Abstract

Cow manure with bedding is renewable organic biomass available around the year on dairy farms. Developing efficient and cost-effective psychrophilic dry anaerobic digestion (PDAD) processes could contribute to solving farm-related environmental, energy, and manure management problems in cold-climate regions. This study was to increase the organic loading rate (OLR), fed to a novel psychrophilic (20 °C) dry anaerobic digestion of 27 % total solid dairy manure (cow feces and wheat straw) in sequence batch reactor (PDAD-SBR), by 133 to 160 %. The PDAD-SBR process operated at treatment cycle length of 21 days and OLR of 7.0 and 8.0 g total chemical oxygen demand (TCOD) kg−1 inoculum day−1 (5.2 ± 0.1 and 5.8 ± 0.0 g volatile solids (VS) kg−1 inoculum day−1) for four successive cycles (84 days) produced average specific methane yields (SMYs) of 147.1 ± 17.2 and 143.2 ± 11.7 normalized liters (NL) CH4 kg−1 VS fed, respectively. PDAD of cow feces and wheat straw is possible with VS-based inoculum-to-substrate ratio of 1.45 at OLR of 8.0 g TCOD kg−1 inoculum day−1. Hydrolysis was the limiting step reaction. The VS removal averaged around 57.4 ± 0.5 and 60.5 ± 5.7 % at OLR 7.0 and 8.0 g TCOD kg−1 inoculum day−1, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Dry anaerobic digestion is increasingly attracting the interest of farmers to digest farm waste and agriculture residue. Cabral et al. (2014) indicated that there are currently more than 200 plants of dry anaerobic digestion worldwide to digest organic material with total solids (TS; Table 1) ranging between 20 and 50 %, mostly in thermophilic operation. In this respect, livestock industry, which produces a large amount of manure requiring treatment and stabilization, can benefit from dry anaerobic digestion. In Canada and USA, cattle generate about 75 and 86 % of the manure produced by livestock, respectively (Hofmann and Beaulieu 2001; Wen et al. 2004). Dairy cow feces and bedding mixtures are composed of 40–50 % biodegradable lingocellulosic biomass which can be converted to CH4 (Abbassi-Guendouz et al. 2012).

Dry anaerobic digestion (DAD) became the process of choice to treat the organic fraction of the municipal solid waste (Cabral et al. 2014; Challen Urbanic et al. 2011; Li et al. 2011b; Ramasamy and Abbasi 2000) because it offers many advantages over wet anaerobic digestion. When compared to wet anaerobic digestion (WAD) systems, DAD requires less reactor volume, requires less energy input for heating and mixing, produces nutrient-richer fertilizer, and has a higher net energy yield (Cabral et al. 2014).

Agricultural wastes and livestock manure DAD (15–20 % TS) have recently been reported (Ahn et al. 2010; Di Maria et al. 2012; Kusch et al. 2008). In a suitability and economic feasibility assessment survey of on-farm DAD for solid manure, crop residues, spoiled hay and silage, and energy crops in Europe, Schäfer et al. (2006) concluded that although DAD is suitable for on-farm conditions, the ideal technologies have not been invented yet. Brown et al. (2012) found that volumetric productivity of DAD (18 % TS) is two to seven times greater compared to that if WAD (5 % TS) for lignocellulosic substrates (wheat straw, switchgrass, corn stover, leaves, and waste paper) based on 30-day batch incubation. Most farm-based anaerobic digestion processes in northern Italy are operated at an organic loading rate (OLR) of 1–3 kg volatile solids (VS) m−3 and retention time greater than 40 days.

Recently, Agriculture and Agri-Food Canada has been developing a psychrophilic dry anaerobic digestion process in sequence batch reactor (PDAD-SBR) for dairy cow feces without and with different levels of straw bedding to stabilize cow manure and convert its biodegradable organics to methane. Massé and Saady (2015a) reported a long-term operation (252 days) of PDAD-SBR for digesting cow feces (TS 13–16 %) with an average specific methane yield (SMY) of 222 ± 27.2 NL CH4 kg−1 VS fed. Moreover, they demonstrated successful operation at TS of 27 % and OLR of 3 g total chemical oxygen demand (TCOD) kg−1 inoculum day−1 for 273 days with an average SMY of 182.9 ± 16.9 NL CH4 kg−1 VS fed (Massé and Saady 2015b). Increasing the OLR fed to a bioreactor is a basic engineering design objective to decrease the bioreactor volume (Luning et al. 2003) and reduce its construction costs. Nevertheless, not many studies are published on the effect of OLR on the performance of dry anaerobic digestion. The goals of this study were to increase the OLR fed to PDAD-SBR of cow feces and wheat straw (27 % TS in feed) by 130–160 % and assess its feasibility at high OLRs (7.0 and 8.0 g TCOD kg−1 inoculum day−1) in long-term study (84 days). Wheat straw has been chosen because it is regularly used as bedding on Canadian dairy farms.

