Abstract

Poly(hydroxyalkanoates) (PHAs) constitute biodegradable polyesters and are considered among the most promising candidates to replace common petrochemical plastics in various applications. To date, all commercial processes for PHA production employ microbial discontinuous fed-batch fermentations. These processes feature drawbacks such as varying product quality and the inevitable periods of downtime for preparation and post-treatment of the bioreactor equipment. An unprecedented approach to PHA production was chosen in the presented work using a multistage system consisting of five continuous stirred tank reactors in series (5-SCR), which can be considered as a process engineering substitute of a continuous tubular plug flow reactor. The first stage of the reactor cascade is the site of balanced bacterial growth; thereafter, the fermentation broth is continuously fed from the first into the subsequent reactors, where PHA accumulation takes place under nitrogen-limiting conditions. Cupriavidus necator was used as production strain. The focus of the experimental work was devoted to the development of a PHA production process characterized by high productivity and high intracellular polymer content. The results of the experimental work with the reactor cascade demonstrated its potential in terms of volumetric and specific productivity (1.85 g L−1 h−1 and 0.100 g g−1 h−1, respectively), polymer content (77%, w/w) and polymer properties (M w = 665 kg/mol, PDI = 2.6). Thus, implementing the technology for 5-SCR production of PHB results in an economically viable process. The study compares the outcome of the work with literature data from continuous two-stage PHA production and industrial PHA production in fed-batch mode.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

General

Nowadays, bio-based and biodegradable polymers are considered to be among the top alternatives to petrochemical synthetics. One family of these materials, which is under consideration for production on a large industrial scale, is represented by poly(hydroxyalkanoates) (PHAs). They are a class of aliphatic microbial polyoxoesters naturally synthesized by a wide range of archaea and eubacterial genera as energy and carbon reserve materials. Among naturally occurring PHAs, short-chain length PHAs (scl-PHA; building blocks harbouring three to five carbon atoms) and medium-chain length PHAs (mcl-PHA; building blocks harbouring 6–14 carbon atoms) have to be distinguished. Like their petrochemical counterparts, scl-PHA are thermoplastic polymers, moldable and water-insoluble (Steinbüchel and Valentin 1995; Steinbüchel and Füchtenbusch 1998). The most common and best scrutinized PHA is poly([R]-3-hydroxybutyrate) (PHB). This compound is known as a rather brittle, highly crystalline and high melting aliphatic polyester with properties similar to many industrial polyolefins, especially with specifics resembling to poly(propylene) (PP). Unlike polyolefins, however, PHAs can be synthesized from renewable feedstocks including agroindustrial wastes by methods of industrial (white) biotechnology. They can be converted to plastic items which, at the end of their service life, can either undergo rapid and complete biodegradation by microorganisms in solid and aqueous media or can be taken as a source for the production of valuable chiral building blocks (3-hydroxy acids) by chemical or enzymatic treatments (Anderson and Dawes 1990; Braunegg et al. 1998; Lee and Lee 2003; Reddy et al. 2003; Khanna and Srivastava 2005; Ren et al. 2005).

In order to compare the environmental performance of biopolymers with petrochemical plastics, the tools of life cycle assessment (LCA) can be applied, which is a standardized method to quantify environmental impacts (Patel et al. 2003). Several studies have been carried out recently which demonstrated that the production of PHAs was more beneficial in a full cradle-to-gate LCA than the production of their petrochemical analogues poly(ethylene) and PP (Akiyama et al. 2003; Harding et al. 2007; Pietrini et al. 2007). Therefore, PHAs are superior in terms of sustainability and environmental protection. In the future, PHA production could be integrated in so-called biorefinery processes and/or be synthesized from intermediate products from such biorefineries. These productions constitute systems similar to petroleum refineries, required to produce fuels and useful chemicals from biomass, encompassing the conversion of all material side streams (Fernando et al. 2006).

However, PHAs are less superior in terms of production costs and certain material properties compared to petrochemical plastics (Hänggi 1995; Sudesh and Iwata 2008). Numerous articles report the factors that are decisive for industrial PHA production, such as raw materials, process design and downstream processing (Chen 2009; Choi and Lee 1999; Koller et al. 2005, 2010a, 2010b, 2010c).

Different possibilities are known for biotechnological PHA production; among them, the continuous mode is the one that should enable high productivities and constant product quality (Zinn et al. 2001; Sun et al. 2007). Although not yet widely applied in biotechnological industrial praxis, continuous culture fermentation strategy has a huge potential. In general, multistage systems provide different cultivation conditions in each stage and thereby approximate the characteristics of a continuous plug flow tubular reactor (CPFR). It is considered that a cascade with at least five reactors in series can be used as a process engineering substitute for a CPFR (Moser 1988; Braunegg et al. 1995). Consequently, this engineering aspect was the background on the development of a multistage system of five continuous stirred tank reactors (CSTRs) in series (5-SCR) in the presented work.

