Abstract

A carbonyl reductase (SCR2) gene was synthesized and expressed in Escherichia coli after codon optimization to investigate its biochemical properties and application in biosynthesis of ethyl (S)-4-chloro-3-hydroxybutanoate ((S)-CHBE), which is an important chiral synthon for the side chain of cholesterol-lowering drug. The recombinant SCR2 was purified and characterized using ethyl 4-chloro-3-oxobutanoate (COBE) as substrate. The specific activity of purified enzyme was 11.9 U mg−1. The optimum temperature and pH for enzyme activity were 45 °C and pH 6.0, respectively. The half-lives of recombinant SCR2 were 16.5, 7.7, 2.2, 0.41, and 0.05 h at 30 °C, 35 °C, 40 °C, 45 °C, and 50 °C, respectively, and it was highly stable in acidic environment. This SCR2 displayed a relatively narrow substrate specificity. The apparent K m and V max values of purified enzyme for COBE are 6.4 mM and 63.3 μmol min−1 mg−1, respectively. The biocatalytic process for the synthesis of (S)-CHBE was constructed by this SCR2 in an aqueous–organic solvent system with a substrate fed-batch strategy. At the final COBE concentration of 1 M, (S)-CHBE with yield of 95.3 % and e.e. of 99 % was obtained after 6-h reaction. In this process, the space-time yield per gram of biomass (dry cell weight, DCW) and turnover number of NADP+ to (S)-CHBE were 26.5 mmol L−1 h−1 g−1 DCW and 40,000 mol/mol, respectively, which were the highest values as compared with other works.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Carbonyl reductases (CBRs, EC 1.1.1.148) are oxidoreductase proteins that catalyze the reduction of a variety of carbonyl compounds such as aldehydes, ketones, and quinones to their corresponding hydroxy derivatives (Forrest and Gonzalez 2000; Hoffmann and Maser 2007). CBRs belong to the family of short-chain dehydrogenases/reductases (SDRs) and widely distributed in microorganisms, plants, and animals (Forrest and Gonzalez 2000). Microorganisms, especially yeasts, are the most important source of CBRs for their diverse properties. A number of CBRs have been purified and characterized from Candida magnoliae (Wada et al. 1998), Kluyveromyces lactis (Yamamoto et al. 2002), Cylindrocarpon sclerotigenum (Saratani et al. 2003), Penicillium citrinum (Itoh et al. 2004), and Pichia stipitis (Cao et al. 2011). Some of CBRs have been cloned and overexpressed in Escherichia coli or Pichia pastoris (An et al. 2012; Engelking et al. 2004; Ye et al. 2009). Due to their chemo-, region-, and enantioselectivities, CBRs are increasingly recognized as attractive tools for the preparation of optically active compounds (Bhattacharyya et al. 2010; Soni and Banerjee 2005).

The optically active alcohols containing at least an asymmetric center are versatile building blocks for production of pharmaceutical and agricultural chemicals (Breuer et al. 2004). Ethyl (S)-4-chloro-3-hydroxybutanoate ((S)-CHBE), one of the optically active alcohols, is an important chiral synthon for the side chain of cholesterol-lowering drug atorvastatin (Lipitor), which is the hydroxymethylglutaryl CoA (HMG-CoA) reductase inhibitor (Roth 2002; Ye et al. 2011). (S)-CHBE also can be used in the synthesis of Slagenins B and C and 1,4-dihydropyridine type β-blockers (Kaliaperumal et al. 2010). The enzymatic asymmetric reduction of ethyl 4-chloro-3-oxobutanoate (COBE), which can be easily synthesized from diketene (Hoff and Anthonsen 1999; Sundby et al. 2003), is a promising way to produce (S)-CHBE (Matsuda et al. 2009; Ye et al. 2011). CBRs are the best suitable catalysts for this reduction reaction. Until now, several CBRs exhibiting high catalytic activity and exquisite selectivity to COBE have been found (Kaliaperumal et al. 2010; Wang et al. 2011; Yasohara et al. 2001). However, the inhibitory effects of COBE on the CBR activities and the decomposition of COBE in aqueous phase are impediments of industrial applications (Engelking et al. 2004). Therefore, it is necessary to explore more efficient CBRs and reasonable reaction system.

Recently, a gene cluster consisting of three CBRs and an alcohol dehydrogenase has been identified from Candida parapsilosis (Nie et al. 2011). One of the three CBRs, SCR2, was an (S)-specific carbonyl reductase and has been used in the production of (S)-1-phenyl-1,2-ethanediol (Zhang et al. 2011). It also has the catalytic activity towards COBE (Nie et al. 2011). However, the biochemical properties of SCR2 have not been described in details, and the catalytic process of COBE to (S)-CHBE by SCR2 has not been studied. In the present study, the SCR2 gene was synthesized and successfully expressed in E. coli BL21 (DE3) after codon optimization. The purification and characterization of the SCR2 from the recombinant E. coli was described, and its application in biosynthesis of (S)-CHBE was also investigated.

Materials and methods

Microorganisms and chemicals

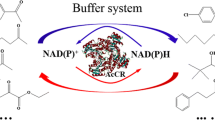

E. coli BL21 (DE3) and pET-28b were used for overexpression of the recombinant SCR2. The E. coli BL21 (DE3)/pET-28b-GDH, in which a glucose dehydrogenase (GDH) gene was cloned, was used for the cofactor regeneration in biosynthesis of (S)-CHBE. COBE and (S)-CHBE were purchased from J&K Scientific Ltd. (Shanghai, China). All other chemicals were of analytical grade purity and commercially available.

