Abstract

Microbial colonization of petroleum industry systems takes place through the formation of biofilms, and can result in biodeterioration of the metal surfaces. In a previous study, two oil reservoir Bacillus strains (Bacillus licheniformis T6-5 and Bacillus firmus H2O-1) were shown to produce antimicrobial substances (AMS) active against different Bacillus strains and a consortium of sulfate-reducing bacteria (SRB) on solid medium. However, neither their ability to form biofilms nor the effect of the AMS on biofilm formation was adequately addressed. Therefore, here, we report that three Bacillus strains (Bacillus pumilus LF4—used as an indicator strain, B. licheniformis T6-5, and B. firmus H2O-1), and an oil reservoir SRB consortium (T6lab) were grown as biofilms on glass surfaces. The AMS produced by strains T6-5 and H2O-1 prevented the formation of B. pumilus LF4 biofilm and also eliminated pre-established LF4 biofilm. In addition, the presence of AMS produced by H2O-1 reduced the viability and attachment of the SRB consortium biofilm by an order of magnitude. Our results suggest that the AMS produced by Bacillus strains T6-5 and H2O-1 may have a potential for pipeline-cleaning technologies to inhibit biofilm formation and consequently reduce biocorrosion.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biofilms are cells attached to a surface and encased in an exopolysaccharide matrix forming a structured community (Hamon and Lazazzera 2001). Most bacteria can attach to surfaces efficiently when they are viable and in a metabolically active state (Jayaraman et al. 1997). A variety of Bacillus species have been shown to form biofilms on metal surfaces and produce elaborate multicellular communities that display conspicuous architectural features, such as fruiting-body-like aerial projections that extend from the biofilm surface (Branda et al. 2004). The top or base of the biofilm has the highest cell density, and water channels often exist for the transport of nutrients and waste (Ren et al. 2002). In addition, some Bacillus species produce highly hydrophobic spores that adhere firmly to various inert substrata. Once this first step of adhesion has been completed, colonization may occur when environmental conditions become favorable to spore germination (Branda et al. 2004; Faille et al. 2001). In the petroleum industry, biofilm formation is usually accompanied by deterioration of metal surfaces of process equipment and pipelines. This biological deposit can drastically modify the corrosion behavior of structural metals and allows enhanced localized alterations in the type and concentrations of specific ions, pH, and oxygen levels (Almeida and de França 1998; Videla 2002). Jack et al. (1992) demonstrated a significant increase in corrosion rates of carbon steel in a continuously flowing freshwater reactor where a biofilm of Bacillus and sulfate-reducing bacteria (SRB) was observed. SRB have been extensively implicated in biocorrosion processes, primarily because of hydrogen sulfide generation. Furthermore, the presence of SRB can result in health and safety risks to workers (Gardner and Stewart 2002).

The nature of the biofilm structure and its formation result in a significant resistance to cleaning of industrial surfaces. Conventional methods of biofilm control and removal are generally inadequate against biofilm-forming bacteria in these industrial settings. The exopolysaccharide matrix secreted by the cells is considered to reduce the effectiveness of biocides by decreasing biocide penetration into the biofilm, and by providing alternative non-lethal biocide reaction sites. Attempts to circumvent this problem have focused on using very high concentrations of biocides which may in turn cause secondary environmental hazards (Jayaraman et al. 1999). Antimicrobial agents may also achieve effectiveness in an indirect way, by stopping growth and allowing natural detachment process to remove the biofilm (Chen and Stewart 2000).