Materials and methods

Microorganism and cultivation conditions

For inoculum preparation, Cupriavidus necator DSM 545 (formerly known as Wautersia eutropha, Ralstonia eutropha, Alcaligenes eutrophus or Hydrogenomonas eutropha; Vandamme and Coenye 2004) was obtained from Deutsche Sammlung von Mikroorganismen und Zellkulturen GmbH, Germany. The strain was cultivated in mineral medium according to Küng (1982), containing (g/L): Na2HPO4⋅2H2O, 4.5; KH2PO4, 1.5; (NH4)2SO4, 1.5; MgSO4⋅7H2O, 0.2; CaCl2⋅2H2O, 0.02; NH4Fe(III)Citrate, 0.05; glucose, 10; and 1 mL/L of trace element stock solution (0.1 g/L ZnSO4⋅7H2O, 0.3 g/L H3BO3, 0.2 g/L CoCl2⋅6H2O, 6 mg/L CuSO4, 20 mg/L NiCl2⋅6H2O, 30 mg/L Na2MoO4⋅2H2O and 25 mg/L MnCl2⋅2H2O). The first seed culture was prepared in 300-mL shaking flasks containing 100 mL of the medium and incubated in a rotary shaker at 140 rpm and 30°C for 40 h. The cultures were then transferred to 1,000-mL shaking flasks containing 400 mL of the medium, incubated under the same conditions as the first seed culture for 24 h and used to inoculate the bioreactor.

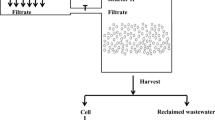

The experiment was designed as a five-stream, five-stage system, with each reactor being provided with a feed stream, enabling control over each individual stage of the cascade system. The fermentation was carried out in Labfors 3 bioreactors (Infors AG, Bottmingen, Switzerland). The five-stage system consisted of one 7.5-L and four 3.6-L vessels, connected in series (Fig. 1). For the start-up of the 5-SCR fermentation, biomass was grown in batch mode in the first reactor until the desired concentration was reached. The fermentation broth was then distributed to the subsequent reactors and the continuous mode of operation was initiated. The batch growth medium consisted of (g/L): Na2HPO4⋅2H2O, 3; KH2PO4, 1; (NH4)2SO4, 8; CaCl2⋅2H2O, 0.02; MgSO4⋅7H2O, 0.5; NH4Fe(III)citrate, 0.05; glucose, 60; sulfuric acid, 1 mL/L; and trace element solution, 3 mL/L. The composition of the balanced growth feed medium was (g/L): KH2PO4, 4.3; NaCl, 0.8; MgSO4⋅7H2O, 0.7; CaCl2⋅2H2O, 0.02; NH4Fe(III)Citrate, 0.05; glucose, 67; sulfuric acid, 0.2 mL/L; and trace element solution, 3 mL/L. The production feeds added to reactors 2–5 each contained 500 g/L of glucose without the other media components.

Schematic flow sheet of the adopted five-stage prototype plant for continuous PHA production. F1, F3, F5, F7, F9 Feed streams for supply of nutritional medium to the bioreactors R1, R2, R3, R4 and R5, respectively. F2, F4, F6, F8 Continuous transfer of fermentation broth to the subsequent vessels. F10 Outlet stream containing the final product. R1–R5 Five CSTRs. Microbial cell growth occurs in R1, whereas in R2–R5, PHA accumulation takes place, provoked by nitrogen-limited conditions

For the fermentation start-up, the biomass for all five bioreactors was cultivated in batch mode in the first vessel and subsequently distributed in equal amounts to the remaining cascade vessels in order to start the continuous mode. This simple start-up strategy was chosen for its simplicity and low operating requirements. One litre of the C. necator culture was used to inoculate the first reactor containing 4 L of nutrient medium, with dissolved medium components for 5 L, hence providing 1 L of fermentation broth per vessel at the end of the batch mode. The cultivation temperature was 30°C and the pH value was maintained at 6.8 by automatic addition of 25% ammonia solution (alkali for the first reactor and nitrogen source for microbial growth in this reactor), 10% sodium hydroxide (alkali for other reactors) or 10% sulfuric acid solution. Dissolved oxygen concentration was maintained at 40% of air saturation in the first reactor and at 20% in the subsequent reactors by automatic adjustment of the agitation and aeration rates. To avoid heavy foam formation, the antifoam agent Struktol J700 was added automatically when necessary.

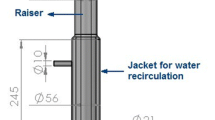

The medium from the storage tank (steam-sterilized 120-L agitator vessel with a 24-L jacket; Andritz, Graz, Austria, serial no. 256, year of manufacture 1989) was periodically filled into a 10-L bottle from which it was continuously pumped in the first reactor with a peristaltic pump (Ismatec ISM829B). The volume of each stage was kept constant by fitting an immersion tube in the vessel to a desired height and transferring the fermentation broth between the reactors through silicone tubes with peristaltic pumps (Watson Marlow 101U). In order to determine and control the actual feed rates, every feed bottle was placed on a digital balance (Kern ILT30K0.2DM). Figure 1 provides the schematic flow sheet of the experimental setup.

Optical density

Optical density was measured for rapid assessment of the cell growth. The measurements were carried out at a wavelength of 420 nm using Spectronic® Genesys™ 2PC spectrophotometer.

Carbohydrate determination

Glucose concentration was determined by liquid chromatography using an Aminex HPX-87C column and a Shimadzu HPLC system consisting of LC-20AD pump, SIL-20AC autosampler, CTO-20AC column oven and RID-10A refractive index detector. Water was used as the mobile phase and the analysis programme was isocratic with a flow of 0.6 mL/min, column temperature of 75°C and detector temperature of 50°C.