Synthesis and cloning of SCR2 gene

The amino acid sequence of SCR2 was obtained from GenBank (Accession no. ACQ99345) (Nie et al. 2011). The codon optimization and synthesis of the nucleotide sequence encoding the SCR2 were carried out as described previously (You et al. 2013). In order to avoid the introduction of 6× his-tag, a termination codon (TAA) was added to the 3'ʹ end of optimized nucleotide sequence. The codon-optimized SCR2 gene was deposited in the GenBank database under accession number KC914393. Finally, the complete sequence was cloned into the pET-28b vector, and the recombinant plasmid was transformed into E. coli BL21 (DE3).

Expression and purification of recombinant SCR2

Cells harboring the synthesized gene were pre-cultured in Luria–Bertani (LB) medium containing (per liter) (Sambrook and Russell 2001): 5 g of yeast extract, 10 g of tryptone, and 10 g of NaCl. 2× YT medium composed of 10 g L−1 yeast extract, 16 g L−1 tryptone, and 5 g L−1 NaCl was used for fermentation process. Kanamycin (Kan, 50 μg mL−1) was added to provide selective pressure during cultivation. Incubations were carried out at 37 °C on a rotary shaker at 150 rpm, and protein expression was induced at 28 °C by the addition of 1.5 % (w/v) lactose when the OD600 reached 1.2. After induction for 10 h, cells were harvested by centrifugation at 4 °C, 8,000×g for 10 min and then stored at −20 °C.

The cells were suspended in 50 mM K2HPO4–KH2PO4 buffer (pH 6.0) and disrupted by sonication for a period of 10 min on ice. The supernatant resulting from centrifugation at 15,000 rpm for 30 min was referred to as crude enzyme. The crude enzyme was mixed with solid ammonium sulfate by stirring. The active precipitate of 60–90 % saturation was collected by centrifugation at 15,000 rpm for 15 min and dissolved in a minimal volume of 50 mM K2HPO4–KH2PO4 buffer (pH 6.0). The samples were dialyzed overnight against the same buffer to remove the high concentration of ammonium sulfate. The dialyzed enzyme solution was applied to an anion ion-exchange column (High Q IEX, 10 mL, Bio-Rad Laboratories) that had been previously equilibrated with 50 mM K2HPO4–KH2PO4 buffer (pH 6.0). The unabsorbed protein fractions were eluted with the same buffer. SCR2 that bound to the column was eluted with 20 mM of NaCl in the equilibrating buffer at a flow rate of 2 mL min−1. Active fractions were collected, pooled, concentrated, and desalted. All purification steps were conducted at 0–4 °C.

The purity and molecular mass of the recombinant SCR2 were determined by sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) analysis, which was carried out with a 5 % acrylamide stacking gel (pH 6.8) and 12 % separating gel (pH 8.8) as described by Laemmli (1970). The protein concentration was estimated by using the bicinchoninic acid (BCA) protein assay kit (Nanjing Key-gen Biotechnology Co., China) based on the reported method (Smith et al. 1985).

Enzyme assay

Enzyme activity was determined with COBE as reducing substrate in a reaction mixture containing 100 mM K2HPO4–KH2PO4 buffer (pH 6.0), 2 mM COBE, and 0.2 mM NADPH. The reduction of COBE was followed by measuring the decrease in the absorption of NADPH using a universal microplate spectrophotometer (Spectramax plus, Molecular Devices, USA) at 340 nm and 45 °C. One unit (U) of activity is defined as the amount of enzyme that consumes 1 μmol of NADPH per minute under the above assay conditions.

Characterization of the recombinant SCR2

Determination of temperature optimum and thermal stability

Enzyme activity was determined at different temperatures in the range of 20–70 °C. The thermal stability of SCR2 was investigated by incubating enzyme at different temperatures. Residual enzyme activity was tested under standard assay conditions. The heat inactivation curves of SCR2 at 30 °C, 35 °C, 40 °C, 45 °C, and 50 °C were constructed. The non-heated enzyme was taken as the control (100 % activity).

Determination of pH optimum and stability

The effects of pH on enzyme activity were examined over a pH range of 4.0–7.4 at 45 °C. The following buffers were used with a concentration of 100 mM: citric acid–sodium citrate buffer (pH 4.0–5.8), K2HPO4–KH2PO4 buffer (pH 5.8–7.2), and Na2HPO4–KH2PO4 buffer (pH 6.9–7.4). For the measurement of pH stability, the enzyme was pre-incubated in buffers of different pH values at 25 °C for 1 h, and the residual activity was determined under standard assay conditions. The non-incubated enzyme was taken as a control.

Effects of metal ions and chemical agents on enzyme activity

The effects of metal ions (Al3+, Fe3+, Fe2+, Mg2+, Ni2+, Zn2+, Ca2+, Mn2+, Ba2+, Cu2+, Cu+, Co2+, Ag+, and Li+) at 1 mM and chemical agents (Tween-20, Tween-80, Triton, SDS, EDTA, DMF, DMSO and DTT) at certain concentration on enzyme activity were studied by pre-incubating the enzyme with the individual reagents for 1 h at 25 °C. The residual activity was measured under standard assay conditions. The enzyme activity in the absence of metal ions and chemical agents was recorded as 100 %.

