Abstract

Agricultural biogas plants were operated in most cases below their optimal performance. An increase in the fermentation temperature and a spatial separation of hydrolysis/acetogenesis and methanogenesis are known strategies in improving and stabilizing biogas production. In this study, the dynamic variability of the bacterial and archaeal community was monitored within a two-phase leach bed biogas reactor supplied with rye silage and straw during a stepwise temperature increase from 55 to 75 °C within the leach bed reactor (LBR), using TRFLP analyses. To identify the terminal restriction fragments that were obtained, bacterial and archaeal 16S rRNA gene libraries were constructed. Above 65 °C, the bacterial community structure changed from being Clostridiales-dominated toward being dominated by members of the Bacteroidales, Clostridiales, and Thermotogales orders. Simultaneously, several changes occurred, including a decrease in the total cell count, degradation rate, and biogas yield along with alterations in the intermediate production. A bioaugmentation with compost at 70 °C led to slight improvements in the reactor performance; these did not persist at 75 °C. However, the archaeal community within the downstream anaerobic filter reactor (AF), operated constantly at 55 °C, altered by the temperature increase in the LBR. At an LBR temperature of 55 °C, members of the Methanobacteriales order were prevalent in the AF, whereas at higher LBR temperatures Methanosarcinales prevailed. Altogether, the best performance of this two-phase reactor was achieved at an LBR temperature of below 65 °C, which indicates that this temperature range has a favorable effect on the microbial community responsible for the production of biogas.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The production of biogas by the anaerobic digestion of agriculturally produced or derived biomass is conducted in most cases below its optimal performance (Ward et al. 2008). Strategies known to improve biogas production are the maintenance of increased fermentation temperatures and the compartmentalization of the biogas reactor, as realized in two-phased or staged systems. Experimental thermophilic biogas reactors achieved higher methane rates and better solids removal than comparable mesophilic systems (Dugba and Zhang 1999). An increased temperature also leads to a reduction in potentially pathogenic bacteria, as indicated by sludge analysis (Buhr and Andrews 1977). This is of particular interest when substrates with potential pathogens such as household waste (Ahring 1995) or feces (Dahlenborg et al. 2001, 2003) are fermented and subsequently used as soil fertilizer. Specialized two-phase biogas systems with a separate hydrolysis/acetogenesis and methanogenesis, which allows for adjusting the operation parameters for each reactor separately, can also improve the biogas yield (Demirer and Chen 2005). Such systems support the settlement of specialized microbial communities, depending on the reactor phases and the conversion process.

Only a few studies have already focused on the microbial community structure within phase-separated systems under mesophilic conditions (Cirne et al. 2007; Klocke et al. 2008; Wang et al. 2010) or thermophilic conditions, supplying beet silage and wheat hydrolysate (Kongjan et al. 2011; Krakat et al. 2010). However, analyses of thermophilic phase-separated systems supplied with substrates with high-fiber content are rather scarce. Furthermore, studies focusing on a further increase in the operation temperature above 70 °C are also rare (Lepistö and Rintala 1996; Nozhevnikova et al. 1999), particularly studies which also considered the microbial community structure.

The stabilization of the microbial community during biogas production especially at high temperatures may be supported by bioaugmentation. Recently, the bioaugmentation of biogas systems—either by pure cultures (e.g., Caldicellulosiruptor, Bagi et al. 2007; Nielsen et al. 2007) or by compost communities (Neumann and Scherer 2011)—improved the biogas efficiency within a completely mixed thermophilic reactor as well as in mesophilic and thermophilic two-staged systems.

In this study, we analyzed the influence of temperature increases within the leach bed reactor of a two-phase leach bed biogas system on the microbial community by applying terminal restriction fragment (TRF) length polymorphism (TRFLP) and 16S rRNA gene library analyses. Although, the TRFLP method, a high-throughput fingerprint tool, comprises some limitations concerning the resolution of complex microbial communities, it is a valuable tool for tracking microbial dynamics (e.g., Kitts 2001; Schutte et al. 2008). To support the TRFLP results and to identify the TRFs that were obtained, 16S rRNA gene libraries were constructed.

The subject reactor system was developed to ensure an efficient conversion of high-fiber crop material. It consisted of a leach bed reactor (LBR) for anaerobic degradation of the substrate and a downstream anaerobic filter reactor (AF) for methanogenesis. The aims were (1) to monitor the dynamics of the hydrolytic and acidogenic bacteria community in the LBR during a stepwise temperature increase from 55 to 75 °C, (2) to track the impact of bioaugmentation with compost on the bacterial community in the LBR at high fermentation temperatures, and (3) to consider the impact of temperature increase within the LBR on the methanogenic archaea community residing within the AF, operated at a constant temperature of 55 °C.

Material and methods

Reactor setup and sampling

The system analyzed in this study, which was operated since 2006, was previously described in detail by Rademacher et al. (2012). In short, it consisted of a gastight LBR (net volume 100 L), an effluent storage reactor (HS, net volume 60 L), and a downstream AF (net volume 30 L) with 390 packings (Bioflow 40; Rauschert, Judenbach-Heinersdorf, Germany). The LBR was supplied discontinuously with 10 kg of rye silage and 0.5–1.0 kg of straw material, having a retention time of 21 days. The distribution of intermediates as well as a consistent temperature and moisture level was accomplished by circulating the leachate. The AF was operated continuously at 55 °C, whereas the temperature of the LBR was increased from 55 to 75 °C in increments of 5 °C. Each temperature regime was kept constant for three fermentation periods of 21 days each. After the temperature regime of 70 °C, a bioaugmentation was conducted by adding 4-week-old compost (5 kg; Biowork, Schmergow, Germany), comprising thermophilic microorganisms, to the substrate while maintaining the temperature of 70 °C. After two fermentations with compost lasting 21 days, rye silage and straw without compost were digested in the LBR at 70 °C. After this fermentation, the temperature regime in the LBR was increased following the previous scheme up to 75 °C.

Three of these biogas reactor systems were set up and were operated in parallel. Samples were mainly taken from the first reactor system during the second or third fermentation period of each temperature regime allowing the microbial community to adapt to the increased temperature. The second and third reactor system was analyzed at specific time points to confirm the reproducibility of the results.