Nitrogen source (NH +4 ) determination

NH +4 was volatilized from the cell-free supernatant by adjusting the pH value to a strong alkaline pH value by the addition of ionic strength buffer solution containing 5 M NaOH, 0.05 M Na2-EDTA, 10% MeOH and a colour indicator. Finally, the created NH3 was measured electrochemically as determined by an Orion ion-selective electrode. As reference, standard solutions of ammonium sulphate at the following concentrations were used: 30, 100, 300, 1,000 and 3,000 ppm.

CDM determination

A gravimetrical method was used to determine the biomass concentration expressed as cell dry mass (CDM) in fermentation samples. Five millilitres of the culture broth was centrifuged in pre-weighed glass screw-cap tubes for 20 min at 10°C and 4,000 rpm in a Heraeus Megafuge 1.0 R refrigerated centrifuge. The supernatant was decanted and used for substrate analysis. The cell pellets were washed with distilled water, re-centrifuged, frozen and lyophilized to a constant mass. CDM was determined as the weight difference between the tubes containing cell pellets and empty tubes. The determination was done in duplicate. The lyophilized pellets were subsequently used for the determination of PHB content as described below.

PHB determination

PHB was determined by acidic methanolysis of lyophilized biomass and subsequent gas chromatography (GC) according to Braunegg et al. (1978). Pure PHB (ICI, London, UK) was used as the reference material. The gas chromatographic analysis was performed with a 6850 Network GC System (Agilent Technologies) equipped with a 25-m × 0.32 × 0.52-μm HP5 capillary column and a flame ionization detector (FID). Helium (Linde, purity = 4.6) was used as the carrier gas with a split ratio of 1:10, hydrogen (Linde, purity = 5.0) and synthetic air (Linde, purity = “free of hydrocarbons”) as detector gases and nitrogen (Linde, purity = 5.0) as auxiliary gas. The temperature programme was the following: initial temperature—50°C; rate 1—20°C/min; final temperature 1—200°C; final time 1—0 min; final temperature 2—300°C; final time 2—5 min. Determination was done in duplicate.

PHB content in CDM

The content of PHB in CDM (%PHB) was calculated on the basis of the GC results according to the subsequent Eq. 1:

PHB isolation

Samples of the fermentation broth were centrifuged for 30 min at 4°C and 6,000 rpm in a Sorvall® RC-5B Refrigerated Superspeed centrifuge (DuPont Instruments); the obtained cell pellets were frozen and lyophilized.

The dry biomass was stirred with the tenfold quantity (mass) of ethanol for 1 day at ambient temperature in order to remove the lipid components. Decreased cell mass was separated from the ethanol solution of the extracted lipids by vacuum filtration; subsequently, ethanol was recycled via vacuum-assisted distillation using a rotary evaporator. The remaining cell mass was air-dried.

To extract PHB, the cell mass was stirred with the 30-fold quantity of chloroform for 1 day under light protection. The solution of PHA in chloroform was separated from the residual cell mass via vacuum-assisted filtration; afterwards, the major part of the chloroform was removed via vacuum-assisted distillation using a rotary evaporator until a viscous solution was obtained (concentration of PHB in viscous solution approximately 40 g/L). Thereof, PHB was precipitated by adding the tenfold amount of ice-cooled ethanol to the chloroform solution, separated by vacuum filtration and left at ambient temperature in a fume hood for the remaining solvent to evaporate, resulting in highly pure PHB samples.

Molecular weight determination and thermal analysis

Molecular weight measurements were performed by size exclusion chromatography (SEC) in chloroform at 25°C using a Jasco PU-1580 high-performance liquid chromatograph (HPLC) connected to a Jasco 830-RI detector and equipped with two PLgel 5-μm mixed-C columns, a Perkin Elmer LC-75 UV detector and a Jasco 830 RI refraction index detector. As eluent, amylene-stabilized chloroform was used at a 1.0-mL/min flow rate. Twelve monodisperse polystyrene standards with molecular weights from 500 to 1,400.000 g/mol were used for calibration. Samples were prepared at concentrations of approximately 0.5% (w/v).

Thermal analysis was performed using a Mettler TA 4000 System instrument consisting of a differential scanning calorimeter (DSC-30) and a STARe software. For the determination of the thermodynamic characteristics, DSC samples of 5–10 mg were weighed in 40-μL aluminium pans; an empty pan was used as reference. The DSC temperature calibration was performed using three standard materials (In, Pb and Zn); the energy calibration was done by an indium standard. Measurements were carried out under an 80-mL/min nitrogen flow rate according to the following protocol: first and second heating from −20°C to 200°C at 10°C min−1 and first cooling (quenching after the first heating) from 200 to −20°C at 100°C min−1 with 3 min of isotherm to stabilize the lowest temperature. The thermal parameters of the isolated PHAs were taken from the DSC trace recorded on the second heating. The degree of crystallinity (X c) was determined by considering the value of the melting enthalpy of 146 J/g for the 100% crystalline PHB (Barham et al. 1984).

