Abstract

Adding a supporting material to a methanogenic bioreactor treating garbage slurry can improve efficiency of methane production. However, little is known on how characteristics (e.g., porosity and hydrophobicity) of the supporting material affect the bioreactor degrading garbage slurry. We describe the reactor performances and microbial communities in bioreactors containing hydrophilic or hydrophobic sheets, or fibrous hydrophilic or hydrophobic sponges. The porosity affected the efficiency of methane production and solid waste removal more than the hydrophilic or hydrophobic nature of the supporting material. When the terminal restriction fragment length polymorphism technique was used at a lower organic loading rate (OLR), microbial diversities in the suspended fraction were retained on the hydrophobic, but not the hydrophilic, sheets. Moreover, real-time quantitative polymerase chain reaction (PCR) performed at a higher OLR revealed that the excellent performance of reactors containing fibrous sponges with high porosity (98%) was supported by a clear increase in the numbers of methanogens on these sponges, resulting in larger total numbers of methanogens in the reactors. In addition, the bacterial communities in fractions retained on both the hydrophobic and hydrophilic fibrous sponges differed from those in the suspended fraction, thus increasing bacterial diversity in the reactor. Thus, higher porosity of the supporting material improves the bioreactor performance by increasing the amount of methanogens and bacterial diversity; surface hydrophobicity contributes to maintaining the suspended microbial community.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In Japan, the large amount of organic solid wastes (e.g., garbage) produced every year is coped with by dumping it in landfills or incinerating it, both of which produce environmental problems (Haruta et al. 2005; Ueno et al. 2007). Consequently, there is now a great deal of the social interest in the recycling of organic solid wastes. Anaerobic digestion using methane fermentation is one approach to addressing this problem, as it has minimal environmental impact and reduces sludge production, and its end products can be used as an energy source (Farhadian et al. 2007). The up-flow anaerobic sludge blanket (UASB) process is the most popular anaerobic system for wastewater treatment; however, UASB is not adapted for treatment of waste with organic solids (Ueno et al. 2007). Anaerobic biological reactors utilized for the treatment of organic solid wastes include a two-stage system (phase separation in an acidogenic process and a methanogenic processes) and a packed-bed system (Angelidaki et al. 2006; Sasaki et al. 2007; Ueno et al. 2007). Because of its higher loading rate and greater biogas yield, the packed-bed system has recently gained much attention (Tatara et al. 2004, 2008; Umaña et al. 2008). In this system, supporting materials are installed in the reactor (Rickard et al. 2004; Tatara et al. 2008) so that they can be used for biomass retention; because of this, the efficiency of anaerobic degradation is significantly improved.

The retention of microorganisms in a bioreactor is influenced by the physical characteristics of the support material. For instance, the surface hydrophobicity of microorganisms is important for their adhesion onto a hydrophobic surface (Pringle and Fletcher 1983; Van Pelt et al. 1985; Van Loosdrecht et al. 1987), and is a key determinant of a supporting material’s suitability for generation of syntrophic–methanogenic consortia in anaerobic digesters of fatty acids (Chauhan and Ogram 2005). In addition, from the analysis of the performance of the methanogenic reactor decomposing wastewater and total microbial amount retained, supporting materials with a porous structure were concluded to be advantageous for microbial adherence (Show and Tay 1999; Picanço et al. 2001). However, there have been few detailed comparative analyses of structures of microbial communities retained on supporting materials with varying characteristics, which degrade organic solid waste. During anaerobic bioprocesses, organic solid waste is degraded by complex microbial communities that include hydrolytic, acidogenic, syntrophic, and methanogenic microorganisms (Ahring 2003). Consequently, it is important to know the relationship between the properties of a supporting material and the microbial community degrading the organic solid waste and microbial community should be related to reactor performance. In the packed-bed methane fermentation system, the bulk solution is flowed, and the retained fraction is always exposed to destructive or wash-out stress, which profoundly affects the microbial community (Gjaltema et al. 1997; Rickard et al. 2004). The structures of microbial community in such an environment need to be assessed.

To address these issues, we constructed completely stirred tank reactors packed with different supporting material. Our objective was to investigate how the characteristics of the supporting material influence reactor performance and the structure of microbial communities in methanogenic reactors degrading garbage slurry. The main characteristics examined were the surface properties (i.e., hydrophobic vs. hydrophilic) and the porosity of the material.

Materials and methods

Supporting materials

We prepared six types of supporting materials; glass sheet (GS), polyethylene sheet (PES), carbon sheet (CS), glass fibrous sponge (GF), polyethylene fibrous sponge (PEF), and carbon fibrous sponge (CF). Table 1 lists the surface properties and specifications of these supporting materials. The size of each supporting material was equalized (width: 23.0 mm; length: 70.0 mm) and the contact angles were measured as described previously (Ohmura et al. 1993). The thicknesses of GS, PES, CS, GF, PEF, and CF were 3, 3, 3, 5, 2.4, and 2.4 mm, respectively. The porosities of GF, PEF, and CF were determined using the air pycnometer method (Type 1000, Tokyo Science, Tokyo, Japan).

