Abstract

The numerous physiological functions of the nonessential amino acid L-aspartate, the semi-essential amino acid L-arginine, and the essential amino acid L-lysine, made them attractive for a wide range of nutritional and/or therapeutic applications. Furthermore, the administration of these amino acids as mixtures or as dipeptides for higher bioavailability is scientifically approved, and various commercial products of these forms are already available on the market. Although the industrial production of dipeptides is, with few exceptions, in an early stage, several strategies have been established and are compared in this review. Additionally, the recent developments in the technical production of aspartate–arginine and aspartate–lysine dipeptides from the biopolymer cyanophycin produced in microorganisms are discussed. Cyanophycin-derived dipeptides are produced exclusively by biotechnological procedures, probably possess higher bioavailability and may be used as better alternatives to the widely applied amino acid mixtures. Thus, the pivotal advantages and the potential applications of these dipeptides as well as of their constituting amino acids in nutrition and therapy are also discussed. Special emphasis is dedicated to arginine due to its numerous physiological roles in many cardiovascular, genitourinary, gastrointestinal, and immune disorders.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Protein malnutrition causes an impaired systemic immune function and therefore raises susceptibility to infection (Meredith et al. 1990; Dock et al. 2004). Hydrolyzed protein diets are used as nitrogen source for the recovery of malnourished patients (Meredith et al. 1990). These diets contain di- and tripeptides, which are more efficiently utilized than intact proteins or free amino acids, have greater nutritional value, and are better absorbed (at an up to 185% higher rate than in the free form). Until the 1970s, it was believed that proteins must be hydrolyzed to amino acids in the gut lumen first before absorption could occur. Later, the physiological importance of oligopeptides became evident when their appearance and subsequent disappearance in the human gut lumen after a protein meal was discovered (Silk et al. 1975). Absorption studies in patients with genetically impaired transport of certain amino acids showed normal absorption of these amino acids when they were administered in the dipeptide form (Silk et al. 1975; Leonard et al. 1976). Consequently, oligopeptide transporters in gut are now known to play a major role in the completion of protein digestion. This knowledge revealed the importance of precise information about digestion mechanisms of protein and amino acids for human health (Daniel et al. 2006). Also in animal and fish farming, such data are necessary to ensure growth balance and thereby reducing feeding costs (Ahmed and Khan 2004).

Several species of cyanobacteria including Spirulina were promoted as nutritional sources for humans and animals (Kihlberg 1972; Ross and Dominy 1990). Spirulina has protein contents of higher than 60% (wt/wt) and is often associated with nutritional benefits (Kihlberg 1972). Consequently, it was chosen as the “best food for the future” during the United Nations World Food Conference in 1974. As Spirulina was included in the sustainable development agenda, governments of several member states of the United Nations formed an organization named: Intergovernmental Institution for the use of Micro-algae Spirulina Against Malnutrition (IIMSAM) (www.iimsam.org). The organization objective is based on Spirulina as key driver to eradicate malnutrition and to achieve food security throughout the world. Spirulina has been proposed also by the American National Aeronautics and Space Administration (NASA) and the European Space Agency (ESA) as one of the primary foods to be cultivated during long-term space missions (M. G. Tadros, 1989. NASA–CR-185329; J. F. Cornet and G. Dubertret. Workshop on artificial ecological systems. DARA–CNES, Marseille, Fr., 24–26 Oct. 1990.).

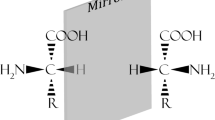

Cyanophycin Grana Polypeptide (CGP), which is an intracellular storage polymer of most cyanobacteria including Spirulina, was already discovered in 1887 (Sallam et al. 2009). Most genera of cyanobacteria and also several heterotrophic bacteria harbor a functional cyanophycin synthetase gene (cphA) and synthesize CGP (Sallam and Steinbüchel 2009b; Steinle et al. 2009). The branched polymer consists of equimolar amounts of arginine and aspartic acid arranged in the form of a poly(aspartic acid) backbone, with arginine moieties linked to the β-carboxyl group of each aspartic acid by its α-amino group (Fig. 1). CGP occurs in the cytoplasm usually as insoluble intracellular membraneless granules (Steinle et al. 2009). Several cyanobacterial cphA genes were heterologously cloned in Escherichia coli, Corynebacterium glutamicum, Ralstonia eutropha, and Pseudomonas putida and were successfully applied for large scale production of CGP (Fig. 1). Recently, CGP was also produced in tobacco and potato plants (Neumann et al. 2005) and in yeast (Steinle et al. 2009). CGP produced in recombinant strains contains also small amounts of lysine (Sallam et al. 2009; Steinle et al. 2009) while ornithine, citrulline, and canavanine were in vitro incorporated in CGP using extracted CphAs (Berg 2003; Steinle et al. 2009). Ornithine and citrulline were recently detected as constituents of CGP in metabolically engineered transgenic yeasts (Steinle et al. 2009).

a Chemical structure of the aspartic acid–arginine dipeptide building block of CGP (n = 90–400). The aspartic acid in the backbone is shown in black, whereas arginine is shown in grey. b Phase-contrast micrograph of R. eutropha H16-PHB–4-∆eda (pBBR1MCS-2::cphA6308/edaH16) after 72 h cultivation in MSM containing 1.5% (wt/vol) sodium gluconate (fed batch fermentation) (Voss 2005). c Electron micrograph of R. eutropha H16-PHB–4 (pBBR1MCS-2::cphA7120) cultivated for 48 h in MSM medium containing 1.5% (wt/vol) sodium gluconate and 0.2% (wt/vol) each of aspartate and arginine (Voss 2005)

CGP-producing organisms are widely spread in different natural habitats. However, it is resistant against hydrolytic cleavage by several proteases and arginase (Berg 2003) but is degraded by intracellular or by extracellular CGPases (CphB and CphE, respectively). Bacteria possessing CphE were found in various habitats. CphEPa, CphEBm, and CphEal were isolated and characterized from Pseudomonas anguilliseptica BI, Bacillus megaterium BAC19, and the facultative anaerobic Pseudomonas alcaligenes DIP1, respectively (Sallam et al. 2009). Also strictly anaerobic bacteria such as Sedimentibacter hongkongensis KI produced an extracellular CGPase and degraded CGP (Obst et al. 2005). All known CGPases produced water soluble β-dipeptides from CGP which were then transported into the cells to be further catabolized (Sallam et al. 2009).

The administration of amino acids as dipeptides and in particular as mixtures was scientifically approved, and products containing these preparations have been commercialized (Duruy 1968; Sellier 1979; De-Aloysio et al. 1982; Elsair 1985; Lamm et al. 2003; Barbul et al. 1990; Tables 1 and 2). On the other hand, the wide spread occurrence of CGP-degrading bacteria in several investigated mammalian, avian, and fish gut flora (Sallam and Steinbüchel 2009b) indicated that CGP is probably digested and absorbed in the digestive tract. Thus, CGP was suggested to be a highly bioavailable form (as β-dipeptides) for the administration of its constituting amino acids in nutrition and therapy. Accordingly, a large-scale process for the downstream production of β-dipeptides from CGP was recently designed and optimized (Sallam et al. 2009). The aim of this article is to provide a general overview on the properties, production techniques, physiological transport, as well as on the proven nutritional and therapeutic applications of synthetic dipeptides or mixtures of amino acids that can be replaced by CGP dipeptides.