Materials and methods

Experimental setup

The experimental work consisted of two simultaneous experiments of operating psychrophilic (20 °C) anaerobic sequence batch reactors (SBRs) at two organic loading rates (OLRs) of 7.0 and 8.0 g TCOD kg−1 inoculum day−1 to digest a mixture of cow feces and wheat straw (TS = 27 % in feed). The treatment cycle length (TCL) has been maintained at 21 days measured from the time of feeding to the next feeding. The effects of OLR on CH4 production and process stability have been assessed during a long-term study (84 days) consisting four successive treatment cycles.

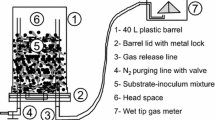

Bioreactor

Two sets of duplicate 40-L cylindrical barrel bioreactors have been operated as SBR at TCL of 21 days in a temperature-controlled room (20 °C). The working volume ranged between 7.2 and 8.5 L based on the volumes of the feed and inoculum used. The reactors were fitted with two gas lines—one for purging nitrogen gas immediately after feeding the substrate to maintain an anaerobic condition, and the second to release and quantify the biogas produced (Fig. 1).

Inoculum and substrate

The initial inoculum was obtained in a laboratory-scale (30 L; TS = 27 %) psychrophilic (20 °C) anaerobic sequence batch reactor fed with fresh dairy manure and wheat straw (27 % TS); the performance of the seeding inoculum has been reported previously (Saady and Massé 2013). Starting from the second cycle forward, 6 kg of the digestate from the previous cycle has been used as inoculum for the next cycle in each reactor. Fresh feces from dairy cows were collected at the experimental farm of the Dairy and Swine Research and Development Centre, Agriculture and Agri-Food Canada, Sherbrooke, Quebec (DSRDC). Feces were collected on wood boards, before getting in contact with urine and bedding, transferred into a plastic drum, and stored at 4 °C (for a maximum of 30 days before feeding), and triplicate representative samples have been taken from each batch of cow feces fed to the reactors in each treatment cycle after thorough mixing and homogenization and before feeding the reactors. Physico-chemical characteristics of the inoculum, cow feces, and inoculum-substrate mixture (ISM) before feeding bioreactors are given in Table 2. Two different batches of cow feces from the same experimental farm at DSRDC, Sherbrooke, Quebec, were used during the four cycles as indicated in Table 2 (the first batch has been used for cycles 1 and 2, while the second batch has been used for cycles 3 and 4). Wheat straw was harvested at the DSRDC’s experimental farm during fall 2011 and fall 2012 and chopped (3 mm) using a laboratory mill (Thomas Wiley Laboratory Mill Model 4, Arthur H. Thomas Company, Philadelphia, PA).

The substrate and inoculum have been mixed manually for 5 min during feeding. Every week, the content of the bioreactor is mixed manually for 5 min before sampling the content to ensure that a homogenous and representative sample is taken. No mixing took place during other time of the treatment cycle; therefore, the process can be considered as a static dry anaerobic digestion.

Organic loading rate

Wheat straw and cow feces were mixed manually to obtain the desired substrate TS content (27 %) while maintaining the design OLR of 7.0 and 8.0 g TCOD kg−1 inoculum day−1 (equivalent to 5.15 ± 0.06 and 5.86 ± 0.02 g VS kg−1 inoculum day−1). The mass of inoculum, feces, and/or straw fed to each bioreactor at the beginning of the successive cycles, the organic loading rate (OLR), and VS-based inoculum-to-substrate ratio (ISR) are given in Table 3.

