Abstract

Proteomic analysis was performed to determine and differentiate the composition of the secretomes of Phanerochaete chrysosporium CIRM-BRFM41, a peroxidase hypersecretory strain grown under ligninolytic conditions and on softwood chips under biopulping conditions. Extracellular proteins from both cultures were analyzed by bidimensional gel electrophoresis and matrix-assisted laser desorption/ionization time-of-flight tandem mass spectrometry. A total of 37 spots were identified. The secretome in liquid synthetic medium comprised mainly peroxidases, while several wood-degrading enzymes and enzymes involved in fungal metabolism were detected in biopulping cultures on softwood. This prompted an analysis of the impact of secretome modulation in the presence of softwood chips. Biotreated wood was submitted to kraft cooking and chemical bleaching using chlorine dioxide. The fungal pre-treatment led to a significant increase in pulp yield and a better bleachability of the pulp. This bleachability improvement could be explained by the production of specific lignocellulose-degrading enzymes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The white-rot fungus Phanerochaete chrysosporium can efficiently and selectively remove lignin when grown on lignocellulosic biomass and has therefore been adopted as a model organism in the study of lignin biodegradation and related biotechnological applications, such as biopulping, biobleaching and pulp mill effluents treatment. Initial studies mainly focused on its ligninolytic system now considered as well described (Kersten and Cullen 2007). Phanerochaete is able to produce two extracellular peroxidases, lignin peroxidase (LiP, EC 1.11.1.14) and manganese peroxidase (MnP, EC 1.11.1.13; Gold and Alic 1993; Cullen and Kersten 2004, for review). The essential components of the ligninolytic system also include H2O2-generating enzymes that supply the peroxidase catalytic cycle, the most studied being glyoxal oxidase (GLX, EC 1.1.3.-), which is an extracellular copper radical oxidase produced in coordination with the peroxidases and activated by LiP (Kersten and Kirk 1987; Kersten 1990). Several cellulolytic enzymes including endoglucanases (EC 3.2.1.4), cellobiohydrolases (EC 3.2.1.91), and β-glucosidases (EC 3.2.1.21) have also been biochemically characterized (Kirk and Cullen 1998). The P. chrysosporium hemicellulose degrading system has been less extensively studied, but several xylan-degrading enzymes have been isolated and characterized (Dobozi et al. 1992; Castanares et al. 1995; Brumer et al. 1999). Despite the large body of data accumulated on the P. chrysosporium lignocellulolytic complex, most studies have remained limited to individual enzymes. The recently sequenced genome of P. chrysosporium revealed hundreds of genes with predicted roles in lignocellulose degradation (Martinez et al. 2004), of which 240 were annotated as encoding carbohydrate-active enzymes, including 166 glycoside hydrolases. Genome analysis also revealed several families of structurally related genes, in particular genes encoding lignocellulolytic enzymes (Larrondo et al. 2005; Kersten and Cullen 2007). To date, little is known about the conditions governing expression of most of these genes, but individual studies have shown that the regulation of plant cell-wall-degrading enzymes in filamentous fungi occurs in gene transcription by means of various environmental and cellular factors. It has been demonstrated that the synthesis of lignocellulolytic enzymes is subject to carbon induction and/or catabolic repression (Aro et al. 2005). With the sequencing of the P. chrysosporium genome and the development of proteomic methods, it had become possible to comprehensively overview the enzymes involved in lignocellulosic biomass degradation that are secreted under varying environmental conditions. Vanden Wymelenberg et al. (2005, 2006a) reported studies of the P. chrysosporium secretome cultivated on cellulose and in carbon- and nitrogen-limited media. Since these studies focused on secretion on defined synthetic media, they might not reflect the secretome composition on natural substrates like wood or other lignocellulosic substrates. To date, only two proteomic analyses from P. chrysosporium cultures restricted to hardwood substrates have been reported (Abbas et al. 2005; Sato et al. 2007). In order to provide further insight into secretome adaptation in relation to carbon sources, we report the first proteomic analysis of proteins secreted by P. chrysosporium grown on softwood chips under conditions close to those used in biopulping. Biopulping was defined as the use of lignin-selective fungi for the pretreatment of wood for mechanical or chemical pulping in pulp and paper manufacture. P chrysosporium was shown to be efficient for both biomechanical (Akhtar et al. 1997) and bio-kraft pulping (Kang et al. 2003). The protein secretion profile obtained under those conditions was compared to that obtained on a synthetic liquid medium promoting the production of peroxidases. Biopulping conditions should provide information not only on enzyme secretion under conditions close to those of natural white-rot fungi growth but also on the impact of the secretome modulation on the bleachability of the chemical pulp obtained.

Materials and methods

Fungal strain and culture conditions

The P. chrysosporium (I-1512) deposited as CIRM-BRFM41 (Centre International de Ressources Microbiennes-Champignons Filamenteux) was selected for its ability to secrete high level of peroxidases. This strain is a dikaryotic mutant derived by random mutagenesis from the wild-type P. chrysosporium BKM-F-1767. The strain was kept on malt agar slants at 4 °C.

Fungal cultures were grown either under ligninolytic culture conditions in a liquid synthetic medium previously developed to promote peroxidase production under carbon limitation (Laugero et al. 1996; Herpoël et al. 1999) or on softwood in biopulping culture conditions. Inoculum was obtained from precultures grown for 5 days at 37 °C in Roux flasks containing 200 ml of synthetic medium according to Laugero et al. (1996). The mycelium mat was filtered and blended for 60 s with sterile water using an Ultraturax blender. The mycelium suspension was used to inoculate the liquid medium and the softwood chips.