Synthesis and large-scale production of dipeptides

There are much more natural β-amino acids than proteinogenic α-amino acids, and this number is even exceeded by the various γ-amino acids. Whereas unusual amide linkages, in which γ-carboxylic groups and ɛ-amino groups are involved, can be found in natural polymers such as poly(ɛ–l-lysine) and poly(γ-glutamic acid), until now, no natural peptides that are solely composed of β-amino acids have been described. However, many natural products of bacterial origin like bestatin, of plant origin like paclitaxel (Taxol) or of human and animal origin like carnosine contain β-amino acids (Geueke and Kohler 2007).

In industry, two major strategies of peptide synthesis are well established, the chemical (Merrifield 1963; Berg 2003) and the enzymatic methods (Yagasaki and Hashimoto 2008). In the following section, both principles will be mentioned briefly and two examples for the large scale production of defined dipeptides will be discussed in detail: (1) The production of the sweetener aspartame, which is a combined upstream approach of the chemical and the enzymatic principles, and (2) the production of β-dipeptides from CGP which is a downstream enzymatic approach.

Chemical synthesis

Two main methods are known for the chemical synthesis of peptide: solid phase and solution synthesis. The former method is favored because the peptide is synthesized while immobilized on a solid resin. This allows the reaction to be terminated at anytime and subsequently harvesting intermediate products like di- or tripeptides without much effort required for purification (Merrifield 1963). The general principle of chemical peptide synthesis depends on the targeted alternation between protecting and exposing amino or carboxylic groups of amino acids using special protecting groups and chemicals, respectively, to push the reaction in the desired direction.

The chemical synthesis of β-peptides was published in 1996 for the first time (Seebach et al. 1996), and since then, the special features of these compounds have been investigated intensively (Geueke and Kohler 2007). Although any dipeptide can be synthesized by chemical methods, fulfilling the researcher's demands, the high production costs prevented wider commercialization (Yagasaki and Hashimoto 2008).

An example for such a process is the synthesis of β-Asp-Arg primers for in vitro synthesis of CGP (Berg 2003). For this, a TentaGel resin SPHB-Arg(Pmc)-Fmoc (Rapp Polymere, Tübingen, Germany) was used. To this resin, arginine is bound, and its α-amino group is protected by a Fmoc (fluorenyl-9-methoxy-carbonyl) group while the ε-amino group is protected by a Pmc group (2,2,5,7,8-pentamethylchroman-6-sulfonyl). The first reaction step is the removal of the Fmoc group by piperidin in a dimethylformamide (DMF) solution to expose the α-amino group of arginine. The next reaction involves the amino acid aspartate, with the α-carboxyl group protected by a OtBu (tertiary butyl) group and the α-amino group protected by a BOC (tertiary butyloxycarbonyl) group (Berg 2003). The peptide bond between the exposed α-amino group of arginine and the free β-carboxyl group of aspartate is formed in presence of the reagents TBTU (O-(1H-Benzotriazol-1-yl)-N,N,N′,N′-tetramethyluronium tetrafluoroborate) and DMF. Finally, the dipeptide is separated from the resin, and all protection groups are removed by incubation in presence of a special mixture of trifluoroacetic acid, phenol, water, and triisobutyl-silane (Berg 2003).

Enzymatic synthesis

In comparison to the chemical synthesis of peptides, enzymatic synthesis comprise several advantages because it is environmentally friendly and provides highly complex stereospecific peptides. Moreover, it needs less time and is often also cost-effective. Other factors involved in enzymatic processes are largely variable in comparison to chemical processes. Among these are the cultivation costs for enzyme production and those for purification of the end product. However, these factors can be largely optimized (Mooibroek et al. 2007; Sallam et al. 2009).

While the ribosomal synthesis is the main system for peptide formation in organisms, other enzymatic machineries conducting peptide synthesis have been found in nature. These include nonribosomal peptide synthetase (NRPS), polyglutamate synthase, glutathione synthase, d-alanine–d-alanine ligase, and l-amino acid α-ligase (Lal). These systems use unprotected amino acids and catalyze only peptide–forming reactions. Recently, Lal has been demonstrated to be useful for dipeptide production (Yagasaki and Hashimoto 2008).

NRPSs of various bacteria and fungi synthesize many therapeutically important peptides. These enzymes consist of several modules, each adding one particular amino acid to a growing peptide. Each module contains at least three domains: (1) an adenylation domain (A-domain) identifies and activates the substrate amino acid as an aminoacyl-AMP accompanied with hydrolysis of ATP to AMP and pyrophosphate. (2) The activated amino acid is then transferred to 4’-phosphopantetheine moiety of the thiolation domain (T-domain) with the release of AMP. (3) Then the adjacent condensation domain (C-domain) catalyzes the formation of the peptide bond. Additionally, each NRPS contains one thioesterase domain (Te-domain) which catalyzes the release of the peptide from the enzyme complex (Yagasaki and Hashimoto 2008).

Modular engineering of NRPS has been applied to dipeptide synthesis. For this, an artificial NRPS was designed by combining the A-domain, which recognizes Ile, from the bacitracin-biosynthetic NRPS in B. licheniformis and the A-domain, which recognizes Leu, from the tyrocidine-biosynthetic NRPS in B. brevis (Doekel and Marahiel 2000). The resulting NRPS was expressed in E. coli, and the purified enzyme was demonstrated to produce Ile-Leu in the presence of ATP. However, such approaches in general rendered low product yields in living cells and, therefore, NRPS engineering needs a lot of developments to be applied practically (Yagasaki and Hashimoto 2008).

The thermostable aminopeptidase of Streptomyces septatus TH-2 represents a good example for enzymes able to synthesize different dipeptides. This enzyme can catalyze the reaction between a wide range of free amino acids and aminoacyl-OMe (aminoacyl-methyl esters) in several solvents. Although several dipeptide methylesters could be synthesized in this manner, the application of this enzyme was also confined to the laboratory scale (Glansdorff and Xu 2007).

Most recently, Kyowa Hakko Bio Co. Ltd., a daughter company of the Japanese Kyowa Hakko Kirin Co. Ltd., which focuses on fine-/bio-chemicals and chemical products, announced the discovery of an enzyme from B. subtilis that reacts with a variety of amino acids to yield diverse dipeptides. Alanyl-glutamine was chosen to be the first product and should overcome the poor stability and solubility of glutamine in water which prevented its nutritional applications. Accordingly, Kyowa Hakko Bio positioned dipeptides as “amino acids of the next generation” (http://www.kyowa.eu). In fact, considering the enhanced characteristics of dipeptides in comparison to their constituting amino acids in the free form, and the fast developing know-how over the last years, this term seems very plausible.

Large scale production of dipeptides

Except for the recently published process for the production of dipeptides from CGP (see below), large scale production of dipeptides with defined composition is an upstream technique (Nagayasu et al. 1994). With an estimated total market volume of 18,000 tons in 2006 and an additional 18,000 tons estimated to be produced in China (Ajinomoto Co., Inc. Fact sheet 2006; Sprenger 2007), aspartame is a good example for the large-scale production of dipeptides. Aspartame is a dipeptide-methylester of aspartic acid and phenylalanine and has a 200-fold higher sweetening effect than sucrose. The raw materials for this technique are l-aspartate and d,l-phenylalanine-OMe. During manufacturing, the amino group of l-aspartic acid must be protected by a benzyloxycarbonyl group to allow only its α-carboxylic group to react with the phenylalanine-OMe. Both dipeptide components are linked together by the thermostable enzyme thermolysin from B. thermoproteolyticus, which integrates only l-phenylalanine-OMe in the resulting α-aspartame. Finally, the protecting group is chemically removed from the aspartate residues (Nagayasu et al. 1994).

