; Rosa et al. 2011). Furthermore, ATPS have been successfully used in various other applications, such as the large-scale separation and production of engineered proteins (Selber et al. 2004), multi-stage ATPE of human antibodies (Rosa et al. 2009), or the initial primary DSP for the partial purification of industrial enzymes (Naganagouda and Mulimani 2008). In terms of process simplicity and low-cost of the phase-forming components, the large-scale extraction and purification of enzymes is feasible by using appropriate scale-up techniques, which have been used for some successful enzyme applications on a large-scale ATPE (Hustedt et al. 1988; Kula et al. 1982; Naganagouda and Mulimani 2008). Furthermore, ATPE has been successfully utilized for the separation and purification of biomolecule mixtures (Shahriari et al. 2010; Tanuja et al. 1997) and several biological active substances, such as human antibodies (Azevedo et al. 2009a), whey proteins (Alcântara et al. 2011), amylases (Kammoun et al. 2009), and lectins (Nascimento et al. 2010). In particular, ATPS have been extensively used for the recovery and purification of valuable biopharmaceuticals, like monoclonal antibodies, as an alternative to conventional chromatographic techniques (Azevedo et al. 2009a, b, c; Mao et al. 2010; Muendges et al. 2015; Oelmeier et al. 2011; Platis and Labrou 2006; Rosa et al. 2009). Moreover, PEG–salt ATPS have been integrated in different processes regarding bioconversion, fermentation, cell disruption, and affinity partitioning, as discussed with various other applications in the following chapters. Furthermore, the mechanistic understanding and in silico modeling of protein partitioning in ATPS are highly important aspects and the main key for the broad applicability of ATPS in the pharmaceutical industry and to meet regulatory demands, but these aspects will be not within the scope of this review and can be read elsewhere, such as in the publication reported by Dismer et al. 2013.

Single- and multi-stage extraction

Partial or complete purification of proteins and enzymes is obtained in the DSP by ATPS which can be used as a single- or multi-stage extraction method depending on the specific recovery and purification requirements (Albertsson et al. 1990; Benavides and Rito-Palomares 2008; Benavides et al. 2011; Raghavarao et al. 1995). In general, single-stage extraction is more suitable for the primary purification, i.e., removal of cell debris and other contaminants, whereas multi-stage extraction is used when the product recovery yield and/or purity requirements cannot be obtained in one single separation stage (Benavides et al. 2011; Raghavarao et al. 1995). As an alternative, the process conditions and system parameters can be changed in consecutive extraction stages for further increasing the process performance, which is recommended for the recovery of high valuable products, when the target product cost can compensate the cost related to the consumption of phase-forming components and process operation (Benavides and Rito-Palomares 2008; Benavides et al. 2011). A common process is consisting of two consecutive separation stages, at which the first stage is used as a selective extraction step, whereas the second is a back extraction (Benavides et al. 2011). Simplified single- and multi- or two-stage extraction processes based on PEG–salt ATPS (Fig. 2) can be performed in batch or continuous mode. In this context, a single-stage extraction process can be exemplarily characterized by a selective extraction stage, resulting in a PEG-rich top phase containing the target product and a salt-rich bottom phase with the contaminants (Fig. 2a). On the other hand, a multi- or two-stage extraction process (Fig. 2b) can be described by a first selective extraction stage excluding the contaminants of the salt-rich bottom phase from the feedstock and creating a PEG-rich top phase enriched in the target product (Fig. 2a). Afterwards, the target product is partitioned in the second extraction stage (back extraction) into the bottom phase by using a fresh salt-rich back extraction solvent facilitating a recycling of the top phase (Fig. 2b).

Single- (a) and multi-stage (b) extraction processes based on PEG–salt ATPS for the separation, recovery, and purification of biological products, adapted from Benavides et al. (2011)

Moreover, multi-stage ATPE processes have been explored using several additional techniques, such as the countercurrent distribution (CCD) and countercurrent chromatography (CCC) for the separation, recovery, and purification of biological products (Albertsson 1986, 1990; Benavides et al. 2011; Diamond and Hsu 1992; Raghavarao et al. 1995; Shibusawa et al. 1998; Walter et al. 1985). In the CCD, biomolecules are separated according to their affinity for both immiscible aqueous phases which are moving in opposite or countercurrent directions, mixed in a chamber and then settled down by gravity or centrifugation to facilitate aqueous two-phase separation (Åkerlund 1984; Albertsson 1965; Benavides et al. 2011; Diamond and Hsu 1992). In this context, the PEG-rich top phase is transferred off in one and the salt-rich bottom phase in the opposite direction in order to generate a new thermodynamic equilibrium (Benavides et al. 2011). Hence, the contact of both phases is resulting in a large number of transfer steps (60 to 120) used for the separation of biomolecules with different partition coefficients (Albertsson 1986; Diamond and Hsu 1992; Kula et al. 1982). On the other hand, the CCC is a high-resolution chromatography technique based on the principle of the CCD, in which the stationary phase is retained in a column by gravity or centrifugation (Ito and Bowman 1971; Shibusawa et al. 1998), providing several advantages over high-performance liquid chromatography (HPLC), such as higher processing capability, low pressure drops, and lower maintenance cost (Benavides et al. 2011; Shibusawa et al. 1998). Thereby, phase-forming system components of low-MW and low-viscosity are preferentially used due to a reduced component deposition on the inner walls of the CCC equipment, an increased mass transfer between the phases and lower pressure drops (Benavides et al. 2011). The CCC does not have discrete transfer stages (like CCD) and is a continuous extraction operation resulting in a large number of transfer units as exhibited in HPLC (Diamond and Hsu 1992; Raghavarao et al. 1995). Furthermore, as the CCC does not have any solid support beads (like chromatography), all disadvantages arising from them, like biomolecule denaturation, sample contamination, and adsorption loss, are reduced (Diamond and Hsu 1992; Raghavarao et al. 1995). Several examples of single- und multi-stage extractions using PEG–salt ATPS are summarized in Table 1.

Process integration

Since too many unit operations in the DSP of biological products are usually resulting in lower product recovery yields, there is an increasing demand in the biotechnological industry to establish new scalable and efficient product recovery processes for the development of new biological products (Benavides et al. 2008, 2011). In this context, process integration of unit operations is a common approach for DSP optimization by combining two or more discrete unit operations into one single unit operation, thus reducing the total number of unit operations, while the product recovery yield is increased without compromising its purity (Benavides et al. 2008, 2011; Rito-Palomares 2004). In this context, four major process integration techniques using PEG–salt ATPS are available, viz., (1) extractive bioconversion, (2) extractive fermentation, (3) extractive disruption, and (4) extractive purification (Benavides et al. 2008, 2011), as depicted in Fig. 3 and outlined separately ahead.

Process integration techniques using PEG–salt ATPS: a extractive bioconversion = reaction + extraction; b extractive fermentation = fermentation + extraction; c extractive disruption = cell disruption + extraction; d extractive purification = affinity + extraction, adapted from Benavides et al. (2011)

Extractive bioconversion

Extractive bioconversions are consisting of the synthesis of a biological product in one phase (e.g., PEG-rich top phase) using a biocatalyst (e.g., enzyme) and a continuous separation as well as in situ recovery of the synthesized target product toward the opposite biocatalyst-free phase (e.g., salt-rich bottom phase) (Fig. 3a) (Andersson and Hahn-Hägerdal 1990; Benavides et al. 2011; Zijlstra et al. 1998). Hence, a biochemical reaction is taking place in the aqueous phase containing the biocatalyst (enzyme or microorganism), while the target product is partitioned and recovered in the opposite biocatalyst-free phase (Andersson and Hahn-Hägerdal 1990; Benavides et al. 2008). That means, ATPS provide an interesting technique for a simultaneous synthesis, recovery, and purification of a biological product by using biocatalysts, at which the substrate or biocatalyst (e.g., enzyme, microorganism) is partitioned into one phase, while the target product (e.g., protein) is partitioned into the opposite phase (Albertsson et al. 1990; Diamond and Hsu 1992). This extraction/separation can be only facilitated when enzymes and target products are completely partitioned into opposite phases, at which this complete partitioning is the main difficulty in extractive bioconversion (Andersson and Hahn-Hägerdal 1990; Cabral 2007; Kondo et al. 1994). However, this difficulty has been overcome by using enzymes as whole cell preparations (Tomáška et al. 1995), an immobilization of enzymes on ultrafine silica particles (Kondo et al. 1994), and a chemical coupling of enzymes to PEG (Mukataka et al. 1992). Furthermore, it is necessary for an efficient extraction/separation that enzymes maintain their stability under the operational conditions containing pH changes and the use of high reactant concentrations (Andersson et al. 1984). Since the target product is continuously removed without losing the biocatalyst and not enriched in the reactive biocatalyst-containing phase, the target product is preferentially synthesized owing to the thermodynamic equilibrium (Benavides et al. 2008, 2011; Ratanapongleka 2010). Furthermore, the biocatalyst can be retained and reused by recycling of the biocatalyst-containing phase and a biocatalyst-free target product phase is available for a further DSP (Cabral 2007; Zijlstra et al. 1998). ATPS are especially beneficial for in situ product recovery in extractive bioconversions due to a relatively mild environment for biocatalysts providing biocompatibility and the suitability for the extraction of hydrophilic products like proteins (Albertsson 1986; Andersson and Hahn-Hägerdal 1990; Cabral 2007; Hustedt et al. 1988; Kula et al. 1982; Zijlstra et al. 1998). Furthermore, ATPS have shown potential for increasing product yield and overall productivity of extractive bioconversions which have a scale-up potential (Andersson and Hahn-Hägerdal 1990; Ratanapongleka 2010; Zijlstra et al. 1998). An increasing product yield may be obtained by decreasing product inhibition through immediately removing target product or by preventing product degradation through diminishing product residence time in the biocatalyst vicinity (Zijlstra et al. 1998). Moreover, this in situ product recovery technique is providing a continuous processing with biocatalyst retention, resulting in a high improved overall volumetric productivity (Zijlstra et al. 1998). Several examples of extractive bioconversions in PEG–salt ATPS are shown in Table 2.