For growth in liquid culture, 250-ml baffled Erlenmeyer flasks containing 100 ml of basal medium were inoculated with 16 mg (dry weight) of mycelium. The fungus was immobilized on 14 polyurethane foam cubes (2 × 2 × 1 cm each). Incubation was carried out at 37 °C for 4 days with continuous stirring at 120 rpm. The culture was flushed with 100% O2 for 1 min daily. For growth on softwood, black pine (Pinus nigra) wood chips were prepared. The sampling technique used to obtain wood chips was developed by the Forêt, Cellulose, Bois-Construction, Ameublement-ex-Association Forêt Cellulose (FCBA) Technological Institute and consisted of a portable drilling machine equipped with a 20-mm carpenter drill (auger). Half-circle samples of 2.5-cm diameter were obtained (da Silva Perez et al. 2004). Experiments were conducted in a 1-l Erlenmeyer flask containing 30 g (dry weight) of softwood chips autoclaved at 120 °C for 20 min. The substrate was moistened with basal medium to obtain a final moisture content of 75% and inoculated with 60 mg (dry weight) of blended mycelium. Cultivation was carried out statically at 37 °C for 21 days. Sterilized softwood chips treated in the same conditions but without fungal inoculation were used as an abiotic control.

Protein extract preparation

To prepare extracellular proteins from liquid cultures, the liquid broth was filtered through a 0.45-µm filter, concentrated, and washed with ten volumes of Milli-Q water using a 10-kDa cutoff membrane (Amicon system, Millipore Bradford, USA).

Extracellular proteins were extracted from wood chips with 50 mM sodium acetate buffer (pH 5.4) for 1 h at 4 °C under slight shaking. Three successive extractions were performed using 100 ml buffer. Crude extracts were recovered by filtration through Miracloth filters (mean pore diameter, 21.5 µm; Calbiochem, USA). The combined supernatants were treated with 5% (w/v) polyvinyl-polypyrrolidone (PVPP, Sigma Chemical) pretreated with hydrochloric acid as described previously (Charmont et al. 2005) at 4 °C for 1 h with gentle stirring. The mixture was then centrifuged at 5,300×g for 15 min to remove PVPP. The supernatant was finally ultrafiltrated and diafiltered against ten volumes of Milli-Q water using a 10-kDa cutoff membrane (Amicon system, Millipore Bradford).

The total protein concentration of protein extracts was determined using the Bio-Rad Dc protein assay kit (Bio-Rad). Aliquots of extracellular protein samples were stored at −80 °C for further two-dimensional gel electrophoresis (2DE) experiments.

Manganese peroxidase assay

Manganese peroxidase activity was determined using the method previously described by Paszczynski et al. (1986).

Protein separation by 2D-gel electrophoresis

Immobiline DryStrips (18 cm, pH 3–5.6, Amersham Biosciences) were passively rehydrated overnight at room temperature with protein extracts diluted in rehydratation solution (DeStreak solution, Amersham Biosciences), supplemented with 2% (v/v) 4–7 IPG buffer and 2.8 mg/ml dithiothreitol to a final volume of 350 µl per strip. Sample loads were 50 or 100 µg of proteins from softwood or liquid cultures per strip, respectively. Isoelectric focusing was performed on a Multiphor II system at 20 °C. Running conditions were set according to the Immobiline DryStrip manufacturer’s guidelines. Following isoelectric focusing, each strip was equilibrated for 10 min in 10 ml of sodium dodecyl sulfate (SDS) equilibration buffer [50 mM Tris–HCl, pH 6.8, 6 M urea, 30% (v/v) glycerol, 1% (w/v) SDS, a trace of bromophenol blue] containing 25 mM dithiothreitol. A second equilibration step was then performed in the same SDS equilibration buffer containing 250 mM iodoacetamide instead of dithiothreitol. The strips were then loaded onto 14% homogeneous acrylamide gels and sealed with 0.5% (w/v) agarose in SDS running buffer [25 mM Tris base, 192 mM glycine, 0.1% (w/v) SDS]. The second dimensional separation was performed using an Ettan™ DALT system (Amersham) at 0.5 W/gel and 16 °C overnight, followed by 17 W/gel for 3 h. After electrophoresis, the acrylamide gels were silver-stained according to Rabilloud et al. (1988), a staining method compatible with MS analysis.

Protein identification by matrix-assisted laser desorption/ionization time-of-flight tandem mass spectrometry

For protein identification, a slightly modified procedure that was originally developed by Shevchenko et al. (1996) was used for in-gel digestion. Briefly, the most interesting visually detected silver-stained protein spots were excised from the SDS polyacrylamide gel electrophoresis (SDS-PAGE) gels. The resulting sliced gels were washed with 100 mM sodium thiosulfate/30 mM potassium ferricyanide (1:1) as described by Gharahdaghi et al. (1999) and dried in a Speed Vac concentrator (Bioblock, Illkirch, France). Digestion was then performed using sequencing grade modified trypsin (Promega, Charbonnières, France) at 0.5 µg per sample in 25 µl of 50 mM ammonium bicarbonate, pH 8.0, for 18 h at 37 °C. The reaction was stopped by the addition of 2 µl of 5% trifluoroacetic acid (TFA, Pierce, Touzart & Matignon, Vitry-sur-Seine, France). The supernatants containing peptides were then dried in a Speed-Vac and maintained at −20 °C until MS analysis.

The supernatants were analyzed by matrix-assisted laser desorption/ionization quadrupole time-of-flight (MALDI-QTOF) mass spectrometry. One microliter of collected peptides was deposited onto the MALDI target plate, and 1 µl of matrix solution (10 g/l cyano-4-hydroxycinnamic acid diluted 1:5 with a solution containing 0.1% TFA and 70% acetonitrile) was added to the spot. Once the spots dried on the target plate, the plate was introduced into a hybrid QTOF mass spectrometer Qstar XL (MDS Sciex, Toronto, Canada). oMALDI Xpert 2.0 software was used for the MALDI MS and MS/MS experiments. The samples were ionized with a laser beam (λ = 337 nm), and each spectrum was an average of 250 to 500 laser shots. The more representative monocharged ions were automatically submitted to fragmentation with a collision energy close to 0.05 eV/Da (Wattenberg et al. 2002). The oMALDI Xpert 2.0 software treated each sample well individually, generating an MS peak list used as a “survey scan” to determine peptide precursors for MS/MS acquisition. The full dataset (MS/MS) was then searched against the translated P. chrysosporium v2.1 gene model database (http://www.jgi.doe.gov/whiterot) by using the MASCOT v.2.1 software program (Matrix Science). This database deduced from the genome of P. chrysosporium strain RP78, a homokaryotic derivative of BKM-F-1767, consists of 10,048 putative protein-encoding sequences. Protein sequences were submitted to BlastP analyses against the National Center for Biotechnology Information non-redundant database and against the Carbohydrate-Active EnZyme (CAZy) database for the identified glycoside hydrolases (http://www.cazy.org; Henrissat 1991).

