Abstract

In this study, the production of enantiomerically pure (1R,4S,6S)-6-hydroxy-bicyclo[2.2.2]octane-2-one ((−)-2) through stereoselective bioreduction was used as a model reaction for the comparison of engineered Saccharomyces cerevisiae and engineered Escherichia coli as biocatalysts. For both microorganisms, over-expression of the gene encoding the NADPH-dependent aldo-keto reductase YPR1 resulted in high purity of the keto alcohol (−)-2 (>99% ee, 97–98% de). E. coli had three times higher initial reduction rate but S. cerevisiae continued the reduction reaction for a longer time period, thus reaching a higher conversion of the substrate (95%). S. cerevisiae was also more robust than E. coli, as demonstrated by higher viability during bioreduction. It was also investigated whether the NADPH regeneration rate was sufficient to supply the over-expressed reductase with NADPH. Five strains of each microorganism with varied carbon flux through the NADPH regenerating pentose phosphate pathway were genetically constructed and compared. S. cerevisiae required an increased NADPH regeneration rate to supply YPR1 with co-enzyme while the native NADPH regeneration rate was sufficient for E. coli.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Optically pure keto alcohols are important building blocks for the production of pharmaceuticals and fine-chemicals (Hilterhaus and Liese 2007; Liese et al. 2006; Patel 2006). NADPH-dependent reductases with high regio- and stereoselectivity have been exploited to generate chiral alcohols from prochiral ketones without using protective groups, which are commonly used in classical organic synthesis (Chartrain et al. 2001; Schmid et al. 2001). Furthermore, enzymes and whole-cell system, which operate under mild conditions such as ambient temperature and pH, limit the utilisation of hazardous material and can use renewable resources (Woodley 2008). To properly evaluate a biocatalyst for a desired process it is necessary to consider the market requirements. The ideal biocatalyst for industrial scale biotransformation has been described as: (1) an efficient enzyme production system, (2) cultivable and non-pathogenic, (3) genetically stable, (4) highly active in the desired reaction, (5) flexible with respect to substrate selectivity, (6) having minimal side reactions and (7) stable under optimal reaction conditions (Burton 2001).

Saccharomyces cerevisiae, known as baker’s yeast, accepts a wide range of xenobiotic ketones and reduces them to optically pure alcohols (D'Arrigo et al. 1997; Johanson et al. 2005; Stewart 2000). In addition, S. cerevisiae is cheap, generally regarded as safe (GRAS) and easily available, which has made it a popular biocatalyst. However, biotransformation with baker’s yeast may result in mixtures of products due to the presence of reductases with overlapping substrate specificity and mixed stereoselectivity (Johanson et al. 2005).

To minimise the formation of product mixtures, the Gram negative bacterium Escherichia coli has been used to express yeast reductases for whole cell bioreduction of α- and β-ketoesters (Kaluzna et al. 2004; Rodriguez et al. 2000). E. coli is an attractive host for heterologous protein expression since it grows rapidly to high density in inexpensive substrates, which results in high volumetric productivity of the desired protein (Terpe 2006). Furthermore, it is considered to have a naturally lower NADPH-dependent reductase activity compared to S. cerevisiae (Kaluzna et al. 2004). Therefore, recombinant E. coli has sometimes been the preferred organism in whole cell biotransformations (Ishige et al. 2005).

Equally important as the high expression of a specific reductase is the availability and regeneration rate of the co-enzyme NADPH needed in the reaction. In an ideal system the rate of reduction, i.e. co-enzyme consumption, would be equal to the rate of co-enzyme production or otherwise one of the two substrates limits the other (Katz et al. 2003). In S. cerevisiae, NADPH is mainly produced in the pentose phosphate pathway (PPP) by glucose-6P dehydrogenase (G6PDH) and 6-phosphogluconate dehydrogenase (6-PDH) (Stryer 2000), although other enzymes, such as acetaldehyde dehydrogenase (ALD6) (Grabowska and Chelstowska 2003) and isocitrate dehydrogenase (IDP2) (Minard and McAlister-Henn 2001) may also generate cytosolic NADPH. The yield of NADPH per glucose-6P entering the PPP is two moles of NADPH per mole of glucose. The total theoretical yield of NADPH is higher, six moles NADPH per mole glucose, since carbon is recirculated into the PPP through gluconegenesis in the Embden–Meyerhof pathway (EMP) (Bruinenberg 1986). In E. coli, NADPH is produced in the PPP (Csonka and Fraenkel 1977), by isocitrate dehydrogenase (Csonka and Fraenkel 1977) and malic enzyme (Csonka and Fraenkel 1977; Murai et al. 1971). In addition, E. coli harbours transhydrogenase activity (Csonka and Fraenkel 1977; Sauer et al. 2004), which converts NADH to NADPH when so required. In fact, the transhydrogenase activity has been ascribed to contribute up to 35–45% of total NADPH in E. coli growing on glucose aerobically (Sauer et al. 2004).

Targeted metabolic engineering has been used to improve the NADPH regeneration rate in S. cerevisiae (Katz et al. 2003) and in E. coli (Ema et al. 2006; Kataoka et al. 1998). Furthermore, whole-cell-catalysed bioreduction in S. cerevisiae has been improved by redirecting the carbon flux from the EMP to the NADPH producing PPP through decreased activity of phosphoglucose isomerase (PGI) (Katz et al. 2002). However, this strategy has so far not been assessed for E. coli-catalysed reactions.

