Abstract

Verticillium lecanii is an entomopathogen with high potential in biological control of pests. We developed a solid-state fermentation with sugarcane bagasse as carrier absorbing liquid medium to propagate V. lecanii spores. Using statistical experimental design, we optimized the medium composition for spore production. We first used one-factor-at-a-time design to identify corn flour and yeast extract as the best carbon and nitrogen sources for the spore production of V. lecanii. Then, we used two-level fractional factorial design to confirm corn flour, yeast extract, and KH2PO4 as important factors significantly affecting V. lecanii spore production. Finally, we optimized these selected variables using a central composite design and response surface method. The optimal medium composition was (grams per liter): corn flour 35.79, yeast 8.69, KH2PO4 1.63, K2HPO4 0.325, and MgSO4 0.325. Under optimal conditions, spore production reached 1.1 × 1010 spores/g dried carrier, much higher than that on wheat bran (1.7 × 109 spores/g initial dry matter).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The excessive use of chemical pesticides causes worldwide environmental contamination and pesticide residual problems in food and feed. Replacing chemical pesticides with biopesticides has received increasing interests for plant pest management. Verticillium lecanii is an entomopathogenic fungus with a broad range of hosts including insects: Coleoptera (Barson 1976), Orthopteta (Johnson et al. 1988; Khachatourians 1992), Homoptera (Hall and Burges 1979; Milner and Lutton 1986), and Lepidoptera (Gopalakrishnan 1989). It also parasites some plant disease pathogens such as cucumber powdery mildew (Verhaar et al. 1996) and chrysanthemum rust fungi (Whipps 1993).

For the biological control by this biopesticide, large numbers of spores are needed. Solid-state fermentation (SSF) and submerged fermentation (SmF) are popular systems for fungal sporulation. SmF is usually faster and easier to control system parameters (Tunga et al. 1998). However, volumetric spore productivity by SmF is relatively low compared with SSF. SSF can use relatively cheap agricultural byproducts such as wheat bran, rice bran, and other hulls of cereals or legumes (Feng et al. 2000; Zhu et al. 1996). However, natural substrates in SSF have some disadvantages such as excessive thickness of the substrate layer, low porosity, or inadequate internal structures that disturb the aeration, heat removal, and inefficient nutrient uptake (Hölker and Lenz 2005; Marin-Cervantes et al. 2008). It is impossible to separate residual solid substrate from biomass in SSF systems, and direct estimation of growth is not attainable. Recently, SSF using inert carriers such as ion exchange resins and polyurethane foams was developed. Inert carriers present high porosity, low density, relatively high water absorption, and a satisfactory environment for fungal growth, where the nutrients from a liquid medium are absorbed (Auria et al. 1995). The use of inert carrier allows direct biomass determination, renewable use, cleaner extractions, good aeration, and heat removal (Zhu et al. 1994; Marin-Cervantes et al. 2008). Although sugarcane bagasse is not a strict inert carrier, for most fungi, it is a carrier with high porosity, low density, and relatively high water absorption. Therefore, we first explored the use of sugarcane bagasse as carrier that absorbed liquid medium in solid-state fermentation for spore production of V. lecanii. Liquid medium optimization was done using statistical experimental design.

Generally, medium is optimized with the one-variable-at-a-time method, in which all variables but one are held at a constant level, and then the optimum level of the variables to be tested is determined. This method is simple, but it is laborious and time consuming if there are lots of factors to be determined. Therefore, we used two steps statistical experiments to optimize the medium of V. lecanii for spore production with sugarcane bagasse as carrier in SSF. The first step is to screen important variables, followed by estimation of optimal levels of these variables. The fractional factorial design (De Meo et al. 1985; Christen and Raimbault 1991) is well established and a widely used statistical technique for screening of different variables. Following the first step screening, the second step is optimizing all the significant factors collectively by central composite design (CCD) (Box and Wilson 1951) using response surface methodology (RSM). Basically, this optimization process involves three major steps: performing the statistically designed experiments, estimating the coefficients in a mathematical model, and predicting the response and checking the adequacy of the model. Several researchers in biotechnology have applied these techniques for optimization of different parameters (Francis et al. 2003; Imandi et al. 2007; Singh and Satyanarayana 2006). Here, we report the application of fractional factorial design and composite design to optimize spore production of V. lecanii with sugarcane bagasse as carrier in solid-state fermentation.