For bacterial community analysis, the leachate was sampled at days 7 and 21 of one fermentation period for each temperature regime. The selection of these sampling days was performed after analyzing the bacterial community dynamics during the fermentation of one charge of substrate at 60 °C (LBR), sampling the leachate at days 0, 2, 7, 14, and 21 and the digestate at day 21. A volume of 50 mL of leachate was taken from the plug of the effluent storage reactor, and 50 g of digestate was sampled from the LBR. To support the findings of the bacterial community dynamics during the temperature increase within the first reactor system, the second and third biogas reactor was also analyzed at the temperature regimes of 65 and 70 °C.

For the archaeal community analysis, the biofilm on the surface of one packing out of the AF was analyzed for each temperature regime of the LBR. The packings that were analyzed were removed at the end of the 21-day fermentation process to prevent a disturbance of the biogas production process. Prior to the biofilm detachment, the packing was rinsed with 1× phosphate-buffered saline (PBS) to remove the planktonic cells. Afterwards, the biofilm was detached using a sterile scalpel. All samples were stored at −20 °C until further processing.

Simultaneously to the operation of the reactors, process parameters were determined throughout the experiment. The biogas and methane yield, measured as described in Schönberg and Linke (2012), are listed in Table 1. The degradation rate of the organic material was calculated based on the organic dry matter (ODM) before and after the fermentation and was corrected by the nondegradable lignin fraction of the substrate. The concentrations of acetic acid, n-butyric acid, propionic acid, ethanol, and propanol (Fig. 1) were analyzed by gas chromatography (CP-3800; Varian, Palo Alto, USA). The pH was measured using a pH meter 340i (WTW, Weilheim, Germany). The total ammonia concentration (NH +4 –N + NH3–N) was determined after Kjeldahl, and the concentration of free ammonia (NH3–N) was calculated according to Anthonisen et al. (1976).

Determination of total cell counts

To determine the total cell counts, the LBR leachate samples of the first reactor were fixed immediately after sampling. Therefore, the samples were washed two times with 1× PBS and were incubated with three volumes of 3.7 % formaldehyde at 4 °C over night. After incubation, the samples were centrifuged and the pellets obtained were washed two times with 1× PBS. Finally, the pellets were resuspended in equal parts of 1× PBS and 96 % ethanol. All samples were stored at −20 °C until further processing. For the cell count analysis, the fixed samples were washed and afterwards sonicated according to Nettmann et al. (2010). The samples were analyzed in triplicates and applied to a Teflon-coated slide, which was covered with 0.1 % gelatine and 0.01 % CrK(SO4)2. Afterwards, the samples were stained using 5 μL Citifluor AF1 antifading reagent and 0.2 μL 4′,6-diamidino-2-phenylindole (DAPI; 33 μg mL−1). The detection of stained microbial cells was performed under an Olympus BX51 fluorescent microscope (Olympus, Hamburg, Germany) at a magnification of 600, using the filter set WU for DAPI detection. Images of the samples were taken with a digital Olympus DP72 camera, applying the software cell F (Olympus, Hamburg, Germany). For each triplicate of the samples, about 1,000 stained cells were counted from randomly taken images. The calculation of the total cell count was performed according to Raizada (2004).

DNA extraction and amplification

The genomic DNA was extracted by means of the Fast DNA® SPIN Kit for Soil (Mp Biomedicals, Heidelberg, Germany), according to the manufacturer’s instruction. For each sample, three subsamples were extracted using 2 mL of leachate and 0.2 g of digestate from the LBR for the bacterial community analysis and 0.2 g of the packing’s biofilm from the AF for the archaeal community analysis.

For the amplification of the bacterial 16S rRNA gene, the 27f forward primer (5′ AGAGTTTGATCMTGGCTCAG 3′, Lane 1991; Sipos et al. 2007) labeled with Cy5 (5′ end) and the 926r reverse primer (5′ CCGTCAATTCMTTTRAGTTT 3′, Després et al. 2007; Weisburg et al. 1991) were used. The amplification of the archaeal 16S rRNA gene was achieved using the Ar109f forward primer (5′ ACKGCTCAGTAACACGT 3′, Großkopf et al. 1998) also labeled with Cy5 (5′ end) and the Ar912r reverse primer (5′ CTCCCCCGCCAATTCCTTTA 3′; Lueders and Friedrich 2000; all primers: Biomers, Ulm, Germany). The following reaction mix was used for the amplification in a total volume of 25 μL: 2.5 μL 10× PCR buffer, 2 mM (Bacteria assay) or 2.5 mM (Archaea assay) MgCl2, 0.2 mM dNTPs, 0.4 μM of each primer, and 1 U of the recombinant Taq DNA polymerase (all provided by Fermentas, St. Leon-Rot, Germany). The thermal profile for amplification was as follows: initial denaturation at 95 °C for 3 min, denaturation at 94 °C for 30 s, annealing at 51 °C (Bacteria assay) or 52 °C (Archaea assay) for 30 s, elongation at 72 °C for 90 s, steps 2–4 were repeated 25 times (Bacteria assay) and 28 times (Archaea assay), followed by a final extension at 72 °C for 8 min. Positive controls were set up using genomic DNA purified from the following cultures: Escherichia coli (DSM 1116), Pseudomonas fluorescens (DSM 50090), Clostridium tyrobutyricum (DSM 2637), Methanothermobacter thermautotrophicus (DSM 1053), Methanosarcina thermophila (DSM 1825), and Methanoculleus marisnigri (DSM 1498). After amplification, the PCR products were purified using the QIAquick PCR Purification Kit (Qiagen, Hilden, Germany), according to the manufacturer’s instructions.

