Abstract

Volatile compounds produced by yeast during fermentation greatly influence the organoleptic qualities of wine. We developed a model to predict the combined effects of initial nitrogen and phytosterol content and fermentation temperature on the production of volatile compounds. We used a Box–Behnken design and response surface modeling to study the response of Lalvin EC1118® to these environmental conditions. Initial nitrogen content had the greatest influence on most compounds; however, there were differences in the value of fermentation parameters required for the maximal production of the various compounds. Fermentation parameters affected differently the production of isobutanol and isoamyl alcohol, although their synthesis involve the same enzymes and intermediate. We found differences in regulation of the synthesis of acetates of higher alcohols and ethyl esters, suggesting that fatty acid availability is the main factor influencing the synthesis of ethyl esters whereas the production of acetates depends on the activity of alcohol acetyltransferases. We also evaluated the effect of temperature on the total production of three esters by determining gas–liquid balances. Evaporation largely accounted for the effect of temperature on the accumulation of esters in liquid. Nonetheless, the metabolism of isoamyl acetate and ethyl octanoate was significantly affected by this parameter. We extended this study to other strains. Environmental parameters had a similar effect on aroma production in most strains. Nevertheless, the regulation of the synthesis of fermentative aromas was atypical in two strains: Lalvin K1M® and Affinity™ ECA5, which produces a high amount of aromatic compounds and was obtained by experimental evolution.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nutrients and temperature are two important factors that influence wine fermentation (Luparia et al. 2004; Blateyron and Sablayrolles 2001; Valero et al. 1998; Sablayrolles and Barre 1993; Bely et al. 1990). These parameters also affect many aspects of yeast metabolism, including the formation of volatile compounds that contribute significantly to the organoleptic qualities of wines (Swiegers et al. 2005). Several studies have assessed the influence of assimilable nitrogen content on the production of fermentative aromas such as higher alcohols, their acetates and ethyl esters (reviewed in Bell and Henschke 2005). In general, there is a direct relationship between initial nitrogen content and higher alcohol concentration when nitrogen content is low, whereas an inverse relationship is found at moderate to high nitrogen quantities (Carrau et al. 2008; Jiménez-Martí et al. 2007; Vilanova et al. 2007, 2012). Acetates of higher alcohols and ethyl esters show a more simple relationship with nitrogen concentration: an increase in initial nitrogen content is associated with an increase in ester production (Torrea et al. 2011; Ugliano et al. 2010; Garde-Cerdán and Ancín-Azpilicueta 2008; Hernandez-Orte et al. 2006). Nevertheless, in some cases, the addition of nitrogen can impair the production of esters, depending on yeast strain and chemical composition of the must (Jiménez-Martí et al. 2007; Beltran et al. 2005).

Fermentation temperature is another variable that affects the final concentration of fermentative aromas in wine (Torija et al. 2003). For example, high concentrations of esters are obtained at low temperatures (Molina et al. 2007; Beltran et al. 2006). However, the effect of temperature on the synthesis of higher alcohols is more complex. Molina et al. (2007) showed that only the concentration of 2-phenylethanol increases with increasing temperature whereas Beltran et al. (2006) observed an increase in the concentration of all higher alcohols. In these studies, the concentrations of volatile compounds were determined in the liquid phase, and therefore these values do not reflect the real capability of yeast to produce these compounds.

It recently became possible to determine the biological production and the physical evaporation of volatile compounds by performing gas–liquid balances (Morakul et al. 2011, 2013). For six volatile compounds (propanol, isobutanol, isoamyl alcohol, isoamyl acetate, ethyl hexanoate and ethyl octanoate), we calculated the amount accumulated in the liquid and the amount lost in the gas. The addition of these quantities gives the biological production of these compounds by yeast. With this approach, overall losses in the exhaust gas can be calculated at any temperature (Mouret et al. 2014a; Morakul et al. 2013). Losses in exhaust gas are negligible for higher alcohols but much greater for esters, and are essentially dependent on both the volatility and the hydrophobicity of each aroma compound (Mouret et al. 2014b; Morakul et al. 2013). At a given temperature, the overall percentage lost is almost completely independent of the fermentation kinetics (Mouret et al. 2014a).

The effect of lipids on the formation of volatile compounds produced by yeasts has been less studied than the effect of temperature (Varela et al. 2012; Mauricio et al. 1997). Moreover, these studies were carried out with the addition of ergosterol, which is a yeast sterol that is not present in grape musts.

Most previous studies examining the production of volatile compounds have investigated the effect of one or two fermentation parameters. The objective of this study was to evaluate the effect of three environmental factors simultaneously: the initial concentration of assimilable nitrogen and lipids, and the fermentation temperature. We used a mixture of phytosterols (β-sitosterol, campesterol, stigmasterol) as a lipid source as this combination closely resembles the composition of natural grape must (Lefur et al. 1994). We used a Box–Behnken design to build a model for each volatile compound describing the simple effects of these three factors as well as the interactions between these parameters (Box and Behnken 1960). We carried out gas–liquid balances for these volatile compounds (Mouret et al. 2014b; Morakul et al. 2013) and we used a mathematical model to predict the gas–liquid ratio of the fermentative aromas throughout the fermentation process (Morakul et al. 2011). These experiments were carried out with a commercial wine yeast strain. Finally, we compared the aroma production of several other yeast strains under the two extreme conditions predicted by the model to assess the effect of genetic background on the production of fermentative aromas and to evaluate the generality of our findings.

Materials and methods

Yeast strains

Seven commercial Saccharomyces cerevisiae yeast strains were used: Lalvin EC1118®, Affinity™ ECA5, Lalvin FC9 EDV®, Lalvin ICV D47®, Lalvin ICV K1M®, Lalvin Rhône 2226® (all produced by Lallemand SA, Montreal, Canada), and UCD522 (University of California, Davis, USA). Fermentation flasks were inoculated with 10 g/hl active dry yeast previously rehydrated for 30 min at 37 °C in a 50 g/l glucose solution (1 g of dry yeast diluted in 10 ml of this solution).

