Abstract

We report in this study an improved system for cell-free protein synthesis at high temperatures using the lysate of Thermococcus kodakaraensis. Previous work indicated that cell-free protein synthesis of ChiAΔ4, a derivative of T. kodakaraensis chitinase, was observed within a temperature range of 40–80°C, and the maximum yield of the ChiAΔ4 synthesized was approximately 1.3 μg/ml. To increase productivity of the system, the following approaches were taken. First, the process of lysate preparation was examined, and we found that omitting the preincubation (runoff) step was especially effective to increase the translational activity of lysate. Second, the concentrations of each reaction mixture were optimized. Among them, the requirement of a high concentration of potassium acetate (250 mM) was characteristic to the T. kodakaraensis system. Third, a mutant strain of T. kodakaraensis was constructed in which a heat shock transcriptional regulator gene, phr, was disrupted. By using the lysate made from the mutant, we observed an increase in the optimum reaction temperature by 5°C. Through these modifications to the system, the yield of ChiAΔ4 was dramatically increased to 115.4 μg/ml in a batch reaction at 65°C, which was about 90 times higher than that in the previous study. Moreover, in the optimized system, a high speed of protein synthesis was achieved: over 100 μg/ml of ChiAΔ4 was produced in the first 15 min of reaction. These results indicate that the system for cell-free protein synthesis based on T. kodakaraensis lysate has a high production potential comparable to the Escherichia coli system.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cell-free protein synthesis is a valuable method to synthesize protein in vitro by using cell lysate and mRNA (or DNA) as a template. A common methodology for cell-free protein synthesis is to use the lysates from various organisms. In particular, systems using Escherichia coli and wheat germ lysates have been developed greatly through improvements in lysate preparation (Endo and Sawasaki 2003; Kim et al. 2006a; Liu et al. 2005), optimization of the reaction mixture composition (Kawarasaki et al. 1995; Kigawa et al. 1999), or genetic alterations of host cells (Jiang et al. 2002). As a result, over 300 μg/ml of productivity with the E. coli system (Kim et al. 2006b; Zawada and Swartz 2006) and 55 μg/ml of productivity with the wheat germ system (Nakano et al. 1996) were achieved in 1 h of batch reaction.

Previously, we reported the development of a novel system for cell-free protein synthesis that can be operated at high temperatures using a lysate of Thermococcus kodakaraensis. T. kodakaraensis KOD1 is a hyperthermophilic archaeon isolated from a solfatara on Kodakara Island, Kagoshima, Japan (Atomi et al. 2004; Morikawa et al. 1994). The organism can grow between 60 and 100°C with an optimal growth temperature of 85°C. Using the system, synthesis of ChiAΔ4, a truncated form of T. kodakaraensis chitinase (Tanaka et al. 1999), was observed within a temperature range of 40 to 80°C. Although cell-free protein synthesis was observed at an elevated temperature, the maximum yield of the synthesized protein remained at 1.3 μg/ml. In addition, there was a significant difference between the optimal growth temperature of T. kodakaraensis (85°C) and the optimal temperature of cell-free protein synthesis (65°C). Around the optimal growth temperature, the speed of protein synthesis inside the cells should be very rapid, and therefore, if the optimal reaction temperature of cell-free protein synthesis can be increased close to 85°C, there is a possibility that the yield of protein synthesized might increase as a result of a higher speed of protein synthesis.

To improve the productivity of the T. kodakaraensis system, we have examined the lysate preparation process as well as the reaction mixture composition. In addition, gene manipulation of T. kodakaraensis relating to an intracellular heat shock regulator was tested, and its effect on cell-free protein synthesis was evaluated. As a result, over 100 μg/ml of productivity was achieved with the T. kodakaraensis system in a 15-min batch reaction.

Materials and methods

Chemicals

Sulfur, Tris–acetate, ammonium acetate, polyethyleneglycol 8000 (PEG8000), potassium phosphoenolpyruvate (PEP), trehalose, ectoin, and hydroxyectoin were purchased from Wako Pure Chemical Industries (Osaka, Japan). ATP, GTP, CTP, UTP, 20 amino acids, and betaine hydrochloride were from Sigma (St. Louis, MO, USA). The RNase inhibitor was an RNAsecure™ from Ambion (Austin, TX, USA). All the other reagents were obtained from Nacalai Tesque (Kyoto, Japan).