TRFLP analysis

The concentrations of the PCR amplicons were determined photometrically using a NanoPhotometer (Implen, München, Germany). A total of 200 ng DNA was digested enzymatically in a total volume of 20 μL at 37 °C for 4 h using 10 U of each, MspI and Hin6I, in the case of the Bacteria assay, or AluI for the Archaea assay (all enzymes provided by Fermentas). Subsequently, the digested products were purified by ethanol precipitation, using 300 μL 75 % ethanol and 0.1 volume of 3 mol L−1 sodium acetate. The precipitated DNA was resuspended in 20 μL (Archaea assay) or 40 μL (Bacteria assay) HPLC–H2O. The electrophoretic separation and fluorescent detection of digestion fragments were conducted using a GenomeLab™ GeXP Genetic Analysis System (Beckman Coulter, Krefeld, Germany). Each sample was loaded together with 0.5 μL of standard-sized DNA (600) labeled with D1 dye (Beckman Coulter, Krefeld, Germany), comprising fragments from 60 to 640 nucleotides. The samples were filled up to a volume of 30 μL with sample loading solution (SLS, Beckman Coulter, Krefeld, Germany) and separated for 70 min with a voltage of 4.8 kV.

The recording and analysis of data were performed with the GeXP analysis software (version 10.2). The size of the TRFs was calculated with the quartic model based on the migration time of the size standard. Due to the applied size standard, only fragments between 60 and 650 bp were analyzed. Further, the fragments showing fluorescence intensities below 370 rfu were not measurable within a linear range and therefore removed from the study. The data obtained were subsequently normalized by focusing on the total fluorescence intensity of peak heights, corresponding to Dunbar et al. (2001). The alignment of TRFs (clustering threshold 0.8) was conducted applying the T-Rex software (Culman et al. 2009). For further downstream analysis, only TRFs were used, which are represented in at least two of the conducted triplicates per sample. For the bar chart, TRFs with a relative abundance below 3 % of the total detected fluorescence intensity were removed from the analysis. Then, the relative abundance of each TRF was calculated based on the standardized and aligned data set according to Wang et al. (2010) and displayed using SigmaPlot 8.0 (Systat Software, Erkrath, Germany). The nonmetric multidimensional scaling (NMDS) was constructed on the basis of the rank order of a Bray–Curtis similarity matrix, which was constructed using the EstimateS software version 8.0.0 (Colwell 2006). The NMDS was performed applying the Statistica software (StatSoft, Hamburg, Germany). The stress value obtained for this NMDS was 0.05, indicating a very good ordination (Clarke 1993).

Construction of 16S rRNA gene clone libraries and identification of TRFs

For the bacterial clone libraries, the microbial DNA extracted from the leachate (day 7) of the first LBR, operated at 55 and 75 °C, was used. For the archaeal clone library, the microbial DNA from the packing’s biofilm within the AF, operated at 55 °C (LBR temperature 55 °C), was employed. Bacterial and archaeal 16S rRNA gene fragments were amplified by PCR, using primers (unlabeled) and temperature adjustments as described above. After purification, the PCR products were cloned into a pGem®-T vector (Promega, Mannheim, Germany) and subsequently transformed into E. coli JM 109 cells (Promega). White colonies were selected randomly, grown over night, and recombinant plasmids were extracted using the NucleoSpin® plasmid kit (Macherey-Nagel, Düren, Germany). The successful cloning was verified by means of a restriction digest using NcoI and SalI (Fermentas), according to the manufacturer’s instructions. For each of the three 16S rRNA gene libraries, 96 plasmids with inserts of expected length were sequenced (GATC Biotech AG, Konstanz, Germany) and checked for anomalous (e.g., chimeric) sequences using the software Mallard 1.02 (Ashelford et al. 2006). This software processes a pairwise comparison between query sequences and the reference sequence E. coli K12 (accession no. U00096) based on the pintail algorithm (Ashelford et al. 2005), which leads to the identification of anomalous sequences. A total of 9 % of all sequences were identified as anomalous and excluded from further data analysis.

Operational taxonomic units (OTUs) were defined as group of sequences with a p-distance of 0.03 to each other, applying the software Mega 5 (Tamura et al. 2011). Afterwards, all sequences were blasted against the NCBI nr/nt database (excluding uncultured and environmental sample sequences) and assigned to it. The archaeal OTUs were indicated at rank genus and the bacterial OTUs at rank order.

To identify TRFs, plasmids of interest were amplified using T7 (5′ TAATACGACTCACTATAGGG 3′) and SP6 (5′ ATTTAGGTGACACTATAG 3′) primers. The following reaction protocol was performed using a total volume of 20 μL: 2 μL 10 × PCR buffer, 1.5 mM MgCl2, 0.2 mM dNTPs, 0.2 μM of each primer, and 0.8 U of the recombinant Taq DNA polymerase (all provided by Fermentas). The thermal profile started with an initial denaturation at 94 °C for 2 min, followed by a denaturation step at 94 °C for 30 s, an annealing step at 47 °C for 1 min, and an elongation step at 70 °C for 2 min. The steps 2–4 were repeated 30 times and finished by a final extension at 70 °C for 10 min. After purification, a second PCR was applied focusing on the bacterial or archaeal 16S rRNA gene, using the TRFLP primers and the thermal profile described above. The PCR products obtained were purified, digested, precipitated by ethanol, and finally analyzed on the GenomeLab™ GeXP Genetic Analysis System, as described before. The identification and taxonomic assignment of TRFs previously monitored for the reactor samples were conducted on the basis of the cloned 16S rRNA gene sequences, resolving a TRF of similar size.

All determined nucleotide sequences are deposited in the database of the ENA-EMBL-Bank with the following accession numbers: HE804839-HE804914 and HE804915-HE804988 for the bacterial 16S rRNA gene libraries derived from the LBR at 55 and 75 °C, respectively, and HE804989-HE805076 for the archaeal 16S rRNA gene library derived from the AF (LBR at 55 °C).

Results

Biogas reactor performance

The temperature of the LBR was increased from 55 up to 75 °C in increments of 5 °C, whereas the AF was kept constant at 55 °C. The process parameters of the two-phase biogas reactors were analyzed at the mentioned temperature regimes within the LBR and AF and were indicated for the first reactor system.

