Abstract

In the present paper, the degradation of phenanthrene, a model polycyclic aromatic hydrocarbon compound, by the Mycobacterium strain 6PY1 was optimized in a biphasic culture medium. The optimization and modeling were performed using the design of experiments methodology. The temperature, the silicone oil/mineral salts medium volume ratio, and the initial cell concentration, were used as the central composite design parameters. In all experiments, the phenanthrene was degraded to undetectable levels. Response surface methodology was successfully employed to derive an empirical model describing the rate and time of degradation and to deduce the optimal degradation conditions. As a result of the optimization processes, the optimal responses for the degradation rate, the volumetric degradation rate, and the 90% degradation time were estimated to be 0.172 mg h−1, 22 mg l−1 h−1, and 18 h, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polycyclic aromatic hydrocarbons (PAHs) are environmentally ubiquitous and recalcitrant organic contaminants produced naturally or as a result of incomplete combustion of organic materials. The persistence of PAHs is an environmental concern and has attracted much attention because many of these compounds have been reported to be carcinogenic and mutagenic (Cerniglia 1992; Cerniglia 1993). Many approaches have been proposed to destroy or render this type of contaminant, such as landfilling, solvent extraction, high-temperature incineration, and various types of chemical decomposition (Jonker and Koelmans 2002; Ledakowicz et al. 1999; Yip et al. 2006). However, bioremediation has been considered as a promising potential option for PAH elimination in comparison to the previously conventional practices. As such, it uses relatively low-cost, low-technology techniques, which generally have a high public acceptance and can often be carried out on-site (Vidali 2001). In this context, many review articles have described the ability of numerous soil microorganisms to biotransform and mineralize PAHs (Prabhu and Phale 2003; Kim et al. 2005). Among them, mycobacteria oxidize the greatest variety of PAHs (Boldrin et al. 1993; Miyata et al. 2004; Churchill et al. 1999; Cerniglia 2003; Guerin and Jones 1988). Improving this microbial-based technique consists mainly of exploring the influential process factors (Wong et al. 2002; Zaidi and Imam 1999; Kastner et al. 1998; Mac-Leod and Daugulis 2005). One of the key factors recently investigated was the use of a non-aqueous-phase liquid (NAPL), which was considered promising because it overcomes the low solubility of PAHs and, hence, enhances their bioavailability (Ascon-Cabrera and Lebeault 1993). However, very little work has been performed to integrate the process factors in an optimization study of PAH degradation (Martin and Sivagurunathan 2003).

The aim of the present work was to model and optimize the degradation of phenanthrene, a model PAH compound, by a Mycobacterium strain (6PY1) in agitated biphasic cultures. The impacts of different parameters were explored via response-surface methodology (RSM). The factors investigated were the incubation temperature, the NAPL (silicone oil) to mineral salts medium (MSM) dispersed volume ratio, and the initial cell concentration. The optimization responses selected were the degradation rate (mg h−1), the volumetric degradation rate (mg l−1 h−1), and the time required for 90% of degradation. Elucidation of the optimal phenanthrene degradation conditions will provide information for future scaling-up projects.

Materials and methods

Chemicals

Phenanthrene (98% purity) was purchased from Sigma-Aldrich-Chemie, Lyon, France. Acetonitrile (99.5%) was purchased from Acros Organics, Noisy le Grand, France. Silicon oil 47V20 with a density of 0.95 was obtained from Chemie-Plus, France. Aquasil was purchased from Pierce, PER-BIO, Brebières, France. All other chemicals were commercial products of the highest purity available.

Bacterial strain and culture conditions

Mycobacterium strain 6PY1, which has previously been described (Krivobok et al. 2003), was isolated from PAH-contaminated soil by successive cultures, with pyrene as the sole source of carbon. Initially, successive precultures were grown in 100-ml sterile plastic pots (diameter: 4.5 cm, depth: 7.5 cm) pretreated with Aquasil and containing 50 ml MSM and 12 ml silicone oil. The organic phase was the phenanthrene-containing medium, where it was dissolved by heating at a concentration of 0.5 g l−1. The MSM was used as the aqueous phase and contained, per liter, 1.6 g K2HPO4, 0.4 g KH2PO4, 1 g KNO3, 0.2 g MgSO4.7H2O, 0.1 g CaCl2.2H2O, 0.1 g NaCl, 0.01 g FeCl3.6H2O, and 0.02 g yeast extract; the pH was adjusted to 7.1 (Walter et al. 1991). The precultures were incubated in the dark at 30 °C in a rotary shaker (Bottimengen TR-150, Infors) at 150 rpm. Once a phenanthrene-adapted preculture was obtained, it was used to inoculate the cultures of the central composite design (CCD).

