Abstract

The biosynthesis of succinic acid from wheat flour was investigated in a two-stage bio-process. In the first stage, wheat flour was converted into a generic microbial feedstock either by fungal fermentation alone or by combining fungal fermentation for enzyme and fungal bio-mass production with subsequent flour hydrolysis and fungal autolysis. In the second stage, the generic feedstock was converted into succinic acid by bacterial fermentation by Actinobacillus succinogenes. Direct fermentation of the generic feedstock produced by fungal fermentation alone resulted in a lower succinic acid production, probably due to the low glucose and nitrogen concentrations in the fungal broth filtrate. In the second feedstock production strategy, flour hydrolysis conducted by mixing fungal broth filtrate with wheat flour generated a glucose-rich stream, while the fungal bio-mass was subjected to autolysis for the production of a nutrient-rich stream. The possibility of replacing a commercial semi-defined medium by these two streams was investigated sequentially. A. succinogenes fermentation using only the wheat-derived feedstock resulted in a succinic acid concentration of almost 16 g l–1 with an overall yield of 0.19 g succinic acid per g wheat flour. These results show that a wheat-based bio-refinery employing coupled fungal fermentation and subsequent flour hydrolysis and fungal autolysis can lead to a bacterial feedstock for the efficient production of succinic acid.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Development of bio-refineries has recently attracted increasing attention as a means to provide sustainable alternative solutions to depleting petroleum resources and environmental pollution. Many chemicals, which could only be produced by chemical processes in the past, could potentially be generated biologically from renewable substrates (Ragauskas et al. 2006). Among them, succinic acid is a potential platform chemical for the production of various high value-added derivatives. The applications of succinic acid and its derivatives include surfactants, detergents, foods and pharmaceuticals (Zeikus et al. 1999). The production of succinic acid from natural derived feedstock would alleviate the dependence on oil supply for the production of platform chemicals.

Recently, the fermentative production of succinic acid has been widely investigated with a large number of bacteria, including Anaerobiospirillum succiniciproducens, Actinobacillus succinogenes, Mannheimia succiniciproducens, Escherichia coli, Penicillium simplicissimum and Enterococcus faecalis (Donnelly et al. 1998; Gallmetzer et al. 2002; Guettler and Jain 1996; Guettler et al. 1996, 1999; Kang et al. 2000; Lee et al. 2001, 2002, 2005; Nghiem et al. 1997; Van der Werf et al. 1997; Zeikus et al. 1999). Among the media used, synthetic fermentation media give high final succinic acid concentration and productivity, but they are very expensive and do not facilitate bulk succinic acid production economically. Cheaper fermentation media such as whey, wood hydrolysate and cane molasses have also been investigated to substitute expensive carbon sources in batch, fed-batch and continuous fermentations (Agarwal et al. 2006; Kim et al. 2004; Lee et al. 2000, 2003a, b; Samuelov et al. 1999). However, to date, the fermentative production of succinic acid from wheat flour has not been reported.

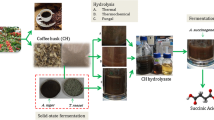

Wheat is a potentially important raw material for sustainable processes especially in the UK. Preliminary critical review and economic analysis have shown that wheat can be an efficient and cost-competitive renewable feedstock for chemical production (Koutinas et al. 2004a). At the Satake Centre for Grain Process Engineering, a viable wheat-based bio-refining strategy leading to the production of a generic microbial feedstock has been successfully developed. (Webb and Wang 1997; Wang et al. 2002; Webb et al. 2004; Koutinas et al. 2005). In the study reported here, succinic acid has been used as a model product for this bio-refining strategy to convert wheat flour into fine chemicals by a two-stage bio-process, as shown in Fig. 1. In Stage I, wheat flour was converted into microbial feedstock via two alternative process schemes. In Scheme 1, the wheat flour was converted into microbial feedstock by A. awamori alone (Fig. 1a); while in Scheme 2, enhancement of nutrients in the feedstock was achieved by flour hydrolysis and fungal autolysis exploiting the enzymes and fungal bio-mass produced during A. awamori fermentation (Fig. 1b). The resultant feedstocks from both schemes were subsequently fermented by A. succinogenes to produce succinic acid in Stage II.

