Abstract

Cost-effective conversion of lignocellulose hydrolysate to optically pure lactic acid is commercially attractive but very challenging. Bacillus coagulans JI12 was isolated from natural environment and used to produce L-lactic acid (optical purity > 99.5 %) from lignocellulose sugars and acid hydrolysate of oil palm empty fruit bunch (EFB) at 50 °C and pH 6.0 without sterilization of the medium. In fed-batch fermentation with 85 g/L initial xylose and 55 g/L xylose added after 7.5 h, 137.5 g/L lactic acid was produced with a yield of 98 % and a productivity of 4.4 g/L h. In batch fermentation of a sugar mixture containing 8.5 % xylose, 1 % glucose, and 1 % L-arabinose, the lactic acid yield and productivity reached 98 % and 4.8 g/L h, respectively. When EFB hydrolysate was used, 59.2 g/L of lactic acid was produced within 9.5 h at a yield of 97 % and a productivity of 6.2 g/L h, which are the highest among those ever reported from lignocellulose hydrolysates. These results indicate that B. coagulans JI12 is a promising strain for industrial production of L-lactic acid from lignocellulose hydrolysate.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lignocellulosic biomass, including forestry, agricultural, and agroindustrial wastes, is an abundant, renewable, and cheap carbon source. It is usually composed of cellulose (35–50 %), hemicellulose (20–40 %), and lignin (10–30 %) (Saha 2003). Lignocellulosic biomass can be utilized as a feedstock of fermentable sugars for producing value-added fuels and chemicals. Empty fruit bunch (EFB) of oil palm trees is a rich lignocellulose resource in Southeast Asia especially in Indonesia and Malaysia, which produce over 80 % of the world's palm oil. It is estimated that 1.1 t of EFB is generated per ton of palm oil produced. At present, EFB is either burnt or left mulching on the ground, which is not only environmentally unfriendly but also a waste of this precious resource.

Lactic acid has wide applications in food, feed, cosmetics, and textile industries as well as in producing polylactic acid, a promising biodegradable polymer. Currently, lactic acid is commercially produced from starchy materials using Lactobacillus species at 30–42 °C (Hofvendahl and Hahn-Hägerdal 2000; John et al. 2007). The starchy materials do not only contribute to a significant proportion of lactic acid production cost but also compete with food and feed supply. Lactic acid has been reported to be produced from lignocellulosic biomass but mainly using the cellulosic fraction possibly due to the fact that most microbes have difficulty in digesting pentose sugars and that the by-products in hydrolysates generated during various pretreatments are inhibitory to microbes (Mussatto and Teixeira 2010). However, complete utilization of all lignocellulose sugars is essential for cost-effective production of lactic acid from lignocellulose. Lactobacilli including L. pentosus, L. brevis, L. lactis, and L. bifermentans have been used to produce lactic acid from acid hydrolysates of various agricultural wastes (Bustos et al. 2007; Garde et al. 2002; Givry et al. 2008; Laopaiboon et al. 2010; Moldes et al. 2006), but most of them utilize the phosphoketolase pathway for metabolizing C5 sugars, leading to the formation of equal molar amounts of acetic acid and lactic acid with a theoretical lactic acid yield of only 60 % (Patel et al. 2006). In addition, the formation of a large amount of acetic acid would complicate the downstream processing for product separation and purification, increasing the production cost. It has been reported that microwave-alkali pretreated EFB was converted to lactic acid by Rhizopus oryzae (Hamzah et al. 2009), but the lactic acid productivity reached only 0.09–0.12 g/L h, which is too low to be commercially acceptable.