Lignin analyses

All lignin analyses were performed as duplicate analyses and, on extract-free wood, ground to pass a 0.5-mm sieve before solvent extraction (toluene-EtOH; 2:1, EtOH, and H2O). The lignin content of the extract-free samples was determined by the Klason method using 300 mg of extract-free sample, according to the standard procedure (Dence 1992). Klason lignin content was calculated as a weight percentage of the extract-free wood.

Lignin structure was evaluated by thioacidolysis. The thioacidolysis reagent was prepared by introducing 2.5 ml of BF3 etherate (Aldrich) and 10 ml of ethanethiol EtSH (Aldrich) into a 100-ml flask and adjusting the final volume to 100 ml with dioxane (pestipur grade). The extract-free wood (10 mg) was added to 10 ml of reagent and 1 ml of a solution of the gas chromatography (GC) internal standard heinecosane (Aldrich, 0.25 mg/ml in CH2Cl2) in a glass tube closed with a Teflon-lined screwcap. Thioacidolysis was performed at 100 °C (oil bath) for 4 h. The cooled reaction mixture was diluted with 30 ml of water, and pH was adjusted to 3.0 to 4.0 (aqueous 0.4 M NaHCO3). The reaction mixture was extracted with CH2Cl2 (three times with 30 ml). The combined organic extracts were dried over Na2SO4 and then evaporated under reduced pressure at 40 °C. The final residue was redissolved in approximately 1 ml of CH2Cl2 before silylation and GC–MS analyses with a Saturn 2100 ion trap instrument (Varian) running in electronic impact mode (70 eV). The quantitative analysis of the main p-hydroxyphenyl (H) and guaiacyl (G) lignin-derived monomers, analyzed as their trimethylsilylated derivatives, was carried out from specific ion chromatograms reconstructed at m/z 239 for the H monomers and 269 for the G monomers. In addition to the lignin-derived conventional H and G monomers, we also evaluated the thioacidolysis-released vanillic acid on ion chromatograms reconstructed at m/z (312+297) and after identification with the appropriate reference compound.

Kraft cooking and bleaching of the bio-treated wood

Kraft cooking was performed in a 1-l laboratory rotating batch reactor at 170 °C under the following conditions: active alkali charge, 24% (as NaOH); sulfidity, 35%; and liquor to wood (L/W) ratio, 4:1. The cooking was carried out at 170 °C (reached in 90 min) for 210 min. The moisture content of the brown (unbleached) pulps obtained was determined in order to calculate pulp yields. Kappa numbers were determined according to international standard ISO 302:1981. Residual alkalinity of the cooking liquor was determined by hydrochloric acid titration.

The pulps were then submitted to a conventional bleaching sequence as D0E1D1E2D2 (D, chlorine dioxide stage; and E, alkaline extraction). The bleaching stages were carried out in sealed polyethylene bags placed in water baths held at the required temperature. Chemical charges (expressed in percent of dry weight of pulp) were as follows.

For the D0 stage, the ClO2 charge was calculated on the basis of the kappa number of the pulps using the following relationship: % ClO2 = (kappa factor) × (kappa number)/2.63. Two kappa factor values (0.19 and 0.22) were applied for each pulp. Fifty percent of the ClO2 charge applied in the D0 stage was applied in the D1 stage, and 0.3% ClO2 was applied in the D2 stage. The NaOH charges were 1.5% in E1 and 0.8% in E2. The bleaching stages were performed at 10% consistency and 70 °C except for the D0 stage, which was carried out at 55 °C. The duration was 1 h for the D0 and E stages, and 2 h for the D1 and D2 stages.

Residual amounts of ClO2 were determined by titration with 0.1 N sodium thiosulfate.

Pulp brightness and intrinsic viscosity were determined according to international standards ISO 2470:1999 and ISO 5351-1:1981, respectively.

Results

Identification of extracellular proteins of P. chrysosporium

As a first investigation, a 2D map of the proteins secreted by P. chrysosporium was established after liquid-culture growth-promoting secretion of ligninolytic enzymes. This 2D map was compared to that obtained on softwood substrate under biopulping culture conditions. Preliminary protein analysis using IPG strips in the pH range 3–10 demonstrated that all the proteins were separated between pH 3 and 5.6. Consequently, extracellular proteins were resolved by 2D-PAGE in this pH range and visualized after silver staining. For each growth conditions, several replicates of 2D gels of protein extracts prepared from independent cultures were analyzed. The gels presented are representative of all experiments conducted (Fig. 1). Molecular sizes of the extracellular proteins ranged from 19 to 110 kDa, and their isoelectric points ranged between 3.6 to 5.4 for both culture conditions, but the general protein spot distribution pattern was different. The 2D gel from liquid culture revealed the presence of eight major dense protein spots around 45–50 kDa (Fig. 1a). In contrast, the 2D gel from solid-state culture was much more heterogeneous, with protein spots of low to high staining intensity distributed throughout the gel (Fig. 1b).

Protein spots of moderate to high staining intensity were excised from the gels for analysis by MALDI-TOF tandem mass spectrometry. In total, 37 spots were reported from both culture conditions, but some of them were identified only with a single peptide and thus should be considered provisional (Tables 1 and 2). The lack of reliable identification for the other protein spots may be due to small amounts of biological material and (or) to post-translational modifications known to affect identification (Baldwin 2004). Several spots were assigned to the same protein, suggesting the presence of protein isoforms and/or degraded forms.

In the ligninolytic culture conditions, the eight most prominent spots were identified as peroxidases. Three of these eight spots were identified as manganese peroxidases and five as lignin peroxidases. We also identified spots of lower molecular weights that could correspond to peroxidases’ proteolytic products. Six spots were assigned to other proteins: two isoforms of a putative GDSL-like lipase, a putative α-1,2-mannosidase, a putative aspartic protease, a putative serine protease, and a protein of unknown function.

