Abstract

After over 100 strains of Aureobasidium spp. isolated from mangrove system were screened for their ability to produce exopolysaccharide (EPS), it was found that Aureobasidium pullulans var. melanogenium P16 strain among them could produce high level of EPS. Under the optimal conditions, 65.3 g/L EPS was produced by the P16 strain within 120 h at flask level. During 10-L batch fermentation, when the medium contained 120.0 g/L sucrose, 67.4 g/L of EPS and 23.1 g/L of cell dry weight in the culture were obtained within 120 h, leaving 0.78 g/L of reducing sugar and 11.4 g/L of total sugar in the fermented medium. It should be stressed that during the fermentation, no melanin was observed. After purification, the purified EPS was confirmed to be pullulan. This is the first time to report that A. pullulans var. melanogenium P16 strain isolated from the mangrove system can produce high level of pullulan.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pullulan which is a linear α-d-glucan, made mainly of maltotriose repeating units interconnected by α-(1,6) linkages is the water-soluble homopolysaccharide produced extracellularly by Aureobasidium spp. (Li et al. 2013). The regular alternation of α-1,4 and α-1,6 bonds results in two distinctive properties of structural flexibility and enhanced solubility. Pullulan has many potential applications in food, medical, pharmaceutical, agricultural, and cosmetic industries (Prajapati et al. 2013). It also has been thought that the pullulans produced may have many physiological functions for the producers. (a) It may provide mechanisms for storing carbon or energy or water for the cells; (b) the extracellular pullulan may protect the producers from damage by UV light, heavy metals, organic pollutants, oxidants, and low water activity; (c) it may be one part of structural components of cell wall (Li et al. 2013).

So far, the genus Aureobasidium spp. have been divided into four species, Aureobasidium pullulans, Aureobasidium leucospermi, Aureobasidium proteae, and Aureobasidium thailandense (Peterson et al. 2013) and A. pullulans has been known to have five varieties. In fact, more new species in this genus will be identified according to our research (Li et al. 2013). However, most of the researchers who work on pullulan production think that pullulan is produced by A. pullulans (Prajapati et al. 2013; Chi et al. 2009). Therefore, it is still unknown which species of the genus or which variety of A. pullulans can produce high level of pullulan. At the same time, most of the pullulan producers were isolated from various plant leaves and flowers (Sharma et al. 2013; Duan et al. 2008). However, in recent years, many strains of A. pullulan isolated from marine environments also have been found to be able to produce pullulan (Wu et al. 2012).

Although pullulan has been used in various industries for several decades, relatively little is understood about the mechanisms of pullulan biosynthesis and secretion in Aureobasidium spp. If the pullulan biosynthesis, regulation, and secretion in Aureobasidium spp. are elucidated, it will be very easy to enhance pullulan yield using molecular methods (Prajapati et al. 2013). Therefore, a new pathway was proposed in our recent review article (Fig. 1; Li et al. 2013). The first step is uridine 5′-diphosphate glucose (UDPG)-mediated attachment of a d-glucose residue to the lipid molecule (Lph) via phosphoester bridge. The second stage involves continuous transfer of the d-glucose residue from UDPG to give lipid-linked isomaltose and an isopanosyl or pyranosyl residues that are polymerized into pullulan chain. So, α-phosphoglucose mutase, UDPG-pyrophosphorylase, several glucosyltransferases, and pullulan synthetase are involved in pullulan biosynthesis in Aureobasidium spp. (Li et al. 2013; Duan et al. 2008). It was found that many yeasts isolated from mangrove system can produce killer toxin, single-cell protein, and polymalic acid (Sun et al. 2012; Buzdar et al. 2011; Ma et al. 2013). However, it is still completely unknown whether Aureobasidium spp. isolated from mangrove system can produce high level of pullulan or not. Therefore, in this study, the ability to produce EPS by different strains of Aureobasidium spp. isolated from the mangrove systems was examined. Finally, A. pullulans var. melanogenum P16 strain among them was found to be able to produce high level of EPS, and the produced EPS was characterized.