NMR Analysis

NMR spectra were recorded on a Varian Gemini 200 spectrometer using a Sparc 4 (Sun) console and VNMR 6.1B software. Spectra were processed using MacFID 1D 5.3 (Tecmag) software. NMR spectra were recorded on 5–10% (w/v) solutions, in deuterated solvents, at 25°C, with tetramethylsilane as internal standard. 1H NMR spectra were recorded at 200 MHz using the following spectral conditions: 3-kHz spectral width, 308 impulse, 2-s acquisition time, 16 transients. 13C NMR spectra were recorded at 50.15 MHz with totally decoupled protons. Spectral conditions were as follows: 13.5-kHz spectral width, 60–708 impulse, 0.8-s acquisition time, 1-s delay, 16,000–100,000 transients. For the 13C NMR DEPT experiments, the following further conditions were adopted: 143-Hz J¼, 2-s delay.

Results

The initial biomass concentration in the first bioreactor was 1.6 g/L, and it increased to 27 g/L after 23 h of batch cultivation (Fig. 2). At that time, the fermentation broth was distributed to the other four cascade reactors (1 L each) and the continuous mode of system operation was initiated by starting the five feed streams as well as the outflow pump. Feeding rates, reactor working volumes, dilution rates and residence times are listed in Table 1. The working volume in vessel R5 was kept higher in comparison to the previous ones in order to increase the substrate conversion, i.e. to minimize the residual glucose concentration in the cascade outflow.

CDM did not change significantly in the first reactor after the start of the continuous mode, levelling off at around 26 g/L (Fig. 2). However, at the beginning of the continuous cultivation, PHB granules constituted a significant part of the total biomass. The PHB concentration was 6.6 g/L after 23 h (Fig. 3), corresponding to 24% (w/w) of the entire cellular biomass. During the first 35 h of continuous operation, the PHB content dropped to very low values of <2% due to the actual carbon limitation, but the total biomass concentration in the first stage remained constant as a consequence of increased catalytically active biomass.

The first reactor reached steady state after 68 h with an average biomass concentration of 26 g/L and a PHB content of 4% (w/w). The PHB content was <2% for most of the fermentation time.

With a time delay, the other reactors reached steady state as well, R2 after 68 h, R3 after 98 h, R4 after 116 h and R5 after 139 h. Biomass concentration and PHB contents in the production vessels levelled off at 42 g/L and 37% (R2), 59 g/L and 60% (R3), 71 g/L and 72% (R4), and 81 g/L and 77% (R5).

Average values of CDM and PHB between 139 and 261 h were used to calculate the values for%PHB, Q x, Q P and q p; the results are shown in Table 2. CDM of 81 g/L and PHB concentration of 63 g/L were achieved in the cascade outflow, which corresponds to an exceptionally high PHB content of 77%. Overall volumetric productivities for biomass and PHB were 2.39 and 1.85 g L−1 h−1, respectively; the specific PHB production rate, q P, amounted to 0.100 g g−1 h−1. Among the four production vessels (R2–R5), the third reactor displayed the highest PHB volumetric productivity of 3.27 g L−1 h−1, which decreased thereafter to 1.50 g L−1 h−1 in the fifth reactor. The specific PHB production rate showed the same trend, having the highest value of 0.139 g g−1 h−1 in the third reactor. Biomass and PHB yields from glucose were 0.37 and 0.29 g/g for the entire process, respectively. The actual concentration of nitrogen source was 0 in all stages; the concentration of glucose amounted at 2.0 g/L in the cascade outflow. The concentration of residual biomass (RB) dropped from 25 g/L (R1) to 19 g/L (R5) due to cell death because of nitrogen deficiency (see Table 2).

A polymer sample was extracted from the lyophilized biomass from the cascade outflow after a 250-h incubation for the assessment of chemical structure by NMR, determination of molecular weight by SEC and thermal analysis by DSC. The characterization of the PHA sample by 1H NMR and 13C NMR clearly indicated the PHA structure as attributable to the homopolymer PHB. The average molecular weight (M w) of PHB from R5 was 665 kg/mol with a polydispersity index of 2.6. Considering the fact that other bio-based polymers like polylactic acid have much lower molecular masses and can be used for melt processing, the value of M w obtained in the work at hand is high enough for the classical melt processing. This means that PHB presents a very narrow temperature processing window (extrusion, 155-170°C; injection moulding, 160–175°C) due to the ease of its thermal degradation near melting point (Rossell et al. 2006; Nascimento et al. 2009) and slow crystallization process. Consequently, this polymer needs to be additivated when processed. However, the new value of PHB M w after pelletization presents viscosity characteristics that permit its processing by melting (Falcone 2004). Besides, the values for melting temperature, glass transition temperature and degree of crystallinity were 178°C, 2.9°C and 68%, respectively, which are in agreement with typical values for the homopolymer PHB found in the literature (Anderson and Dawes 1990).

In accordance with this analysis, the quality of the produced PHB appears to be suitable for applications in polymer processing by means of melt blow extrusion technology. Because of the high melting points, the investigated polymers might undergo thermal degradation during melt processing due to pyrolysis of the aliphatic secondary esters of the repeating units. This problem can be overcome by co-feeding of propionic acid (Taniguchi et al. 2003) or valeric acid (Doi et al. 1990) during the biosynthesis. These compounds act as precursors for the formation of 3-hydroxyvalerate (3HV) units that significantly lower the product’s melting point. The resulting material should be less susceptible to decomposition during processing from the melt (Doi et al. 1990).