Materials and methods

Materials

Corn flour and soybean powder were purchased from local Wu-Mart supermarket (self-brand, Hangzhou, Zhejiang, China). Yeast extract and peptone were purchased from Hangzhou Microbiology Institute (Hangzhou, Zhejiang, China). Glucose was from Sigma-Aldrich China (Shanghai, China).

Experiments

Microorganism and inoculum preparation

V. lecanii (CBS 102071) was purchased from CBS (Utrecht, Netherlands). A spore suspension was obtained as follows: V. lecanii was grown on potato dextrose agar (PDA) in Petri dishes at 25 °C for 7 days. The spores were harvested from the surface by pouring sterile 0.1% Tween-80 to wash off the spores. The spore concentration was measured by counting with a hemacytometer under microscope. The spore suspension was used to inoculate the subsequent fermentation immediately. V. lecanii was routinely maintained on PDA slants at 4 °C by regular sub-cultivation (no longer than 3 months).

Solid-state fermentation

Wheat bran was purchased from local market and used as substrate for comparison. Wheat bran (5 g) was mixed with 3.5 mL tap water in a 250-mL Erlenmeyer flask and autoclaved at 121 °C for 20 min. After cooling down to room temperature, the bran was inoculated with 0.5 mL spore suspension (106 spores mL−1). Fermentation was carried out at 25 °C for 6 days under relatively humidity of 97%.

Sugarcane was purchased from local market, and juice was pressed off by a juice extractor, and sugarcane bagasse was washed to ensure free of sugar, then dried, and cut into 4 mm pieces. Sugarcane bagasse (2 g) was mixed with 7 mL liquid medium in a 250-mL Erlenmeyer flask and autoclaved at 121 °C for 20 min. Medium pH was adjusted to 6.0. After cooling down to room temperature, medium was inoculated with 0.5 mL spore suspension (106 spores mL−1). Fermentation was done at 25 °C for 8 days under relatively humidity of 97%.

Selection of best carbon and nitrogen sources for liquid medium

The medium designed by Blackburn and Hayes (1966) was used as basal medium with some minor modifications. The basal medium contained (grams per liter of distilled water): maltose, 10; NaNO3, 2.0; MgSO4, 0.5; KH2PO4, 0.5; and K2HPO4, 0.65. Various simple and complex carbon (corn flour, glucose, soluble starch) and nitrogen sources (peptone, yeast extract, soybean powder) were used individually as carbon and nitrogen source while other components were kept constant. The spore production was determined after 72 h of fermentation at 25 °C under relative humidity of 97%.

Experimental design and data analysis

Two-level fractional factorial design

The important factors were screened by the fractional factorial design (De Meo et al. 1985; Christen and Raimbault 1991; Zhu et al. 1996). Therefore, we used two-level fractional factorial design to identify important variables, which allows for screening of five variables with only eight experiments. We used FF0508 as abbreviation of this two-level fractional factorial design, where 5 was the number of variables, 8 was the quantity of experimental numbers. Each variable was represented at two levels, high and low denoted by (1) and (−1); details are given in Tables 1 and 2. The Statistics Package for Social Science (SPSS) software 13.0 (SPSS, Chicago, IL, USA) was used for analyzing the experimental data.

Central composite design

The CCD is one of RSM. After identifying components significantly affecting the spore production, a central composite design was adopted to optimize concentrations of the important factors (corn flour, yeast extract, and KH2PO4), which were selected from the two-level fractional factorial design (FF0508). The full central composite design, based on three basic principles of an ideal experimental design, primarily consists of a complete 2n factorial design, where n is the number of test variables; center points (n 0 ≥ 1) and two axial points on the axis of each design variable at a distance of r from the design center. Hence, the total number of design points is \(N = 2^n + 2n + n_0 \). For statistical calculations the variables, X i are coded as x i according to Eq. 1:

Where x i is dimensionless value of an independent variable, X i is the real value of an independent variable, X 0i is the real value of the independent variable at the center point, and ΔX i is the step change. All independent variables are coded to five levels (Table 3).