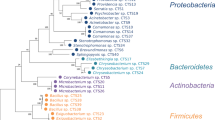

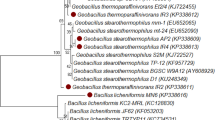

In a previous study (Korenblum et al. 2005), three strains isolated from a Brazilian oil reservoir, Bacillus subtilis (LFE-1), Bacillus firmus (H2O-1), and Bacillus licheniformis (T6-5), were shown to produce antimicrobial substances (AMS). These AMS inhibited the growth of different Bacillus strains, including Bacillus pumilus strain LF4, which was chosen as the indicator strain for the inhibitory tests. Two of these strains (T6-5 and H2O-1) also inhibited an SRB consortium (named T6lab, isolated from the same Brazilian oil reservoir) in agar-containing medium. These AMS showed to be stable in a wide range of temperature and pH. The AMS produced by strains H2O-1 was resistant to high temperatures (100°C for 1 h) while the AMS produced by T6-5 remained active even after being autoclaved. Furthermore, both AMS were stable in acid and alkaline pH (3.5–9.5). AMS produced by B. licheniformis T6-5 was detected on the second day of growth, when the number of spores had increased. The production of AMS by B. firmus H2O-1 was detected during the first day and was stable throughout the rest of the growth cycle. This antimicrobial activity seems to be induced under nonsporulating conditions as a secondary metabolite. Commercial proteolytic enzymes tested were not able to modify the antimicrobial activity presenting in the culture supernatants of the two producer strains. According to the SDS-PAGE analysis, the T6-5 AMS showed an inhibitory zone related to a region of ca. 20 kDa. However, H2O-1 AMS inhibitory zones were related to a region of high molecular mass (90–120 kDa). Nevertheless, in those studies, experiments focused on biofilm formation were not performed. Therefore, in the present study, we report on biofilm formation by the different strains studied and on the inhibitory effect of AMS produced by strains T6-5 and H2O-1 against biofilms of B. pumilus strain LF4 and T6lab SRB consortium. The use of indigenous bacteria for combating undesirable bacterial colonization in oil production facilities is an important step in the control of unwanted biofilm formation in process equipment.

Materials and methods

Bacterial strains and growth conditions

Bacillus licheniformis strain T6-5, B. firmus strain H2O-1 and B. pumilus strain LF4 were originally isolated from an oil reservoir in Brazil and are described in detail elsewhere (Korenblum et al. 2005). These strains were grown at 30°C for 18 h in Luria–Bertani broth (LB) containing 10 g tryptone, 5 g yeast extract, 5 g NaCl per liter of distilled water, pH 7.0–7.2. The T6lab SRB consortium, also obtained from the same oil reservoir in Brazil (Korenblum et al. 2005), was grown at 30°C in VM medium I (Zinkevich and Beech 2000) purged with a N2 flux to achieve anaerobiosis. Cultures were maintained in long-term storage by freezing at −20°C.

Preparation of Bacillus biofilms

Biofilms of Bacillus strains (LF4, T6-5 and H2O-1) were prepared by inoculating circular glass cover slides with a mid-log phase culture (106 cells/ml) grown in LB medium. Before each experiment, the surface of the glass cover slides (13 mm diameter and 1.2 mm thick) was treated with a cleaning solution (40 g potassium dichromate, 400 ml distilled water, 40 ml sulfuric acid), rinsed thoroughly with distilled water and with 70% ethanol in water, rinsed again with distilled water, and autoclaved before use. The device for biofilm formation was a 24-well-plate with a glass cover slide in each well. Two milliliters of the cell suspension was added to each well, covering the glass surfaces, and were incubated at 30°C for 24 h. Three glass slides were removed every 2 h (up to 12 h) and one last sampling was analyzed at 24 h. The glass slides were rinsed three times with PBS (phosphate buffer saline) before biofilm cells enumeration.

Enumeration of attached Bacillus cells

Biofilm cells were enumerated (30 fields) using DAPI 0.1 mg/ml (4′,6-diamidino-2-phenylindole) or acridine orange 30 mg/ml for direct counts in a fluorescence microscope (Zeiss Axioplan 2).