In recent years, Bacillus coagulans strains have attracted much attention owing to their strong ability to ferment pentose sugars to L-lactic acid using the pentose phosphate pathway with a theoretical yield of 100 % by producing 5 mol of lactate from 3 mol of pentose (Patel et al. 2006; Tanaka et al. 2002). In addition, B. coagulans is moderately thermophilic and capable of growing and fermenting at 50–55 °C, which reduces the risk of microbial contamination as the conventional mesophilic contaminants can hardly grow at this temperature range (Abdel-Banat et al. 2010). Moreover, B. coagulans is able to grow in simpler media than those used for cultivating conventional lactic acid bacteria (Patel et al. 2006). Using B. coagulans strains, 13.7–74.7 g/L of lactic acid was produced from hydrolysates of straws, wood chips, sugar cane, and corn fiber as well as corncob molasses in various fermentation processes, with yields of 43–94 % and productivities of 0.1–0.8 g/L h (Bischoff et al. 2010; Maas et al. 2008; Neureiter et al. 2004; Patel et al. 2004, 2005; Walton et al. 2010; Wang et al. 2010). Here, we report the lactic acid production from lignocellulose sugars and acid hydrolysate of EFB using B. coagulans JI12 that was newly isolated from the natural environment in Singapore, which, to the best of our knowledge, gave the highest lactic acid productivity and yield ever reported from lignocelluloses hydrolysates.

Materials and methods

Chemicals and materials

EFB of oil palm trees was provided by Wilmar International Limited, Singapore. All chemicals used were of an analytical grade and obtained from Sigma-Aldrich unless otherwise specified.

Isolation and identification of thermophilic lactic acid-producing bacteria

Soil samples (2.0 g) were collected from natural parks, wetlands, and gardens in Singapore and enriched in 25 mL of mineral salt broths (per liter: 1 g (NH4)2SO4, 2 g KH2PO4, 2 g NaCl, 0.2 g MgSO4·7H2O, 0.05 g MnSO4·7H2O, 0.01 g FeSO4·7H2O, modified from Patel et al. (2006)) containing 20 g/L xylose, 1 g/L yeast extract, and 12 g/L CaCO3 at 50 °C overnight without agitation. The suspensions were then serially diluted and plated on mineral salt agar plates containing (gram per liter): xylose 10, yeast extract 0.5, and agar 10 at pH 5.0. The plates were then kept in an incubator at 50 °C for 1–2 days until colonies occurred clearly. The colonies were picked up and cultivated in mineral salt medium containing (per liter): 2 g (NH4)2SO4, 2 g KH2PO4, 2 g NaCl, 0.2 g MgSO4·7H2O, 0.05 g MnSO4·7H2O, 0.01 g FeSO4·7H2O, 10 g yeast extract, and 50 g xylose or glucose. CaCO3 (30 g/L) was added to neutralize the lactic acid produced to maintain the pH at 5.3–5.5. After 48 h of incubation at 50 °C without agitation, the strain with the highest L-lactic acid production from both xylose and glucose was selected and designated as JI12. The strain was deposited under Accession No. PTA-13254 in the American Type Culture Collection (ATCC).

Strain JI12 was identified based on its 16S rDNA sequence. The partial 16S rDNA region was amplified using the primers F27 (5′-AGAGTTTGATCCTGGCTCAG-3′) and 1492R (5′-GGTTACCTTGTTACGACTT-3′) (Lane 1991). The PCR amplification was performed for 30 cycles in an iCycler Thermal Cycler (Bio-Rad Laboratories Inc., Hercules, CA, USA). Each cycle consisted of a 30-s denaturation step at 95 °C, a 30-s annealing step at 42 °C, and a 1.5-min extension step at 72 °C. The amplified DNA fragments were sequenced at AITbiotech (Singapore) and analyzed by a similarity search in the GenBank database using the BLAST algorithm.

Batch and fed-batch fermentations of xylose, glucose, and L-arabinose

For preparing seed culture, strain JI12 was grown overnight in 100 mL mineral salt medium containing 5 % (w/v) xylose or glucose and 3 % (w/v) CaCO3 in 250 mL conical flasks at 50 °C and 200 rpm. Cells were collected by centrifugation at 4,000 rpm for 10 min and then resuspended in 50 mL fresh mineral salt medium for use as the seed culture.

Batch and fed-batch fermentations were carried out in a 2-L fermenter (BIOSTAT® B plus, Statorius Stedim Biotech, Germany) containing 1 L of fermentation medium at 50 °C and 100 rpm. The fermentation medium was composed of (per liter): 2 g (NH4)2SO4, 2 g KH2PO4, 2 g NaCl, 0.2 g MgSO4·7H2O, 0.05 g MnSO4·7H2O, 0.01 g FeSO4·7H2O, 10 g (for batch) or 20 g (for fed batch) yeast extract, and different amounts of sugars, as required. In fed-batch fermentations, xylose was fed by directly adding xylose powder into the fermentor. NaOH (10 or 15 M) was automatically added to maintain the broth pH at 6.0. The fermentation medium was immediately used without sterilization after the preparation (open fermentation).