The proposed pathway of pullulan biosynthesis from glucose by yeasts (Li et al. 2013)

Materials and methods

Yeast strains and cultivation media

The yeast strain P16 (collection number 2A00620 at the Marine Microorganisms Culture Collection of China) of Aureobasidium spp. isolated from mangrove systems in Hainan Province of China was used in this study and stored at −80 °C in this laboratory. The medium for growth of the seed culture contained 6.0 % sucrose, 0.3 % yeast extract, 0.5 % K2HPO4, 0.02 % MgSO4·7H2O, 0.1 % NaCl, and 0.06 % (NH4)2SO4. The cultivation time and temperature were 48 h and 28 °C, respectively. The medium for EPS production consisted of 12.0 % sucrose, 0.3 % yeast extract, 0.5 % K2HPO4, 0.02 % MgSO4·7H2O, 0.1 % NaCl, 0.06 % (NH4)2SO4. The potato dextrose agar (PDA) was 100 ml of potato extract containing 12.0 g of sucrose and 2.0 g of agar.

Sampling

The roots, stems, branches, leaves, barks, fruits, and flowers (35 °C, summer of 2012) from 12 species of the mangrove plants at six different places in Hainan Province of China were used as the sources for yeast isolation in this study. Latitude and longitude of the sampling sites at DongZaiGou, Haikou, Hainan Province are N19°53′ E110°19.

Yeast isolation

Two grams of the roots, stems, branches, leaves, barks, fruits, and flowers from the different mangrove trees were immediately suspended in 50.0 ml of sterile YPD medium containing 1.0 % yeast extract, 2.0 % polypeptone and 2.0 % glucose, supplemented with 0.05 % chloramphenicol in 250-ml shaking flasks after the sampling and cultivated at 25 °C for 5 days. After suitable dilution of the cell cultures, the dilute was plated on YPD plates with 0.05 % chloramphenicol and the plates were incubated at 20–25 °C for 5 days. Different colonies from the plates were transferred to the YPD slants, respectively.

Screening of EPS-producing yeasts

Each yeast strain obtained above was aerobically grown in the medium for growth of the seed culture for 24 h at 28 °C, and a total of 2.5 ml of the cultures was inoculated into the flask containing 50.0 ml of the EPS production medium. The flasks were aerobically incubated at 28 °C and 180 rpm for 3 days. The culture obtained was centrifuged at 5,000×g and 4 °C for 5 min. EPS in the supernatant was obtained and quantitative determination of EPS was performed as described below. At the same time, each yeast strain obtained above was streaked on PDA plate. After incubation at 28 °C for 4 days, EPSs secreted by the yeast colonies were observed. Finally, the yeast strain P16 among them was found to produce the highest level of EPS. Therefore, the yeast strain was used in the subsequent studies.

Morphological analysis

The yeast strain P16 was inoculated on the PDA plate for microscopic analysis and colony characterization. The plate was incubated in the dark at 28 °C for 6 days. Microscopic observations employed Olympus U-LH100HG fluorescent microscope with 40× objective under blue light. Images were recorded using the cellSens Standard software.

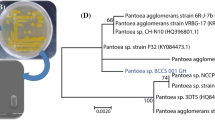

DNA extraction, PCR amplification, sequencing, and phylogenetic analysis

Total genomic DNA from the strain P16 was extracted according to the methods described by Sambrook et al. (1989). To estimate phylogenetic relationships among strain P16 and the typical strains reported on internet, amplification, and sequencing of internal transcribed spacer (ITS) from the strain P16 were performed using the primers IT5: 5′-TCCGTAGGTGAACCTGCGG-3′ and IT6: 5′-TCCTCCGCTTATTGATATGC-3′ (Josefa et al. 2004). The sequence (the accession number of ITS was KF531936) obtained above was aligned using BLAST analysis (http://blast.ncbi.nlm.nih.gov/Blast.cgi, last accessed 18 October 2007). The sequences which shared over 98 % similarity with currently available sequences were considered to be the same species, and multiple alignments were performed using ClustalX 1.83 and phylogenetic tree was constructed using MEGA 4.0 (Tamura et al. 2007).