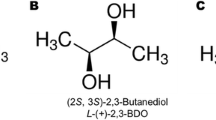

In the present study, the ability of engineered S. cerevisiae and engineered E. coli to produce optically active alcohols from prochiral precursors through whole-cell bioreduction was compared. The NADPH-dependent carbonyl reduction of bicyclo[2.2.2]octane-2,6-dione (1) to its corresponding keto alcohol (1R,4S,6S)-6-hydroxy-bicyclo[2.2.2]octane-2-one ((−)-2) catalysed by the S. cerevisiae aldo-keto reductase YPR1 (Johanson et al. 2008), was used as model reaction (Fig. 1). The availability of NADPH needed for the biotransformation was increased by metabolic engineering of the EMP and PPP. In particular, the effect of combining the deletion of PGI1 with the over-expression of ZWF1, coding for the protein Glucose-6-P dehydrogenase, the first enzyme of PP pathway, (Fig. 2) was studied. To the best of our knowledge this is the first comparative study of S. cerevisiae and E. coli as biocatalysts for asymmetric carbonyl reduction of the same ketone substrate and with the same reductase under identical conditions. Moreover, the modification of the carbon fluxes through the EMP and PPP was systematically evaluated in both S. cerevisiae and E. coli in order to improve the NADPH-dependent whole cell reactions.

Two moles of NADPH are formed per mole G6P entering the PPP. By deleting PGI and over-expressing G6PDH the carbon flux rate through the PPP is increased. NADPH is generated at a faster rate which in turn increases the rate of carbonyl reduction. EMP Embden-Meyerhof pathway, non-ox. PPP non-oxidative pentose phosphate pathway, PGI phosphoglucose isomerase, G6PDH glucose-6-phosphate dehydrogenase, 6-PGL 6-phosphogluconate lactonase, 6-PGDH 6-phosphogluconate dehydrogenase

Materials and methods

Strains and cultivation conditions

S. cerevisiae and E. coli strains used in this study are listed in Table 1. S. cerevisiae strain EBY44 [MATα, ura3-52, leu2-3, 112, trpl-289, his3-A1 MAL2-8c, MAL3, SUC3, ura3::pgi1-1Δ] was constructed from its parental strain ENY.WA-1A [MATα, ura3-52, leu2-3, 112, trpl-289, his3-A1 MAL2-8c, MAL3, SUC3] as described earlier (Boles and Zimmermann 1994). E. coli DH5α (Life Technologies, Rockville, MD, USA) and Top10 (Invitrogen™, CA, USA) were used for subcloning before yeast and bacterium transformation, respectively. Strain BL21 (Invitrogen™, CA, USA) was used for gene knockout, over-expression and whole cell bioreduction. All strains were stored as 15% glycerol stocks in liquid media at −80 °C.

S. cerevisiae strains were plated on YNB-media plates (6.7 g/L YNB without amino acids (Difco, Becton, Dickinson, Sparks, MD, USA), 20 g/L fructose, 2 g/L glucose and 20 g/L agar) and incubated for 3–4 days at 30 °C before use. S. cerevisiae strains were pre-grown in 0.25-L Erlenmeyer flasks containing 25 mL YNB-medium (6.7 g/L YNB without amino acids, 20 g/L fructose and 2 g/L glucose; 100 mM potassium phthalate pH 5.5) at 180 rpm and 30 °C for 3–4 days. Cells were then inoculated at OD620nm = 0.2 in 100 mL YNB-medium in 1-L Erlenmeyer flasks and grown at 180 rpm and 30 °C until early stationary phase was reached.

E. coli strains were plated on a Luria-Bertani (LB)-medium (Sambrook et al. 1989) (10 g/L Bacto-tryptone, 5 g/L yeast extract, 10 g/L NaCl and 20 g/L agar) and incubated over night at 37 °C before use. E. coli strains were pre-grown in 5 mL SOB medium (20 g/L tryptone, 5 g/L yeast extract, 0.5 g/L NaCl, 186.0 mg/L) at 180 rpm and 37 °C over night. Subsequently, strains were inoculated at OD620nm = 0.2 in 150 mL SOB medium with ampicillin (Calbiochem, Darmstadt, Germany) and/or kanamycin (Sigma-Aldrich, St Louis, MO, USA) when needed. When OD620nm reached 0.7 1 mM IPTG was added to induce protein expression during approximately 16 h at 180 rpm and 30 °C.

Construction of strains

Standard techniques for DNA manipulation were used as described previously (Sambrook et al. 1989). Plasmids used in this study are listed in Table 2. Restriction and ligation enzymes were purchased from Fermentas (St. Leon-Rot, Germany). Primers were purchased from Eurofins MWG Operon (Ebersberg, Germany). DNA extraction from agarose gels and purification of PCR products were performed with the QIAquick extraction kit (Qiagen, Hilder, Germany). Plasmid DNA was prepared with the Biorad miniprep kit (Hercules, CA, USA). Sequencing was performed at Eurofins MWG Operon (Ebersberg, Germany).