Effects of organic solvents on enzyme activity

The effects of organic solvents on enzyme activity were investigated. The organic solvents used were hexane, cyclohexane, heptane, isooctane, dodecane, ethyl acetate, butyl acetate, benzene, toluene, xylene, dimethyl phthalate, and petroleum ether. The enzyme solution was incubated with an organic solvent in equal volumes for 1 h at 25 °C. The residual activity was tested under standard assay conditions. The enzyme activity in the absence of organic solvent was recorded as 100 %.

Substrate specificity and kinetic analysis

The substrate specificity was determined by replacing COBE in the reaction mixture with methyl 4-chloroacetoacetate, ethyl acetoacetate, 2,3-butanedione, acetophenone, 2-hydroxyacetophenone, acetone, butanone, 2-pentanone, 3-pentanone, 2-hexanone, 2-heptanone, 2-octanone, cyclohexanone, acetylacetone, 2,5-hexanedione, and 5,5-dimethyl-l,3-cyclohexanedione.

Kinetic parameters were calculated from the Lineweaver–Burk plot of enzyme activities using COBE, methyl 4-chloroacetoacetate or ethyl acetoacetate as substrates at concentrations ranging from 5 to 40 mM with a fixed NADPH concentration of 0.2 mM (Lineweaver and Burk 1934; Wang et al. 2011).

Applications of SCR2 in biosynthesis of ethyl (S)-4-chloro-3-hydroxybutanoate

Biosynthesis of (S)-CHBE in aqueous phase system

The crude enzymes of SCR2 and GDH were used as biocatalysts in the biosynthesis of (S)-CHBE. Biotransformation reactions were performed in 50 mL 3-neck flasks stirring with a magnetic bar at 300 rpm. Each reaction mixture (20 mL) comprising a certain concentration of COBE and glucose and 25 μmol L−1 NADP+ in 100 mM K2HPO4–KH2PO4 buffer (pH 6.0) was pre-incubated in a water-bath at selected temperature for 10 min. The crude enzymes (equivalent to 12 mg DCW) of SCR2 cells and GDH cells were then added into the flask, and the incubation was continued until the end of the reaction. The pH of the reaction mixture was controlled at a certain value with 2 M K2HPO4. Samples were taken periodically and extracted with ethyl acetate. The concentrations of COBE and (S)-CHBE in the organic layer were monitored by gas chromatography directly. The yield was calculated using the following formula: yield = M p/M S × 100 %, where M p is the mole of (S)-CHBE in product, and M S is the mole of COBE added.

Biosynthesis of (S)-CHBE in aqueous organic solvent system

The reaction mixture (10 mL) consisting of a certain concentration of COBE and glucose and 25 μmol L−1 NADP+ in 100 mM K2HPO4–KH2PO4 buffer (pH 6.3) was mixed with an equal volume of selected organic solvent in 50 mL 3-neck flasks and stirred with a magnetic bar at 300 rpm and then pre-incubated in a water-bath at 35 °C for 10 min. The crude enzymes (equivalent to 36 mg DCW) of SCR2 cells and GDH cells were then added into the flask and the incubation continued until the end of the reaction. The pH was adjusted to 6.3 with 2 M K2HPO4 during reaction.

Substrate fed-batch strategy

In fed-batch mode, the initial concentrations of COBE and glucose were 100 and 120 mM for aqueous phase system, and 300 and 360 mM for aqueous–organic solvent system, respectively. In addition, 33.3 mM of COBE and glucose for aqueous phase system, 100 mM of COBE and glucose for aqueous–organic solvent system were added into the reaction mixture at 30, 40, 60, 90, 120, 150, and 180 min (180 min was for aqueous–organic solvent system only), respectively. The amount of crude enzyme of SCR2 and GDH were equal to 36 mg DCW for aqueous phase system, and 60 mg for aqueous–organic solvent system, respectively. The other conditions were 25 μmol L−1 NADP+, 35 °C, and pH 6.3.

Analytical methods

The amount of COBE and (S)-CHBE was measured by gas chromatography (Agilent 7890A system, USA) equipped with a flame ionization detector and an AT-FFAP capillary column (30 m × 0.25 mm, 0.33 μm film thickness). Nitrogen was used as carrier gas at a flow rate of 1.5 mL min−1. The inlet and detector temperatures were set at 230 °C and 250 °C, respectively. The column temperature was held for 2 min at 140 °C, elevated at 50 °C min−1 to 200 °C, and held for 2.9 min at 200 °C. The retention times of COBE and (S)-CHBE were 3.29 and 4.45 min, respectively. Optical purity was determined by GC-14C gas chromatography (Shimadzu, Japan) equipped with FID detector and a G-TA chiral capillary column (30 m × 0.25 mm, 0.12 μm film thickness) using helium as carrier gas. The inlet and detector temperatures were all set at 220 °C. The column temperature was programmed from 110 °C and raised to 140 °C at a rate of 2 °C min−1. The retention times of (R)-CHBE and (S)-CHBE were 11.67 and 12.08 min, respectively.

Results

Purification of the recombinant SCR2

After purification, the recombinant SCR2 was purified to electrophoretic homogeneity by two-step procedure as described above. Table S1 in the supplementary material summarizes the results of the purification efficiency of this enzyme. In the first step, the crude enzyme extract was concentrated by ammonium sulfate precipitation. The precipitate of 60–90 % saturation showed a specific activity of 7.7 U mg−1 of protein. The precipitate was then successfully subjected to High Q anion exchange chromatography after desalination. At each stage of purification, the specific activity was increased. After the final purification step, the purified SCR2 appeared as a single protein band on SDS-PAGE gel with a molecular mass of approximate 34 kDa (Fig. S1 in the supplementary material). The yield of purified enzyme was 62.6 % with specific activity of 11.9 U mg−1 and 7.0-fold purification. Calculations of the values from Table S1 and SDS-PAGE analysis revealed that SCR2 can be steadily produced as soluble forms at levels over 380 mg L−1 of culture, which is higher than those of the wild-type SCR2 gene expressed in E. coli BL21(DE3) pMgK with pET-21c vector and E. coli BL21 (DE3) with pET-28c(+) vector (Nie et al. 2011; Zhang et al. 2011). The purified enzyme was then used to investigate its biochemical properties.