The organic loading rate (OLR) has been calculated based on the masses of VS and TCOD of the substrate fed (Table 3). ISR was expressed in kilograms of total VS fed per kilogram VS of inoculum. The ISR was 1.66 ± 0.02 at OLR of 7.0 g TCOD kg−1 inoculum day−1 and 1.45 ± 0.02 at OLR of 8.0 g TCOD kg−1 inoculum day−1.

Biogas measurement

Biogas volume produced was measured daily using calibrated wet tip gas meters while the biogas components (CH4, H2S, CO2) were determined weekly using a Hach Carle 400 AGC gas chromatograph (GC) (Chandler Engineering, Houston, TX) at 85 °C with a helium gas flow rate of 30 mL min−1. The GC calibration was performed weekly with a standard gas (27.3 % CO2, 1.01 % N2, 71.16 % CH4, 0.53 % H2S). Methane production is reported in normalized liters (NL CH4). Total cumulative CH4 yield was established at the end of each digestion cycle. Specific CH4 yield for a TCL of 21 days was calculated for each cycle as the ratio of CH4 produced over the mass of VS fed to the reactor at the beginning of the cycle.

Analytical methods

Samples were collected from each bioreactor and analyzed weekly for volatile fatty acids (VFAs), TS, VS, and pH. Total chemical oxygen demand (TCOD) was determined before and after each treatment cycle. TCOD, TS, VS, alkalinity, and pH were determined using standard methods (APHA 1992). VFA concentration was measured with a PerkinElmer gas chromatograph model 8310 (PerkinElmer, Waltham, MA), equipped with a DB-FFAP high-resolution column.

Fiber analysis

The complex substrate (cow feces and wheat straw) was subjected to fiber analysis to determine their content of cellulose, hemicellulose, and lignin. Hemicellulose can be calculated as the difference between neutral detergent fiber (NDF) and acid detergent fiber (ADF), cellulose as the difference between acid detergent fiber and acid detergent lignin (ADL) (Bauer et al. 2009).

Results

Further to the characteristics of cow feces given in Table 2, it contained TCOD of 155.2 and 169.0 g kg−1 during cycles 1–2 and 3–4, respectively. The fiber content of cow feces fed during cycles 1–2 was 24.39 % (cellulose), 19.28 % (hemicellulose), and 12.74 % (lignin) while that fed during cycles 3–4 contained 26.33 % (cellulose), 16.35 % (hemicellulose), and 10.67 % (lignin). Wheat straw had a TCOD of 1097 g kg−1 while its fiber composition was 38.61 % (cellulose), 25.14 % (hemicellulose), and 7.3 % (lignin). Throughout the experiments, the concentration of H2S was always less than 0.06 %.

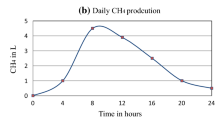

Methane production

The profiles of methane production expressed as specific methane yield (SMY) in the bioreactors are shown in Fig. 2. The maximum SMYs calculated during the successive cycles are given in Table 4. The average of the SMY at OLR of 7.0 and 8.0 g TCOD kg−1 inoculum day−1 is 147.1 ± 17.2 and 143.2 ± 11.7 NL CH4 kg−1 VS fed, respectively. The coefficient of variation for the duplicate reactors operated at OLR of 7.0 g TCOD kg−1 inoculum day−1 was 3.2 ± 1.3 %, while at OLR 8.0 g TCOD kg−1 inoculum day−1, it was 2.8 ± 1.1 %. The overall averages of the SMY at both OLR are not statistically different (based Tukey’s multiple comparison test at 95 % confidence interval).

The percentage of methane in biogas ranged between 53.3 ± 0.9 and 56.4 ± 0.3 with an overall average of 54.5 ± 1.1 and 54.7 ± 1.1 at OLR of 7.0 and 8.0 g TCOD kg−1 inoculum day−1, respectively (Fig. 3). No statistical difference in the percentage of CH4 in biogas could be detected between inoculum fed at 7.0 and 8.0 g TCOD kg−1 inoculum day−1.

Notice that wheat straw provided 69.2 ± 2.1 % of fibers in the feed at OLR of 7 and 8 g TCOD kg−1 inoculum day−1. Generally, wheat straw provided 61.7 ± 2.6 % of the feed TCOD, 65.2 ± 3.0 % of the feed VS, and 19.2 ± 0.9 % of feed mass (Supplementary Table S1).