The most complex experimental setup was applied for the presented cascade fermentation, with each reactor being provided with an extra feed stream. This five-stream, five-stage setup for the experiments enhanced the stability of the system and enabled a better control over each individual stage. With such experimental design, the feed rates and dilution rates can be varied independently and adapted to the physiological state of the microorganism in each individual stage of the reactor cascade. Hence, only the necessary amount of substrate is added into each stage and the amount of the non-converted substrate is kept at a minimum level (data not shown). As a result, high degrees of substrate conversion and an exceptionally high productivity of the system, especially considering the specific productivity for PHB, could be achieved.

Steady-state biomass concentration of 26 g/L with a PHB content of 4% was produced in the first reactor at a dilution rate of 0.139 h−1. Biomass and product concentrations in the cascade outflow were 81 and 63 g/L, respectively, resulting in a high PHB content of 77%. Volumetric productivities of 2.39 g L−1 h−1 for biomass and 1.85 g L−1 h−1 for PHB were obtained. The specific PHB production rate amounted to 0.100 g g−1 h−1, which is an exceedingly high value for such a high-density continuous fermentation. Specific PHB production rates obtained with C. necator are usually in the range between 0.032 g g−1 h−1 for industrial fed-batch fermentations (Choi and Lee 1999; Nonato et al. 2001) and 0.065 g g−1 h−1 for optimized laboratory-scale experiments which included the use of pure oxygen for aeration of the bioreactor (Ryu et al. 1997) or 0.056 g g−1 h−1 using air for oxygen supply on laboratory scale (Kim et al. 1994). This means that the rate of polymer synthesis per unit of catalytically active biomass obtained in the reactor cascade was threefold that of a comparable industrial process and significantly higher than in optimized laboratory-scale fed-batch reactor (FBR) production. The polymer characterization by NMR and thermal analysis (DSC) of the PHB samples displayed typical PHB properties (Doi 1990).

Discussion

Original studies on continuous PHA production were published by Ramsay et al. (1990). One-stage chemostat at a dilution rate of 0.15 h−1 with C. necator grown on glucose produced 5 g/L of biomass with a PHB content of 33%. Similar results were obtained with Alcaligenes latus grown on sucrose at the same dilution rate of 0.15 h−1; biomass concentration and PHB content were 4 g/L and 40%, respectively. When grown on glucose and various amounts of propionic acid of up to 5 g/L, A. latus produced P(3HB-co-3HV) with the content of 3HV comonomer in the PHA of up to 20%. Substitution of propionic acid by valeric acid resulted in higher 3HV contents in the copolymer. The uptake of sucrose was inhibited when high concentrations of propionic acid were applied (8.5 g/L). In a two-stage chemostat, the excess glucose from the first reactor was metabolized in the second vessel, and a copolymer with 11% of 3HV was obtained (Ramsay et al. 1990).

Several other studies were conducted to produce the copolymer P(3HB-co-3HV) with C. necator in one-stage continuous cultures. P(3HB-co-3HV) was produced from fructose and propionic acid with a maximum PHA productivity of 0.31 g L−1 h−1, whilst the 3HV content in copolymers ranged from 11% to 79%. It turned out that the number average molecular weight (M n) increased with the dilution rate (Koyama and Doi 1995). Employing sodium propionate as the precursor for 3HV, the continuous culture systems did not reach significant steady states when its concentration exceeded 7 g/L (Yu et al. 2005). Zinn et al. (2003) grew C. necator in a chemostat culture under stoichiometric limitation of carbon (varying mixtures of butyric and valeric acid) by keeping constant the ratio of nitrogen to carbon source in the feed stream. The isolated PHAs showed high molecular weights at low polydispersities. In addition, the authors found out that the composition of the produced copolyesters was in accordance with a nonlinear function of the substrate mixtures.

All single-stage experiments with C. necator resulted in rather low concentrations of active biomass and low intracellular PHA contents. These are expected outcomes since PHA production by C. necator occurs in a non-growth-associated mode. This means that the phase of formation of active biomass under balanced nutritional conditions can be clearly distinguished from the subsequent phase of predominant diverting of the intracellular carbon flux towards PHA formation (Steinbüchel and Schlegel 1991). For such organisms, optimal conditions for both cell growth and PHA accumulation cannot be maintained in a single-stage system. Therefore, a multistage system should be more suitable for PHA production, and in fact, the results from a two-stage chemostat were superior to those from one-stage experiments. Du et al. used two CSTRs in series, with a volume of 1.2 L for the first stage and 1.4 L for the second one. The first stage produced mainly cell mass, resulting in the maximal CDM of 27.1 g/L at 0.21 h−1 of dilution rate. The conditions in the second stage were favourable for the PHB production, giving the maximal CDM of 47.6 g/L at 0.14 h−1 of dilution rate. The maximal PHB productivity reached 1.43 g L−1 h−1 at a dilution rate of 0.12 h−1, but with relatively low PHB content at around 48%. Therefore, the authors obtained fairly good results for CDM, PHB concentration and productivity, but not simultaneously (Du et al. 2001a, b).

Few other studies in a two-stage continuous system were conducted with other microorganisms like the production of P(3HB-co-4HB) by Delftia acidovorans from acetic acid and γ-butyrolactone (Mothes and Ackermann 2005) or mcl-PHA production by Pseudomonas oleovorans from alkanes (Jung et al. 2001).

As discussed above, the only study published so far on multistage continuous production of PHAs with C. necator was based on experiments with only two reactors in series (2-SCR; Du et al. 2001a, b). Glucose was used as the carbon source and PHB accumulation was triggered by nitrogen limitation. The study concentrated on the effects of different dilution rates on biomass and PHB concentrations and corresponding productivities. The results of that study are directly compared, as reported in Table 3, with the outcome of the presented 5-SCR.