Effects of temperature and pH on enzyme activity and stability

The effects of temperature on enzyme activity were studied by incubating the enzyme at different temperature from 20 °C to 70 °C. The enzyme activity increased as the temperature increased from 20 °C to 45 °C and showed a stable maximum at 45 °C (Fig. 1a). However, the enzyme activity decreased rapidly when the temperature was above 60 °C. The thermal stability of purified SCR2 is depicted in Fig. 1b. The enzyme was stable at lower temperature. About 80 % of enzyme activity was maintained after 6 h of incubation at 30 °C. However, its activity was completely lost after incubation at 50 °C for 30 min. The half-lives of recombinant SCR2 were 16.5, 7.7, 2.2, 0.41, and 0.05 h, at 30 °C, 35 °C, 40 °C, 45 °C, and 50 °C, respectively.

Effects of temperature and pH on enzyme activity and stability. a Optimal temperature. The enzyme activity was determined at different temperatures by the standard assay method. b Thermal stability. The purified enzymes were incubated at different temperature for varying periods of time. The residual activity was tested under standard assay conditions. The non-heated enzyme was taken as a control. c Optimal pH. The enzyme activity was determined in buffers of various pH values by the standard assay method. d pH stability. The pH stability was assessed under standard assay conditions after the enzyme had been incubated in various buffers for 1 h at 25 °C. The non-incubated enzyme was taken as a control. All reactions were performed in triplicate

The enzyme activity was monitored at different pH from 4.0 to 7.4. The optimal pH for recombinant SCR2 was 6.0, with 87.2 % and 87.8 % of the maximum activity appeared at pH 5.2 and pH 6.6, respectively (Fig. 1c). The pH stability profile showed that the recombinant SCR2 is highly stable in acidic environment, and more than 90 % of its original activity was maintained when exposed at the pH between 4.0 and 6.0 for 60 min at 25 °C (Fig. 1d).

Effects of metal ions and chemical agents on the activity of recombinant SCR2

The effects of various metal ions on enzyme activity of the purified SCR2 are shown in Table 1. The enzyme was not activated by any of the tested metal ions. Cu2+, Fe2+, Cu+, and Ag+ completely inhibited the enzyme activity at 1 mM, while Al3+ and Ni2+ showed no significant influence on enzyme activity at the same concentration. The other tested metal ions showed slight inhibition on the enzyme activity.

The effects of other chemical agents on enzyme activity are presented in Table 2. Most of the tested chemical agents had a little influence on enzyme activity. Tween-20, Tween-80, and Triton X-100 at 1 % or 5 % (w/v) slightly stimulated the activity by 9–19 %. The metal chelator EDTA also slightly affected the enzyme activity. However, the enzyme activity was strongly inhibited by SDS.

Effects of organic solvents on the activity of recombinant SCR2

The sensitivity of recombinant SCR2 to several organic solvents was also investigated. As shown in Table 3, the activity of recombinant SCR2 was promoted by butyl acetate, isooctane, and dimethyl phthalate. The other tested organic solvents caused different inhibition except heptane which showed no significant effect on enzyme activity. The maximum inhibition of around 80 % was observed with ethyl acetate.

Substrate specificity and kinetic parameters of the recombinant SCR2

The utility of enzymes often depends on their substrate specificity due to their ability to discriminate among different substrates. The activities of the purified SCR2 towards various substrates are summarized in Table 4. This enzyme displayed a relatively narrow substrate specificity. Only four texted compounds (COBE, methyl 4-chloroacetoacetate, ethyl acetoacetate and 2,3-butanedione) in this study were reduced by the purified enzyme, and the highest activity was observed with COBE. The kinetic parameters of purified SCR2 to these compounds are shown in Table 4. The enzyme showed a lower K m (6.4 mM) and higher V max (63.3 μmol min−1 mg−1) for COBE compare that for methyl 4-chloroacetoacetate and ethyl acetoacetate.

Bioreduction of COBE to (S)-CHBE in aqueous phase system

The bioreduction conditions including temperature, pH, and substrate concentration were investigated in details. Temperature plays an important role in a biotransformation system, which can affect a lot of factors including the activity and thermal stability of biocatalysts, the speeds of molecules, the activation energy of the catalytic reaction, and the stability of substrate and product. The effects of different reaction temperatures ranging from 15 °C to 50 °C on (S)-CHBE yield are shown in Fig. 2a. After 30-min reaction, the yield was very low at 15 °C, and increased to a maximum level at 35 °C while raising the temperature, and then abruptly declined with further increase of temperature. It is surprising that the yield at 45 °C, the optimum temperature for CBR activity, was only 3.2 %. Thus, it was considered that the high temperature had affected the GDH activity before impacting the SCR2 activity. The effects of various reaction pHs on (S)-CHBE yield are shown in Fig. 2b. It shows that the high yields of (S)-CHBE (above 95 %) between pH 6.0 and 6.5 with a highest yield (97.5 %) around pH 6.3 were obtained. Otherwise, the enantiomeric excess (e.e.) of product was not affected by temperature or pH.