Feed material

Artificial garbage slurry (AGS) was used as a model of organic solid waste. The composition of AGS was as follows (in grams per liter); commercial dog food (Vita-one, Nihon Pet Food, Tokyo, Japan), 20 or 40; KH2PO4, 1.1; and K2HPO4, 1.7. NiCl2·6H2O and CoCl2·6H2O were added to adjust Ni2+ and Co2+ concentrations to 0.10 and 0.12 mg l−1, respectively. The characteristics of AGS (2% dog food) were as follows: dichromate chemical oxygen demand (CODcr), 19.0 gCODcr l−1; suspended solid (SS), 10.7 g l−1.

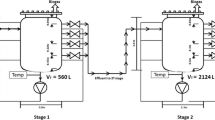

Construction and operation of bioreactors

Duplicate anaerobic reactors were prepared in which each contained one of the six types of supporting material. In each reactor, two sheets of the supporting material were attached with a steel wire using silicon and fixed. In addition, the two reactors without supporting material were also prepared and served as controls, giving a total of 14 reactors. The details of the completely stirred tank reactors packed with the supporting material are described elsewhere (Sasaki et al. 2009). In brief, each glass reactor had a working volume of 250 ml and was sealed with a silicon stopper. The contents of the reactor were thoroughly mixed using a magnetic stirrer, and temperature was maintained at 55 °C. The seed sludge was collected from a thermophilic anaerobic digester (Kajima Technical Research Institute, Tokyo, Japan). The methane production rate of the seed sludge was 390 ml l−1 day−1 at an organic loading rate (OLR) of 1.9 gCODcr l−1 day−1. The seed sludge contained 2.5 × 1012 copies/reactor of prokaryotic 16 S rRNA gene. The reactors were run in semicontinuous mode, i.e., once a day, a predetermined volume was discharged through the plug using a syringe, and an equivalent amount of fresh AGS was added. Simultaneously, 0.5 N NaOH was added to maintain the pH in the reactors at a value higher than 7.2 throughout the experiment.

The time schedules for changing the OLR and the hydraulic retention time (HRT) are presented in Fig. 1. From day 0 to day 53, the OLR was increased in a stepwise manner by reducing the HRT after fluctuations in the gas production rate had declined to under ±12%. Because of deterioration of the reactors containing GS, PES, or CS and the controls without supporting material, the operation was stopped on day 53 at an OLR of 4.6 gCODcr l−1 day−1 (HRT: 4.2 days), and the suspended fraction in each reactor was then sampled for microbial analysis. In addition, used GS, PES, and CS in the reactor were also sampled for microbial analysis. At the same time, the support material and suspended fraction in one of the two reactors containing CF were sampled, and operation of that reactor ended. The remaining five reactors containing GF, PEF, and CF were operated at an OLR of 6.1 gCODcr l−1 day−1 (HRT: 3.1 days, substrate: 2% dog food) from day 54 to day 63 and at an OLR of 12.2 gCODcr l−1 day−1 (HRT: 3.1 days, substrate: 4% dog food) from day 64 to day 73. The steady state of five operations was established by operating for a period three times the length of the HRT (10 days). At an OLR of 12.2 gCODcr l−1 day−1 (day 73), samples of the suspended fractions and the used GF, PEF, and CF were collected from those reactors for analysis of retained SS and microbial communities. To collect retained biomass, sampled GF, PEF, and CF were vigorously shaken by vortexing in phosphate-buffered saline (PBS), after which any remaining biomass was scraped off.

Analytical procedures

The suspended fraction in the reactor was periodically sampled and analyzed at the end point of each OLR. CODcr and SS were determined according to the Japanese Industrial Standard K-0102. Volatile fatty acids (VFA) were monitored using a HPLC system (GL-7400, GL Sciences, Tokyo, Japan) equipped with a TSKgel OApak-A,P column (Tosoh, Tokyo, Japan). Biogas production was measured using the water displacement method. The methane, carbon dioxide, and hydrogen contents of the biogas were measured by gas chromatography as described previously (Sasaki et al. 2009).

DNA extraction

Biomass retained on the supporting materials and in the suspended fraction from the reactors were centrifuged at 5,000×g and the resultant pellets were suspended in Tris–EDTA buffer ([pH 8.0], 100 mM Tris–HCl, 40 mM EDTA). Whole sheets or determined fraction of fibrous sponges were used to extract DNA. DNA was extracted from the pellets using repeated beads beating in the presence of sodium dodecyl sulfate and phenol-chloroform-isoamyl alcohol (25:24:1), after which the DNA was purified using a QIAamp DNA micro kit (Qiagen, Hilden, Germany) as described previously (Sasaki et al. 2009).