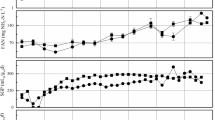

During the whole experiment, the pH remained nearly constant in both reactor compartments (LBR 7.53 ± 0.35; AF 7.89 ± 0.13). The concentration of total nitrogen (1.20 ± 0.11 g L−1) and free ammonia (0.32 ± 0.06 g L−1) in the AF also remained constant. However, several parameters, such as the biogas yield, altered severely during the temperature increase. Whereas the biogas yield of the first three temperature steps (55 to 65 °C) was nearly the same, with a mean value of 611 ± 8 L kg −1oS , the biogas yield decreased by 29 % at 70 °C (Table 1). To introduce additional thermophilic microorganisms to the system and, hence, to strengthen the reactor performance, a bioaugmentation with compost was conducted at 70 °C. As a result, an increase in the biogas yield by 15 % was obtained. However, this increased biogas yield did not persist during the following experiments with LBR temperatures of 75 °C.

Simultaneous to changes in the biogas yield, the degradation potential of organic dry matter also decreased. Between 55 and 65 °C, a high degradation of ODM could be achieved with values of 79.5, 77.6, and 61.2 %, respectively. Then, it declined to 39.0 % at 70 °C, 52.2 % after bioaugmentation at 70 °C, and 32.4 % at 75 °C. This indicates that the bioaugmentation has a positive effect on the degradation of ODM.

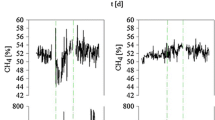

The impact of temperature increase could also be observed by analyzing different intermediates in the leachate, such as acetic acid, n-butyric acid, propionic acid, and alcohol. The concentrations of each intermediate were rather similar between 55 and 65 °C (Fig. 1). Above 65 °C, the maximal concentration of the acetic acid (Fig. 1a) and n-butyric acid (Fig. 1b) decreased strongly, whereas the propionic acid concentration (Fig. 1c) showed a lower reduction. However, the highest concentration of all intermediates was measured during the first 9 days of the fermentation independent of the LBR temperature. Interestingly, above 65 °C, the decomposition of the acetic acid was prolonged in comparison to the lower temperatures. This effect was reduced after the bioaugmentation, but appeared again at 75 °C.

In contrast to the carboxylic acids, the concentration of alcohols, i.e., ethanol and propanol, was slightly increased at hyperthermophilic temperatures. At 75 °C, an alcohol concentration with a mean value of 0.15 g L−1 was measurable during the first 5 days of the fermentation (Fig. 1d). At lower temperatures, the alcohol concentration was below the detection level of 0.02 g L−1, in most cases.

Total cell counts of the leachate derived from the LBR

The increase in the operation temperature led to a reduction in cell densities, as determined by fluorescence microscopy. At 55 °C, an average of 2.7 ± 0.6 × 1010 cells mL−1 were detected. A first reduction in the total cell count to 1.6–1.7 ± 0.2 × 1010 cells mL−1 appeared after a temperature increase to 60 °C. At 70 °C, the total cell count was decreased to a total of 6.2 ± 1.3 × 109 cells mL−1. The following bioaugmentation with compost led to no positive effect on cell densities. After the bioaugmentation at 70 °C, as well as at 75 °C, the average total cell counts were 4.6 ± 1.1 × 109 cells mL−1.

Bacterial community dynamics in the LBR during the anaerobic digestion of one charge of silage

The bacterial community dynamic in the LBR which was operated at 60 °C was tracked by a TRFLP analysis of the leachate and the digestate. During the digestion of one charge of silage, the bacterial community underlay certain alterations (Fig. 2). At the beginning (day 0) and the end (day 21) of the digestion, comparatively similar community structures were observed. In the middle phase, the community structure varied significantly. Major differences of the community were observed after 7 days of fermentation. In conclusion, the bacterial community altered in a cyclic pattern during the 21-day digestion process.

Nonmetric multidimensional scaling (NMDS) of Bray–Curtis values for the pairwise similarity of microbial community structures as determined by the TRFLP analyses. TRFLP profiles were determined for samples taken from the LBR at different time points during the 21-day fermentation of one charge of rye silage at 60 °C. L0-L21 samples of the leachate at days 0–21, D21 samples of the digestate at day 21

Impact of the temperature increase on the bacterial community in the LBR

As consequence of the previous results, days 7 and 21 were chosen to follow the bacterial community dynamics during the temperature increase in the LBR by TRFLP analysis. A substantial alteration in the bacterial community structure was observed after a temperature increase in the LBR. Up to 65 °C, the bacterial community consisted mostly of species belonging to the Clostridiales order. Above 70 °C, members of the Bacteroidales, Clostridiales, and Thermotogales orders dominated the bacterial community structure in the LBR.

More specifically, in the case of an LBR temperature of 55 and 60 °C, the TRFLP pattern at day 7 showed five prevalent TRFs (TRF 84, 151, 167, 217, and 304; Fig. 3a). The sequence analysis of these TRFs revealed the highest similarities to species belonging to the Clostridiales order (Fig. 3). Only the phylogenetic affiliation of TRF 84 remained unknown, due to the absence of a corresponding reference sequence within the 16S rRNA gene clone libraries. At 65 °C, slight changes in the bacterial community structure were detectable. For instance, within the sample derived from day 7 of the fermentation, the relative abundance of the TRFs 84 and 167 was elevated twofold, whereas other fragments disappeared (TRF 217) or decreased strongly (TRF 304, Fig. 3a).

Dynamics of the bacterial community structure within the leachate of the LBR at days 7 (a) and 21 (b) during temperature increases from 55 to 75 °C. TRFs with a relative abundance above 3 % of the total fluorescence intensity were displayed. In asterisks, analysis after bioaugmentation with compost, in brackets the accession number and sequence identity of the sequence are given, producing the best alignment to the query 16S rRNA sequence, as indicated by a BLAST analysis against the NCBI nr/nt database, without uncultured and environmental sample sequences

In accordance with the changes in chemical parameters and biogas yield, severe alterations of the bacterial community structure were observed at 70 °C. TRFs which were prevalent before disappeared and vice versa. Taking the bacterial community structure at day 7 of the fermentation as example, the TRFs 167, and 304 (all Clostridiales affiliated, Fig. 3) decreased strongly or disappeared, whereas the fragments TRF 208, 214, and 221 were identified for the first time (Fig. 3a). TRF 214 was prevalently detected in relative abundance at 27–44 % from 70 °C. TRF 214 and 221 showed the highest similarity to the Acetomicrobium genus (Bacteroidales, Fig. 3). The phylogenetic origin of the TRF 208 was not ascertainable. At 75 °C, a further fragment, TRF 194, appeared which was affiliated to the Fervidobacterium genus (Thermotogales, Fig. 3).