It can be seen that the biomass and PHB concentrations obtained from the five-stage prototype assembly at least are double those reported in the literature reference. The comparison of the overall volumetric productivities for PHB shows an advantage of one third in favour of the five-stage process. Furthermore, the cascade experiment was carried out at a higher dilution rate of 0.139 h−1 compared with 0.075 h−1 of the two-stage process, which means that higher throughput of the product could be achieved with five reactors in series. Hence, from this comparison, it is clear that the results obtained from the 5-SCR are superior in all categories over those reported in the literature for the two-stage process.

In order to accurately estimate the potential of the 5-SCR cascade for industrial PHA production, the system has to be compared with other processes as well. PHAs are usually produced in fermentations in FBRs. It is interesting to compare the PHA production process employing the five-stage reactor cascade with an already existing commercial process. An excellent example is the integrated process for the production of sugar, ethanol and PHB in Brazilian sugar mills. After 45–50 h of FBR fermentation, also with C. necator as production organism, 120–150 g/L of biomass with a PHB content of 65–70% is obtained (Nonato et al. 2001; Koller et al. 2010a). Furthermore, the authors report a yield coefficient of PHB from inverted sugar of 0.32 g/g and volumetric productivity for PHB of 1.44 g L−1 h−1. On laboratory scale, the highest volumetric productivity for PHB using the same organism was reported with 2.42 g L−1 h−1 (Kim et al. 1994). A comparison between the productivity parameters of the processes based on FBRs, the 2-SCR process according to Du et al. (2001a, b) and the 5-SCR process are collected in Table 3.

From this comparison, it is visible that although higher biomass concentrations have been achieved in the FBR processes, the 5-SCR showed excellent performance in terms of high polymer content and, what is most important, high productivity. The high PHB content of 77% (w/w) that was achieved with the 5-SCR would have a considerably positive effect on the polymer recovery costs and consequently on the overall production costs of PHB. These recovery cost could be abated mainly due to the use of a smaller amount of digesting agents for separating PHAs from the residual biomass with consequent abatement of the relevant waste disposal.

The most important result that was accomplished with the 5-SCR was the substantial increase in volumetric productivity for PHB and its specific production rate compared with the industrial FBR. Whilst the overall volumetric productivity for PHB was 1.44 g L−1 h−1 in the FBR fermentation, it amounted to 1.85 g L−1 h−1 in the 5-SCR fermentation with more than 20% bonus for this last process. Even a higher increase could be achieved for the specific PHB production rate. The value for q P of 0.100 g g−1 h−1 obtained in the 5-SCR was threefold that of the FBR fermentation (0.032 g g−1 h−1). This result suggests that a threefold amount of polymer can be produced per unit of catalytically active biomass and time with the 5-SCR when compared with typical FBR fermentation. Compared with an optimized laboratory-scale PHB production using C. necator, this value is nearly doubled (0.100 vs. 0.056 g g−1 h−1, respectively; Kim et al. 1994).

As already mentioned previously, a high volumetric productivity is desirable for PHA production on a commercial scale. When different processes are compared, the one with the higher productivity gets along with downsized equipment for the production of equivalent amounts of PHA per year.

Introducing the volumetric productivity for PHB of 1.44 g L−1 h−1, determined for the industrial process implemented in the Brazilian sugar mills (Nonato et al. 2001), and the volumetric productivity for PHB of 1.85 g L−1 h−1 achieved in the 5-SCR in the above equation allows estimating that the total working volume of the 5-CSR would be only 78% of the volume of the FBR process. These results demonstrate the benefit which would arise from the employment of the cascade process for the continuous production of PHB. Production costs could be significantly reduced by using five smaller reactors with a lower total volume instead of one larger vessel.

Future works should focus on the effect of different dilution rates regarding productivities, specific productivities, percentages of PHA in biomass and polymer quality. In addition, the application of low-cost substrates like cheese whey, glycerol phase from the biodiesel production or hydrolysates of cellulosic and lignocellulosic materials should be tested under the experimental conditions described in the work at hand. This could be beneficial for further reduction of the production costs. Also, the application of genetically engineered strains with high volumetric productivity for PHA from surplus and waste products like cheese whey, as reported by Ahn et al. (2000) or Lee (1996a, b) should be checked concerning economic viability. Especially the application of a suitable carbon substrate will be decisive for the costs of the biopolymer production (Lee 1996a; Koller et al. 2010c).

Due to the flexibility of the system, the properties of the final product can be fine-tuned, e.g. by triggering the polymer composition by co-substrate additions in each vessel. This way, the route is opened for a broad range of potential applications of the products, such as simple packaging materials; carrier materials for controlled release of active compounds, e.g. in the pharmaceutical field; materials in surgery (implants, wound dressing, pins, etc.); or starting materials for chiral fine chemicals (Lee 1996b; Zinn et al. 2001).

In addition, the industrial implementation of the outcomes of this study requires the expertise of chemical engineers concerning the up-scaling of the process. This demands the dimensioning of the equipment units like storage tanks, heating and cooling systems, aeration system and control units for pH value, dissolved oxygen and antifoaming agents for pilot- and industrial-scale plants.