The second-degree polynomials (Eq. 2) are fitted with the SPSS 13.0 (SPSS, Chicago, IL, USA) to estimate the response of the dependent variable:

Where y is the measured response; b 0 is the intercept term; b i, b ij, and b ii are the measures of the effects of variables x i, x ixj, and \(x_i^2 \), respectively. The variable x ixj represents the first-order interaction between xi and x j (i < j).

Assessment of spore yield

The final cultural samples were ground in a mortar and then mixed with 50 mL distilled water containing 0.1% (v/v) Tween-80 in a laboratory blender for 2 min to extract the spores from the substrate thoroughly. The spore suspension was diluted appropriately to a proper density that could be identified by microscopic counting with a hemocytometer. Spore yield was expressed as spores per gram initial dry matter (IDM) with wheat bran and spores per g dried carrier (DC) with sugarcane bagasse. The results were the means of triplicate determination of three independent samples.

Results

Selection of best carbon and nitrogen sources

The effect of various carbon and nitrogen sources on V. lecanii spore production with sugarcane bagasse was studied based on the basic medium with one-factor design. For carbon selection, NaNO3 was used as the sole nitrogen source and inorganic salts were kept constant; 20 g/L glucose, corn flour, and soluble starch was used as carbon source, individually. Similarly, for nitrogen selection, maltose was used as the sole carbon source and inorganic salts kept constant; 10 g/L peptone, yeast extract, and soybean powder was used as nitrogen source, individually. Results are given in Table 4.

Among the various carbon sources used, V. lecanii (CBS 102071) had almost the same spore production: corn flour (6.9 × 109 spores/g DC), soluble starch (6.7 × 109 spores/g DC), and glucose (6.3 × 109 spores/g DC). Among nitrogen sources, yeast extract (6.8 × 109 spores/g DC), soybean powder (6.7 × 109 spores/g DC), and peptone (6.4 × 109/g DC) had similar spore production.

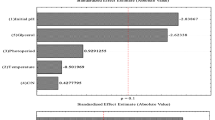

Identification of important medium constituents using fractional factorial design

Table 2 shows the results from the FF0508 design and the corresponding fractional factorial experimental design matrix for screening of important variables. The resulting effects (E Xi) of the variables on the responses, the associated F values, and significant levels are shown in Table 5. A p value less than 0.10 for the three variables (corn flour (X 1), yeast extract (X 2), and KH2PO4 (X 3)) indicated that they were significant. The p value more than 0.10 for the two variables (K2HPO4 (X 4) and MgSO4 (X 5)) indicated that they were less significant. The increase in the concentration of corn flour, MgSO4, and K2HPO4 had positive effects on spore production (Table 5). An increase in the concentration of yeast extract and KH2PO4 had negative effects on spore production. With the help of p values, corn flour, yeast extract, and KH2PO4 were selected for further optimization based on their most significant effects on spore production.

The fractional factorial design was a powerful tool to rapidly identify which medium constituents affect most significantly the spore production of V. lecanii. However, the optimal concentrations of medium components could not be determined. Therefore, CCD and RSM analysis were used to further optimize the concentrations of medium components.

Optimization of the selected medium constituents using CCD

CCD is a very useful tool to determine the optimal level of medium constituents and their interaction. Based on the fractional factorial design, where corn flour, yeast extract, and KH2PO4 were identified for their significant effects on spore production, a CCD was used for further optimization. The concentrations of those major nutrients tested are given in Table 3. Other nutrient concentrations were set at their center point tested in the fractional factorial design. The CCD design matrix and the observed production are given in Table 6.

The RSM analysis for the optimization of medium constituents by SPSS 13.0 showed that spore production (y) was a function of the concentration of corn flour (x 1), yeast extract (x 2), and KH2PO4 (x 3). The following second-order polynomial equation was found to represent the spore production adequately:

Where y is the response value, that is, the spore production, and x 1, x 2, and x 3 are the coded levels of corn flour, yeast extract, and KH2PO4, respectively.

