Abstract

An asymmetric hydrogen-transfer biocatalyst consisting of mutated Rhodococcus phenylacetaldehyde reductase (PAR) or Leifsonia alcohol dehydrogenase (LSADH) was applied for some water-soluble ketone substrates. Among them, 4-hydroxy-2-butanone was reduced to (S)/(R)-1,3-butanediol, a useful intermediate for pharmaceuticals, with a high yield and stereoselectivity. Intact Escherichia coli cells overexpressing mutated PAR (Sar268) or LSADH were directly immobilized with polyethyleneimine or 1,6-diaminehexane and glutaraldehyde and evaluated in a batch reaction. This system produced (S)-1,3-butanediol [87% enantiomeric excess (e.e.)] with a space time yield (STY) of 12.5 mg h−1 ml−1 catalyst or (R)-1,3-butanediol (99% e.e.) with an STY of 60.3 mg h−1 ml−1 catalyst, respectively. The immobilized cells in a packed bed reactor continuously produced (R)-1,3-butanediol with a yield of 99% (about 49.5 g/l) from 5% (w/v) 4-hydroxy-2-butanoate over 500 h.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Enantioselective organic synthesis is useful for producing chiral synthons for pharmaceuticals and agricultural chemicals. Chiral metal complexes such as BINAP-Ru have been successfully used as catalysts in a number of cases of enantioselective reductions (Noyori and Ohkuma 2001). However, in some reactions, difficulties remain in attaining sufficient optical purity and productivity. To overcome the disadvantages of conventional synthetic processes, biocatalytic transformation using enzymes has been applied to the asymmetric synthesis of optically pure substances (Breuer et al. 2004).

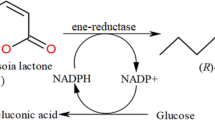

Many examples of the reduction in ketones with reductases and dehydrogenases have been described because such processes theoretically produce alcohol with 100% conversion from a ketone (Hummel and Kula 1989; Wong and Whitesides 1994; Hummel 1997; Nakamura et al. 2003). However, in most cases, they have the disadvantages of a narrow substrate spectrum and low productivity due to the need for a cofactor regeneration system such as reduced form of nicotinamide adenine dinucleotide (NADH) and reduced form of nicotinamide adenine dinucleotide phosphate (NADPH), although they show rather high enantioselectivity. Therefore, such bioreduction processes are only economical when the cofactor can be regenerated in situ in a second catalytic cycle, for example, formate/formate dehydrogenase (Yamamoto et al. 2005) or glucose/glucose dehydrogenase (Shimizu et al. 1998).

From the point of view of NAD(P)H regeneration, 2-propanol is another suitable hydrogen donor because of its chemical properties and low cost (Bradshaw et al. 1992; Stampfer et al. 2003; Kosjek et al. 2004). We have reported that phenylacetaldehyde reductase (PAR; Itoh et al. 1997) from styrene-assimilating Rhodococcus sp. strain ST-10 (former Corynebacterium sp.) and alcohol dehydrogenase (ADH) from Leifsonia sp. S749 strain (LSADH; Inoue et al. 2005a) are both unique NAD+-dependent ADHs, which show a broad substrate range and a high enantioselectivity, respectively, to give (S)-/(R)-alcohols from various carbonyl compounds without an additional coenzyme regeneration system (Itoh et al. 1999, 2002; Inoue et al. 2005b, 2006). As the enzymes are able to regenerate NADH in the presence of 2-propanol as a hydrogen donor, a recombinant PAR/LSADH system is regarded as providing a superior asymmetric hydrogen-transfer reduction process. In addition, we have succeeded in increasing the activity of PAR in a concentrated 2-propanol solution (>15%) by protein engineering to obtain Sar268: mutated PAR containing 6 substitutions (E12G, D42V, K67R, L125M, S173P, A327V; Makino et al. 2005).

In this paper, we describe the immobilization of Escherichia coli cells overexpressing Sar268 or LSADH and the application of this system for the continuous production of water-soluble chiral alcohols in a packed bed reactor. We also discuss the 2-propanol solution system [lower than 20% (v/v)], which is suitable for recombinant E. coli whole-cell systems.