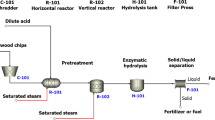

Acid hydrolysis of oil palm EFB

Acid hydrolysate of EFB was prepared following the procedures as described previously (Zhang et al. 2012). EFB fiber was sun-dried and ground to small particles by a knife mill with 1-mm screen followed by oven drying at 80 °C overnight before use. EFB compositions were analyzed following the standard protocols (Yan et al. 2009). Dried EFB powder (150 g) was added into 450 mL water containing 2 % (w/v) of H2SO4 and 0.8 % (w/v) of H3PO4 in a 1 L Parr reactor (Fike, Blue Springs, MO, USA). The hydrolysis was conducted at 130 °C for 60 min. Afterwards, the hydrolysate was collected by filtration to remove the solid, overlimed by adding solid Ca(OH)2 to pH 11 and then adjusted to pH 6.0 by adding 5 M H2SO4 as reported by Martinez et al. (2001). The resultant gypsum was removed by centrifugation and the supernatant was recovered as the hydrolysate.

Batch fermentation of acid hydrolysate of EFB

Seed cultures were prepared as described above. The cells were collected and resuspended in 50 mL of EFB hydrolysate for use as the inoculum. Into 550 mL of EFB hydrolysate in a 2-L fermenter was added 1 % of yeast extract and 0.2 % of (NH4)2SO4, followed by inoculation of 50 mL of the prepared inoculum. Ca(OH)2 (35 %, w/v) was used to neutralize the produced lactic acid to maintain pH at 6.0.

Analytical methods

Xylose, glucose, L-arabinose, lactic acid, acetic acid, and furans were analyzed using a High Performance Liquid Chromatography (HPLC) system (LC-10AT, refractive index detector SPD-10A, Shimadzu, Kyoto, Japan) equipped with a Bio-Rad Aminex HPX-87H column (300 × 7.8 mm, Bio-Rad Laboratories Inc., Hercules, CA, USA) at 50 °C. The mobile phase was 12 mM H2SO4 at 0.65 mL/min. Signals were detected by a refractive index detector. The optical purity of lactic acid was checked on the same HPLC equipped with a Mitubishi MCI(R) GEL CRS15W column (50 × 4.6 mm, Mitubishi Chemical, Tokyo, Japan) at 30 °C using 2 mM CuSO4 as the mobile phase at 0.4 mL/min. The optical purity of L-lactic acid is defined as follows:

Results

Identification of the thermophilic lactic acid-producing strain JI12

Strain JI12 was identified as B. coagulans according to its 16S rDNA sequence (GenBank Accession No. KC248200), which showed 99.3 % identity to those of several other B. coagulans strains. Similar to other B. coagulans strains (Patel et al. 2006), B. coagulans JI12 produced lactic acid as the primary product in fermentation of hemicellulose sugars under anaerobic conditions. The optimal temperature for cell growth and lactic acid production was found to be 50 °C by experiments with temperatures ranging from 30 to 60 °C, and the optical purity of L-lactic acid was determined to be >99.5 % by chiral HPLC. The L- and D-lactate dehydrogenase genes were cloned from B. coagulans JI12 using primers designed based on the conserved regions of these genes in other B. coagulans strains and sequenced, showing up to 100 % and 99 % similarities with those of other B. coagulans strains, respectively. However, analysis of the gene sequences indicates a frameshift mutation between the 142th and 145th bases in the D-lactate dehydrogenase gene of B. coagulans JI12.