The overall average of the specific CH4 production rate (NL CH4 kg−1 VS day−1) of the replicate bioreactors at OLR of 7.0 and 8.0 g TCOD kg−1 inoculum day−1 is 7.1 ± 0.4 and 6.7 ± 0.6 NL CH4 kg−1 VS day−1, respectively. The values of the overall averages of specific CH4 production rate at OLR of 7.0 and 8.0 g TCOD kg−1 inoculum day−1 are not significantly different from each other (based on Tukey’s multiple comparison test at 95 % confidence interval).

Volatile fatty acid production

The profiles of VFAs produced in the replicate bioreactors were almost identical (data not shown). A typical VFA profile during a typical cycle operated at OLR of 7.0 g TCOD kg−1 inoculum day−1 is shown in Fig. 4. Throughout the successive cycles at OLR of 7.0 and 8.0 g TCOD kg−1 inoculum day−1, acetic acid concentration peaked immediately after feeding to levels between 1500 and 2000 mg L−1 but was consumed within a week in all replicate bioreactors, and its concentreations were maintained within 100 ± 50 mg L−1 indicating that methanogensis reaction from acetate was not a rate-limiting step. Similarily, propionic acid peaked to levels between 500 and 750 mg L−1 after feedings and was consumed within a week to levels of 200 mg L−1 and after another week to levels close to the detection limits of the instrument (50 ± 10 mg L−1). The profile of proinoic acid in the replicate bioreactots was similar to that of acetic acid.

Butyric acid peaked also to levels between 500 and 750 mg L−1 after feedings and was consumed within a week to levels of 250 mg L−1 and then to levels close to the detection limits of the instrument (25 ± 10 mg L−1) within another week. The concentrations of other volatile fatty acids (isobutyric, isovaleric, and valeric acid) were less than 100 mg L−1 immediately after feeding and less than 50 mg L−1 during the remaining time of the TCL. No differences have been observed among the VFA profiles associated with the different OLRs applied.

Solids reduction

The profiles of the TS sand VS in the replicate bioreactors were similar (data not shown). A typical profile of VS during a typical cycle operated at OLR of 7 g TCOD kg−1 inoculum day−1 is shown in Fig. 5. Generally, the TS and VS contents of the reactor content at the end of the treatment cycles averaged around 20.9 ± 0.3 and 18.7 ± 0.1 % at OLR of 7.0 g TCOD kg−1 inoculum day−1, respectively, while at OLR of 8.0 g TCOD kg−1 inoculum day−1, they averaged around 21.1 ± 0.4 and 19.0 ± 0.2 %, respectively. A mass balance of the VS revealed that the VS removal efficiency averaged around 57.4 ± 0.5 and 60.5 ± 5.7 % at OLR of 7.0 and 8.0 g TCOD kg−1 inoculum day−1, respectively.

Discussion

Feasibility of PDAD-SBR has been demonstrated for digesting cow feces (13–16 % TS) during long-term operation (252 days) with an average specific methane yield (SMY)of 222 ± 27.2 NL CH4 kg−1 VS fed at OLR of 5.0 g TCOD kg−1 inoculum day−1 (Massé and Saady 2015a). Furthermore, the feasibility of digesting dairy manure (cow feces and wheat straw) at 27 % TS in PDAD-SBR has successfully been demonstrated at OLR of 3 g TCOD kg−1 inoculum day−1 in long-term operation (273 days); it yielded an average SMY of 182.9 ± 16.9 NL CH4 kg−1 VS fed (Massé and Saady 2015b). The results of this study answers the following question: Is it possible to have a high-rate PDAD-SBR? In this study, the OLR has been increased by 130–165 % and the performance and stability of psychrophilic anaerobic sequence batch bioreactors in terms of specific methane yield, volatile fatty acid levels, and TS and VS removal have been assessed during four successive cycles (84 days) at OLR of 7.0 and 8.0 g TCOD kg−1 inoculum day−1.

Specific methane yield (overall average of 146.0 ± 9.9 NL CH4 kg−1 VS of cow feces and wheat straw) obtained during the eight successive cycles at both OLRs examined with a variation coefficient of 8.6 % indicates a stable and reproducible process. Based on Tukey’s multiple comparison test at 95 % confidence interval, the overall averages of the SMY at each OLR are not statistically different which means that the performance of the psychrophilic dry anaerobic digestion in sequence batch reactor operated at TCL of 21 days has not been affected by increasing the OLR by 14.3 % (from 7.0 to 8.0 g TCOD kg−1 inoculum day−1). The ability of the PDAD-SBR process to withstand such increase in the OLR without showing signs of instability indicates its robustness.