This apparent shift in the bacterial community structure at 70 °C after 7 days of the fermentation was also observed after analyzing the community at the end (day 21) of the fermentation process (Fig. 3b). Furthermore, the analysis of the two identical two-phase biogas reactors also showed the shift from a Clostridiales-dominated community towards a prevalence of Acetomicrobium sp. (TRF 214 and TRF 221; Fig. 4) indicating a reproducible impact of the temperature on the bacterial community structure within these two-phase biogas reactors.

Dynamics of the bacterial community structure within the LBR leachate of the three identical biogas reactors at 65 and 70 °C (each analyzed at day 7). TRFs with a relative abundance above 3 % of the total fluorescence intensity were displayed. The second and third reactors were the technical replicates of the first system analyzed. For phylogenetic affiliation of the TRFs, refer to Fig. 3

The bioaugmentation with compost conducted at an LBR temperature of 70 °C introduced several different bacteria with unknown affiliation to the bacterial community resulting in a slightly varied TRFLP pattern in comparison to the fermentation at 70 °C before the bioaugmentation (Fig. 3).

Furthermore, as expected from our previous results, the composition of the bacterial community showed strong differences between the TRF profiles observed at days 7 (Fig. 3a) and 21 (Fig. 3b), particularly at LBR temperatures between 55 and 65 °C. For instance, TRF 151 strongly dominated the profiles at the end of the fermentation at 55 and 60 °C in contrast to the samples derived from day 7. Additionally, TRFs that were relatively abundant at day 7 were decreased at day 21, such as the TRFs 167 and 304. At LBR temperatures above 65 °C, fewer differences were observed within the TRFLP profiles of days 7 and 21 (Fig. 3).

Bacterial community structure in the LBR as revealed by 16S rRNA gene library analysis

The results of the analysis of two bacterial 16S rRNA gene libraries, constructed from leachate samples of the LBR at 55 °C (76 clones, 30 OTUs) and 75 °C (74 clones, 17 OTUs), confirmed the alterations from Clostridiales to Bacteroidales within the bacterial community obtained by TRFLP analysis. At 55 °C, 80 % of the total clones and 60 % of the total OTUs were assigned to Clostridiales (Table 2). Their relative abundance was strongly reduced, accounting for 12 % of total clones and 41 % of the total OTUs at 75 °C. Simultaneously, the number of sequences assigned to the Bacteroidales order increased strongly from 3 % (55 °C) to 62 % (75 °C) of the total clones (Table 2).

Additionally, 16S rRNA sequences related to the Actinomycetales, Halanaerobiales, Pseudomonadales, and Synergistales orders were also detected at 55 °C and were absent at 75 °C (Table 2). In contrast, 16S rRNA sequences related to the Burkholderiales and particularly the Thermotogales orders were absent at 55 °C and showed a relative abundance at 1 and 10 % of the total clones at 75 °C, respectively (Table 2).

Archaeal community structure in the AF during the temperature increase in the LBR

During the increase in the operational temperature of the LBR, the temperature of the AF was kept constant at 55 °C. To monitor the methanogenic archaeal community, the biofilm on the surface of a packing in the AF was analyzed at each LBR temperature regime.

The archaeal TRF 339, affiliated to the Methanothermobacter genus (Methanobacteriales), and TRF 628, affiliated to the Methanosarcina genus (Methanosarcinales), were prevalent during the whole experiment (Fig. 5). During the temperature increase in the LBR, both TRFs showed an uneven progress. At 55 °C, the archaeal community consisted mostly of members of the Methanobacteriales order, whereas species belonging to the Methanosarcinales order dominated the archaeal community structure at 75 °C (Fig. 5).

Dynamics of the archaeal community structure in the AF (55 °C) during temperature increases in the LBR (55–75 °C). TRFs with a relative abundance above 3 % of the total fluorescence intensity were displayed. In brackets the accession number and sequence identity of the sequence are given, producing the best alignment to the query 16S rRNA sequence, as indicated by BLAST analysis against the NCBI nr/nt database, without uncultured and environmental sample sequences

In addition to these TRFs, further fragments were identified. TRF 107, which was prevalent at 55 °C, was assigned to members of the Methanobacteriales, Methanomicrobiales, and Methanosarcinales orders (Fig. 5). Additionally, TRF 337, corresponding to the Methanobacteriales, and TRF 430, corresponding to three members of the Methanomicrobiales order, were less detected (Fig. 5).

Within the 16S rRNA gene clone library, a total of 12 OTUs were identified (Table 3) after analyzing the biofilm derived from the AF (LBR 55 °C). About 50 % of the OTUs obtained belonged to the Methanobacteriales order, and within this order, the Methanobacterium and Methanothermobacter genera were found. Further, Methanomicrobiales and Methanosarcinales were also identified at 33 and 17 % of the total OTUs, respectively, confirming the results of the archaeal TRFLP approach at 55 °C (LBR).

Discussion

The microbial community response to temperature increases (55 to 75 °C) in the LBR within an experimental two-phase leach bed biogas reactor was analyzed by the TRFLP method. Depending on the temperature increase, alterations in the microbial community structure and process parameters, such as the biogas yield or intermediate production, occurred.

Variation of the bacterial community structure during the digestion of silage

The bacterial community structure shifted in a cyclic pattern during the fermentation of one charge of silage at a constant LBR temperature of 60 °C. Due to the batch feeding in this study, the maximal concentration of the intermediates that were produced, such as acetic acid, was achieved during the first 9 days of the fermentation. It was here that the strongest alterations within the bacterial community structure occurred. Other studies also showed a highly diverse and changing community although the whole system remained stable (Fernandez et al. 1999; Krakat et al. 2010). However, in contrast to our study, those studies analyzed continuously fed CSTRs.