Real-time quantitative PCR analysis

Real-time PCR was performed using a LightCycler 1.5 (Roche Diagnostics, Tokyo, Japan) and LightCycler TaqMan Master (Roche Diagnostics). The primer set of March-0348 and Arch-786 were used with the double-dye probe of March-0515 for measuring the copy number of 16 S rRNA from methanogenic archaea (Sawayama et al. 2004). The primer set Uni340F and Uni806R were used with the double-dye probe of Uni516F for prokaryotes (Takai and Horikoshi 2000). All the double-dye probes were labeled with FAM at their 5’ end and TAMRA at their 3’ end. The concentrations of the primers and the TaqMan probe were 0.5 and 0.2 µM, respectively. Quantitative measurement by real-time PCR was conducted in triplicate. The amplification protocol entailed initial denaturation for 10 min at 95 °C, followed by 40 cycles of denaturation for 10 s at 95 °C, annealing for 45 s at 50 °C, and elongation for 1 s at 72 °C. The RNA gene standards for methanogenic archaea and prokaryotes were plasmids prepared using a pGEM-T Easy Vector System (Promega, Tokyo, Japan) after PCR of Methanosarcina barkeri (JCM 10043) using the primer sets Arch21F (Delong 1992) and U1492r, or PCR of Escherichia coli (IAM 1264) using the primer sets B8f and U1492r (Lane 1991). To calculate the total copy number per reactor, the copy number per DNA-extracted area of the supporting material or volume of the bulk was multiplied by the total area or volume.

Terminal restriction fragment length polymorphism (T-RFLP)

PCR amplification was performed using AmpliTaqGold (Applied Biosystems, Tokyo, Japan). The primer sets used were Ba27f (E. coli positions 8–27) and Ba907r (E. coli positions 907–926) for the domain Bacteria (Lane 1991; Lueders and Friedrich 2002), or Ar109f (E. coli positions 109–125) and Ar912rt (E. coli positions 912–934) for the domain Archaea (Lueders et al. 2004). For terminal restriction fragment length polymorphism (T-RFLP) analysis, the Ba27F primer and Ar912rt primers were fluorescently labeled on their 5’ ends with carboxyfluorescein. The PCR protocol entailed an initial denaturation for 10 min at 94 °C; 25 cycles of denaturation for 45 s at 94 °C, annealing for 30 s at 52 °C, and elongation for 90 s at 72 °C; and a final 5-min elongation at 72 °C.

The products of the PCR amplification described above were purified using a QIAquick PCR purification kit (QIAGEN, Tokyo, Japan). Approximately 200 ng of the amplicons were then digested using 10 U of the restriction enzymes MspI (New England Biolabs, Tokyo, Japan) for Bacteria and Taq αI (New England Biolabs) for Archaea. The enzymatic digestions were carried out as instructed by the manufacturer. Aliquots (1.0 µl) of the digested amplicons were then mixed with 18 μl of Hi–Di formamide and 0.45 µl of an ROX-labeled GeneScan 500-bp internal size standard (Applied Biosystems), after which the mixtures were denatured at 95 °C for 3 min, chilled over ice, and subjected to electrophoresis using an Applied Biosystems 3130xl Genetic Analyzer (Applied Biosystems). The sizes and heights of the 5’-terminal restriction fragments (T-RFs) were then determined by the GeneMapper software version 3.7 (Applied Biosystems), and the data obtained were aligned and normalized in each sample. Peaks with heights lower than 100 fluorescence units were filtered out, and fragments smaller than 50 bp were excluded from the final data matrix. The percentages of single terminal restriction fragments were calculated on the basis of their relative abundances with respect to the total peak height of all T-RFs.

Cloning and sequencing of the archaeal 16 S rRNA genes

Using the primers Ar109f and Ar912rt, archaeal 16 S rRNA gene fragments were amplified from DNA extracted from the biomass retained on the CF at day 53, after which the ligated PCR products were then transformed into E. coli JM109 using the pGEM-T Easy Vector System (Promega, Tokyo, Japan). Plasmids were extracted from the 30 cloned cells and purified using a GenElute plasmid Miniprep Kit (Sigma, St. Louis, MO, USA), after which sequencing reactions were carried out with a BigDye Terminator v3.1 Cycler Sequencing Kit (Applied Biosystems). Nucleotide sequencing was performed with an Applied Biosystems 3130xl Genetic Analyzer (Applied Biosystems). All sequences were checked for chimeric artifacts by using the CHIMERA_CHECK program from the Ribosomal Database Project (Maidak et al. 2001). Sequences with a similarity of 99% or greater were grouped as operational taxonomic units (OTUs).

Nucleotide sequence accession numbers

The GenBank/EMBL/DDBJ accession numbers for the 16 S rRNA gene sequences of the clones are AB490316 to AB490319.

