Abstract

Sulphur-containing compounds in wine have been extensively studied because of their effect on wine flavour and quality. In this study, an enzyme that degrades sulphur-containing amino acids was cloned and characterised from two Oenococcus oeni strains of oenological origins. The enzyme has features of a cystathionine-γ-lyase (EC 4.4.1.1), a pyridoxal-5-phosphate-dependent enzyme catalysing an α,γ-elimination reaction of l-cystathionine to produce l-cysteine, α-ketobutyrate and ammonia. Moreover, it was able to catalyse an α,β-elimination reaction producing homocysteine, pyruvate and ammonia from l-cystathionine. An elimination reaction of l-cysteine and dl-homocysteine was also efficiently catalysed by the enzyme, resulting in the formation of hydrogen sulphide. Furthermore, the ability to demethiolate methionine into methanethiol, an unfavourable volatile sulphur compound in terms of wine aroma, was observed. The findings of this work suggest that O. oeni seems to play a minor role in the production of volatile sulphur compounds during the vinification process as the optimal conditions were far from the harsh wine environment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Although hundreds of chemical compounds have been identified in grapes and wines, only a few actually contribute to the sensory perception of wine aroma and flavour (Polásková et al. 2008). Formation of aroma in wine is a complex process and mainly carried out by the microflora present during alcoholic fermentation and malolactic fermentation (MLF). The metabolic activity, as well as the kinetics of both fermentations, will influence the sensory profile of the wine depending on the vinification techniques and the physical and chemical composition of the wine. Besides the primary function of lactic acid bacteria (LAB) to conduct MLF, they can also alter the wine composition (Liu 2002); however, these activities as well as the sensory impact of LAB are less well understood and poorly characterised when compared to wine yeast. Swiegers et al. (2005) listed the possible pathways by which LAB are able to produce volatile compounds by, e.g. metabolising grape components or modifying the yeast derived secondary metabolites. Although the genome of Oenococcus oeni has been sequenced and analysed (Mills et al. 2005), there is limited information on the genes in this bacterium or their potential contribution to wine aroma. The only genes which have been cloned and characterised are alsD and alsS (Garmyn et al. 1996) which are involved in the diacetyl synthesis, conferring “buttery” aroma and flavour in wine (Bartowsky and Henschke 2004). Recently, Sumby et al. (2009) reported on the cloning and characterisation of EstB28, the first esterase from O. oeni to be characterised with the potential to alter the ester profile of wine.

Among the wine substrates catabolised by LAB, amino acids represent the most important source of nitrogen, carbon and sulphur for sulphurous amino acids (Pripis-Nicolau et al. 2004). Extensive research has been carried out on the enzymes responsible for volatile sulphur compounds (VSC) produced in dairy-associated LAB (Bruinenberg et al. 1997; Seefeldt and Weimer 2000; Yvon and Rijnen 2001; Fernandez et al. 2002; Gente et al. 2007; Irmler et al. 2008; Hanniffy et al. 2009) while VSC production by wine-related LAB is not well documented. VSC can also contribute to the wine aroma, with some compounds being classified as detrimental to wine quality, depending on their concentration; other compounds can contribute positively to the bouquet of wine (Mestres et al. 2000; Landaud et al. 2008). Pripis-Nicolau et al. (2004) demonstrated that strains of O. oeni converted methionine to diverse VSC. One of these, 3-(methylthio)-propionic acid, is characterised by chocolate and roasted odours and mainly contribute to the aroma of red wines. The production of methionol by different wine LAB has also been reported (Henick-Kling 1995; Ugliano and Moio 2005). The pathways leading to VSC biosynthesis are only partially studied in O. oeni, whereas they are well-known in LAB and, more importantly, in cheese microflora, in which VSC are important cheese-flavour components. Vallet et al. (2008) studied pathways that produce VSC and showed that methional and 2-oxo-4-(methylthio)-butyric acid are key intermediates for VSC synthesis from methionine in O. oeni; however, the metabolic pathway in O. oeni for the formation of these compounds is not yet clarified. The conversion of sulphur-containing amino acids into VSC proceeds via two distinct routes, transamination and elimination (Yvon and Rijnen 2001; van Kranenburg et al. 2002; Ardo 2006). The first pathway goes through α-keto acid intermediates and is mainly initiated by a transamination reaction catalysed by aminotransferases. The second one is initiated by elimination reaction catalysed by lyases which cleave the side chain of amino acids. The possible involvement of lyases in VSC biosynthesis has been mainly studied in cheese. The activity of cystathionine β-lyase (CBL) and cystathionine γ-lyase (CGL), pyridoxal-5′-phosphate (PLP)-dependent enzymes, has been detected in several LAB such as Lactococcus lactis (Alting et al. 1995), Lactobacillus fermentum (Smacchi and Gobbetti 1998), Lactobacillus helveticus and Lactobacillus casei (Dias and Weimer 1998; Irmler et al. 2008). Moreover, these enzymes have been purified and characterised (Bruinenberg et al. 1997; Smacchi and Gobbetti 1998; Gente et al. 2007; Irmler et al. 2008). The CBL converts l-cystathionine to l-homocysteine, pyruvate and ammonia via α,β-elimination reaction. The CGL converts l-cystathionine to l-cysteine, α-ketobutyrate and ammonia via α,γ-elimination reaction. Although their main function is anabolic, they also possess α,β- and α,γ-elimination activities (Landaud et al. 2008). Moreover, it was shown that the enzymes are capable of converting other sulphur-containing substrates via α,γ-elimination reaction (Weimer et al. 1999; Yvon and Rijnen 2001).