Batch and fed-batch fermentations of xylose by B. coagulans JI12

Figure 1 shows the batch fermentations at different xylose concentrations with a fermentation time ranging from 20 h to 70 h. When the initial xylose concentration was below 95 g/L, B. coagulans JI12 was able to consume all the xylose-producing L-lactic acid up to 81 g/L. From 166 g/L of initial xylose, the final L-lactic acid concentration reached only 70.4 g/L (Fig. 1a) with a significant amount of xylose left unconsumed. Significant decreases in the average productivity of lactic acid were observed when the initial sugar concentration was increased from 78 to 95 g/L and further to 166 g/L (Fig. 1b).

After optimizing the seed cultivation time from 30 to 16 h and replacing 10 M NaOH with 15 M NaOH as the neutralizing agent, both lactic acid titer and productivity were further improved. Under the optimized conditions, up to 80.5 g/L of lactic acid was produced from 82 g/L xylose with an average productivity of 4.5 g/L h and a yield of 98 % (Fig. 2a). The lactic acid yield (%) was defined as gram of lactic acid produced per gram of sugar consumed.

Xylose consumption (unfilled diamond), L-lactic acid production (unfilled triangle), and cell growth (OD600, unfilled circle) in batch (a) and fed-batch (b) fermentations by Bacillus coagulans JI12. Fermentations were conducted in mineral salt medium with 1 % (batch fermentation) or 2 % (fed-batch fermentation) yeast extract (w/v) as nitrogen source at pH 6.0 and 50 °C. The age of inoculums was 16 h, and 15 M NaOH was used as the neutralizing agent

The fed-batch fermentation was initiated with 85 g/L of xylose and 55 g/L xylose (powder) was added at 7.5 h when the sugar concentration dropped below 35 g/L (Fig. 2b). From 5.5 to 13.5 h, the lactic acid productivity (10.7 g/L h) remained almost unchanged. Afterwards, the fermentation rate started to decrease rapidly until 31 h when the fermentation was completed, giving 137.5 g/L of lactic acid. The overall average of lactic acid productivity was 4.4 g/L h and the yield was 98 %.

Fermentation of mixed xylose, glucose, and L-arabinose by B. coagulans JI12

Glucose and L-arabinose were also tested as the carbon sources for fermentation by B. coagulans JI12. In batch fermentations, glucose and L-arabinose were both used at a concentration of 50 g/L. As shown in Table 1, 48.6 and 48.4 g/L of lactic acid were produced with average productivities of 4.4 and 4.2 g/L h, respectively. The lactic acid yield in both cases reached 97 %.

Figure 3a shows the sugar consumption, lactic acid production, and cell growth in the batch fermentation of a mixture of 85 g/L xylose, 10 g/L glucose, and 10 g/L L-arabinose by B. coagulans JI12. Figure 3b shows a similar fermentation experiment conducted using a sugar mixture of 47 g/L xylose, 3 g/L glucose, and 13 g/L L-arabinose prepared based on the actual sugar compositions in the acid hydrolysate of oil palm EFB (Fig. 3b). Figure 3a shows that 10 g/L of glucose was converted to L-lactic acid within 7 h, and the consumption of the same amount of L-arabinose took 13 h, whereas 85 g/L of xylose was completely consumed within 21 h. All the three sugars were completely consumed producing 102 g/L of L-lactic acid with an average productivity of 4.8 g/L h and a yield of 98 %. Figure 3b shows that glucose and L-arabinose were used up within 2 and 4 h, respectively, whereas 47 g/L of xylose was completely consumed within 8.5 h. At the end of fermentation, 60 g/L of lactic acid was produced with a productivity of 7.1 g/L h and a yield of 95 %.

Glucose (unfilled inverted triangle), xylose (unfilled diamond), and arabinose (unfilled circle) consumption; L-lactic acid production (unfilled triangle); and cell growth (OD600, filled circle) of mixed sugar fermentation by Bacillus coagulans JI12. Fermentations were conducted in mineral salt medium with 1 % yeast extract (w/v) as nitrogen source at pH 6.0 and 50 °C, and 8.5 % xylose, 1 % glucose, and 1 % L-arabinose (a) or 4.7 % xylose, 0.3 % glucose, and 1.3 % L-arabinose (b) were used as the carbon sources. The age of inoculums was 16 h, and 15 M NaOH (a) or 35 % Ca(OH)2 (b) was used as the neutralizing agent