The regression equation was evaluated by the coefficient of correlation (R) and the determination coefficient (R 2). Here, the value of R (0.959) indicates a high agreement between the experimental and predicted values. The value of determination R 2 (0.92) indicates that the response model can explain 92% of the total variations. The value of adjusted determination coefficient (R 2 = 0.848) was also high enough to indicate the significance of the model.

The corresponding analysis of variance (ANOVA) is given in Table 7. The F value is a measure of the variation of the data about the mean. Generally, if the calculated F value is several times greater than the tabulated F value, the model is a good prediction of the experimental results. Here, ANOVA analysis of the regression model indicates that the model is highly significant. This is evidently seen from the calculated F value (=12.810) and a very low probability value (p > F = 0.000217). The computed F value (=12.810) is also greater than the tabulated F value (F (9, 10) = 4.94) at 0.01 level. It indicates that the second-order polynomial is highly significant.

The regression coefficients, Student’s t test, and p values were used as a tool to check the significance of each coefficient, also indicating the interaction strength between each independent variable. It can be seen from the degree of significance (Table 8) that corn flour, yeast extract, and KH2PO4 (p < 0.05) are more significant than the other factors. These data suggest that the concentrations of corn flour, yeast extract, and KH2PO4 have a direct relationship with the spore production in this medium. The interaction of corn flour, yeast extract, and KH2PO4 are significant (p < 0.05), but interactions of corn flour × yeast extract and yeast extract × KH2PO4 are less significant (p < 0.10). The interaction of corn flour × KH2PO4 is insignificant because p value is more than 0.10.

The 3D response surface and the 2D contour plots of the regression model are used to explain the effects of the independent variables and interactive effects of independent variables on the response. The shape of the corresponding contour plots indicates whether the mutual interactions between the independent variables are significant or not. From the 3D response surface plots and the 2D corresponding contour plots, the optimal values of the independent variables and the corresponding response could be predicted. The interaction between each independent variable pair could be understood. The maximum predicted value is indicated by the surface confined in the smallest ellipse in the contour diagram. The spore production for different concentrations of the variables can be predicted from Fig. 1, corresponding to the interactive effects of three important variables, respectively. It can be seen from Fig. 1 that the response surface of each variable is almost independent of the concentration of the other. The interactions of three variables are not significant. The plots show that optimal corn flour concentration is around 35 g/L for yeast extract and KH2PO4 about 7 and 1.5 g/L.

Three-dimensional mesh plot and 2D contour plot of spore production of V. lecanii: a the effect of corn flour (X 1) and yeast extract (X 2) on spore production (Y) with other components set at center level; b the effect of yeast extract (X 2) and KH2PO4 (X 3) on spore production (Y) with other components set at center level; c the effect of corn flour (X 1) and KH2PO4 (X 3) on spore production (Y) with other components set at center level

Based on the fractional factorial design, a CCD was used for further optimization. One second-order polynomial equation was found to represent the spore production adequately. The predicted optimum levels of corn flour, yeast extract, and KH2PO4 were obtained by applying the regression analysis to Eq. 3: x 1 = 0.157, x 2 = −0.437, x 3 = 0.263, and y = 23.054, which correspond to X 1 = 35.79 g/L, X 2 = 8.69 g/L, X 3 = 1.63 g/L, and Y = 1.0 × 1010 spores/g DC.

Verification of the predicted values was conducted according to the above optimal conditions. The practical corresponding response was 1.1 × 1010 spores/g DC, much greater than using wheat bran (1.7 × 109 spores/g IDM) for spore production (Table 9). This result corroborated the validity and the effectiveness of this model. The optimal concentrations of medium components (grams per liter) are made up of corn flour 35.79, yeast extract 8.69, KH2PO4 1.63, K2HPO4 0.325, and MgSO4 0.325. Under the optimal condition, 1.0 × 1010 spores/g DC could be produced in theory and 1.1 × 1010 spores/g DC in practical experiment.