Treatment of LF4 biofilm with the antimicrobial substances (AMS) produced by B. licheniformis T6-5 and B. firmus H2O-1

Two different approaches were used to test the efficacy of the AMS produced by B. licheniformis T6-5 and B. firmus H2O-1. The first approach analyzed the effect of the AMS on biofilm formation. For this purpose, the AMS produced by strains T6-5 and H2O-1 were added separately (2 ml) in a 24-well-plate containing one glass cover slide per well. The production of AMS was carried out as described by Korenblum et al. (2005). The LB medium was used to grow the producer strains for 96 h. After incubation of the two producer strains, each culture was then centrifuged (12,000 g, 20 min) and the supernatants (crude preparations) filtered in 0.45 μm pore filters (Millipore, São Paulo, Brazil). The filtrates were lyophilized and resuspended (to a 10-fold concentration) in LB. Activity was determined by the highest dilution giving a halo. Arbitrary units (AU) per milliliter were defined as the reciprocal of the greatest dilution of the supernatant that showed a zone of inhibition ×1,000, divided by the volume of supernatant applied on the spot. The AMS were added in each well at ca. 3,000 AU/ml. A mid-log phase culture of strain LF4 was also inoculated (106 cells/ml) in the 24-well-plates containing one glass cover slide per well and adherence was observed every 2 h up to 12 h of incubation. The sampling and enumeration were performed as described above.

The second approach aimed to evaluate the sensitivity of a pre-established LF4 biofilm to each AMS. Biofilms of LF4 were grown on the glass cover slides, and after 6 h of incubation the LB medium was removed and fresh LB was added to the wells together with the AMS produced by the strains T6-5 and H2O-1. Two controls were performed in parallel: (a) the LB medium was not removed and no AMS was added and (b) fresh LB without AMS was added to the wells. Following 18-h incubation period in the presence of AMS, three cover slides were sampled every 2 h. Again, the slides were washed three times in sterile PBS, and cells were enumerated as described above. These slides were also analyzed by scanning electron microscopy (SEM). The slides were rinsed with sterile distilled water and fixed with 2.5% glutaraldehyde (w/v) in 0.1 M cacodylate buffer (pH 7.6) for 2 h. The slides were rinsed three times with the buffer, dehydrated in an acetone series (35–100%, seven steps, 10 min each), critical point dried and gold coated. The slides were examined with a scanning electron microscope (DSM-940, Zeiss).

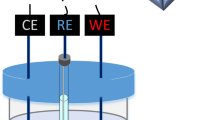

Preparation of SRB biofilm

SRB biofilm was grown on borosilicate glass coupons (12.7 mm diameter and 1.5 mm thick—BioSurface Technologies Corporation, Bozeman, MT), which were soaked in 70% ethanol for 30 min, rinsed with distilled water and autoclaved before use. The coupons were fitted into a continuous flow bioreactor (BioSurface Technologies Corporation, Bozeman, MT) which was used to grow the T6lab SRB consortium, forming an anaerobic biofilm. Twenty four borosilicate glass coupons were inserted into the reactor and the entire system was autoclaved before use. The sterile VM medium I (Zinkevich and Beech 2000; 400 ml) introduced into the reactor was purged for 3 h with filtered (0.2 μm) ultra-pure N2 to achieve anaerobiosis. A mid-log phase planktonic culture of T6lab SRB consortium was used to inoculate the biofilm reactor. This system was incubated in batch mode for 20 h at 30°C, at which time continuous flow was initiated (1 ml/min) and SRB biofilms were grown for 4 days. A continuous sterile ultra-pure N2 purge was carried out at a flow rate of 200 ml/h. Coupons were removed aseptically from the reactor in an anaerobic chamber and placed inside a 24-well-plate for subsequent testing, staining, and bacterial counting. The surface of the coupon was aseptically scraped with a sterile spatula and the material suspended in 10 ml of sterile PBS solution flushed with N2. The cell number in the suspension was determined by most probable number (MPN; Hamilton 1985).

Treatment of the SRB biofilm with the antimicrobial substance produced by H2O-1

To observe the effect of AMS produced by strain H2O-1 against a pre-established SRB biofilm, borosilicate glass coupons were subjected to this AMS using a 24-well-plate for 24 h at room temperature inside the anaerobic chamber. Negative controls did not contain AMS. After 24 h, the AMS was removed by pipetting it out from the wells and the coupons were washed three times with sterile PBS solution flushed with N2, before staining and bacterial counts were performed.