The substrate mixture fed contained cow feces and wheat straw; both contain lignocellulose fibers such as cellulose which requires long retention time to be biodegraded by the anaerobic consortia of microorganisms, and its hydrolysis has been reported to be the rate-limiting step (Noike et al. 1985) particularly when it is fed in solid substrate or particulate form such as cattle manure (Myint and Nirmalakhandan 2006). Therefore, sequence batch reactor is suitable for digesting lignocellulosic substrates because it offers long solid retention time which allows wheat straw to contribute to methane production. In this study, the SBR at 21-day TCL with the ISR used provided sufficient solid retention time (SRT) to degrade lignocellulose fibers. Nevertheless, the TCL is relatively short when compared to previously published data (Table 5) for dry anaerobic digestion conducted under mesophilic conditions. The ISR used in this study might look relatively high compared to the values used in WAD; however, the VS-based ISR values used in this study (1.43–1.68) are justified by the hard conditions. Notice that at psychrophilic conditions, the rate of reaction is lower than that at mesophilic conditions. Moreover, the type of substrate and its TS content are much higher than those used in WAD.

Volatile fatty acid (acetate, propionate, butyrate, and other short-chain fatty acids) profiles indicated that acetogensis and methnogensis steps were not rate-limiting. The VFA concentrations and the progress of methane production during the successive cycles suggest a pseudo steady state condition and indicate that acetogenic and methanogenic reactions proceeded fairly well. Hence, hydrolysis was the rate-limiting step. The relative stability of the pH profile around 7.8 ± 0.6 (Fig. 5) was due to the high alkalinity (10.14 ± 0.86 g CaCO3 L−1) of the reactor content which was contributed mainly by cow feces.

The VS removal efficiency achieved was on average 57.4 ± 0.5 and 60.5 ± 5.7 %, and the percentage of methane in biogas was on average 54.5 ± 1.1 and 54.7 ± 1.1 at OLR of 7.0 and 8.0 g TCOD kg−1 inoculum day−1, respectively. However, there is potential for more VS degradation and increase in the specific methane yield by increasing the TCL. The latter would require lager bioreactor size.

The results have been compared with the reported performance of mesophilic and thermophilic DAD of various substrates (Table 5) because no relevant data are available in the literature on the performance of psychrophilic DAD. The overall average yield (145.1 ± 2.8 NL CH4 kg−1 VS of cow feces and wheat straw) of the eight cycles operated at OLR of 7.0 and 8.0 g TCOD kg−1 inoculum day−1 (equivalent to 5.15 ± 0.06 and 5.86 ± 0.02 g VS fed kg−1 inoculum day−1) obtained in this study after 21 days of psychrophilic (20 °C) incubation is smaller than the yield 160 NL CH4 kg−1 VS of dairy manure, straw, and oat husk (TS 17 % at OLR of 3.4 g VS kg−1 inoculum day−1) reported by Schäfer et al. (2006) for Jarna biogas plant in Sweden which operates at 38 °C and retention time of 22 days. The data reported from Jarna plant is for steady state condition where the inoculum was adapted to the substrate and the operation condition for 3 years at the time of the study reported by Schäfer et al. (2006). The average SMYs (147.1 ± 17.2 and 143.2 ± 11.7 NL CH4 kg−1 VS fed) obtained in this study at OLR of 5.15 ± 0.06 and 5.86 ± 0.02 g VS kg−1 inoculum day−1 are 20 % smaller than the 181 L CH4 kg−1 VS of beef manure and straw (TS 18 % and OLR of 3.2 g VS kg−1 inoculum day−1) at 32 °C and retention time of 28 days reported by Schäfer et al. (2006) (Table 5). Compared to Schäfer et al. (2006) result, the current study demonstrated an increase of 30 % in the feed TS, increase of 62.5 to 81.25 % in OLR, and a decrease in the treatment cycle length of 25 %. The increase of the OLR from 3.2 to 5.8 g VS kg−1 inoculum day−1 results in a 55 % reduction in the required volume of the bioreactor. Notice that the high yields (>250 NL CH4 kg−1 VS fed) reported by Li et al. (2011a, b) was for TS of 16 % and TCL of 63 days in mesophilic anaerobic digestion of cow manure and wastewater sludge. Similarly, the yield reported by Sun et al. (1987) in Table 5 have been obtained for long retention times (168 days) and low OLR (0.35 g TCOD kg−1 inoculum day−1) in mesophilic operations with substrate including corn stover. Achieving a stable dry anaerobic digestion of cow manure and wheat straw (TS of 27 %) at high rate (OLR of 7.0 and 8.0 g TCOD kg−1 inoculum day−1 equivalent to 5.1 ± 0.0 and 5.8 ± 0.0 g VS kg−1 inoculum day−1) in psychrophilic conditions and over long-term operation (189 days) is a significant improvement given that 30 % TS has been recently identified as a threshold above which methanogensis was strongly inhibited in mesophilic (35 °C) cardboard batch anaerobic digestion (Abbassi-Guendouz et al. 2012).