Recently, a downstream triphasic enzymatic process for the technical production of β-dipeptides from CGP was described (Sallam et al. 2009). The first phase of the process comprises the technical isolation and purification of CGP from biomass depending on solubility characteristics of the biopolymer. The second phase comprises the fermentative production of an extracellular CGPase (CphEal) from P. alcaligenes strain DIP1. This phase takes less than 15 h requiring only 2 g l−1 of citrate as sole carbon source, and very low concentrations of either CGP, the dipeptides thereof, or aspartate for induction. The third phase of the process comprises the degradation of highly concentrated CGP suspensions (up to 100 g l−1) to β-dipeptides via CphEal crude preparations. High reaction temperatures (>50°C) and short reaction periods (<4 h) of the enzyme reduce the risk of contamination. The overall efficiency of the third phase was 91%, and the used CphEal powder can be recovered, to high extents, for reuse. The process produces CGP dipeptides with purity grade of above 99% and is applicable at any desired scales using common industrial equipments (Sallam and Steinbüchel 2009a).

Dipeptide absorption and transport

Protein digestion and the transport of nutrients or xenobiotics across the plasma membrane of cells are essential for life. In ruminants, the major part of dietary protein is degraded by the rumen flora to amino acids and peptides. Amino acids are incorporated into microbial protein or passed to the next parts of the digestive tract or absorbed directly across the rumen wall into the blood (Sallam and Steinbüchel 2009b). In man, the physiological importance of oligopeptides became apparent when their luminal concentrations were found much higher than that of free amino acids after a controlled protein diet (Daniel et al. 2006). Other enzymatic studies found no hydrolytic activities in the intestinal lumen but high intracellular dipeptidase activities in the mucosal cells (Kim et al. 1972). Dipeptide transport is very important in individuals who are deficient in a transporter for a particular amino acid, since the separate dipeptide transport allows the uptake of this deficient amino acid (Silk et al. 1975; Leonard et al. 1976).

In bacteria

Besides providing cells with amino acids for metabolism, peptide transport plays an important role in sporulation, chemotaxis, and signaling processes. Bacteria possess three peptide transport systems, which are well characterized in E. coli and other bacteria (reviewed by Daniel et al. (2006)). Two of these, the oligopeptide permease (Opp) and the dipeptide permease (Dpp), belong to the large family of ATP-binding cassette (ABC) transporters. Both membrane protein complexes specifically transport different oligopeptides through the cell membrane on the expense of ATP. The third peptide transport system in bacteria transports di- and tripeptides and belongs to the Peptide TRansporter (PTR) family. The latter is the main transport route for amino acids and is the only system conserved in yeast and higher eukaryotes (Daniel et al. 2006).

After the degradation of proteins to di- and tripeptides outside the cells via extracellular proteases, they get access to the periplasmic space by passive diffusion and are then actively transported to the cell interior by PTR proteins. The required energy is generated through an electrochemical proton gradient initiated by the respiratory chain under NADH consumption. Cotransport of neutral and cationic dipeptides by PTR proteins requires one proton while anionic dipeptides need two protons to be transported into the cell (one proton is required to neutralize the negative charge of the side chain) (Steel et al. 1997). In the cytoplasm, the dipeptides are then separated into their free amino acids to be further metabolized (Daniel et al. 2006).

In mammals

Peptide transport in mammals was first thought to be a Na+-dependent process. Later, it was shown to be energized, like in bacteria, yeast, and plants, by a proton gradient which exists across brush-border membranes. The carrier system PEPT (SLC15 family) for di- and tripeptides includes two variants; the intestinal PEPT1 (SLC15A1) and the renal isoform PEPT2 (SLC15A2) (Daniel et al. 2006). However, PEPT1 is also expressed in kidney, pancreas, extrahepatic bile duct, and liver, while PEPT2 is expressed also in lung, brain, mammary gland, pituitary gland, testis, prostate, ovary, uterus, and eye (Biegel et al. 2006). In the intestine, PEPT1 is located in the apical membrane of the intestinal epithelium and transports di- and tripeptides from the intestinal lumen to the epithelial cell interior. The free amino acids resulting from hydrolysis of di- and tripeptides are then transported via amino acid transporters in the basolateral membrane to the blood and then to other body tissues. The driving force of PEPT1 and PEPT2 for active peptide transport is provided by an inwardly directed H+ gradient and an inside-negative membrane potential. The H+ gradient is generated and maintained by the combined action of a Na+/H+ exchanger at the apical membrane and a Na+/K+ ATPase at the basolateral membrane (Biegel et al. 2006).

PEPT1 and PEPT2 transport almost all possible di- and tripeptides in stereoselective manner with preference for l-α-amino acids and their derivatives (such as β-lactam antibiotics) (Tsuji et al. 1986). Peptides containing solely d- or four or more amino acids are not accepted. This means that about 400 dipeptides and 8,000 tripeptides can be transported by PEPT1 which was therefore described as “nonspecifically specific” (Daniel et al. 2006). High transport capacity and prominent expression of PEPT1 throughout the small intestine made PEPT1 a prime target for drug delivery because its drug substrates have an excellent oral availability (Brandsch et al. 2004; Daniel et al. 2006).

Industrial production, physiology and applications of aspartate, arginine, and lysine

Previously, amino acids were either classified as nonessential (dispensable) or essential (nondispensable). However, recent advances in nutritional therapy revealed the necessity of certain amino acids for maintaining tissue protein homeostasis during critical illness (Meredith et al. 1990; Witte and Barbul 2003). Hence, an alternative classification was proposed that redefines certain amino acids as being conditionally nondispensable (Laidlaw and Kopple 1987). This made the use of such amino acids, solely or as part of a complete nutritional regimen, attractive to improve nutritional outcome, immune response, and tissue recovery. In the following section, findings regarding synthesis, physiology, and benefits of the three amino acids that also constitute CGP, are discussed. These amino acids are: the nonessential l-aspartic acid, the semi-essential l-arginine, and the essential amino acid l-lysine. A special emphasis is given on the important “nutraceutical” arginine due to its numerous physiological effects.

l-Aspartic acid

This dicarboxylic amino acid has a molecular mass of 133.10 g/mol and most of it is found in proteins while small amounts are also found as free acid in body fluids and in plant tissues. l-Aspartic acid has been produced industrially since the 1960s in Japan. For this, aspartase of E. coli, fumarate and ammonia were used. After polyacrylamide gel-immobilized cells were used, a fumarase lacking E. coli mutant with high aspartase activity was developed, l-aspartic acid has been produced industrially with immobilized cells thereof until today (Oikawa 2007). Recently reported thermostable aspartases from other bacteria like Cytophaga sp. KUC-1 and Bacillus sp. YM55-1 are considered as highly potential for improving the production of l-aspartic acid (Oikawa 2007).

l-Aspartate is a main constituent of the natural biopolymer CGP, and in addition of being one of the two amino acids constituting the synthetic sweetener aspartame; it is also used since 1965 for the industrial production of l-alanine in Japan (Chibata et al. 1965). For this, an aspartate 4-decarboxylase from P. dacunhae was the enzyme of choice. This procedure went through many developments until a combined procedure was achieved in 1982. The latter technique produces l-alanine from fumarate and ammonia by using immobilized P. dacunhae and E. coli with aspartate ammonia-lyase (aspartase) (Oikawa 2007).

