Abstract

In a water-organic solvent, two-phase conversion system, CoQ10 could be produced directly from solanesol and para-hydroxybenzoic acid (PHB) by free cells of Sphingomonas sp. ZUTE03 and CoQ10 concentration in the organic solvent phase was significantly higher than that in the cell. CoQ10 yield reached a maximal value of 60.8 mg l−1 in the organic phase and 40.6 mg g−1-DCW after 8 h. CoQ10 also could be produced by gel-entrapped cells in the two-phase conversion system. Soybean oil and hexane were found to be key substances for CoQ10 production by gel-entrapped cells of Sphingomonas sp. ZUTE03. Soybean oil might improve the release of CoQ10 from the gel-entrapped cells while hexane was the suitable solvent to extract CoQ10 from the mixed phase of aqueous and organic. The gel-entrapped cells could be re-used to produce CoQ10 by a repeated-batch culture. After 15 repeats, the yield of CoQ10 kept at a high level of more than 40 mg l−1. After 8 h conversion under optimized precursor’s concentration, CoQ10 yield of gel-trapped cells reached 52.2 mg l−1 with a molar conversion rate of 91% and 89.6% (on PHB and solanesol, respectively). This is the first report on enhanced production of CoQ10 in a two-phase conversion system by gel-entrapped cells of Sphingomonas sp. ZUTE03.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Coenzyme Q10 (also known as ubiquinone-10) has been used successfully as an orally administrated prophylaxis and therapy for various diseases such as cardiovascular disease and mitochondrial respiratory-chain diseases (Choi et al. 2005), because of its inert toxicity and minimal side effects. It could also be used as an antioxidant in cosmetics and pharmaceuticals due to its role in protecting membrane phospholipids, lipoproteins and DNA from free radical-induced oxidative damage (Szkopinska 2000). In addition, Coenzyme Q10 (CoQ10) is usually recommended as a supplement to 3-hydroxy-3-methylglutaryl coenzyme A reductase inhibitors (statins), which are common drugs for patients with severe heart failure (Choi et al. 2005; Folkers et al. 1990; Mortensen et al. 1997; Overvad et al. 1999). The use of CoQ10 as a complementary therapy in heart failure will increase in proportion to the growth of the ageing population and the expansion in statins consumption. Economical production of CoQ10 using biological processes will become more important due to the growing demands of the pharmaceutical industry (Choi et al. 2005).

CoQ10 can be produced by chemical synthesis (Negishi et al. 2002), semi-chemical synthesis (Lipshutz et al. 2002), and microbial conversion. Wild-type strains and chemical mutants of various microorganisms, including bacteria (e.g., Agrobacterium, Rhodobacter, and Paracoccus) and yeasts (e.g., Candida, Rhodotorula, and Saitoella) have been reported as CoQ10 producers. Further strain development and optimization of fermentation strategies and environmental parameters has resulted in yield improvement of CoQ10 in mutant strains (Gu et al. 2006a; Sakato et al. 1992; Wu et al. 2003; Yen and Chiu 2007). Recombinant cells of various microorganism containing the key genes involved in CoQ10 biosynthesis (Lee et al. 2004; Park et al. 2005; Zhang et al. 2007a; Zhang et al. 2007b; Zhang et al. 2007c; Cheng et al. 2010) and metabolic modification of microorganism also improved CoQ10 yields (Choi et al. 2009; Lee et al. 2008; Matthews and Wurtzel 2000; Wu et al. 2005; Zahiri et al. 2006).

Among reported CoQ10-producing microorganism, Agrobacterium tumefaciens exhibited the highest CoQ10 yield in a fed-batch fermentation process (Gu et al. 2006b; Ha et al. 2007a; Ha et al. 2007b; Ha et al. 2008). The CoQ10 yield of A. tumefaciens reached 526 mg l−1 after 96 h fed-batch fermentation in a 2.8 l bioreactor, and increased to 626.5 mg l−1 CoQ10 at a pilot scale (300 l) in a pH-stat fed-batch system. Among mutant strains for high CoQ10 production, Rhodopseudomonas spheroids KY8598 exhibited the highest CoQ10 yield up to 770 mg l−1 (Cluis et al. 2007). However, lower cost and higher yield of CoQ10 remains a major research aim of biochemical engineering for the industrial production of CoQ10 using biological processes (Jeya et al. 2010). Process simplification and integration is one favorable pathway towards economical production of valuable metabolites by microbes. For example, the process of simultaneous extraction and fermentation has been applied successfully in lactic acid fermentation (Kwon et al. 1996). It is well known that the accumulation of primary metabolites can result in feedback inhibition in cells (Lin et al. 1997; Shiio and Miyajima 1969). As a kind of primary metabolite within the cell, the gradual accumulation of CoQ10 would cause the inhibition of the bioconversion of CoQ10. Prompt removal of the CoQ10 out of the cell might conduce to maintain continual synthesis of CoQ10.