Influence of temperature on the fermentative bacterial community in the LBR

The bacterial community structure is strongly affected by the temperature as indicated by the TRFLP and 16S rRNA gene library analyses. Between 55 and 65 °C, members of the Clostridiales were detected as being the most prevalently fermentative bacteria in the LBR. At temperatures above 65 °C, a member of the Bacteroidales order dominated the TRFLP pattern, which is identified as being closely related to the Acetomicrobium genus. Species of this genus grow at temperatures of up to 75 °C (Goodfellow et al. 2010). In addition, Acetomicrobium-degraded carbohydrates, such as glucose and cellobiose, lead to the fermentation end products acetate, lactate, ethanol, CO2, and H2 (Goodfellow et al. 2010). In other studies, Bacteroidales were only detected in mesophilic and not in thermophilic fermentations. As example, Kongjan et al. (2011) did not identify members of the Bacteroidales order when analyzing a two-stage UASB reactor system at 70 and 50 °C supplied with wheat hydrolysate. Furthermore at 75 °C, a member of the Thermotogales (Fervidobacterium sp.) was detected in our system. Members of the Fervidobacterium genus use various hexoses for energy metabolism and produce lactate, CO2, H2, acetate, as well as ethanol (Cai et al. 2007; Patel et al. 1985). According to the changes in the bacterial community, severe alterations in the degradation potential of ODM occurred above 65 °C. The reduced potential to degrade carbohydrates may be induced by the strong decrease in members of the Clostridiales order. Furthermore, a degradation of cellulose for the species of the Acetomicrobium genus has not been reported to date (Goodfellow et al. 2010). This supports the findings of a diminished degradation potential at temperatures from 70 °C. Although such changes may also be triggered by the decrease in the cell count at 70 °C, the remaining cell concentration of 109 cells mL−1 should be suitable for carbohydrate degradation and the downstream methanogenesis.

Above 65 °C, the intermediate production also changed. The fermentation end products of the prevalent bacteria above 65 °C may explain the slight increase in ethanol and at least the strong reduction in n-butyric acid at these temperatures. Due to the fact that the intermediate butyrate can be converted into acetate (Wu et al. 1993), the decrease in n-butyric acid also affects the acetic acid-producing bacteria. Therefore, the acetic acid concentration was also reduced at temperatures above 65 °C. A diminished consumption of the acetic acid by acid-consuming microorganisms, such as syntrophic acetate-oxidizing bacteria or acetoclastic methanogens, could also be assumed, due to a prolonged decomposition of acetic acid in the leachate at 70 and 75 °C. Ahring et al. (2001) identified a disturbance between acid-producing and acid-consuming microorganisms in CSTRs already at 65 °C. Interestingly, after the bioaugmentation with compost at 70 °C, the produced acetic acid was converted more rapidly than during the fermentation at 70 °C without a previous bioaugmentation. Therefore, the bioaugmentation seemed to stabilize the bacterial community, which led to an increased degradation of ODM by 13 % and therefore to an increased biogas yield of 15 %. This is in accordance with a recently published study of Neumann and Scherer (2011), who achieved an increase in biogas yield of 6 % after bioaugmentation with compost during continuous mesophilic fermentations. However, the improvements of the bioaugmentation were not conserved during a further temperature increase to 75 °C. Nevertheless, repeated bioaugmentation with compost might be a valuable tool for the stabilization of thermophilic fermentative bacterial communities. Furthermore, an inoculation of specialized bacteria, which are capable of carbohydrate degradation at high temperatures, could lead to further improvements. First works on this have already been published by different authors (e.g., Bagi et al. 2007; Nielsen et al. 2007), who have inoculated several reactor types with Caldicellulosiruptor.

Influence of temperature increase in the LBR on the archaeal community in the AF

The archaeal community structure, residing in the AF at 55 °C, showed inconsistent alterations during the temperature manipulation in the LBR. At LBR temperatures of 55 °C, a TRF, affiliated to the Methanosaeta genus, was identified. During the ongoing experiment, Methanosaeta disappeared from the biofilm within the AF, although the temperature of the AF, its pH, and its concentration of free ammonia remained constant. Above 65 °C, a decrease in intermediate production in the LBR and therefore also in the AF was observed. A reduced acetic acid concentration combined with the thermophilic temperature of the AF (55 °C) means favorable conditions for the syntrophic acetate oxidation and an advantage over the acetoclastic methanogenesis (Ahring 1995). Syntrophic acetate-oxidizing bacteria interact in cooperation with H2 scavengers such as hydrogenotrophic methanogens. In this study, Methanobacteriales, particularly Methanothermobacter, which conducts hydrogenotrophic methanogenesis (Wasserfallen et al. 2000), was prevalently detected throughout the experiment indicating such syntrophic interactions.

Interestingly, Methanosarcina was also prevalent, particularly at higher temperatures. Methanosarcina utilize acetate as well as CO2/H2 as precursors to methanogenesis. Due to the fact that the acetic acid concentration also alternated during the 21-day fermentation period at LBR temperatures above 65 °C, Methanosarcina may accomplish both methanogenic pathways, according to the apparent VFA supply.

In conclusion, the results of this study revealed that the microbial community structure in a two-phase biogas reactor is subject to substantial alterations during the increase in fermentation temperatures, which are presumably responsible for the decrease in the reactor’s performance. At temperatures above 65 °C, the bioaugmentation with compost proved to be effective in stabilizing the hydrolytic/acidogenic active community. However, this effect did not persist during the further temperature increase. Particularly at hyperthermophilic conditions above 65 °C, members of the Bacteroidales order became predominant in the hydrolysis of crop biomass. Therefore, it can be assumed that these microorganisms are acting as competitors to members of the Clostridiales order for carbohydrate degradation. The changes within the hydrolytic/acidogenic community might also be the reason for the alterations observed in the methanogenic population in the downstream anaerobic filter reactor. This is particularly true of the emergence of mixotrophic Methanosarcina sp. instead of strictly hydrogenotrophic methanogens, such as Methanothermobacter sp.