To more completely characterise lyases of wine-associated LAB, the enzymes and their structural genes must be fully investigated. This paper describes the identification, heterologous expression and biochemical characterisation of a cystathionine lyase from two O. oeni strains. These enzymes have the ability to carry out both the α,β-elimination and α,γ-elimination reactions on sulphur-containing amino acids such as cystathionine, cysteine, homocysteine and methionine.

Materials and methods

Strains, media and growth conditions

Two commercial O. oeni strains (R1105, R1106) (Lallemand, Toulouse, France) were used in this study. Both strains have been deposited in the German Collection of Microorganisms and Cell Cultures under the following numbers: DSM14493 (R1105) and DSM14511 (R1106).

The strains were grown in modified MRS (Roth, Karlsruhe, Germany) supplemented with 20% pasteurised apple juice (Geisenheim Research Center, Germany) and the pH was adjusted to 5.2. The LAB strains were cultured at 30 °C. Escherichia coli strains BL21(DE3) and DH5-α were grown in Luria-Bertani (LB) broth at 37 °C on a rotary wheel at 220 rpm. Selective antibiotic concentration was 100 μg/mL of ampicillin (Sigma Aldrich, Steinheim, Germany) when required.

DNA isolation and manipulations

Total O. oeni genomic DNA was isolated as described by Lewington et al. (1987). Plasmid DNA from E. coli DH5-α was extracted with the GeneJET™ Plasmid Miniprep Kit (Fermentas GmbH, St. Leon-Rot, Germany) according to the manufacturer’s recommendations. All cloning steps were conducted according to standard procedures as described in Sambrook and Russell (2001). T4 DNA ligase and all restriction enzymes were purchased from Roche (Mannheim, Germany). Primers for the polymerase chain reaction (PCR) were obtained from Integrated DNA Technologies, Inc. (Coralville, IA, USA). PCR was performed with Ex Taq polymerase (TaKaRa, Bio Inc., Shiga, Japan) in a TRIO-Thermoblock (Biometra, Göttingen, Germany) according to the parameters specified. PCR resulting fragments were separated by 1% agarose gel electrophoresis, and when required, purified with ™Gel Extraction Kit (Fermentas GmbH) according to the protocol supplied by the manufacturer.

Cloning and heterologous expression of cgl

Both O. oeni strains were tested for the presence of the cystathionine gamma lyase (cgl) gene (OEOE_1758/EC:4.4.1.1) by PCR amplification. Primers were designed based on the O. oeni PSU-1 genome sequence (GenBank accession no. CP000411.1). Purified genomic DNA served as template in the PCR. To allow subsequent cloning, NdeI and BamHI sites were introduced at the 5′ and 3′ ends of the primers (designed in this study): 5′-GTCCATATGATGAAATTCAATACAAAACTTATTCATG-3′ and 5′-ATCGGATCCCTAAATCTTGCTGAATGAC-3′ (restriction sites are underlined). Amplification included denaturation at 94 °C for 2 min followed by 35 cycles of denaturation at 94 °C for 1 min, annealing at 50 °C for 1 min and polymerization at 72 °C for 1.20 min. A final elongation step was performed at 72 °C for 5 min.

Plasmids pET14.b::cgl05 and pET14.b::cgl06 were constructed by inserting the amplified PCR products from O. oeni R1105 and R1106 into the NdeI and BamHI restriction enzyme sites of pET14b (Studier et al. 1990). E. coli DH5-α was used as a host strain for cloning and maintenance of the plasmids. E. coli BL21(DE3) was used for the expression of the cgl gene under the control of an inducible T7 promoter.

DNA sequencing

The amplified products were cloned into the pGEM-T Easy (Promega, Cape Town, South Africa) vector and transformed into E. coli DH5-α. DNA sequencing was performed by the Central Analytical Facility of Stellenbosch University, South Africa. DNA sequences were obtained by performing cycle sequencing reactions using the Applied Biosystems BigDye Terminator Ready Reaction Kit v3.1, following the manufacturer’s instructions. Samples were run on an Applied Biosystems 3130xl Genetic Analyzer and analysed using a Sequencing Analysis 5.2 software.