Fermentation of EFB hydrolysate by B. coagulans JI12

The composition of EFB was determined as: 36.1 ± 2.4 % of glucan, 23.3 ± 1.3 % of xylan, 3.4 ± 0.5 % of arabinan, 20.9 ± 0.7 % of Klason lignin, and 16.5 ± 0.9 % of others. In the hemicellulose hydrolysate prepared, the compositions were: 3.64 ± 0.38 g/L of glucose, 58.62 ± 3.57 g/L of xylose, 8.90 ± 0.92 g/L of L-arabinose (71.16 ± 4.08 g/L total sugars), 18.39 ± 0.81 g/L of acetic acid, 1.92 ± 0.47 g/L of furfural and 0.16 ± 0.09 g/L of 5-hydroxymethylfurfural (HMF). The acid hydrolysate of EFB was pooled and used as the carbon source for lactic acid production after overliming. The overlimed hydrolysate contained 63.1 g/L of total sugars, consisting of 4.7 g/L of glucose, 48.8 g/L of xylose, and 9.6 g/L of L-arabinose. The concentrations of the HPLC detectable inhibitors were: acetic acid 19.17 g/L, furfural 0.41 g/L, and HMF 0.01 g/L.

Fermentations were conducted in duplicate using overnight (16 h) grown cells of B. coagulans JI12 as inoculums and 35 % of Ca(OH)2 as the neutralizing agent and a typical experiment is presented in Fig. 4. Similar to the fermentation of mixed sugars, the consumptions of glucose, xylose, and L-arabinose in the EFB hydrolysate started almost simultaneously with glucose and L-arabinose being completely consumed within 5 h and xylose being used up within 9.5 h, giving 59.2 g/L of L-lactic acid with an average productivity of 6.2 g/L h and a yield of 97 %. The furfural (0.41 g/L) in the hydrolysate was completely metabolized within 5 h before the complete consumption of all sugars.

Glucose (unfilled inverted triangle), xylose (unfilled diamond), and arabinose (unfilled circle) consumption; L-lactic acid production (unfilled triangle); and cell growth (OD600, filled circle) of EFB hydrolysate fermentation by Bacillus coagulans JI12. Fermentation was conducted at pH 6.0 and 50 °C with supplement of 1 % yeast extract (w/v) and 0.2 % (NH4)2SO4. The age of inoculums was 16 h, and 35 % Ca(OH)2 was used as the neutralizing agent

Discussion

B. coagulans has become a promising candidate for industrial production of lactic acid owing to its good thermotolerance and strong ability to utilize pentose sugars. B. coagulans JI12 is able to produce L-lactic acid with an optical purity as high as 99.5 %. The frameshift mutation in the D-lactate dehydrogenase gene that leads to a premature stop codon, thus a shortened protein product, might be responsible for the production of L-lactic acid as the sole optical isomer.

The maximal lactic acid productivity was achieved at a xylose concentration of 80 g/L in batch fermentation of xylose. After optimization of batch and fed-batch fermentations taking 80 g/L as the initial xylose concentration, the lactic acid productivity reached 4.4 and 4.5 g/L h, respectively, with a lactic acid yield of 98 % in both cases. These productivities and yields on xylose are much higher than those of other lactic acid-producing bacteria ever reported. A number of traditional lactic acid bacteria are able to produce lactic acid from xylose through the phosphoketolase pathway or the combined use of phosphoketolase pathway and pentose phosphate pathway (Tanaka et al. 2002), resulting in lower lactic acid yields. For instance, L. lactis IO-1 produced 33.3 g/L of lactic acid from 70.3 g/L xylose with a yield of 67 % (Tanaka et al. 2002). A newly isolated Enterococcus mundtii was reported to produce 94.5 g/L of lactic acid from 104 g/L of xylose at a productivity of 1.3 g/L h and a yield of 85 % (Abdel-Rahman et al. 2011). B. coagulans strains have attracted much attention in recent years owing to their homofermentative conversion of pentoses to lactic acid through the pentose phosphate pathway with a theoretical yield of 100 % (Patel et al. 2006; Tanaka et al. 2002). B. coagulans 36D1 produced 89.1 g/L of lactic acid from 120 g/L of xylose with a productivity and a yield of 1.86 g/L h and 88 %, respectively (Ou et al. 2011). B. coagulans JI12, to the best of our knowledge, gave the highest lactic acid productivity and yield on xylose ever reported.