The S. cerevisiae glucose 6-P dehydrogenase gene (ZWF1) was amplified from genomic DNA using the following primers with specific restriction sites, forward primer; SCZWF1F, 5’-GCA GGA TCC ATG AGT GAA GGC CCC GTC AAA TTC G-3’ (BamHI restriction site in bold) and reverse primer, SCZWF1R, 5’-CCT GTG CAC CTA ATT ATC CTT CGT ATC TTC TGG C-3’ (Alw21I restriction site in bold). The amplicon was restricted with BamHI and Alw21I whereas the cloning vector Yplac128(HXT7)-XI (kindly provided by Dr. Maurizio Bettiga) was restricted with BamHI and PstI where after ligation was performed with T4 nucleotide ligase. The resulting plasmid Yplac128(HXT7)-ZWF1 was linearised with BstXI and then used to transform S. cerevisiae strains ENY.WA-1A and EBY44 (Gietz et al. 1995). Uracil, leucine and trypthophane auxotrophies were reversed by transforming the yeast strains with PCR-products of URA3, LEU2 and TRP1 as described previously (Karhumaa et al. 2005), thus keeping only HIS3 as marker for introduction of the multicopy plasmid. Finally, plasmid p423GPD-YPR1 (Johanson et al. 2008) was used to transform the S. cerevisiae strains, generating strains TMB4310, TMB4311, TMB4312 and TMB4313 (Table 1). A control S. cerevisiae strain, TMB4306, with plasmid p423(GPD) (Mumberg et al. 1995) was constructed in parallel.

The phosphoglucose isomerase gene in E. coli strain BL21 was deleted as described previously (Baba et al. 2006). The kanamycin resistance gene was amplified from pUG6 (Guldener et al. 1996) with primers ECDELPGIF 5’-ATG AAA AAC ATC AAT CCA ACG CAG ACC GCT GCC TGG CCC TTA ATA TAA CTT CGT ATA ATG TAT GCT-3’ and ECDELPGIR 5’-TTA ACC GCG CCA CGC TTT ATA GCG GTT AAT CAG ACC CAC TAG TGG ATC TGA TAT CAC CTA ATA ACT-3’. Regions in bold are homologous with the E. coli PGI gene sequence. PGI deletion was confirmed both by PCR and by enzyme activity measurement. For cloning in E. coli, the S. cerevisiae YPR1 gene was amplified from p423GPD-YPR1 with primers: ECYPR1F 5’-GAA GAT CTA CCA TGC CTG CTA CG-3’ (BglII restriction site in bold) and ECYPR1R 5’-AAC TGC AGC TCA TTG GAA AAT TGG GAA GG-3’ (PstI restriction site in bold). The PCR product was restricted with BglII and PstI, followed by ligation into pRSETB (Invitrogen™, CA, USA) previously restricted with the same enzymes, resulting in plasmid pRSETB-YPR1. The E. coli ZWF gene was amplified from BL21 genomic DNA using the following primers with specific restriction sites ECZWFF 5'-CGT GAA TTC ATG GCG GTA ACG CAA ACA GCC C-'3 (EcoRI restriction site in bold) and ECZWFR 5’-CGT AAG CTT TTA CTC AAA CTC ATT CCA GGA ACG ACC-3’(HindIII restriction site in bold). The PCR product and plasmid pRSFDueT™ (Novagen, Darmstadt, Germany) was restricted with EcoRI and HindIII, followed by ligation which resulted in plasmid pRSFDueT-ZWF. Once pRSETB-YPR1 and pRSFDueT-zwf sequences were confirmed plasmids were inserted into E. coli BL21, resulting in strains TMB2006, TMB2007 and TMB2008 and TMB2009 (Table 1). A control E. coli strain, TMB2005, with plasmids pRSETB and pRSFDueT was constructed in parallel. All strain constructs were confirmed to give increased or decreased enzyme activity subsequent to over-expression or deletion of the respective genes (Fig. 3).

Enzyme activity

For the determination of specific enzyme activity, S. cerevisiae and E. coli cells were grown to early stationary phase and overnight, respectively. After growth cells were harvested by centrifugation at 5,000×g for 5 min and then washed once with distilled water and centrifuged again at 5,000×g for 5 min. Fresh cells were weighted and suspended in Y-per yeast or B-per bacteria extraction protein reagent (Pierce, Rockford, IL, USA) for the final concentration of 0.5 mg/mL followed by incubation on a turning table at room temperature for 50 min. Cell debris was spun down for 5 min at 16,100 ×g (Hermle Labortechnik Z160M table centrifuge, Wehingen, Germany). The supernatant was collected and frozen at −20 °C until further analyzed. Protein concentration was determined with Coomassie Protein Assay Reagent (Pierce, Rockford, IL, USA). Bovine serum albumin (BSA) was used to determine the standard curve. YPR1 activity was assayed by following the oxidation of NADPH at 340 nm using an Ultrospec 2100pro spectrophotometer (Amersham Bioscences, Sweden). Data were collected using the software program SWIFTII (Amersham Bioscences, Sweden). Samples were diluted so that the absorbance decreased linearly during 5 min. One unit of activity corresponds to 1 μmol NADPH consumed per minute at 30ºC. The assay contained potassium phosphate buffer (100 mM, pH 7), NADPH (200 μM), substrate 1 (22 mM) and cell extract. PGI and G6PDH activities were determined as described before (Bergmeyer 1974).