Fermentation media

Fermentation was carried out on synthetic medium (SM) that simulates standard grape juice (Bely et al. 1990). The SM used in this study contained 200 g/l of sugar (100 g/l of glucose and 100 g/l of fructose); 6 g/l of malic acid; 6 g/l of citric acid; 750 mg/l of KH2PO4, 500 mg/l of K2SO4, 250 mg/l of MgSO4·7H2O, 155 mg/l of CaCl2·2H2O, 200 mg/l of NaCl; vitamins (mg/l): myo-inositol (20), calcium pantothenate (1.5), thiamin hydrochloride (0.223), nicotinic acid (2), pyridoxine (0.25), biotin (0.003); oligoelements (in milligram per liter): MnSO4·H2O (4), ZnSO4·7H2O (4), CuSO4·5H2O (1), CoCl2·6H2O (0.4), H3BO3 (1), (NH4)6Mo7O24 (1). The pH of the medium was adjusted to 3.3 with NaOH 10 M.

The nitrogen source was composed of ammonium chloride and amino acids. Three concentrations of assimilable nitrogen were used in the study: 70, 200, and 330 mg/l. The composition of the stock solution of amino acids was (in gram per liter): tyrosine (1.4), tryptophan (13.7), isoleucine (2.5), aspartate (3.4), glutamate (9.2), arginine (28.6), leucine (3.7), threonine (5.8), glycine (1.4), glutamine (38.6), alanine (11.1), valine (3.4), methionine (2.4), phenylalanine (2.9), serine (6.0), histidine (2.5), lysine (1.3), cysteine (1.0), and proline (46.8). To obtain 70 mg/l of assimilable nitrogen in the MS, 2.16 ml of this solution, and 75 mg/l of NH4Cl were added to the medium; for 200 mg/l, 6.16 ml of amino acid solution, and 220 mg/l of NH4Cl were added; and for 330 mg/l, 10.16 ml of amino acid solution, and 360 mg/l of NH4Cl were added.

SM medium was supplemented with three different concentrations of phytosterols (85451, Sigma Aldrich): 2, 5, and 8 mg/l to satisfy the lipid requirements of yeast cells during anaerobic growth. The stock solution was composed of 15 g/l of phytosterols in Tween 80 and ethanol (1:1, v/v).

Fermentation conditions

Anaerobiosis was obtained by bubbling argon in the medium for 20 min. Fermentation was performed in 330-ml flasks, containing 280 ml of SM, equipped with fermentation locks to maintain anaerobiosis at 20, 24, and 28 °C, with continuous magnetic stirring (150 rpm). Fermentation was monitored by CO2 release: the amount of CO2 released was determined by measuring weight loss three times per day.

Measurement of assimilable nitrogen

Ammonium concentration was determined enzymatically (R-Biopharm, Darmstadt, Germany).

The free amino acid content of the must was determined by cation exchange chromatography, with post-column ninhydrin derivatization (Biochrom 30, Biochrom, Cambridge, UK) as described by Crépin et al. (2012).

Determination of metabolite concentrations

Ethanol, glycerol, succinate and acetate concentrations were determined by HPLC (HPLC 1290 Infinity, Agilent Technologies, Santa Clara, California, USA) on a Phenomenex Rezex ROA column (Agilent Technologies, Santa Clara, California, USA) at 60 °C. The column was eluted with 0.005 N H2SO4 at a flow rate of 0.6 ml/min. Acetic acid concentration was determined with a UV meter at 210 nm; the concentrations of the other compounds were determined with a refractive index detector. Analysis was carried out with the Agilent EZChrom software package.

Analysis of volatile compounds by gas chromatography/mass spectrometry

Materials

Ethyl acetate, ethyl propanoate, ethyl 2-methylpropanoate, ethyl butanoate, ethyl 2-methylbutanoate, ethyl 3-methylbutanoate, ethyl hexanoate, ethyl octanoate, ethyl decanoate, ethyl dodecanoate, ethyl lactate, diethyl succinate, 2-methylpropyl acetate, 2-methylbutyl acetate, 3-methyl butyl acetate, 2-phenylethyl acetate, 2-methylpropanol, 2-methylbutanol, 3-methylbutanol, hexanol, 2-phenylethanol, propanoic acid, butanoic acid, 2-methylpropanoic acid, 2-methylbutanoic acid, 3-methylbutanoic acid, hexanoic acid, octanoic acid, decanoic acid, and dodecanoic acid were supplied by Sigma-Aldrich (Steinheim, Germany). Labeled d7-butanoic acid purchased from CDS (Sainte-Foix-La-Grande, France) was used as a standard. The other polydeuterated standards were prepared as follows. d5-Ethyl esters were made by adding the corresponding acid chlorides drop wise to d6-ethanol under argon. The solution was stirred for 1 h at room temperature, washed with aqueous potassium carbonate, dried and the target products distilled as described by Siebert et al. (2005). Phenyl acetic-2,2-d2 acid (prepared by adding 305 mg phenyl acetic-2,2-d2 acid to 5 ml of diethyl ether anhydrous) was added to lithium aluminum deuteride (prepared by adding 143 mg of LiAld4 to 2 ml ether anhydrous) to synthetize d4-phenylethanol. The solution was prepared in an ice bath. The mixture was then stirred at room temperature for 1 h until the reaction was complete. Water (2 ml) and sulfuric acid 15 % (3.5 ml) were added, and the product, d4-phenylethanol was recovered with diethyl ether and distilled.

Standard solutions

Stock solutions of each compound were prepared in 100 % ethanol. A combined standard solution was prepared for each group (ethyl esters, acetates, alcohols, and acids) from the stock solutions. Solutions for calibration were prepared by adding various amounts of the combined standard solutions to synthetic wine. The stability of the solutions was verified regularly by gas chromatography-atomic emission detection.

Preparation of samples for the analysis of volatile compounds

A total of 10 μl of a solution of deuterated standards diluted in ethanol (100 μg/ml) was added to the synthetic wine (5 ml) in a 15-ml pyrex tube with a Teflon cap (Supelco, Bellefonte, Pennsylvania, USA). One milliliter of dichloromethane was added and the mixture was gently shaken for 20 min on shaking table. The samples were centrifuged for 5 min at 2,000 rpm at 4 °C to separate the aqueous and organic phases. The organic phase was recovered in a 4-ml vial and a second extraction was performed on the remaining aqueous phase: 1 ml of dichloromethane was added, the samples were shaken for 20 min, and then centrifuged for 5 min at 2,000 rpm at 4 °C. The organic phase was added to the same 4-ml vial containing the organic phase from the first extraction. The organic phase was dried with anhydrous Na2SO4 to remove all traces of aqueous phase. A total of 1.5 ml of the organic phase was transferred to a vial and evaporated under nitrogen flux to a final volume of 0.5 ml. The sample was then transferred to an insert (Supelco, Bellefonte, Pennsylvania, USA), returned to the vial and closed.