Materials and methods

Micro-organisms

Two different micro-organisms were used in this study. A. awamori 2B.361 U2/1 (Lab collection) was utilised in fungal fermentations. Sporulation and storage have been described previously (Koutinas et al. 2001). The other micro-organism, A succinogenes ATCC 55618 was utilised in bacterial fermentation, which was obtained from the American Type Culture Collection (ATCC).

Media and conditions

The wheat used was a soft variety (Consort), harvested in 2003 and supplied by Fisher Seed and Grain Limited (Cranswick, East Yorkshire, UK). The wheat flour was produced by a laboratory hammer mill (Perten Instruments, Sweden) fitted with a 0.5 mm sieve. The composition of the wheat flour was reported by Koutinas et al. (2004b). Fungal fermentations were conducted in a 10-l bioreactor (6-l working volume). Wheat flour suspensions (8% w/v, on a dry basis) were the sole media in fungal fermentations. These were initially gelatinised at 75°C for 10 min. The desired temperature was reached by sparging 1 bar live steam into the flour suspensions. The gelatinised flour was subsequently diluted to the desired concentration (8% w/v) with tap water. To prevent foaming, 0.002% (v/v) of silicone anti-foam was added to the complex medium. The suspension was then sterilised at 121°C for 120 min. It was transferred into the fermenter while still hot so as to prevent tubes clogging due to increase in viscosity at lower temperature. The fungal fermentation was conducted at 30°C, 300 rpm agitation speed and 1 vvm aeration rate. The pH was controlled at 4.5 by adding 2 M HCl or 2 M NaOH solutions. The inoculation procedure of fungal fermentations was described in a previous publication (Koutinas et al. 2001).

For bacterial fermentation, commercial trypticase soya agar (TSA) and trypticase soya broth (TSB) were used for inoculum preparation as the solid and liquid seed culture media, respectively. In the case of fermentation in a 1.8-l bioreactor, semi-defined and wheat-derived media were used. The semi-defined medium contained (Guettler et al. 1996; l−1) the following: glucose 50 g; yeast extract, 5 g; NaH2PO4.H2O, 1.16 g; Na2HPO4, 0.31 g; NaCl, 1.0 g; MgCl2.6H2O, 0.2 g; CaCl2.2H2O, 0.2 g; B12, 10 μg; biotin, 200 μg; folic acid, 200 μg; thiamine, 500 μg; riboflavin, 500 μg; niacin, 500 μg; pantothenate, 500 μg; p-aminobenzoate, 500 μg; lipoic acid, 500 μg; B6, 1 μg; silicone anti-foam, 0.5 ml. Fungal broth filtrate or mixtures of wheat flour hydrolysate and/or fungal autolysate to desired glucose and free amino nitrogen concentrations were used for succinic acid fermentation. A. succinogenes was grown on TSA plates at 30°C for 4 days and then transferred to 200 ml Duran bottles containing 50 ml TSB medium for incubation at 30°C and 120 rpm for 48 h. Batch fermentations were carried out at 37°C in a 1.8-l bench-top bioreactor (Electrolab 351, Tewkesbury, UK) with 0.8-l working volume. Fermentation pH was controlled between 6.6 and 6.8 by 10 M NaOH solution. The broth was sparged with 0.5 vvm CO2 and mixed by a 200-rpm agitation speed. For fermentations with the semi-defined medium, the medium was autoclaved for 20 mins at 121°C. For fermentations using the fungal broth filtrate or flour hydrolysate and/or fungal autolysate, the medium was filter-sterilised by a 0.2 μm membrane filter (Filter capsule Whatman® Polycap) and aseptically added into the bioreactor. The inoculum size of batch fermentation was 4%.

Flour hydrolysis and fungal autolysis

The fungal fermentation of 8% (w/v) wheat flour was terminated at 96 h. Its broth filtrate that was rich in glucoamylase was used to hydrolyse wheat flour components to produce a glucose-rich stream (flour hydrolysate), while its solid residue was used for fungal autolysis to produce a nitrogen-rich stream (fungal autolysate). The procedures of flour hydrolysis and fungal autolysis were described in Koutinas et al. (2004b).

Analytical techniques

Bacterial growth was determined by optical density (OD) measurements at 660 nm (spectrophotometer Cecil CE1020 1000 Series). Glucose concentration was determined by a glucose analyser (Analox, UK). Free amino nitrogen concentration in liquid sample was analysed by the ninhydrin colorimetric method (Lie 1973).