Expression and purification of His-tagged proteins

E. coli BL21(DE3) harbouring the pET14.b::cgl05 and pET14.b::cgl06 plasmids were grown in 200 mL of LB broth supplemented with the required antibiotic to an OD600nm of 0.6 at 37 °C at 220 rpm. Induction of genes was performed under the control of the isopropyl-β-d-thiogalactopyranoside (IPTG)-inducible promoter by adding 0.4 mM of IPTG. The cultures were grown for another 4 h at 30 °C at 220 rpm. The E. coli cells were harvested (5,000 rpm, 4 °C, 15 min), washed twice with 0.2 M sodium phosphate buffer (pH 7.4) and frozen at −20 °C. The frozen pellet was resuspended in 4 mL of binding buffer (20 mM sodium phosphate (pH 7.4), 150 mM NaCl, 20 mM imidazole) and approximately 0.2 g of glass beads (212–300 μm) was added. Vigorous agitation in a Mini-BeadBeater-8 (Biospec Products, Inc.) was used for the disruption of the cells. The extract was cleared by centrifugation (5,000 rpm, 4 °C, 10 min) and then applied to a 1-mL HiTrap Chelating HP column (GE Healthcare, Uppsala, Sweden) which had been loaded with 0.5 mL 0.1 M NiSO4 and equilibrated with binding buffer. The column was then washed with binding buffer, and bound proteins were subsequently eluted with 20 mM sodium phosphate buffer (pH 7.4), 500 mM NaCl and 500 mM imidazole. Removal of the imidazole was done by applying the eluate to NAP columns (GE Healthcare) which had been equilibrated with 20 mM sodium phosphate (pH 7.4) beforehand according to the manufacturer’s instructions. The eluted protein fractions were analysed by sodium dodecylsulfate-polyacrylamide gel electrophoresis (SDS-PAGE) and visualised by colloidal Coomassie brilliant blue staining.

The protein concentration was determined by the Bio-Rad protein assay (Bio-Rad Laboratories GmbH, Munich, Germany) based on the method of Bradford (1976), with bovine serum albumin as the standard.

Determination of enzyme activity

The standard reaction mixture of 200 μL consisted of 50 mM sodium phosphate (pH 6.8 or 5.5), 5 μM PLP, various concentrations of substrate (0.1–25 mM final concentration) and enzyme solution (5 μg/200 μL). The reactions were performed at 37 °C. Following substrates were tested: l-cystathionine, l-cysteine, dl-homocysteine and l-methionine. The release of thiols from cystathionine and methionine was determined by adding 5,5′-dithiobis(2-nitrobenzoic acid) (DTNB) as described by Uren (1987). A yellow colouration developed when thiols were released and was recorded at 3-min intervals at 412 nm for 60 min or every 10 min for 3 h. Production of α-keto acids was determined with 3-Methyl-2-benzothiazolinone as described by Esaki et al. (1987). α-Keto acid identification was carried out by high-performance liquid chromatography (HPLC). Therefore, assays were stopped after 40 min of incubation by the addition of 2 μL of H2SO4 (380 mM) and by heating at 95 °C for 5 min. The release of volatile sulphur compounds was measured by gas chromatography-pulsed flame photometric detection (GC-PFPD) as described below. The Hanes–Woolf transformation (S/V vs. 1/S), where V is the formation rate of either thiols or keto acids (micromol per minute per milligramme protein) and S is the concentration (millimolar) of each substrate, was used to calculate K m and V max values. All assays were performed in triplicate.

To assay cystathionine synthase activity, the purified enzyme was incubated with O-succinyl-L-homoserine in the presence of l-cysteine. The formation of acids from the substrates was analysed by HPLC.

Influence of temperature, pH and ethanol on enzyme activity

The influence of temperature was studied by pre-incubating the purified enzyme for 30 min at five temperatures across the range of 20 to 75 °C. The effect of pH on enzyme activity was determined by varying the pH of the reaction mixture across the range pH 3.0 to 9.0 using 0.1 M sodium phosphate buffer. Furthermore, the impact of the presence of ethanol at four concentrations from 5% to 15% (v/v) was investigated. Enzyme activities were determined as described above.

HPLC analysis

Separation of the filtrate was performed on an Aminex HPX-87H (300 by 7.8 mm; Bio-Rad) protected with a SecurityGuard™ cartridge system (Phenomenex). The operating conditions were as follows: a flow rate of 0.5 mL/min, 46 °C and detection at 210 nm. The mobile phase was 3.8 mM H2SO4. Pyruvate and α-ketobutyrate (Sigma-Aldrich) were used as standards.

Gas chromatography-pulsed flame photometric detection

Detection of VSC was carried out by GC-PFPD analysis. The enzymatic assays were done as described above in a 1-mL final volume. When methionine was used as a substrate, the reaction mixture was incubated for 6 h instead of 40 min. Sample preparation and analysis of VSC were performed as described previously (Rauhut et al. 2005; Irmler et al. 2008).