Optimization of the medium for EPS production

The strain P16 was grown in the medium for growth of the seed culture at 28 °C and 180 rpm for 48 h. A total of 2.5 ml of the cultures was inoculated into the flask containing 50.0 ml of the EPS production medium supplemented with different kinds of carbon sources and with different concentrations of sucrose and yeast extract. The flasks were aerobically incubated at 28 °C and 180 rpm for 3 days. The culture obtained was centrifuged at 5,000×g and 4 °C for 5 min. The EPS in the supernatant and the washed cells were obtained and quantitative determination of EPS was performed as described below.

Batch fermentation

EPS production by the strain P16 was also carried out in the 10-L fermentor [BIOQ-6005-6010B, Huihetang Bio-Engineering Equipment (Shanghai) CO-LTD]. The seed cultures were prepared as described above. The fermentation was carried out in the fermentor equipped with baffles, a stirrer, heating element, oxygen sensor, and temperature sensor. Three hundred milliliters of the seed culture were transferred into 6.5 L of the EPS production media containing 12.0 % sucrose and 0.3 % yeast extract. The fermentation was performed under the conditions of agitation speed of 300 rpm, aeration rate of 6.5 L/min, temperature of 28 °C, and fermentation period of 132 h. Only 20.0 ml of the culture was collected in the interval of 12 h and was centrifuged at 5,000×g and 4 °C for 5 min, and EPS, reducing sugar, and total sugar in the supernatant obtained were determined as described below. The cell dry weight in 20.0 ml of the culture during the 10-L fermentation was also determined as described below.

Purification and quantitative determination of EPS

The culture obtained during the 10-L fermentation was heated at 100 °C in water bath for 15 min, then was cooled to room temperature. The heated culture was centrifuged at 14,046×g and 4 °C for 5 min to remove cells and other precipitates. The supernatant (10.0 ml) was transferred into a test tube, then 20.0 ml of cold ethanol (absolute ethanol or 95 % ethanol) was added to the test tube and mixed thoroughly and held at 4 °C for 12 h to precipitate the extracellular polysaccharide. After removal of residual ethanol, the precipitate was dissolved in 10.0 ml of deionized water at 80 °C and the solution was dialyzed against deionized water for 48 h to remove small molecules in the solution. After the EPS was precipitated again by using 20.0 ml of the cold ethanol, the precipitate was dried at 80 °C to a constant weight (Lee et al. 2001).

Hydrolysis of the purified extracellular polysaccharide and assay of reducing sugar

To assay the component of the extracellular polysaccharide, the purified precipitate was vacuum desiccated to no alcohol by using a vacuum pump, then 0.1 g of the purified precipitate was dissolved in 10 ml of deionized water at 80 °C water bath. The dissolved substrate was hydrolyzed by incubating the mixture of 1.0 ml of the substrate, 0.9 ml of 50 mM sodium acetate and acetic acid buffer (pH 4.5) and 0.1 ml of pullulanase (Sigma) for 15 min at 60 °C (Duan et al. 2013). The released reducing sugar was determined using the Nelson–Somogyi method (Spiro 1966).

Fourier-transform infrared (FT-IR) analysis of the purified EPS

The purified EPS obtained was characterized using FT-IR spectroscopy (a Nicolet Nexus FTIR 470 spectrophotometer). Two milligrams of the purified EPS sample were mixed with 60 mg of 95 % potassium bromide powder. The mixture was desiccated overnight at 50 °C under vacuum. The FT-IR spectra were taken using potassium bromide pellets of the purified EPS and standard pullulan obtained from sigma over arrange of 4,000–400 cm−1 at a rate of 16 scans with a resolution of 2 cm−1.