Furthermore, in situ extraction of CoQ10 by a non-aqueous phase contributes to the simplification of downstream processing and cost decrease. Thus, we previously designed a coupled fermentation–extraction process and succeeded to improve CoQ10 yield by Sphingomonas sp. ZUTE03 (Zhong et al. 2009). However, other metabolites or residual component in medium might be extracted by hexane from the mixed phase of fermentation broth, which might result in the cost increase of CoQ10 purification. Biotransformation has many advantages over chemical synthesis (Wang et al. 2002) and fermentation in a complex medium. A biotransformation process of CoQ10 directly from precursors in a water-organic solvent, two-phase system might decrease the cost of downstream purification, because fewer metabolites would be extracted into organic phase. Meanwhile, such system is also equal to conversion–extraction couple process, which might contribute to enhance the production of CoQ10. Therefore, a conversion process for CoQ10 production by Sphingomonas sp. ZUTE03 was evaluated in this study. To our knowledge, this is the first report on production of CoQ10 directly from precursors in a two-phase conversion system.

Materials and methods

Chemicals

CoQ10 (purity above 99.9%) was purchased from Wako Pure Chemical Industries (Osaka, Japan). Solansol was purchase from Sanqiang Biotech Co. Ltd. (Weifang, China). Other chemicals were purchased locally.

Strain and culture conditions

Sphingomonas sp. ZUTE03, which exhibited greater ability of CoQ10 production, was isolated from soil from the banks of the Qiantang River, Zhejiang Province, China. The strain has been deposited at China Center for Type Culture Collection (CCTCC) under the accession number CCTCC M207084.

The seed medium contained 20 g l–1 glucose, 10 g l–1 peptone, 10 g l–1 yeast extract, and 5 g l–1 NaCl. The initial pH of the above medium was adjusted to 7.0 with 2 M NaOH. The prepared medium was then transferred into 250 or 500 ml Erlenmeyer flasks and autoclaved at 115°C for 30 min. All experimental cultures were incubated at 180 rpm and 28°C.

CoQ10 production in a two-phase conversion system containing solanesol and PHB

A bioconversion system for CoQ10 production was batch-type cultivation and designed as follows. One loop of strain ZUTE03 from a slant was inoculated into 100 ml seed medium in a 250 ml flask. After 24 h incubation at 180 rpm and 28°C, cells were harvested by centrifugation at 4,000 rpm and 4°C for 10 min, and then suspended in the 40 ml aqueous phase, phosphate-buffer saline (PBS, 0.1 M, pH = 5), mixed with the 10 ml isopropyl alcohol (as the organic phase) for the consequential bioconversion at 28°C and 180 rpm for 12 h.

According to the result of our previous study, 164.4 mg l−1 para-hydroxybenzoic acid (PHB), 750 mg l−1 solanesol, and the mixture, were dissolved in 10 ml isopropyl alcohol respectively, and then mixed with 40 ml cells suspension in a 250 ml flask as a bioconversion system. After 12 h incubation at 28°C and 180 rpm, CoQ10 yield in the cells was determined to evaluate the effect of precursors or precursor combination on the CoQ10 production by bioconversion process.

To select a suitable organic solvent for the bioconversion process, isopropyl alcohol, hexane, and ethanol were added as the 10 ml organic component in the 50 ml bioconversion system to evaluate their effect on intracellular CoQ10 yield.