Results

DNA sequencing and sequence analysis

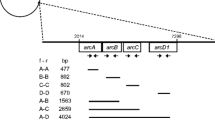

The two O. oeni strains were tested for the presence of the cgl gene (OEOE_1758) and were successfully amplified from both strains by PCR. The amplified PCR product consisted of 1,140 nucleotides encoding a deduced protein of 379 amino acids. The sequences were aligned with the O. oeni strain PSU-1 genome sequence (GenBank accession no. CP000411.1), and analysis showed that the sequences were highly homologous to PSU-1. Four nucleotides in R1105 and six nucleotides in R1106 compared to PSU-1 (Online Source 1) were different leading to two respectively four amino acid substitutions. The deduced sequence of R1105 showed amino acid substitutions at position 184 and 291. Leucine was replaced with phenylalanine and cysteine with arginine. For strain R1106 the alanine at position 121 and the serine at position 328 were exchanged to threonine and glycine, respectively. In addition, strain R1106 had the same amino acid substitutions as R1105 at the positions 184 and 291.

Expression of cgl into E. coli

The cgl genes from R1105 and R1106 were cloned into pET14b. The E. coli BL21 (DE3) transformants containing either the pET14.b::cgl05 or the pET14.b::cgl06 plasmid were induced and soluble recombinant His-tagged proteins named Cgl05 and Cgl06 were obtained. Proteins were then purified under native conditions by affinity chromatography. Enzyme purification was monitored by analysing aliquots of protein fractions from each chromatography step by SDS-PAGE. A single polypeptide band of approximately 40 kDa (predicted 41.5 kDa) was observed in the final enzyme preparation (Fig. 1). The purified enzymes were then used for further biochemical characterisation.

Determination and characterisation of enzyme activity

Substrate specificity of both recombinant CGLs, Cgl05 and Cgl06, were determined using various substrates by assaying the formation of the products. Both showed high activity towards the degradation of l-cystathionine. They also degraded all other substrates tested. Table 1 shows the comparison of recombinant CGL isolate from O. oeni R1105 (CGL05) and R1106 (CGL06). There were no statistical significant differences in the kinetic parameters between the two strains. DTNB was added to measure the release of thiols from cystathionine and methionine. Figure 2 shows the thiol production of the enzyme using l-methionine and l-cystathionine at various substrate concentrations. The values of the controls (assays without enzyme) were subtracted from the values of the assays with enzyme. Using methionine as substrate, we observed an enzyme-catalysed cleavage to free thiols; however, we were not able to saturate the reaction with methionine. For this reason, V max and K m could not be determined.

Thiol production curves in the presence of l-methionine (a) and l-cystathionine (b) by incubating the recombinant Cgl05. Illustrated are sample values less the control values. Similar results were obtained with Cgl06 (data not shown). a The final substrate concentrations were 20 mM (diamond), 10 mM (square), 5 mM (triangle), 2 mM (multiplication sign), 1.5 mM (asterisk), 1 mM (circle). b The final substrate concentrations were 2 mM (diamond), 1 mM (square), 0.5 mM (triangle), 0.2 mM (multiplication sign), 0.15 mM (asterisk), 0.1 mM (circle), 0.05 mM (plus sign) and 0.02 mM (minus sign). Experiments were carried out in triplicate

By using l-cystathionine as substrate, the activity of the purified enzymes was highest at pH 8.0. No activity was observed at a pH below 6.5. In contrast, l-methionine was degraded at pH 5.5 and 6 (Online Source 2).

To clarify whether an α,β- or an α,γ-elimination took place, products released during the enzyme reactions were analysed. First, α-keto acids were determined by HPLC. The results showed that cystathionine was degraded into pyruvate and α-ketobutyrate. Furthermore, it was found that pyruvate and α-ketobutyrate were formed from l-cysteine and dl-homocysteine, respectively (Fig. 3). Assays performed with each substrate in absence of the enzyme served as controls. Chemical degradation to organic acids was not detected (data not shown). Second, it was observed that reactions containing l-cysteine, dl-homocysteine or l-cystathionine as a substrate released a strong hydrogen sulphide scent (rotten egg odour) after incubation. This was confirmed by GC-PFPD (Fig. 4). Finally, the formation of ammonia was confirmed by using an enzymatic analysis kit (Boehringer, Mannheim, Germany) (data not shown).

HPLC analysis of assays carried out with purified enzyme (CGL05) at pH 6.8 for 30 min and l-cysteine (a), l-cystathionine (b), dl-homocysteine (c), O-succinyl-L-homoserine (d), and O-succinyl-L-homoserine and l-cysteine (e). Similar results were obtained with CGL06 (data not shown). Peaks were identified by retention time. AKB, α-ketobutyrate

To study whether the enzyme also exhibits cystathionine synthase activity, CGL05 and CGL06 were incubated with O-succinyl-L-homoserine in the presence and absence of L-cysteine. HPLC analysis showed that the CGL proteins formed α-ketobutyrate and succinate from O-succinyl-L-homoserine. Incubation of O-succinyl-L-homoserine together with l-cysteine resulted in the formation of pyruvate, α-ketobutyrate and succinate (Fig. 3). Serine was studied as a putative substrate, but it was not degraded. In order to confirm the release of methanethiol from methionine, GC-PFPD was utilised. Very low levels or no methanethiol, dimethyl disulphide and dimethyl trisulphide (DMTS) were detected in the headspace of the sample with methionine in the absence of enzyme, whereas the addition of enzyme, resulted in a release of methanethiol, dimethyl disulfide (DMDS) and DMTS (Fig. 4).