Bioreduction of 1

Diketone 1 was synthesised as described elsewhere (Widegren et al. 2006). Cell dry weight (dw) was determined in duplicate by filtering a known volume of cell suspension through nitrocellulose filters (Pall, MI, USA) with 0.45 μm pore size for yeast and 0.22 μm for bacteria. Filters were washed with distilled water, dried in a microwave oven at 350 W for 3 min, cooled in a dessicator and weighed. Bioreduction of 1 (0–60 g/L) was performed with 5 g dw/L of freshly grown cells in 100 mM potassium phosphate buffers at pH 5.5 and 30ºC for S. cerevisiae and pH 7.0 and 37ºC for E. coli strains, respectively. Glucose (200 or 20 g/L) was added as co-substrate at the start of the reaction. Concentration of 1 and glucose were determined by high-performance liquid chromatography (HPLC; Waters, Miford, MA, USA) with an Aminex HPX-87 hydrogen ion exchange column (Bio-Rad, Hercules, CA, USA) using 5 mM H2SO4 as mobile phase and refractive index detection (RID-6A, Shimadzu, Kyoto, Japan). The temperature and the flow rate were 30 °C and 0.6 mL/min, respectively. Enantiomeric excess (ee) and diastereomeric excess (de) of product (−)-2 were determined by gas chromatography (GC) analysis as previously described (Johanson et al. 2008).

Cell viability

Cell viability was determined every 24 h during bioreduction. Samples were diluted in sterile water and plated on YNB-media plates for S. cerevisiae and LB-media plates with ampicillin for E. coli strains. Colony forming units (CFU/mL) were counted after incubation for 3–4 days at 30 °C for S. cerevisiae and 1 day at 37 °C for E. coli.

Results

Five different strains of S. cerevisae and E. coli each were constructed with or without altered glucose metabolism. They were systematically investigated for its ability to produce (−)-2 through asymmetric NADPH-dependent carbonyl reduction of 1 (Table 1). All strains except the control strains TMB4306 (CTRL) and TMB2005 (CTRL) over-expressed YPR1, encoding the yeast aldo-keto reductase YPR1. The metabolic carbon flux was modified in strains of S. cerevisiae and E. coli, by over-expression of ZWF in TMB4311 (YPR1, ZWF1) and TMB2007 (YPR1, ZWF), deletion of PGI in TMB4312 (YPR1, ∆PGI) and TMB2008 (YPR1, ∆PGI) and the combination of PGI deletion and ZWF over-expression in TMB4313 (YPR1, ZWF1, ∆PGI) and TMB2009 (YPR1, ZWF, ∆PGI) (Table 1).

Enzyme activity

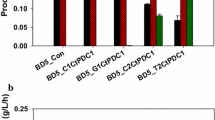

To confirm and compare the altered enzyme levels in the genetically engineered strains, enzyme activities of YPR1, G6PDH and PGI were determined in cell extracts (Fig. 3).

S. cerevisiae and E. coli strains expressing YPR1 had significantly higher reductase activity than their respective control strains (Fig. 3a); ten- to 20-fold for S. cerevisiae and 40 to 90-fold for E. coli. The reductase activity in cell extract of strains over-expressing YPR1 was about two times higher in E. coli than in S. cerevisiae, except for strains in which PGI was also deleted, where the activities were the same (Fig. 3a).

The control G6PDH activity was significantly higher (about 12-fold) in S. cerevisiae than in E. coli (Fig. 3b). S. cerevisiae strain TMB4311 (YPR1, ZWF1) which combined over-expression of YPR1 and ZWF1 had approximately four times higher G6PDH activity than the corresponding E. coli strain TMB2007 (YPR1, ZWF). S. cerevisiae strain TMB4313 (YPR1, ZWF1, ∆PGI1) had three times lower G6PDH activity than S. cerevisiae strain TMB4311 (YPR1, ZWF1), probably caused by fewer Yplac128-ZWF1 constructs inserted in the chromosome.

The PGI activity was generally two to three times higher in E. coli than in S. cerevisiae for strains with the intact gene (Fig. 3c). Also, for E. coli strains with deleted PGI, the activity was higher than for the corresponding S. cerevisiae strains. While S. cerevisiae strains with PGI1 deletion had no measurable activity, the corresponding E. coli strains displayed background activity (1–2 U/mg), converting fructose 6-P into glucose 6-P under the chosen assay conditions. Thus, the carbon flux in PGI-deleted E. coli does not exclusively enter through the PPP; deletion of PGI still significantly decreased the carbon flux through EMP.

Optimal reaction conditions

For S. cerevisiae the optimal substrate concentration for high reaction rate had previously been determined to 17 g/L 1 (Johanson et al. 2008). The glucose concentration was 200 g/L to assure its availability throughout the bioconversion for yeast strains with 100% PGI activity.