Determination of reducing sugar and total sugar

Reducing sugar in the fermented media was determined by the Nelson–Somogyi method (Spiro 1966). Residual total sugar was measured as reduction of sugar after hydrolysis of the fermented media (10 ml of the fermented media, 10 ml of 25 % HCl and 30 ml of distilled water were mixed and heated in a boiling water bath for 3 h) (Chi et al. 2001).

Measurement of cell dry weight

Cell dry weight was measured according to the methods described by Chi et al. (2001).

Results

Screening of the strains of Aureobasidium spp. for their ability to produce high level of EPS

After isolation and purification of the yeast strains from the different samples in the mangrove system, the colonies of over 100 strains obtained were found to be similar to those of Aureobasidium spp. as described by Kurtzman and Fell (2000; Fig. 2). After the ability to yield EPS by over 100 strains of Aureobasidium spp. isolated from the mangrove systems was examined, our results showed that only the strain P16 among them could produce the highest level of EPS as there was a large amount of the secreted EPS around the colonies grown on the PDA plate (Fig. 2). Therefore, the strain P16 was used for the subsequent investigation.

Identification of the strain P16

The colonies of the strain P16 grown on the PDA plate exhibited characteristics of Aureobasidium spp. (data not shown). It has been well known that Aureobasidium spp. have three distinctive forms that are elongated branched septate filaments, large chlamydospores, and smaller elliptical yeast-like cells (Sharma et al. 2013). Indeed, it could be observed from Fig. 3 that the strain P16 had yeast-like cells and large chlamydospores. ITS sequence of the strain P16 was determined and aligned and the phylogenetic tree of ITS was constructed as described in “Materials and methods”. After the search for similarities between ITS of the isolate P16 and those of the type strains in the National Center for Biotechnology Information database, the results showed that many phylogenetically related Aureobasidium spp. were similar to the strain P16 obtained in this study and the similarities between the ITS of the isolate and that of the most closely related strain A. pullulans var. melanogenum CBS109800 were 99 % (Fig. 4). The topology of the phylograms confirmed that the strain P16 was assigned to one strain of A. pullulans var. melanogenum (Fig. 4).

Optimization of the medium for EPS production

It has been well known that the high C/N ratio in the medium is required for microbial EPS biosynthesis (Chi and Zhao 2003). Therefore, it is important to optimize carbon sources and nitrogen concentrations in the medium in order to enhance EPS production by A. pullulans var. melanogenum P16 used in this study. After effects of different carbon sources on EPS production by A. pullulans var. melanogenum P16 were tested, the results in Fig. 5a showed sucrose was the most suitable for EPS production. It can be seen from the data in Fig. 5b that 12.0 % sucrose was the most suitable for EPS production by the strain P16. The results in Fig. 5c indicated that 0.3 % yeast extract was the most suitable for EPS production by the strain P6. Under these conditions, the results in Fig. 6 showed that the titer of EPS was 65.3 ± 2.1 g/L, cell mass was 18.7 g/L, the yield was 0.81 ± 0.2 g/g of sucrose and the productivity was 0.54 ± 0.1 g/L/h at the flask level.

EPS production by 10-L fermentation

To scale up for EPS production from sucrose, 10-L fermentation was carried out. During the fermentation, EPS yield, cell growth, and changes in reducing sugar and total sugar concentrations were monitored. The results in Fig. 7 showed that during the 10-L fermentation, 67.4 ± 4.5 g/L of EPS in the fermented medium was attained from sucrose of 12.0 % and dried cell mass in the culture was 23.01 g/L within 120 h. It also can be observed from the data in Fig. 7 that the yield of 0.62 ± 0.04 g/g of the consumed sucrose and the productivity of 0.56 ± 0.1 g/L/h were reached within 120 h of the fermentation. Furthermore, 1.1 % total sugar and only a small amount of reducing sugar (0.078 %) were left in the fermented medium (Fig. 7), suggesting that 90.5 % of the sugar was used for EPS production and cell growth by the strain P16.