References

Ahn WS, Park SJ, Lee SY (2000) Production of poly(3-hydroxybutyrate) by fed-batch culture of recombinant Escherichia coli with a highly concentrated whey solution. Appl Environ Microbiol 66:3624–3627

Akiyama M, Tsuge T, Doi Y (2003) Environmental life cycle comparison of polyhydroxyalkanoates produced from renewable carbon sources by bacterial fermentation. Pol Degrad Stabil 80:183–194

Anderson AJ, Dawes EA (1990) Occurrence, metabolism, metabolic role, and industrial uses of bacterial polyhydroxyalkanoates. Microbiol Rev 54:450–472

Barham PJ, Keller A, Otun EL, Holmes PA (1984) Crystallization and morphology of a bacterial thermoplastic: poly-3-hydroxybutyrate. J Mater Sci 19:2781–2794

Braunegg G, Sonnleitner B, Lafferty RM (1978) A rapid gas chromatographic method for the determination of poly-β-hydroxybutyric acid in microbial biomass. Eur J Appl Microbiol Biotechnol 6:29–37

Braunegg G, Lefebvre G, Renner G, Zeiser A, Haage G, Loidl-Lanthaler K (1995) Kinetics as a tool for polyhydroxyalkanoate production optimization. Can J Microbiol 41:239–248

Braunegg G, Lefebvre G, Genser KF (1998) Polyhydroxyalkanoates, biopolyesters from renewable resources: physiological and engineering aspects. J Biotechnol 65:127–161

Chen CQ (2009) A microbial polyhydroxyalkanoates (PHA) based bio- and materials industry. Chem Soc Rev 38:2434–2446

Choi J, Lee SY (1999) Factors affecting the economics of polyhydroxyalkanoate production by bacterial fermentation. Appl Microbiol Biotechnol 51:13–21

Doi Y (1990) Microbial polyesters. VHC Publishers, New York, pp 33–61. ISBN 0-471-18732-1

Doi Y, Segawa A, Kawaguchi Y, Kunioka M (1990) Cyclic nature of poly(3-hydroxyalkanoate) metabolism in Alcaligenes eutrophus. FEMS Microbiol Lett 55:165–169

Du G, Chen J, Yu J, Lun S (2001a) Continuous production of poly-3-hydroxybutyrate by Ralstonia eutropha in a two-stage culture system. J Biotechnol 88:59–65

Du G, Chen J, Yu J, Lun S (2001b) Kinetic studies on poly-3-hydroxybutyrate formation by Ralstonia eutropha in a two-stage continuous culture system. Process Biochem 37:219–227

Falcone DMB (2004) Influence of incorporation of poly(lactic acid)—PLA, of wood powder and other additives over physical–mechanical behaviour of poly(hydroxybutyrate)—PHB. MSc thesis UFSCar, SP, Brazil

Fernando S, Adhikari S, Chandrapal C, Murali N (2006) Biorefineries: current status, challenges, and future direction. Energy Fuels 20:1727–1737

Hänggi UJ (1995) Requirements on bacterial polyesters as future substitute for conventional plastics for consumer goods. FEMS Microbiol Rev 16:213–220

Harding KG, Dennis JS, von Blottnitz H, Harrison STL (2007) Environmental analysis of plastic production processes: comparing petroleum-based polypropylene and polyethylene with biologically-based poly-β-hydroxybutyric acid using life cycle analysis. J Biotechnol 130:57–66

Jung K, Hazenberg W, Prieto M, Witholt B (2001) Two-stage continuous process for the production of medium-chain-length poly(3-hydroxyalkanoates). Biotechnol Bioeng 72:19–24

Khanna S, Srivastava A (2005) Recent advances in microbial polyhydroxyalkanoates. Process Biochem 40:607–619

Kim BS, Lee SC, Lee SY, Chang HN, Chang YK, Woo SI (1994) Production of poly(3-hydroxybutyric acid) by fedbatch culture of Alcaligenes eutrophus with glucose concentration control. Biotechnol Bioeng 43:892–898

Koller M, Bona R, Braunegg G, Hermann C, Horvat P, Kroutil M, Martinz J, Neto J, Varila P, Pereira L (2005) Production of polyhydroxyalkanoates from agricultural waste and surplus materials. Biomacromolecules 6:561–565

Koller M, Hesse P, Kutschera C, Bona R, Nascimento J, Ortega S, Agnelli J, Braunegg G (2010a) Sustainable embedding of the bioplastic poly-(3-hydroxybutyrate) into sugarcane industry: principles of a future-oriented technology in Brazil. In: Weller M, Hubner C, Eyerer P (eds) Polymers—opportunities and risks II. Springer, Berlin, pp 81–96

Koller M, Salerno A, de Sousa M, Dias M, Reiterer A, Braunegg G (2010b) Modern biotechnological polymer synthesis: a review. Food Technol Biotechnol 48:255–269

Koller M, Atlić A, Dias M, Reiterer A, Braunegg G (2010c) Microbial PHA production from waste raw materials. In: Microbiology monographs, 2010, volume 14/2010, pp 85–119. doi:10.1007/978-3-642-03287-5_5

Koyama N, Doi Y (1995) Continuous production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by Alcaligenes eutrophus. Biotechnol Lett 17:281–284

Küng W (1982) Wachstum und poly-d-(−)-3-hydroxybuttersäure—akkumulation bei Alcaligenes latus. Diploma thesis at Graz University of Technology, Austria