Succinic acid, acetic acid, formic acid and lactic acid were determined by high performance liquid chromatography (Star Varian Chromatography Workstation) with a UV detector (Prostar 330 PDA). The analytical column was PL Hi-Plex H 8 μm 300 × 7.7 mm, (Polymer Laboratories) proceeded by a guard column. The analysis was carried out under the following conditions: sample volume 20 μl, flow phase 0.1% (v/v) trifluoroacetic acid (TFA), flow rate 0.6 ml min−1; column temperature 60°C (column oven: Jasco CO-965). Samples were centrifuged by a bench-top micro-centrifuge at 130,000 rpm for 5 min, diluted with double-distilled water and then filtered by a 0.45-μm Nylon membranes filter (Phenomex, UK).

Results

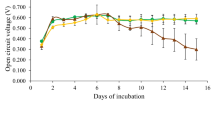

To examine the behaviour of A. succinogenes, fermentations with the semi-defined medium were firstly performed. Figure 2 shows time profiles of glucose consumption, OD and products formation of a typical fermentation with the semi-defined medium. The initial glucose concentration after sterilisation was 45 g l−1 and was consumed completely by 50 h. The main products were succinic acid (27.9 g l−1), acetic acid (10.3 g l−1) and formic acid (5.5 g l−1) corresponding to a ratio of 100:40:20. The glucose to succinic acid production yield was 0.62 g g−1glucose.

Glucose, fermentation products and OD profiles for the bacterial fermentation on semi-defined medium. Filled squares represent glucose; open triangles represents succinic acid; filled circles represent acetic acid; filled inverted triangles represent formic acid; open diamonds represent lactic acid; open circles represent cell optical density

Conversion of wheat flour to succinic acid via Scheme 1 and bacterial fermentation

In this case, succinic acid production was carried out directly after fungal fermentation to produce the feedstock for the bacterial (succinic acid) fermentation. Wheat flour (8% w/v) was initially fermented by A. awamori and the fermentation broth filtrate collected at 96 h was used after neutralisation. Figure 3a shows the results of a typical A. awamori fermentation with 8% wheat flour. After 96 h fungal fermentation, the broth filtrate contained about 30 g l−1 glucose and 100 mg l−1 free amino nitrogen.

Succinic acid production via Scheme 1 and the bacterial fermentation. a Typical time profiles of glucose and free amino nitrogen in a fermentation of A. awamori in 8% (w/v) wheat flour. (Adapted from Koutinas et al. 2004b); b Glucose, fermentation products and OD profiles of a bacterial fermentation on fungal broth filtrate. Filled squares represent glucose; open inverted triangles represent free amino nitrogen; open triangles represent succinic acid; filled circles represent acetic acid; filled inverted triangles represent formic acid; open diamonds represent lactic acid; open circles represent cell optical density

Figure 3b presents time profiles of glucose consumption, OD and product formation during a typical A. succinogenes fermentation of the fungal broth filtrate. The fermentation was completed after 50 h when glucose was depleted. Compared with the fermentation using the semi-defined medium (Fig. 2), A. succinogenes exhibited a similar specific growth rate of 0.13 h−1 and a similar maximal OD of 4.5. At the end of the fermentation, about 5.0 g l−1 succinic acid had been produced corresponding to an overall yield of 0.063 g g−1 wheat flour. Compared to the by-product formation in the semi-defined medium, a significant increase in lactic acid production (2.9 g l−1) was observed.

Conversion of wheat flour to succinic acid via Scheme 2 and bacterial fermentation

Although the above investigations using Scheme 1 demonstrated that it is feasible to produce succinic acid by the two-stage fermentation process, the succinic acid concentration, productivity and yield were relatively low. One reason seemed to be the limitation of initial carbon source (30 g l−1 glucose) and nitrogen source (100 mg l−1 free amino nitrogen) in the fungal broth filtrate. To enhance nutrient concentrations in wheat-derived media for bacterial fermentations, the processes of flour hydrolysis and fungal autolysis were applied (Scheme 2). Subsequently, sequential replacements of glucose, yeast extract, vitamins and minerals in the semi-defined medium using flour hydrolysate and/or fungal autolysate were investigated.