Gas chromatography/mass spectrometry analysis

Samples were analyzed with a Hewlett Packard (Agilent Technologies, Santa Clara, California, USA) 6890 gas chromatograph equipped with a CTC Combi PAL Autosampler AOC-5000 (Shimadzu, Columbia, USA) and coupled to a HP 5973 mass spectrometry detector (HP, now Agilent Technologies, Santa Clara, California, USA). The instrument was controlled and the data analyzed with HP G1701DA ChemStation software (HP, now Agilent Technologies, Santa Clara, California, USA). The gas chromatograph was fitted with a 30 m × 0.25 mm Phenomenex fused silica capillary column ZB-WAX, 0.25 μm film thickness (Agilent Technologies, Santa Clara, California, USA). The carrier gas was helium, linear velocity 36 cm/s, flow rate 1.0 ml/min in constant flow mode. The initial oven temperature was 40 °C for 3 min. The temperature was increased by 4 °C/min until it reached 220 °C, and was held at this temperature for 20 min. The injector and the transfer line were held at 250 °C. The sample volume injected was 2 μl, and the splitter, at 10:1, was opened after 30 s. The focus liner (Agilent Technologies, Santa Clara, California, USA) was deactivated and tapered with glass wool (2–4 mm). The mass spectrometer quadrupole temperature was set at 150 °C, the source was set at 230 °C, and the transfer line was held at 250 °C. For quantification, mass spectra were recorded in Selected Ion Monitoring (SIM) mode with positive ion electron impact at 70 eV. The ions monitored in SIM runs are shown in Electronic supplementary material (ESM) Table S1. The ion in bold for each compound was typically used for quantification, because it had the best signal-to-noise and the least interference from other wine components. The other ions were used as qualifiers.

The method of extraction and analysis of aromatic compounds (higher alcohols, esters, and fatty acids) used in this study is routinely used for the extraction of volatile compounds from a synthetic medium of fermentation. The calibration functions obtained were linear throughout the concentration range used. The reference calibrants were prepared on the same day with the same mix of deuterated standards used to spike the samples of fermentation for analysis. Spiked standard additions of unlabeled analytes at concentrations in the middle of the calibration range were prepared in reference medium (alcoholic solution, 12 % ethanol, 6 g/l malic acid, pH 3.3). New QC samples were prepared with every set of samples to build the calibration curves.

Experimental design

Statistical analysis was performed with R software, version 2.14.2 (R Development Core Team 2012) and the rsm library (Lenth 2009).

A Box–Behnken experimental design was applied to investigate the effects of three independent variables (initial nitrogen and phytosterol content and temperature of fermentation) and to calculate the optimal combination of treatment conditions for the production of volatile compounds with a limited number of experimental runs. This design was used to study the production of 36 volatile compounds for the Lalvin EC1118® strain.

A total of 16 experiments were performed, including four at the center of the experimental domain.

In this experimental design, there were three-coded factor levels: −1, 0, +1 in which −1 corresponded to the low level of each factor, 1 to the high level, and 0 to the mid-level. The actual level of each factor was calculated with the following equation (Box and Behnken 1960):

The effect of the three independent variables on each volatile compound (Y) was modeled with a polynomial response surface:

where x 1, x 2 and x 3 represent the coded values of initial nitrogen content, initial phytosterol content and temperature of fermentation, respectively, Y is the predicted response, β 0 is the intercept term, β i is the linear coefficient, β ii is the quadratic coefficient, and β ij is the interaction coefficient and ε are independent N (0, σ 2) error terms.

If necessary, a simplified model was fitted for some compounds by suppressing the interactive terms of the equation according to validity criteria (ESM Table S2). The equations of the models (Eq. 2) obtained for each volatile compound are provided in ESM Table S2.

In addition, the normality of residual distributions and homogeneity of variance were studied with standard diagnostic graphs; no violation of the assumptions was detected.

The accuracy and general ability of each polynomial model described above was evaluated by a lack of fit test, the Fisher test and the adjusted coefficient of determination adjR2.

The reliability of the fitted models was overall very good: each polynomial model gave a non-significant lack of fit test at a 0.05 threshold (except for hexanoic and octanoic acid compounds), a significant Fisher test at a 0.05 threshold (except for isoamyl alcohol and phenylethanol) and a range of adjR2 between 42 and 99 %.

For graphical representations of the surface responses, a custom version of the persp() function was used.

To assess the effect of the genetic background of the strain, fermentation was conducted in triplicate under the two extreme conditions predicted by the model (330 mg/l of assimilable nitrogen, 2 mg/l of phytosterols at 20 °C and 70 mg/l of assimilable nitrogen, 8 mg/l of phytosterols to 28 °C). A principal component analysis (PCA) was carried out with the FactoMineR package (Husson et al. 2012) to provide an overview of the dataset.

Calculation of losses

The quantity of isoamyl acetate, ethyl hexanoate and ethyl octanoate effectively produced by yeast (that is called total production in the next sections) was calculated from the final value of liquid content and the fermentation temperature with the following equation:

where P is the total production of a volatile compound (expressed in milligram per liter), C liq is the measured liquid concentration (expressed in milligram per liter) and % T is the overall percentage loss depending on the fermentation temperature, T.

Results

We sought to identify the effect of temperature and initial nitrogen and lipid content on the production of volatile compounds. We used a Box–Behnken design to minimize the number of factor combinations required to evaluate the effects of these three factors. Sixteen fermentations were performed with the Lalvin EC1118® strain at three different temperatures and three different nitrogen and lipid concentrations (Table 1; from 20 to 28 °C, from 70 to 330 mgN/L of assimilable nitrogen, and from 2 to 8 mg/l of phytosterols). The concentrations of metabolites and volatile compounds obtained for each fermentation are provided in Table S3.

The Box–Behnken design enabled us to plot changes to the concentrations of volatile compounds according to the three environmental parameters and also enabled us to build an associated mathematical model. With this model, we were able to assign each parameter (nitrogen, phytosterols, temperature) a “weight” and thus classify these three parameters according to their influence on the synthesis of each volatile compound (Table 2). The size of the effect can be determined from the level of significance expressed by the p value (p). Based on the sign of the β coefficients (Eq. 2) of the polynomial surface response, we can determine whether the effect of the fermentative parameter on the production of the studied volatile compound was positive or negative. We also studied the interactions between parameters (i.e., the effect of one factor depending on the value of another), as well as the non-linear effects of these parameters, called quadratic effects.