After the optimal organic solvent was selected, yields of CoQ10 in the organic solvent and inside the cells were measured, respectively. The results suggested a couple conversion–extraction process was feasible. Therefore, a conversion system for the coupled process was designed again, which contained 30 ml aqueous phase (0.1 M, pH 5, PBS containing 164.4 mg l−1 PHB) and 20 ml organic phase (i.e., extraction solvent containing 750 mg l−1 solanesol) in a 250 ml flask. Based on a previous report (Benga et al. 1984) and our previous results (Zhong et al. 2009), 2% soybean oil, was selected as the cell membrane permeability accelerant in this experiment. Then, the time course of CoQ10 production by free cells was measured in the same bioconversion system.

CoQ10 production by gel-entrapped cells in a two-phase conversion system

One loop of strain ZUTE03 from a slant was inoculated into 100 ml seed medium in a 250 ml flask. After 24 h incubation at 180 rpm and 28°C, cells were harvested by centrifugation at 4,000 rpm and 4°C for 10 min, and then suspended in saline solution. Then, 4 ml of suspension containing the same quantity of cells (adjusted to same OD600) was mixed with 40 ml 2% sodium alginate, and dripped down to 40 ml 4% calcium chloride in a 250 ml flask to form gel-entrapped cells.

In a 250 ml flask, about 600 particles of cell-entrapped gel was mixed with 50 ml bioconversion system containing 2% soybean oil. The aqueous phase PBS was replaced by acetate buffer because PBS caused the break of gels, when in repeated batch. The volume of organic phase was increased to 25 ml hexane (containing 100 mg l−1 solanesol) with 25 ml 0.2 M acetate buffer (pH 4.6, containing 50 mg l−1 PHB). The extract solvent was collected from the upper layer of the broth as the analytical sample for CoQ10 yield at an interval of 4 h.

Extraction and measurement of CoQ10

For the residual broth of simple bioconversion process, cells were harvested by centrifugation at 15,000 rpm and 4°C for 15 min with a centrifuge (Sanyo, Japan). After washing the cell pellet twice with distilled water, 2 g cell pellet was transferred into a fresh round-bottom flask (150 ml) and mixed with 0.35 g pyrogallic acid, 1.25 g KOH, 9.5 ml methanol and 3.5 ml distilled water. The mixture was kept in reflux state at a 90°C water bath for 30 min before cooling rapidly with tap water, and then transferred to a separating funnel where it was mixed with 40 ml hexane. After vortexing vigorously for 5 min, the upper organic phase was collected in a fresh tube. The extraction procedure was repeated twice and the extracted solvent was collected together followed by a concentration process in a rotary vacuum evaporator. After overnight storage at 4°C, impurities such as cholesterol would be precipitated. After removal of impurities by filtration, the solvent quantity was adjusted accurately to 50 ml with hexane before CoQ10 assay.

For the residual broth from the coupled conversion–extraction process, the upper layer of the non-aqueous phase was recovered by a separating funnel. The non-aqueous phase was then concentrated in a rotary vacuum evaporator. After overnight storage at 4°C, impurities such as cholesterol would be precipitated. After removal of impurities by filtration, the solvent quantity was adjusted accurately to 50 ml with hexane before CoQ10 assay.

CoQ10 concentrations in all the liquid samples were analyzed by high-performance liquid chromatography (HPLC; SPD-10AVP, SHIMADZU, Japan) equipped with Agilent SB-C18 (4.6 × 150 mm). A mixture of methanol and hexane (83:17 by volume) was used as the mobile phase at a flow rate of 0.6 ml min−1, UV detector wavelength 275 nm, and a sampling quantity of 20 μl.

Measurement of solanesol and PHB

After removal of impurities by filtration through a 0.45 μm microfiltration membrane, solanesol concentrations in all the liquid samples were analyzed by HPLC (Agilent 1100, USA) equipped with Agilent ZORBAX SB-C18 (5 μm, 4.6 × 150 mm). HPLC-grade ethanol was used as the mobile phase at a flow rate of 1 ml min−1, UV detector wavelength 215 nm, and a sampling quantity of 20 μl.

After removal of impurities by filtration through a 0.45 μm microfiltration membrane, PHB concentrations in all the liquid samples were also analyzed by HPLC (Agilent 1100, USA) equipped with Agilent ZORBAX SB-C18 (5 μm, 4.6 × 150 mm). A methanol solution (60% by volume) was used as the mobile phase at a flow rate of 1 ml min−1, UV detector wavelength 254 nm, and a sampling quantity of 10 μl.