Aspartic acid is slightly soluble in water and more water–soluble in the salt form. Dietary aspartate is absorbed from the small intestine by active transportation to enter the portal circulation. In liver, much of it is metabolized to protein, purines, and pyrimidines. Derivatives of l-aspartate can also serve as a source for energy in the citric acid cycle and is therefore supposed to be effective against fatigue (see also below: Asp-Arg). Aspartate is used in drug delivery for cations like Mg2+, K+, Ca2+, Zn2+, or for other amino acids to increase their bioavailability (Cynober 2003). Aspartic acid has also been administrated orally for treatment of drug addiction, management of chronic fatigue and treatment of liver cirrhosis (Ruey and Van Scott 2008).

l-Arginine

l-Arginine is a strongly basic amino acid with a molecular mass of 174.2 g/mol and is found in most proteins. It contains four nitrogen atoms per molecule and is therefore the most abundant nitrogen carrier in humans and animals (Appleton 2002). Microbial production of arginine is well established on the commercial level. However, production strategies are being developed to obtain higher concentrations employing recombinant strains of C. glutamicum subsp. flavum which is a natural producer of glutamate, the precursor of arginine (Utagawa 2004). A multiple mutant thereof produced arginine to a concentration of 25.3 g/L.

Also strains of E. coli were reported to achieve high productivity. For example, an l-isoleucine auxotroph of E. coli produced up to 19.3 g/L arginine in an improved procedure on glucose (Gusyatiner et al. 2005). Furthermore, argR-engineered strains of E. coli having plasmids containing an additional argA gene and a heterologous argJ gene were reported to produce 13 to 14 g/L (Sakanyan et al. 2005). Strategies to suppress the catabolic pathways and to enhance membrane transport of arginine are expected to improve its future microbial production.

Arginine is essential for human infants and fish (Glansdorff and Xu 2007), whereas for human adults as well as in general for mammals, it is considered semi-essential because it is synthesized de novo (endogenous). In the kidney, most endogenous arginine is derived from citrulline, a by-product of glutamine metabolism in gut or liver. However, because biosynthesis does not increase to meet elevated body requirements of arginine during mental or physical stress, dietary intake (approximately 5–6 g/day for an average human (Witte and Barbul 2003)) remains the primary determinant of plasma arginine levels.

About 50% of the ingested arginine is directly utilized in the small bowel, while the other 50% are released into the portal circulation. In general, about half of the ingested arginine is rapidly converted to ornithine, primarily by the enzyme arginase (Modolell et al. 1995; Witte and Barbul 2003). Ornithine, in turn, can be metabolized to glutamate and proline, or through the enzyme ornithine decarboxylase into polyamines (Boutard et al. 1995). The remaining arginine is processed by one of four other enzymes: nitric oxide synthase (to become nitric oxide), arginine:glycine amidinotransferase (to become creatine), arginine decarboxylase (to become agmatine), or arginyl-tRNA synthetase (to become arginyl-tRNA, a precursor to protein synthesis) (Vodovotz et al. 1993).

Although little is known about the exact mechanism, arginine has significant effects on endocrine functions in humans and animals, particularly on adrenal and pituitary secretory functions. Arginine is the biologic precursor of nitric oxide (NO), an endogenous messenger molecule involved in many endothelium-dependent functions in the cardiovascular system (Witte and Barbul 2003). Thus, many of the clinical effects of arginine are thought to be mediated by its effects on the endothelial-derived relaxing factor. NO-synthase has two variants (Rohdewald and Ferrari 2004); the constitutive (cNOS) with its isoforms eNOS (in vascular endothelial lining) and nNOS (in neurons), and the inducible variant (iNOS) found in macrophages, white blood cells, fibroblasts, endothelial cells, and keratinocytes. The function of NO may differ with its cellular localization; fibroblast NO supports collagen synthesis, while endothelial NO affects angiogenesis, and macrophage NO is cytostatic to bacteria. On the other side, arginase competes with NOS for the natural substrate l-arginine. l-hydroxyarginine and nitrite, the intermediate and end product, respectively, of the NO pathway, are both strong arginase inhibitors (Hrabak et al. 1996). Conversely, urea, the end product of arginase activity, inhibits NO formation (Witte and Barbul 2003). The involvement of l-arginine in these and other bio-vital processes initiated numerous studies in cardiovascular, gastrointestinal, genitourinary, and other physiological fields (Table 3).

l-Lysine

l-Lysine is a basic amino acid, has a molecular weight of 146.19 g/mol, and carries a positive charge at physiological pH. This essential amino acid is one of the most important amino acids applied as animal feed supplement because feed based on grains like corn are poor in lysine. Therefore, enormous research efforts have been invested to develop microorganisms capable of over-producing this amino acid (Wittmann and Becker 2007).

As in case with arginine, C. glutamicum is applied for production of lysine. The only other species used for lysine production are recombinant E. coli strains (Wittmann and Becker 2007). The industrial lysine production is done at the 500 m3 scale with a global production of more than 750,000 tons per year (Wittmann and Becker 2007) from cane molasses, beet molasses, sucrose, and dextrose. Many developments have led to more economical processing and to a number of different lysine preparations which are well established on the market including: liquid lysine (50% purity), liquid lysine sulfate (20–30% purity), or granulated lysine sulfate (40–50% purity). The latter contains the entire fermentation broth without separation of biomass reducing costs and having an additional nutritional value (Wittmann and Becker 2007).

Ingested l-lysine is absorbed from the lumen of the small intestine into the enterocytes by active transport. A portion thereof is metabolized within the enterocytes while the rest is transported via the portal circulation. In liver, lysine is incorporated into proteins or is metabolized to l–α-aminoadipic acid semialdehyde, which is further metabolized to acetoacetyl-CoA. The remaining lysine is transported to the various tissues of the body (Cynober 2003).

Lysine has many functions. It serves as a precursor for glycogen, glucose, and lipids, and it serves also directly for energy production. It is concentrated in muscles, promotes bone growth, and enhances the formation of collagen (Voet and Voet 2004), which is the basic matrix of the connective tissues (see before), skin, cartilage, and bone. Lysine deficiency may contribute to reduced growth and immunity, impaired sperm health, along with an increase in urinary calcium. This latter suggested that lysine may help to prevent osteoporosis through better absorption and deposition of calcium (Flodin 1997).

Recommended dosages, side effects, and contraindications

Supplemental doses of the above discussed amino acids are largely variable depending on the conditions to be treated. However, the normal dietary needs of lysine for average human are estimated to be 0.75–1 g daily to avoid deficiency problems. Doses of arginine used in clinical research varied from as little as 0.5 g/day for oligospermia to as much as 30 g/day for cancer, preeclampsia, and premature uterine contractions. Significant adverse effects are not reported on the supplementation of these amino acids. However, many of their effects need to be confirmed with long-term studies. For reviews, also regarding contra-reports, refer to Flodin (1997), Dean and Pryor (2001), and Appleton (2002).