Effects of temperature (a) and pH (b) on yield of (S)-CHBE. a Reactions were carried out in 100 mM K2HPO4–KH2PO4 buffer with 100 mM COBE, 120 mM glucose, 25 μmol L−1 NADP+, 0.6 g L−1 DCW SCR2 and 0.6 g L−1 DCW GDH at various temperatures for 30 min. pH was controlled at 6.0 by 2 M K2HPO4. b Reactions were carried out in 100 mM K2HPO4–KH2PO4 buffer with 100 mM COBE, 120 mM glucose, 25 μmol L−1 NADP+, 0.6 g L−1 DCW SCR2 and 0.6 g L−1 DCW GDH at 35 °C for 30 min. pH was controlled at different values by 2 M K2HPO4. All reactions were performed in triplicate

The bioreduction reactions were also performed at different concentration of COBE. As shown in Fig. 3a, the yield of (S)-CHBE maintained over 95 % at the low substrate concentration up to 100 mM. The amount of (S)-CHBE increased with the increase in initial COBE concentration up to 140 mM and showed a maximum concentration of 127.9 mM. Due to the inhibition of COBE in the reaction system, the yield and concentration of (S)-CHBE were declined quickly when the concentration of COBE exceeded 140 mM.

Effects of the substrate concentration on yield of (S)-CHBE. a In aqueous phase system: reactions were carried out in 100 mM K2HPO4–KH2PO4 buffer with various concentrations of COBE and glucose, 25 μmol L−1 NADP+, 0.6 g L−1 DCW SCR2, and 0.6 g L−1 DCW GDH at 35 °C, pH 6.3 for 1 h; b In aqueous–organic solvent system: reactions were carried out in K2HPO4–KH2PO4 buffer–butyl acetate system with various concentrations of COBE and glucose, 25 μmol L−1 NADP+, 1.8 g L−1 DCW SCR2 and 1.8 g L−1 DCW GDH at 35 °C, pH 6.3 for 1 h

Bioreduction of COBE to (S)-CHBE in aqueous–organic solvent system

The effects of organic solvents on CBR activity have been described above. Because of the low solubility of COBE and (S)-CHBE in alkane solvents such as heptane and isooctane (data not shown), these solvents were not suitable for the construction of aqueous–organic solvent system although they did not significantly affect the enzyme activity. Therefore, butyl acetate, dimethyl phthalate, benzene, and toluene were tested for the bioreduction of COBE to (S)-CHBE. Table 5 shows that all yields of aqueous–organic solvent systems can reach 97 % or more, except toluene which showed a yield of 91.1 %. In consideration of the high boiling point of dimthyl phthalate and the toxicity of benzene, butyl acetate was finally selected to construct the aqueous–organic solvent system for the bioreduction. The effects of initial COBE concentrations on yields of (S)-CHBE in aqueous–organic solvent system were also investigated (Fig. 3b). When the initial COBE concentration was below 500 mM, the yield of (S)-CHBE was maintained over 95 %, and the amount of (S)-CHBE was increased with further increase in the substrate concentration, but the yield was decreased. The concentration and yield of (S)-CHBE were 714 mM and 79 %, respectively, at the initial COBE concentration of 900 mM.

Elevation of substrate concentration by fed-batch strategy

The fed-batch strategy was used to reduce the substrate inhibition and increase the substrate concentration for industrial application. The results are shown in Fig. 4. Under the conditions described in “Materials and Methods” section, the COBE concentration was increased from 100 mM to 233.3 mM in aqueous phase system (Fig. 4a). (S)-CHBE with a yield of 92.1 % and 99 % e.e. was obtained after a 120-min reaction, and the amount of (S)-CHBE was no further increased even if COBE was continued to add. In aqueous–organic solvent system (Fig. 4b), the concentration of COBE was reached 1 M by 7 times-addition. And the yield of (S)-CHBE was 95.3 % in 6 h. The space-time yield per gram of biomass of this asymmetric reduction was 26.5 mmol L−1 h−1 g−1 DCW, and the calculated turnover number of NADP+, defined as the amounts (S)-CHBE formed per mole NADP+ added, was about 40,000 mol/mol.

Elevation of substrate concentration by fed-batch strategy. a In aqueous phase system. The reaction conditions were: 100 mM COBE, 120 mM glucose, 25 μmol L−1 NADP+, 1.8 g L−1 DCW SCR2, 1.8 g L−1 DCW GDH, 35 °C and pH 6.3. 33.3 mM COBE and 33.3 mM glucose were added into the reaction mixture at 30, 40, 60, 90, 120, and 150 min. b In aqueous–organic solvent system. The reaction conditions were: 300 mM COBE, 360 mM glucose, 25 μmol L−1 NADP+, 3 g L−1 DCW SCR2, 3 g L−1 DCW GDH, 35 °C and pH 6.3. 100 mM COBE and 100 mM glucose were added into the reaction mixture at 30, 40, 60, 90, 120, 150, and 180 min

Discussion

It is found that the asymmetric reduction of carbonyl compounds by carbonyl reductase is one of the most practical routes for producing chiral alcohols, which can be used for the synthesis of industrially important chemicals (Yu et al. 2009). (S)-CHBE, one of the statin intermediates, can be synthesized from COBE by CBR (Kita et al. 1999; Ye et al. 2011). In previous studies, a newly CBR (SCR2) from C. parapsilosis has been identified (Nie et al. 2011). This enzyme has the ability to catalyze the reduction of COBE with novel anti-Prelog stereoselectivity (Nie et al. 2011). The present study is aimed at the biochemical properties of SCR2 and the catalytic process of (S)-CHBE synthesis by SCR2.