Results

Reactor performances

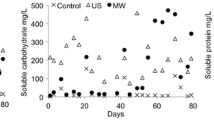

At the beginning of the operation, the OLR was gradually increased in all reactors. After OLR was reached to 4.6 gCODcr l−1 day−1, clear differences in reactor performance were apparent between the reactors containing sheets or no supporting material and those containing fibrous sponges. Rates of gas production by reactors without supporting material or containing GS, PES, or CS gradually declined to 150–360 ml l−1 day (Fig. 2a), and the methane content in gas produced at an OLR of 4.6 gCODcr l−1 day−1 (day 53) declined to 19–42% (Fig. 2b). At the same time, large VFA accumulations (84–157 mM) were observed in these reactors (Fig. 2c), and the efficiencies of COD and SS removal declined to 29–35% and 22–33%, respectively (Fig. 3). By contrast, the reactors containing GF, PEF, or CF tolerated an OLR of 4.6 gCODcr l−1 day−1, as indicated by the higher gas production rates (1,100–1,270 ml l−1 day−1), higher methane content (54–63%), greater efficiency of COD and SS removal (COD, 74–77%; SS, 53–60%), and lower VFA concentrations (9–32 mM).

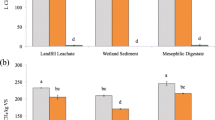

The relationship between the OLR and the efficiency of COD (a) and SS (b) removal. COD removal efficiency was calculated as follows: COD removal efficiency (%) = [(CODin − CODout)/CODin] × 100, where CODin is the COD of the substrate and CODout is the COD of the bulk. SS removal efficiency was calculated as follows: SS removal efficiency (%) = [(SSin − SSout)/SSin] × 100, where SSin is the SS of the substrate and SSout is the SS of the bulk

We then compared the steady state performances of reactors containing GF, PEF, and CF at OLR of 6.1 and 12.2 gCODcr l−1 day−1 (days 54 to 73). After OLR was increased to 12.2 gCODcr l−1 day−1, reactors containing PEF or CF showed the best performances among the three reactor types tested, as confirmed by the high gas production rate (2,340–2,780 ml l−1 day−1), high methane content (50–53%), and efficient removal of COD and SS (COD, 58–67%; SS, 41–49%), and low VFA concentrations (28–44 mM). On the other hand, the reactors containing GF deteriorated, as indicated by the low gas production rate (1,560 ml l−1 day−1), low methane content (13%), low efficiency of COD and SS removal (COD, 41%; SS, 29%), and high VFA accumulation (131 mM). At the end point of the operation at an OLR of 12.2 gCODcr l−1 day−1 (day 73), the VFAs consisted of lactate, formate, acetate, propionate, and butyrate, among which the main product was the acetate (GF, 98.1 mM; PEF, 34.2 mM; CF, 23.5 mM). In addition, the amounts of adherent biomass including solid materials and microorganisms, retained as SS in the reactor containing GF, PEF, and CF, were 113, 453, and 610 mg, respectively.

Quantitative description of the prokaryote and methanogenic archaea

At the end point of the operation at an OLR of 4.6 gCODcr l−1 day−1 (day 53), the 16 S rRNA gene copy numbers for the microbial and methanogenic populations in the suspended or retained fractions from the reactors containing GS, PES, CS, and CF or no supporting material were estimated using real-time PCR assays (Table 2). In the suspended fractions from these reactors, prokaryotic, and methanogenic 16 S rRNA gene amounts were similar ((1.9–6.1) × 1012 copies/reactor and (1.0–2.2) × 1011 copies/reactor, respectively). On all supporting materials (GS, PES, CS, and CF), the ratios of methanogenic copy number to prokaryotic one were high (22.3–59.1%), as compared with those in the suspended fractions (2.9–6.9%), which suggests the presence of the supporting material enhances the retention of methanogens. In each reactor, however, the amount of prokaryotic and methanogenic rRNA gene on sheets (GS, PES, and CS) were only 0.2–1.3% of those in the suspended fraction. In addition, prokaryotic and methanogenic copy numbers on the hydrophilic sheet (GS) were comparable to those on hydrophobic sheets (PES and CS). By contrast, in the fraction retained on CF, which is highly porous, the prokaryotic and methanogenic copy numbers were dramatically higher, corresponding to 54.8% and 504.3% of those in the suspended fraction of the reactors, respectively. These values were at least 163 times (for prokaryotes) and 416 times (for methanogens) greater than those on sheets. As a result, the copy number of methanogens, particularly those in the total fraction (retained fraction + suspended fraction) from the reactor containing CF, was at least 5.8 times that of the methanogens in the reactors containing sheets or those without the supporting material; this increase was mainly due to the porous nature of CF. We therefore conclude that many methanogenic archaea were retained on the porous supporting materials.

At the end point of the operation at 12.2 gCODcr l−1 day−1 (day 73), the same real-time PCR assay was applied to reactors containing GF, PEF, and CF (Table 2). For the reactor containing GF, which has low porosity, the prokaryotic and methanogenic 16 S rRNA gene copy numbers and the ratios of methanogens to prokaryotes in the suspended and retained fractions were the lowest among the three reactor types. In the fraction retained on PEF or CF, which are highly porous, the methanogenic 16 S rRNA gene copy numbers were high (3.8 × 1011 and 1.5 × 1012 copies/reactor, respectively), as compared with that in the fraction retained on GF (5.1 × 1010 copies/reactor). Within the reactors containing PEF or CF, the ratio of methanogens in the retained fraction to those in the suspended fraction was high (134% and 231%, respectively). At the same time, the ratios of methanogens to prokaryotes in the retained fraction were increased to 22.0% and 35.6% in the case of PEF and CF, respectively. We therefore concluded that a highly porous supporting material is favorable for increasing the methanogenic archaea.