Combinations of aspartate, arginine, and lysine in nutrition and therapy

Aspartate and arginine

Aspartate and arginine are favorably administrated together and were often investigated for different physiological disorders. In general, both amino acids can be also administrated as dipeptide for all above mentioned applications. The following section summarizes the research results on the administration of mixtures of these amino acids. These reports emerged from studies on cardiovascular functions, wound therapy, endocrine disorders, athletic performance or genitourinary conditions. Due to the inaccurate description of the connections between the amino acids in most reports, the substances discussed are designated as reported in literature or by the manufacturer.

“Aspartate d’arginine” (Sargenor®) was produced by VIATRIS Pharma since 1965 for the treatment of asthenia and improving athletic performance and the immune response. Sargenor® is now produced and distributed by several companies in Europe often under the trade name Sangenor®. Sargenor® was tested clinically in 1965 for the first time against physical and psychic asthenia, and the positive effect was later confirmed (Duruy 1968). Impressive effects on enduring performance have been reported after prolonged intake of Sargenor® causing decreased blood lactate concentrations and heart rates during submaximal exercise and increased oxygen uptake with workload increments (Sellier 1979; Schmid et al. 1980; Burtscher et al. 2005). Other positive effects were also reported on lipid metabolism where “arginine aspartate” intake for only 2 weeks caused lower total cholesterol concentrations (Hurson et al. 1995).

Orally administrated “arginine aspartate” was reported to cause a 60% increase in hGH levels during slow wave sleep. This was tested on five healthy subjects, in the age between 20 and 35 years, receiving 250 mg−1 kg−1 day−1 for 7 days (Besset et al. 1982). Another study described promising results after treating 12 normal adults with one large dose (37.5 g) of oral “arginine aspartate”, which caused small but significant release of serum hGH (Elsair 1985). All these results rendered Sargenor® and similar products (Table 1) to be widely used by body builders, athletes and patients to increase training effects as well as exercise tolerance (Macintyre 1987).

Besides the healing benefits known for arginine itself (see before), also “Arginine–aspartate” supplementation enhanced wound healing and the immune functions of T-cells (Barbul et al. 1990; Witte and Barbul 2003). In another study, dietary “arginine aspartate” (30 g/day for 2 weeks) significantly enhanced wound collagen accumulation in healthy elderly human volunteers (Witte and Barbul 2003).

Orally administrated “arginine–aspartate” was also reported to induce positive effects in treatment of some types of cancer. It induced antimetastatic effects on salivary adenoid cystic carcinoma in mice, accompanied by inhibited pulmonary metastatic foci formation and prolonged survival. Further in vitro and in vivo experiments confirmed these results (Appleton 2002; Li et al. 2002).

In the field of dental health, plaque, the closely adhering spongy organic material on teeth surfaces, was found to accept certain peptides within its matrix. Peptides consisting of 2–4 amino acids with at least one being arginine, were shown to be stored in plaque protected from dilution and to restore mouth pH to a non-carious level (≥6.1). These oligomers were effective even when provided simultaneously with carbohydrates and thereby suitable to be included in common dental products (Kleinberg 1980).

Preparations of l-arginine and l-aspartate were also applied for treatment of genitourinary disorders (Christianson 2005). Erectile dysfunction (ED) is common in 25% of males aged 45–70 years with moderate grade and in 10% thereof with severe grade (Kernohan et al. 2004). Recently, “l-arginyl aspartate” was used as a component of several pharmaceuticals for the treatment of male ED such as Prelox® (Lamm et al. 2003) which contains 0.7 g “L-Arginine Aspartate” per tablet. Prelox® is manufactured by Biolab S.A. GmbH (Waterloo, Belgium) and is distributed in the US and Europe. Clinical studies on Prelox® showed improved erectile function in 5% and 92% of forty men with ED after receiving three doses of each 1 g of “l-arginyl aspartate” (Sargenor®) alone, or together with Pycnogenol® (stimulates NOS secretion), respectively (Stanislavov and Nikolova 2003). During a long-term study, 50 men suffering ED, lowered semen volume, reduced sperm motility and morphological abnormalities of sperms, were treated first with Sargenor® alone for 1 month; 10% of these men experienced normal erection. After addition of Pycnogenol® to the treatment for the second month, the percentage of men with normal erection increased to 80%. After 1 year of treatment, sperm quality was significantly improved and 42% of the couples achieved pregnancy (Lamm et al. 2003; Stanislavov and Nikolova 2003). The later observation confirmed previous studies on the use of “arginine aspartate” where several months supplementation increased sperm count and quality (Tanimura 1967; Schellen and Declerq 1978; De-Aloysio et al. 1982) and improved fertility (Schacter et al. 1973).

Similar to human infants, arginine is an essential amino acid for fish. Thus, dietary arginine deficiency causes reduced growth rate, lowered immune response, and increased mortality (Ahmed and Khan 2004). A recent feeding study on rainbow trout alevins showed that synthetic dipeptides can replace up to 50% of the dietary protein content of a commercially available diet. In comparison to the latter control diet, replacement with dipeptides rendered—in contrast to free amino acids—similar growth, survival rate and concentration of indispensable amino acids in fish muscle. On the other hand, withdrawal of arginine-containing dipeptides from the diet caused a drastic decrease in growth and increased mortality (Bendik et al. 2006).

Aspartate and lysine

Clinical reports on preparations consisting of aspartate and lysine are scarce. However, the use of such preparations in treatment of muscular fatigue and temporary and involuntary muscular contractions is described (Morelle and Lauzanne-Morelle 1984). In general, dipeptides containing lysine can be expected to induce positive effects in the application fields known for free lysine or its salts (see before) but with higher bioavailability.

Arginine and lysine

Arginine and lysine act synergistically on the release of growth hormone (GH) (Suminski et al. 1997), and their concentrations are very important in human and animal nutrition (Ahmed and Khan 2004). Low lysine/arginine ratios have a hypocholesterolemic effect (Sánchez et al. 1998) and thus, protein mixtures with Arg/Lys ratio of at least 5.5:1 were reported to be effective for patients with cardiovascular diseases (Radha et al. 2006). In contrast, and because proteins of herpes simplex virus are rich in l-arginine, a high lysine to arginine ratio in the diet is known to help reducing viral replication, healing time, and the cytopathogenicity during outbreaks (Flodin 1997).

Recent research suggested that l-lysine and l-arginine together are possibly even better than the arginine/ornithine combination in stimulating hGH, and thereby improving muscle building, weight gain, and immune support. In 15 healthy male subjects in the age between 15 and 20 years, 1.2 g of arginine pyroglutamate combined with l-lysine hydrochloride significantly elevated GH levels from two to eight times (Isidori et al. 1981). Another study indicated that ingestion of 1.5 g arginine and 1.5 g lysine under resting conditions causes an acute increase in GH secretion (Suminski et al. 1997).