Extractive fermentation

Extractive fermentations are further extraction strategies containing in situ product recovery and simultaneously performed fermentation and product separation processes (Banik et al. 2003). Furthermore, these techniques are involving the growth of an expression system synthesizing an extracellular target product in one of the aqueous phases (e.g., PEG-rich top phase), while the expressed target product is partitioned toward the opposite phase to be recovered (e.g., salt-rich bottom phase) (Fig. 3b) (Benavides et al. 2011). Thereby, aqueous biphasic systems are inoculated with the expression system growing selectively in a particular phase, while the continuously secreted target product is partitioned toward the opposite phase (Benavides et al. 2011). This approach is representing an attractive technology for the continuous removal of the target product from fermentation broth as it is produced by the expression system, thus overcoming low product yields in conventional fermentation processes due to product inhibition and recovering the target product in one cell-free phase, while the expression system is continuing its production in the opposite phase (Benavides et al. 2008, 2011; Rito-Palomares 2004; Sinha et al. 2000). That means, extractive fermentation or in situ product recovery is involving the integration of an extractive step as the first DSP step for the removal of the target product simultaneous to its synthesis and it is providing a technological solution to overcome limitations of product inhibition and low-volumetric productivity properties of biotechnological processes (Banik et al. 2003). Overall, extractive fermentations can only be used when the target product is secreted by the expression system, i.e., when it is extracellular; thus, they are limited to the recovery of extracellular target products (Benavides et al. 2008; Rito-Palomares 2004). Various examples of extractive fermentations in PEG–salt ATPS are represented in Table 3.

Extractive disruption

In contrast to extractive fermentations, when the target product is not secreted into the culture media and is therefore intracellular, cell disruption is necessary in order to release the target product or for the recovery of intracellular target products (Benavides et al. 2008, 2011; Rito-Palomares 2004). In this context, extractive disruption, i.e., the application of ATPS for the integration of cell disruption and the primary recovery of intracellular target products is representing an attractive approach (Benavides et al. 2008, 2011; Rito-Palomares 2004). Thereby, cell disruption or permeation can be performed chemically or mechanically within the ATPS leading to a homogenous solution which is afterwards allowed to settle down in order to promote aqueous two-phase separation (Benavides et al. 2011). Hence, cell disruption of the expression system and a selective separation of the released target product in a particular aqueous phase (e.g., PEG-rich top phase) as well as partition of cell debris in the opposite phase (e.g., salt-rich bottom phase) or a probable formation of an interphase between the top and bottom phase by the cell debris are simultaneously achieved in a single unit operation (Fig. 3c) (Benavides et al. 2008, 2011; Rito-Palomares and Lyddiatt 2002; Rito-Palomares 2004). Generally, the process conditions for the extractive disruption of a biomolecule (e.g., protein) from disintegrated cells should be chosen in such a way that the protein is preferentially partitioned into the top phase, while the solid cell material/cell debris is normally partitioned into the bottom phase (Hustedt et al. 1985b; Kula et al. 1982). On the other hand, the reverse case is rather disadvantageous regarding phase separation on a technical scale since the performance of a centrifugal separator is highly decreased by a high solid concentration in the top phase (Hustedt et al. 1985b). Finally, the target product yield and quality can be increased by extractive disruption due to economic process benefits related to the reduction of unit operations (Rito-Palomares 2004). Different examples of extractive disruptions in PEG–salt ATPS are shown in Table 4.

Extractive purification

In addition to the application of ATPS as a primary recovery technique, these systems are also suitable for partial purifications of a target product (Benavides et al. 2008). In this context, ATPS are containing chemically modified phase-forming polymers (e.g., PEG) and the addition of affinity ligands (biological or chemical molecules) is usually leading to a significant enhancement of the selectivity and purification factor of the target product in aqueous two-phase affinity partitioning (ATPAP) or extractive purification by using bioaffinity-enhanced ATPS, at which a product-ligand complex may be built and partitioned in one of the phases (e.g., PEG-rich top phase), while the contaminants are partitioned into the opposite phase (e.g., salt-rich bottom phase) (Fig. 3d) (Benavides et al. 2008, 2011; Liu et al. 2011; Park et al. 2007). Hence, bioaffinity-enhanced ATPS enable the integration of primary recovery and purification of target products in one single stage, thus considerably increasing the potential of ATPS for purifying a target product (Benavides et al. 2008, 2011). In general, ATPAP or affinity partitioning and separation in ATPS may be achieved by two different techniques, viz., (1) free ligand addition and (2) ligand-coupled components (Benavides et al. 2011), as illustrated in Fig. 4.

The first technique is consisting of the addition of affinity ligands (molecules with a specific affinity for a particular target product) to ATPS which can be free in solution (Liu et al. 2011; Park et al. 2007), resulting in an uneven partition of the ligands between the phases (Benavides et al. 2011). These free ligands are inducing a partition shift of the target biomolecule without any chemical modification of the phase-forming components (Azevedo et al. 2009a; Ruiz-Ruiz et al. 2012). Finally, when the target product is added to ATPS, it is partitioned selectively into the free ligand-rich phase (Fig. 4a) (Benavides et al. 2011). In the second technique, ATPS are totally or partially formed by using derivate phase-forming components containing covalently attached affinity ligands specific for a particular target product (Benavides et al. 2011; Liu et al. 2011; Park et al. 2007). In other words, a chemical modification of the phase-forming components is taking place by attaching affinity ligands with specificity for the target biomolecule (Cordes et al. 1987; Ruiz-Ruiz et al. 2012). Consequently, when the target product is added to ATPS, it is partitioned preferentially toward the ligand-coupled-rich phase (Fig. 4b) (Benavides et al. 2011). Hence, ligands covalently bound to one of the phase-forming components are useful in order to direct protein extractions according to the ligand which is predominantly partitioned with the polymer in one phase (Kula and Selber 2002). In this context, there is an equilibrium of partition and protein-ligand complex formation in affinity extraction processes according to Fig. S1 in the Supplementary Material (Kula and Selber 2002). This affinity extraction technique is a reactive process, whose extraction efficiency is depending on the number of binding protein sites and the dissociation constant of the complex, at which the latter may be differing in both phases (Cordes et al. 1987; Kula and Selber 2002). In this technique, a covalent coupling of ligands to one of the phase-forming components is usually requiring complex chemical procedures involving activation and a grafting stage (Benavides et al. 2011). In case of PEG–salt ATPS, PEG has to be chemically active and is easily amenable to derivatization due to its terminal hydroxyl groups, thus strategies focus on active hydroxyl groups present in polymers (Azevedo et al. 2009c; Liu et al. 2011; Ruiz-Ruiz et al. 2012). These active hydroxyl groups provide a chemical nature allowing a further covalent coupling of affinity ligands or addition of nucleophilic groups present in amino acids, peptides, and proteins; hence, nucleophilic substitutions and additions are resulting in protein coupling (Andrews et al. 1990; de Gouveia and Kilikian 2000; Head et al. 1989; Ruiz-Ruiz et al. 2012). Several examples of traditional procedures for activation of PEG molecules for ATPAP have been reported by Harris et al. (1984) and Ruiz-Ruiz et al. (2012). In this context, ATPAP strategies could be developed by using PEG derivatives as affinity ligands, such as PEG–trimethylamine, PEG–palmitate, PEG–benzoate, and/or PEG–phenylacetamide (Ruiz-Ruiz et al. 2012). Generally, cofactors or inhibitors of the target protein can be used as affinity ligands, at which ligands based on textile dyes are more often used than natural ligands (Kula and Selber 2002). Besides textile dyes, metal chelators are also used as attractive ligands, as they are robust and cheap chemicals applicable in PEG–salt ATPS offering a useful selectivity (Kula and Selber 2002). Furthermore, various syntheses of PEG derivatives have been reported by Harris (1985). Overall, ligand-coupled components are used preferentially since there is no previous characterization of the partitioning behavior of free ligands necessary (Benavides et al. 2011). Nevertheless, the application of free ligands is emphasized by recent researchers in order to avoid chemical activations of polymers (Ruiz-Ruiz et al. 2012). Several examples of extractive purifications in PEG–salt ATPS are highlighted in Table 5.