Materials and methods

Chemicals

Polyethyleneimine (PEI) P-70 (30% solution, mean molecular weight of 70,000) was purchased from Wako Pure Chemicals, Osaka, Japan, and (S)-(+)-/(R)-(−)-1,2-propanediols, (S)-(+)-/(R)-(−)-1,3-butanediols, (R,R)-(−)-/(S,S)-(+)-2,3-butanediols, 4-hydoroxy-2-butanone, diacetyl, 6-diaminohexane and glutaraldehyde (GA) from Tokyo Kasei, Tokyo, Japan.

Bacterial strains, vectors, and culture conditions

pSar268 or pKELA expression vector, which encodes sar268 (Makino et al. 2005) or lsadh (Inoue et al. 2006) described in our previous reports, was used to produce Sar268 or LSADH in E coli cells. E. coli JM109 (recA1, endA1, gyrA96, thi, hsdR17 \( {\left( {r_{K} ^{ - } \,m_{K} ^{ + } } \right)} \), e14− (mcrA −), supE44, relA1, Δ(lac-proAB)/F′[traD36, proAB +, lac I q, lacZΔM15]), and E. coli XL1BlueMRF′ (recA1, thi, endA1, supE44, gyrA46, relA1, hsdR17, lac/F′[proAB +lac I qlacZΔM15::Tn10 Tetr]) were used as host strains for the expression of Sar268 and LSADH, respectively. E. coli cells were cultivated at 37°C in Luria-Bertani (LB) medium (1% tryptone, 0.5% yeast extract, and 0.5% NaCl, pH 7.0) containing 0.01% ZnCl2 and 0.1 mg/ml ampicillin for E. coli (pSar268) and in LB medium containing 0.1 mg/ml ampicillin for E. coli (pKELA) unless otherwise noted. For induction of the gene under the control of the lac or tac promoter for E. coli (pSar268 or pKELA), 0.4 mM isopropyl β-d-thiogalactoside (IPTG) was added to LB medium. In the case of E. coli (pSar268), IPTG was added at the start of cultivation, and the cells were further cultured for 24 h. In the case of E.coli (pKELA), the cells were grown without IPTG to the growth level of A660 nm of 0.5, and then, IPTG was added to the culture medium, and the cells were cultivated for 24 h in all.

Enzyme assay

Sar268 or LSADH activity was assayed spectrophotometrically at 25°C by measuring the decrease in the absorbance of NADH at 340 nm. The reaction mixture consisted of 3.0 μmol of acetophenone, 0.4 μmol of NADH, 75 μmol of potassium phosphate buffer (KPB; pH 7.0), and 10 μl of enzyme solution, in a total volume of 1.5 ml for Sar268, and the same conditions except 2,2,2-trifluoroacetophenone as a substrate for LSADH. One unit of enzyme was defined as the amount that converted 1 μmol of NADH (ɛ = 6,220 M−1 cm−1) in 1 min under these conditions.

Immobilization procedure and microscopic analysis

E. coli cells collected by centrifugation (10,000×g, 15 min) from 1 l of culture broth were washed once with saline and suspended in 100 ml of water. PEI P-70 or 1,6-diaminohexane (DAH) solution previously adjusted to pH 7.0 with conc. HCl was added to the suspension to a final concentration between 0.5 and 3.0% (w/v). After stirring for 30 min at room temperature, the cell aggregates were centrifuged and resuspended in 100 ml of 20 mM KPB (pH 7.0). GA solution was added to the suspension to a final concentration of 0.5% (w/v), and the suspension was stirred for 30 min at room temperature. The collected cell aggregates were washed with 20 mM KPB (pH 7.0) and then 0.1 M NH4HCO3 (pH 7.0). The suspension (10 ml) was subjected to freeze-drying for 48 h, and the obtained immobilized cells were broken into a coarse powder in a mortar with a pestle.

To check the enzyme leakage from the immobilized cells, the cells were suspended in 2 ml of buffer and disrupted with glass beads using a Multi-beads Shocker (Yasui Kikai, Osaka, Japan) in a 2-ml polypropylene tube at 2,000 rpm for 2 min at 4°C, and after centrifugation, the enzyme activity in the supernatant solution was measured.