Confocal scanning laser microscopy

T6lab SRB consortium biofilms treated with AMS H2O-1 and the control coupons were stained with a Live/Dead BacLight fluorescence kit (L-7007; Molecular Probes, Eugene, OR, USA) for 30 min in the anaerobic chamber, washed three times with distilled water, and flushed with N2. Stained biofilms were observed with a confocal scanning laser microscope (Leica DMRXE, Leica Microsystems. Wetzlar GmbH, Germany) equipped with a 63× water immersion objective lens. A 488-nm argon laser and a 561-nm krypton laser were used to collect the fluorescent microbial image.

Statistical analysis

All studies on biofilm formation were performed in triplicate. Total counts obtained by cell epifluorescent microscopy were averages of 30 counts. Results were expressed as mean values and the standard deviation was given as required.

Results

Biofilm formation by Bacillus strains

The three strains tested (Bacillus licheniformis T6-5, B. firmus H2O-1 and B. pumilus LF4) adhered to the glass cover slides and formed biofilms. As shown in Fig. 1, after 5 to 6 h of incubation, all three strains reached the maximum adhesion concentration (ca. 105 cells/mm2). The surface concentration of adhered cells at 6 h of biofilm formation was approximately two orders of magnitude higher than the number of cells attached at the first time point analyzed, indicating that this increase in the number of attached cells might be a result of the division of the adhered cells and primarily a consequence of attachment of planktonic cells. No additional increase in the number of sessile cells was observed at later time points. A severe decrease in the number of attached H2O-1 cells (less than ten attached cells/mm2) was observed after 8 h of incubation. The other two strains showed about 104 attached cells/mm2 after 24 h, when they have already reached the stationary phase.

Biofilm formation by Bacillus strains. Cell concentration of different Bacillus strains in the single-species biofilm formed on the glass cover slide over time: LF4 (filled diamond), H2O-1 (filled square) and T6-5 (empty upright triangle). Each data point is an average of the result obtained in three glass cover slides, and error bars indicate the standard error

Inhibitory activity of the AMS produced by strains T6-5 and H2O-1 against biofilm formation

Without the addition of AMS, strain LF4 remained adhered to the glass cover slides during the 24 h of the experiment. On the other hand, when either the AMS T6-5 or AMS H2O-1 was introduced to the wells, the initial attached LF4 cell number decreased immediately (Fig. 2). However, the effect of the two AMS on the LF4 attachment profile varied considerably (Fig. 2). The AMS H2O-1 appeared to act more quickly than AMS T6-5. Nevertheless, after 12 h of incubation, no adhered cells were observed after the treatment with either AMS (Fig. 2).

Inhibitory activity of the AMS produced by strains T6-5 and H2O-1 against biofilm formation. Cell concentration of Bacillus strain LF4 in the biofilms formed on the glass cover slides over time. LB broth (control without AMS, filled diamond), LB broth with AMS T6-5 (filled square) and LB broth with AMS H2O-1 (empty upright triangle). Each data point is an average of the result obtained in three glass cover slides, and error bars indicate the standard error

Removal of the pre-established LF4 biofilm

To test the efficacy of AMS against a pre-established biofilm, B. pumilus LF4 was grown for 6 h on glass cover slides. After this growth period, fresh LB broth was added with and without AMS. As shown in Fig. 3, both AMS substances were very effective at removing LF4 biofilm. A 98.2% reduction in the biofilm cell counts was observed after the first 2 h of contact with both AMS. Thereafter, the pre-established biofilms were completely removed. From the fourth hour to the end of the experiment, no attached cells were observed when LF4 was treated with H2O-1 AMS; however, with T6-5 AMS cells appeared to attach and detach during the first 12 h of the experiment. After 12 h, no cells were observed to attach (Fig. 3).