Lee SY (1996a) Plastic bacteria?: Progress and prospects for polyhydroxyalkanoate production in bacteria. Trends Biotechnol 14:431–438

Lee SY (1996b) Bacterial polyhydroxyalkanoates. Biotechnol Bioeng 49:1–14

Lee SY, Lee Y (2003) Metabolic engineering of Escherichia coli for production of enantiomerically pure (R)-(−)-hydroxycarboxylic acids. Appl Environ Microbiol 69:3421–3426

Moser A (1988) Bioprocess technology: kinetics and reactors. Springer, New York

Mothes G, Ackermann J-U (2005) Synthesis of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) with a target mole fraction of 4-hydroxybutyric acid units by two-stage continuous cultivation of Delftia acidovorans P4a. Eng Life Sci 5:58–62

Nascimento JF, Pachekoski WM, Agnelli JAM (2009) Environmentally degradable polymeric composition and method for obtaining an environmentally degradable polymeric composition. US2009/0023836 A1—Assignee by PHB INDUSTRIAL S.A., Serrana, SP, BR

Nonato RV, Mantelatto PE, Rossell CE (2001) Integrated production of biodegradable plastic, sugar and ethanol. Appl Microbiol Biotechnol 57:1–5

Patel M, Bastioli C, Marini L, Würdinger E (2003) Life-cycle assessment of bio-based polymers and natural fiber composites. In: Steinbüchel A (ed) Biopolymers, vol 10. Wiley-VCH, Weinheim, pp 409–452

Pietrini M, Roes L, Patel MK, Chiellini E (2007) Comparative life cycle studies on PHB based composites as potential replacement for conventional petrochemical plastics. Biomacromolecules 8:2210–2218

Ramsay BA, Lomaliza K, Chavarie C, Dubé B, Bataille P, Ramsay JA (1990) Production of poly-(β-hydroxybutyric-co-β-hydroxyvaleric) acids. Appl Environ Microbiol 56:2093–2098

Reddy CSK, Ghai R, Rashmi KVC (2003) Polyhydroxyalkanoates: an overview. Biores Technol 87:137–146

Ren Q, Grubelnik A, Hoerler M, Ruth K, Hartmann R, Felber H, Zinn M (2005) Bacterial poly(hydroxyalkanoates) as a source of chiral hydroxyalkanoic acids. Biomacromolecules 6:2290–2298

Rossell CEV, Mantelatto PE, Agnelli JAM, Nascimento J (2006) Sugar-based biorefinery—technology for integrated production of poly(3-hydroxybutyrate), sugar, and ethanol. In: Kamm B, Gruber PR, Kamm M (eds) Biorefineries—industrial processes and products. Status quo and future directions, vol. 1. Wiley-VCH, Weinheim, pp 209–225

Ryu HW, Hahn SK, Chang YK, Chang HN (1997) Production of poly(3-hydroxybutyrate) by high cell density fed-batch culture of Alcaligenes eutrophus with phosphate limitation. Biotech Bioeng 55:28–32

Steinbüchel A, Füchtenbusch B (1998) Bacterial and other biological systems for polyester production. Trends Biotechnol 16:419–427

Steinbüchel A, Schlegel HG (1991) Physiology and molecular genetics of poly(β-hydroxyalkanoic acid) synthesis in Alcaligenes eutrophus. Molec Mikrobiol 5:535–542

Steinbüchel A, Valentin H (1995) Diversity of bacterial polyhydroxyalkanoic acids. FEMS Microbiol Lett 128:219–228

Sudesh K, Iwata T (2008) Sustainability of biobased and biodegradable plastics. Clean 36:433–442

Sun Z, Ramsay JA, Guay M, Ramsay BA (2007) Fermentation process development for the production of medium-chain-length poly-3-hydroxyalkanoates. Appl Microbiol Biotechnol 75:475–485

Taniguchi I, Kagotani K, Kimura Y (2003) Microbial production of poly(hydroxyalkanoates) from waste edible oils. Green Chem 5:545–548

Vandamme P, Coenye T (2004) Taxonomy of the genus Cupriavidus: a tale of lost and found. Int J Syst Evol Microbiol 54:2285–2289

Yu ST, Lin CC, Too JR (2005) PHBV production by Ralstonia eutropha in a continuous stirred tank reactor. Process Biochem 40:2729–2734

Zinn M, Witholt B, Egli T (2001) Occurence, synthesis and medical application of bacterial polyhydroxyalkanoate. Adv Drug Deliv Rev 53:5–21

Zinn M, Weilenmann H-U, Hany R, Schmid M, Egli T (2003) Tailored synthesis of poly([R]-3-hydroxybutyrate-co-3-hydroxyvalerate) (PHB/HV) in Ralstonia eutropha DSM 428. Acta Biotechnol 23:309–316

Acknowledgement

The study was enabled by the financial support provided by BASF SE for the research projects “Evaluation of strains and process for the production of PHA—step 1 and 2” which is gratefully acknowledged by the authors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Atlić, A., Koller, M., Scherzer, D. et al. Continuous production of poly([R]-3-hydroxybutyrate) by Cupriavidus necator in a multistage bioreactor cascade. Appl Microbiol Biotechnol 91, 295–304 (2011). https://doi.org/10.1007/s00253-011-3260-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-011-3260-0