Observation of immobilized E. coli cells by scanning electron microscopy (SEM) was performed with a Hitachi S-2400 scanning electron microscope. The specimens were coated with gold using an ion spattering apparatus, and SEM was performed at 5 kV.

Reaction conditions

The reaction mixture consisted of 0.05 mmol of KPB (pH 7.0), 10–50 mg of each substrate, 1 μmol of NAD+, 10% (v/v; 1.3 mmol) 2-propanol, and 10 mg of immobilized cells corresponding to the cells obtained from a 10-ml culture and containing approximately 4 units of Sar268 (for acetophenone) or 25 units of LSADH (for trifluoroacetophenone) in a total volume of 1 ml in a 2-ml polypropylene tube. The reaction proceeded for 24 h at 25°C with shaking (2,500 rpm) in a Bioshaker MBR-022 (Taitec, Saitama, Japan). The conversion yield and enantiomeric purity of the product were determined on the basis of the peak areas of ketone substrates and alcohol products in gas chromatograph (GC) as described in the next section.

Analyses of substrates and products

Quantitative analysis of ketone substrates and products was performed with a GC apparatus (Shimadzu GC-14 system, Kyoto, Japan) equipped with a Thermon 1000 (5% on Chromosorb W) packed column (0.25 cm by 2 m) and a flame ionization detector (FID). Nitrogen gas was used as a carrier at 50 ml/min, and injection and detection temperatures were 200 and 240°C, respectively. The column temperature was maintained isothermally at 100°C. Under these conditions, 4-hydroxy-2-butanone and 1,3-butanediol were detected at 4.0 and 6.1 min, respectively. Acetophenone and 1-phenylethanol were analyzed by GC in the same manner as 4-hydroxy-2-butanone and 1,3-butanediol except that the column temperature was 120°C. Acetophenone and 1-phenylethanol were detected at 5.1 and 8.7 min, respectively. An aliquot of the reaction mixture was withdrawn and analyzed directly by GC.

The product was extracted three times with 0.4 ml of ethyl acetate from the reaction mixture (1 ml) following the addition of solid NaCl to saturation, and thoroughly dried with anhydrous Na2SO4, and the solvent was removed by evaporation. As chemical modification was necessary to determine the absolute configurations of 1,2-propanediol, 1-chloro-2-propanol, and 1,3-butanediol, the products were converted into acetyl derivatives with anhydrous acetyl chloride. One hundred microliters of acetyl chloride was added to each product and maintained at 0°C for 15 min, and then, 100 μl of water was added to the solution to eliminate unreacted acetyl chloride. Acetyl derivatives of alcohol products were extracted twice with 0.5 ml of ethyl acetate. The ethyl acetate layer was washed several times with water and dried with anhydrous Na2SO4 and used for the analysis. In the case of 2,3-butanediol, it was reacted with trifluoroacetic anhydride in the same manner as with acetyl chloride to give the trifluoroacetyl derivative.

Acetyl or trifluoroacetyl derivatives of the alcohols produced were analyzed by GC using a Hewlett Packard HP 6800 GC system equipped with a chiral capillary column (CP-cyclodextrin-β-236-N19, 0.25 mm × 25 m, Chrompack, Midderberg, The Netherlands) with an FID. GC was carried out under the following conditions: a column temperature of 40°C for the trifluoroacetyl derivative of 2,3-butanediol, injection and detection temperatures of 250°C, and a flow rate of 0.5 ml min-1 of He (linear velocity 17 cm/s), and split ratio of 50; a column temperature of 60°C for the acetyl derivative of 1-chloro-2-propanol; 80°C for 1,2-propanediol; 85°C for 1,3-butanediol, injection and detection temperatures of 200°C, and the same flow rate of He and split ratio as for 2,3-butanediol. The retention time was 11.8 min for the trifluoroacetyl derivative of (R,S)-, 12.6 min for (S,S)-, and 12.8 min for (R,R)-2,3-butanediol; 9.4 min for (S)- and 10.4 min for (R)-1-chloro-2-propanol; 11.4 min for (S)- and 12.4 min for (R)-1,2-propanediol; 18.5 min for (S)- and 20.1 min for (R)-1,3-butanediol, respectively. The absolute configuration of 1-phenylethanol was determined as described previously using the same GC apparatus (Itoh et al. 1997).