The glucose content in the hydrolysate and the free amino nitrogen content in the fungal autolysate achieved 240 and 1.3 g l−1, respectively. The latter corresponds to the free amino nitrogen content of a 26 g l−1 yeast extract solution. Mixing the two streams in appropriate proportions can easily meet the requirements for succinic acid fermentation by A. succinogenes.

Using flour hydrolysate to replace commercial glucose

As flour hydrolysate contains sufficient glucose, it could be used as a cost-effective alternative to replace commercial glucose in the succinic acid fermentation. However, as it is a complex material it could also contain possible inhibitory compounds. To investigate this, a fermentation was carried out using a modified semi-defined medium that contained flour hydrolysate instead of commercial glucose. The initial glucose concentration was 43 g l−1 after dilution and sterilisation (Fig. 4a), only slightly lower than that in the semi-defined medium. Compared to the fermentation using the semi-defined medium (Fig. 2), this fermentation resulted in a similar final succinic acid concentration of about 27.2 g l−1 and a similar yield of about 0.64 g g−1glucose. Moreover, the one using flour hydrolysate led to a higher productivity of 1.01 g l−1 h−1, indicating that flour hydrolysate was a superior carbon source compared to commercial glucose alone.

Glucose and fermentation product profiles for succinic acid fermentations. a Using flour hydrolysate as the major carbon source; b Using flour hydrolysate replacing glucose and vitamins; c Using fungal autolysate replacing yeast extract, together with flour hydrolysate replacing commercial glucose and vitamins; d Using only flour hydrolysate and fungal autolysate. Filled squares represent glucose; open triangles represent succinic acid; filled circles represent acetic acid; filled inverted triangles represent formic acid

As shown in Fig. 4a, the major by-products of the succinic acid fermentation with flour hydrolysate are acetic acid (9.2 g l−1) and formic acid (6.1 g l−1). This was in agreement with the fermentation on the semi-defined medium (Fig. 2), suggesting no significant change in metabolic pathways according to the usage of either commercial glucose or flour hydrolysate.

Using flour hydrolysate to replace both glucose and vitamins

Vitamins are crucial components in succinic acid fermentations. In media free of vitamins, poor A. succinogenes growth was observed (data not shown). Thus the addition of vitamins is essential but substituting the addition of commercial vitamins by the vitamins naturally present in flour hydrolysate would improve process economics. Figure 4b shows the results of a fermentation by A. succinogenes using more concentrated flour hydrolysate without the addition of commercial vitamins. The equivalent glucose concentration at the beginning of the fermentation was approximately 70 g l−1. This fermentation led to 35.6 g l−1 succinic acid with a yield of 0.82 g succinic acid per g consumed glucose, confirming that the addition of commercial vitamins is unnecessary in media containing flour hydrolysate.

Using fungal autolysate to replace yeast extract

Commercial yeast extract is a product of yeast autolysis. Considering the likely similarity of chemical components between A. awamori and common yeasts, it can be assumed that the fungal autolysate might be a feasible alternative to yeast extract as a nutrient source. Further to the fermentation using a medium with glucose and vitamins substituted by flour hydrolysate, fungal autolysate was explored as a direct replacement for yeast extract. As shown in Fig. 4c, about 23.2 g l−1 succinic acid was produced by the end of the fermentation, corresponding to a yield of 0.54 g g−1 glucose. The main by-products were formic acid (7.4 g l−1) and lactic acid (2.6 g l−1). Acetic acid could not be quantified because a peak from another unidentified by-product overlapped by the acetic acid peak.

Succinic acid fermentation using only flour hydrolysate and fungal autolysate

Fermentations using a mixture of only flour hydrolysate and fungal autolysate were performed to investigate the possibility of fully replacing the semi-defined medium. Results of a typical such fermentation are shown in Fig. 4d. The initial glucose and free amino nitrogen concentrations were 45 and 500 mg l−1, respectively. Although A. succinogenes exhibited a slightly lower specific growth rate than the fermentation on the semi-defined medium, 15.9 g l−1 succinic acid had been produced after 51 h. The main by-products were acetic acid (8 g l−1) and formic acid (6 g l−1). This demonstrates clearly that the wheat-based generic feedstock contains sufficient essential nutrients for the succinic acid fermentation by A. succinogenes.

Table 1 compares succinic acid production on the semi-defined medium and on the wheat-derived media.