Removal of the pre-established LF4 biofilm. Cell concentration of Bacillus strain LF4 in the biofilms formed on the glass cover slides over time. LB broth (control, filled diamond), fresh LB broth (control without AMS, filled square), fresh LB broth with AMS H2O-1 (filled circle) and fresh LB broth with AMS T6-5 (filled upright triangle). Each data point is an average of the result obtained in three glass cover slides, and error bars indicate the standard error

The biofilms used as controls were incubated without AMS. The control, where fresh LB was added, not only did the cells stay attached, but they showed approximately 1 log increase in the number of attached cells (Fig. 3). This result was confirmed by observation using scanning electron microscopy. Figure 4a shows a 6 h-LF4 biofilm with the addition of fresh LB medium. Besides this control, another control was done without adding new medium (Fig. 4b), which shows many cells with an empty cytoplasm, possibly lysed from the scarcity of nutrients, since the medium was not renewed. In Fig. 4c, the spent LB medium was exchanged for fresh LB after 6 h of biofilm growth. The cells appeared to remain intact and formed a developed biofilm. Filamentous structures could be observed connecting the cells forming a multilayer cell complex, suggesting the presence of extracellular polymeric substance. In this condition, the fresh LB-enhanced cell viability and the maintenance of the biofilm structure. However, when AMS was added, as shown in Fig. 4d, no cells were observed on the glass surface after 18 h of contact with the pre-established biofilm.

Inhibitory activity of the AMS produced by strain H2O-1 against T6lab SRB biofilm formation

The capability of T6lab SRB cells to adhere to borosilicate coupons was tested in a continuous flow system. Scanning confocal laser images of biofilms stained with Live/Dead Baclight (Fig. 5a) show that the maximum biofilm thickness observed in the SRB culture was 240 μm above the glass surface. With the highest fluorescence intensity at a biofilm depth of approximately 100 μm, it can be seen, in Fig. 5a, that the SRB consortium maintained a higher cell density away from the glass surface, above a dispersed base of underlying cells. The biofilm covered the surface fairly homogenously; green cells were dominant, indicating cell viability. However, reddish dead cells were also present as clusters. The maximum fluorescence intensity of the red clusters was three times lower than the green stained cells. The MPN technique showed that the scraped biofilm reached ca. 2.4 × 107 culturable cells/mm2.

Confocal scanning laser microscopic analysis. Graphs of threshold area versus depth in an SRB consortium biofilm a untreated and b treated with AMS H2O-1. Depicted in the lower right corner of each graph, maximum intensity projection images (all confocal sections in a single field of view) of x–y optical sections of SRB biofilms a untreated and b treated with AMS H2O-1. Scale bar 30 μm

Using confocal scanning laser microscopy, it was observed that the pre-established SRB biofilm was drastically reduced using the H2O-1 AMS. Figure 5b shows that total (red and green) fluorescence intensity decreased approximately 94% compared with the non-treated biofilm (Fig. 5a), indicating that cellular vitality and cell number were significantly reduced. Both greenish and reddish cells were present as clusters in the treated biofilm. Although the reduction in fluorescence intensity was observed, it cannot be correlated with the removal of the polysaccharide matrix from the borosilicate coupon, since the treated biofilm thickness did not change when compared to the control biofilm.

Discussion

Different studies have already shown that Bacillus strains are capable of forming biofilms on glass surfaces and can produce antimicrobial compounds (Hamon and Lazazzera 2001; Kearns et al. 2004; Korenblum et al. 2005; Li and Logan 2004). The data obtained here showing that Bacillus licheniformis T6-5, B. firmus H2O-1, and B. pumilus LF4 can form biofilms corroborate with those observations. Bacillus strains are found in great number in a variety of biofilms where these strains survive desiccation or other environmental stresses, while there are sufficient nutrients present to support metabolic activity (Hamon and Lazazzera 2001; Kearns et al. 2004; Li and Logan 2004). One can speculate that AMS-producing Bacillus strains are more competitive than non-producing strains within a biofilm.