Stability of enzyme on repeated use

Enzyme stability was examined in subsequential batch reactions performed over a period of 15 h at 30°C using 1% acetophenone for Sar268 or 12 h at 30°C using 1% 4-hydroxy-2-butanone for LSADH. The reaction conditions were described in “Reaction conditions”. After each reaction, the immobilized cells were washed with 50 mM KPB (pH 7.0) and centrifuged to eliminate the remaining substrate and product.

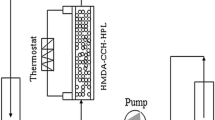

Continuous production of (R)-1,3-butanediol in a packed bed reactor

Immobilized E. coli XL1-Blue (LSADH) cells (10 ml:1 g dry weight containing about 250 U of LSADH activity) were packed in a small column (15 by 60 mm). The reaction mixture consisting of 5% (w/v) 4-hydroxy-2-butanone, 10% (v/v) 2-propanol, 1 mM NAD+, and 50 mM KPB (pH 7.0) was added into the column at a flow rate of 10 ml h-1 at 30°C, and the product was analyzed according to the methods in “Analyses of substrates and products”.

Results

Substrate and stereospecificity of Sar268 and LSADH

We have shown that PAR and LSADH are unique NAD+-dependent ADHs with a broad substrate range of more than 40 ketones and display high stereoselectivity for generating (S)- and (R)-form alcohols, respectively, without an additional coenzyme regeneration system (Itoh et al. 1997, 1999, 2002; Inoue et al. 2005a, b, 2006). For determining the stereospecificity of Sar268 and LSADH, the absolute configurations of the alcohol products from some water-soluble ketones were measured as an acetyl or trifluoroacetyl derivative. Table 1 shows the relative activity and stereoselectivity for the reductive reaction of Sar268 and LSADH for short-chain alkyl ketones (C3–C4), which we had not tested in our previous work. As we expected, Sar268 followed Prelog’s rule (Prelog 1964) to produce (S)-form alcohols, and LSADH followed anti-Prelog’s rule to produce (R)-form alcohols from these ketones. Although the stereoselectivities of Sar268 towards these ketones were not satisfactory except 4-hydroxy-2-butanone [87% enantiomeric excess (e.e.), S-form], those of LSADH were high enough.

Preparation and evaluation of immobilized E. coli cells catalyst

Whole E. coli cells that had sufficiently accumulated Sar268 or LSADH were directly immobilized by cross-linking with GA and PEI/DAH. Enzyme leakage from immobilized E. coli (Sar268) cells was tested following disruption with glass beads by hard mixing, which is one of the strongest disruption methods. The enzyme activity in the supernatant solution was only 1–1.5% of that obtained from the cells treated with 3% PEI and 0.5% GA and 2.2% of that from the cells treated with 3% DAH and 0.5% GA, respectively. As the treatment with PEI and GA showed the best results, for further experiments, immobilization protocols using GA in combination with PEI were adopted. As the enzyme proteins were tightly immobilized in E. coli cells coated with PEI and GA polymer, enzyme activity eluted from the immobilized E. coli cells was not detected under the general reaction conditions. As shown in Fig. 1a, a clear cell aggregate form of immobilized biocatalyst was observed by SEM. The density of dry immobilized E. coli biocatalyst was 0.1 ± 0.01 g/ml.

Repeated use of immobilized E. coli biocatalyst

Figure 2 shows the repeated use of immobilized E. coli (Sar268) biocatalyst on batch reaction for the reduction in acetophenone. The reaction was successively carried out as described in “Materials and methods,” and the data were compared with that of intact E. coli (Sar268) cells. Interestingly, intact E. coli cells also showed sufficient activity until the seventh successive reaction (total 96 h) without loss of activity, suggesting that enzyme proteins were retained in E. coli cells during the reaction. As illustrated in Fig. 1b, the 2-propanol solution system requires no other detergents to increase the permeability of cells and can make it possible for the enzyme to efficiently interact with cofactors, substrates, and hydrogen donor (2-propanol) in the cells.