Large-scale extraction and purification

Extractions and purifications of proteins, such as enzymes, using ATPS have been successfully performed on a large scale for more than a decade (Cunha and Aires-Barros 2002). Thereby, the partitioning of proteins in ATPS is a promising large-scale extraction and purification technique containing an increasing application for large-scale processes in industry and providing a technically and economically attractive alternative to traditional bioseparation processes (Albertsson 1986; Diamond and Hsu 1992; Hustedt et al. 1985a, b; Kroner et al. 1984; Kula and Selber 2002). PEG–salt ATPS are most commonly used in large-scale applications because they have a general applicability, a relatively suitable viscosity and density difference, as well as biodegradability and non-toxicity (Diamond and Hsu 1992; Gu 2000). Moreover, the intensive large-scale application of PEG–salt ATPS is mainly attributed to economic considerations (Albertsson et al. 1990). Several examples of large-scale applications and patents are summarized in Table 6 and Table S1 in the Supplementary Material, respectively, addressing large-scale extractions and purifications of various proteins in PEG–salt ATPS. Since these macromolecules are used in all biotechnology-related applications, as they are the most versatile biomolecules in terms of functionality and structure, PEG–salt ATPS are primarily used for the large-scale extraction and purification of proteins, such as enzymes, therapeutic proteins, and functional proteins as additives (Benavides et al. 2011). Different investigations have been carried out concerning enzyme recoveries with applications in food, paper, and detergent industry, as well as in medical treatments and bioremediation (Benavides et al. 2011). Moreover, an extensive research has been conducted regarding applications for the primary recovery and partial purification, as well as for understanding the separation behavior of therapeutic proteins, such as monoclonal and polyclonal antibodies, α-interferon, and blood/serum-related proteins in ATPS due to an ever-increasing interest in using therapeutic proteins for the treatment and prevention of a wide range of diseases (Andrews and Asenjo 2010; Benavides et al. 2011). Furthermore, the recovery and purification of functional proteins used in the cosmetic and food industry, as well as in molecular biology have been reported (Benavides et al. 2011). For instance, phycobiliproteins, i.e., colored proteins forming a part of the photosynthetic apparatus of cyanobacteria and reel algae, like B-phycoerythrin and C-phycocyanin, have been partitioned and partially purified in ATPS (Benavides et al. 2011). These proteins are used as color agents for cosmetic and food products, as well as applied in microscopy and molecular biology as fluorescent colorant for labeling and immunodetection (Benavides and Rito-Palomares 2006; Benavides et al. 2011; Rito-Palomares et al. 2001; Ruiz-Ruiz et al. 2013).

Technical aspects

Large-scale protein recovery using ATPS is requiring two technical operations, viz., (1) mixing of the phase components followed by phase dispersal and (2) phase separation (Cunha and Aires-Barros 2002; Hustedt et al. 1985b). In batch processes, equilibration is usually obtained by using stirred vessels or mixer-settler devices (Cunha and Aires-Barros 2002; Hustedt et al. 1985b; Kula and Selber 2002; Papamichael and Hustedt 1994). A few minutes (e.g., 10 min) of gentle stirring are normally enough in order to obtain phase and partition equilibrium (Cunha and Aires-Barros 2002; Fauquex et al. 1985; Hustedt et al. 1985a, b). The fast (≤30 s) approach to equilibrium (Fauquex et al. 1985) due to low interfacial tension between both phases is facilitating a very small droplet formation, and hence a large interface for mass transfer with low energy input (Cunha and Aires-Barros 2002; Hustedt et al. 1985a, b; Kula and Selber 2002). After phase equilibration is achieved, the phases have to be separated into a top and bottom phase which is carried out either by settling under gravitational force for fast-settling PEG–salt systems or by continuously operating common centrifugal separators (Cunha and Aires-Barros 2002; Hustedt et al. 1985a; Kula and Selber 2002). The latter is recommended at a high viscosity or low density difference between the phases (Hustedt et al. 1985a; Kula and Selber 2002). Furthermore, centrifugation is resulting in higher yields as entrainment is avoided at higher g forces, at which optimal feed rates of the suspension up to 3 L/min corresponding to a residence time of about 16 s have been reported using small disk stack separators (Hustedt et al. 1985a; Kula and Selber 2002). After the initial separation step, the PEG-rich top phase is often mixed with salts to form a secondary phase, at which experimental conditions are selected according to a partitioning of the target protein into the salt-rich bottom phase and a further processing after phase separation (Kula and Selber 2002). Furthermore, ultrafiltration, centrifugation, adsorption, or electrophoreses can be used for protein isolation from PEG-rich top phases, at which ultrafiltration or diafiltration is preferably used in large-scale processes in order to concentrate and condition the target product from the secondary salt-rich bottom phase, while the PEG-rich top phase may be recycled (Hustedt et al. 1985b; Johansson 1994; Kula and Selber 2002). Besides this, a secondary salt-rich bottom phase may be applied under certain conditions to a chromatographic support, like hydrophobic interaction matrices (Kula and Selber 2002).

Although most of the ATPE processes are usually carried out in the batch mode operation, they are also suitable for continuous processing, which is often more cost-effective due to an efficient use of time and space with consequently low labor cost (Espitia-Saloma et al. 2014; Hustedt et al. 1985a, b; Kula and Selber 2002). Hence, ATPE processes performed in a continuous or semi-continuous operation mode in the biotechnological industry are resulting in reduced process time and cost, as well as increased process yields (Espitia-Saloma et al. 2014; Igarashi et al. 2004; Vázquez-Villegas et al. 2011). Owing to these advantages, many promising research areas within continuous ATPS operation mode are now available, such as the bioaffinity partitioning (Ruiz-Ruiz et al. 2012) and separation of PEGylated proteins (Mayolo-Deloisa et al. 2011), in order to recover different biomolecules, operational models for process optimization, large-scale operation, phase recirculation, etc. (Espitia-Saloma et al. 2014). In general, continuous processing in production lines can be divided into the co-, cross-, and countercurrent flow, at which the last is the most efficient production line in large-scale processes due to higher yields and lower chemical consumptions (Kula and Selber 2002; Papamichael and Hustedt 1994). Countercurrent extraction has been studied for various multi-stage extraction processes, while the continuous cross-current extraction has been investigated experimentally in pilot scale (Kula and Selber 2002; Vázquez-Villegas et al. 2015). Enzyme extraction has been successfully carried out using more than 500 kg yeast per day in a computer-controlled process (Hustedt et al. 1987; Kula and Selber 2002). The procedure could also be applied for continuous enzyme extraction from bacterial cell homogenates (Hustedt and Papamichael 1988; Kula and Selber 2002). Furthermore, several other cross-current extraction processes have been developed so far (Hustedt et al. 1985b, 1988; Papamichael and Hustedt 1994; Veide et al. 1984). For instance, fumarase has been recovered from Brevibacterium ammoniagenes by a two-stage extraction process (Hustedt et al. 1985a, b; Kroner et al. 1984). Since multiple partition stages are required in order to improve the extraction efficiency or achieve a higher purification by using ATPS, several multi-stage devices used in the chemical industry for liquid–liquid ATPE processes have been studied (Kula and Selber 2002). Thereby, the performance of the raining bucket or Graesser contactor has been best investigated for the separation of α-lactalbumin from cheese whey, resulting in a space time yield of 29 g/L per reactor volume and day, as well as a reduced rotation speed from 20 to 2–5 rpm when working with PEG–salt ATPS, while the rotational direction has been additionally reversed in order to reduce the mixing intensity and avoid flooding (Dos Reis Coimbra et al. 1994, 1995; Kula and Selber 2002). Other devices studied for multi-stage extractions are, e.g., the mixer-settler (Veide et al. 1984), Kühni columns (Hustedt et al. 1980), spray columns (Jafarabad et al. 1992), and the Podbielniak extractor (Kula et al. 1982), which can be operated successfully with particular precautions against flooding (Kula and Selber 2002). Furthermore, liquid–liquid extraction equipment and methodology for ATPE of proteins on a large scale using different multi-stage devices employed for continuous ATPE processes, such as novel designed mixer-settler units, conventional column contactors (e.g., plate column, packed column, York-Sheibel column), and various other contactors and devices for enhancing mass transfer and improving protein recoveries have been reported in literature (Cunha and Aires-Barros 2002; Espitia-Saloma et al. 2014; Kula et al. 1982; Raghavarao et al. 1995).