B. coagulans JI12 was also found to be able to convert glucose and L-arabinose to L-lactic acid homofermentatively with high productivities (Table 1). Xylose, glucose, and L-arabinose are the three major sugar components of hemicellulose with xylose accounting for 60–70 % or above (Bennett 1958). Two mixtures of xylose, glucose, and L-arabinose were thus prepared to simulate the sugar components in acid hydrolysates of lignocelluloses (Fig. 3). For both mixtures, consumption of the three sugars was initiated almost simultaneously. It has been reported that glucose repressed the xylose metabolism by Candida tropicalis, where the consumption of xylose started only after glucose concentration was reduced to below 5 g/L (Kastner et al. 2001). In the mixed sugar fermentation by B. coagulans JI12, the consumption of xylose (85 g/L) and glucose (10.6 g/L) started simultaneously, giving lactic acid productivities of 1.90 g/L h and 2.35 g/L h, respectively, within the first 3 h (Fig. 3a), indicating that glucose repression was almost negligible.

The comparison of fermentations of simulated sugar mixtures (Fig. 3b) and real EFB hydrolysate (Fig. 4) with similar sugar compositions indicates that the lactic acid productivity of real EFB hydrolysate was slightly lower (6.2 g/L h vs. 7.1 g/L h), which could be ascribed to the presence of inhibitors (furfural, HMF, acetic acid, etc.) generated during the pretreatment. Overliming of acid hydrolysates has been reported to partially remove the inhibitors such as furans (Martinez et al. 2001), but not acetic acid, which might inhibit microbial growth as it could enter the cell membrane and decrease intracellular pH, consequently affecting cellular metabolisms (Lima et al. 2004; Rodríguez-Chong et al. 2004). It is worth mentioning that B. coagulans JI12 was able to detoxify furfural left in the overlimed hydrolysate in the early stage of fermentation (data not shown). Furfural might be converted to less toxic metabolites such as furfuryl alcohol or furoic acid as reported for other microorganisms (Gutiérrez et al. 2006).

The comparison of lactic acid production from hemicellulose hydrolysates by B. coagulans JI12 and other microbes is shown in Table 2. Although the continuous production of lactic acid by L. pentosus from trimming vine shoot hydrolysate reached a productivity of up to 3.1 g/L h, the maximal lactic acid titer and yield were only 24.5 g/L and 74 %, respectively (Patel et al. 2004). In batch fermentation of wheat bran syrup by immobilized cells of L. bifermentans, the lactic acid productivity reached 1.4 g/L h, which was, to the best of our knowledge, the highest lactic acid productivity reported in batch fermentation of hemicellulose hydrolysates prior to our work, but its lactic acid yield was only 80 % and a costly medium, MRS, was used in the fermentation (Givry et al. 2008). Compared to the conventional lactic acid bacteria, thermophilic Bacillus strains have a few advantages including rapid growth in simple media and low risk of contamination in open fermentation. In fed-batch fermentation, Bacillus sp. XZL9 produced 74.7 g/L of lactic acid from corncob molasses, which is the highest titer ever reported for lactic acid production from hemicellulose hydrolysate, but the lactic acid productivity and yield were only 0.38 g/L h and 50 %, respectively (Wang et al. 2010). For lactic acid production by free cells in batch fermentations of hemicellulose hydrolysates reported in literature, the best results were achieved by Bacillus sp. 17C5, which produced 55.8 g/L of lactic acid from sugar cane bagasse at a productivity of 0.8 g/L h and a yield of 90 % (Bustos et al. 2007), but our study showed that B. coagulans JI12 gave higher lactic acid titer (59.2 g/L), productivity (6.2 g/L h), and yield (97 %) in the fermentation of EFB hydrolysate. The excellent performance of B. coagulans JI12 makes it a very promising strain for industrial production of L-lactic acid from lignocellulosic biomass.