The results in Fig. 2 indicate that the concentration of PEI used for immobilization influenced the operational stability of immobilized cells, and the cells treated with 3% PEI showed better stability than those treated with lower PEI concentrations (0.5 and 1%). Thus, the combination of 3% PEI and 0.5% GA was used for the immobilization of E. coli cells. The immobilized E. coli biocatalyst could be used more than 30 times (for about 500 h) with no decrease in conversion. The yields of around 85% (not 100%) observed during the batch reactions were due to the equilibrium between acetophenone and 1-phenylethanol (K eq = [1-phenylethanol][NADH]/[acetophenone][NAD+][H+] = 5.7 × 107 M-1; Itoh et al. 1997). It was confirmed that there was no decrease in the enantioselectivity of acetophenone reduction by the immobilized E. coli biocatalyst (99% e.e.) after successive batch reactions (600 h).

Figure 3 shows the repeated use of immobilized E. coli (LSADH) cells with 3% PEI and 0.5% GA in the same manner as for E. coli (Sar268) cells. The batch reaction data for the reduction in 4-hydroxy-2-butanone were compared with those for intact E. coli (LSADH) cells. The results were very similar to those observed for E. coli (Sar268). The intact E. coli cells were stable through a total of seven successive reactions (total 84 h) and then rapidly lost their activity on further use. The half-life of the enzyme activity in the intact E. coli cells calculated from the data was 130 h, while the immobilized E. coli (LSADH) biocatalyst retained more than 90% conversion yield until 40 successive uses (about 480 h), and its conversion activity gradually decreased. The half-life of the biocatalyst calculated from our data was 600 h, indicating that immobilization with 3% PEI and 0.5% GA can prolong the half-life of E. coli biocatalyst about five times.

We measured the initial reduction rates of two immobilized biocatalysts on batch reactions using 3 or 5% concentrations of 4-hydroxy-2-butanone to calculate the space time yield (STY). The STY of immobilized E. coli (Sar268) was 12.5 mg h−1 ml−1 catalyst (about 0.1 g) in 3% 4-hydroxy-2-butanone and those of E. coli (LSADH) were 60.3 mg h−1 ml−1 catalyst in 3% and 75.0 mg mg h−1 ml−1 catalyst in 5% 4-hydroxy-2-butanone.

Continuous operation of immobilized E. coli biocatalyst to produce (R)-1,3-butanediol

On the basis of the above results, the operational stability and productivity of immobilized E. coli (LSADH) biocatalyst for the reduction in 4-hydroxy-2-butanone to (R)-1,3-butanediol was studied in a packed bed reactor (15 by 60 mm) containing 10 ml of catalyst. As the STY of E. coli (LSADH) cells was 75.0 mg mg h−1 ml−1 catalyst in 5% 4-hydroxy-2-butanone, the productivity of this column reactor was predicted to be 750 mg h−1/10 ml catalyst. Experiments were performed at the resident time of 1 h (flow rate of reaction mixture at 10 ml h−1) using 5% 4-hydroxy-2-butanone in the inflow solution. The results in Fig. 4 showed that this reactor was stable for at least 500 h and then gradually lost its activity. The conversion yield of 4-hydroxy-2-butanone was 99% (49.5 g/l of (R)-1,3-butanediol), suggesting the existence of equilibrium between 4-hydroxy-2-butanone and (R)-1,3-butanediol. After a 500-h continuous reaction, the reactor (10-ml catalyst) produced approximately 250 g of (R)-1,3-butanediol (99% e.e.) with 99% conversion. The optical purity of produced (R)-1,3-butanediol maintained 99% e.e, when the conversion yield decreased after 600-h continuous reaction.

Discussion

As shown in Table 1, the stereoselectivities of Sar268 and LSADH decreased as the chain length of alkyl ketones decreased, as these enzymes show almost 100% stereoselectivity towards medium-chain alkyl ketones of between C5 and C8 and aryl ketones (Itoh et al. 1997, 2002; Inoue et al. 2005b). Indeed, this tendency was more evident for Sar268 than for LSADH. However, the e.e. of (S)-and (R)-1,3-butanediols produced from 4-hydroxy-2-butanone were 87 and 99% and that of (2R,3R)-2,3-butanediol from diacetyl was 92%, which were acceptable for practical usage. The results indicated that Sar268 and LSADH were useful biocatalysts for producing such water-soluble short-chain chiral diol or halohydrin compounds if the enzyme’s stereoselectivity could be further improved by protein engineering.