Scale-up

One of the major advantages of ATPS is the easy scale-up potential through the use of commercially available extraction equipment and machinery commonly used for organic aqueous extractions in the chemical industry (Cunha and Aires-Barros 2002; Kula et al. 1982; Kula and Selber 2002; Raghavarao et al. 1995). The ease of scaling up combined with high obtained partition coefficients is providing potential applications in the large-scale DSP of proteins (Cunha and Aires-Barros 2002). In this context, several authors (Hart et al. 1994; Kroner et al. 1982; Schütte et al. 1983) have demonstrated the feasibility of the scale-up potential by a proportional linear increase of the amount of process chemicals requiring centrifugation equipment which is commercially available and can be selected according to the Sigma concept (Kula and Selber 2002). This concept, introduced by Ambler 1959, is a common method for comparing the settling area of a centrifuge with the one of a gravity settling tank capable of the same separation performance as the centrifuge resulting in a centrifugal settling area or an equivalent separation area which is commonly used to describe the clarification process in a centrifuge and is an index of its size (Ambler 1959; Boychyn et al. 2000; Mannweiler 1989). Thereby, extractive enzyme recovery has been performed on scales varying from 10 mL to more than 1 m3 of the phase system, at which a scaling up from 10 mL containing a proportional increase of the amount of all process chemicals yielded to similar results, within experimental error, for the extraction process of various biomolecules, like enzymes (Hustedt et al. 1985a), as reported exemplarily for the purification of leucine dehydrogenase from Bacillus sphaericus (Schütte et al. 1983), as well as presented in an extensive study on the purification of formate dehydrogenase (FDH) from Candida boidinii (Kroner et al. 1982). In Table S2 in the Supplementary Material, the scale-up data of Kroner et al. (1982) are represented for the purification of FDH from C. boidinii in a PEG–potassium phosphate system, in which the yield of FDH obtained in 10 mL scale partition steps is compared with the yield observed in process scale during the purification of FDH, resulting in similar data, even at the highest scale-up factor close to 40,000 (Kula et al. 1982). In other words, a scale-up of nearly 40,000 was carried out for several separation steps without any significant changes in yield (Kula and Selber 2002). Thereby, the fast approach to phase equilibrium with gentle stirring and mixing, the fact that the partitioning of target products is independent of process scale and product concentration (in the range of practical interest), as well as an efficient and reliable phase separation are contributing to advantageous circumstances for scale-up (Hustedt et al. 1985a). On the other hand, scale-up is further facilitated by the abovementioned commercial availability of the required equipment and machinery owing to the high standard of extraction technologies in the chemical industry, e.g., separators covering a wide variety of sizes (Hustedt et al. 1985a; Kula et al. 1982).

Recycling of process chemicals

The application of ATPS in large-scale processes is not only depending on technical potential and feasibility but is also strongly depending on the overall process economics, at which the high chemical and waste disposal cost regarding the consumption of chemicals and corresponding wastewater treatment can be strongly reduced by recycling of the process chemicals or phase-forming components (Datar 1986; Greve and Kula 1991; Hustedt et al. 1985a, b; Kula and Selber 2002; Rito-Palomares and Lyddiatt 2000). As the potential commercial value of products, such as proteins, is easily compromised by a relative high PEG concentration in the top phase of PEG–salt ATPS, the residual amount of PEG has to be removed along with salt by ultrafiltration or diafiltration for large-scale extractions and purifications of proteins (Gu 2000; Hummel et al. 1985; Hustedt et al. 1985a; Raghavarao et al. 1995; Rito-Palomares and Lyddiatt 2000; Rito-Palomares 2004). In this context, the influence of PEG recycling upon target product partitioning has been evaluated in a two-stage PEG–salt ATPE process containing a first and back extraction stage with integrated phase recycling and an ultrafiltration unit, as illustrated in Fig. S2 in the Supplementary Material (Gu 2000; Hustedt et al. 1985a; Raghavarao et al. 1995; Rito-Palomares et al. 1994; Rito-Palomares 2004; Rito-Palomares and Lyddiatt 2000). Thereby, solid-PEG and salt are dissolved in a biological suspension resulting in the formation of a first PEG–salt system representing the first extraction stage, in which contaminants are removed from the biological source and partitioned into the salt-rich bottom phase, while the soluble target product is enriched in the generated PEG-rich top phase (Rito-Palomares and Lyddiatt 2000; Rito-Palomares 2004). Afterwards, the bottom phase containing the contaminants is discarded, while the top phase is mixed with a fresh salt solution leading to the formation of a second PEG–salt system representing the second extraction stage (back extraction), in which the target product is partitioned into the new formed salt-rich bottom phase facilitating the removal and recycling of PEG or the second top phase which can be reused in a new first extraction stage, while the final bottom phase containing the target product is further processed by passing through an ultrafiltration unit yielding to the recovery of a concentrated target product and a salt solution (Hustedt et al. 1985a; Raghavarao et al. 1995; Gu 2000; Rito-Palomares and Lyddiatt 2000; Rito-Palomares 2004). Finally, the salt solution generated by ultrafiltration can be concentrated and directly recycled and reused in the back extraction stage, thus reducing the consumption of fresh salt involved in this process stage (Rito-Palomares and Lyddiatt 2000). According to Hustedt (1986), recycling of phosphate-rich bottom phase can be carried out for up to four cycles without any significant influence upon process performance by saving of 45 wt% of the required fresh phosphate solution (Rito-Palomares and Lyddiatt 2000). Furthermore, phosphate could be recycled from solid-free process streams by crystallization at 6 °C (Hustedt et al. 1985a; Kula and Selber 2002). Moreover, a few examples of PEG–salt ATPE processes with integrated phase recycling and ultrafiltration are shown in Table S3 in the Supplementary Material. For instance, a successful recycling of most of PEG from secondary extraction has been performed by Papamichael et al. (1992) in a two-stage ATPE process of fumarase from baker’s yeast, in which the consumption of PEG and potassium phosphate could be reduced by 50 and 12 %, respectively (Kula and Selber 2002; Raghavarao et al. 1995). Furthermore, fumarase from B. ammoniagenes could be successfully purified according to the above described ATPE process, allowing a reduced chemical consumption of up to 40 % (Hustedt et al. 1985a, b; Kroner et al. 1984).

Economic aspects

The cost of the recovery and purification of proteins using ATPE processes are depending on various factors, such as actual system and scale (Kula and Selber 2002). For instance, a comparison between a downstream process of Bacillus α-amylase using a conventional method and ATPS was exemplarily carried out at Miles Inc., at which the latter was performed in a 50,000-L large-scale process requiring fewer stages, thus resulting in higher yields (80 to 95 vs. 70 %) and reduced cost of 35 to 50 % (Kim et al. 1988; Kula and Selber 2002). Moreover, ATPS have several advantages over traditional techniques for protein purifications and a few comparative investigations are reported in literature. In this context, Nitsawang et al. (2006) studied the purification of papain from wet Carica papaya latex by extraction in a PEG 6000–ammonium sulfate system and compared this ATPE process with a conventional technique based on a two-step salt precipitation. This comparison revealed that ATPS are providing a significantly higher papain recovery (∼88 vs. 49 %) and purity (100 vs. ∼89 %) in a much shorter processing time. Furthermore, Aguilar et al. (2006) investigated the purification of penicillin acylase from a recombinant strain of Escherichia coli using a PEG 1450–phosphate system and performed a direct comparison of this ATPE process with an ion-exchange chromatography (IEC) process, at which the proposed ATPE process proved to be favored and more cost-effective due to a reduced number of unit operations (from 7 to 4), higher enzyme recovery (97 vs. 48 %), as well as an economic analysis based upon significantly reduced cost of each unit operation and separating agents. Additionally, in a study by Naganagouda and Mulimani (2008) referring to the purification of α-galactosidase from Aspergillus oryzae using a PEG 4000–phosphate system a comparison between an ATPE and IEC process was carried out, resulting in a preferred ATPE process with a reduced number of unit operations (from 5 to 3) and a higher enzyme recovery (87.6 vs. 11.5 %).