Under the biopulping culture conditions on softwood, two putative enzymes involved in lignin biodegradation were identified: a LiP isoform encoded by lipE and a copper-radical oxidase. No protein spot corresponding to MnP could be detected under these culture conditions. However, since P. chrysosporium CIRM-BRFM41 was selected for its manganese peroxidase hypersecretion capability (Herpoël et al. 1999), MnP activity assays were performed, and MnP activity could be detected in the extracellular protein extract from wood culture. Various glycoside hydrolases that were also identified were analyzed through the CAZy database to determine their family and putative function. They included the cellobiohydrolases Cel7D and Cel7C (Uzcategui et al. 1991; Muñoz et al. 2001), and the xyloglucanase Xgh74B (Ishida et al. 2007). Other possible enzymes potentially active on wood components were detected, including the candidate β-mannanase Man5C, a GH3 family protein related to bacterial proteins with β-glucosidase, β-xylosidase, and α-l-arabinosidase activities. We also detected a candidate family Δ-4,5-unsaturated β-glycosidase, a GH92 family protein related to bacterial α-1,2-mannosidases, and a GH37 family protein related to animal α,α-trehalases. Four other spots were assigned to genes encoding hypothetical or unknown proteins.

Effect of the fungal treatment on the softwood lignin

The effect of the biopulping treatment on the lignin content and structure of the pine samples was evaluated by measuring the Klason lignin content and the lignin-derived guaiacyl (G) and p-hydroxyphenyl (H) monomers released by thioacidolysis. Their recovery yield is a good indicator of the frequency of H and G units only involved in β-O-4 bonds in the lignin polymer. In addition, we measured the recovery yield of vanillic acid, a minor thioacidolysis monomer that originates from cell wall-bound vanillic acid. The values obtained are presented in Table 3. Although Klason lignin content and total (H+G) thioacidolysis yield (calculated on the basis of the Klason lignin content) did not appear to be significantly affected by the fungal treatment, there was a 22% increase in thioacidolysis-released vanillic acid and a 24% decrease in the relative frequency of H monomer following the fungal treatment.

Effect of the fungal treatment on kraft cooking and bleaching

Table 4 shows the results obtained after conventional kraft cooking of the softwood chips. Pulp yield was higher after the fungal treatment, but the kappa number obtained after the kraft cooking and the effective alkali consumed were both slightly higher than in the abiotic controls.

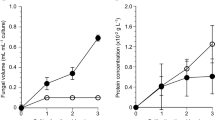

The bleachability of the biokraft pulp was evaluated by applying a conventional elemental chlorine-free D0E1D1E2D2 bleaching sequence to the pulp, with two initial ClO2 charges applied in the D0 stage. The effect of the fungal treatment was not visible after the D0 stage as both biokraft pulp, and the control showed the same brightness (Fig. 2). Nonetheless, there was a significant increase in biokraft pulp brightness after the D1 stage. The brightness values plateaued in the D2 stage but the differences were still visible: An increase of 1.5% and 0.4% ISO brightness was measured for the low ClO2 charge (kappa factor of 0.19) and the high ClO2 charge (kappa factor of 0.22), respectively. Figure 3 shows final brightness as a function of chlorine dioxide consumption. For any given brightness value, ClO2 consumption was lower after the fungal treatment. A 3% ClO2 saving, corresponding to 1 kg/t of pulp, could have been calculated to reach a final brightness value of 89% ISO.

Discussion

This work focused on the study of P. chrysosporium secretome adaptation on softwood under biopulping conditions. The extracellular protein profile obtained in those conditions was compared to the secretome obtained in ligninolytic culture conditions.

As expected, most of the proteins identified in the ligninolytic culture were linked to lignin biodegradation and assigned to peroxidases. Three spots were identified as the products of mnp1, mnp2, and mnp5 genes. A fourth spot was assigned to mnp1 or mnp4, with no discrimination possible, as previously reported (Vanden Wymelenberg et al. 2006a). The corresponding proteins differ by a single amino-acid residue. Two out of the ten known LiP isozymes (Gaskell et al. 1994) were putatively identified on the basis of a single peptide (LiPD and LiPE). Because the peptide sequence assigned to LipD was detected in several spots (8, 9, 10, 11, and 12), we can propose this isozyme for these spots. This hypothesis is furthermore confirmed by a previous study. Indeed, the two peptide sequences corresponding to LipD and LipE in our study were the same as the ones previously identified by LC–MS/MS (Vanden Wymelenberg et al. 2006a, b). The five LiPD isoforms identified exhibited isoelectric point values varying from 4.6 to 4.9. LiPD is known to be the main LiP isozyme produced under carbon-starved conditions (Stewart and Cullen 1999), in agreement with the number of LiP spots detected and assigned to LiPD.

We also detected a number of spots of lower molecular weights that could correspond to degraded forms of peroxidases. This may be explained by the presence of proteolytic enzymes. Bonnarme et al. (1993) demonstrated the early but non-extensive proteolytic degradation of lignin peroxidases by aspartic and thiol proteases from P. chrysosporium CIRM-BRFM41 (formerly I-1512) grown under the same culture conditions as used in this study. Here, the presence of proteases was revealed by the identification of an aspartic protease and, potentially, a serine protease with respect to its identification accuracy. These proteases have already been detected in previous P. chrysosporium secretome analyses in ligninolytic cultures (Vanden Wymelenberg et al. 2006a) and on oak substrate under stationary liquid culture and solid-state culture conditions (Sato et al. 2007). However, the exact role played by these proteases in the peroxidases and other extracellular protein degradations remains to be elucidated.