Phenanthrene extraction analytical procedure

Silicone oil samples were periodically withdrawn under sterile conditions and then centrifuged at 12,000×g for 5 min to separate the emulsified liquid phases. One hundred microliters of the upper layer was extracted with 1 ml acetonitrile by shaking for 120 s, utilizing a vortex (top-mix 11118, Bioblock). The amount of phenanthrene in the diluted acetonitrile extracts was quantified by measuring the absorbance at 250 nm in a UV spectrophotometer (UV mini 1240, Shimadzu).

Protein analysis

The initial inoculum concentration was determined by protein analysis using the Lowry method.

Experimental design and statistical analysis

To ensure that the experiments were maximally informative, a CCD was applied using the Design-Expert statistical software (version 7.1.1) for regression and graphical analysis. The incubation temperature (20, 25, 30 °C), the organic to aqueous phase fraction (0.1, 0.25, 0.4), and the initial cell concentrations (0.06, 4.45, 9 μg protein/ml MSM) were chosen as the design parameters and designated as A, B, and C, respectively. Each parameter had three levels: the maximum value corresponds to +1, the minimum one to −1, and the center point to 0, as shown in Table 1. The optimization responses selected were the time for 90% of phenanthrene consumption (Y 3) and two expressions for the phenanthrene biodegradation rate as follows: the phenanthrene biodegradation rate in mg.h-1 (Y 1) and the phenanthrene volumetric biodegradation rate in mg.h-1.l-1 (Y 2). The CCD cultures were inoculated with three different cell concentrations. They contained different organic to aqueous phase fractions and were incubated in the respective temperatures according to the statistical design. All cultures were agitated at 150 rpm.

Results

Developing and checking the adequacy of the models

The actual design of the experiments and the results are shown in Table 2. After running all the trials (20 runs), a model was computed from which unacceptable measurements were excluded. The optimum levels of the selected variables were obtained by solving the regression equation and by analyzing the response surface contour and surface plots. The statistical significance of the results was determined through analysis of variance (ANOVA for response surface) at the 95% confidence level (p < 0.05) unless parameters were considered as insignificant.

The present study was undertaken to investigate the combined effect of a set of factors, namely, incubation temperature (A), silicone oil/MSM ratio (B), and initial cell concentration (C). The reduced empirical models from the 20 runs of the CCD and after excluding all the insignificant terms are as follows:

The adequacy of these quadratic models at the 95% confidence level was examined using the statistics summarized in Table 3. The three models were significant and navigate the design space, as was evident from the F test with a very low probability value for each model. A further adequacy test was conducted by running a confirmation experiment within the design range but not included in the CCD to examine the validity of the model. The experiment coordinates were 30 °C, 0.1, and 0.74 μg/ml MSM for temperature, silicone oil/MSM ratio, and initial cell concentration, respectively. The actual results of the three responses Y 1, Y 2, and Y 3 were 0.055 mg h−1, 10.5 mg l−1 h−1, and 44 h, respectively, and were in good agreement with responses deduced mathematically (0.053 mg h−1, 10.54 mg l−1 h−1, 52 h).

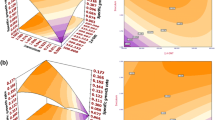

Optimum degradation rate

By virtue of the response surface plots fitted by the models previously mentioned and generated by the Design Expert, the main interaction effects were identified. Figure 1 shows the interaction effect of incubation temperature and oil/MSM ratio on the phenanthrene degradation rate, where the initial cell concentration was kept at level +1. It was evident from the response surface that the phenanthrene degradation rate increased with the incubation temperature (20–30 °C) and oil/MSM fraction (0.1–0.4v/v), reaching a maximum of 0.172 mg h−1 at 30 °C and 0.4 v/v. Figure 2 illustrates the fact that increasing both the inoculum concentration and the silicone oil/MSM ratio increased the degradation rate (Prokop et al. 1972). The maximum degradation rate was observed at an initial cell concentration of 9 μg protein/ml and the highest level of silicone oil volume ratio of 40%. Interestingly, the rise in the degradation rate with the initial inoculum concentration was obvious at low silicone oil ratios but became less marked as the ratio increased (Fig. 2).