Furthermore, Omidinia et al. (2010) investigated the purification of phenylalanine dehydrogenase from recombinant Bacillus badius using a PEG 6000–K2HPO4 system and performed a direct comparison of this ATPE process with a conventional chromatography process consisting of an ammonium sulfate precipitation and two anion-exchange chromatography steps after cell disruption, resulting in a favored ATPE process containing a reduced number of unit operations (from 10 to 5), higher enzyme recovery (96.7 vs. 25 %) and specific activity (4213.4 vs. 553.6 U/mg), shorter process time (4 vs. 48 h), lower process costs (4 vs. 20 €), and an improved enzyme thermostability (9 vs. 3 months). In addition, the application of ATPE for the purification of phytase from Aspergillus niger has been studied by Bhavsar et al. (2012) and compared with a traditional multi-step chromatography process composed of salt precipitation and column chromatography, at which a reduction in the number of unit operations (from 7 to 1), higher phytase recovery (98.5 vs. 20 %) within a shorter process time (3 vs. 96 h), and an improved thermostability were obtained by using a PEG 6000/8000–sodium citrate system. Moreover, Mohammadi and Omidinia (2013) studied the recovery and purification of recombinant Pseudomonas fluorescens proline dehydrogenase from inclusion bodies by using an integrated process which combined the partitioning in a PEG 1000–sodium carbonate system with a simultaneous refolding and reconstitution process and performed a comparison of the integrated process with a multi-step affinity chromatography process, resulting in a favored integrated process covering a reduced number of unit operations (from 9 to 6), a higher enzyme purification factor (27 vs. 11), reduced process time (from 36 to 1.45 h), and a higher enzyme stability time (6 vs. 2 months). Furthermore, in a study by Nascimento et al. (2013) a PEG 8000–sodium citrate system was used for the recovery and purification of the lectin Cramoll 1,4 from Cratylia mollis and a comparison between the ATPE and a multi-step affinity chromatography process was performed, which revealed a reduced number of unit operations (from 10 to 4) with a higher Cramoll 1,4 recovery (125 vs. 69 %) and purification factor (13.25 vs. 11) in the ATPE process. Overall, the results of the comparative studies are demonstrating that ATPS can be preferably used as alternative methods over conventional DSP techniques for the large-scale extraction and purification of proteins, making the whole ATPE processes more cost-effective than traditional methods.

Conclusions

As evident from this review, PEG–salt ATPS have the feasibility to operate as a promising and efficient liquid–liquid extraction technology for the DSP of various proteins and enzymes. Furthermore, ATPS provide several advantages over conventional DSP methods, such as biocompatibility, technical simplicity, process integration, continuous operation capability, and an easy scale-up potential. Therefore, these systems have gained importance for a wide range of applications in several biotechnological fields. For instance, ATPS have demonstrated to be highly suitable for different integrated downstream processes, resulting in a significant reduction of the total number of unit operations, and consequently reduced overall cost. Moreover, ATPS can be carried out in a continuous operation mode, which is representing a technically and economically attractive alternative over traditional DSP technologies for the extraction, recovery, and purification of proteins and other biomolecules on a large scale. Thereby, ATPS are providing the ability to recover proteins in a reduced number of unit operations with a higher recovery and purity within a shorter process time, thus making the whole ATPE process often more cost-effective than traditional techniques. In general, ATPS can overcome some of the limitations currently faced with conventional DSP methods in terms of their versatile advantages. Therefore, continuously processed ATPS have been used on a large scale as a promising technology for the DSP of proteins, such as enzymes, functional proteins, and high-valuable biopharmaceuticals (e.g., monoclonal antibodies) covering various applications in the pharmaceutical, food, and chemical industry. However, since PEG–salt ATPS may cause environmental problems due to a large amount of phase-forming components, high chemical consumption and corresponding wastewater treatment are major concerns in industry for large-scale applications of these systems. In this context, high chemical and waste disposal cost can be strongly reduced by recycling of process chemicals using an ultrafiltration unit. Since only a few reports of PEG–salt ATPE processes with integrated phase recycling and ultrafiltration are available, allowing a reduced chemical consumption, further studies have to focus on phase recycling approaches for addressing these issues. Additionally, a high salt (e.g., phosphate, sulfate) concentration used in ATPS is causing further waste disposal and consequently environmental problems. Hence, nowadays, benign phase-forming salts, such as biodegradable citrate and volatile ammonium carbonate, are preferentially utilized, providing environmentally suitable ATPS. Overall, further investigations have to be considered regarding the development of new strategies for an efficient recycling and disposition of phase-forming components in order to solve the occurred environmental problems. Finally, addressing these optimization strategies may further promote PEG–salt ATPS as an attractive and versatile liquid–liquid extraction technology for the DSP of proteins and enzymes, as well as alternative analytical applications.

References

Aguilar O, Albiter V, Serrano-Carreón L, Rito-Palomares M (2006) Direct comparison between ion-exchange chromatography and aqueous two-phase processes for the partial purification of penicillin acylase produced by E. coli. J Chromatogr B 835(1–2):77–83. doi:10.1016/j.jchromb.2006.03.016

Aguirre C, Concha I, Vergara J, Riveros R, Illanes A (2010) Partition and substrate concentration effect in the enzymatic synthesis of cephalexin in aqueous two-phase systems. Process Biochem 45(7):1163–1167. doi:10.1016/j.procbio.2010.03.002

Åkerlund H-E (1984) An apparatus for counter-current distribution in a centrifugal acceleration field. J Biochem Biophys Methods 9(2):133–141. doi:10.1016/0165-022X(84)90004-6

Albertsson P-Å (1965) Thin-layer countercurrent distribution. Anal Biochem 11(1):121–125. doi:10.1016/0003-2697(65)90050-3

Albertsson P-Å (1986) Partition of cell particles and macromolecules. Wiley, New York

Albertsson P-Å, Johansson G, Tjerneld F (1990) Aqueous two-phase separations. In: Asenjo JA (ed) Separation processes in biotechnology Bioprocess Technology, vol 9. Marcel Dekker, New York, pp 287–327

Alcântara LAP, Minim LA, Minim VPR, Bonomo RCF, da Silva LHM, da Silva MCH (2011) Application of the response surface methodology for optimization of whey protein partitioning in PEG/phosphate aqueous two-phase system. J Chromatogr B 879(21):1881–1885. doi:10.1016/j.jchromb.2011.05.007

Ambler CM (1959) The theory of scaling up laboratory data for the sedimentation type centrifuge. J Biochem Microbiol Technol Eng 1(2):185–205. doi:10.1002/jbmte.390010206

Andersson E, Hahn-Hägerdal B (1990) Bioconversions in aqueous two-phase systems. Enzym Microb Technol 12(4):242–254. doi:10.1016/0141-0229(90)90095-8

Andersson E, Mattiasson B, Hahn-Hägerdal B (1984) Enzymatic conversion in aqueous two-phase systems: deacylation of benzylpenicillin to 6-aminopenicillanic acid with penicillin acylase. Enzym Microb Technol 6(7):301–306. doi:10.1016/0141-0229(84)90057-7

Andrews BA, Asenjo JA (2010) Theoretical and experimental evaluation of hydrophobicity of proteins to predict their partitioning behavior in aqueous two phase systems: a review. Sep Sci Technol 45(15):2165–2170. doi:10.1080/01496395.2010.507436

Andrews BA, Head DM, Dunthorne P, Asenjo JA (1990) PEG activation and ligand binding for the affinity partitioning of proteins in aqueous two-phase systems. Biotechnol Tech 4(1):49–54. doi:10.1007/BF00156610

Azevedo AM, Gomes AG, Rosa PAJ, Ferreira IF, Pisco AMMO, Aires-Barros MR (2009a) Partitioning of human antibodies in polyethylene glycol–sodium citrate aqueous two-phase systems. Sep Purif Technol 65(1):14–21. doi:10.1016/j.seppur.2007.12.010

Azevedo AM, Rosa PAJ, Ferreira IF, Aires-Barros MR (2009b) Chromatography-free recovery of biopharmaceuticals through aqueous two-phase processing. Trends Biotechnol 27(4):240–247. doi:10.1016/j.tibtech.2009.01.004

Azevedo AM, Rosa PAJ, Ferreira IF, Pisco AMMO, de Vries J, Korporaal R, Visser TJ, Aires-Barros MR (2009c) Affinity-enhanced purification of human antibodies by aqueous two-phase extraction. Sep Purif Technol 65(1):31–39. doi:10.1016/j.seppur.2008.03.006

Bach E, Sant’Anna V, Daroit DJ, Corrêa APF, Segalin J, Brandelli A (2012) Production, one-step purification, and characterization of a keratinolytic protease from Serratia marcescens P3. Process Biochem 47(12):2455–2462. doi:10.1016/j.procbio.2012.10.007

Banik RM, Santhiagu A, Kanari B, Sabarinath C, Upadhyay SN (2003) Technological aspects of extractive fermentation using aqueous two-phase systems. World J Microbiol Biotechnol 19(4):337–348. doi:10.1023/A:1023940809095