Discussion

In this study, a wheat-based bio-refining strategy has been investigated for the fermentative production of succinic acid via two schemes. In Scheme 1 (shown in Fig. 1a), the broth filtrate of an A. awamori fermentation was used directly as a medium for succinic acid fermentation. Without the supplement of other nutrients, this filtrate provided sufficient nutrients for A. succinogenes growth and accessible carbon source for the synthesis of succinic acid (Fig. 3b). However, the fermentation resulted in a relatively low specific growth rate and a low succinic acid production in comparison to fermentations using a semi-defined medium (Fig. 2). This is probably due to the low nutrient concentrations in the fungal broth filtrate. In a typical fungal fermentation of wheat flour (8% w/v), the highest glucose concentration reached was only around 50 g l−1 (Koutinas et al. 2004b). Increasing the wheat flour concentration for the fungal fermentation is impossible because of the significant increase in viscosity, making it difficult to operate. Moreover, the nitrogen source was quite low (100 mg l−1 free amino nitrogen), equivalent to only 2 g l−1 yeast extract. The low glucose and free amino nitrogen concentrations of the fungal broth filtrate limits its potential as a feedstock for the production of highly concentrated fine chemicals.

In Scheme 2 (shown in Fig. 1b) to improve the nutrient concentrations (especially glucose and free amino nitrogen) of the wheat-derived feedstock, the fungal broth filtrate was mixed with wheat flour to perform flour hydrolysis, while the residual fungal cells were allowed autolysis. From the flour hydrolysis, a stream with a glucose concentration of around 240 g l−1 was produced. This was nearly four times higher than that of the fungal broth filtrate. The substitution of commercial glucose by flour hydrolysate provided a medium that resulted in a 27.2 g l−1 succinic acid production (Fig. 4a), which was 5.4 times higher than that using the fungal broth filtrate. Compared with the fermentation on the semi-defined medium, the fermentation with flour hydrolysate resulted in a similar succinic acid concentration and yield but with a higher productivity (Table 1). This is probably due to the nutrient richness of the flour hydrolysate, such as nitrogen source, minerals and vitamins (Wang et al. 2002). Moreover, a relatively concentrated flour hydrolysate contained sufficient quantity of essential vitamins for A. succinogenes growth and succinic acid formation (Fig. 4b), suggesting that the addition of expensive commercial vitamins is not necessary with this medium.

Fungal autolysate produced by the wheat-based bio-refining strategy contained up to 1.6 g l−1 free amino nitrogen (Koutinas et al. 2005), which was 16 times higher than that in the fungal broth filtrate. It successfully replaced yeast extract as a cost-effective nitrogen source in the fermentative production of succinic acid (Fig. 4c). Significantly, even the fermentation using only flour hydrolysate and fungal autolysate led to a succinic acid production of 15.9 g l−1 and an overall yield of 0.19 g g−1 wheat flour (Fig. 4d). In this scenario, all components of the fermentation medium used were the products of the wheat-based bio-refinery without the addition of any commercial carbon source, nitrogen source, vitamins or minerals.

In general, fermentations using naturally derived substrates have resulted in relatively low succinic acid concentrations. Values of between 12 and 24 g l−1 have been reported for a variety of raw materials (Agarwal et al. 2006; Kim et al. 2004; Lee et al. 2000, 2003a, b; Samuelov et al. 1999), while fermentations with semi-defined media have resulted in concentrations of around 100 g l−1 (Guettler et al. 1996; Vemuri et al. 2002). This suggests that some nutrients are present in limiting concentrations in the natural feedstocks. In comparison to fermentations using only wheat-based generic feedstock (Fig. 4d), the presence of additional minerals led to increased succinic acid production (Fig. 4c). This indicates that some minerals might not be contained in the wheat-derived feedstock in sufficient amounts. Sodium for example has been shown to be vital in the bio-synthesis of succinic acid (Lee et al. 1999). It has been reported that the sodium concentration of wheat flour is only 30 mg kg−1 (Pomeranz 1988). Thus the theoretical sodium concentration in the flour hydrolysate is only 10 mg l−1. This is less than 2% of the sodium used in the semi-defined medium (Guettler et al. 1996), suggesting mineral concentration could indeed be a limiting factor for succinic acid production using the mixture of flour hydrolysate and fungal autolysate. The addition of certain kinds of minerals into wheat-derived media would therefore benefit to the production of succinic acid. Besides the optimisation of fermentation media, explorations of other fermentation types, such as fed-batch fermentations and continuous fermentations, were reported to be superior to batch fermentations alone in terms of succinic acid yields and productivities (Kim et al. 2004; Lee et al. 2000, 2003a; Samuelov et al. 1999). These methods are expected to result in improvement of succinic acid production in the fermentations with wheat-derived media.