The optimal temperature and pH of this recombinant SCR2 were similar with those of other yeasts CBR, which show the greatest activity over a range of temperatures from 30 °C to 60 °C and at a pH range of 5.0–7.0 (Cao et al. 2011; Kataoka et al. 1992; Wada et al. 1998; Yamamoto et al. 2004). The carbonyl reductases SCR1 and SCR3 from the same gene cluster, which showed 70.6 % and 81.4 % of sequence identities to SCR2, respectively, also had the same optimum pH range and showed strong activity toward COBE with distinct stereoselectivity (Nie et al. 2011). The effects of metal ions and chemical agents on the activity of SCR2 were determined. Obviously, all metal ions tested in this study had no activation to the activity of the recombinant SCR2 and the enzyme was also insensitive to EDTA, which indicate that SCR2 is not a metalloenzyme. However, SDS completely inhibited the activity of SCR2. This inhibition may be the result of the changing of the microenvironment of tyrosine and tryptophan groups of enzyme by SDS. Because SDS is an ionic detergent with a long hydrophobic tail which binds to the hydrophobic side chains of amino acids. The recombinant SCR2 showed a restricted substrate specificity as the carbonyl reductase from C. sclerotigenum IFO 31855 (Saratani et al. 2003), while the SCR1, SCR3, and the carbonyl reductase from C. magnoliae showed a broad substrate spectrum (Nie et al. 2011; Wada et al. 1998; Wada et al. 1999). From the analysis of the relative activities and kinetic parameters of purified SCR2 toward these substrates, the recombinant SCR2 showed the highest catalytic efficiency towards COBE, which would allow the application of this enzyme in the production of (S)-CHBE in large scale.

The biosynthesis of (S)-CHBE from COBE was studied using the crude enzyme of recombinant SCR2. Several biocatalytic processes for the synthesis of (S)-CHBE were compared with each other (Table 6) (An et al. 2012; Kataoka et al. 2006; Kizaki et al. 2001; Wang et al. 2011; Ye et al. 2010). To our knowledge, the substrate and product inhibition was always the limitation of large-scale applications in many biotransformation reactions (Ezeji et al. 2004; Pan and Syu 2005). This type of inhibition has been reported in the asymmetric reduction of COBE and can be overcome by utilizing substrate fed-batch strategy and an aqueous–organic solvent two-phase system (Kaliaperumal et al. 2010; Kizaki et al. 2001; Wang et al. 2011; Xu et al. 2006). In this study, these two methods were also taken to cope with the inhibition and the substrate concentration was increased from 100 mM to 1 M. In present fed-batch strategy, the substrate was frequently supplemented at the beginning of the reaction that is different with the fed-batch strategies reported previously in which the substrate was supplemented in the same interval (Kaliaperumal et al. 2010; Xu et al. 2006). This fed-batch strategy could give full play to the enzyme activity. The space-time yield (26.5 mmol L−1 h−1 g−1 DCW) is by far the highest one due to the short reaction time (Table 6), though the final concentration of substrate (1 M) in this study is lower than the highest value in the literature (Wang et al. 2011). Another strategy to minimize the product and substrate inhibition is immobilization (Abida et al. 2009). It could also increase the enzyme reusability (Rao et al. 2008) that is difficult to achieve using crude enzyme solution.

In addition, the regeneration of coenzyme was another important issue for the coenzyme-dependent synthesis (Ye et al. 2011). The GDH and glucose were used for the regeneration of the coenzyme in this study. The turnover number (40,000 mol/mol) of NADP+ to (S)-CHBE in this study is the highest one as compared with other works (Table 6). However, the price of NADP+ was more expensive than NAD+. If the coenzyme dependency of SCR2 can be modified from NADPH-specific to NADH, which has been achieved on the carbonyl reductase from C. magnolia (Morikawa et al. 2005) and C. parapsilosis (Zhang et al. 2009), the production costs will decline further.

In conclusion, this work describes the recombinant expression, purification, and characterization of a novel CBR. The biocatalytic process for the synthesis of (S)-CHBE by this CBR is also described. The highest space-time yield and turnover number of NADP+ are displayed in this biosynthesis system. Future work will attempt to immobilize the enzyme to improve the tolerance of SCR2 on the substrate and product and increase the enzyme reusability. The modification of coenzyme dependency of SCR2 by rational or irrational protein design methods will also be considered.

References

Abida A, Shah AUQ, Aliya R, Samina I, Abid A (2009) Calcium alginate: a support material for immobilization of proteases from newly isolated strain of Bacillus subtilis KIBGE-HAS. WASJ 7:1281–1286

An M, Cai P, Yan M, Hao N, Wang S, Liu H, Li Y, Xu L (2012) A novel reductase from Candida albicans for the production of ethyl (S)-4-chloro-3-hydroxybutanoate. Biosci Biotechnol Biochem 76:1210–1212

Bhattacharyya MS, Singh A, Banerjee UC (2010) Immobilization of intracellular carbonyl reductase from Geotrichum candidum for the stereoselective reduction of 1-naphthyl ketone. Bioresour Technol 101:1581–1586

Breuer M, Ditrich K, Habicher T, Hauer B, Kesseler M, Sturmer R, Zelinski T (2004) Industrial methods for the production of optically active intermediates. Angew Chem Int Ed Engl 43:788–824