T-RFLP analysis of the suspended and retained fractions for each supporting material

To assess microbial diversity, T-RFLP analysis was used to determine the bacterial and archaeal community fingerprint patterns for the suspended and retained fractions. The relative abundances of T-RFs are presented as the averages of the triplicate experiments.

At the end point of the operation at an OLR of 4.6 gCODcr l−1 day−1 (day 53), all bacterial T-RFs in the suspended fractions were also detected in the retained fractions for reactors packed with PES, CS, or CF (Fig. 4a), though the retained fractions contained T-RFs that were not present in the suspended fractions. In other words, larger numbers of bacterial T-RFs were detected in the retained fractions (10, 10, and 12 for PES, CS, and CF, respectively) than in the suspended fractions (6, 5, 6, and 6 for control, PES, CS, and CF, respectively). Similarly, in the reactor packed with GS, the number of T-RFs in the retained fraction (12) was higher than that in the suspended fraction (9); however, T-RFs with sizes of 69 and 570 bp found in suspended fraction were not detected in the retained fraction, although they were often found in both fractions in the case of the other reactors.

Community dynamics of Bacteria (a) and Archaea (b) determined by T-RFLP analysis. The relative abundances of T-RFs generated from the samples are shown. Samples are labeled according to the type of supporting material (control, GS, PES, CS, GF, PEF, and CF). For reactors containing each supporting material, S and R indicate the suspended and retained fractions, respectively. Samples in lanes 1−9 were collected at an OLR of 4.6 gCODcr l−1 day−1 (day 53), while those in lanes 10−15 were collected at an OLR of 12.2 gCODcr l−1 day−1 (day 73)

At the end point of the operation at an OLR of 4.6 gCODcr l−1 day−1, the archaeal T-RFLP profiles were composed of three T-RFs 84, 92, and 186 bp in length (Fig. 4b). To identify major archaeal T-RFLP peaks, clone library analysis was used to obtain sequence information from the fraction retained on CF, after which randomly selected clones were examined by T-RFLP to compare the corresponding fingerprint patterns. With this approach, the aceticlastic methanogen Methanosarcina spp. (Zinder et al. 1985) and the hydrogenotrophic methanogen Methanothermobacter spp. (Wasserfallen et al. 2000) were detected (Table 3). The Methanosarcina sp.-related sequences corresponded to the 186-bp T-RF, while the 92-bp T-RF was assigned to Methanothermobacter sp. In each reactor containing GS, PES, CS, or CF, the relative abundance of Methanosarcina sp.-related T-RF in the retained fraction was higher than in the suspended fraction, and was especially high on CF. This suggests that Methanosarcina sp. was abundant on each supporting material, particularly on highly porous material.

At the end point of the operation at an OLR of 12.2 gCODcr l−1 day−1 (day 73), T-RFLP analysis was used to investigate the structures of microbial communities in reactors containing GF, PEF, and CF. The difference of bacterial T-RFLP profiles between suspended fraction and retained fraction was observed in each reactor. The numbers of bacterial T-RFs in the retained fractions (12, 13, and 10 for GF, PEF, and CF, respectively) were higher than or equal to those in the suspended fractions (7, 9, and 10 for GF, PEF, and CF, respectively), but there was no tendency for T-RFs in the retained fraction to include T-RFs in the suspended fraction. The appearance of a new major T-RF with the size of 81 bp reflects the succession of T-RFLP profiles as the OLR was increased from 4.6 to 12.2 gCODcr l−1 day−1. However, a 259-bp T-RF that was major T-RF at an OLR of 4.6 gCODcr l−1 day−1 was also detected again as a major T-RF in the retained fraction of each reactor, suggesting this T-RF-related microbe was retained on porous supporting materials. Consequently, the total numbers of T-RFs in the suspended and retained fractions from the reactors containing GF, PEF, and CF (14, 15, and 16 for GF, PEF, and CF, respectively) were higher than in the suspended fractions.

At the end point of the operation at an OLR of 12.2 gCODcr l−1 day−1, the archaeal T-RFLP profiles were again composed of three T-RFs of 84, 92, and 186 bp in length. The relative abundance of Methanosarcina sp.-related T-RFs was high in the retained fractions, particularly in reactors containing PEF and CF (53% and 73%, respectively). On the other hand, it was low in the fraction retained on GF (6%).