Analysis of cell mass

Biomass was calculated according to a standard curve of the relationship between optical density of cells and dry cell weight (DCW) of Sphingomonas sp. ZUTE03. Cells were harvested by centrifugation (12,000 rpm, 10 min, 4°C) from 5 ml liquid culture each time. The optical density of cells was determined at 550 nm using a spectrophotometer (752, Shanghai, China) after the cells were washed three times with 5 ml 50 mM potassium phosphate buffer (pH 7.0).

Statistical analysis methodology

Each sample in the experiment was in triplicate. Software Origin 8.0 was used to draw the figures with error bars.

Results

CoQ10 conversion by free Sphingomonas sp. ZUTE03 in a two-phase conversion system

After 12 h incubation with precursors, the cells of Sphingomonas sp. ZUTE03 were harvested from the conversion system by centrifuge and the CoQ10 yield inside cells was measured. The result was shown in Fig. 1. It indicated that the addition of precursor could improve the CoQ10 yield. However, the combination of solanesol and PHB was most effective. It coincided with the pathway of CoQ10 biosynthesis, in which both solanesol and PHB were the key precursors and should be supplied simultaneously (Cluis et al., 2007). In addition, it was also approved that the conversion system was feasible for the CoQ10 conversion directly from precursors.

Because the precursor solanesol is not soluble in the aqueous phase, one kind of organic solvent should be added in the conversion system to increase the solubility of precursor in reaction system and reduce the mass transfer resistance. In addition, the organic solvent might be able to extract the product CoQ10 simultaneously. However, the organic solvent might be harmful to the cells and result in the activity decrease of enzymes in the cell. Therefore, the most suitable organic solvent should be selected for the optimal conversion system. In this study, isopropyl alcohol, alcohol, and hexane were chosen as the potential organic phase in the conversion system to evaluate their effect on the CoQ10 yield in the cells.

It was found that CoQ10 yield was the highest with hexane and lowest with isopropyl alcohol as organic phase (data not shown). Additionally, hexane is not mutual soluble with the aqueous phase while isopropyl alcohol and alcohol are. Under static condition, the hexane phase could be separated easily from the aqueous phase. Under shaking condition, the hexane phase could partially mix with aqueous phase and might result in the substrate-cell contact and the better conversion in the cells. So hexane was chosen as the organic phase for the following study. Additionally, after 48 h cultivation with hexane, more than 86% cells kept alive (plate counting method).

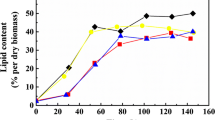

The distribution of CoQ10 inside and outside of cells was measured when hexane was employed as the organic phase in the conversion system and 2% soybean oil was added as cell membrane permeability accelerator. The result (Fig. 2 a) showed that the CoQ10 concentration in hexane was significantly higher than that inside the cells during the conversion time ranged from 12 to 20 h. In this study, more than 30 times higher CoQ10 yield was achieved in the hexane than inside cells. It suggested that the hexane could extract the CoQ10 continuously from the cells and result in the high CoQ10 concentration in hexane phase due to the removing of product inhibition inside the cells. In addition, the hexane phase was easy to be separated from the aqueous phase. Therefore, it would be helpful to the downstream purification and analysis. Additionally, CoQ10 yield reach a maximal value of 60.8 mg l−1 and 40.6 mg g−1-DCW after 8 h and kept at a high level until 20 h (Fig. 2 b). The achievement of the maximal CoQ10 yield in such a short time would be favorable for industrial application. Thus, we chose 8 h for the following coupled conversion–extraction process experiment in the two-phase system.

CoQ10 production by gel-entrapped cells in a two-phase conversion system

Before evaluating the CoQ10 production by gel-entrapped cells with a coupled conversion–extraction process, the permeability of CoQ10 in the alginate gel was measured. It was found that more than 91% of CoQ10 released from the gel and transferred into the organic phase after 4 h indicating that the CoQ10 could be released from the alginate gel. In addition, CoQ10 concentration in the organic phase could keep at the same level for at least 12 h. However, CoQ10 concentration decreased after 16 h, suggesting that it should better extract the final product from the organic phase as soon as possible after it reached the maximal yield.