Barbosa JMP, Souza RL, Fricks AT, Zanin GM, Soares CMF, Lima ÁS (2011) Purification of lipase produced by a new source of Bacillus in submerged fermentation using an aqueous two-phase system. J Chromatogr B 879(32):3853–3858. doi:10.1016/j.jchromb.2011.10.035

Belter PA, Cussler EL, Hu W-S (1988) Bioseparations. Wiley, New York

Benavides J, Rito-Palomares M (2006) Simplified two-stage method to B-phycoerythrin recovery from Porphyridium cruentum. J Chromatogr B 844(1):39–44. doi:10.1016/j.jchromb.2006.06.029

Benavides J, Rito-Palomares M (2008) Practical experiences from the development of aqueous two-phase processes for the recovery of high value biological products. J Chem Technol Biotechnol 83(2):133–142. doi:10.1002/jctb.1844

Benavides J, Aguilar O, Lapizco-Encinas BH, Rito-Palomares M (2008) Extraction and purification of bioproducts and nanoparticles using aqueous two-phase systems strategies. Chem Eng Technol 31(6):838–845. doi:10.1002/ceat.200800068

Benavides J, Rito-Palomares M, Asenjo JA (2011) Aqueous two-phase systems. In: Moo-Young M (ed) Comprehensive biotechnology. Principles and practices in industry, agriculture, medicine and the environment, 2nd edn. Academic Press, Burlington, pp 697–713

Bezerra RP, Borba FKSL, Moreira KA, Lima-Filho JL, Porto ALF, Chaves AC (2006) Extraction of amylase from fermentation broth in poly (ethylene glycol) salt aqueous two-phase system. Braz Arch Biol Technol 49(4):547–555. doi:10.1590/S1516-89132006000500003

Bhavsar K, Ravi Kumar V, Khire JM (2012) Downstream processing of extracellular phytase from Aspergillus niger: chromatography process vs. aqueous two phase extraction for its simultaneous partitioning and purification. Process Biochem 47(7):1066–1072. doi:10.1016/j.procbio.2012.03.012

Bim MA, Franco TT (2000) Extraction in aqueous two-phase systems of alkaline xylanase produced by Bacillus pumilus and its application in kraft pulp bleaching. J Chromatogr B 743(1–2):349–356. doi:10.1016/S0378-4347(00)00223-1

Birkenmeier G, Vijayalakshmi MA, Stigbrand T, Kopperschläger G (1991) Immobilized metal ion affinity partitioning, a method combining metal-protein interaction and partitioning of proteins in aqueous two-phase systems. J Chromatogr A 539(2):267–277. doi:10.1016/S0021-9673(01)83935-2

Boychyn M, Doyle W, Bulmer M, More J, Hoare M (2000) Laboratory scaledown of protein purification processes involving fractional precipitation and centrifugal recovery. Biotechnol Bioeng 69(1):1–10. doi:10.1002/(SICI)1097-0290(20000705)69:1, <1::AID-BIT1>3.0.CO;2-4

Bradoo S, Saxena RK, Gupta R (1999) Partitioning and resolution of mixture of two lipases from Bacillus stearothermophilus SB-1 in aqueous two-phase system. Process Biochem 35(1–2):57–62. doi:10.1016/S0032-9592(99)00032-1

Cabral JMS (2007) Cell partitioning in aqueous two-phase polymer systems. In: Kumar A, Galaev I, Mattiasson B (eds) Cell separation, vol 106, Advances in biochemical engineering/biotechnology. Springer, Berlin, pp 151–171

Canales M, Ballesteros C, Moreno-Cid JA, Espinosa AM, Villar M, de la Fuente J (2009) Extractive bioconversion to produce the Aedes albopictus akirin in an aqueous two-phase system supporting Pichia pastoris growth and protein secretion. Biochem Eng J 46(2):105–114. doi:10.1016/j.bej.2009.04.014

Chang HN, Lee Y-H, Lee CY (1992) Continuous production of 6-APA in an aqueous two-phase system. Ann NY Acad Sci 672(1):643–648. doi:10.1111/j.1749-6632.1992.tb35684.x

Chen J-P, Wang C-H (1991) Lactose hydrolysis by β-galactosidase in aqueous two-phase systems. J Ferment Bioeng 71(3):168–175. doi:10.1016/0922-338X(91)90104-O

Chouyyok W, Wongmongkol N, Siwarungson N, Prichanont S (2005) Extraction of alkaline protease using an aqueous two-phase system from cell free Bacillus subtilis TISTR 25 fermentation broth. Process Biochem 40(11):3514–3518. doi:10.1016/j.procbio.2005.03.052

Cordes A, Kula M-R (1986) Process design for large-scale purification of formate dehydrogenase from Candida boidinii by affinity partition. J Chromatogr B 376:375–384. doi:10.1016/S0378-4347(00)80853-1

Cordes A, Flossdorf J, Kula MR (1987) Affinity partitioning: development of mathematical model describing behavior of biomolecules in aqueous two-phase systems. Biotechnol Bioeng 30(4):514–520. doi:10.1002/bit.260300408

Costa M, Cunha M, Cabral JS, Aires-Barros M (2000) Scale-up of recombinant cutinase recovery by whole broth extraction with PEG-phosphate aqueous two-phase. Bioseparation 9(4):231–238. doi:10.1023/A:1008162209596

Cunha T, Aires-Barros R (2002) Large-scale extraction of proteins. Mol Biotechnol 20(1):29–40. doi:10.1385/MB:20:1:029

Cunha MT, Costa MJL, Calado CRC, Fonseca LP, Aires-Barros MR, Cabral JMS (2003) Integration of production and aqueous two-phase systems extraction of extracellular Fusarium solani pisi cutinase fusion proteins. J Biotechnol 100(1):55–64. doi:10.1016/S0168-1656(02)00225-0

Datar R (1986) Economics of primary separation steps in relation to fermentation and genetic engineering. Process Biochem 21(1):19–26

de Gouveia T, Kilikian BV (2000) Bioaffinity extraction of glucoamylase in aqueous two-phase systems using starch as free bioligand. J Chromatogr B 743(1–2):241–246. doi:10.1016/S0378-4347(00)00031-1

Diamond AD, Hsu JT (1992) Aqueous two-phase systems for biomolecule separation. In: Fiechter A (ed) Bioseparation. Advances in biochemical engineering, vol 47. Springer, Berlin, pp 89–135

Dismer F, Alexander Oelmeier S, Hubbuch J (2013) Molecular dynamics simulations of aqueous two-phase systems: understanding phase formation and protein partitioning. Chem Eng Sci 96:142–151. doi:10.1016/j.ces.2013.03.020

Dos Reis CJ, Thömmes J, Kula M-R (1994) Continuous separation of whey proteins with aqueous two-phase systems in a Graesser contactor. J Chromatogr A 668(1):85–94. doi:10.1016/0021-9673(94)80095-2

Dos Reis CJ, Thömmes J, Meirelles AJ, Kula MR (1995) Performance of a Graesser contactor in the continuous extraction of whey proteins: mixing, mass transfer and efficiency. Bioseparation 5(5):259–268

Espitia-Saloma E, Vázquez-Villegas P, Aguilar O, Rito-Palomares M (2014) Continuous aqueous two-phase systems devices for the recovery of biological products. Food Bioprod Process 92(2):101–112. doi:10.1016/j.fbp.2013.05.006

Fauquex P-F, Hustedt H, Kula M-R (1985) Phase equilibration in agitated vessels during extractive enzyme recovery. J Chem Technol Biotechnol 35(1):51–59. doi:10.1002/jctb.280350110

Fernandes S, Johansson G, Hatti-Kaul R (2001) Purification of recombinant cutinase by extraction in an aqueous two-phase system facilitated by a fatty acid substrate. Biotechnol Bioeng 73(6):465–475. doi:10.1002/bit.1081

Gavasane MR, Gaikar VG (2003) Aqueous two-phase affinity partitioning of penicillin acylase from E. coli in presence of PEG-derivatives. Enzym Microb Technol 32(6):665–675. doi:10.1016/S0141-0229(03)00032-2

Greve A, Kula M-R (1991) Recycling of salts in partition protein extraction processes. J Chem Technol Biotechnol 50(1):27–42. doi:10.1002/jctb.280500105

Gu T (2000) Liquid-liquid partitioning methods for bioseparations. In: Satinder A (ed) Separation science and technology, vol 2, handbook of bioseparations. Academic Press, New York, pp 329–364

Guan Y, Wu X-Y, Treffry TE, Lilley TH (1992) Studies on the isolation of penicillin acylase from Escherichia coli by aqueous two-phase partitioning. Biotechnol Bioeng 40(4):517–524. doi:10.1002/bit.260400410