In this study, the possibility of developing a wheat-based bio-refinery for the production of succinic acid was investigated. This wheat-based bio-refining concept would result in improvement of process economics by using wheat-derived media in comparison to semi-defined media. The estimation of the raw material cost and operating cost of the generic feedstock produced via Scheme 2 has been carried out (Koutinas et al. 2004a; Webb et al. 2004). It demonstrated that the overall cost of wheat-based generic feedstock is cheaper than the purchase price of purified dextrose and glucose syrup when the plant capacity is more than 90 m3 (flour hydrolysate stream) per day. Moreover, when the plant capacity exceeds 550 m3 per day, the overall cost is lower than the price of starch hydrolysate (Webb et al. 2004). Consideration of the usage of the cheap low grade wheat or wheat milling by-products and the integration of generic feedstock production into succinic acid fermentation process, the cost could be further reduced. The experimental results reported in this study show that a wheat-based bio-refinery could lead to a generic feedstock for the efficient production of succinic acid.

References

Agarwal L, Isar J, Meghwanshi GK, Saxena RK (2006) A cost effective fermentative production of succinic acid from cane molasses and corn steep liquor by Escherichia coli. J Appl Microbiol 100:1348–1354

Donnelly MI, Millard CS, Clark DP, Chen MJ, Rathke JW (1998) A novel fermentation pathway in an Escherichia coli mutant producing succinic acid, acetic acid, and ethanol. Appl Biochem Biotechnol 70–72:187–198

Gallmetzer M, Meraner J, Burgstaller W (2002) Succinate synthesis and excretion by Penicillium simplicissimum under aerobic and anaerobic conditions. FEMS Microbiol Lett 210:221–225

Guettler M, Jain M (1996) Method for making succinic acid, Anaerobiospirillum succiniciproducens variants for use in process and methods for obtaining variants. US patent 5,521,075

Guettler M, Jain M, Rumler D (1996) Method for making succinic acid, bacterial variants for use in the process, and methods for obtaining variants. US patent 5,573,931

Guettler M, Rumler D, Jain M (1999) Actinobacillus succinogenes sp. nov., a novel succinic-acid-producing strain from the bovine rumen. Int J Syst Bacteriol 49:207–216

Kang K-H, Yun J-S, Ryu H-W (2000) Effect of culture conditions on the production of succinate by Enterococcus faecalis RKY1. J Microbiol Biotechnol 10:1–7

Kim DY, Yim SC, Lee PC, Lee WG, Lee SY, Chang HN (2004) Batch and continuous fermentation of succinic acid from wood hydrolysate by Mannheimia succiniciproducens MBEL55E. Enzyme Microb Technol 35:648–653

Koutinas A, Belafi-Bako K, Kabiri-Badr A, Toth A, Gubicza L, Webb C (2001) Enzymatic hydrolysis of polysaccharides: Hydrolysis of starch by an enzyme complex from fermentation by Aspergillus awamori. Food Bioprod Process 79:41–45

Koutinas AA, Wang R, Webb C (2004a) Evaluation of wheat as generic feedstock for chemical production. Ind Crop Prod 20:75–88

Koutinas AA, Wang R, Webb C (2004b) Restructuring upstream bioprocessing: technological and economical aspects for production of a generic microbial feedstock from wheat. Biotechnol Bioeng 85:524–538

Koutinas AA, Wang RH, Webb C (2005) Development of a process for the production of nutrient supplements for fermentations based on fungal autolysis. Enzyme Microb Technol 36:629–638

Lee PC, Lee WG, Kwon S, Lee SY, Chang HN (1999) Succinic acid production by Anaerobiospirillum succiniciproducens: effects of the H2/CO2 supply and glucose concentration. Enzyme Microb Technol 24:549–554

Lee PC, Lee WG, Kwon S, Lee SY, Chang HN (2000) Batch and continuous cultivation of Anaerobiospirillum succiniciproducens for the production of succinic acid from whey. Appl Microbiol Biotechnol 54:23–27