According to our previous study results (Zhong et al. 2009), propendiol, Tween-80, and soybean oil might be the candidates as cell membrane permeability accelerators on the CoQ10 production with the coupled process of conversion–extraction in the two-phase system. Therefore, the effect of propendiol, Tween-80, and soybean oil on the CoQ10 production by the gel-trapped cells was also evaluated. It was found that the cell-entrapped alginate gels broke after 8 h reaction with Tween-80 which meant Tween-80 was not suitable for the calcium alginate gel-entrapped cells. When propendiol and soybean oil were employed as cell membrane permeability accelerators, the gels did not break. However, the CoQ10 yield with soybean oil as cell membrane permeability accelerator was significantly higher than that with propendiol as cell membrane permeability accelerator (P < 0.01; data not shown). Therefore, soybean oil was selected as the cell membrane permeability accelerator for the following experiments. The results (Fig. 3) indicated that the CoQ10 yield with soybean oil was significantly higher than that without soybean oil (P < 0.01), and that CoQ10 yield could reach a high level (51.6 mg l−1 and 38.5 mg g−1-DCW) only after 8 h in the conversion system using conversion–extraction coupled process.

CoQ10 production by a repeated-batch culture of gel-entrapped cells

CoQ10 production by a repeated-batch culture of calcium alginate gel-entrapped cells was also evaluated. It was found the cell-entrapped gels broke in repeat-batch culture with PBS in conversion system, while cell-entrapped gels kept well without any significant influence on the production of CoQ10 or conversion when using acetate buffer as buffer system. Thus, acetic acid buffer (pH 4.6) was selected as a substitute aqueous phase, in which no gel broke again. The result (Fig. 4) indicated that the gel-entrapped cells could repeat CoQ10 production by coupled conversion–extraction process. After 15 times repeats of 8 h batch culture, CoQ10 yield kept at higher level of more than 40 mg l−1. CoQ10 yield was also found to reach the highest level only after 8 h in the conversion system using coupled conversion–extraction process. To reach the maximal yield in such a short time meant the lowering of cost especially for the large scale production, which suggested that the coupled process was favorable to its industrial application.

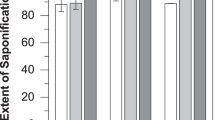

Optimization of precursor concentration for CoQ10 production by gel-entrapped cells

Among the above results, the maximal molar conversion rate of CoQ10 from PHB was only 80%. It suggested that the optimization of precursor concentration played key role in the improvement of the molar conversion rate. Both single-factor test and orthogonal test were carried out to evaluate the effect of precursor additional concentration on the CoQ10 yield, conversion rate and residual concentration of precursors. The results of single-factor test (Fig. 5 a, b) showed that both higher CoQ10 yield and the highest conversion rate were achieved when 40 mg l−1 PHB was added with 100 mg l−1 solanesol. When PHB concentration increased to 50 and 60 mg l−1, no significant improvement of CoQ10 yield and conversion rate was observed while the residual PHB increased. Both higher CoQ10 yield and the highest conversion rate were achieved when 70 mg l−1 soalnesol was added with 40 mg l−1 PHB (Fig. 5 c, d). When solanesol concentration increased to 80, 90, or 100 mg l−1, no significant improvement of CoQ10 yield and conversion rate occurred while the residual solanesol increased. Thus, the optimal concentration of precursors seemed to be 40 mg l−1 PHB with 70 mg l−1 solanesol. However, further optimization of precursor concentration is necessary. Thus, a double-factor orthogonal experiment using L9 (3)3 was designed to optimize precursor concentration and evaluate the effect of the reciprocal effect between solanesol and PHB on the CoQ10 yield. The results demonstrated that solanesol and PHB had stronger effect on CoQ10 yield and conversion rate (larger margin, R A, B, C of solanesol = 2.4, 2.2, 1.6, R A, B, C of PHB = 4.2, 1.7, 2.3) than the reciprocal effect between solanesol and PHB (smaller margin, R A, B, C = 0.3, 0.4, 0.6). Thus, the optimal additional concentrations could be determined by the k values of solanesol and PHB, which were 70 and 35 mg l−1, respectively (Tables 1 and 2). Under this optimal concentration, the maximal CoQ10 yield was up to 52.2 mg l−1, while the conversion rate on PHB and solanesol reached 91% and 89.6%, respectively.