Hydrolysis of the purified EPS

As mentioned above, pullulan consists of maltotriose repeating units joined by α-1,6 linkages (Chi et al. 2009). Pullulanase specifically acts on α-1,6 linkages of pullulan molecules, releasing maltotriose and increasing the amount of the reducing sugar. In order to confirm that the purified EPS is pullulan with α-1,6 linkages, the purified EPS was hydrolyzed and the released reducing sugar was determined as described in “Materials and methods”. The results in Fig. 8 indicated that after hydrolysis of the purified EPS by pullulanase, the reducing sugar in the reaction system was greatly increased compared to that in the blank, suggesting that the purified EPS was pullulan with α-1,6 linkages.

FTIR spectroscopy of the purified EPS

It can be clearly observed from the data in Fig. 9 that FT-IR spectra for standard pullulan (Sigma) used as a reference and for the purified EPS produced by A. pullulans var. melanogenium P16 were almost identical. Both the spectra of the standard pullulan and the purified EPS showed a strong absorption at a stretching frequency of 3,385.96 m−1 which was characteristic of the presence of repeating units of OH groups in sugars. The absorption at 2,923.1 cm−1 indicated the presence of sp3 hybridized C–H bonds, characteristics of alkane compounds in both the cases. The presence of α-d glucopiranoside bond was confirmed by absorption at 842.49 cm−1 whereas absorption at 753.7 cm−1 indicated the presence of α-(1,4)-d-glucosidic bond, and absorption at 1,018.64 cm−1 proved the presence of α-(1,6)-d-glucosidic linkages. These absorption patterns at various stretching frequencies confirmed the identity of the purified EPS as pullulan (Chouhury et al. 2011).

Discussion

In this study, over 100 yeast strains were isolated from the samples in mangrove system and the strain P16 among them could produce the highest level of EPS (Fig. 2). After traditional and molecular identifications, the strain P16 was found to be one member of A. pullulans var. melanogenum (Figs. 3 and 4). This is the first time to report that A. pullulans var. melanogenum isolated from the mangrove system can produce high level of pullulan. In our previous studies (Sun et al. 2012), the yeast Wickerhamomyces anomalus HN1-2 isolated from the mangrove ecosystem was found to be able to produce both high level of both killer toxin and single cell protein. The yeast Kluyveromyces siamensis HN12-1 isolated from the mangrove ecosystem was found to be able to produce killer toxin against the pathogenic yeast (Metschnikowia bicuspidata WCY) in crab (Buzdar et al. 2011). A novel Aureobasidium sp. P6 strain isolated from the mangrove system can produce more than 98.7 g/L of Ca2+-PMA (Ma et al. 2013). So far, most of the pullulan producers have been found to be A. pullulans (Prajapati et al. 2013; Chi et al. 2009; Zalar et al. 2008). In fact, A. pullulans has five varieties: A. pullulans var. pullulans, A. pullulans var. melanogenum, A. pullulans var. aubasidani Yurlova, A. pullulans var. subplaciale, and A. pullulans var. namibiae (Li et al. 2013). Therefore, it is still under investigation in our laboratory to which variety most of the pullulan producers belong, especially the producers which can produce a large amount of pullulan and have potential application in industries. According to the characteristics of A. pullulans var. melanogenum, it can produce melanin (Singh and Saini 2012). However, during industrial pullulan production, melanin production must be avoided (Prajapati et al. 2013; Singh and Saini 2012). Fortunately, as described below, A. pullulans var. melanogenum P16 used in this study did not produce any melanin during the EPS production.