Market research and analysis of Asp-Arg, Asp-Lys, and CGP in commercial products

Several commercial products containing arginine and aspartate (indicated as a single ingredient) were identified on the global market (Table 1). Of those, we ordered and analyzed only three; high-performance liquid chromatography (HPLC) analysis of the three products revealed the presence of both amino acids at about equimolar amounts (unpublished data). However, the amino acids were found in the free form rather than in the dipeptide form. Confirmatory HPLC analysis of hydrolyzed samples showed the same peak pattern as that of unhydrolyzed samples which confirmed that the whole content of both amino acids existed in the free form (unpublished data). Other commercial aspartate–arginine dipeptides were offered for research purposes (Sigma-Aldrich, Steinheim, Germany). These chemicals were available only in mg amounts for research purposes at relatively high prices. In fact, only these dipeptides were confirmed by our analysis to be “true” dipeptides.

In case of commercial products containing lysine aspartate, few market products were identified such as Alleviate® sport cream from Neways Inc. (Utah, USA). Alleviate® contains “lysine aspartate” and is indicated to relieve the “burning” feeling in muscles after exercise. However, no clinical research was provided to confirm this effect.

It appears that higher bioavailability is often claimed to be caused by ionic linkages that might connect two amino acids, for example, where aspartate and arginine act as anion and cation, respectively. Such substances are often considered dipeptides. In fact, these ionic linkages might be temporarily stable in solution only at specific pH values, and they are not covalently linked as the designation “dipeptide” clearly implies. Therefore, such commercial products should be referred to as amino acid mixtures and not to as dipeptides. Subsequently, a higher bioavailability of the mixed amino acids in these products should not be expected because, after ingestion, such ionic linkages would surly never reach the intestinal dipeptide transporters in the intact state.

During a recent investigation in our laboratory (Sallam and Steinbüchel 2009b), and to investigate whether the famous sense of well-being of Spirulina is associated with the presence of CGP itself, three Spirulina products available on the German market were analyzed for the presence of CGP. Two products; from Sanatur GmbH (Singen, Germany) and Greenvally GmbH (Berlin, Germany) consisted of 100% Spirulina platensis, while the third variant from Aurica GmbH (Schwalbach-Elm, Germany) contained 40% thereof. After subjecting the cells to the standard extraction and purification procedures for CGP, HPLC analysis of acid-hydrolyzed samples thereof revealed that the three products contained CGP (0.06%, 0.13% and 0.15% (wt/wt), respectively). The latter analysis showed also that all resulting CGPs consisted of the typical amino acids of cyanobacterial CGP, i.e., aspartate and arginine.

Biotechnological production of CGP as raw material for dipeptides

Bio–source materials are attractive because they are often considered as environmentally friendly and more suitable to obtain specific products with better functionality. New strategies were developed for the production of amino acids through initial production of non-ribosomal peptides on agro-waste materials where CGP represents a good example (Mooibroek et al. 2007). In this regard, CGP was successfully produced at large scale on Protamylasse™ (AVEBE, The Netherlands), which is the main waste stream (120,000 m3 annually) during starch extraction from potatoes. Current large scale fermentation strategies enabled the production of comparably large amounts of CGP (up to 50%, wt/wt, of CDW) over short periods (13–70 h) (Mooibroek et al. 2007; Sallam et al. 2009; Steinle et al. 2009; unpublished data). Thus, the interest in CGP as a potential raw material has constantly increased over the last years and is expected to expand in the near future. Several approaches are currently under optimization including alternative substrates, better fermentation strategies, or developing new hosts for CGP as shown recently in plants (Neumann et al. 2005) and yeast (Steinle et al. 2009). Such developments led to the prediction that CGP price may go down below €1,000 per ton in the future (Mooibroek et al. 2007). This would make CGP even more attractive as intermediate for commercial production of its dipeptides.

Currently, besides aspartame, only the dipeptide l-alanyl-l-glutamine is available on a wide commercial level. Products of this dipeptide are used as infusions to recovery patients with immunosuppression, postoperative complications or malnutrition and are distributed by several providers. Mediatech Inc. (Manassas, Virginia, USA) offers for example l-alanyl-l-glutamine as a 0.2 M solution in 100 ml bottles for $28.39 (about €21.5) which represents a kilogram price of about €4732. Similarly, the kilogram price of Sargenor® is about €3,500. Assuming that CGP-dipeptides are, as expected, at least as effective as these products in several fields of application, it can be predicted that CGP-dipeptides would reach a market price of over €3,000. On the other hand, production costs play an important role in commercializing CGP-dipeptides as for any newly developed product. The production costs of one kilogram of CGP in a small production unit (one 5,000 L fermenter) with a production capacity of 1,250 kg/year are currently between €250 and €500 which remains affordable considering the expected market price of these high value “fine chemicals”.

Variability of CGP dipeptides

Beside the industrial and the biomedical applications, which are anticipated for CGP on the account of its amino acid content or its dipeptides, other potential applications can be expected for CGP or CGP–like polymers with other constituting amino acids. For example, CGP with high lysine contents or with canavanine, citrulline or ornithine beside or instead of arginine as shown by in vitro studies with purified CphAs (Berg 2003) as well as by in vivo biosynthesis using recombinant engineered yeast strains (Steinle et al. 2009). Hydrolysis of such CGP variants would expand the range of CGP dipeptides and consequently their scope of application. In this regard, aspartate–ornithine is proved to be highly effective for the treatment of liver disorders (Kircheis et al. 1997) and several products thereof, most probably as mixtures, are commercially available for the oral administration or as infusions (Table 2), aspartate–glutamate might support hypercholesterolemia treatment (Yanni et al. 2005), aspartate–citrulline is a better alternative for aspartate–arginine in many application fields (Cynober 2003), while CGP dipeptides containing canavanine, which is, conversely to arginine, a selective inhibitor of inducible nitric oxide synthases, would help in treating septic shocks (Mansart et al. 2003).

In conclusion, the CGP containing Spirulina products surely have gone through numerous clinical tests before commercialization. Thus, extracted CGP and CGP-dipeptides probably have no toxic effects. Additionally, the known effects and applications of Spirulina are almost similar to those shown for arginine, which suggests that these effects may be in part due to its high arginine content (about 6%) including that of CGP. The α–β-peptide bonds in CGP dipeptides and their steric structure assume strongly that they will act as substrates for the PEPT system to be absorbed after ingestion. In this case, the use of CGP and/or its dipeptides would be an ideal approach for oral administration of the constituting amino acids as therapeutic and/or nutritional agents. Therefore, CGP represents an ideal natural source for dipeptides which are expected to be more effective in lower doses than their constituting amino acids in the free form. Absorption, safety, and the effect of CGP and its dipeptides still have to be confirmed and are currently under investigation. On the other side, the recent improvements in CGP production appear promising for a wide range of economically feasible commercial products in the near future.