The specific methane yields obtained in this study provide evidence that at OLR of 7.0 and 8.0 g TCOD kg−1 inoculum day−1, PDAD of cow manure and straw is technically feasible at TS 27 % and is as efficient as mesophilic DAD. Therefore, a high-rate psychrophilic (20 °C) dry anaerobic digestion of cow feces and wheat straw (feed TS = 27 %) in sequence batch reactor with VS-based inoculum-to-substrate ratio of 1.66 ± 0.02 at OLR of 7.0 g TCOD kg−1 inoculum day−1 and 1.45 ± 0.02 at OLR of 8.0 g TCOD kg−1 inoculum day−1 is a feasible biotechnology for cold-climate regions.

References

Abbassi-Guendouz A, Brockmann D, Trably E, Dumas C, Delgenès J-P, Steyer J-P, Escudié R (2012) Total solids content drives high solid anaerobic digestion via mass transfer limitation. Bioresour Technol 111:55–61. doi:10.1016/j.biortech.2012.01.174

Ahn HK, Smith MC, Kondrad SL, White JW (2010) Evaluation of biogas production potential by dry anaerobic digestion of switchgrass-animal manure mixtures. Appl Biochem Biotechnol 160:965–975

APHA (1992) Standard methods for the examination of water and wastewater, 18th edn. American Public Health Association, Washington

Bauer A, Bösch P, Friedl A, Amon T (2009) Analysis of methane potentials of steam-exploded wheat straw and estimation of energy yields of combined ethanol and methane production. J Biotechnol 142:50–55

Blanco D, Lobato A, Fernández C, Escapa A, Gómez X (2010) Batch dry anaerobic codigestion of sheep manure and potato waste. In: Cordovil C, Ferreira L (eds) In Proc. 14th RAMIRAN International Conf., Lisboa, Portugal

Brown D, Shi J, Li Y (2012) Comparison of solid-state to liquid anaerobic digestion of lignocellulosic feedstocks for biogas production. Bioresour Technol 124:379–386. doi:10.1016/j.biortech.2012.08.051

Cabral C, Eveillard F, Heer L, Oertig M (2014) Tapping into the large potential of organics recycling, using dry anaerobic digestion – the European experience. Paper presented at the The Canadian Waste Resource Symposium, Vancouver 2 - 4 April 2014, Canada. http://www.swanabc.org/swanabc2_5/lounge/technical-library-docs/doc_download/301-dry-anaerobic-digestion-the-european-experience

Challen Urbanic JM, VanOpstal B, Parker W (2011) Anaerobic digestion of the organic fraction of municipal solid waste (OFMSW)—Full fcale vs laboratory results. J Solid Waste Technol Manag 37:33–39. doi:10.5276/jswtm.2011.33

Comino E, Rosso M, Riggio V (2010) Investigation of increasing organic loading rate in the co-digestion of energy crops and cow manure mix. Bioresour Technol 101:3013–3019. doi:10.1016/j.biortech.2009.12.025

Di Maria F, Gigliotti G, Sordi A, Micale C, Massaccesi L (2012) Start up of a pre-industrial scale solid state anaerobic digestion cell for the co-treatment of animal and agricultural residues. In: ECOS 2012–The 25th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems., Perugia, Italy, June 26-29