The effect of temperature and ethanol on enzyme activity was determined by using l-cystathionine as a substrate (Online source 3 and 4). The enzyme was stable up to 56 °C and was not inhibited by 15% (v/v) ethanol. After several weeks of storage at 4 °C or −20 °C, both enzyme preparations still showed cystathionine lyase activity.

Discussion

This research focused on the cloning and biochemical characterisation of a cystathionine lyase from two oenological O. oeni strains.

Only a few studies have been conducted on the amino acid catabolism of wine LAB, with the exception of arginine (Liu and Pilone 1998); however, the catabolism of amino acids by wine LAB is expected to have an impact on wine quality, given that a range of compounds can be produced, such as aldehydes, alcohols and acids, in addition to amines. Over 20 LAB genomes have been fully sequenced (Kleerebezem et al. 2003; Liu et al. 2005; Mills et al. 2005; Claesson et al. 2006; Mayo et al. 2008). The available genomic information provides additional possibilities to study the flavour-forming potential of LAB; however, biochemical methods are necessary to investigate enzymatic function, substrate specificity and activity of the genes of interest. Since methionine and cysteine are generally present in only limited quantities in wine, the formation of VSCs will depend on both biosynthesis and catabolic pathways of methionine and cysteine; however the metabolism of sulphur-containing amino acids is diverse, especially considering the existence of multiple alternative pathways as well as several possible chemical reactions which also can contribute to VSC formation.

In this study, it was shown that O. oeni possesses a gene encoding a cystathionine lyase which is highly conserved among the three compared O. oeni strains. Applying comparative sequence analysis, Liu et al. (2008) revealed that genes encoding cystathionine lyases fall into two distinct families named CBL/CGL and CBL, which share little sequence similarity. The in silico translation of cgl of O. oeni was compared with other known and predicted CBL/CGL sequences using NCBI protein blast. Besides being nearly identical with the CGL (OEOE_1758) of O. oeni PSU-1, it showed 73% identity with the CBL/CGL of Lactobacillus salivarius UCC118 and ATCC 11741; 72% with the CGL of Lactobacillus reuteri DSM 20016 and 70% with Lactobacillus fermentum ATCC 14931. Furthermore, it showed 67% identity with Ctl1 of Lactobacillus casei FAM18168 67% with Ctl2 of Lactobacillus casei FAM18108, 60% with MetC of Lactococcus lactis subsp. cremoris SK11 and 55% with YrhB of Bacillus subtilis str. 168. The latter four genes also belong to the CBL/CGL family and have experimentally been shown to encode a cystathionine lyase exhibiting dual CBL/CGL activity. Probably all enzymes belonging to “CBL/CGL” may display a mixture of cystathionine β- and γ-lyase activities. It implies that LAB enzymes in this subcluster could have either solo CGL activity or a dual CBL/CGL activity (Liu et al. 2005). In this study, the gene product of cgl also showed dual CBL/CGL activity and formed pyruvate, α-ketobutyrate and hydrogen sulphide from cystathionine, released pyruvate and hydrogen sulphide from cysteine, and generated methanethiol from methionine. These observations suggest that cystathionine can be broken down in two possible steps. First, α-ketobutyrate, pyruvate, cysteine, homocysteine and ammonia are formed. Second, cysteine and homocysteine are further metabolised to pyruvate, α-ketobutyrate, ammonia and hydrogen sulphide. Interestingly, Cgl05 and Cgl06 also formed α-ketobutyrate and succinate from O-succinyl-L-homoserine. A combination of cysteine and O-succinyl-L-homoserine resulted in the additional release of pyruvate; however, compared with O-succinyl-L-homoserine as the sole substrate, the peak area of α-ketobutyrate was significantly reduced. This implies that the compound is used for cystathionine biosynthesis, and we think that the enzyme exhibits also cystathionine synthase activity.

These results lead to the conclusion that Cgl05 and Cgl06 are multifunctional PLP-dependent enzymes that on the one hand degrade cystathionine by an α,β- and an α,γ-elimination reaction and on the other hand exhibit cystathionine γ-synthase activity when O-succinyl-L-homoserine and l-cysteine are present. This attribute has also been reported for MetB of Lactobacillus casei (Irmler et al. 2008) and was found for Ctl1 (S. Irmler, personal communication). DMDS and DMTS probably arise from the chemical oxidation of methanethiol (Parliment et al. 1982; Chin and Lindsay 1994; Yvon and Rijnen 2001). Recently, it was shown, that in the presence of PLP, methanethiol can also be generated chemically (Wolle et al. 2006). In this study, CGL showed demethiolation activity on methionine and the amount of methanethiol produced was considerably higher than its formation in the absence of the enzyme. Based on these results, we propose that cgl of O. oeni is involved in the transsulphuration pathways of cystathionine, cysteine, homocysteine and methionine (Fig. 5).