A number of methods have been proposed for controlling biofilm formation in different oil production facilities, including the use of biocides as glutaraldehyde, anthraquinone, and tetrakishydroxymethylphosphonium sulfate (THPS; Cooling et al. 1996; Gardner and Stewart 2002). However, over time the efficacy of these biocides may be questionable as cases of microbial resistance have already been reported (Gardner and Stewart 2002), and also they may be a risk to human health and the environment. In the oil industry, as different AMS-producing Bacillus species are discovered and characterized, these biocide alternatives can be integrated into treatment strategies to prevent colonization of disadvantageous bacteria and subsequent biofilm formation. These cleaning strategies may eliminate the need for high biocide doses in favor of biosynthetic alternatives.

In the search for inhibitory substances, many authors have worked with wild or genetically modified strains, aiming at producing compounds effective against biofilm formation and biocorrosion (Jayaraman et al. 1999; Örnek et al. 2002; Zuo and Wood 2004). Ren et al. (2002) have previously shown the inhibition of planktonic growth of a Bacillus strain by 40 μg/ml furanone. However, they did not succeed in completely preventing biofilm formation on metal surface. Therefore, new AMS producer strains are still required for application in different environments, such as a petroleum reservoir. In this study, the effectiveness of the AMS produced either by B. lichenifornis T6-5 or B. firmus H2O-1 was demonstrated by the inhibition of biofilm formation and by the removal of the pre-established 6-h biofilm formed by the strain LF4 on glass surface. This surface was chosen to avoid the formation of corrosion products that might interfere in microscopic visualization. Li and Logan (2004) have already compared different surfaces (glass and metallic surfaces) and observed that there was no significant (P = 0.26) effect of surface roughness on bacterial adhesion.

Industrial cleaning procedures should take into account the remaining cell debris after biofilm removal, as a remaining biofilm may facilitate subsequent attachment of unwanted microorganisms. The final outcome of a biofilm removal procedure should be assessed by the number of cells remaining viable after a treatment and by assaying cell residue on the cleaned surface (Parkar et al. 2004). Gardner and Stewart (2002) showed that glutaraldehyde, a commercial biocide commonly used by petroleum industries, suppressed the activity of SRB at a concentration of 100 mg/l. However, they also showed that the biofilm thickness did not change significantly, indicating incomplete biofilm removal. Besides that, corrosion may be greater than before due to remaining cells and residues. Fang et al. (2002) also demonstrated that the degree of corrosion increased significantly when SRB biofilms were exposed to toxic metals and chemicals, since treatment did not inhibit biofilm growth on the test coupons. In the present study, crude extracts of the two AMS tested were shown to be efficient for inhibiting and completely removing a B. pumilus strain LF4 biofilm. The H2O-1 AMS also significantly reduced the SRB biofilm (Fig. 5), but did not completely remove all cell matter. A longer treatment time or a more purified AMS may be required for achieving complete removal of an existing SRB biofilm.

Finally, the present study demonstrated the ability of AMS produced by B. firmus H2O-1 and B. licheniformis T6-5 strains to prevent colonization, remove existing biofilms, and impact biofilm structure. These results suggest that the AMS studied here may have applications in preventing biofilm formation and then we contemplate potential efficacy in reducing biocorrosion.

References

Almeida MAN, de França FP (1998) Biofilm formation on brass coupons exposed to a cooling system of an oil refinery. J Int Microbiol Biotechnol 20:39–44

Branda SS, González-Pastor JE, Dervyn E, Ehrlich D, Losick R, Kolter R (2004) Genes involved in formation of structured multicellular communities by Bacillus subtilis. J Bacteriol 186:3970–3979

Chen X, Stewart PS (2000) Biofilm removal caused by chemical treatments. Water Res 34:4229–4233

Cooling FB, Maloney CL, Negel E, Tabinowski J, Odom JM (1996) Inhibition of sulfate respiration by 1,8-dihydroxyanthraquinone and other anthraquinone derivatives. Appl Environ Microbiol 62:2999–3004