Discussion

Relationship between microbial community structure and reactor performance

Microbial communities reportedly vary depending upon reactor conditions (Lee et al. 2008, 2009). In our study, for example, reactors containing different supporting materials performed differently with respect to degradation of COD and SS, VFA accumulation, and methane gas production. By comparing the structures of the microbial communities with the reactor performance, we determined the microbial structures (i.e., quantitatively from the real-time PCR results and qualitatively from the T-RFLP and cloning results) that help enhance the reactor performance. Reactors with higher numbers of microorganisms, particularly methanogens, and/or better retention of biomass on the supporting material showed better performance. Good retention of methanogens, which play a role in the final process of methanogenesis (Ahring et al. 2003), is an important element of stable reactor operation. In addition, we found that a higher ratio of methanogens to total microorganisms was also advantageous for reactor performance. It has been reported that methanogenic archaea account for about 19–25% of total organisms in the sewage sludge (Sawayama et al. 2004) or the granular sludge (Sekiguchi et al. 1998). In our study, methanogenic fractions in reactors showing better performances (i.e., those containing PEF and CF) were maintained at 13–25%, as a result of selective increases in methanogens on the supporting material, which complemented the low methanogenic component in the suspended fraction (6.8–11.0%). In addition, a high degree of porosity of the supporting material facilitated the increase of methanogens, particularly aceticlastic methanogens, which reportedly account for 70% of methane production (Ahring et al. 2003). In our study, the ratio of aceticlastic methanogen to the total methanogens on highly porous supporting material was comparatively high (49–73%). Thus, better reactor performance appears to correlate with large numbers of methanogens, predominantly aceticlastic methanogens, and a high ratio of methanogens to total microorganisms.

Our study demonstrated that retention on sheets or fibrous sponges often produced greater microbial diversity than the planktonic conditions. In addition, retention on fibrous sponges produced different microbial populations than suspensions. Consequently, greater microbial diversity was achieved in reactors containing supporting material. The higher microbial diversity in reactors containing PEF and CF, on which microbial amount occupied a considerable part in the reactor, would be expected to play an important role for improving degradation efficiency and increasing operational stability.

Effect of hydrophobicity

We also assessed the effect of surface hydrophobicity on the structure of microbial communities within bioreactors. Hydrophobic interaction between cells and the surface of a support material has been reported to be an important determinant of a material’s ability to retain microorganisms (Van Loosdrecht et al. 1987; Chauhan and Ogram 2005). In our study, the structures of microbial communities differed between hydrophilic and hydrophobic surfaces. A hydrophilic surface might affect the lack of universal organisms on it in our reactors. Although at the lower OLR (4.6 gCODcr l−1 day−1) hydrophobicity had little effect on numbers of retained microbes or on the size of the methanogenic archaeal fraction, hydrophobic material retained microbial diversity in the suspended fraction, including Bacteria and Archaea, as shown in the T-RFLP results. Hydrophobic material would enable microorganisms to withstand the detachment force, thereby maintaining the microbial diversity of the suspended fraction. This finding is consistent with that of Bos et al. (2000), who reported that surface hydrophobicity has a significant effect on retention of bacteria subjected to the detachment force of potassium phosphate solution. However, careful consideration of the various cell properties such as surface structure and charge, extrapolymeric substance, motility, and cometabolism is still lacking (Davey and O’Tool 2000). Also, cell-to-cell surface and interface interactions in the biofilm formed on hydrophobic material would have a significant influence on the retention of microorganisms. In the biofilm, repeated cycling of microbial attachment and detachment would occur; however, at the HRT of 4.2 days, the microbial community in the biofilm should not change rapidly. In addition, the conditioning films of organic compounds formed immediately adjacent to the surface of the supporting material surface should be considered, as organic compounds may be adsorbed onto the supporting material and alter the surface properties prior to microbial attachment (Bakker et al. 2004).

Effect of porosity

We found that the performance of the reactors containing fibrous sponges was better than that of reactors containing sheets. In addition, by comparing real-time PCR results of fibrous sponges with those of sheets, porosity was shown to have a great effect on the number of retained microorganisms or methanogens without regard to surface hydrophobicity or hydrophilicity. A complex, three-dimensional structure consisting of micoroorganisms, microbial aggregates, and organic materials is reportedly constructed in the interstices of fibrous sponges (Sasaki et al. 2007); this three-dimensional structure would be expected to have a greater effect on retention of microorganisms than the surface characteristics of supporting material.

Our data also indicated that the structure of bacterial communities at a steady state of higher OLR (12.2 gCODcr l−1 day−1) was different in the suspended and retained fractions in reactors containing fibrous sponges, although the archaeal communities were similar. In addition, the specific bacteria that were minor in the suspended fraction and had been dominant at a lower OLR remained dominant in the retained fraction. This phenomenon was similar to one reported by Huang et al. (2008), who showed that bacterial communities in the biofilm and planktonic biomass are similar under low flux but differ under high flux in membrane bioreactors, and that specific bacterial groups became dominant in the biofilm under high flux. Thus, a microbial community embedded in a fibrous sponge creates its own niches, which differ from those in suspended microbial communities. In this way, a fibrous sponge would increase the total bacterial diversity.