Effect of fermentation conditions on central metabolism

Regardless of the fermentation conditions used, complete dryness (residual sugars ≤2 g/l) was reached at the end of fermentation and the concentration of assimilable nitrogen at the end of the growth phase was equal to zero. The fermentation time was shorter when the initial nitrogen content and/or the temperature value were increased (Table 1), which is consistent with observations in other studies (Colombie et al. 2005; Blateyron and Sablayrolles 2001). The concentration of lipids did not affect the fermentation kinetics.

The amount of ethanol produced in all conditions was similar, whereas we observed significant differences in the concentrations of succinic acid, acetic acid and glycerol produced.

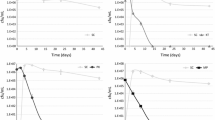

The final concentration of succinic acid was greatly influenced by nitrogen content (p < 0.001), which had a negative effect on the production of this compound. The model also revealed positive effects for both temperature and phytosterol concentrations, an interaction between these two factors, as well as quadratic effects of all three factors. The response surfaces showed that the production of succinic acid was highest at low assimilable nitrogen content and at high temperature and lipid content (Fig. 1a).

For glycerol, the model described the same simple effects as those observed for succinic acid (Fig. 1a, b), and we observed quadratic effects for nitrogen and temperature.

The production of acetic acid was mainly influenced by the lipid content. The final concentration of acetate was highest at low phytosterol content (Fig. 1c), consistent with the negative effect (p < 0.01) given by the model. Nitrogen content had a quadratic effect on the production of this compound.

Effect of fermentation conditions on the synthesis of aromas

Overall, we observed that nitrogen concentration was the factor that had the greatest effect on a large number of volatile compounds. Its simple effect was always positive, i.e., the final concentration of volatile compounds increased with the initial nitrogen content. Temperature and lipid content had moderate effects on some compounds. Moreover, these effects were either positive or negative.

Higher alcohols

The effect of fermentative parameters depended on the higher alcohol considered (Table 2). For 2-phenylethanol, we only observed a negative quadratic effect of nitrogen (Fig. 2a). Temperature and lipid content were positively correlated with isobutanol synthesis and we also found an interaction between nitrogen and phytosterol content for this compound. These effects were clearly observable in response surface (Fig. 2b).

The synthesis of isoamyl alcohol was positively correlated with lipid content (Fig. 2c) and nitrogen content had a negative quadratic effect on the production of this compound. We also observed two interactions: one between nitrogen and phytosterol content and another between phytosterol content and temperature.

By contrast, the final concentration of propanol was only affected by the initial nitrogen content (p < 0.001), which had a positive effect on its production (Table 2). The shape of the response surfaces of propanol was completely different from that of other higher alcohols (Fig. 2d). Propanol production was directly proportional to the initial nitrogen concentration.

Acetates of higher alcohols

Nitrogen content was positively correlated with the liquid concentration of all acetates of higher alcohols (p < 0.001; Fig. 3), in line with other studies (Torrea et al. 2011; Ugliano et al. 2010; Hernandez-Orte et al. 2006). Moreover, the model described a positive, quadratic effect of temperature on the production of isoamyl acetate and isobutyl acetate and a negative effect of nitrogen on that of 2-phenylethylacetate.

Ethyl esters

The final liquid concentration of all ethyl esters was strongly influenced by the three parameters studied (nitrogen, lipids, and temperature). Nitrogen content was positively correlated with the final liquid concentration of ethyl esters, whereas temperature and phytosterol content were negatively correlated.

Nevertheless, ethyl esters responded differently to changes in fermentation parameters and could be divided into two distinct groups according to their behavior. The compounds belonging to these two groups are distinguished by the length of their carbon chain or their molecular weight. The first group contained ethyl butanoate and ethyl hexanoate whereas the second group contained ethyl octanoate.

Initial nitrogen concentration had a similar effect on the production of the three studied ethyl esters, but the effects of temperature and lipid content were different between the two groups. The production of the three ethyl esters significantly increased with initial nitrogen content (Fig. 4; Table 2), consistent with previous studies (Torrea et al. 2011; Garde-Cerdán and Ancín-Azpilicueta 2008). The final liquid concentration of ethyl butanoate and ethyl hexanoate was maximal at low temperature (20 °C), whereas the highest final concentration of ethyl octanoate was obtained at an intermediate temperature (24 °C), underlining the quadratic effect of temperature for this particular compound. Lipid concentration was negatively correlated with the synthesis of ethyl butanoate and ethyl hexanoate (Fig. 4a). However, the relationship between initial phytosterol concentration and final ethyl octanoate concentration was more complex: the lowest amount of ethyl octanoate was produced at the intermediate value of lipid content (5 mg/l), and the quantities produced at 2 and 8 mg/l of phytosterols were similar (Fig. 4b).

Calculation of the total production of esters

Yeast produces fermentative aromas which are released into the liquid phase. These compounds partly evaporate and are lost in the exhaust gas (especially esters), due to their volatility and hydrophobicity. The accumulation of volatile compounds in the liquid therefore depends on both their biological production by yeast and the physical phenomenon of evaporation. The total amount of fermentative aromas produced by yeast can be obtained by calculating the accumulated amount in the liquid phase and the amount lost in gas.

We previously established a method to evaluate the percentage of volatile compounds lost in gas (Mouret et al. 2014b; Morakul et al. 2011). With this approach, we were thus able to calculate the total production of volatile compounds by yeast. Losses in the exhaust gas strongly depend on the volatile compound studied. These losses are negligible for higher alcohols (less than 1 %) but reach high values for esters (Mouret et al. 2014b; Morakul et al. 2011). Therefore, we only show here response surfaces and associated models for the total production of esters.

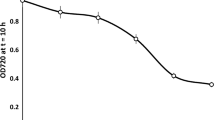

Temperature had a stronger quadratic effect on the total production of isoamyl acetate than on the concentration of this compound in liquid (Table 2; Fig. 3).