Faille C, Fontaine F, Benezech TJ (2001) Potential occurrence of adhering living Bacillus spores in milk product processing lines. Appl Microbiol 90:892–900

Fang HHP, Xu L-C, Chan K-Y (2002) Effects of toxic metals and chemicals on biofilm and biocorrosion. Water Res 36:4709–4716

Gardner LR, Stewart PS (2002) Action of glutaraldehyde and nitrite against sulfate-reducing bacterial biofilms. J Ind Microbiol Biotechnol 29:354–360

Hamilton WA (1985) Sulphate-reducing bacteria and anaerobic corrosion. Ann Rev Microbiol 39:195–217

Hamon MA, Lazazzera BA (2001) The sporulation transcription factor Spo0A is required for biofilm development in Bacillus subtilis. Mol Microbiol 42:1199–1209

Jack RF, Ringelberg DB, White DC (1992) Differential corrosion rates of carbon steel by combinations of Bacillus sp., Hafnia alvei and Desulfovibrio gigas established by phospholipid analysis of electrode biofilm. Corr Sci 33:1843–1853

Jayaraman A, Earthman JC, Wood TK (1997) Corrosion inhibition by aerobic biofilms on SAE 1018 steel. Appl Microbiol Biotechnol 52:267–275

Jayaraman A, Mansfeld FB, Wood TK (1999) Inhibiting sulfate-reducing bacteria in biofilms by expressing the antimicrobial peptides indolicidin and bactenecin. J Int Microbiol Biotechnol 22:167–175

Kearns DB, Chu F, Branda RK, Losick R (2004) A master regulator for biofilm formation by Bacillus subtilis. Mol Microbiol 55:739–749

Korenblum E, von der Weid I, Santos ALS, Rosado AS, Sabastián GV, Coutinho CMLM, Magalhães FCM, Paiva MM, Seldin L (2005) Production of antimicrobial substances by Bacillus subtilis LFE-1, B. firmus H2O-1 and B. licheniformis T6-5 isolated from an oil reservoir in Brazil. J Appl Microbiol 98:667–675

Li B, Logan BE (2004) Bacterial adhesion to glass and metal-oxide surfaces. Colloid Surf 36:81–90

Örnek D, Jayaraman A, Syrett BC, Hsu CH, Mansfeld FB, Wood K (2002) Pitting corrosion inhibition of aluminum 2024 by Bacillus biofilmes secreting polyaspartate or g-polyglutamate. Appl Microbiol Biotechnol 58:651–657

Parkar SG, Flint SH, Brooks JD (2004) Evaluation of the effect of cleaning regimes on biofilms of thermophilic bacilli on stainless steel. J Appl Microbiol 96:110–116

Ren D, Sims JJ, Wood TK (2002) Inhibition of biofilm formation and swarming of Bacillus subtilis by (5Z)-4-bromo-5-(bromomethylene)-3-butyl-2(5H)-furanone. Lett Appl Microbiol 34:293–299

Videla HA (2002) Prevention and control of biocorrosion. Int Biodeterior Biodegrad 49:259–270

Zinkevich VV, Beech IB (2000) Screening of sulfate-reducing bacteria in colonoscopy samples from healthy and colitic human gut mucosa. FEMS Microbiol Ecol 34:147–155

Zuo R, Wood TK (2004) Inhibiting mild steel corrosion from sulfate-reducing and iron-oxidizing bacteria using gramicidin-S-producing biofilmes. Appl Microbiol Biotechnol 65:747–753

Acknowledgements

This work was supported by the National Research Council of Brazil (CNPq) and PETROBRAS. E. Korenblum greatly appreciates the American Society for Microbiology for the Fellowship for Latin America.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Korenblum, E., Sebastián, G.V., Paiva, M.M. et al. Action of antimicrobial substances produced by different oil reservoir Bacillus strains against biofilm formation. Appl Microbiol Biotechnol 79, 97–103 (2008). https://doi.org/10.1007/s00253-008-1401-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-008-1401-x