To ensure comparison under optimal conditions for both microorganisms the optimal substrate (diketone) and co-substrate (glucose) concentrations for E. coli were determined. E. coli strain TMB2006 (YPR1) over-expressing YPR1 was used for the bioreduction of 1 at different substrate (0–60 g/L) and co-substrate (0–80 g/L) concentrations with constant cell density (5 gdw/L) (Fig. 4a, b). The amount of converted substrate was about the same (∼10 g/L) at initial substrate concentrations between 10 and 60 g/L (Fig. 4a). Thus, full conversion of 1 was only achieved at low concentrations (<10 g/L). Also, the consumption of the co-substrate glucose was approximately 10 g/L regardless of initial substrate and co-substrate concentration (Fig. 4a, b). This suggested an inactivation of E. coli, which was independent of substrate and co-substrate concentration and which occurred when ∼10 g/L 1 or ∼10 g/L glucose had been converted. The E. coli viability remained stable up to an initial substrate concentration of 40 g/L and decreased only slightly at 60 g/L (Fig. 4a), which further supported the fact that inactivation of E. coli was independent of the substrate concentration. In contrast, glucose was toxic for E. coli at high concentrations and resulted in total loss of viability at 80 g/L (Fig. 4b).

Optimization of a substrate and b glucose concentration for E. coli catalysed reactions. The E. coli strain TMB2006 (YPR1) was used to determine optimal substrate and glucose concentration. Bars indicate conversion of BCO2,6D (a) or glucose (b). Viability is represented by dotted lines with diamonds

For E. coli, 17 g/L 1 and 20 g/L glucose were well below the concentration where viability and substrate conversion are affected. Hence, the substrate concentration was set to 17 g/L 1 for both microorganisms and the glucose concentration was set to 200 and 20 g/L for S. cerevisiae and E. coli, respectively.

Production of (−)-2

To investigate the differences of S. cerevisiae and E. coli, the bioreduction of 1 was performed at the above determined concentrations and followed over time (Fig. 5a–c).

Bioreduction of dione 1 catalysed by genetically engineered aS. cerevisiae and bE. coli strains. CTRL (open diamond), YPR1 (open square), YPR1, G6PDH (open triangle), YPR1, ΔPGI (multiplication symbol), YPR1, ΔPGI, G6PDH (open circle). Consumption of 1 by the best strains from S. cerevisiae (YPR1, ΔPGI, G6PDH (open circle)) and E. coli (YPR1 (open square)) are displayed together in (c). Black and grey lines represent initial conversion rate with R 2 = 0.99

For S. cerevisiae, over-expression of YPR1 increased the de from 85.1% to 95.0–98.3% (Table 3, Fig. 5a). Over-expression of YPR1 in S. cerevisiae with natural PGI and G6PDH activities led to a 2.6-fold increase in reaction rate. The reaction rate was further increased by over-expressing ZWF1 (3.1-fold) or deleting PGI1 (4.5-fold). However, the highest reaction rate was achieved when ZWF1 over-expression was combined with PGI1 deletion in strain TMB4313 (YPR1, ΔPGI, ZWF1), which also over-expressed YPR1 (8.1-fold increase). In this strain the reaction reached almost full conversion of 17 g/L 1 within 72 h (95%) (Fig. 5a).

For E. coli, the effect of over-expressing YPR1 was more pronounced than for S. cerevisiae (Table 3, Fig. 5b). The low de obtained with the control strain, 32.7%, increased to 96.9% and the initial reduction rate increased 2.5-fold when YPR1 was over-expressed in E. coli with unaltered PGI and G6PDH activities. In fact, the manipulation of the bacterial PPP did not improve the reaction, and although the initial reaction rates did not differ very much, the conversion was significantly higher for E. coli strain TMB2006 (YPR1), which only over-expresses YPR1 (Fig. 5a, b and Table 3).

Except for the control strains, the volumetric productivity and co-substrate yield were generally higher in E. coli than in S. cerevisae (Table 3, Fig. 5c). The best E. coli strain, TMB2006 (YPR1), had higher initial reduction rate, volumetric productivity and co-substrate yield than the best S. cerevisiae strain, TMB4313 (YPR1, ΔPGI1, ZWF1) (Table 3, Fig. 5c). In contrast, almost full conversion of 17 g/L 1, 95%, was reached with the S. cerevisiae strain while the E. coli strain only reached 83%.

Co-substrate consumption

For S. cerevisiae, the initial glucose consumption rate was about five times lower for strains with PGI1 deletion (Table 3). Furthermore, strains with non-altered PGI activity consumed 119–140 g of glucose while PGI deleted strains only consumed 15–26 g (Fig. 6). Over-expression of ZWF1 reduced the initial glucose consumption rate but to a lesser extent than for the PGI deleted strains. When PGI1 deletion was combined with ZWF1 over-expression, the initial glucose consumption rate was only marginally affected, 0.68 g/L/h, compared to the strain where in which only PGI was deleted, 0.75 g/L/h. The reduction of the total amount of glucose consumed with the yeast strain combining over-expressed YPR1 with over-expressed ZWF1 and deleted PGI1 resulted in a 23-fold increased co-substrate yield (3).

Glucose consumption during bioreduction of dione 1 catalysed by genetically engineered aS. cerevisiae and bE. coli strains. CTRL (open diamond), YPR1 (open square), YPR1, G6PDH (open triangle), YPR1, ΔPGI (multiplication symbol), YPR1, ΔPGI, G6PDH (open circle). The initial concentration was 200 g/L and 20 g/L for S. cerevisiae and E. coli, respectively

Glucose consumption in E. coli was about the same in all strains (Table 3, Fig. 6b). Furthermore, the glucose consumption in E. coli stopped after 12 h (Fig. 6b), while it continued throughout the reaction for all S. cerevisiae strains (Fig. 6a). The highest co-substrate yield was obtained with the E. coli strain only over-expressing YPR1 (ninefold increase).