Guan Y, Lilley TH, Treffry TE, Zhou C-L, Wilkinson PB (1996) Use of aqueous two-phase systems in the purification of human interferon-α1 from recombinant Escherichia coli. Enzym Microb Technol 19(6):446–455. doi:10.1016/S0141-0229(96)00051-8

Harris JM (1985) Labratory synthesis of polyethylene glycol derivatives. J Macromol Sci, Part C: Polym Rev J 25(3):325–373. doi:10.1080/07366578508081960

Harris JM, Struck EC, Case MG, Paley MS, Yalpani M, Van Alstine JM, Brooks DE (1984) Synthesis and characterization of poly(ethylene glycol) derivatives. J Polym Sci: Polym Chem Ed 22(2):341–352. doi:10.1002/pol.1984.170220207

Hart RA, Lester PM, Reifsnyder DH, Ogez JR, Builder SE (1994) Large scale, in situ isolation of periplasmic IGF-I from E. coli. Nat Biotechnol 12(11):1113–1117. doi:10.1038/nbt1194-1113

Head DM, Andrews BA, Asenjo JA (1989) Epoxy-oxirane activation of PEG for protein ligand coupling. Biotechnol Tech 3(1):27–32. doi:10.1007/BF01876217

Hotha S, Banik RM (1997) Production of alkaline protease by Bacillus thuringiensis H 14 in aqueous two-phase systems. J Chem Technol Biotechnol 69(1):5–10. doi:10.1002/(SICI)1097-4660(199705)69:1, <5::AID-JCTB661>3.0.CO;2-I

Hummel W, Schütte H, Kula M-R (1983) Large scale production of D-lactate dehydrogenase for the stereospecific reduction of pyruvate and phenylpyruvate. Eur J Appl Microbiol Biotechnol 18(2):75–85. doi:10.1007/BF00500828

Hummel W, Schütte H, Kula M-R (1985) D-2-hydroxyisocaproate dehydrogenase from Lactobacillus casei. Appl Microbiol Biotechnol 21(1-2):7–15. doi:10.1007/BF00252354

Hustedt H (1986) Extractive enzyme recovery with simple recycling of phase forming chemicals. Biotechnol Lett 8(11):791–796. doi:10.1007/BF01020824

Hustedt H, Papamichael N (1988) Automated continuous crosscurrent extraction of proteins. Ann NY Acad Sci 542(1):135–139. doi:10.1111/j.1749-6632.1988.tb25818.x

Hustedt H, Kroner K-H, Menge U, Kula M-R (1980) Enzyme purification by liquid-liquid extraction. In: Weetall HH, Royer GP (eds) Enzyme engineering, vol 5. Springer, New York, pp 45–47

Hustedt H, Kroner K-H, Kula M-R (1985a) Applications of phase partitioning in biotechnology. In: Walter H, Brooks DE, Fisher D (eds) Partitioning in aqueous two-phase system theory, methods, uses, and applications to biotechnology, vol 1. Academic Press, London, pp 529–587

Hustedt H, Kroner K-H, Menge U, Kula M-R (1985b) Protein recovery using two-phase systems. Trends Biotechnol 3(6):139–144. doi:10.1016/0167-7799(85)90102-7

Hustedt H, Börner B, Kroner KH, Papamichael N (1987) Fully automated continuous crosscurrent extraction of enzymes in a two-stage plant. Biotechnol Tech 1(1):49–54. doi:10.1007/BF00156287

Hustedt H, Kronor K-H, Papamichael N (1988) Continuous cross-current aqueous two-phase extraction of enzymes from biomass: automated recovery in production scale. Process Biochem 23(5):129–137

Igarashi L, Kieckbusch TG, Franco TT (2004) Xylanase mass transfer studies in aqueous two-phase systems using spray and sieve plate columns. Bioprocess Biosyst Eng 26(3):151–157. doi:10.1007/s00449-003-0329-x

Ito Y, Bowman RL (1971) Countercurrent chromatography. Anal Chem 43(13):69A–75A. doi:10.1021/ac60307a767

Jafarabad KR, Sawant SB, Joshi JB, Sikdar SK (1992) Enzyme and protein mass transfer coefficient in aqueous two-phase systems—I. Spray extraction columns. Chem Eng Sci 47(1):57–68. doi:10.1016/0009-2509(92)80200-V

Johansson G (1994) Recovery of proteins and phase-forming chemicals. In: Walter H, Johansson G (eds) Aqueous two-phase systems: methods in enzymology, vol 228, Aqueous two-phase systems. Academic Press, London, pp 569–573

Kammoun R, Chouayekh H, Abid H, Naili B, Bejar S (2009) Purification of CBS 819.72 α-amylase by aqueous two-phase systems: modelling using response surface methodology. Biochem Eng J 46(3):306–312. doi:10.1016/j.bej.2009.06.003

Kim CY, Brewer JW, Brothers CE, Farver TF, Lee EK (1988) Recovery of extracellular enzyme from fermentation broth by aqueous phase system. In: 3rd Chemical Congress of North America, Toronto, Canada, June 5-10

Kondo A, Urabe T, Higashitani K (1994) Bioconversions in an aqueous two-phase system using enzymes immobilized on ultrafine silica particles. J Ferment Bioeng 77(6):700–703. doi:10.1016/0922-338X(94)90158-9

Kroner K-H, Schütte H, Stach W, Kula M-R (1982) Scale-up of formate dehydrogenase by partition. J Chem Technol Biotechnol 32(1):130–137. doi:10.1002/jctb.5030320117

Kroner KH, Hustedt H, Kula M-R (1984) Extractive enzyme recovery: economic considerations. Process Biochem 19:170–179

Kuhlmann W, Halwachs W, Schügerl K (1980) Racemat-Spaltung von Aminosäuren durch Immobilisierung von Acylase im wäßrigen Zweiphasensystem. Chem Ing Tech 52(7):607–607. doi:10.1002/cite.330520720

Kula M-R, Selber K (2002) Protein purification, aqueous liquid extraction. In: Flickinger MC, Drew SW (eds) Encyclopedia of bioprocess technology, vol 4, Fermentation, biocatalysis, and bioseparation. Wiley, New York, pp 2179–2191

Kula M-R, Kroner K-H, Hustedt H (1982) Purification of enzymes by liquid-liquid extraction. In: Fiechter A (ed) Reaction engineering. Advances in biochemical engineering, vol 24. Springer, Berlin, pp 73–118

Liao L-C, Ho CS, Wu W-T (1999) Bioconversion with whole cell penicillin acylase in aqueous two-phase systems. Process Biochem 34(5):417–420. doi:10.1016/S0032-9592(98)00099-5

Ling Y-Q, Nie H-L, Su S-N, Branford-White C, Zhu L-M (2010) Optimization of affinity partitioning conditions of papain in aqueous two-phase system using response surface methodology. Sep Purif Technol 73(3):343–348. doi:10.1016/j.seppur.2010.04.020

Liu Y, Yu YL, Chen MZ, Xiao X (2011) Advances in aqueous two-phase systems and applications in protein separation and purification. Can J Chem Eng Technol 2(2):1–7

Madhusudhan MC, Raghavarao KSMS (2011) Aqueous two phase extraction of invertase from baker’s yeast: effect of process parameters on partitioning. Process Biochem 46(10):2014–2020. doi:10.1016/j.procbio.2011.07.014

Madhusudhan MC, Raghavarao KSMS, Nene S (2008) Integrated process for extraction and purification of alcohol dehydrogenase from Baker’s yeast involving precipitation and aqueous two phase extraction. Biochem Eng J 38(3):414–420. doi:10.1016/j.bej.2007.08.007

Mannweiler K (1989) The recovery of biological particles in high-speed continuous centrifuges with special reference to feed-zone break-up effects. Dissertation, University of London

Mao LN, Rogers JK, Westoby M, Conley L, Pieracci J (2010) Downstream antibody purification using aqueous two-phase extraction. Biotechnol Prog 26(6):1662–1670. doi:10.1002/btpr.477

Marcos JC, Fonseca LP, Ramalho MT, Cabral JMS (1998) Variation of penicillin acylase partition coefficient with phase volume ratio in poly(ethylene glycol)–sodium citrate aqueous two-phase systems. J Chromatogr B 711(1–2):295-299. 10.1016/S0378-4347(97)00633-6

Marini A, Imelio N, Picó G, Romanini D, Farruggia B (2011) Isolation of a Aspergillus niger lipase from a solid culture medium with aqueous two-phase systems. J Chromatogr B 879(22):2135–2141. doi:10.1016/j.jchromb.2011.05.042

Mayolo-Deloisa K, González-Valdez J, Guajardo-Flores D, Aguilar O, Benavides J, Rito-Palomares M (2011) Current advances in the non-chromatographic fractionation and characterization of PEGylated proteins. J Chem Technol Biotechnol 86(1):18–25. doi:10.1002/jctb.2498