References

Ahmed I, Khan MA (2004) Dietary arginine requirement of fingerling Indian major carp, Cirrhinus mrigala (Hamilton). Aquac Nutr 10:217–225

Appleton J (2002) Arginine: clinical potential of a semi-essential amino acid. Altern Med Rev 7:512–522

Barbul A, Lazarou SA, Efron DT, Wasserkrug HL, Efron G (1990) Arginine enhances wound healing and lymphocyte immune responses in humans. Surgery 108:331–336

Bendik FT, Lee KJ, Zhang Y, Failla M, Dabrowski K (2006) Optimization of dipeptide–protein mixtures in experimental diet formulations for rainbow trout (Oncorhynchus mykiss) alevins. Aquaculture 254:517–525

Berg H (2003) Untersuchungen zu Funktion und Struktur der Cyanophycin-Synthetase von Anabaena variabilis ATCC 29413. Dissertation. Humboldt–Universität zu Berlin, Germany

Besset A, Bonardet A, Rondouin G, Descomps B, Passouant P (1982) Increase in sleep related GH and Prl secretion after chronic arginine aspartate administration in man. Acta Endocrinol 99:18–23

Biegel A, Knütter I, Hartrodt B, Gebauer S, Theis S, Luckner P, Kottra G, Rastetter M, Zebisch K, Thondorf I, Daniel H, Neubert K, Brandsch M (2006) The renal type H1=peptide symporter PEPT2: structure–affinity relationships. Amino Acids 31:137–156

Boutard V, Havouis R, Fouqueray B, Philippe C, Moulinoux JP, Baud L (1995) Transforming growth factor-beta stimulates arginase activity in macrophages. Implications for the regulation of macrophage cytotoxicity. J Immunol 155:2077–2084

Brandsch M, Knütter I, Leibach FH (2004) The intestinal H+/peptide symporter PEPT1: structure–affinity relationships. Eur J Pharm Sci 21:53–60

Burtscher M, Brunner F, Faulhaber M, Hotter B, Likar R (2005) The prolonged intake of l-arginine-l-aspartate reduces blood lactate accumulation and oxygen consumption during submaximal exercise. J Sports Sci Med 4:314–322

Chibata IT, Kakimoto J, Kato J (1965) Enzymatic production of l-alanine by Pseudomonas dacunhae. Appl Microbiol 13:638–645

Christianson DW (2005) Arginase: structure, mechanism, and physiological role in male and female sexual arousal. Acc Chem Res 38:191–201

Cynober LA (2003) Metabolic and therapeutic aspects of amino acids in clinical nutrition, 2nd edn. CRC Press LLC, Boca Raton

Daniel H, Spanier B, Kottra G, Weitz D (2006) From bacteria to man: Archaic proton-dependent peptide transporters at work. Physiology 21:93–102

De-Aloysio D, Mantuano R, Mauloni M, Nicoletti G (1982) The clinical use of arginine aspartate in male infertility. Acta Eur Fertil 13:133–167

Dean W, Pryor K (2001) Growth hormone: amino acids as GH secretagogues—a review of the literature. Vit Res News. Available at http://www.vrp.com (accessed Feb. 2010)

Dock DB, Aguilar-Nascimento JE, Latorraca MQ (2004) Probiotics enhance the recovery of gut atrophy in experimental malnutrition. Biocell 28:143–150

Doekel S, Marahiel MA (2000) Dipeptide formation on engineered hybrid peptide synthetases. Chem Biol 7:373–384

Duruy A (1968) Expertise clinique de l´aspartate d´arginine. Med Int 1:203

Elsair C (1985) Effets de l’arginine, administrie par voie orale. C R Soc Biol 179:608–611

Flodin NW (1997) The metabolic roles, pharmacology, and toxicology of lysine. J Am Coll Nutr 16:7–21

Geueke B, Kohler HP (2007) Bacterial beta-peptidyl aminopeptidases: on the hydrolytic degradation of beta-peptides. Appl Microbiol Biotechnol 74:1197–1204

Glansdorff N, Xu Y (2007) Microbial arginine biosynthesis: pathway, regulation and industrial production. In: Wendisch VF (ed) Amino acid biosynthesis-pathways, regulation and metabolic engineering, vol 5, Microbiology Monographs. Springer, Berlin, pp 219–258

Gusyatiner MM, Leonova TV, Ptitsyn LR, Yampolskaya TA (2005) l-Arginine producing Escherichia coli and method of producing l-arginine. US Patent 6841365

Hrabak A, Bajor T, Temesi A, Meszaros G (1996) The inhibitory effect of nitrite, a stable product of nitric oxide (NO) formation, on arginase. FEBS Lett 390:203–206

Hurson M, Regan MC, Kirk SJ, Wasserkrug HL, Barbul A (1995) Metabolic effects of arginine in a healthy elderly population. J Parenter Enteral Nutr 19:227–230

Isidori A, Lo-Monaco A, Cappa M (1981) A study of growth hormone release in man after oral administration of amino acids. Curr Med Res Opin 7:475–481

Kernohan AFB, McIntyre M, Hughes DM, Tam SW, Worcel M, Reid JL (2004) An oral yohimbine/l-arginine combination (NMI 861) for the treatment of male erectile dysfunction: a pharmacokinetic, pharmacodynamic and interaction study with intravenous nitroglycerine in healthy male subjects. Br J Clin Pharmacol 59:85–93

Kihlberg R (1972) The microbe as a source of food. Annu Rev Microbiol 26:427–466

Kim YS, Kim YW, Birtwhis W (1972) Peptide hydrolases in brush border and soluble fractions of small intestinal mucosa of rat and man. J Clin Invest 51:1419–1430

Kircheis G, Nilius R, Held C, Berndt H, Buchner M, Gortelmeyer R, Hendricks R, Krüger B, Kuklinski B, Meister H, Otto H, Rink C, Rösch W, Stauch S (1997) Therapeutic efficacy of l-ornithine-l-aspartate infusions in patients with cirrhosis and hepatic encephalopathy: results of a placebo-controlled, doubleblind study. Hepatology 25:1351–1360

Kleinberg I (1980) Means and method for improving defenses against caries. US Patent 4225579

Laidlaw SA, Kopple JD (1987) Newer concepts of the indispensable amino acids. Am J Clin Nutr 46:593–605

Lamm S, Schönlau F, Rohdewald P (2003) Prelox® for improvement of erectile function: a review. Eur Bull Drug Res 11:29–37

Leonard JV, Marrs TC, Addison JM, Burston D, Clegg KM, Lloyd JK, Matthews DM, Seakins JW (1976) Intestinal absorption of amino acids and peptides in Hartnup disorder. Pediatr Res 10:246–249

Li F, Yu G, Li S, Peng S, Fu J, Wu D (2002) An antimetastatic study of Arg-Asp (RD) on salivary adenoid cystic carcinoma in vivo. Chin J Stomatol 37:87–89

Macintyre JG (1987) Growth hormone and athletes. Sports Med 4:129–142

Mansart A, Bollaert P, Levy B, Nicolas M, Mallié J (2003) Comparative effects of dexamethasone and l-canavanine in experimental septic shock. Eur J Pharmacol 475:61–67

Meredith JW, Ditesheim JA, Zaloga G (1990) Visceral protein levels in trauma patients are greater with peptide diet than with intact protein diet. J Trauma 30:825–828

Merrifield R (1963) Solid phase peptide synthesis. I. The synthesis of a tetrapeptide. J Am Chem Soc 85:2149–2154

Modolell M, Corraliza IM, Link F, Soler G, Eichmann K (1995) Reciprocal regulation of the nitric oxide synthase/arginase balance in mouse bone marrow-derived macrophages by TH1 and TH2 cytokines. Eur J Immunol 25:1101–1104

Mooibroek H, Osterhuis N, Giuseppin M, Toonen M, Franssen H, Scott E, Sanders J, Steinbüchel A (2007) Assessment of technological options and economical feasibility for cyanophycin biopolymer and high-value amino acid production. Appl Microbiol Biotechnol 77:257–267

Morelle JV, Lauzanne-Morelle EMT (1984) Derivatives of lysine and aspartic acid. US Patent 4447366