A porous structure contributed to high retention of methanogens as the real-time PCR results showed. Moreover, an increase in methanogens in the suspended fraction of reactors containing highly porous fibrous sponges would be reflected from an increase of methanogens in the retained fraction. Release of retained biomass from the supporting material back into the bulk fluid may have a beneficial effect on reactor performance if significant microorganisms are supplied. For instance, we observed increases in the amount of Methanosarcina sp. on highly porous supporting material. Methanosarcina sp. would tend to attach and aggregate in the inner region of the supporting material to avoid destructive stress in the suspended fraction (Sasaki et al. 2007). Retention and proliferation of acetate-removing microoraganisms such as Methanosarcina sp. (Zinder et al. 1985) within a reactor is an important factor contributing to stable operation because substantial accumulation of acetate is often observed in reactors whose performance is deteriorating (Hori et al. 2006).

The attached bacterial activity would be different from planktonic existence because methanogenic ratio to prokaryotes differed significantly between the suspended fraction and retained fractions. Methanogens are known to aid bacterial metabolic ability through syntrophic interaction (Stams and Plugge 2009). On the supporting material, the degradation ability of bacterial cells may be elevated.

References

Ahring BK (2003) Perspectives for anaerobic digestion. Adv Biochem Eng Biotechnol 81:1–30

Angelidaki I, Chen X, Cui J, Kaparaju P, Ellegaard L (2006) Thermophilic anaerobic digestion of source-sorted organic fraction of household municipal solid waste: start-up procedure for continuously stirred tank reactor. Water Res 40:2621–2628

Bakker DP, Busscher HJ, Van Zanten J, De Varies J, Klijnstra JW, Van der Mei HC (2004) Multiple linear regression analysis of bacterial deposition to polyurethane coatings after conditioning film formation in the marine environment. Microbiology 150:1779–1784

Bos R, Van der Mei HC, Gold J, Busscher HJ (2000) Retention of bacteria on substratum surface with micro-patterned hydrophobicity. FEMS Microbiol Lett 189:311–315

Chauhan A, Ogram A (2005) Evaluation of support matrices for immobilization of anaerobic consortia for efficient carbon cycling in waste regeneration. Biochem Biophys Res Commun 327:884–893

Davey ME, O’Tool GA (2000) Microbial biofilms: from ecology to molecular genetics. Microbiol Mol Biol Rev 64:847–867

Delong EF (1992) Archaea in coastal marine environments. Proc Natl Acad Sci USA 89:5685–5689

Farhadian M, Borghei M, Umrania VV (2007) Treatment of beet sugar wastewater by UAFB bioprocess. Bioresour Technol 98:3080–3083

Gjaltema A, Van der Marel N, Van Loosdrecht MCM, Heijnen JJ (1997) Adhesion and biofilm development on suspended carriers in airlift reactors: hydrodynamic conditions versus surface characteristics. Biotechnol Bioeng 55:880–889

Haruta S, Nakamura T, Nakamura K, Hemmi H, Ishii M, Igarashi Y, Nishino T (2005) Microbial diversity in biodegradation and reutilization processes of garbage. J Biosci Bioeng 99:1–11

Huang LN, De Wever H, Diels L (2008) Diverse and distinct bacterial communities induced biofilm fouling in membrane bioreactors operated under different conditions. Environ Sci Technol 42:8360–8366

Hori T, Haruta S, Ueno Y, Ishii M, Igarashi Y (2006) Dynamic transition of the methanogenic population in response to the concentration of volatile fatty acids in a thermophilic anaerobic digestor. Appl Environ Microbiol 72:1623–1630

Lane DJ (1991) 16 S/23 S rRNA sequencing. In: Stackebrandt E, Goodfellow M (eds) Nucleic acid techniques in bacterial systematics. Wiley, New York, pp 115–175

Lee C, Kim J, Shin SG, Hwang S (2008) Monitoring bacterial and archaeal community shifts in a mesophilic batch reactor treating a high-strength organic wastewater. FEMS Microbiol Ecol 65:544–554

Lee C, Kim J, Hwang K, O’Flaherty V, Hwang S (2009) Quantitative analysis of methanogenic community dynamics in three anaerobic batch digesters treating different wastewaters. Water Res 43:157–165

Lueders T, Friedrich MW (2002) Effects of amendment with ferrihydrite and gypsum on the structure and activity of methanogenic populations in rice field soil. Appl Environ Microbiol 68:2484–2494

Lueders T, Manefield M, Friedrich MW (2004) Enhanced sensitivity of DNA- and rRNA-based stable isotope probing by fractionation and quantitative analysis of isopycnic centrifugation gradients. Environ Microbiol 6:73–78

Maidak B, Cole JR, Lilburn TG, Parker CT, Saxman PR, Farris RJ, Garrity GM, Olsen GJ, Schmidt TM, Tiedje JM (2001) The RDP-II (Ribosomal Database Project). Nucleic Acid Res 29:173–174