Optimum volumetric degradation rate

From an economic point of view, the use of a 40% silicone oil/MSM ratio is not really cost-effective for scaling-up purposes. Hence, the volumetric biodegradation rate expression was included in the analysis in an effort to find out if a high volumetric degradation rate was attainable using low silicone oil ratios. Figure 3 represents the volumetric biodegradation rate (based on the organic volume) plotted against the initial cell concentration and the silicone oil/MSM ratio. The volumetric biodegradation rate increased in parallel with the initial cell concentration but decreased proportionally with the silicone oil/MSM ratio. Thus, the optimum response of 22 mg l−1 h−1 was attained at the maximum initial cell concentration (9 μg/ml) and the minimum silicone oil/MSM ratio (0.1) of the design (experiment 15). The dependence of the volumetric degradation rate on the temperature and initial cell concentration is depicted in Fig. 4. The optimum temperature in the design range was 30 °C.

Optimum 90% degradation time

The model describing the time of degradation suggests that the response is dependent on all three design parameters. Figure 5 describes the variation of the 90% degradation time with the silicone oil/MSM ratio and the initial cell concentration. It is obvious that the time of degradation decreases as the initial cell concentration increases. On the other side, an oil/MSM ratio of 0.1 and a temperature of 30 °C gave the minimum time of degradation, which was about 18 h (Fig. 6).

Discussion

The microbial PAH degradation has been intensively reported in the literature. However, there is little information, especially pertaining to the optimization of PAHs degradation. Therefore, the present work was initiated to fill a part of this void by optimizing the phenanthrene removal conditions via the response surface methodology. A similar methodology has been successfully applied to optimize other microbial PAHs degradation (Launen et al. 1999).

The principal approach to enhance the degradation rate is by favoring the substrate mass-transfer, which is mainly governed by the size of the interfacial area. An optimal interfacial area is often accomplished by increasing the dispersed organic volume fraction. The volumetric liquid–liquid interfacial area, a (m2 m−3), can be calculated as Bailey & Ollis (1986):

where d sm (m3.m−2) is the Sauter mean (surface averaged) droplet diameter and Φ corresponds to the dispersed phase volume fraction, which is the ratio of the NAPL volume to the total liquid volume (phase ratio). This equation reveals that the interfacial area increases with a decrease in the mean drop size and with an increased phase ratio. However, it is also known that drop diameters have a tendency to increase with an increase in the phase ratio (Prokop et al. 1972; Prokop and Erikson 1972; Gutierrez and Erikson 1977). Ascon-Cabrera and Lebeault (1995) have studied the effect of variations of the organic phase volume (8.3–83% v/v silicone oil) on the interfacial area and observed maximal values between 20% and 40%. The optimal fraction of the silicone oil concords with the 40% optimal value obtained in this work to get the maximum degradation rate (Y 1). On the other hand, the optimal volumetric degradation rate (Y 2) was recorded at a silicon oil volume ratio of 0.1. This result is not contradictory to the previously discussed finding because the response (Y 2) did not take into account the whole organic volume; hence, the interfacial area variations were excluded. The optimal volumetric degradation rate recorded in this study (22 mg l−1 h−1) is similar to that reported by Munoz et al. (2003) but much higher than the rates obtained by Guieysse et al. (2001), Tian et al. (2002), and Doddamani and Ninnekar (2000), which were 2.8, 5.0, and 7.0 mg l−1 h−1, respectively.

It is also important to highlight that there was a clear positive correlation between the inocculum amount and the two phenenthrene removal rates (Y 1) and (Y 2). However, this direct relashionship became less marked as the oil/MSM proportion increased. It is hypothesized that increasing the cell concentration enhances the interfacial area by increasing biosurfactants secretion (Ascon-Cabrera and Lebeault 1995; Hommel 1990; Oberbremer and Müller-Hurtig 1989; Allen et al. 1992). This hypothesis could be supported by the fact that emulsions were observed at the biphasic interface. Furthermore, the lag period in phenanthrene degradation was shortened as the initial cell concentration increased (results not shown). However, high silicone oil volume ratios hinder the effect of the cell concentration parameter by diluting the concentration of biosurfactant secreted by the cells. This result concords with the observations of Munoz et al. (2003), who found that at a silicone oil/MSM ratio of 0.25 the inoculum concentration had no significant effect on the maximum degradation rate.