By-product formation

The by-products found by the two microorganisms differed somewhat, which illustrated the difference in how glucose was metabolised. The main by-products from the breakdown of glucose during reduction of 1 with resting S. cerevisiae cells were in the order; ethanol > glycerol > acetate (data not shown) which confirms with previous reports (Katz et al. 2002). The effect of over-expressing ZWF1 on by-product formation was marginal, while the deletion of PGI significantly decreased the amount of by-products, due to an overall decrease in glucose consumption (Fig. 6a and Table 3).

The E. coli strains produced acetate and no other by-product was detected in the HPLC analysis. Over-expression of ZWF1 did not significantly influence the acetate production (Table 3). For strains with deleted PGI, the acetate formation within 48 h of bioreduction was significantly lower than for other strains (Table 3).

Viability of biocatalysts during bioreduction

Cell viability was followed during bioreduction (Fig. 7a, b). The same cell density was used for both microorganisms (5 gdw/L) and due to difference in cell size the initial viable count was higher for E. coli than S. cerevisiae. Cell viability decreased faster for E. coli strains than for S. cerevisiae strains, as shown for the E. coli control strain which had a fivefold higher viability decrease rate (Log CFU/mL/h) than the S. cerevisiae control strain (Fig. 7a, b). After 48 h of bioreduction, the viable count for S. cerevisiae was about 6.5 Log (CFU/mL), while it was only about 5 Log (CFU/mL) for E. coli.

Discussion

This is to the best of our knowledge the first study that systematically compares the performance of engineered S. cerevisiae and engineered E. coli for stereoselective whole cell bioreductions under identical experimental conditions. The two microorganisms were significantly different as biocatalysts with regards to initial reaction rate, volumetric productivity, degree of conversion, robustness, NADPH regeneration capacity, and co-substrate yield. However, the keto alcohol (−)-2 was produced with equally high optical purity (97–98%), which illustrated that the activity of potential competing reductases with other enantio- and diastereomeric preferences than the over-expressed YPR1 could be disregarded in both S. cerevisiae and E. coli.

The initial reduction rate, volumetric productivity and co-substrate yield were slightly higher for E. coli than for S. cerevisiae. However, the robustness of baker’s yeast allowed glucose consumption and NADPH regeneration to proceed for a longer period of time, which resulted in higher degree of conversion of diketone 1. Furthermore, this implies that it may be possible to recycle the S. cerevisiae cells for sequential bioreduction of 1. The toughness of yeast has previously been demonstrated by its capability to maintain catalytic reduction activity in organic solvents (Nikolova and Ward 1992; Salter and Kell 1995) and in continuously operated processes (Chin-Joe et al. 2002; Milagre et al. 2005).

The impact of high NADPH regeneration rate for efficient bioreduction was demonstrated by comparing five strains of each microorganism with different NADPH-regenerating capacity. In S. cerevisiae, the initial reaction rate and productivity of the keto alcohol was significantly improved by increasing the NADPH regeneration rate through over-expression of ZWF1, deletion of PGI1 or the combination of both alterations. This agrees with previous results, which demonstrated positive influence of both higher G6PDH activity (Kwon et al. 2006) and reduced PGI activity (Katz et al. 2003) on NADPH-dependent bioreductions catalysed by recombinant S. cerevisiae over-expressing specific reductases. Furthermore, the combination of over-expressing ZWF1 and deleting PGI1 was cumulative with respect to the NADPH regeneration rate and formation rate of keto alcohol (−)-2. NADPH may still limit the reaction and its regeneration rate could be further increased by also over-expressing GND1 encoding 6-phosphogluconate dehydrogenase (6-PGDH), which is the second NADPH-regenerating step in the oxidative PPP (Fig. 2).

In addition to increased NADPH availability, the deletion of PGI1 decreased glucose consumption for S. cerevisiae to the same level as for E. coli. The rate ratio, i.e. the ratio of the initial glucose consumption rate and the initial reduction rate, decreased from 43.9 to 1.0 g glucose/g 1, which is close to the previously calculated theoretical rate ratio 0.66 g glucose/g 1 (Katz et al. 2003). Hence, nearly all NADPH that were regenerated in the PPP during glucose consumption was used up in the reduction of 1.

Increased G6PDH activity and reduced PGI activity in E. coli did not improve bioreduction of 1, as observed for S. cerevisiae. This indicates that the natural availability of NADPH may have been sufficient to sustain the over-expressed YPR1. When a similar system was investigated the results were also interpreted in terms of sufficient availability of NADPH in E. coli (Walton and Stewart 2004). However, bioreduction of 1 was actually worsened when genetic modifications in the PP pathway were introduced. This suggests that NADPH availability did not increase but rather decreased.

In E. coli NADPH is supplied mainly by a membrane-bound transhydrogenase (Kromer et al. 2006). Therefore, the genetic manipulations to increase NADPH availability in the PPP may have increased compensatory activity of enzyme(s) regulating NADP(H) pools, such as UdhA, a transhydrogenase that converts NADPH to NADH (Hua et al. 2003; Sauer et al. 2004). Another compensatory response to increased NADPH regeneration through PPP could be redirecting the flux from the NADPH producing isocitrate dehydrogenase to the glyoxylate shunt, as previously suggested (Hua et al. 2003). Furthermore, downregulation of the NADP+-linked malic enzyme, which produces acetyl-CoA via pyruvate (Murai et al. 1971), may contribute to decreased NADPH formation. The latter is supported by significantly reduced acetate production by PGI deleted E. coli strains (Table 3) and agrees with earlier observations where the carbon flux through malic enzyme was negligible in PGI deleted E. coli (Hua et al. 2003).