By contrast, the simple effect of temperature on the production of ethyl hexanoate and ethyl octanoate was lost when the total production of these compounds was considered (Fig. 4). However, the quadratic effect of temperature on the production of ethyl octanoate was still present. The response surface representing the total production of ethyl hexanoate did not change with temperature, whereas the corresponding response surface for the liquid concentration declined with increasing temperature (Fig. 4a). Similarly, the response surface of total ethyl octanoate showed less variation with temperature than the response surface of its liquid concentration, but the relationship between temperature and the total production of ethyl octanoate remained non-monotonous (Fig. 4b).

Effect of yeast genetic background

The production of volatile compounds varies substantially depending on the strain (Blanco et al. 2013; Barbosa et al. 2012; Camarasa et al. 2011); however, the variability in the regulation of the synthesis of these compounds has been poorly documented. Nevertheless, it was recently shown that variations in the expression level of individual transcription factors are involved in phenotypic differences observed within the S. cerevisiae species, including the production of volatile compounds (Rossouw et al. 2012). We therefore decided to extend our study to six other wine yeast strains. The production of volatile compounds was studied in two extreme conditions predicted by the model, associated with maximal (330 mg/l of assimilable nitrogen, 2 mg/l of phytosterols at 20 °C) or minimal (70 mg/l of assimilable nitrogen, 8 mg/l of phytosterols at 28 °C) production of esters.

We first found that the production of volatile compounds due to changes in fermentation conditions varied in the same direction for all tested strains. We then performed two PCA to investigate the effect of genetic background: one analysis of the concentration values considering the two conditions of fermentation as independent, and a second analysis considering the percentage of variation in the production of volatile compounds between the two conditions.

In the PCA of the concentration values (Fig. 5a), the first two dimensions accounted for 85 % of the total variation. The two conditions of fermentation were separated by axis 1, which was related to esters. The dispersion of strains was greatest when the nitrogen content was high. The Affinity™ ECA5 strain, which we previously obtained by experimental evolution (Cadière et al. 2011), showed the highest production of aroma compounds.

Principal component analysis: with the concentration values considering the two conditions of fermentation as independent (a), with the percentage of variation in the production of volatile compounds between the two conditions (b). PR: propanol, ISO: isobutanol, IA: isoamyl alcohol, PHE: 2-phenylethanol, EA: ethyl acetate, ISA: isobutyl acetate, IAA: isoamyl acetate, PEA: 2-phenylethyl acetate, EB: ethyl butanoate, EH: ethyl hexanoate, EO: ethyl octanoate

In the PCA representing the percentage of variation in the production of volatile compounds between the two conditions (Fig. 5b), the first two axes accounted for 72 % of the total variation. Lalvin ICV K1M® and Affinity™ ECA5 were clearly separated from the other strains. Lalvin ICV K1M® was separated from the other strains due to variations in the production of isobutanol, isobutyl, and isoamyl acetate. Affinity™ ECA5 was discriminated on the basis of the production of ethyl esters.

Discussion

In this study, we investigated the combined effect of initial assimilable nitrogen content, phytosterol content, and fermentation temperature on yeast metabolism and particularly on the synthesis of fermentative volatile compounds. We first observed notable variations in central metabolism. Although the effect of initial nitrogen concentration on succinic acid synthesis is still unclear from studies in the literature (Torrea et al. 2011; Beltran et al. 2005; Varela et al. 2004), we found a clear inverse relationship between initial nitrogen concentration and succinic acid synthesis (Fig. 1a). In the presence of a high concentration of assimilable nitrogen, especially ammonium, α-ketoglutarate is principally used to form glutamate. By contrast, at lower concentrations of assimilable nitrogen, the pool of α-ketoglutarate is partly rerouted to form succinic acid via the oxidative branch of the TCA cycle, because less glutamate is formed from α-ketoglutarate due to the low availability of nitrogen (Camarasa et al. 2003). Therefore, the synthesis of succinic acid acts as a safety valve to prevent accumulation of α-ketoglutarate.

Another important finding is the effect of a high amount of phytosterols on the production of acetic acid. Indeed, the production of acetic acid was low at high concentrations of phytosterols whereas that of succinic acid was high. A plausible explanation for these metabolic variations is that the requirement for acetyl-CoA, a precursor for lipid biosynthesis, is low in the presence of exogenous lipids (phytosterols). In addition, the pool of cytoplasmic acetyl-CoA not used to produce lipids may be converted into citrate by the citrate synthase Cit2p. Citrate may be subsequently transported to the mitochondria and participate in the synthesis of the succinic acid via the TCA cycle.

Our model showed that the tested parameters affected the production of succinic acid and glycerol to a similar extent, which may reflect the necessity for the cell to balance the production of these two compounds to fulfill redox constraints. Indeed, the synthesis of succinic acid via the oxidative branch of the TCA cycle leads to the production of NADH, and glycerol plays a major role in the reoxidation of NADH. We estimated the amount of produced and consumed NADH at the lowest and highest nitrogen concentrations tested (SM70 and SM330, the other two parameters were equal). On average, the amount of NADH produced (18.2 mmol) was comparable to the amount of NADH consumed (15.4 mmol). Thus, the redox balance is equilibrated, supporting the view of a redox link between succinic acid and glycerol.

The main objective of this study was to investigate the effect of environmental parameters on the total production of volatile compounds. We observed major effects on the production of higher alcohols. Notably, the production of propanol was positively affected by high initial nitrogen concentration and was independent of temperature and phytosterol content (Fig. 2d). Indeed, for the sixteen fermentations, there was a linear correlation between the final propanol concentration and the initial assimilable nitrogen content (regression coefficient = 0.9459). Therefore, overall propanol production can be considered as a quantitative marker for the initial concentration of assimilable nitrogen (Mouret et al. 2014a; Clement et al. 2013). This behavior is consistent with the fact that propanol is produced from α-ketobutyrate, the synthesis of which is linked to nitrogen but not carbon metabolism (Boulton et al. 1995).

We observed a more complex effect for the other higher alcohols. Nitrogen content had a quadratic effect on 2-phenylethanol, explaining the response surface curvature around 200 mg/l of assimilable nitrogen (Fig. 2a). This optimal dose of nitrogen is consistent with previous findings (Jiménez-Martí et al. 2007; Vilanova et al. 2007). We have previously shown that an imbalance of a specific amino acid (addition of valine) led to a change in the flavor profiles (Clement et al. 2013). However, in this case, the added valine (835 mg/l) is much higher than the variability found naturally in grape must (between 8 and 140 mg/l, Sauvage et al. 1993).