The degradation tests performed in this study also showed that the time for 90% degradation (Y 3) was shortened as the inoculum size increased. As noted earlier, the influence of the initial cell concentration may be related to biosurfactant excretion, which increases phenanthrene bioavailability and thereby shortens the lag time and reduces the whole time required for degradation. On the other side, the minimum time for 90% degradation (Y 3) was obtained using the minimum silicone oil/MSM fraction. The effect of the silicon oil/MSM fraction was expected because lower silicone oil volumes contained lower quantity of phenanthrene, so shorter time was required to degrade the whole quantity. Finally, the concluded models and optimum conditions will cater for phenanthrene degradation scaling up in a two-phase partitioning bioreactor.

In conclusion, the CCD selected as a response surface methodology was successfully applied to perform the complete set of optimized variables values for the biodegradation of phenanthrene in biphasic medium. The maximum degradation rate of phenanthrene was 0.172 mg h−1 at a combination of the highest levels of initial cell concentration, temperature, and silicone oil/MSM ratio in the experimental design, which were 9 μg/ml protein, 30 °C, and 40% (v/v), respectively. Unlike the first response (Y 1), the maximum volumetric degradation rate (22 mg l−1 h−1) was attained at a 10% silicone oil/MSM ratio. Therefore, it was considered economically more feasible. The optimum (minimum) time for 90% of degradation was attained at a temperature of 30 °C and a silicone oil/MSM ratio of 10%.

References

Allen PG, Francy DS, Duston KL, Thomas JM, Ward CH (1992) Biosurfactant production and emulsification capacity of subsurface microorganisms. Soil decontamination using biological processes. Dechema, Karlsruhe, Germany, pp 58–66

Ascon-Cabrera MA, Lebeault J (1995) Interfacial area effects of a biphasic aqueous/organic system on growth kinetics of xenobiotic-degrading microorganisms. Appl Microbiol Biotechnol 43:1136–1141

Ascon-Cabrera M, Lebeault JM (1993) Selection of xenobiotic-degrading microorganisms in a biphasic aqueous-organic system. Appl Environ Microbiol 59:1717–1724

Bailey JE, Ollis DF (1986) Biochemical engineering fundamentals, 2nd edn. McGraw-Hill, New York

Boldrin B, Tiehm A, Fritzsche C (1993) Degradation of phenanthrene, fluorene, fluoranthene, and pyrene by a Mycobacterium sp. Appl Environ Microbiol 59:1927–1930

Cerniglia CE (2003) Recent advances in the biodegradation of polycyclic aromatic hydrocarbons by Mycobacterium species. NATO Sci Ser Ser IV Earth Environ Sci 19:51–73

Cerniglia CE (1993) Biodegradation of polycyclic aromatic hydrocarbons. Curr Opin Biotechnol 4:331–338

Cerniglia CE (1992) Biodegradation of polycyclic aromatic hydrocarbons. Biodegradation 3:351–368

Churchill SA, Harper JP, Churchill PF (1999) Isolation and characterization of a Mycobacterium species capable of degrading three- and four-ring aromatic and aliphatic hydrocarbons. Appl Environ Microbiol 65:549–552

Doddamani HP, Ninnekar HZ (2000) Biodegradation of phenanthrene by a Bacillus species. Curr Microbiol 41:11–14

Guerin WF, Jones GE (1988) Mineralization of phenanthrene by a Mycobacterium sp. Appl Environ Microbiol 54:937–944

Guieysse B, Cirne MdDTG, Mattiasson B (2001) Microbial degradation of phenanthrene and pyrene in a two-liquid phase-partitioning bioreactor. Appl Microbiol Biotechnol 56:796–802

Gutierrez JR, Erickson LE (1977) Hydrocarbon uptake in hydrocarbon fermentations. Biotechnol Bioeng 19:1331–1349

Hommel RK (1990) Formation and physiological role of biosurfactants produced by hydrocarbon-utilizing microorganisms. Biosurfactants in hydrocarbon utilization. Biodegradation 1:107–119

Jonker MTO, Koelmans AA (2002) Extraction of polycyclic aromatic hydrocarbons from soot and sediment: solvent evaluation and implications for sorption mechanism. Environ Sci Technol 36:4107–4113

Kastner M, Breuer-Jammali M, Mahro B (1998) Impact of inoculation protocols, salinity, and pH on the degradation of polycyclic aromatic hydrocarbons (PAHs) and survival of PAH-degrading bacteria introduced into soil. Appl Environ Microbiol 64:359–362