Cao H, Mi L, Ye Q, Zang GL, Yan M, Wang Y, Zhang YY, Li XM, Xu L, Xiong JA, Ouyang PK, Ying HJ (2011) Purification and characterization of a novel NADH-dependent carbonyl reductase from Pichia stipitis involved in biosynthesis of optically pure ethyl (S)-4-chloro-3-hydroxybutanoate. Bioresour Technol 102:1733–1739

Engelking H, Pfaller R, Wich G, Weuster-Botz D (2004) Stereoselective reduction of ethyl 4-chloro acetoacetate with recombinant Pichia pastoris. Tetrahedron-Asymmetr 15:3591–3593

Ezeji TC, Qureshi N, Blaschek HP (2004) Acetone butanol ethanol (ABE) production from concentrated substrate: reduction in substrate inhibition by fed-batch technique and product inhibition by gas stripping. Appl Microbiol Biotechnol 63:653–658

Forrest GL, Gonzalez B (2000) Carbonyl reductase. Chem Biol Interact 129:21–40

Hoff BH, Anthonsen T (1999) Lipase-catalyzed resolution of esters of 4-chloro-3-hydroxybutanoic acid: effects of the alkoxy group and solvent on the enantiomeric ratio. Tetrahedron-Asymmetr 10:1401–1412

Hoffmann F, Maser E (2007) Carbonyl reductases and pluripotent hydroxysteroid dehydrogenases of the shortchain dehydrogenase/reductase superfamily. Drug Metab Rev 39:87–144

Itoh N, Asako H, Banno K, Makino Y, Shinohara M, Dairi T, Wakita R, Shimizu M (2004) Purification and characterization of NADPH-dependent aldo-keto reductase specific for beta-keto esters from Penicillium citrinum, and production of methyl (S)-4-bromo-3-hydroxybutyrate. Appl Microbiol Biotechnol 66:53–62

Kaliaperumal T, Kumar S, Gummadi SN, Chadha A (2010) Asymmetric synthesis of (S)-ethyl-4-chloro-3-hydroxybutanoate using Candida parapsilosis ATCC 7330. J Ind Microbiol Biotechnol 37:159–165

Kataoka M, Hoshino-Hasegawa A, Thiwthong R, Higuchi N, Ishige T, Shimizu S (2006) Gene cloning of an NADPH-dependent menadione reductase from Candida macedoniensis, and its application to chiral alcohol production. Enzyme Microb Technol 38:944–951

Kataoka M, Sakai H, Morikawa T, Katoh M, Miyoshi T, Shimizu S, Yamada H (1992) Characterization of aldehyde reductase of Sporobolomyces Salmonicolor. Biochimica Et Biophysica Acta 1122:57–62

Kita K, Kataoka M, Shimizu S (1999) Diversity of 4-chloroacetoacetate ethyl ester-reducing enzymes in yeasts and their application to chiral alcohol synthesis. J Biosci Bioeng 88:591–598

Kizaki N, Yasohara Y, Hasegawa J, Wada M, Kataoka M, Shimizu S (2001) Synthesis of optically pure ethyl (S)-4-chloro-3-hydroxybutanoate by Escherichia coli transformant cells coexpressing the carbonyl reductase and glucose dehydrogenase genes. Appl Microbiol Biotechnol 55:590–595

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Lineweaver H, Burk D (1934) The determination of enzyme dissociation constants. J Am Chem Soc 56:658–666

Matsuda T, Yamanaka R, Nakamura K (2009) Recent progress in biocatalysis for asymmetric oxidation and reduction. Tetrahedron-Asymmetr 20:513–557

Morikawa S, Nakai T, Yasohara Y, Nanba H, Kizaki N, Hasegawa J (2005) Highly active mutants of carbonyl reductase S1 with inverted coenzyme specificity and production of optically active alcohols. Biosci Biotechnol Biochem 69:544–552

Nie Y, Xiao R, Xu Y, Montelione GT (2011) Novel anti-Prelog stereospecific carbonyl reductases from Candida parapsilosis for asymmetric reduction of prochiral ketones. Org Biomol Chem 9:4070–4078

Pan JL, Syu MJ (2005) Kinetic study on substrate and product inhibitions for the formation of 7-amino-3-deacetoxy cephalosporanic acid from cephalosporin G by immobilized penicillin G acylase. Biochem Eng J 23:203–210

Rao CS, Madhavendra SS, Rao RS, Hobbs PJ, Prakasham RS (2008) Studies on improving the immobilized bead reusability and alkaline protease production by isolated immobilized Bacillus circulans (MTCC 6811) using overall evaluation criteria. Appl Biochem Biotechnol 150:65–83

Roth BD (2002) The discovery and development of atorvastatin, a potent novel hypolipidemic agent. Prog Med Chem 40:1–22

Sambrook J, Russell DW. (2001) Molecular cloning: A laboratory manual, 3rd edn. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, New York, pp A2.2

Saratani Y, Uheda E, Yamamoto H, Nishimura A, Yoshizako F (2003) Purification and properties of a carbonyl reductase involved in stereoselective reduction of ethyl 4-chloro-3-oxobutanoate from Cylindrocarpon sclerotigenum IFO 31855. Biosci Biotechnol Biochem 67:1417–1420

Smith PK, Krohn RI, Hermanson GT, Mallia AK, Gartner FH, Provenzano MD, Fujimoto EK, Goeke NM, Olson BJ, Klenk DC (1985) Measurement of protein using bicinchoninic acid. Anal Biochem 150:76–85