Although methanethiol was formed from methionine, the affinity of the enzyme towards methionine was much lower than towards cystathionine. This has been observed before in Lactococcus lactis spp cremoris (Bruinenberg et al. 1997) and Lactobacillus casei (Irmler et al. 2009). Previous studies showed that for both strains used in this study, methionine is essential for growth (Krieger et al., unpublished). This implies, they either lack the enzymes needed for biosynthesis of this amino acid or the pathways are interrupted. Moreover, it was shown that an addition of cysteine and glutathione to a wine after alcoholic fermentation can promote the growth of LAB and MLF (Rauhut et al. 2004); however, this effect seemed to be influenced by the substrate concentration and by the general nutrient composition of the wine (Rauhut et al. 2004). VSC production by whole cells of oenococci has not been broadly studied in literature. It was shown that O. oeni is able to produce VSC such as methanethiol, dimethyldisulphide, methional, methionol and 3-(methylthio)-propionic acid (Pripis-Nicolau et al. 2004; Rauhut et al. 2008a, b); however, the increased production of these compounds was observed at substrate concentrations far over the usual levels found in wine after alcoholic fermentation. Furthermore, Rauhut et al. (2008a, b) observed that the catabolism of methionine to VSC was affected by the pH value of the media. Since free sulphur-containing amino acids are usually deficient in wine after alcoholic fermentation, production of these enzymes in oenococci would be suppressed in the wine environment. Therefore, their contribution to VSC is probably minimal. According to Pripis-Nicolau et al. (2004), no increase of VSC which are associated with off-flavours could be detected in wine or wine-like media after the addition of methionine in amounts that can be generally expected in wines. Yeast on the other hand, can synthesise these sulphur-containing amino acids through sulphate and sulphite reduction sequence pathway from inorganic sources such as sulphate and sulphite, which are usually abundant in grape must (Moreira et al. 2002; Swiegers and Pretorius 2007). Moreover, VSC can be produced from other sulphur sources like bisulphite added to the must or from precursors present in grapes. It was demonstrated that some vinification practices could result in an increased formation of VSC (Karagiannis and Lanaridis 1999; Ribéreau-Gayon et al. 2000; Zoecklein 2007).

A better knowledge of the mechanisms of the production of VSC and the genes encoding the enzymes involved is important to improve the understanding of how LAB contribute to the wine aroma during MLF and is therefore a major interest to maintain the quality of wines. Climate change and vinification practices have frequently resulted in wines with high alcohol concentrations [>13% (v/v)]. In our study, ethanol contents up to 15% (v/v) had no impact on the enzyme activity. Moreover, the enzymes were stable at temperatures suitable for the wine production and storage. Based on the findings reported in this study, it remains questionable whether the CGL will retain at least partial activity under the harsh wine making conditions since the cgl products became inactive at wine-like pH levels. Further work with natural substrates and whole cells of O. oeni will be necessary to determine its influence on the VSC production in wine.

References

Alting AC, Engels WJM, van Schalkwijk S, Exterkate FA (1995) Purification and characterization of cystathionine β-lyase from Lactococcus lactis subsp. cremoris B78 and its possible role in flavor development in cheese. Appl Environ Microbiol 61(11):4037–4042

Ardo Y (2006) Flavour formation by amino acid catabolism. Biotechnol Adv 24(2):238–242

Bartowsky EJ, Henschke PA (2004) The ‘buttery’ attribute of wine-diacetyl-desirability, spoilage and beyond. Int J Food Microbiol 96(3):235–252

Bradford MM (1976) A rapid and sensitive method for the quantification of microgram quantities of protein utilizing the princible of protein-dye binding. Anal Biochem 72:248–254

Bruinenberg PG, De Roo G, Limsowtin G (1997) Purification and characterization of cystathionine γ-lyase from Lactococcus lactis subsp. cremoris SK11: Possible role in flavor compound formation during cheese maturation. Appl Environ Microbiol 63(2):561–566

Chin H-W, Lindsay RC (1994) Ascorbate and transition-metal mediation of methanethiol oxidation to dimethyl disulfide and dimethyl trisulfide. Food Chem 49(4):387–392

Claesson MJ, Li Y, Leahy S, Canchaya C, van Pijkeren JP, Cerdeno-Tárraga AM, Parkhill J, Flynn S, O’Sullivan GC, Collins JK, Higgins D, Shanahan F, Fitzgerald GF, van Sinderen D, O’Toole PW (2006) Multireplicon genome architecture of Lactobacillus salivarius. PNAS 103(17):6718–6723

Dias B, Weimer B (1998) Conversion of methionine to thiols by Lactococci, Lactobacilli, and Brevibacteria. Appl Environ Microbiol 64(9):3320–3326

Esaki N, Soda K, William BJ, Griffith OW (1987) l-Methionine γ-lyase from Pseudomonas putida and Aeromonas. Meth Enzymol 143:459–465