References

Abdel-Banat BMA, Hoshida H, Ano A, Nonklang S, Akada R (2010) High-temperature fermentation: how can processes for ethanol production at high temperatures become superior to the traditional process using mesophilic yeast? Appl Microbiol Biotechnol 85:861–867

Abdel-Rahman M, Tashiro Y, Zendo T, Hanada K, Shibata K, Sonomoto K (2011) Efficient homofermentative L-(+)-lactic acid production from xylose by a novel lactic acid bacterium, Enterococcus mundtii QU 25. Appl Environ Microbiol 77:1892–1895

Bennett E (1958) Carbohydrate analysis, direct estimation of xylose in hemicelluloses. J Agric Food Chem 6:618–619

Bischoff K, Liu S, Hughes S, Rich J (2010) Fermentation of corn fiber hydrolysate to lactic acid by the moderate thermophile Bacillus coagulans. Biotechnol Lett 32:823–828

Bustos G, De la Torre N, Moldes A, Cruz J, DomÃnguez J (2007) Revalorization of hemicellulosic trimming vine shoots hydrolyzates trough continuous production of lactic acid and biosurfactants by L. pentosus. J Food Eng 78:405–412

Garde A, Jonsson G, Schmidt A, Ahring B (2002) Lactic acid production from wheat straw hemicellulose hydrolysate by Lactobacillus pentosus and Lactobacillus brevis. Bioresour Technol 81:217–223

Givry S, Prevot V, Duchiron F (2008) Lactic acid production from hemicellulosic hydrolyzate by cells of Lactobacillus bifermentans immobilized in Ca-alginate using response surface methodology. World J Microbiol Biotechnol 24:745–752

Guo W, Jia W, Li Y, Chen S (2010) Performances of Lactobacillus brevis for producing lactic acid from hydrolysate of lignocellulosics. Appl Biochem Biotechnol 161:124–136

Gutiérrez T, Ingram L, Preston J (2006) Purification and characterization of a furfural reductase (FFR) from Escherichia coli strain LYO1—an enzyme important in the detoxification of furfural during ethanol production. J Biotechnol 121:154–164

Hamzah F, Idris A, Rashid R, Ming S (2009) Lactic acid production from microwave-alkali pre-treated empty fruit bunches fibre using Rhizopus oryzae pellet. J Appl Sci 9:3086–3091

Hofvendahl K, Hahn-Hägerdal B (2000) Factors affecting the fermentative lactic acid production from renewable resources. Enzyme Microb Technol 26:87–107

John RP, Nampoothiri KM, Pandey A (2007) Fermentative production of lactic acid from biomass: an overview on process developments and future perspectives. Appl Microbiol Biotechnol 74:524–534

Kastner JR, Eiteman MA, Lee SA (2001) Glucose repression of xylitol production in Candida tropicalis mixed-sugar fermentations. Biotechnol Lett 23:1663–1667

Lane D (1991) 16S/23S rRNA sequencing. In: Stackebrandt E, Goodfellow M (eds) Nucleic acid techniques in bacterial systematics. Wiley, New York, pp 115–175

Laopaiboon P, Thani A, Leelavatcharamas V, Laopaiboon L (2010) Acid hydrolysis of sugarcane bagasse for lactic acid production. Bioresour Technol 101:1036–1043

Lima LHA, das Gracas de Almeida Felipe M, Vitolo M, Torres FAG (2004) Effect of acetic acid present in bagasse hydrolysate on the activities of xylose reductase and xylitol dehydrogenase in Candida guilliermondii. Appl Microbiol Biotechnol 65:734–738

Maas R, Bakker R, Jansen M, Visser D, De Jong E, Eggink G, Weusthuis R (2008) Lactic acid production from lime-treated wheat straw by Bacillus coagulans: neutralization of acid by fed-batch addition of alkaline substrate. Appl Microbiol Biotechnol 78:751–758

Martinez A, Rodriguez M, Wells M, York S, Preston J, Ingram L (2001) Detoxification of dilute acid hydrolysates of lignocellulose with lime. Biotechnol Prog 17:287–293

Moldes A, Torrado A, Converti A, Dominguez J (2006) Complete bioconversion of hemicellulosic sugars from agricultural residues into lactic acid by Lactobacillus pentosus. Appl Biochem Biotechnol 135:219–227