Minami NM, Kilikian BV (1998) Separation and purification of glucoamylase in aqueous two-phase systems by a two-step extraction. J Chromatogr B 711(1–2):309–312. doi:10.1016/S0378-4347(98)00039-5

Mohammadi HS, Omidinia E (2013) Process integration for the recovery and purification of recombinant Pseudomonas fluorescens proline dehydrogenase using aqueous two-phase systems. J Chromatogr B 929:11–17. doi:10.1016/j.jchromb.2013.03.024

Muendges J, Stark I, Mohammad S, Górak A, Zeiner T (2015) Single stage aqueous two-phase extraction for monoclonal antibody purification from cell supernatant. Fluid Phase Equilib 385:227–236. doi:10.1016/j.fluid.2014.10.034

Mukataka S, Haynes CA, Prausnitz JM, Blanch HW (1992) Extractive bioconversions in aqueous two-phase systems: enzymatic hydrolysis of casein proteins. Biotechnol Bioeng 40(2):195–206. doi:10.1002/bit.260400202

Naganagouda K, Mulimani VH (2008) Aqueous two-phase extraction (ATPE): an attractive and economically viable technology for downstream processing of Aspergillus oryzae α-galactosidase. Process Biochem 43(11):1293–1299. doi:10.1016/j.procbio.2008.07.016

Nascimento KS, Rosa PAJ, Nascimento KS, Cavada BS, Azevedo AM, Aires-Barros MR (2010) Partitioning and recovery of Canavalia brasiliensis lectin by aqueous two-phase systems using design of experiments methodology. Sep Purif Technol 75(1):48–54. doi:10.1016/j.seppur.2010.07.008

Nascimento CO, Soares PAG, Porto TS, Costa RMPB, Lima CA, de Lima Filho JL, Coelho LCBB, dos Santos Correia MT, da Cunha C, MdG PALF (2013) Aqueous two-phase systems: new strategies for separation and purification of lectin from crude extract of Cratylia mollis seeds. Sep Purif Technol 116:154–161. doi:10.1016/j.seppur.2013.05.012

Nfor BK, Ahamed T, van Dedem GWK, van der Wielen LAM, van de Sandt EJAX, Eppink MHM, Ottens M (2008) Design strategies for integrated protein purification processes: challenges, progress and outlook. J Chem Technol Biotechnol 83(2):124–132. doi:10.1002/jctb.1815

Ng HS, Tan CP, Chen SK, Mokhtar MN, Ariff A, Ling TC (2011) Primary capture of cyclodextrin glycosyltransferase derived from Bacillus cereus by aqueous two phase system. Sep Purif Technol 81(3):318–324. doi:10.1016/j.seppur.2011.07.039

Nitsawang S, Hatti-Kaul R, Kanasawud P (2006) Purification of papain from Carica papaya latex: aqueous two-phase extraction versus two-step salt precipitation. Enzym Microb Technol 39(5):1103–1107. doi:10.1016/j.enzmictec.2006.02.013

Oelmeier SA, Dismer F, Hubbuch J (2011) Application of an aqueous two-phase systems high-throughput screening method to evaluate mAb HCP separation. Biotechnol Bioeng 108(1):69–81. doi:10.1002/bit.22900

Omidinia E, Shahbaz Mohamadi H, Dinarvand R, Taherkhani H-A (2010) Investigation of chromatography and polymer/salt aqueous two-phase processes for downstream processing development of recombinant phenylalanine dehydrogenase. Bioprocess Biosyst Eng 33(3):317–329. doi:10.1007/s00449-009-0327-8

Papamichael N, Hustedt H (1994) Enzyme recovery by continuous crosscurrent extraction. In: Walter H, Johansson G (eds) Aqueous two-phase systems, vol 228. Academic Press, San Diego, pp 573–584

Papamichael N, Börner B, Hustedt H (1992) Continuous aqueous phase extraction of proteins: Automated processing and recycling of process chemicals. J Chem Technol Biotechnol 54(1):47–55. doi:10.1002/jctb.280540110

Park H-M, Lee S-W, Chang W-J, Koo Y-M (2007) Affinity separation by protein conjugated IgG in aqueous two-phase systems using horseradish peroxidase as a ligand carrier. J Chromatogr B 856(1–2):108–112. doi:10.1016/j.jchromb.2007.05.036

Pavlou AK, Reichert JM (2004) Recombinant protein therapeutics—success rates, market trends and values to 2010. Nat Biotechnol 22(12):1513–1519. doi:10.1038/nbt1204-1513

Platis D, Labrou NE (2006) Development of an aqueous two-phase partitioning system for fractionating therapeutic proteins from tobacco extract. J Chromatogr A 1128(1–2):114–124. doi:10.1016/j.chroma.2006.06.047

Porto TS, Silva GM M e, Porto CS, Cavalcanti MTH, Neto BB, Lima-Filho JL, Converti A, Porto ALF, Pessoa A Jr (2008) Liquid–liquid extraction of proteases from fermented broth by PEG/citrate aqueous two-phase system. Chem Eng Process 47(4):716–721. doi:10.1016/j.cep.2006.12.004

Prinz A, Koch K, Górak A, Zeiner T (2014) Multi-stage laccase extraction and separation using aqueous two-phase systems: experiment and model. Process Biochem 49(6):1020–1031. doi:10.1016/j.procbio.2014.03.011

Raghavarao KSMS, Rastogi NK, Gowthaman MK, Karanth NG (1995) Aqueous two-phase extraction for downstream processing of enzymes/proteins. In: Saul LN, Allen IL (eds) Advances in applied microbiology, vol 41. Academic Press, New York, pp 97–171

Raja S, Murty VR, Thivaharan V, Rajasekar V, Ramesh V (2011) Aqueous two phase systems for the recovery of biomolecules—a review. Sci Technol 1(1):7–16. doi:10.5923/j.scit.20110101.02

Ratanapongleka K (2010) Recovery of biological products in aqueous two phase systems. Int J Chem Eng Appl 1(2):191–198. doi:10.7763/IJCEA.2010.V1.33

Rito-Palomares M (2004) Practical application of aqueous two-phase partition to process development for the recovery of biological products. J Chromatogr B 807(1):3–11. doi:10.1016/j.jchromb.2004.01.008

Rito-Palomares M, Hernandez M (1998) Influence of system and process parameters on partitioning of cheese whey proteins in aqueous two-phase systems. J Chromatogr B 711(1–2):81–90. doi:10.1016/S0378-4347(98)00011-5

Rito-Palomares M, Lyddiatt A (1996) Impact of cell disruption and polymer recycling upon aqueous two-phase processes for protein recovery. J Chromatogr B 680(1–2):81–89. doi:10.1016/0378-4347(95)00500-5

Rito-Palomares M, Lyddiatt A (2000) Practical implementation of aqueous two-phase processes for protein recovery from yeast. J Chem Technol Biotechnol 75(7):632–638. doi:10.1002/1097-4660(200007)75:7, <632::AID-JCTB248>3.0.CO;2-7

Rito-Palomares M, Lyddiatt A (2002) Process integration using aqueous two-phase partition for the recovery of intracellular proteins. Chem Eng J 87(3):313–319. doi:10.1016/S1385-8947(01)00241-8

Rito-Palomares M, Middelberg APJ (2002) Aqueous two-phase systems for the recovery of a recombinant viral coat protein from Escherichia coli. J Chem Technol Biotechnol 77(9):1025–1029. doi:10.1002/jctb.673

Rito-Palomares M, Huddleston JG, Lyddiatt A (1994) Phase recycling in aqueous two-phase partition processes: impact upon practical implementation of protein recovery from brewery waste. In: Pyle DL (ed) Separations for biotechnology 3, vol 158. Royal Society of Chemistry, Cambridge, pp 413–419

Rito-Palomares M, Dale C, Lyddiatt A (2000) Generic application of an aqueous two-phase process for protein recovery from animal blood. Process Biochem 35(7):665–673

Rito-Palomares M, Nuñez L, Amador D (2001) Practical application of aqueous two-phase systems for the development of a prototype process for c-phycocyanin recovery from Spirulina maxima. J Chem Technol Biotechnol 76(12):1273–1280. doi:10.1002/jctb.507

Rosa PAJ, Azevedo AM, Sommerfeld S, Mutter M, Aires-Barros MR, Bäcker W (2009) Application of aqueous two-phase systems to antibody purification: a multi-stage approach. J Biotechnol 139(4):306–313. doi:10.1016/j.jbiotec.2009.01.001

Rosa PAJ, Azevedo AM, Sommerfeld S, Bäcker W, Aires-Barros MR (2011) Aqueous two-phase extraction as a platform in the biomanufacturing industry: economical and environmental sustainability. Biotechnol Adv 29(6):559–567. doi:10.1016/j.biotechadv.2011.03.006