We found that 2-propanol solutions lower than 20% (v/v) were useful for recombinant E. coli whole-cell systems if the enzyme was active and stable under these conditions because 2-propanol increases not only the permeability of the cell membrane for cofactors such as NAD+/NADH and various substrates/products but also the solubility of some water-insoluble ketone substrates without causing leakage of enzyme molecules from the cells, as illustrated in Fig. 1b. It is evident that using 2-propanol solution is more effective for immobilized whole-cell system than for intact whole-cell system (Figs. 2 and 3).

We observed that the concentration of PEI used for immobilization influenced the operational stability of immobilized cells, and the cells treated with 3% PEI showed better stability than those treated with lower PEI concentrations (Fig. 2). The immobilized E. coli biocatalyst could be used more than 30 times (for about 500 h) with no decrease in conversion. Thus, our simple cross-linking immobilization method using PEI and GA for E. coli cells is very useful to increase the stability of this biocatalyst during operation. In addition, it makes it possible to store the E. coli biocatalyst as a dry powder before use. We observed that there was no loss of activity at least for 3 months at −20°C for both catalysts in storage. As described in previous reports (Bahulekar et al. 1991; Bai and Yang 2005), there are many variations of methods to immobilize cells or enzymes using PEI and GA. Our procedure, described here, is much simpler than previously reported ones, and therefore, it would be useful to apply it for many recombinant E. coli cells systems for biotransformation in combination with polar organic solvent–aqueous systems.

We have recently succeeded in increasing the STY of E. coli (LSADH) twofold (to about 150.0 mg mg h−1 ml−1 catalyst in 5% 4-hydroxy-2-butanone) by changing the E. coli host from XL1-Blue to BL21 (Inoue et al. 2006). Therefore, the productivity of this continuous bioreduction process could be further improved by the combination of optimizing reaction conditions, recycling of NAD+/NADH and 2-propanol in the reaction mixture, and so on. Matsuyama et al. (1993; Yamamoto et al. 1999) reported an oxidative racemic resolution of (R,S)-1,3-butanediol to produce (R)-1,3-butanediol by Candida parapsilosis secondary ADH. This bioprocess is industrially used by Daicel Chemical Industries, Osaka, Japan. We expect the bioreduction process with immobilized recombinant E. coli cells (LSADH) to be another practical way to produce a large amount of (R)-1,3-butanediol.

References

Bahulekar R, Ayyangar NR, Ponrathnam S (1991) Polyethyleneimine in imobilization of biocatalysts. Enzyme Microb Technol 13:858–868

Bai Y, Yang ST (2005) Biotransformation of R-2-hydroxy-4-phenylbutyric acid by d-lactate dehydrogenase and Candida boidinii cells containing formate dehydrogenase coimmobilized in a fibrous bed bioreactor. Biotechnol Bioeng 92:137–146

Bradshaw CW, Fu H, Shen GJ, Wong CH (1992) A Pseudomonas sp. alcohol dehydrogenase with broad substrate specificity and unusual stereospecificity for organic synthesis. J Org Chem 57:1526–1532

Breuer M, Ditrich K, Habicher T, Hauer B, Keeler M, Sturmer R, Zelinski T (2004) Industrial methods for the production of optically active intermediates. Angew Chem Int Ed 43:788–824

Hummel W (1997) New alcohol dehydrogenases for the synthesis of chiral compounds. Adv Biochem Eng Biotechnol 58:145–184

Hummel W, Kula MR (1989) Dehydrogenases for the synthesis of chiral compounds. Eur J Biochem 184:1–13

Inoue K, Makino Y, Itoh N (2005a) Purification and characterization of a novel alcohol dehydrogenase (LSADH) from Leifsonia sp. S749, a promising biocatalyst for an asymmetric hydrogen-transfer bioreduction. Appl Environ Microbiol 71:3633–3641