Mussatto S, Teixeira J (2010) Lignocellulose as raw material in fermentation processes. In: Mendez-Vilas A (ed) Current research, technology and education topics in applied microbiology and microbial biotechnology, vol 2. Formatex Research Center, Badajoz, pp 897–907

Neureiter M, Danner H, Madzingaidzo L, Miyafuji H, Thomasser C, Bvochora J, Bamusi S, Braun R (2004) Lignocellulose feedstocks for the production of lactic acid. Chem Biochem Eng Q 18:55–64

Ou MS, Ingram LO, Shanmugam K (2011) L (+)-Lactic acid production from non-food carbohydrates by thermotolerant Bacillus coagulans. J Ind Microbiol Biotechnol 38:599–605

Patel M, Ou M, Ingram L, Shanmugam K (2004) Fermentation of sugar cane bagasse hemicellulose hydrolysate to L(+)-lactic acid by a thermotolerant acidophilic Bacillus sp. Biotechnol Lett 26:865–868

Patel M, Ou M, Ingram L, Shanmugam K (2005) Simultaneous saccharification and co-fermentation of crystalline cellulose and sugar cane bagasse hemicellulose hydrolysate to lactate by a thermotolerant acidophilic Bacillus sp. Biotechnol Prog 21:1453–1460

Patel M, Ou M, Harbrucker R, Aldrich H, Buszko M, Ingram L, Shanmugam K (2006) Isolation and characterization of acid-tolerant, thermophilic bacteria for effective fermentation of biomass-derived sugars to lactic acid. Appl Environ Microbiol 72:3228–3235

Rodríguez-Chong A, Alberto Ramírez J, Garrote G, Vázquez M (2004) Hydrolysis of sugar cane bagasse using nitric acid: a kinetic assessment. J Food Eng 61:143–152

Saha B (2003) Hemicellulose bioconversion. J Ind Microbiol Biotechnol 30:279–291

Tanaka K, Komiyama A, Sonomoto K, Ishizaki A, Hall S, Stanbury P (2002) Two different pathways for D-xylose metabolism and the effect of xylose concentration on the yield coefficient of L-lactate in mixed-acid fermentation by the lactic acid bacterium Lactococcus lactis IO-1. Appl Microbiol Biotechnol 60:160–167

Walton S, Bischoff K, van Heiningen A, Van Walsum G (2010) Production of lactic acid from hemicellulose extracts by Bacillus coagulans MXL-9. J Ind Microbiol Biotechnol 37:823–830

Wang L, Zhao B, Liu B, Yu B, Ma C, Su F, Hua D, Li Q, Ma Y, Xu P (2010) Efficient production of L-lactic acid from corncob molasses, a waste by-product in xylitol production, by a newly isolated xylose utilizing Bacillus sp. strain. Bioresour Technol 101:7908–7915

Yan L, Zhang H, Chen J, Lin Z, Jin Q, Jia H, Huang H (2009) Dilute sulfuric acid cycle spray flow-through pretreatment of corn stover for enhancement of sugar recovery. Bioresour Technol 100:1803–1808

Zhang D, Ong YL, Li Z, Wu JC (2012) Optimization of dilute acid-catalyzed hydrolysis of oil palm empty fruit bunch for high yield production of xylose. Chem Eng J 181–182:636–642

Acknowledgments

This work was supported by the Science and Engineering Research Council (SERC) of the Agency for Science, Technology and Research (A*STAR) under the Value-Added Chemicals from Lignocellulose (VACL) Program (SERC grant no. 0921590133; ICES/10-474A01, NUS/R-279-000-309-305). Thanks are given to Ms. Ong Yee Ling for help with preparing the EFB hydrolysate. All authors have agreed to submit this manuscript to the “Applied Microbiology and Biotechnology.”

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ye, L., Hudari, M.S.B., Zhou, X. et al. Conversion of acid hydrolysate of oil palm empty fruit bunch to L-lactic acid by newly isolated Bacillus coagulans JI12. Appl Microbiol Biotechnol 97, 4831–4838 (2013). https://doi.org/10.1007/s00253-013-4788-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-013-4788-y