Phytosterol content had a similar effect on the production of isobutanol and isoamyl alcohol (Fig. 2b, c). This effect may be partly explained by impairment in the activity of alcohol acetyl transferases in the presence of lipids. These enzymes catalyze the conversion of higher alcohols into the corresponding esters (EC 2.3.1.84). Indeed, the expression of ATF1 is repressed by lipids (Fujii et al. 1997). By contrast, other parameters (nitrogen and temperature) affected differently the production of isobutanol and isoamyl alcohol (Table 2) and the response surfaces of these two compounds had fairly different shapes (Fig. 2b, c). In particular, nitrogen content affected the production of isoamyl alcohol but not that of isobutanol. By contrast, only the synthesis of isobutanol was affected by temperature. Thus, the production of isobutanol and isoamyl alcohol is differently regulated by the fermentation parameters, despite the fact that they are produced from a common intermediate, α-ketoisovalerate. Further studies involving the quantitative analysis of these pathways are required to understand better the regulation of the synthesis of these compounds.

Nitrogen content positively influenced the production of all acetates of higher alcohols. This effect is in line with previous findings (Mouret et al. 2014b; Torrea et al. 2011; Garde-Cerdán and Ancín-Azpilicueta 2008) and consistent with the fact that the synthesis pathways of these compounds are partly linked to nitrogen metabolism via the Ehrlich pathway (Hazelwood et al. 2008). Thus, the initial concentration of assimilable nitrogen is a major factor that influences the production of these aroma compounds and can be varied to increase the concentration of these compounds.

Temperature had a quadratic effect on the production of isoamyl acetate. The total production of this compound was lowest at 24 °C and quite similar at 20 and 28 °C. This indicates that temperature affects the regulation of the metabolic pathways involved in the production of isoamyl acetate. Therefore, variations of the final liquid concentration of this compound due to temperature are a result of both evaporation and modifications of yeast metabolism.

The production of each higher alcohol and its corresponding acetate were differently affected by the fermentative parameters. However, all acetates of higher alcohols were similarly affected by these factors. This suggests that the production of acetates of higher alcohols is more related to the enzymatic activity of alcohol acetyltransferases (Atf1 and Atf2) than to the availability of higher alcohols.

Temperature, phytosterols, and nitrogen concentrations all had significant, simple effects on the production of ethyl esters, indicating that the accumulation of ethyl esters in liquid can be modulated through several fermentation parameters. The final concentration of ethyl esters was positively correlated with initial nitrogen content, in line with previous studies (Torrea et al. 2011; Garde-Cerdán and Ancín-Azpilicueta 2008). This connection between assimilable nitrogen and ethyl esters is surprising because these volatile compounds are produced through lipid metabolism (Saerens et al. 2008; Swiegers et al. 2005). This suggests that the precursor of these esters, acyl-CoA, is synthetized from α-ketoacids. S. cerevisiae can synthesize isobutyryl-CoA from α-ketoisovalerate through a branched-chain α-ketoisovalerate dehydrogenase (EC 1.2.4.4). Isobutyryl-CoA could then be converted to butanoyl-CoA, the precursor of ethyl butanoate. The enzyme catalyzing this final reaction, isobutyryl-CoA mutase (EC 5.4.99.13), is present in many microorganisms, such as Streptomyces or Mycobacterium but its existence has not been reported in S. cerevisiae.

By contrast, the effect of phytosterols on the synthesis of ethyl esters was not surprising, as ethyl esters derive from lipid metabolism (Saerens et al. 2008; Swiegers et al. 2005). The de novo synthesis of lipids is repressed in the presence of exogenous fatty acids (Chirala 1992), which limits the extracellular accumulation of fatty acids that are used to synthesize ethyl esters. We were able to measure the concentrations of fatty acids (butanoic, hexanoic, and octanoic acid) with our assay, and could therefore estimate the effect of environmental factors (nitrogen and phytosterol contents) on the production of these molecules. The model showed that the behavior of fatty acids was quite similar to that observed for ethyl esters (data not shown). Notably, the concentration of fatty acids was negatively correlated with phytosterol concentration and positively correlated with initial nitrogen concentration. Thus, the formation of ethyl esters seems more dependent on the availability of precursors (fatty acids) than on the expression of the EHT1 and EEB1 genes encoding acyl coenzyme A/ethanol O-acyltransferases.

Overall, our study of the effect of temperature highlights the utility of gas–liquid balances to estimate the total production of a compound by yeast and to differentiate the physical effect (evaporation) from the metabolic effect of temperature. Indeed, we recently demonstrated that the effect of temperature on yeast metabolism is overestimated if the concentration of metabolites in the liquid is considered in isolation (Mouret et al. 2014a, b; Morakul et al. 2013). For example, the simple effect of temperature on the synthesis of ethyl hexanoate and ethyl octanoate was no longer significant when total production was considered instead of liquid accumulation. Nonetheless, the quadratic effect was retained. These results indicate that the effect of temperature on the liquid accumulation of ethyl esters is mainly due to evaporation. Nevertheless, yeast metabolism is also affected to a small extent, especially the production of ethyl octanoate. For this particular compound, total production peaked at 24 °C (Fig. 4b). This may partly explain why ethyl octanoate and ethyl hexanoate could be classified into two distinct groups.

The main conclusions obtained with Lalvin EC1118® were valid for six other strains studied. Indeed, the production of isobutyl acetate and isoamyl acetate were correlated whereas that of their precursors, isobutanol and isoamyl alcohol, were not (Fig. 5a). This observation confirms the results described by the model showing that changes in the fermentation parameters had different effects on the accumulation of these two higher alcohols, whereas the response of their acetates was similar. The three ethyl esters were correlated in this PCA, which is consistent with the results obtained by the model showing that the response of these esters to environmental parameters was similar.

We examined the effect of genetic background on the regulation of the production of volatile compounds by studying the two PCA together. Strains were discriminated not only by the production of fermentative aromas but also by the regulation of their synthesis. Two strains, Lalvin ICV K1M® and Affinity™ ECA5, are particularly useful to illustrate these differences. The concentrations of volatile compounds produced by Lalvin ICV K1M® resembled those of the other strains; however, the regulation of their production was very unusual in this strain. The regulation of the production of volatile compounds was also atypical in the Affinity™ ECA5 strain but the quantity of compounds produced was very different from that of other strains. This was especially true of fermentation conditions in which ester synthesis was high. The Affinity™ ECA5 strain was obtained by adaptive evolution of Lalvin EC1118® (Cadière et al. 2011) and is characterized by an overproduction of higher alcohols and acetate esters (Cadière et al. 2012). Our study reveals substantial differences in the regulatory networks of these two strains, which could be ascribed to natural existing variation (Lalvin ICV K1M®) or to mutations selected during experimental evolution (Affinity™ ECA5).