References

Ahring BK (1995) Methanogenesis in thermophilic biogas reactors. Antonie Van Leeuwenhoek 67:91–102. doi:10.1007/BF00872197

Ahring BK, Ibrahim AA, Mladenovska Z (2001) Effect of temperature increase from 55 to 68 °C on performance and microbial population dynamics of an anaerobic reactor treating cattle manure. Water Res 35:2446–2452. doi:10.1016/S0043-1354(00)00526-1

Anthonisen AC, Loehr RC, Prakasam TBS, Srinath EG (1976) Inhibition of nitrification by ammonia and nitrous acid. J Water Pollut Control Fed 48:835–852

Ashelford KE, Chuzhanova NA, Fry JC, Jones AJ, Weightman AJ (2005) At least 1 in 20 16S rRNA sequence records currently held in public repositories is estimated to contain substantial anomalies. Appl Environ Microbiol 71:7724–7736. doi:10.1128/AEM.71.12.7724-7736.2005

Ashelford KE, Chuzhanova NA, Fry JC, Jonas AJ, Weightman AJ (2006) New screening software shows that most recent large 16S rRNA gene clone libraries contain chimeras. Appl Environ Microbiol 72:5734–5741. doi:10.1128/AEM.00556-06

Bagi Z, Acs N, Balint B, Horvath L, Dobo K, Perei KR, Rakhely G, Kovacs KL (2007) Biotechnological intensification of biogas production. Appl Microbiol Biotechnol 76:473–482. doi:10.1007/s00253-007-1009-6

Buhr HO, Andrews JF (1977) The thermophilic anaerobic digestion process. Water Res 11:129–143. doi:10.1016/0043-1354(77)90118-X

Cai J, Wang Y, Liu D, Zeng Y, Xue Y, Ma Y, Feng Y (2007) Fervidobacterium changbaicum sp. nov., a novel thermophilic anaerobic bacterium isolated from a hot spring of the Changbai Mountains, China. Int J Syst Evol Microbiol 57:2333–2336. doi:10.1099/ijs.0.64758-0

Cirne DG, Lehtomäki A, Björnsson L, Blackall LL (2007) Hydrolysis and microbial community analyses in two-stage anaerobic digestion of energy crops. J Appl Microbiol 103:516–527. doi:10.1111/j.1365-2672.2006.03270.x

Clarke KR (1993) Nonparametric multivariate analyses of changes in community structure. Aust Ecol 18:117–143. doi:10.1111/j.1442-9993.1993.tb00438.x

Colwell RK (2006) EstimateS: statistical estimation of species richness and shared species from samples. Version 8.0.0. User’s Guide and application. http://purl.oclc.org/estimates. Accessed 4 Jan 2012

Culman SW, Bukowski R, Gauch HG, Cadillo-Quiroz H, Buckley DH (2009) Software open access T-REX: software for the processing and analysis of T-RFLP data. BMC Bioinformatics 10:171. doi:10.1186/1471-2105-10-171

Dahlenborg M, Borch E, Radström P (2001) Development of a combined selection and enrichment PCR procedure for Clostridium botulinum types B, E, and F and its use to determine prevalence in fecal samples from slaughtered pigs. Appl Environ Microbiol 67:4781–4788. doi:10.1128/AEM.67.10.4781-4788.2001

Dahlenborg M, Borch E, Radström P (2003) Prevalence of Clostridium botulinum types B, E and F in faecal samples from Swedish cattle. Int J Food Microbiol 82:105–110. doi:10.1016/S0168-1605(02)00255-6

Demirer GN, Chen S (2005) Two-phase anaerobic digestion of unscreened dairy manure. Process Biochem 40:3542–3549. doi:10.1016/j.procbio.2005.03.062

Després VR, Nowoisky JF, Klose M, Conrad R, Andreae MO, Pöschl U (2007) Characterization of primary biogenic aerosol particles in urban, rural, and high-alpine air by DNA sequence and restriction fragment analysis of ribosomal RNA genes. Biogeosciences 4:1127–1141

Dugba PN, Zhang RH (1999) Treatment of dairy wastewater with two-stage anaerobic sequencing batch reactor systems—thermophilic versus mesophilic operations. Bioresour Technol 68:225–233. doi:10.1016/S0960-8524(98)00156-4

Dunbar J, Ticknor LO, Kuske CR (2001) Phylogenetic specificity and reproducibility and new method for analysis of terminal restriction fragment profiles of 16S rRNA genes from bacterial communities. Appl Environ Microbiol 67:190–197. doi:10.1128/AEM.67.1.190-197.2001

Fernandez A, Huang SY, Seston S, Xing J, Hickey R, Criddle C, Tiedje J (1999) How stable is stable? Function versus community composition. Appl Environ Microbiol 65:3697–3704

Goodfellow M, Kämpfer P, Chun J, De Vos P, Rainey FA, Whitman WB (2010) Volume four: the Bacteroidetes, Spirochaetes, Tenericutes (Mollicutes), Acidobacteria, Fibrobacteres, Fusobacteria, Dictyoglomi, Gemmatimonadetes, Lentisphaerae, Verrucomicrobia, Chlamydiae, and Planctomycetes. In: Krieg NR, Staley JT, Brown DR, Hedlund BP, Paster BJ, Ward NL, Ludwig W, Whitman WB (eds) Bergey’s manual® of systematic bacteriology. Springer, New York, pp 1–931

Großkopf R, Janssen PH, Liesack W (1998) Diversity and structure of the methanogenic community in anoxic rice paddy soil microcosms as examined by cultivation and direct 16S rRNA gene sequence retrieval. Appl Environ Microbiol 64:960–969

Kitts CL (2001) Terminal restriction fragment patterns: a tool for comparing microbial communities and assessing community dynamics. Curr Issues Intest Microbiol 2:17–25

Klocke M, Nettmann E, Bergmann I, Mundt K, Souidi K, Mumme J, Linke B (2008) Characterization of the methanogenic Archaea within two-phase biogas reactor systems operated with plant biomass. Syst Appl Microbiol 31:190–205. doi:10.1016/j.syapm.2008.02.003

Kongjan P, Thong S, Angelidaki I (2011) Performance and microbial community analysis of two-stage process with extreme thermophilic hydrogen and thermophilic methane production from hydrolysate in UASB reactors. Bioresour Technol 102:4028–4035. doi:10.1016/j.biortech.2010.12.009