Discussion

It is well known that the addition of precursors could improve the yield of CoQ10 in fermentation system. For example, Li et al. (2005) reported that the addition of some pure precursors, like PHB, isoprene and beta-carotene, significantly improved CoQ10 yield by a bacterial strain CPU0402. Bule and Singhal (2009) reported natural precursors, such as carrot juice and tomato juice, enhanced production of CoQ10 by Pseudomonas diminuta NCIM 2865. However, there exist few reports on CoQ10 production directly from the precursors by microbes. In this study, we found that CoQ10 could be produced directly from the precursors, solanesol and PHB, by free cells of Sphingomonas sp. ZUTE03 in a two-phase conversion system. The most excited findings were that higher CoQ10 yield in organic phase was achieved and the mechanism might attribute to that a coupled conversion–extraction process improved CoQ10 yield of free cells. CoQ10 could also be produced directly from PHB and solanesol by gel-entrapped cells of Sphingomonas sp. ZUTE03 with a coupled conversion–extraction process in the two-phase system, which could be improved by the addition of soybean oil and hexane. Soybean oil might improve the release of CoQ10 from the gel-entrapped cells while hexane was the most suitable solvent to extract CoQ10 from the aqueous-organic mixture. CoQ10 could also be produced by a repeated-batch culture of calcium alginate gel-entrapped cells with conversion–extraction process in the two-phase system. After 15 repeats, the CoQ10 yield still kept at a high level of more than 40 mg l−1.

Although the CoQ10 yield in two-phase system of conversion–extraction coupled process was lower than that of fed-batch process in previous reports (Cluis et al. 2007), this study achieved the highest specific CoQ10 yield (Table 3). For instance, R. spheroids (Cluis et al. 2007) exhibited the highest levels of CoQ10 yield among all strains for CoQ10 production. However, the specific CoQ10 yield of R. spheroid was lower than that of this study, suggesting that the coupled process we presented here might potentially be used in combination with fed-batch process to further improve CoQ10 production by R. spheroid. In the same way, we need to increase the cell mass in the coupled process to the same high level as that obtained in fed-batch process to achieve high CoQ10 yield by Sphingomonas sp. ZUTE03. Additionally, the comparison of the maximum volumetric productivity (Table 3) indicated the maximum volumetric productivity for the present study (7.6 mg l−1 h−1) was higher than that for Sekato et al. (5.1 mg l−1 h−1) and for Ha et al. (5.9 mg l−1 h−1), suggesting that this process was superior to fed-batch process.

In comparison to coupled fermentation–extraction process, this study achieved higher CoQ10 yield in shorter time. In addition, the purity of the product in organic phase was higher with fewer impurity substances. Therefore, this kind of coupled process would contribute to the simplification of downstream processing and might result in decreased production cost. However, the necessary research for us to carry out in the future will be the optimization of conversion conditions to improve the CoQ10 yield and the molar conversion rate as well as reduce the residual concentration of precursors.

It was also necessary to design a bioreactor suitable for coupled conversion–extraction process before its application in pilot scale. In this study, the hexane phase was contacted with the aqueous phase by shaking (180 rpm) in a small shake flask (250 ml). To scale up the present process, the performance of contact between organic and aqueous phase in a bioreactor should be taken into consideration. A three-phase fluid bed bioreactor (D inner = 3.6 cm, H = 46 cm) has been constructed in our lab to evaluate the feasibility of the scale up and application of this process. In the bioreactor, it was proved that two phases could be mixed well and high-level CoQ10 production was also achieved (data not shown). Therefore, the process is potential and feasible to be scaled up into a large scale and finally be applied in industrial production of CoQ10.