Soni P, Banerjee UC (2005) Biotransformations for the production of the chiral drug (S)-Duloxetine catalyzed by a novel isolate of Candida tropicalis. Appl Microbiol Biotechnol 67:771–777

Sundby E, De Zotti M, Anthonsen T (2003) The enantioselectivity of reduction of ethyl 4-halo-3-oxobutanoate catalyzed by Geotrichum candidum depends on the cofactor. J Mol Catal B-Enzym 21:63–66

Wada M, Kataoka M, Kawabata H, Yasohara Y, Kizaki N, Hasegawa J, Shimizu S (1998) Purification and characterization of NADPH-dependent carbonyl reductase, involved in stereoselective reduction of ethyl 4-chloro-3-oxobutanoate, from Candida magnoliae. Biosci Biotechnol Biochem 62:280–285

Wada M, Kawabata H, Kataoka M, Yasohara Y, Kizaki N, Hasegawa J, Shimizu S (1999) Purification and characterization of an aldehyde reductase from Candida magnoliae. J Mol Catal B-Enzym 6:333–339

Wang LJ, Li CX, Ni Y, Zhang J, Liu X, Xu JH (2011) Highly efficient synthesis of chiral alcohols with a novel NADH-dependent reductase from Streptomyces coelicolor. Bioresour Technol 102:7023–7028

Xu ZN, Fang LM, Lin JP, Jiang XX, Liu Y, Cen PL (2006) Efficient bioreduction of ethyl 4-chloro-3-oxobutanoate to (S)-4-chloro-3-hydrobutanoate by whole cells Candida magnoliae in water/n-butyl acetate two-phase system. Biotechnol Bioprocess Eng 11:48–53

Yamamoto H, Kimoto N, Matsuyama A, Kobayashi Y (2002) Purification and properties of a carbonyl reductase useful for production of ethyl (S)-4-chloro-3-hydroxybutanoate from Kluyveromyces lactis. Biosci Biotechnol Biochem 66:1775–1778

Yamamoto H, Mitsuhashi K, Kimoto N, Matsuyama A, Esaki N, Kobayashi Y (2004) A novel NADH-dependent carbonyl reductase from Kluyveromyces aestuarii and comparison of NADH-regeneration system for the synthesis of ethyl (S)-4-chloro-3-hydroxybutanoate. Biosci Biotechnol Biochem 68:638–649

Yasohara Y, Kizaki N, Hasegawa J, Wada M, Kataoka M, Shimizu S (2001) Stereoselective reduction of alkyl 3-oxobutanoate by carbonyl reductase from Candida magnoliae. Tetrahedron-Asymmetr 12:1713–1718

Ye Q, Cao H, Zang GL, Mi L, Yan M, Wang Y, Zhang YY, Li XM, Li JA, Xu L, Xiong JA, Ouyang PK, Ying HJ (2010) Biocatalytic synthesis of (S)-4-chloro-3-hydroxybutanoate ethyl ester using a recombinant whole-cell catalyst. Appl Microbiol Biotechnol 88:1277–1285

Ye Q, Ouyang P, Ying H (2011) A review-biosynthesis of optically pure ethyl (S)-4-chloro-3-hydroxybutanoate ester: recent advances and future perspectives. Appl Microbiol Biotechnol 89:513–522

Ye Q, Yan M, Yao Z, Xu L, Cao H, Li ZJ, Chen Y, Li SY, Bai JX, Xiong J, Ying HJ, Ouyang PK (2009) A new member of the short-chain dehydrogenases/reductases superfamily: purification, characterization and substrate specificity of a recombinant carbonyl reductase from Pichia stipitis. Bioresour Technol 100:6022–6027

You ZY, Liu ZQ, Zheng YG, Shen YC (2013) Characterization and application of a newly synthesized 2-deoxyribose-5-phosphate aldolase. J Ind Microbiol Biotechnol 40:29–39

Yu HL, Xu JH, Lu WY, Lin GQ (2009) Discovery and utilization of biocatalysts for chiral synthesis: an overview of Chinese scientists research and development. Adv Biochem Eng Biotechnol 113:1–31

Zhang RZ, Geng YW, Xu Y, Zhang WC, Wang SS, Xiao R (2011) Carbonyl reductase SCRII from Candida parapsilosis catalyzes anti-Prelog reaction to (S)-1-phenyl-1,2-ethanediol with absolute stereochemical selectivity. Bioresour Technol 102:483–489

Zhang RZ, Xu Y, Sun Y, Zhang WC, Xiao R (2009) Ser67Asp and His68Asp substitutions in Candida parapsilosis carbonyl reductase alter the coenzyme specificity and enantioselectivity of ketone reduction. Appl Environ Microbiol 75:2176–2183

Acknowledgments

The supports of this work by the National Basic Research Program of China (973 Program) (No. 2011CB710800), Natural Science Foundation of Zhejiang Province (No. R3110155) and Qianjiang Talent Project of Zhejiang Province are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 39 kb)

Rights and permissions

About this article

Cite this article

You, ZY., Liu, ZQ. & Zheng, YG. Characterization of a newly synthesized carbonyl reductase and construction of a biocatalytic process for the synthesis of ethyl (S)-4-chloro-3-hydroxybutanoate with high space-time yield. Appl Microbiol Biotechnol 98, 1671–1680 (2014). https://doi.org/10.1007/s00253-013-5042-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-013-5042-3