Fernandez M, Kleerebezem M, Kuipers OP, Siezen RJ, van Kranenburg R (2002) Regulation of the metC-cysK operon, involved in sulfur metabolism in Lactococcus lactis. J Bacteriol 184(1):82–90

Garmyn D, Monnet C, Martineau B, Guzzo J, Cavin J, Diviès C (1996) Cloning and sequencing of the gene encoding alpha-acetolactate decarboxylase from Leuconostoc oenos. FEMS Microbiol Lett 145(3):445–450

Gente S, La Carbona S, Guéguen M (2007) Levels of cystathionine γ-lyase production by Geotrichum candidum in synthetic media and correlation with the presence of sulphur flavours in cheese. Int J Food Microbiol 114(2):136–142

Hanniffy SB, Peláez C, Martínez-Bartolomé MA, Requena T, Martínez-Cuesta MC (2009) Key enzymes involved in methionine catabolism by cheese lactic acid bacteria. Int J Food Microbiol 135(3):223–230

Henick-Kling T (1995) Control of malolactic fermentation in wine: energetics, flavour modification and methods of starter culture preparation. J Appl Bacteriol 79:29S–37S

Irmler S, Raboud S, Beisert B, Rauhut D, Berthoud H (2008) Cloning and characterization of two Lactobacillus casei genes encoding a cystathionine lyase. Appl Environ Microbiol 74(1):99–106

Irmler S, Schäfer H, Beisert B, Rauhut D, Berthoud H (2009) Identification and characterization of a strain-dependent cystathionine β/γ-lyase in Lactobacillus casei potentially involved in cysteine biosynthesis. FEMS Microbiol Lett 295(1):67–76

Karagiannis S, Lanaridis P (1999) The effect of various vinification parameters on the development of several volatile sulfur compounds in greek white wines of the cultivars batiki and muscat of Hamburg. Am J Enol Vitic 50(3):334–342

Kleerebezem M, Boekhorst J, van Kranenburg R, Molenaar D, Kuipers OP, Leer R, Tarchini R, Peters SA, Sandbrink HM, Fiers MWEJ, Stiekema W, Lankhorst RMK, Bron PA, Hoffer SM, Groot MNN, Kerkhoven R, de Vries M, Ursing B, de Vos WM, Siezen RJ (2003) Complete genome sequence of Lactobacillus plantarum WCFS1. Proc Natl Acad Sci USA 100(4):1990–1995

Landaud S, Helinck S, Bonnarme P (2008) Formation of volatile sulfur compounds and metabolism of methionine and other sulfur compounds in fermented food. Appl Microbiol Biotechnol 77(6):1191–1205

Lewington J, Greenaway SD, Spillane BJ (1987) Rapid small scale preparation of bacterial genomic DNA, suitable for cloning and hybridization analysis. Lett Appl Microbiol 5:51–53

Liu SQ (2002) Malolactic fermentation in wine—beyond deacidification. J Appl Microbiol 92(4):589–601

Liu S-Q, Pilone GJ (1998) A review: arginine metabolism in wine lactic acid bacteria and its practical significance. J Appl Microbiol 84:315–327

Liu M, van Enckevort FHJ, Siezen RJ (2005) Genome update: lactic acid bacteria genome sequencing is booming. Microbiology 151(12):3811–3814

Liu M, Nauta A, Francke C, Siezen RJ (2008) Comparative genomics of enzymes in flavor-forming pathways from amino acids in lactic acid bacteria. Appl Environ Microbiol 74(15):4590–4600

Mayo B, van Sinderen D, Ventura M (2008) Genome analysis of food grade lactic acid-producing bacteria: from basics to applications. Curr Genomics 9(3):169–183

Mestres M, Busto O, Guasch J (2000) Analysis of organic sulfur compounds in wine aroma. J Chromatogr A 881:569–581

Mills DA, Rawsthorne H, Parker C, Tamir D, Makarova K (2005) Genomic analysis of Oenococcus oeni PSU-1 and its relevance to winemaking. FEMS Microbiol Rev 29(3):465–475

Moreira N, Mendes F, Pereira O, Guedes de Pinho P, Hogg T, Vasconcelos I (2002) Volatile sulphur compounds in wines related to yeast metabolism and nitrogen composition of grape musts. Anal Chim Acta 458(1):157–167

Parliment TH, Kolor MG, Rizzo DJ (1982) Volatile components of Limburger cheese. J Agric Food Chem 30(6):1006–1008

Polásková P, Herszage J, Ebeler SE (2008) Wine flavor: chemistry in a glass. Chem Soc Rev 37:2478–2489

Pripis-Nicolau L, Revel G, Bertrand A, Lonvaud-Funel A (2004) Methionine catabolism and production of volatile sulphur compounds by Oenococcus oeni. J Appl Microbiol 96(5):1176–1184

Rauhut D, Gawron-Scibek M, Beisert B, Kondizor M, Schwarz R, Kürbel H, Grossmann M, Krieger S (2004) Impact of S-containing amino acids and glutathione on growth of Oenococcus oeni and malolactic fermentation. Proceedings of Les XVIes Entretiens Scientifique Lallemand. Porto, Portugal, pp 33–38