Frigon JC, Roy C, Guiot SR (2012) Anaerobic co-digestion of dairy manure with mulched switchgrass for improvement of the methane yield. Bioprocess Biosyst Eng 35:341–349. doi:10.1007/s00449-011-0572-5

Hofmann N, Beaulieu MS (2001) A Geographical Profile of Manure Production in Canada, 2001. Statistics Canada. Catalogue no. 21-601-MIE — No. 077

Kusch S, Oechsner H, Jungbluth T (2008) Biogas production with horse dung in solid-phase digestion systems. Bioresour Technol 99:1280–1292

Li J, Jha AK, He J, Ban Q, Chang S, Wang P (2011a) Assessment of the effects of dry anaerobic codigestion of cow dung with waste water sludge on biogas yield and biodegradability. Int J Physiol Sci 6:3679–3688

Li Y, Park SY, Zhu J (2011b) Solid-state anaerobic digestion for methane production from organic waste. Renew Sust Energ Rev 15:821–826

Lindorfer H, Corcoba A, Vasilieva V, Braun R, Kirchmayr R (2008) Doubling the organic loading rate in the co-digestion of energy crops and manure – A full scale case study. Bioresour Technol 99:1148–1156. doi:10.1016/j.biortech.2007.02.033

Luning L, Van Zundert EHM, Brinkmann AJF (2003) Comparison of dry and wet digestion for solid waste. Water Sci Technol 48:15–20

Mahnert P, Linke B (2009) Kinetic study of biogas production from energy crops and animal waste slurry: effect of organic loading rate and reactor size. Environ Technol 30:93–99. doi:10.1080/09593330802246640

Massé DI, Saady NMC (2015a) Psychrophilic dry anaerobic digestion of dairy cow feces: long-term operation. Waste Manag 36:86–92. doi:10.1016/j.wasman.2014.10.032

Massé DI, Saady NMC (2015b) Psychrophilic dry anaerobic digestion of high solids content dairy manure: long-term operation. Biological Engineering Transactions ASABE 7:99–112. doi:10.13031/bet.7.10704

Myint M, Nirmalakhandan N (2006) Evaluation of first-order, second-order, and surface-limiting reactions in anaerobic hydrolysis of cattle manure. Environ Eng Sci 23:970–980. doi:10.1089/ees.2006.23.970

Noike T, Endo G, Juu EC, Yaguchi JI, Matsumoto JI (1985) Characteristics of carbohydrate degradation and the rate-limiting step in anaerobic digestion. Biotechnol Bioeng 27:1482–1489. doi:10.1002/bit.260271013

Ramasamy EV, Abbasi SA (2000) High-solids anaerobic digestion for the recovery of energy from municipal solid waste (MSW). Environ Technol 21:345–349

Saady NMC, Massé DI (2013) Psychrophilic anaerobic digestion of lignocellulosic biomass: A characterization study. Bioresour Technol 142:663–671. doi:10.1016/j.biortech.2013.05.089

Schäfer W, Lehto M, Teye F (2006) Dry anaerobic digestion of organic residues on-farm - A feasibility study. Agrifood Research Reports 77. MTT Agrifood Research Finland. URL: www.mtt.fi/met/pdf/met77.pdf

Sun GC, Wu YZ, Sha SJ, Liu KX (1987) Dry digestion of crop wastes: Studies on dry anaerobic digestion with agricultural wastes. Biol Waste 20:291–302

Sunarso S, Seno J, Widiasa IN (2012) The effect of feed to inoculums ratio on biogas production rate from cattle manure using rumen fluid as inoculums. IJWR 2:1-4 doi: http://dx.doi.org/10.12777/ijwr.2.1.2012.1-4

Wen Z, Liao W, Chen S (2004) Hydrolysis of animal manure lignocellulosics for reducing sugar production. Bioresour Technol 91:31–39. doi:10.1016/S0960-8524(03)00166-4

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 23 kb)

Rights and permissions

About this article

Cite this article

Massé, D.I., Saady, N.M.C. Dry anaerobic digestion of high solids content dairy manure at high organic loading rates in psychrophilic sequence batch reactor. Appl Microbiol Biotechnol 99, 4521–4529 (2015). https://doi.org/10.1007/s00253-015-6516-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-015-6516-2