Nagayasu T, Miyanaga M, Tanaka T, Sakiyama T, Nakanishi K (1994) Synthesis of aspartame precursor with an immobilized thermolysin in tert-amy1 alcohol. Biotechnol Bioeng 43:1118–1123

Neumann K, Stephan DP, Ziegler K, Hühns M, Broer I, Lockau W, Pistorius EK (2005) Production of cyanophycin, a suitable source for the biodegradable polymer polyaspartate, in transgenic plants. Plant Biotechnol J 3:249–258

Obst M, Krug A, Luftmann H, Steinbüchel A (2005) Degradation of cyanophycin by Sedimentibacter hongkongensis strain KI and Citrobacter amalonaticus strain G isolated from an anaerobic bacterium consortium. Appl Environ Microbiol 71:3642–3652

Oikawa T (2007) Alanine, aspartate, and asparagine metabolism in microorganisms. In: Wendisch VF (ed) Amino acid biosynthesis-pathways, regulation and metabolic engineering, vol 5, Microbiology Monographs. Springer, Berlin, pp 273–288

Radha C, Govindaraju K, Kany TCS, Tiku PK, Singh SA, Gowda LR, Swamylingappa B, Rao ARG, Prakash V, Ramasarma PR (2006) Process for the preparation of high arginine peptides. US Patent 7091001

Rohdewald P, Ferrari V (2004) Attaining sexual wellness and health of the sexual vascular system with proanthocyanidins. Patent Application 2004137081.

Ross E, Dominy W (1990) The nutritional value of dehydrated, blue-green algae (Spirulina platensis) for poultry. Poult Sci 69:794–800

Ruey JYu, Van Scott EJ (2008) Compositions and therapeutic use of N-acetyl aldosamines and N-acetylamino acids. Patent Application 20080214649

Sakanyan V, Marc F, Hovsepyan A, Lecocq M (2005) Microorganisms and method for l-arginine production by fermentation. US Patent 6897048

Sallam A, Steinbüchel A (2009a) Biotechnological production of cyanophycin dipeptides. Patent Application PCT/EP2009/057382

Sallam A, Steinbüchel A (2009b) Cyanophycin-degrading bacteria in digestive tracts of mammals, birds and fish and consequences for possible applications of cyanophycin and its dipeptides in nutrition and therapy. J Appl Microbiol 107:474–484

Sallam A, Kast A, Przybilla S, Meiswinkel T, Steinbüchel A (2009) Biotechnological process for production of β-dipeptides from cyanophycin at technical scale and its optimization. Appl Environ Microbiol 75:29–38

Sánchez A, Rubano D, Shavlik GW, Hubbard R, Horning M (1998) Cholesterolemic effects of the lysine/arginine ratio in rabbits after initial early growth. Arch Latinoam Nutr 38:229–238

Schacter A, Friedman S, Goldman JA, Eckerling B (1973) Treatment of oligospermia with the amino acid arginine. Int J Gynaecol Obstet 11:206–209

Schellen TM, Declerq JA (1978) Arginine aspartate in the treatment of oligozoospermia. Dermatol Monschr 164:578–580

Schmid P, Gleispach H, Wolf W, Pessendorfer H, Schwaberger P (1980) Leistungsbeeinflussung und Stoffwechselveränderungen während einer Langzeitbelastung unter Argininaspartat. Leistungssport 10:486–495

Seebach D, Overhand M, Kühnle FNM, Martinoni B, Oberer L, Hommel U, Widmer H (1996) Β-Peptides: synthesis by Arndt–Eistert homologation with concomitant peptide coupling. Structure determination by NMR and CD spectroscopy and by X-ray crystallography. Helical secondary structure of a β-hexapeptide in solution and its stability towards pepsin. Helv Chim Acta 76:913–941

Sellier J (1979) Intéret de l´aspartate d´arginine sargenor chez des athletes de compétition en périod d´entrainement intensif. Rev Med Toulouse 5:879

Silk DBA, Perrett D, Clark ML (1975) Jejunal and ileal absorption of dibasic amino acids and an arginine-containing dipeptide in cystinuria. Gastroenterology 68:1426–1432

Sprenger GA (2007) Aromatic amino acids. In: Wendisch VF (ed) Amino acid biosynthesis-pathways, regulation and metabolic engineering, vol 5, Microbiology Monographs. Springer, Berlin, pp 93–128

Stanislavov R, Nikolova V (2003) Treatment of erectile dysfunction with Pycnogenol® and l-arginine. J Sex Marital Ther 29:207–213

Steel A, Nussberger S, Romero MF, Boron WF, Boyd CA, Hediger MA (1997) Stoichiometry and pH dependence of the rabbit proton-dependent oligopeptide transporter PepT1. J Physiol 498:563–569

Steinle A, Bergander K, Steinbüchel A (2009) Metabolic engineering of Saccharomyces cerevisiae towards novel cyanophycins with an extended range of constituents. Appl Environ Microbiol. doi:10.1128/AEM.00383-09

Suminski RR, Robertson RJ, Goss FL, Arslanian S, Kang J, DaSilva S, Utter AC, Metz KF (1997) Acute effect of amino acid ingestion and resistance exercise on plasma growth hormone concentration in young men. Int J Sport Nutr 7:48–60

Tanimura J (1967) Studies on arginine in human semen. Part II. The effects of medication with l-arginine-HCl on male infertility. Bull Osaka Med Sch 13:84–89

Tsuji A, Tamai I, Hirooka H, Terasaki T (1986) Β-Lactam antibiotics and transport via the dipeptide carrier system across the intestinal brush-border membrane. Biochem Pharmacol 36:565–567

Utagawa T (2004) Production of arginine by fermentation. J Nutr 134:2854–2857

Vodovotz Y, Bogdan C, Paik J, Xie Q-W, Nathan C (1993) Mechanisms of suppression of macrophage nitric oxide release by transforming growth factor. J Exp Med 178:605–613

Voet D, Voet JG (2004) Biochemistry, 3rd edn. John Wiley and Sons Inc., New York

Voss I (2005). Optimierung der biotechnologischen Produktion von Cyanophycin in rekombinanten Stämmen von Ralstonia eutropha durch metabolic engineering. Dissertation, Westfälische Wilhelms-Universität, Münster, Germany

Witte MB, Barbul A (2003) Arginine physiology and its implication for wound healing. Wound Repair Regen 11:419–423

Wittmann C, Becker J (2007) The l-lysine story: from metabolic pathways to industrial production. In: Wendisch VF (ed) Amino acid biosynthesis-pathways, regulation and metabolic engineering, vol 5, Microbiology Monographs. Springer, Berlin, pp 39–70

Yagasaki M, Hashimoto S (2008) Synthesis and application of dipeptides; current status and perspectives. Appl Microbiol Biotechnol 81:13–22

Yanni AE, Perrea DN, Yatzidis HA (2005) Effect of antiatherogenic l-aspartate and l-glutamate on serum lipoproteins cholesterol and apolipoproteins A-1 and B in rabbits fed with high cholesterol diet. Nutr Metab Cardiovasc Dis 15:161–165

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sallam, A., Steinbüchel, A. Dipeptides in nutrition and therapy: cyanophycin-derived dipeptides as natural alternatives and their biotechnological production. Appl Microbiol Biotechnol 87, 815–828 (2010). https://doi.org/10.1007/s00253-010-2641-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-010-2641-0