In contrast with the secretome composition observed in ligninolytic conditions, after biopulping on softwood chips, only one lignin peroxidase assigned to LiPE was detected and no MnP was identified. However, the peroxidase-matched spots belonged to a gel area with more overlapping spots associated with streaking that affects protein visualization and further identification. Therefore, it can be assumed that some of the unidentified spots in this area may have corresponded to peroxidases. Spot resolution was optimized by decreasing sample loading and by applying a PVPP treatment known to remove wood-derivative phenolic compounds (Charmont et al. 2005), but we could not resolve and identify all the spots. Extraction conditions should also be taken into account because they can affect protein recovery and enzyme activities from wood colonized by fungi. As growth of P. chrysosporium on softwood was characterized by an invasive mycelium, it can be assumed that some secreted protein were occluded and/or adsorbed on wood chips. Consequently, the recovery of such protein might be restricted or excluded by the extraction procedure performed. On the other hand, MnP activity was observed in the protein extract from wood, thus confirming the presence of at least one protein spot corresponding to this enzyme on the gel. LiP activity was not detected despite the identification of a corresponding spot on the gel, but the presence of softwood brown-colored extractive could have affected the enzymatic assay. Besides peroxidases, the cro2-encoded protein described as a H2O2-generating copper-radical oxidase involved in the ligninolytic system of P. chrysosporium was also identified. The production of this protein has been demonstrated in defined medium, but only cro2 transcripts have so far been detected in P. chrysosporium cultures on poplar wood (Vanden Wymelenberg et al. 2006b). However, despite a significant Mascot global score, the secretion of CRO2 on a natural substrate still remains to be confirmed due to its identification by a single peptide.

In addition to the lignin-degrading enzymes, several glycoside hydrolases were also detected, including putative cellulases, hemicellulases, and enzymes involved in fungal metabolism. We detected the cellobiohydrolase Cel7D, which has been demonstrated as the most abundant family 7 cellobiohydrolase secreted by P. chrysosporium when grown on cellulose powder (Vanden Wymelenberg et al. 1993). This enzyme has previously been reported in secretome profiles of this fungus grown on cellulose avicel medium (Vanden Wymelenberg et al. 2005) and on oak substrate under liquid stationary and solid-state culture conditions (Abbas et al. 2005; Sato et al. 2007). The presumptive identification of another family 7 cellobiohydrolase (Cel7C), which has also been detected on cellulose avicel medium (Vanden Wymelenberg et al. 2005), could suggest the production of at least two cellobiohydrolases. Secretome analysis also revealed the presence of candidate β-mannanase Man5C. It is known that the production of β-mannanase can be induced by diverse carbon sources, notably cellulose and mannan-containing substrates (Sachslehner et al. 1998; Puchart et al. 1999; Kansoh and Nagieb 2004). The presence of this enzyme was unsurprising since galactoglucomannans are the major softwood hemicelluloses (Saha 2003). The gly3b gene product, classified in the GH3 family in CAZy, was also detected. Previous BLAST searches in the P. chrysosporium database showed that Gly3B is only 25% identical in sequence to glucan 1,3-β-glucosidase Bgl3A (Vanden Wymelenberg et al. 2005), which is secreted in cellulose-containing media (Li and Renganathan 1998; Igarashi et al. 2003). It should also be noted that BLAST analysis against CAZy revealed that Gly3B has 35% sequence identity to a bifunctional β-xylosidase/α-l-arabinosidase from Thermoanaerobacter ethanolicus (Mai et al. 2000) and to the XglS protein from T. brockii, presenting both β-glucosidase and β-xylosidase activities (Breves et al. 1997), respectively. Interestingly, this protein has previously been reported in secretome studies on avicel (Vanden Wymelenberg et al. 2006a) and on oak substrate (Abbas et al. 2005), suggesting that this enzyme could play a major role in P. chrysosporium metabolism. However, the specificity and activity of this protein remains to be determined. The recently characterized xyloglucanase Xgh74, an enzyme known to be active on xyloglucan (Ishida et al. 2007), was also identified.

Beside the lignocellulose-degrading enzymes, other enzymes involved in fungal metabolism were also identified, including a candidate α-glycosidase-related to GH92 bacterial α-1,2-mannosidases, a candidate GH88 Δ-4,5-unsaturated β-glycosidase, and a candidate α-glycosidase related to GH37 animal α,α-trehalases. The presence of a GH92 candidate α-glycosidase was shown in both culture conditions. Although P. chrysosporium genome analyses demonstrated the presence of four putative genes coding for GH92 candidate α-glycosidases related to bacterial α-1,2-mannosidases (Martinez et al. 2004), the production of these proteins has never been reported in fungi. The α-1,2-mannosidase identified in this study corresponds to a P. chrysosporium GH92 protein model described without predicted signal peptide. Sequence comparison with other GH92 proteins from unpublished Basidiomycetes genomes suggests that this protein is truncated at the N terminus and that a signal-peptide could be present. This can be exemplified by the CC1G_06987.1 protein model (http://www.broad.mit.edu) from the Basidiomycete Coprinopsis cinerea (Coprinus cinereus) but can be found in other Basidiomycetes genomes being presently processed (data not shown). More remotely, a putative GH92 model from the Ascomycete Aspergillus fumigatus (provisional GenBank accession number AFUA_6G13760) shows similar characteristics. Known extracellular fungal α-1,2-mannosidases belong to the GH47 family and are thought to be involved in post-secretion protein deglycosylation (Yoshida et al. 1993; Maras et al. 2000; Stals et al. 2004). Virtually nothing is known about GH92 α-glycosidases in fungi, and the only characterized enzyme belonging to this family was isolated from Mycrobacterium sp. M-90 (Maruyama et al. 1994). One single peptide was presumptively assigned to a GH88 candidate Δ-4,5-unsaturated β-glycosidase. The only known activities within this family are those from Bacillus sp. GL1 and Pedobacter heparinus Δ-4,5-unsaturated β-glycuronidases, which are involved in the biodegradation of oligosaccharides produced by polysaccharides lyases (Nankai et al. 1999; Itoh et al. 2006) and heparin/heparan glycosaminoglycans (Myette et al. 2002), respectively. The exact role of these enzymes in fungi is still unknown but corresponding peptides have also been detected on avicel (Vanden Wymelenberg et al. 2005), suggesting they are involved in plant cell-wall pectin degradation by degrading the unsaturated products resulting from the action of pectin or pectate lyases, or in rearrangements of fungal cell-wall uronic-acid-containing polysaccharides. Furthermore, a hitherto unreported GH37 protein related to animal α,α-trehalases was also detected. Trehalases were shown to be involved in hydrolysis of trehalose, which accumulates in fungal cells and in spores under stress conditions such as growth restriction or desiccation (Jorge et al. 1997; Parrou et al. 2005). The production of trehalases by P. chrysosporium may therefore occur in response to environmental stress, such as nutrient limitation ensured by biopulping culture conditions, to assimilate trehalose as carbon source. Moreover, two types of trehalases, referred to as “acid” and “neutral” trehalases depending on their pH for optimal activity, were characterized in filamentous fungi. The localization of the GH37 protein identified suggests that it is probably an acid trehalase, as these enzymes were shown to be secreted (Parrou et al. 2005). Finally, the secretome on wood contains several proteins of unknown function. These proteins showed low homology with other fungal proteins despite conserved domains detected in some cases. In particular, the hypothetical protein 139777, which contains the conserved domain DUF1237, has already been detected in carbon-starved cultures (Vanden Wymelenberg et al. 2006a).