References

Benga G, Travis BD, Pop VI, Popescu O, Toader S, Holmes RP (1984) The effect of the saturation and isomerization of dietary fatty-acids on the osmotic fragility and water diffusional permeability of rat erythrocytes. Biochim Biophys Acta 775(2):255–259

Bule MV, Singhal RS (2009) Use of carrot juice and tomato juice as natural precursors for enhanced production of ubiquinone-10 by Pseudomonas diminuta NCIM 2865. Food Chem 116:302–305

Cheng B, Yuan QP, Sun XX, Li WJ (2010) Enhanced production of coenzyme Q10 by overexpressing HMG-CoA reductase and induction with arachidonic acid in Schizosaccharomyces pombe. Appl Biochem Biotechnol 160:523–531

Choi JH, Ryu YW, Seo JH (2005) Biotechnological production and applications of coenzyme Q(10). Appl Microbiol Biotechnol 68(1):9–15

Choi JH, Ryu YW, Park YC, Seo JH (2009) Synergistic effects of chromosomal ispB deletion and dxs overexpression on coenzyme Q(10) production in recombinant Escherichia coli expressing Agrobacterium tumefaciens dps gene. J Biotechnol 144(1):64–69

Cluis CP, Burja AM, Martin VJJ (2007) Current prospects for the production of coenzyme Q10 in microbes. Trends Biotechnol 25(11):514–521

Folkers K, Langsjoen P, Willis R, Richardson P, Xia LJ, Ye CQ, Tamagawa H (1990) Lovastatin decreases coenzyme-Q levels in humans. Proc Natl Acad Sci USA 87(22):8931–8934

Gu SB, Yao JM, Yuan QP, Xue PJ, Zheng ZM, Wang L, Yu ZL (2006a) A novel approach for improving the productivity of ubiquinone-10 producing strain by low-energy ion beam irradiation. Appl Microbiol Biotechnol 72(3):456–461

Gu SB, Yao JM, Yuan QP, Xue PJ, Zheng ZM, Yu ZL (2006b) Kinetics of Agrobacterium tumefaciens ubiquinone-10 batch production. Process Biochem 41(8):1908–1912

Ha SJ, Kim SY, Seo JH, Moon HJ, Lee KM, Lee JK (2007a) Controlling the sucrose concentration increases coenzyme Q10 production in fed-batch culture of Agrobacterium tumefaciens. Appl Microbiol Biotechnol 76(1):109–116

Ha SJ, Kim SY, Seo JH, Oh DK, Lee JK (2007b) Optimization of culture conditions and scale-up to pilot and plant scales for coenzyme Q(10) production by Agrobacterium tumefaciens. Appl Microbiol Biotechnol 74(5):974–980

Ha SJ, Kim SY, Seo JH, Sim WI, Moon HJ, Lee JK (2008) Lactate increases coenzyme Q(10) production by Agrobacterium tumefaciens. World J Microbiol Biotechnol 24(6):887–890

Jeya M, Moon HJ, Lee IW, Lee JK (2010) Current state of coenzyme Q(10) production and its applications. Appl Microbiol Biotechnol 85:1653–1663

Kwon YJ, Kaul R, Mattiasson B (1996) Extractive lactic acid fermentation in poly(ethyleneimine)-based aqueous two-phase system. Biotechnol Bioeng 50(3):280–290

Lee JK, Her G, Kim SY, Seo JH (2004) Cloning and functional expression of the dps gene encoding decaprenyl diphosphate synthase from Agrobacterium tumefaciens. Biotechnol Prog 20(1):51–56

Lee PC, Salomon C, Mijts B, Schmidt-Dannert C (2008) Biosynthesis of ubiquinone compounds with conjugated prenyl side chains. Appl Environ Microbiol 74(22):6908–6917

Lin JP, Chen B, Wu JP, Cen PL (1997) L-Lactic acid fermentation in a rotating-disc contactor with simultaneous product separation by ion-exchange. Chin J Chem Eng 5(1):49–55

Lipshutz BH, Mollard P, Pfeiffer SS, Chrisman W (2002) A short, highly efficient synthesis of coenzyme Q(10). J Am Chem Soc 124(48):14282–14283

Li M, Lv WF, Gao XD (2005) Primary investigation on coenzyme Q10 producing bacteria CPU0402. Pharm Biotechnol 12(3):162–166, In Chinese

Matthews PD, Wurtzel ET (2000) Metabolic engineering of carotenoid accumulation in Escherichia coli by modulation of the isoprenoid precursor pool with expression of deoxyxylulose phosphate synthase. Appl Microbiol Biotechnol 53(4):396–400

Mortensen SA, Leth A, Agner E, Rohde M (1997) Dose-related decrease of serum coenzyme Q(10) during treatment with HMG-CoA reductase inhibitors. Mol Aspects Med 18:S137–S144