The titer of EPS produced by the strain P16 was 65.3 ± 2.1 g/L, cell mass was 18.7 g/L, the yield was 0.81 ± 0.2 g/g of sucrose, and the productivity was 0.54 ± 0.1 g/L/h at the flask level (Fig. 6). Maximum pullulan concentration (51.5 g/L), productivity (0.36 g/L/h), and yield (0.8 g/g of sucrose) were achieved after 120 h of fermentation when A. pullulans P56 (a strain deficient in melanin production) was grown in the medium containing 8.0 % sucrose (Youssef et al. 1998). When A. pullulans CGMCC1234 was grown in the medium containing 0.5 % Tween 80, 8.0 % sucrose and 0.09 % yeast extract, 55.5 g/L of pullulan was accumulated in the fermented medium (Sheng et al. 2013). A. pullulans produced the highest pullulan (23.1 g/L) when the initial ammonium sulfate was at 0.5 % (Cheng et al. 2011). A. pullulans CJ001 isolated from sea mud produced 31.25 g/L of melanin-free pullulan (Wu et al. 2012). However, when A. pullulans RBF 4A3 isolated from flowers of Caesulia axillaris was grown in the medium containing 2.0 % corn steep liquor (CSL) and 15.0 % glucose, it produced 88.59 g/L pullulan (Sharma et al. 2013). This means that A. pullulans var. melanogenum P16 can produce much more EPS than most of the yeast strains.

During the 10-L fermentation, 67.4 ± 4.5 g/L of EPS in the fermented medium was attained from sucrose of 12.0 % and dried cell mass in the culture was 23.01 g/L within 120 h (Fig. 7). In the 7-L Applikon fermenter with 5-L working volume, at the end of 96 h of fermentation, 88.6 g of pullulan per liter was produced by A. pullulans RBF 4A3, and the yield was 0.6 g/g of the consumed glucose and the productivity was 0.9 g/L/h (Sharma et al. 2013).

An undesirable characteristic feature of A. pullulans is the production of a melanin-like compound as the presence of melanin in the culture will make purification of pullulan more complex (Chi et al. 2009). Therefore, many native strains or mutants which are deficient in melanin production were used for pullulan production (Wu et al. 2012). Fortunately, during the fermentation, A. pullulans var. melanogenum P16 used in this study did not produce any melanin (data not shown). This may be due to that within 120 h of the cultivation, the yeast cells were still so young that they could not synthesize melanin within this period.

The results in Figs. 8 and 9 confirmed that the EPS produced by A. pullulans var. melanogenum P16 was pullulan.

References

Buzdar MA, Chi Z, Wang Q, Hua MX, Chi ZM (2011) Production, purification, and characterization of a novel killer toxin from Kluyveromyces siamensis against a pathogenic yeast in crab. Appl Microbiol Biotechnol 91:1571–1579

Cheng KC, Demirci A, Catchmark JM, Puri VM (2011) Effects of initial ammonium ion concentration on pullulan production by Aureobasidium pullulans and its modeling. J Food Eng 103:115–122

Chi ZM, Zhao SZ (2003) Optimization of medium and cultivation conditions for pullulan production by a new pullulan-producing yeast. Enzym Microb Technol 33:206–211

Chi ZM, Liu J, Zhang W (2001) Trehalose accumulation from soluble starch by Saccharomycopsis fibuligera sdu. Enzym Microb Technol 38:240–246

Chi ZM, Wang F, Chi Z, Yue LX, Liu GL, Zhang T (2009) Bioproducts from Aureobasidium pullulans, a biotechnologically important yeast. Appl Microbiol Biotechnol 82:793–804

Choudhury AR, Saluja P, Prasad GS (2011) Pullulan production by an osmotolerant Aureobasidium pullulans RBF-4A3 isolated from flowers of Caesulia axillaris. Carbohydr Polym 83:1547–1552

Duan XH, Chi ZM, Wang L, Wang XH (2008) Influence of different sugars on pullulan production and activities of α-phosphoglucose mutase, UDPG-pyrophosphorylase and glucosyltransferase involved in pullulan synthesis in Aureobasidium pullulans Y68. Carbohydr Polym 73:587–593

Duan X, Chen J, Wu J (2013) Optimization of pullulanase production in Escherichia coli by regulation of process conditions and supplement with natural osmolytes. Bioresour Technol 146:379–385

Josefa MCJ, Lyibia MC, Sergio MR (2004) Molecular characterization and ecological properties of wine yeasts isolated during spontaneous fermentation of six varieties of grape must. Food Microbiol 21:149–155

Kurtzman CP, Fell JW (2000) The yeasts. A taxonomic study, fourth revised and enlarged ed. Elsevier: Amsterdam. pp. 222–360.