To evaluate the effect of the fungal treatment on the wood, we characterized the lignin of the biotreated wood chips. Some subtle but nevertheless significant changes were measured. It appeared that the fungal attack mainly targeted the phenolic units of the lignin, since there was only a decrease in the relative frequency of β-O-4-linked H units observed and as these units are essentially terminal units with free phenolic groups (Lapierre and Rolando 1988). This kind of preferential degradation has yet been observed for P. chrysosporium-treated wheat straw in solid-state culture conditions (Camarero et al. 1994). Moreover, the sample subjected to fungal treatment released more vanillic acid upon thioacidolysis. This increase cannot be accounted for by the formation of additional vanillic esters in the cell walls after the fungal treatment but was more likely due to oxidative cleavage of certain lignin side chains, a lignin degradation mechanism which has also been shown for P. chrysosporium (Camarero et al. 1997). Interestingly, the results obtained are similar to those reported for P. chrysosporium lignin-degrading enzymes, in particular for LiP (Toshiaki and Higuchi 1989). We also ran conventional kraft pulping and chlorine dioxide chemical bleaching of the biotreated wood. Despite a significant increase in pulp yield, the fungal treatment had a slight negative effect on the chemical consumption after kraft cooking. The increase in chemical consumption may be attributed to the presence of the fungal biomass, which can also be chemical-consuming (Atik et al. 2006). The kappa number of the pulp was increased after the P. chrysosporium treatment, but kraft pulp bleachability was nevertheless enhanced, as demonstrated by a decrease in chlorine dioxide consumption for the same range of final brightness values. This result can be partially explained by an increase in the amount of alkali-extractible compounds, which is known to be one of the effects of fungal treatments of wood and pulps (Reid 1998). The lignin-degrading enzymes and hemicellulases revealed by secretome analysis are expected to be involved in this bleachability improvement. It can be assumed that the P. chrysosporium-secreted enzymes may modify the wood compounds without a concomitant significant release of biodegradation products. This hypothesis is consistent with the results obtained for the lignin analyses, as the fungal treatment did not affect the lignin content of the wood but nonetheless led to significant lignin modifications. It should be pointed out that the same phenomenon has been observed during the early stages of fungal treatment of wood for biomechanical pulping applications (Akhtar et al. 1998).

In summary, the comparative secretome analysis dealing with fungal culture on synthetic medium and on wood demonstrates that P. chrysosporium readily adapts to changes in environmental conditions. This study presents the first characterization of the P. chrysosporium secretome on softwood under biopulping conditions. Identifying the proteins secreted on a natural substrate and in conditions close to the natural fungal growth conditions has provided a better understanding of lignocellulose breakdown.

References

Abbas A, Koc H, Liu F, Tien M (2005) Fungal degradation of wood: initial proteomic analysis of extracellular proteins of Phanerochaete chrysosporium grown on oak substrate. Curr Genet 47:49–56

Akhtar M, Blanchette RA, Kirk TK (1997) Fungal delignification and biomechanical pulping of wood. In: Scheper T (ed) Advances in biochemical engineering/biotechnology. Springer, Berlin, pp 159–195

Akhtar M, Blanchette RA, Myers G, Kirk TK (1998) An overview of biomechanical pulping research. In: Akhtar M, Young RA (eds) Environmentally friendly technologies for the pulp and paper industry. Wiley, New York, pp 309–340

Aro N, Pakula T, Penttilä M (2005) Transcriptional regulation of plant cell wall degradation by filamentous fungi. FEMS Microbiol Rev 29:719–739

Atik C, Imamoglu S, Bermek H (2006) Impact of xylanase pre-treatment on peroxide bleaching stage of biokraft pulp. Int Biodeterior Biodegrad 58:22–26

Baldwin MA (2004) Protein identification by mass spectrometry: issues to be considered. Mol Cell Proteomics 3:1–9

Bonnarme P, Asther M, Asther Ma (1993) Influence of primary and secondary proteases produced by free and immobilized cells of the white-rot fungus Phanerochaete chrysosporium on lignin peroxidase activity. J Biotechnol 30:271–282

Breves R, Bronnenmeier K, Wild N, Lottspeich F, Staudenbauer WL, Hofemeister J (1997) Genes encoding two different β-glucosidases of Thermoanaerobacter brockii are clustered in a common operon. Appl Environ Microbiol 63:3902–3910

Brumer 3rd H, Sims PF, Sinnott ML (1999) Lignocellulose degradation by Phanerochaete chrysosporium: purification and characterization of the main α-galactosidase. Biochem J 339:43–53

Camarero S, Galletti GC, Martinez AT (1994) Preferential degradation of phenolic lignin units by two white rot fungi. Appl Environ Microbiol 60:4509–4516

Camarero S, Galletti GC, Martínez AT (1997) Demonstration of in situ oxidative degradation of lignin side chains by two white-rot fungi using analytical pyrolysis of methylated wheat straw. Rapid Commun Mass Spectrom 11:331–334

Castanares A, Hay AJ, Gordon AH, McCrae SI, Wood TM (1995) D-Xylan-degrading enzyme system from the fungus Phanerochaete chrysosporium: isolation and partial characterisation of an α-(4-O-methyl)-d-glucuronidase. J Biotechnol 43:183–194

Charmont S, Jamet E, Pont-Lezica R, Canut H (2005) Proteomic analysis of secreted proteins from Arabidopsis thaliana seedlings: improved recovery following removal of phenolic compounds. Phytochemistry 66:453–461