In summary, we developed a model that is useful to predict the combined effects of environmental parameters on the production of fermentative aromas. Our results demonstrate the complex effect of environmental parameters on the synthesis of non-volatile and volatile compounds. This study provides new insight into the synthesis and regulation of aroma compounds and reveals that the effect of environmental parameters depends on the strain. This knowledge offers new perspectives to improve the fermentation process and to select appropriate yeast strains to maximize the production of fermentative aromas.

References

Barbosa C, Mendes-Faia A, Mendes-Ferreira A (2012) The nitrogen source impacts major volatile compounds released by Saccharomyces cerevisiae during alcoholic fermentation. Int J Food Microbiol 160:87–93

Bell SJ, Henschke PA (2005) Implications of nitrogen nutrition for grapes, fermentation and wine. Aust J Grape Wine Res 11:242–295

Beltran G, Esteve-Zarzoso B, Rozes N, Mas A, Guillamon JM (2005) Influence of the timing of nitrogen additions during synthetic grape must fermentations on fermentation kinetics and nitrogen consumption. J Agric Food Chem 53:996–1002

Beltran G, Novo M, Leberre V, Sokol S, Labourdette D, Guillamon JM, Mas A, François J, Rozes N (2006) Integration of transcriptomic and metabolic analyses for understanding the global responses of low-temperature winemaking fermentations. FEMS Yeast Res 6:1167–1183

Bely M, Sablayrolles JM, Barre P (1990) Automatic detection of assimilable nitrogen deficiencies during alcoholic fermentation in enological conditions. J Ferment Bioeng 70:246–252

Blanco P, Mirás-Avalos JM, Pereira E, Orriols I (2013) Fermentative aroma compounds and sensory profiles of Godello and Albariño wines as influenced by Saccharomyces cerevisiae yeast strains. J Sci Food Agric 93:2849–2857

Blateyron L, Sablayrolles JM (2001) Stuck and slow fermentations in enology: statistical study of causes and effectiveness of combined additions of oxygen and diammonium phosphate. J Biosci Bioeng 91:184–189

Boulton RB, Singleton VL, Bisson LF, Kunkee RE (1995) Principles and practices of winemaking. Champman & Hall, New York

Box GEP, Behnken DW (1960) Some new three level designs for the study of quantitative variables. Technometrics 2:455–475

Cadière A, Ortiz-Julien A, Camarasa C, Dequin S (2011) Evolutionary engineered Saccharomyces cerevisiae wine yeast strains with increased in vivo flux through the pentose phosphate pathway. Metab Eng 13:263–271

Cadière A, Aguera E, Caillé S, Ortiz-Julien A, Dequin S (2012) Pilot-scale evaluation the enological traits of a novel, aromatic wine yeast strain obtained by adaptive evolution. Food Microbiol 32:332–337

Camarasa C, Grivet JP, Dequin S (2003) Investigation by 13C-NMR and tricarboxylic acid (TCA) deletion mutant analysis of pathways for succinate formation in Saccharomyces cerevisiae during anaerobic fermentation. Microbiology 149:2669–2678

Camarasa C, Sanchez I, Brial P, Bigey F, Dequin S (2011) Phenotypic landscape of Saccharomyces cerevisiae during wine fermentation: evidence for origin-dependent metabolic traits. PLoS One 6:e25147

Carrau FM, Medina K, Farina L, Boido E, Henschke PA, Dellacassa E (2008) Production of fermentation aroma compounds by Saccharomyces cerevisiae wine yeasts: effects of yeast assimilable nitrogen on two model strains. FEMS Yeast Res 8:1196–1207

Chirala SS (1992) Coordinated regulation and inositol-mediated and fatty acid-mediated repression of fatty acid synthase genes in Saccharomyces cerevisiae. Proc Natl Acad Sci 89:10232–10236

Clement T, Perez M, Mouret JR, Sanchez I, Sablayrolles JM, Camarasa C (2013) Metabolic responses of Saccharomyces cerevisiae to valine and ammonium pulses during four-stage continuous wine fermentations. Appl Environ Microbiol 79:2749–2758

Colombie S, Malherbe S, Sablayrolles JM (2005) Modeling alcoholic fermentation in enological conditions: feasibility and interest. Am J Enol Vitic 56:238–245

Crépin L, Nidelet T, Sanchez I, Dequin S, Camarasa C (2012) Sequential use of nitrogen compounds by Saccharomyces cerevisiae during wine fermentation: a model based on kinetic and regulation characteristics of nitrogen permeases. Appl Environ Microbiol 78:8102–8111

Fujii T, Kobayashi O, Yoshimoto H, Furukawa S, Tamai Y (1997) Effect of aeration and unsaturated fatty acids on expression of the Saccharomyces cerevisiae alcohol acetyltransferase gene. Appl Environ Microbiol 63:910–915

Garde-Cerdán T, Ancín-Azpilicueta C (2008) Effect of the addition of different quantities of amino acids to nitrogen-deficient must on the formation of esters, alcohols, and acids during wine alcoholic fermentation. LWT Food Sci Technol 41:501–510

Hazelwood LA, Daran JM, van Maris AJA, Pronk JT, Dickinson JR (2008) The Ehrlich pathway for fusel alcohol production: a century of research on Saccharomyces cerevisiae metabolism. Appl Environ Microbiol 74:3920

Hernandez-Orte P, Bely M, Cacho J, Ferreira V (2006) Impact of ammonium additions on volatile acidity, ethanol, and aromatic compound production by different Saccharomyces cerevisiae strains during fermentation in controlled synthetic media. Aust J Grape Wine Res 12:150–160

Husson F, Josse J, Le S, Mazet J (2012) FactoMineR: multivariate exploratory data analysis and data mining with R. R package version 1.18. http://CRAN.R-project.org/package=FactoMineR