Ohmura N, Kitamura K, Saiki H (1993) Selective adhesion of Thiobacillus ferroxidans to pyrite. Appl Environ Microbiol 59:4044–4050

Picanço AP, Vallero MVG, Gianotti EP, Zaiat M, Blundi CE (2001) Influence of porosity and composition of supports on the methanogenic biofilm characteristics developed in a fixed bed anaerobic reactor. Water Sci Technol 44:197–204

Pringle JH, Fletcher M (1983) Influence of substratum wettability on attachment of freshwater bacteria to solid surfaces. Appl Environ Microbiol 45:811–817

Rickard AH, McBain AJM, Stead AT, Gilbert P (2004) Shear rate moderates community diversity in freshwater biofilms. Appl Environ Microbiol 70:7426–7435

Sasaki K, Haruta S, Ueno Y, Ishii M, Igarashi Y (2007) Microbial population in the biomass adhering to supporting material in a packed-bed reactor degrading organic solid waste. Appl Microbiol Biotechnol 75:941–952

Sasaki K, Morita M, Hirano S, Ohmura N, Igarashi Y (2009) Effect of adding carbon fiber textiles to methanogenic bioreactors used to treat an artificial garbage slurry. J Biosci Bioeng 108:130–135

Sawayama S, Tada C, Tsukahara K, Yagishita T (2004) Effect of ammonium addition on methanogenic community in a fluidized bed anaerobic digestion. J Biosci Bioeng 97:65–70

Sekiguchi Y, Kamagata Y, Syutsubo K, Ohashi A, Harada H, Nakamura K (1998) Phylogenetic diversity of mesophilic and thermophilic granular sludges determined by 16 S rRNA gene analysis. Microbiology 144:2655–2665

Show KY, Tay JH (1999) Influence of support media on biomass growth and retention in anaerobic filters. Water Res 33:1471–1481

Stams AJM, Plugge CM (2009) Electron transfer in syntrophic communities of anaerobic bacteria and archaea. Nat Rev Microbiol 7:568–577

Takai K, Horikoshi K (2000) Rapid detection and quatification of members of archaeal community by quantitative PCR using fluorogenic probes. Appl Environ Microbiol 66:5066–5072

Tatara M, Yamazawa A, Ueno Y, Fukui H, Goto M, Sode K (2004) High-rate thermophilic methane fermentation on short-chain fatty acids in a down-flow anaerobic packed-bed reactor. Bioprocess Biosyst Eng 27:105–113

Tatara M, Makiuchi T, Ueno Y, Goto M, Sode K (2008) Methanogenesis from acetate and propionate by thermophilic down-flow anaerobic packed-bed reactor. Bioresour Technol 99:4786–4795

Ueno Y, Fukui H, Goto M (2007) Operation of a two-stage fermentation process producing hydrogen and methane from organic waste. Environ Sci Technol 41:1413–1419

Umaña O, Nikolaeva S, Sánchez E, Borja R, Raposo F (2008) Treatment of screened dairy manure by upflow anaerobic fixed bed reactors packed with waste type rubber and a combination of waste type rubber and zeolite: Effect of the hydraulic retention time. Bioresour Technol 99:7412–7417

Van Loosdrecht MCM, Lyklema J, Norde W, Schraam G, Zehnder AJB (1987) The role of bacterial cell wall hydrophobicity in adhesion. Appl Environ Microbiol 53:1893–1897

Van Pelt AWJ, Weerkamp AH, Uyen MHW, Busscher HJ, De Jong HP, Arends J (1985) Adhesion of Streptococcus sanguis CH3 to polymers with different surface free energies. Appl Environ Microbiol 49:1270–1275

Wasserfallen A, Nölling J, Pfister P, Reeve J, De Macario EC (2000) Phylogenetic analysis of 18 thermophilic Methanobacterium isolates supports the proposals to create a new genus, Methanothermobacter gen. nov., and to reclassify several isolates in three species, Methanothermobacter thermautotrophicus comb. nov., Methanobacterium wolfeii comb. nov., and Methanothermobacter marburgensis sp. nov. Int J Syst Evol Microbiol 50:43–53

Zinder SH, Sowers KR, Ferry JG (1985) Methanosarcina thermophila sp. nov., a thermophilic, acetotrophic, methane-producing bacterium. Int J Syst Bacteriol 35:522–523

Acknowledgments

Authors are grateful to Yoji Kitajima and Yoshiyuki Ueno (Environmental Engineering and Bioengineering Group, Kajima Technical Research Institute) for their significant advice on the reactor operation. We also thank Eri Ishihara and Mieko Katsuura for their help. This work was supported by the New Energy and Industrial Technology Development Organization (NEDO).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sasaki, K., Sasaki, D., Morita, M. et al. Efficient treatment of garbage slurry in methanogenic bioreactor packed by fibrous sponge with high porosity. Appl Microbiol Biotechnol 86, 1573–1583 (2010). https://doi.org/10.1007/s00253-010-2469-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-010-2469-7