Inoue K, Makino Y, Itoh N (2005b) Production of (R)-chiral alcohols by a hydrogen-transfer bioreduction with NADH-dependent Leifsonia alcohol dehydrogenase (LSADH). Tetrahedron Asymmetry 16:2539–2549

Inoue K, Makino Y, Dairi T, Itoh N (2006) Gene cloning and expression of Leifsonia alcohol dehydrogenase (LSADH) involved in asymmetric hydrogen-transfer bioreduction to produce (R)-form chiral alcohols. Biosci Biotechnol Biochem 70:418–426

Itoh N, Morihama R, Wang JC, Okada K, Mizuguchi N (1997) Purification and characterization of phenylacetaldehyde reductase from a styrene-assimilating Corynebacterium strain, ST-10. Appl Environ Microbiol 63:3783–3788

Itoh N, Mizuguchi N, Mabuchi M (1999) Production of chiral alcohols by enantioselective reduction with NADH-dependent phenylacetaldehyde reductase from Corynebacterium strain, ST-10. J Mol Catal B Enzym 6:41–50

Itoh N, Matsuda M, Mabuchi M, Dairi T, Wang JC (2002) Chiral alcohol production by NADH-dependent phenylacetaldehyde reductase coupled with in situ regeneration of NADH. Eur J Biochem 269:2394–2402

Kosjek B, Stampfer W, Pogorevc M, Goessler W, Faber K, Kroutil W (2004) Purification and characterization of a chemotolerant alcohol dehydrogenase applicable to coupled redox reactions. Biotechnol Bioeng 86:55–62

Makino Y, Inoue K, Dairi T, Itoh N (2005) Engineering of phenylacetaldehyde reductase for efficient substrate conversion in concentrated 2-propanol. Appl Environ Microbiol 71:4713–4720

Matsuyama A, Kobayashi Y, Ohnishi H (1993) Microbial production of optically active 1,3-butanediol from the racemate. Biosci Biotechnol Biochem 57:685–686

Nakamura K, Yamanaka R, Matsuda T, Harada T (2003) Recent developments in asymmetric reduction of ketones with biocatalysts. Tetrahedron Asymmetry 14:2659–2681

Noyori R, Ohkuma T (2001) Asymmetric catalysis by architectural and functional molecular engineering: practical chemo- and stereoselective hydrogenation of ketones. Angew Chem Int Ed 40:40–73

Prelog V (1964) Specification of the stereospecificity of some oxidoreductases by diamond lattice sections. Pure Appl Chem 9:119–130

Shimizu S, Kataoka M, Kita K (1998) Chiral alcohol synthesis with microbial carbonyl reductases in a water–organic solvent two-phase system. Ann N Y Acad Sci 864:87–95

Stampfer W, Kosjek B, Faber K, Kroutil W (2003) Biocatalytic asymmetric hydrogen transfer employing Rhodococcus ruber DSM44541. J Org Chem 68:402–406

Wong CH, Whitesides G (1994) Enzymes in synthetic organic chemistry. Pergamon, Oxford, UK, pp 131–194

Yamamoto H, Kawada N, Matsuyama A, Kobayashi Y (1999) Cloning and expression in Escherichia coli of a gene coding for a secondary alcohol dehydrogenase from Candida parapsilosis. Biosci Biotechnol Biochem 63:1051–1055

Yamamoto H, Mitsuhashi K, Kimoto N, Kobayashi Y, Esaki N (2005) Robust NADH-regenerator: improved alpha-haloketone-resistant formate dehydrogenase. Appl Microbiol Biotechnol 67:33–39

Acknowledgements

The study was supported in part by Grant-in-Aids for Scientific Research from the Ministry of Education, Culture, Sports, Science and Technology of Japan and Japan Foundation of Applied Enzymology, Osaka, Japan. We wish to thank Sumitomo Chemical, Osaka, Japan for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Itoh, N., Nakamura, M., Inoue, K. et al. Continuous production of chiral 1,3-butanediol using immobilized biocatalysts in a packed bed reactor: promising biocatalysis method with an asymmetric hydrogen-transfer bioreduction. Appl Microbiol Biotechnol 75, 1249–1256 (2007). https://doi.org/10.1007/s00253-007-0957-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-007-0957-1