Lee PC, Lee WG, Lee SY, Chang HN (2001) Succinic acid production with reduced by-product formation in the fermentation of Anaerobiospirillum succiniciproducens using glycerol as a carbon source. Biotechnol Bioeng 72:41–48

Lee PC, Lee SY, Hong SH, Chang HN (2002) Isolation and characterization of a new succinic acid-producing bacterium, Mannheimia succiniciproducens MBEL55E, from bovine rumen. Appl Microbiol Biotechnol 58:663–668

Lee PC, Lee SY, Hong SH, Chang HN (2003a) Batch and continuous cultures of Mannheimia succiniciproducens MBEL55E for the production of succinic acid from whey and corn steep liquor. Bioprocess Biosyst Eng 26:63–67

Lee PC, Lee SY, Hong SH, Chang HN, Park SC (2003b) Biological conversion of wood hydrolysate to succinic acid by Anaerobiospirillum succiniciproducens. Biotech Lett 25:111–114

Lee SJ, Lee D-Y, Kim TY, Kim BH, Lee J, Lee SY (2005) Metabolic engineering of Escherichia coli for enhanced production of succinic acid, based on genome comparison and in silico gene knockout simulation. Appl Environ Microbiol 71:7880–7887

Lie S (1973) EBC [European Brewery Convention]-ninhydrin method for determination of free a-amino nitrogen. J Inst Brewing 79:37–41

Nghiem NP, Davison BH, Suttle BE, Richardson GR (1997) Production of succinic acid by Anaerobiospirillum succiniciproducens. Appl Biochem Biotechnol 63–65:565–576

Pomeranz Y (1988) Wheat: chemistry and technology, 3rd edn. American Association of Cereal Chemistry, St. Paul, MN

Ragauskas AJ, Williams CK, Davison BH, Britovsek G, Cairney J, Eckert CA, Frederick WJ Jr., Hallett JP, Leak DJ, Liotta CL, Mielenz JR, Murphy R, Templer R, Tschaplinski T (2006) The path forward for biofuels and biomaterials. Science 311:484–489

Samuelov NS, Datta R, Jain MK, Zeikus JG (1999) Whey fermentation by Anaerobiospirillum succiniciproducens for production of a succinate-based animal feed additive. Appl Environ Microbiol 65:2260–2263

Van der Werf MJ, Guettler MV, Jain MK, Zeikus JG (1997) Environmental and physiological factors affecting the succinate product ratio during carbohydrate fermentation by Actinobacillus sp. 130Z. Arch Microbiol 167:332–342

Vemuri GN, Eiteman MA, Altman E (2002) Succinate production in dual-phase Escherichia coli fermentations depends on the time of transition from aerobic to anaerobic conditions. J Ind Microbiol Biotechnol 28:325–332

Wang R, Dominguez-Espinosa Rosa M, Leonard K, Koutinas A, Webb C (2002) The application of a generic feedstock from wheat for microbial fermentations. Biotechnol Prog 18:1033–1038

Webb C, Wang R (1997) Development of a generic fermentation feedstock from whole wheat flour, in Cereals: Novel Uses and Processes. Campbell GM, Webb C, McKee SL (eds) Plenum, New York, USA, pp 205–218

Webb C, Koutinas AA, Wang R (2004) Developing a sustainable bioprocessing strategy based on a generic feedstock. Adv Biochem Eng/Biotechnol 87:195–268

Zeikus JG, Jain MK, Elankovan P (1999) Biotechnology of succinic acid production and markets for derived industrial products. Appl Microbiol Biotechnol 51:545–552

Acknowledgement

This research was supported by the Engineering and Physical Sciences Research Council (EP/C530993/1), the UK. The authors gratefully acknowledge the contribution of the Satake Corporation of Japan in providing financial support for the research carried out in the Satake Centre for Grain Process Engineering, the University of Manchester, UK. We are also grateful for the provision of the Overseas Research Students Awards Scheme to S. K.C. Lin by the Universities UK.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Du, C., Lin, S.K.C., Koutinas, A. et al. Succinic acid production from wheat using a biorefining strategy. Appl Microbiol Biotechnol 76, 1263–1270 (2007). https://doi.org/10.1007/s00253-007-1113-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-007-1113-7