Lee JH, Kim JHK, Zhu ZI, Zhan XB, Lee JW, Shin DH (2001) Optimization of conditions for the production of pullulan and high molecular weight pullulan by Aureobasidium pullulans. Biotechnol Lett 23:817–820

Li Y, Chi Z, Wang GY, Wang ZP, Liu GL, Lee CF, Ma ZC, Chi ZM (2013) Taxonomy of Aureobasidium spp. and biosynthesis and regulation of their extracellular polymers. Crit Rev Microbiol Early. DOI: 10.3109/1040841X.2013.826176

Ma Y, Wang GY, Liu GL (2013) Overproduction of poly(β-malic acid) (PMA) from glucose by a novel Aureobasidium sp. P6 strain isolated from mangrove system. Appl Microbiol Biotechnol 97:8931–8939

Peterson SW, Manitchotpisit P, Leathers TD (2013) Aureobasidium thailandense sp. nov. isolated from leaves and wooden surfaces. Int J Syst Evol Microbiol 63:790–795

Prajapati VD, Girish K, Jani GK, Khanda SM (2013) Pullulan: an exopolysaccharide and its various applications. Carbohydr Polym 95:540–549

Sambrook J, Fritsch EF, Maniatis T (1989) Preparation and analysis of eukaryotic genomic DNA. In: Molecular cloning: a laboratory manual, 2nd edn. Cold Spring Harbor Laboratory Press, Beijing, pp 367–370, Chinese translated edn.

Sharma N, Prasad GS, Choudhury AR (2013) Utilization of corn steep liquor for biosynthesis of pullulan, an important exopolysaccharide. Carbohydr Polym 93:95–101

Sheng L, Zhu G, Tong Q (2013) Mechanism study of Tween 80 enhancing the pullulan production by Aureobasidium pullulans. Carbohydr Polym 97:121–123

Singh RS, Saini GK (2012) Biosynthesis of pullulan and its applications in food and pharmaceutical industry. In: Satyanarayana T et al (eds) Microorganisms in sustainable agriculture and biotechnology. Springer, Berlin, pp 509–552

Spiro RG (1966) Analysis of sugars found in glycoproteins. Meth Enzymol 8:3–26

Sun HY, Wang K, Chi Z, Xu HM, Chi ZM (2012) Simultaneous production of single cell protein and killer toxin by Wickerhamomyces anomalus HN1-2 isolated from mangrove ecosystem. Proc Biochem 47:251–256

Tamura K, Dudley J, Nei M, Kumar S (2007) MEGA4: molecular evolutionary genetics analysis (MEGA) software version 4.0. Mol Biol Evol 24:1596–1599

Wu S, Chen J, Pan S (2012) Optimization of fermentation conditions for the production of pullulan by a new strain of Aureobasidium pullulans isolated from sea mud and its characterization. Carbohydr Polym 87:1696–1700

Youssef E, Biliaderis CG, Roukas T (1998) Enhancement of pullulan production by Aureobasidium pullulans using batch culture using olive oil and sucrose as carbon source. Appl Biochem Biotechnol 74:13–30

Zalar P, Gostincar C, de Hoog GS (2008) Redefinition of Aureobasidium pullulans and its varieties. Stud Mycol 61:21–38

Acknowledgments

This work was supported by Hi-Tech Research and Development Program of China (863) (grant no. 2013BAB01B05).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, ZC., Fu, WJ., Liu, GL. et al. High-level pullulan production by Aureobasidium pullulans var. melanogenium P16 isolated from mangrove system. Appl Microbiol Biotechnol 98, 4865–4873 (2014). https://doi.org/10.1007/s00253-014-5554-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-014-5554-5