Krakat N, Westphal A, Satke K, Schmidt S, Scherer P (2010) The microcosm of a biogas fermenter: comparison of moderate hyperthermophilic (60°C) with thermophilic (55°C) conditions. Eng Life Sci 10:520–527. doi:10.1002/elsc.201000064

Lane DJ (1991) 16S/23S rRNA sequencing. In: Stackebrandt E, Goodfellow M (eds) Nucleic acid techniques in bacterial systematics. Wiley, New York, pp 115–147

Lepistö R, Rintala J (1996) Conversion of volatile fatty acids in an extreme thermophilic (76–80°C) upflow anaerobic sludge-blanket reactor. Bioresour Technol 56:221–227

Lueders T, Friedrich M (2000) Archaeal population dynamics during sequential reduction processes in rice field soil. Appl Environ Microbiol 66:2732–2742. doi:10.1128/AEM.66.7.2732-2742.2000

Nettmann E, Bergmann I, Pramschüfer S, Mundt K, Plogsties V, Herrmann C, Klocke M (2010) Polyphasic analyses of methanogenic archaeal communities in agricultural biogas plants. Appl Environ Microbiol 76:2540–2548. doi:10.1128/AEM.01423-09

Neumann L, Scherer P (2011) Impact of bioaugmentation by compost on the performance and ecology of an anaerobic digester fed with energy crops. Bioresour Technol 102:2931–2935. doi:10.1016/j.biortech.2010.11.068

Nielsen HB, Mladenovska Z, Ahring BK (2007) Bioaugmentation of a two-stage thermophilic (68°C/55°C) anaerobic digestion concept for improvement of the methane yield from cattle manure. Biotechnol Bioeng 97:1638–1643. doi:10.1002/bit.21342

Nozhevnikova AN, Kotsyurbenko OR, Parshina SN (1999) Anaerobic manure treatment under extreme temperature conditions. Water Sci Technol 40:215–221. doi:10.1016/S0273-1223(99)00387-X

Patel BKC, Morgan HW, Daniel RM (1985) Fervidobacterium nodosum gen. nov. and spec. nov., a new chemoorganotrophic, caldoactive, anaerobic bacterium. Arch Microbiol 141:63–69

Rademacher A, Zakrzewski M, Schlüter A, Schönberg M, Szczepanowski R, Goesmann A, Pühler A, Klocke M (2012) Characterization of microbial biofilms in a thermophilic biogas system by high-throughput metagenome sequencing. FEMS Microbiol Ecol 79:785–799. doi:10.1111/j.1574-6941.2011.01265.x

Raizada N (2004) In: Berichte aus Wassergüte- und Abfallwirtschaft (ed) Application of molecular-biological method for optimization of anaerobic reactors. Technische Universität München, Garching

Schönberg M, Linke B (2012) The influence of the temperature regime on the formation of methane in a two-phase anaerobic digestion process. Eng Life Sci 12:1–8. doi:10.1002/elsc.201100062

Schutte UME, Abdo Z, Bent SJ, Shyu C, Williams CJ, Pierson JD, Forney LJ (2008) Advances in the use of terminal restriction fragment length polymorphism (T-RFLP) analysis of 16S rRNA genes to characterize microbial communities. Appl Microbiol Biotechnol 80:365–380. doi:10.1007/s00253-008-1565-4

Sipos R, Szekely AJ, Palatinszky M, Revesz S, Marialigeti K, Nikolausz M (2007) Effect of primer mismatch, annealing temperature and PCR cycle number on 16S rRNA gene-targetting bacterial community analysis. FEMS Microbiol Ecol 60:341–350. doi:10.1111/j.1574-6941.2007.00283.x

Tamura K, Peterson D, Peterson N, Stecher G, Nei M, Kumar S (2011) MEGA5: molecular evolutionary genetics analysis using maximum likelihood, evolutionary distance, and maximum parsimony methods. Mol Biol Evol 28:2731–2739. doi:10.1093/molbev/msr121

Wang H, Vuorela M, Keranen AL, Lehtinen TM, Lensu A, Lehtomaki A, Rintala J (2010) Development of microbial populations in the anaerobic hydrolysis of grass silage for methane production. FEMS Microbiol Ecol 72:496–506. doi:10.1111/j.1574-6941.2010.00850.x

Ward AJ, Hobbs PJ, Holliman PJ, Jones DL (2008) Optimisation of the anaerobic digestion of agricultural resources. Bioresour Technol 99:7928–7940. doi:10.1016/j.biortech.2008.02.044

Wasserfallen A, Nolling J, Pfister P, Reeve J, de Macario EC (2000) Phylogenetic analysis of 18 thermophilic Methanobacterium isolates supports the proposals to create a new genus, Methanothermobacter gen. nov., and to reclassify several isolates in three species, Methanothermobacter thermautotrophicus comb. nov., Methanothermobacter wolfeii comb. nov., and Methanothermobacter marburgensis sp. nov. Int J Syst Evol Microbiol 50:43–53

Weisburg WG, Barns SM, Pelletier DA, Lane DJ (1991) 16S ribosomal DNA amplification for phylogenetic study. J Bacteriol 173:697–703

Wu W-M, Thiele JH, Jain MK, Zeikus JG (1993) Metabolic properties and kinetics of methanogenic granules. Appl Microbiol Biotechnol 39:804–811. doi:10.1007/BF00164470

Acknowledgments

Financial support for A. Rademacher and M. Schönberg was provided by the Federal Ministry of Education and Research (BMBF) through Project Management Jülich (PTJ, grant number 03SF0349C). The authors thank M. Jäkel, C. Jost, M. Felgentreu, C. Krumrei, J. Brunner, and K. Mundt for their valuable technical support. Dr. A. Ulrich, Leibniz Center for Agricultural Landscape Research (ZALF), is gratefully acknowledged for his valuable contributions to the discussion concerning TRFLP analysis and data interpretation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rademacher, A., Nolte, C., Schönberg, M. et al. Temperature increases from 55 to 75 °C in a two-phase biogas reactor result in fundamental alterations within the bacterial and archaeal community structure. Appl Microbiol Biotechnol 96, 565–576 (2012). https://doi.org/10.1007/s00253-012-4348-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-012-4348-x