Discussion

The effect of various carbon and nitrogen sources on V. lecanii spore production with sugarcane bagasse as carrier was studied based on the basic medium with one-factor design (Table 4). Among the various carbon sources used, V. lecanii (CBS 102071) had almost the same spore production: corn flour (6.9 × 109 spores/g DC), soluble starch (6.7 × 109 spores/g DC), and glucose (6.3 × 109 spores/g DC), but spore production with the crude carbon source (corn flour) was relatively cheaper compared with other carbon sources. Among nitrogen sources, yeast extract (6.8 × 109 spores/g DC), soybean powder (6.7 × 109 spores/g DC), and peptone (6.4 × 109/g DC) had similar spore production. Yeast extract had relatively high solubility compared with soybean powder and peptone. Thus, corn flour and yeast extract were chosen as the sources of carbon and nitrogen for further optimal experiments, respectively.

In order to identify important medium components, we used fractional factorial experimental design. Corn flour (X 1), yeast extract (X 2), and KH2PO4 (X 3) indicated that they were important variables (Table 5). The increase in the concentration of corn flour had positive effects on spore production. An increase in the concentration of yeast extract and KH2PO4 had negative effects on spore production. The positive effects of corn flour may be caused by the requirement of a large quantity of substrate to synthesize spores. Corn flour is a preferred substrate to synthesize macromolecules (carbohydrates), which is related to sporulation and germination. In addition, corn flour has a low level of trace elements and a high carbohydrate content, which may contribute to spore generation. High carbon (corn flour) concentrations can lead to higher spore production as was reported for other fungi earlier (Ooijkaas et al. 1999). Low nitrogen (yeast extract) concentration is more advantageous for spore production than high nitrogen concentration. This is consistent with some other fungi (Smith and Galbraith 1971). KH2PO4 at high concentrations has a negative effect on spore production. It is possible that the high concentration of KH2PO4 could cause acidification of the culture, resulting in low spore production as the Coniothyrium minitans (McQuilken et al. 1997).

The statistical optimal experiments were useful to optimize the medium components for spore production of V. lecanii with sugarcane bagasse as carrier in solid-state fermentation. After three steps optimization, a high significant quadratic polynomial obtained by the central composite design and RSM was very useful to determine the optimal concentrations of constituents that have significant effects on spore production. Under the optimal concentrations of medium, spore production reached 1.1 × 1010 spores/g dried carrier; it is much greater than wheat bran (1.7 × 109 spores/g initial dry matter). This study demonstrates that waste sugarcane bagasse with high porosity and water absorption can provide an ideal environment and carrier in fungus solid-state fermentation for spore production.

References

Auria RA, Ortiz I, Villegas E, Revah S (1995) Influence of growth and high mould concentration on the pressure drop in solid-state fermentations. Process Biochem 30:751–756

Barson G (1976) Laboratory studies on the fungus Verticillium lecanii, a larval pathogen of the large elm bark beetle (Scolytus scolytus). Ann Appl Biol 83:207–217

Blackburn F, Hayes WA (1966) Studies on the nutrition of Arthrobotrys oligospora Fres. and A. Robusta Dudd: the saprophytic phase. Ann Appl Biol 58:43–50

Box GEP, Wilson KB (1951) On the experimental attainment of optimum conditions. J R Stat Soc (Ser B) 13:1–45

Christen P, Raimbault M (1991) Optimization of culture medium for aroma production by Ceratocystis jmbriuta. Biotechnol Lett 13:521–526

De Meo M, Laget M, Phan-Tan-Luu M, Mathieu D, Dumknil G (1985) Application of experimental designs for optimization of medium and culture conditions in fermentation. Biosci 4:99–102

Feng KC, Liu BL, Tzeng YM (2000) Verticillium lecanii spore production in solid-state and liquid state fermentations. Bioprocess Eng 23:25–29

Francis F, Sabu A, Nampoothiri KM, Ramachandran S, Ghosh S, Szakacs G, Pandey A (2003) Use of response surface methodology for optimizing process parameters for the production of a-amylase by Aspergillus oryzae. Biochem Eng J 15:107–115