In conclusion, the preferred microorganism for stereoselective NADPH-dependent bioreduction depends on the particular application. For the YPR1-catalysed production of (−)-2, the optical purity was equally high with S. cerevisiae and E. coli, while the initial reaction rate, volumetric productivity and co-substrate yield were slightly higher for E. coli than S. cerevisiae. Furthermore, genetic modification of the carbon flux was needed for efficient NADPH regeneration in S. cerevisiae, while the regeneration was already high in E. coli with natural glucose metabolism. However, the yeast’s greater robustness led to a higher degree of conversion for S. cerevisiae than E. coli. The greater robustness also makes S. cerevisiae more applicable to repeated batch and continuous process configurations.

References

Baba T, Ara T, Hasegawa M, Takai Y, Okumura Y, Baba M, Datsenko KA, Tomita M, Wanner BL, Mori H (2006) Construction of Escherichia coli K-12 in-frame, single-gene knockout mutants: the Keio collection. Mol Syst Biol 2:200.0008

Bergmeyer HU (1974) Methods of enzymatic analysis. Verlag Chemie, Academic, London

Boles E, Zimmermann FK (1994) Open reading frames in the antisense strands of genes coding for glycolytic enzymes in Saccharomyces cerevisiae. Mol Gen Genet 243(4):363–368

Bruinenberg PM (1986) The NADP(H) redox couple in yeast metabolism. Antonie Van Leeuwenhoek 52(5):411–429

Burton SG (2001) Development of bioreactors for application of biocatalysts in biotransformations and bioremediation. Pure Appl Chem 73(1):77–83

Chartrain M, Greasham R, Moore J, Reider P, Robinson D, Buckland B (2001) Asymmetric bioreductions: application to the synthesis of pharmaceuticals. J Mol Catal B Enzym 11(4–6):503–512

Chin-Joe I, Haberland J, Straathof AJJ, Jongejan JA, Liese A, Heijnen JJ (2002) Reduction of ethyl 3-oxobutanoate using non-growing baker's yeast in a continuously operated reactor with cell retention. Enzyme Microb Technol 31(5):665–672

Csonka LN, Fraenkel DG (1977) Pathways of NADPH formation in Escherichia coli. J Biol Chem 252(10):3382–3391

D'Arrigo P, Pedrocchi-Fantoni G, Servi S (1997) Old and new synthetic capacities of baker's yeast. Adv Appl Microbiol 44:81–23

Ema T, Yagasaki H, Okita N, Takeda M, Sakai T (2006) Asymmetric reduction of ketones using recombinant E. coli cells that produce a versatile carbonyl reductase with high enantioselectivity and broad substrate specificity. Tetrahedron 62:6143–6149

Gietz RD, Schiestl RH, Willems AR, Woods RA (1995) Studies on the transformation of intact yeast cells by the LiAc/SS-DNA/PEG procedure. Yeast 11(4):355–360

Grabowska D, Chelstowska A (2003) The ALD6 gene product is indispensable for providing NADPH in yeast cells lacking glucose-6-phosphate dehydrogenase activity. J Biol Chem 278(16):13984–13988

Guldener U, Heck S, Fielder T, Beinhauer J, Hegemann JH (1996) A new efficient gene disruption cassette for repeated use in budding yeast. Nucleic Acids Res 24(13):2519–2524

Hilterhaus L, Liese A (2007) Building blocks. Adv Biochem Eng Biotechnol 105:133–173

Hua Q, Yang C, Baba T, Mori H, Shimizu K (2003) Responses of the central metabolism in Escherichia coli to phosphoglucose isomerase and glucose-6-phosphate dehydrogenase knockouts. J Bacteriol 185(24):7053–7067

Ishige T, Honda K, Shimizu S (2005) Whole organism biocatalysis. Curr Opin Chem Biol 9(2):174–180

Johanson T, Katz M, Gorwa-Grauslund MF (2005) Strain engineering for stereoselective bioreduction of dicarbonyl compounds by yeast reductases. FEMS Yeast Res 5(6–7):513–525

Johanson T, Carlquist M, Olsson C, Rudolf A, Frejd T, Gorwa-Grauslund MF (2008) Reaction and strain engineering for improved stereo-selective whole-cell reduction of a bicyclic diketone. Appl Microbiol Biotechnol 77(5):1111–1118

Kaluzna IA, Matsuda T, Sewell AK, Stewart JD (2004) Systematic investigation of Saccharomyces cerevisiae enzymes catalyzing carbonyl reductions. J Am Chem Soc 126(40):12827–12832

Karhumaa K, Hahn-Hagerdal B, Gorwa-Grauslund MF (2005) Investigation of limiting metabolic steps in the utilization of xylose by recombinant Saccharomyces cerevisiae using metabolic engineering. Yeast 22(5):359–368