Cullen D, Kersten PJ (2004) Enzymology and molecular biology of lignin degradation. In: Brambl R, Marzulf GA (eds) The mycota III. Biochemistry and molecular biology. Springer, Berlin, pp 249–273

da Silva Perez D, Moreau J, Nougier P, Themelin A, Chantre G (2004) Effect of storage conditions on the wood and pulp quality of windthrow trees. Proceedings of the 8th European Workshop on Lignocellulosics and Pulps, Latvian State Institute of Wood Chemistry, Riga, Latvia, August 22–25, 2004, pp 295–298

Dence CW (1992) The determination of lignin. In: Lin SY, Dence CW (eds) Methods in lignin chemistry. Springer, Berlin, pp 33–61

Dobozi MS, Szakacs G, Bruschi CV (1992) Xylanase activity of Phanerochaete chrysosporium. Appl Environ Microbiol 58:3466–3471

Gaskell J, Stewart P, Kersten PJ, Covert SF, Reiser J, Cullen D (1994) Establishment of genetic linkage by allele-specific polymerase chain reaction: application to the lignin peroxidase gene family of Phanerochaete chrysosporium. Biotechnology 12:1372–1375

Gharahdaghi F, Weinberg CR, Meagher DA, Imai BS, Mische SM (1999) Mass spectrometric identification of proteins from silver-stained polyacrylamide gel: a method for the removal of silver ions to enhance sensitivity. Electrophoresis 20:601–605

Gold MH, Alic M (1993) Molecular biology of the lignin-degrading basidiomycete Phanerochaete chrysosporium. Microbiol Rev 57:605–622

Henrissat B (1991) A classification of glycosyl hydrolases based on amino-acid sequence similarities. Biochem J 280:309–316

Herpoël I, Asther M, Sigoillot JC (1999) Design and scale up of a process for manganese peroxidase production using the hypersecretory strain Phanerochaete chrysosporium I-1512. Biotechnol Bioeng 65:468–473

Igarashi K, Tani T, Rie K, Masahiro S (2003) Family 3 β-glucosidase from cellulose-degrading culture of the white-rot fungus Phanerochaete chrysosporium is a glucan 1,3-β-glucosidase. J Biosci Bioeng 95:572–576

Ishida T, Yaoi K, Hiyoshi A, Igarashi K, Samejima M (2007) Substrate recognition by glycoside hydrolase family 74 xyloglucanase from the basidiomycete Phanerochaete chrysosporium. FEBS J 274:5727–5736

Itoh T, Hashimoto W, Mikami B, Murata K (2006) Substrate recognition by unsaturated glucuronyl hydrolase from Bacillus sp. GL1. Biochem Biophys Res Comm 344:253–262

Jorge JA, Polizeli ML, Thevelein JM, Terenzi HF (1997) Trehalases and trehalose hydrolysis in fungi. FEMS Microbiol Lett 154:165–171

Kang KY, Jo BM, Oh JS, Mansfield SD (2003) Biopulping of hybrid poplar improves chemical and energy savings during kraft pulping. Wood Fiber Sci 35:594–600

Kansoh AL, Nagieb ZA (2004) Xylanase and mannanase enzymes from Streptomyces galbus NR and their use in biobleaching of softwood kraft pulp. Antonie Van Leeuwenhoek 85:103–114

Kersten PJ (1990) Glyoxal oxidase of Phanerochaete chrysosporium: its characterization and activation by lignin peroxidase. Proc Natl Acad Sci U S A 87:2936–2940

Kersten PJ, Kirk TK (1987) Involvement of a new enzyme, glyoxal oxidase, in extracellular H2O2 production by Phanerochaete chrysosporium. J Bacteriol 169:2195–2201

Kersten P, Cullen D (2007) Extracellular oxidative systems of the lignin-degrading basidiomycete Phanerochaete chrysosporium. Fungal Genet Biol 44:77–87

Kirk TK, Cullen D (1998) Enzymology and molecular genetics of wood degradation by white-rot fungi. In: Young RA, Masood A (eds) Environmentally friendly technologies for the pulp and paper industry. Wiley, New York, pp 273–307

Lapierre C, Rolando C (1988) Thioacidolysis of pre-methylated lignin samples from pine compression and poplar woods. Holzforschung 42:1–4

Larrondo L, Vicuna R, Cullen D (2005) Phanerochaete chrysosporium genomics. In: Arora Berka DKR (ed) Applied mycology and biotechnology. Elsevier, Amsterdam, pp 315–352

Laugero C, Sigoillot JC, Moukha S, Frasse P, Bellon-Fontaine M-N, Bonnarme P, Mougin C, Asther M (1996) Selective hyperproduction of manganese peroxidases by Phanerochaete chrysosporium I-1512 immobilized on nylon net in a bubble column reactor. Appl Microbiol Biotechnol 44:717–723

Li B, Renganathan V (1998) Gene cloning and characterization of a novel cellulose-binding β-glucosidase from Phanerochaete chrysosporium. Appl Environ Microbiol 64:2748–2754

Mai V, Wiegel J, Lorenz WW (2000) Cloning, sequencing, and characterization of the bifunctional xylosidase-arabinosidase from the anaerobic thermophile Thermoanaerobacter ethanolicus. Gene 247:137–143

Maras M, Callewaert N, Piens K, Claeyssens M, Martinet W, Dewaele S, Contreras H, Dewerte I, Penttila M, Contreras R (2000) Molecular cloning and enzymatic characterization of a Trichoderma reesei 1,2-α-d-mannosidase. J Biotechnol 77:255–263

Martinez D, Larrondo LF, Putnam N, Gelpke MD, Huang K, Chapman J, Helfenbein KG, Ramaiya P, Detter JC, Larimer F, Coutinho PM, Henrissat B, Berka R, Cullen D, Rokhsar D (2004) Genome sequence of the lignocellulose degrading fungus Phanerochaete chrysosporium strain RP78. Nat Biotechnol 22:695–700

Maruyama Y, Nakajima T, Ichishima E (1994) A 1,2-α-d-mannosidase from a Bacillus sp.: purification, characterization, and mode of action. Carbohydr Res 251:89–98