Jiménez-Martí E, Aranda A, Mendes-Ferreira A, Mendes-Faia A, li del Olmo M (2007) The nature of the nitrogen source added to nitrogen depleted vinifications conducted by a Saccharomyces cerevisiae strain in synthetic must affects gene expression and the levels of several volatile compounds. Antonie Van Leeuwenhoek 92:61–75

Lefur Y, Hory C, Bard M, Olsson A (1994) Evolution of phytosterols in Chardonnay grape berry skins during last stages of ripening. Vitis 33:127–131

Lenth RV (2009) Response-surface methods in R, using rsm. J Stat Softw 32:1–17

Luparia V, Soubeyrand V, Berges T, Julien A, Salmon JM (2004) Assimilation of grape phytosterols by Saccharomyces cerevisiae and their impact on enological fermentations. Appl Microbiol Biotechnol 65:25–32

Mauricio JC, Moreno J, Zea L, Ortega JM, Medina M (1997) The effects of grape must fermentation conditions on volatile alcohols and esters formed by Saccharomyces cerevisiae. J Sci Food Agric 75:155–160

Molina AM, Swiegers JH, Varela C, Pretorius IS, Agosin E (2007) Influence of wine fermentation temperature on the synthesis of yeast-derived volatile aroma compounds. Appl Microbiol Biotechnol 77:675–687

Morakul S, Mouret JR, Nicolle P, Trelea IC, Sablayrolles JM, Athes V (2011) Modelling of the gas–liquid partitioning of aroma compounds during wine alcoholic fermentation and prediction of aroma losses. Process Biochem 46:1125–1131

Morakul S, Mouret JR, Nicolle P, Aguera E, Sablayrolles JM, Athès V (2013) A dynamic analysis of higher alcohol and ester release during winemaking fermentations. Food Bioprocess Technol 6:818–827

Mouret JR, Camarasa C, Angenieux M, Aguera E, Perez M, Farines V, Sablayrolles JM (2014a) Kinetic analysis and gas–liquid balances of the production of fermentative aromas during winemaking fermentations: effect of assimilable nitrogen and temperature. Food Res Int 62:1–10

Mouret JR, Perez M, Angenieux M, Nicolle P, Farines V, Sablayrolles JM (2014b) Online-based kinetic analysis of higher alcohol and ester synthesis during winemaking fermentations. Food Bioprocess Technol 7:1235–1245

R Development Core Team (2012) R: a language and environment for statistical computing. R Foundation for Statistical Computing, Vienna

Rossouw D, Jacobson D, Bauer F (2012) Transcriptional regulation and the diversification of metabolism in wine yeast strains. Genetics 190:251–261

Sablayrolles J, Barre P (1993) Kinetics of alcoholic fermentation under anisothermal enological conditions. 1. Influence of temperature evolution on the instantaneous rate of fermentation. Am J Enol Vitic 44:127–133

Saerens SMG, Delvaux F, Verstrepen KJ, Dijck PV, Thevelein JM, Delvaux FR (2008) Parameters affecting ethyl ester production by Saccharomyces cerevisiae during fermentation. Appl Environ Microbiol 74:454–461

Sauvage FX, Nicol MZ, Verries C, Sarris J, Pradal M, Robin JP (1993) Free amino acids and some enzymatic activities in ripe grape musts statistical analyses of the varietal effect. Sci Aliment 13:443–462

Siebert TE, Smyth HE, Capone DL, Neuwöhner C, Pardon KH, Skouroumounis GK, Herderich MJ, Sefton MA, Pollnitz AP (2005) Stable isotope dilution analysis of wine fermentation products by HS-SPME-GC-MS. Anal Bioanal Chem 381:937–947

Swiegers JH, Bartowsky EJ, Henschke PA, Pretorius IS (2005) Yeast and bacterial modulation of wine aroma and flavour. Aust J Grape Wine Res 11:139–173

Torija MJ, Beltran G, Novo M, Poblet M, Guillamón JM, Mas A, Rozès N (2003) Effects of fermentation temperature and Saccharomyces species on the cell fatty acid composition and presence of volatile compounds in wine. Int J Food Microbiol 85:127–136

Torrea D, Varela C, Ugliano M, Ancin-Azpilicueta C, Leigh Francis I, Henschke PA (2011) Comparison of inorganic and organic nitrogen supplementation of grape juice—effect on volatile composition and aroma profile of a Chardonnay wine fermented with Saccharomyces cerevisiae yeast. Food Chem 127:1072–1083

Ugliano M, Travis B, Francis IL, Henschke PA (2010) Volatile composition and sensory properties of Shiraz wines as affected by nitrogen supplementation and yeast species: rationalizing nitrogen modulation of wine aroma. J Agric Food Chem 58:12417–12425

Valero E, Millan MC, Mauricio JC, Ortega JM (1998) Effect of grape skin maceration on sterol, phospholipid, and fatty acid contents of Saccharomyces cerevisiae during alcoholic fermentation. Am J Enol Vitic 49:119–124

Varela C, Pizarro F, Agosin E (2004) Biomass content governs fermentation rate in nitrogen-deficient wine musts. Appl Environ Microbiol 70:3392–3400

Varela C, Torrea D, Schmidt SA, Ancin-Azpilicueta C, Henschke PA (2012) Effect of oxygen and lipid supplementation on the volatile composition of chemically defined medium and Chardonnay wine fermented with Saccharomyces cerevisiae. Food Chem 135:2863–2871

Vilanova M, Ugliano M, Varela C, Siebert T, Pretorius IS, Henschke PA (2007) Assimilable nitrogen utilization and production of volatile and non-volatile compounds in chemically defined medium by Saccharomyces cerevisiae wine yeasts. Appl Microbiol Biotechnol 77:145–157

Vilanova M, Siebert TE, Varela C, Pretorius IS, Henschke PA (2012) Effect of ammonium nitrogen supplementation of grape juice on wine volatiles and non-volatiles composition of the aromatic grape variety Albariño. Food Chem 133:124–131

Acknowledgments

This study was supported by the BIOFLAVOUR Cost Action FA0907.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 121 kb)

Rights and permissions

About this article

Cite this article

Rollero, S., Bloem, A., Camarasa, C. et al. Combined effects of nutrients and temperature on the production of fermentative aromas by Saccharomyces cerevisiae during wine fermentation. Appl Microbiol Biotechnol 99, 2291–2304 (2015). https://doi.org/10.1007/s00253-014-6210-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-6210-9