Kataoka M, Sri Rohani LP, Wada M, Kita K, Yanase H, Urabe I, Shimizu S (1998) Escherichia coli transformant expressing the glucose dehydrogenase gene from Bacillus megaterium as a cofactor regenerator in a chiral alcohol production system. Biosci Biotechnol Biochem 62(1):167–169

Katz M, Sarvary I, Frejd T, Hahn-Hagerdal B, Gorwa-Grauslund MF (2002) An improved stereoselective reduction of a bicyclic diketone by Saccharomyces cerevisiae combining process optimization and strain engineering. Appl Microbiol Biotechnol 59(6):641–648

Katz M, Frejd T, Hahn-Hägerdal B, Gorwa-Grauslund MF (2003) Efficient anaerobic whole cell stereoselective bioreduction with recombinant Saccharomyces cerevisiae. Biotechnol Bioeng 84(5):573–582

Kromer JO, Wittmann C, Schroder H, Heinzle E (2006) Metabolic pathway analysis for rational design of L-methionine production by Escherichia coli and Corynebacterium glutamicum. Metab Eng 8(4):353–369

Kwon DH, Kim MD, Lee TH, Oh YJ, Ryu YW, Seo JH (2006) Elevation of glucose 6-phosphate dehydrogenase activity increases xylitol production in recombinant Saccharomyces cerevisiae. J Mol Catal B Enzym 43(1–4):86–89

Liese A, Seelbach K, Wandrey C. 2006. Industrial Biotransformations: Wiley-VCH

Milagre HMS, Milagre CDF, Moran PJS, Santana MHA, Rodrigues JAR (2005) Reduction of ethyl benzoylformate mediated by Saccharomyces cerevisiae entrapped in alginate fibers with double gel layers in a continuously operated reactor. Enzyme Microb Technol 37(1):121–125

Minard KI, McAlister-Henn L (2001) Antioxidant function of cytosolic sources of NADPH in yeast. Free Radic Biol Med 31(6):832–843

Mumberg D, Muller R, Funk M (1995) Yeast vectors for the controlled expression of heterologous proteins in different genetic backgrounds. Gene 156(1):119–122

Murai T, Tokushige M, Nagai J, Katsuki H (1971) Physiological functions of NAD- and NADP-linked malic enzymes in Escherichia coli. Biochem Biophys Res Commun 43(4):875–881

Nikolova P, Ward OP (1992) Whole cell yeast biotransformations in 2-phase systems—effect of solvent on product formation and cell structure. J Ind Microbiol 10(3–4):169–177

Patel RN (2006) Biocatalysis: synthesis of chiral intermediates for drugs. Curr Opin Drug Discov Devel 9(6):741–764

Rodriguez S, Schroeder KT, Kayser MM, Stewart JD (2000) Asymmetric synthesis of beta-hydroxy esters and alpha-alkyl-beta-hydroxy esters by recombinant Escherichia coli expressing enzymes from baker's yeast. J Org Chem 65(8):2586–2587

Salter GJ, Kell DB (1995) Solvent selection for whole cell biotransformations in organic media. Crit Rev Biotechnol 15(2):139–177

Sambrook J, Fritch E, Maniatis T (1989) Molecular cloning: a laboratory manual. Cold Spring harbor Laboratory, Cold Spring Harbor

Sauer U, Canonaco F, Heri S, Perrenoud A, Fischer E (2004) The soluble and membrane-bound transhydrogenases UdhA and PntAB have divergent functions in NADPH metabolism of Escherichia coli. J Biol Chem 279(8):6613–6619

Schmid A, Dordick JS, Kiener A, Wubbolts M, Witholt B (2001) Industrial biocatalysis today and tomorrow. Nature 409:258–268

Stewart JD (2000) Organic transformations catalyzed by engineered yeast cells and related systems. Curr Opin Biotechnol 11(4):363–368

Stryer L (2000) Biochemistry. W. H. Freeman, New York

Terpe K (2006) Overview of bacterial expression systems for heterologous protein production: from molecular and biochemical fundamentals to commercial systems. Appl Microbiol Biotechnol 72(2):211–222

Walton AZ, Stewart JD (2004) Understanding and improving NADPH-dependent reactions by nongrowing Escherichia coli cells. Biotechnol Prog 20(2):403–411

Widegren M, Dietza M, Friberg A, Frejd T, Hahn-Hägerdal B, Gorwa-Grauslund M, Katz M (2006) The synthesis of bicyclo[2.2.2]octan-2, 6-dione revisited. Synthesis 20:3527–3530

Woodley JM (2008) New opportunities for biocatalysis: making pharmaceutical processes greener. Trends Biotechnol 26(6):321–327

Acknowledgements

This work was financed by the Research School in Pharmaceutical Sciences (FLÄK) and the Royal Physiographic Society in Lund and the Swedish research council (VR). We thank Professor Bärbel Hahn-Hägerdal for valuable discussions and Mathieu Heulot for his help with the E. coli-catalysed reductions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Nádia Skorupa Parachin and Magnus Carlquist have contributed equally to the paper.

Rights and permissions

About this article

Cite this article

Skorupa Parachin, N., Carlquist, M. & Gorwa-Grauslund, M.F. Comparison of engineered Saccharomyces cerevisiae and engineered Escherichia coli for the production of an optically pure keto alcohol. Appl Microbiol Biotechnol 84, 487–497 (2009). https://doi.org/10.1007/s00253-009-1964-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-009-1964-1