Muñoz IG, Ubhayasekera W, Henriksson H, Szabó I, Pettersson G, Johansson G, Mowbray SL, Ståhlberg J (2001) Family 7 cellobiohydrolases from Phanerochaete chrysosporium: crystal structure of the catalytic module of Cel7D (CBH58) at 1.32 Å resolution and homology models of the isozymes. J Mol Biol 314:1097–1111

Myette JR, Shriver Z, Kiziltepe T, McLean MW, Venkataraman G, Sasisekharan R (2002) Molecular cloning of the heparin/heparan sulfate delta 4,5 unsaturated glycuronidase from Flavobacterium heparinum, its recombinant expression in Escherichia coli, and biochemical determination of its unique substrate specificity. Biochemistry 41:7424–7434

Nankai H, Hashimoto W, Miki H, Kawai S, Murata K (1999) Microbial system for polysaccharide depolymerization: enzymatic route for xanthan depolymerization by Bacillus sp. strain GL1. Appl Environ Microbiol 65:2520–2526

Parrou JL, Jules M, Beltran G, François J (2005) Acid trehalase in yeasts and filamentous fungi: localization, regulation and physiological function. FEMS Yeast Res 5:503–511

Paszczynski A, Huynh VB, Crawford R (1986) Comparison of ligninase-I and peroxidase-M2 from the white-rot fungus Phanerochaete chrysosporium. Arch Biochem Biophys 244:750–765

Puchart V, Katapodis P, Biely P, Kremnicky L, Christakopoulos P, Vrsanska M, Kekos D, Macris BJ, Bhat MK (1999) Production of xylanases, mannanases, and pectinases by the thermophilic fungus Thermomyces lanuginosus. Enzyme Microb Technol 24:355–361

Rabilloud T, Carpentier G, Tarroux P (1988) Improvement and simplification of low-background silver staining of proteins by using sodium dithionite. Electrophoresis 9:288–291

Reid ID (1998) Fate of residual lignin during delignification of kraft pulp by Trametes versicolor. Appl Environ Microbiol 64:2117–2125

Sachslehner A, Nidetzky B, Kulbe KD, Haltrich D (1998) Induction of mannanase, xylanase, and endoglucanase activities in Sclerotium rolfsii. Appl Environ Microbiol 64:594–600

Saha BC (2003) Hemicellulose bioconversion. J Ind Microbiol Biotechnol 30:279–291

Sato S, Liu F, Koc H, Tien M (2007) Expression analysis of extracellular proteins from Phanerochaete chrysosporium grown on different liquid and solid substrates. Microbiology 153:3023–3033

Shevchenko A, Wilm M, Vorm O, Mann M (1996) Mass spectrometry sequencing of proteins from silver-stained polyacrylamide gels. Anal Chem 68:850–858

Stals I, Sandra K, Geysens S, Contreras R, Van Beeumen J, Claeyssens M (2004) Factors influencing glycosylation of Trichoderma reesei cellulases. I: Post-secretorial changes of the O- and N-glycosylation pattern of Cel7A. Glycobiology 14:713–724

Stewart P, Cullen D (1999) Organization and differential regulation of a cluster of lignin peroxidase genes of Phanerochaete chrysosporium. J Bacteriol 181:3427–3432

Toshiaki U, Higuchi T (1989) Cleavages of aromatic ring and β-O-4 bond of synthetic lignin (DHP) by lignin peroxidase. FEBS Lett 242:325–329

Uzcategui E, Ruiz A, Montesino R, Johansson G, Pettersson G (1991) The 1,4-β-d-glucan cellobiohydrolases from Phanerochaete chrysosporium. I. A system of synergistically acting enzymes homologous to Trichoderma reesei. J Biotechnol 19:271–285

Vanden Wymelenberg A, Covert S, Cullen D (1993) Identification of the gene encoding the major cellobiohydrolase of the white rot fungus Phanerochaete chrysosporium. Appl Environ Microbiol 59:3492–3494

Vanden Wymelenberg A, Sabat, G, Martinez, D, Rajangam AS, Teeri TT, Gaskell J, Kersten PJ, Cullen D (2005) The Phanerochaete chrysosporium secretome: database predictions and initial mass spectrometry peptide identifications in cellulose-grown medium. J Biotechnol 118:17–34

Vanden Wymelenberg A, Minges P, Sabat G, Martinez D, Aerts A, Salamov A, Grigoriev I, Shapiro H, Putnam N, Belinky P, Dosoretz C, Gaskell J, Kersten P, Cullen D (2006a) Computational analysis of the Phanerochaete chrysosporium v2.0 genome database and mass spectrometry identification of peptides in ligninolytic cultures reveal complex mixtures of secreted proteins. Fungal Genet Biol 43:343–356

Vanden Wymelenberg A, Sabat G, Mozuch M, Kersten PJ, Cullen D, Blanchette RA (2006b) Structure, organization, and transcriptional regulation of a family of copper radical oxidase genes in the lignin-degrading basidiomycete Phanerochaete chrysosporium. Appl Environ Microbiol 72:4871–4877

Wattenberg A, Organ AJ, Schneider K, Tyldesley R, Bordoli R, Bateman RH (2002) Sequence dependent fragmentation of peptides generated by MALDI quadrupole time-of-flight (MALDI Q-TOF) mass spectrometry and its implications for protein identification. J Am Soc Mass Spectrom 13:772–783

Yoshida T, Inoue T, Ichishima E (1993) 1,2-α-d-Mannosidase from Penicillium citrinum: molecular and enzymic properties of two isoenzymes. Biochem J 290:349–354

Acknowledgment

This work was supported by the French National Research Agency Program PNRB as part of the Stratégie de Prétraitements Physiques, Enzymatiques et Chimiques Appliquées à la Biomasse-Bio-Ethanol (SPECABBE) project. The authors thank F. Legée and L. Cézard for the lignin analyses.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ravalason, H., Jan, G., Mollé, D. et al. Secretome analysis of Phanerochaete chrysosporium strain CIRM-BRFM41 grown on softwood. Appl Microbiol Biotechnol 80, 719–733 (2008). https://doi.org/10.1007/s00253-008-1596-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-008-1596-x