Rauhut D, Beisert B, Beeres M, Gawron-Scibek M, Kuerbel H (eds) (2005) Pulse flame photometric detection: an innovative technique to analyse volatile sulfur compounds in wine and other beverages. State-of-the-art in flavour chemistry and biology. Deutsche Forschungsanstalt für Lebensmittelchemie, Garching, pp 363–368

Rauhut D, Schäfer V, Beisert B, Lochbühler B, Gawron-Scibek M, Krieger-Weber S (2008a) Formation of aroma-active S-compounds by Oenococcus oeni during malolactic fermentation in wine-like media and wine. Proceedings of Les XXes Entretiens Scientifiques Lallemand, Horens, Denmark, pp 19–24

Rauhut D, Schäfer V, Beisert B, Lochbühler B, Gawron-Scibek M, Krieger-Weber S (2008b) Investigations on the ability of Oenococcus oeni to produce volatile sulfphur compounds during malolactic fermentation (MLF) in wine-like media and wine. 31st World Congress of Vine And Wine, 6th General Assembly of the OIV, Verona Italy: II.080326

Ribéreau-Gayon P, Glories Y, Maujean A, Dubourdieu D (2000) Handbook of enology, the microbiology of wine and vinifications, vol. 1. Wiley, Chichester

Sambrook J, Russell DW (eds) (2001) Molecular cloning: a laboratory manual, 3rd edn. Cold Spring Harbour Labortory, Cold Spring Harbour

Seefeldt KE, Weimer BC (2000) Diversity of sulfur compound production in lactic acid bacteria. J Dairy Sci 83(12):2740–2746

Smacchi E, Gobbetti M (1998) Purification and characterization of cystathionine γ-lyase from Lactobacillus fermentum DT41. FEMS Microbiol Lett 166:197–202

Studier WF, Rosenberg AH, Dunn JJ, Dubendorff JW, David VG (1990) [6] Use of T7 RNA polymerase to direct expression of cloned genes. Meth Enzymol 185:60–89, Academic Press

Sumby KM, Matthews AH, Grbin PR, Jiranek V (2009) Cloning and characterization of an intracellular esterase from the wine-associated lactic acid bacterium Oenococcus oeni. Appl Environ Microbiol 75(21):6729–6735

Swiegers J, Pretorius I (2007) Modulation of volatile sulfur compounds by wine yeast. Appl Microbiol Biotechnol 74(5):954–960

Swiegers JH, Bartowsky E, Henschke P, Pretorius IS (2005) Yeast and bacteria modulation of wine aroma and flavour. Aust J Grape Wine Res 11:139–173

Ugliano M, Moio L (2005) Changes in the concentration of yeast-derived volatile compounds of red wine during malolactic fermentation with four commercial starter cultures of Oenococcus oeni. J Agric Food Chem 53(26):10134–10139

Uren JR (1987) Cystathionine β-lyase from Escherichia coli. Meth Enzymol 143:483–486

Vallet A, Lucas P, Lonvaud-Funel A, de Revel G (2008) Pathways that produce volatile sulphur compounds from methionine in Oenococcus oeni. J Appl Microbiol 104(6):1833–1840

van Kranenburg R, Kleerebezem M, van Hylckama VJ, Ursing BM, Boekhorst J, Smit BA, Ayad EHE, Smit G, Siezen RJ (2002) Flavour formation from amino acids by lactic acid bacteria: predictions from genome sequence analysis. Int Dairy J 12(2–3):111–121

Weimer B, Seefeldt K, Dias B (1999) Sulfur metabolism in bacteria associated with cheese. Antonie Leeuwenhoek 76(1):247–261

Wolle DD, Banavara DS, Rankin SA (2006) Short communication: empirical and mechanistic evidence for the role of pyridoxal-5′-phosphate in the generation of methanethiol from methionine. J Dairy Sci 89(12):4545–4550

Yvon M, Rijnen L (2001) Cheese flavour formation by amino acid catabolism. Int Dairy J 11:185–201

Zoecklein B (2007) Factors impacting sulfur-like off odors in wine and winery options. 8th Annual Enology and Viticulture British Columbia Wine Grape Council Conference, Penticton, British Columbia, Canada. (http://www.fst.vt.edu/extension/enology/downloads/SLOFactorsFinal.pdf)

Acknowledgments

We wish to thank Lallemand Inc., especially Dr. S. Krieger-Weber, for putting the two O. oeni strains at our disposal and for the partial financing of the research project.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 3912 kb)

Rights and permissions

About this article

Cite this article

Knoll, C., du Toit, M., Schnell, S. et al. Cloning and characterisation of a cystathionine β/γ-lyase from two Oenococcus oeni oenological strains. Appl Microbiol Biotechnol 89, 1051–1060 (2011). https://doi.org/10.1007/s00253-010-2911-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-010-2911-x