Negishi E, Liou SY, Xu CD, Huo SQ (2002) A novel, highly selective, and general methodology for the synthesis of 1, 5-diene-containing oligoisoprenoids of all possible geometrical combinations exemplified by an iterative and convergent synthesis of coenzyme Q(10). Org Lett 4(2):261–264

Overvad K, Diamant B, Holm L, Holmer G, Mortensen SA, Stender S (1999) Coenzyme Q(10) in health and disease. Eur J Clin Nutr 53(10):764–770

Park YC, Kim SJ, Choi JH, Lee WH, Park KM, Kawamukai M, Ryu YW, Seo JH (2005) Batch and fed-batch production of coenzyme Q(10) in recombinant Escherichia coli containing the decaprenyl diphosphate synthase gene from Gluconobacter suboxydans. Appl Microbiol Biotechnol 67(2):192–196

Sakato K, Tanaka H, Shibata S, Kuratsu Y (1992) Agitation aeration studies on coenzyme-Q10 production using rhodopseudomonas-sphaeroides. Biotechnol Appl Biochem 16(1):19–28

Shiio I, Miyajima R (1969) Concerted inhibition and its reversal by end products of aspartate kinase in brevibacterium flavum. J Biochem 65(6):849–859

Szkopinska A (2000) Ubiquinone. Biosynthesis of quinone ring and its isoprenoid side chain. Intracellular localization. Acta Biochim Pol 47(2):469–480

Wang ZF, Huang YL, Rathman JF, Yang ST (2002) Lecithin-enhanced biotransformation of cholesterol to androsta-1, 4-diene-3, 17-dione and androsta-4-ene-3, 17-dione. J Chem Technol Biotechnol 77:1349–1357

Wu ZF, Du GC, Chen J (2003) Effects of dissolved oxygen concentration and DO-stat feeding strategy on CoQ(10) production with Rhizobium radiobacter. World J Microbiol Biotechnol 19(9):925–928

Wu Z-f, Du G-c, Chen J (2005) Effects of culture conditions on coenzyme Q(10) production by Rhizobium radiobacter by metabolic flux analysis. Weishengwu Xuebao 45(2):231–235

Yen HW, Chiu CH (2007) The influences of aerobic-dark and anaerobic-light cultivation on CoQ(10) production by Rhodobacter sphaeroides in the submerged fermenter. Enzyme Microb Technol 41(5):600–604

Zahiri HS, Yoon SH, Keasling JD, Lee SH, Kim SW, Yoon SC, Shin YC (2006) Coenzyme Q(10) production in recombinant Escherichia coli strains engineered with a heterologous decaprenyl diphosphate synthase gene and foreign mevalonate pathway. Metab Eng 8(5):406–416

Zhang DW, Li Z, Wang FH, Shrestha B, Tian PF, Tan TW (2007a) Expression of various genes to enhance ubiquinone metabolic pathway in Agrobacterium tumefaciens. Enzyme Microb Technol 41:772–779

Zhang DW, Shrestha B, Li ZP, Tan TW (2007b) Ubiquinone-10 production using Agrobacterium tumefaciens dps gene in Escherichia coli by coexpression system. Mol Biotechnol 35(1):1–14

Zhang DW, Shrestha B, Niu WN, Tian PF, Tan TW (2007c) Phenotypes and fed-batch fermentation of ubiquinone-overproducing fission yeast using pp t1 gene. J Biotechnol 128(1):120–131

Zhong W, Fang J, Liu H, Wang X (2009) Enhanced production of CoQ(10) by newly isolated Sphingomonas sp ZUTE03 with a coupled fermentation-extraction process. J Ind Microbiol Biotechnol 36(5):687–693

Acknowledgment

This study was supported by the Science and Technology Department of Zhejiang Province of PR China under Grant No. 2007C23035, for which the authors are grateful.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhong, W., Wang, W., Kong, Z. et al. Coenzyme Q10 production directly from precursors by free and gel-entrapped Sphingomonas sp. ZUTE03 in a water-organic solvent, two-phase conversion system. Appl Microbiol Biotechnol 89, 293–302 (2011). https://doi.org/10.1007/s00253-010-2876-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-010-2876-9