Gopalakrishnan C (1989) Susceptibility of cabbage diamondback moth Plutella xylostella L. to the entomofungal pathogen Verticillium lecanii (Zimmerm.) Viegas. Cur Sci 58:1256–1257

Hall RA, Burges HD (1979) Control of aphids in glasshouses with the fungus Verticillium lecanii. Ann Appl Biol 93:235–246

Hölker U, Lenz J (2005) Solid-state fermentation—are there any biotechnological advantages? Curr Opin Microbiol 8:301–306

Imandi SB, Bandaru VVR, Somalanka SR, Garapati HR (2007) Optimization of medium constituents for the production of citric acid from byproduct glycerol using doehlert experimental design. Enzyme Microb Technol 40:1367–1372

Johnson DL, Huang HC, Harper AM (1988) Mortality of grasshoppers (Orthoptera; Acridiae) inoculated with a Canadian isolate of the fungus V. lecanii. J Invertebr Pathol 52:335–342

Khachatourians GG (1992) Virulence of five Beauveria strains, Paecilomyces farinosus, and Verticillium leanii against the migratory grasshopper, Melanoplus sanguinipes. J Invertebr Pathol 59:212–214

Marin-Cervantes MC, Matsumoto Y, Ramırez-Coutino L, Rocha-Pino Z, Viniegra G, Shirai K (2008) Effect of moisture content in polyurethane foams as support for solid-substrate fermentation of Lecanicillium lecanii on the production profiles of chitinases. Process Biochem 43:23–32

McQuilken MP, Budge SP, Whipps JM (1997) Effects of culture media and environmental factors on conidial germination, pycnidial production and hyphal extension of Coniothyrium minitans. Mycol Res 101:11–17

Milner RJ, Lutton GG (1986) Dependence of Verticillium lecanii (Fungi: Hyphomycetes) on high humidities for infection and sporulation using Myzus persicae (Homoptera: Aphididae) as host. Environ Entomol 15:380–382

Ooijkaas LP, Wilkinson EC, Tramper J, Buitelaar RM (1999) Medium optimization for spore production of Coniothyrium minitans using statistically based experimental designs. Biotechnol Bioeng 64:92–100

Singh B, Satyanarayana T (2006) A marked enhancement in phytase production by a thermophilic mould Sporotrichum thermophile using statistical designs in a cost-effective cane molasses medium. J Appl Microbiol 101:344–352

Smith JE, Galbraith JC (1971) Biochemical and physiological aspects of differentiation in the fungi. Adv Microb Physiol 5:45–134

Tunga R, Banerjee R, Bhattacharyya BC (1998) Optimizing some factors affecting protease production under solid-state fermentation. Bioprocess Eng 19:187–190

Verhaar MA, Hijwegen T, Zadoks JC (1996) Glasshouse experiments on biocontrol of cucumber powdery mildew (Sphaerotheca fuliginea) by the mycoparasites Verticillium lecanii and Sporothrix rugulosa. BioControl 6:353–360

Whipps JM (1993) A review of white rust (Puccinia horiana Henn.) disease on chrysanthemum and the potential for its biological control with V. lecanii (Zimm.) Viegas. Ann Appl Biol 122:173–187

Zhu Y, Smits JP, Knol WK, Bol J (1994) A novel solid-state fermentation system using polyurethane foam as inert carrier. Biotechnol Lett 16:643–648

Zhu Y, Knol W, Smits JP, Bol J (1996) Medium optimization for nuclease Pl production by Penicillium citrinum in solid-state fermentation using polyurethane foam as inert carrier. Enzyme Microb Technol 18:108–112

Acknowledgment

This work was supported by a research grant from the Science and Technology Department of Zhejiang Province, China (2007C24016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, Y., Xu, X. & Zhu, Y. Optimization of Verticillium lecanii spore production in solid-state fermentation on sugarcane bagasse. Appl Microbiol Biotechnol 82, 921–927 (2009). https://doi.org/10.1007/s00253-009-1874-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-009-1874-2