Kim J, Shim S, Lee C (2005) Degradation of phenanthrene by bacterial strains isolated from soil in oil refinery fields in Korea. J Microbiol Biotechnol 15:337–345

Krivobok S, Kuony S, Meyer C, Louwagie M, Willison JC, Jouanneau Y (2003) Identification of pyrene-induced proteins in Mycobacterium sp. strain 6PY1: Evidence for two ring-hydroxylating dioxygenases. J Bacteriol 185:3828–3841

Launen LA, Pinto LJ, Moore MM (1999) Optimization of pyrene oxidation by Penicillium janthinellum using response-surface methodology. Appl Microbiol Biotechnol 51:510–515

Ledakowicz S, Miller JS, Olejnik D (1999) Oxidation of PAHs in water solutions by ultraviolet radiation combined with hydrogen peroxide. Int J Photoenergy 1:55–60

MacLeod CT, Daugulis AJ (2005) Interfacial effects in a two-phase partitioning bioreactor: degradation of polycyclic aromatic hydrocarbons (PAHs) by a hydrophobic Mycobacterium. Process Biochem (Oxford, United Kingdom) 40:1799–1805

Martin A, Sivagurunathan M (2003) Optimization of the biodegradation of naphthalene by a microorganism isolated from petroleum contaminated soil. Meded Fac Landbouwkd Toegep Biol Wet 68:175–178

Miyata N, Iwahori K, Foght JM, Gray MR (2004) Saturable, energy-dependent uptake of phenanthrene in aqueous phase by Mycobacterium sp. strain RJGII-135. Appl Environ Microbiol 70:363–369

Munoz R, Guieysse B, Mattiasson B (2003) Phenanthrene biodegradation by an algal–bacterial consortium in two-phase partitioning bioreactors. Appl Microbiol Biotechnol 61:261–267

Oberbremer A, Mueller-Hurtig R (1989) Aerobic stepwise hydrocarbon degradation and formation of biosurfactants by an original soil population in a stirred reactor. Appl Microbiol Biotechnol 31:582–586

Prabhu Y, Phale PS (2003) Biodegradation of phenanthrene by Pseudomonas sp. strain PP2: novel metabolic pathway, role of biosurfactant and cell surface hydrophobicity in hydrocarbon assimilation. Appl Microbiol Biotechnol 61:342–351

Prokop A, Erickson LE (1972) Growth models of cultures with two liquid phases. VII. Substrate dissolved in dispersed phase. Effect of dispersed phase volume and temperature. Biotechnol Bioeng 14:571–586

Prokop A, Ludvik M, Erickson LE (1972) Growth models of cultures with two liquid phases. VIII. Experimental observations on droplet size and interfacial area. Biotechnol Bioeng 14:587–608

Tian L, Ma P, Zhong J (2002) Kinetics and key enzyme activities of phenanthrene degradation by Pseudomonas mendocina. Process Biochem (Oxford, United Kingdom) 37:1431–1437

Vidali M (2001) Bioremediation. An overview. Pure Appl Chem 73:1163–1172

Walter U, Beyer M, Klein J, Rehm HJ (1991) Degradation of pyrene by Rhodococcus sp. UW1. Appl Microbiol Biotechnol 34:671–676

Wong JWC Lai KM, Wan CK, Ma KK, Fang M (2002) Isolation and optimization of PAH-Degradative bacteria from contaminated soil for PAHs bioremediation. Water Air Soil Pollut 139:1–13

Yip H, Chiu S, Yu J, Wong P (2006) Comparison of photocatalytic oxidation and ozonation in degrading of polycyclic aromatic hydrocarbons. Hum Ecol Risk Assess 12:270–276

Zaidi BR, Imam SH (1999) Factors affecting microbial degradation of polycyclic aromatic hydrocarbon phenanthrene in the Caribbean coastal water. Mar Pollut Bull 38:737–742

Acknowledgments

Arwa Abdelhay was supported by a doctoral grant from the Palestinian Hydrology Group (Water and Environmental Resources Development).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdelhay, A., Magnin, JP., Gondrexon, N. et al. Optimization and modeling of phenanthrene degradation by Mycobacterium sp. 6PY1 in a biphasic medium using response-surface methodology. Appl Microbiol Biotechnol 78, 881–888 (2008). https://doi.org/10.1007/s00253-008-1365-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-008-1365-x