Construction of T. kodakaraensis Δphr strain

Disruption of phr gene (TK2291) by double-crossover homologous recombination was performed using the technique developed for T. kodakaraensis as described previously (Sato et al. 2003, 2005). The plasmid DNA used for disruption of phr was constructed as follows. A DNA fragment containing the phr coding region together with its flanking regions (about 1,000 bp) was amplified with the primer sets PKHR-L1 (5′-TGTCGTTCCAAAGCCAAAGG-3′) and PKHR-R2 (5′-TGTCTCTCCCTCTTCCCTGG-3′) using genomic DNA of T. kodakaraensis KOD1 as a template and was inserted into the HincII site of pUC118. Using the constructed plasmid DNA as a template, the flanking regions of phr along with the plasmid backbone were amplified using primer sets PKHR-L2 (5′-CCCTTTCCCTAACCCAAAGT-3′) and PKHR-R1 (5′-GAAGTCGTTAAAGGAGAAAG-3′), and the amplified fragment was designated as L-Phr. A PvuII–PvuII restriction fragment (763 bp) containing the pyrF marker gene was excised from pUD2 (Sato et al. 2005), and ligation was performed with L-Phr to construct the plasmid for phr disruption (pUPhr). A T. kodakaraensis uracil-auxotroph strain, KU216 (Sato et al. 2005), was used as a host strain for transformation, and pyrF + strain with uracil prototrophy was selected. The genotype of a Δphr strain was confirmed by PCR amplification of a DNA fragment with a length corresponding to that of Δphr locus (data not shown), and the constructed strain was named KHR1.

Preparation of T. kodakaraensis S30 extract

T. kodakaraensis KC1 (ΔchiA) (Endoh et al. 2006) and KHR1 (Δphr) were precultured at 85°C for about 12 h until A 660 reached 0.2–0.4 in a nutrient-rich medium (MA-YT) (Kanai et al. 2005) containing 0.5% (w/v) elemental sulfur under anaerobic conditions. The preculture was used to inoculate 800 ml culture with MA-YT medium supplemented with 0.5% (w/v) sodium pyruvate. This was cultured under anaerobic conditions at 85°C until A 660 reached 0.6–0.7 (about 14 h). Cells were harvested by centrifugation at 5,000×g for 10 min and washed two times with artificial seawater (0.8× Marine Art SF solution) (Tomita Pharmaceuticals, Naruto, Japan) supplemented with 0.05% (v/v) 2-mercaptoethanol.

The preparation of the S30 extract used for cell-free protein synthesis was performed based on our previous method (Endoh et al. 2006), unless stated otherwise, under RNase-free conditions. Cells were suspended in S30 buffer (1.27 ml per gram of wet cells), which was composed of 10 mM Tris–acetate buffer (pH 7.4), 14 mM magnesium acetate, 60 mM potassium acetate, and 1.0 mM dithiothreitol (DTT). T. kodakaraensis cells were disrupted with a French press (FA-003, Thermo Electron, Waltham, MA, USA), and DTT was added to the resulting lysate to a final concentration of 1.0 mM (10 μl per milliliter of lysate). The lysate was then centrifuged at 30,000 × g for 30 min at 4°C. The upper four-fifths of the supernatant was collected, and a second 30,000 × g centrifugation was repeated for 30 min at 4°C, again collecting only the upper four-fifths of the supernatant. The mixture was then dialyzed three times (45 min each) against the 40 times volume of S30 buffer using 7000 MWCO dialysis tubes (Pierce Chemical, Rockford, IL, USA). After centrifugation at 4,000 × g for 10 min, the resulting supernatant was used as S30 extract. Protein concentration was determined by the Bio–Rad protein assay system (Bio–Rad, Hercules, CA, USA) with bovine serum albumin as the standard. S30 extract was stored at −80°C until use.

mRNA preparation

mRNA encoding ChiAΔ4 was prepared with the T7 RiboMAX™ Express RNA system (Promega, Madison, WI, USA) using a plasmid DNA, pTRC1 (Endoh et al. 2006), treated with EcoRI as a template. The prepared mRNA was suspended in RNase-free water and stored at −80°C until use.

Cell-free protein synthesis reaction

The cell-free protein synthesis reaction was performed in a 30-μl batch scale using mRNA encoding ChiAΔ4 as a template. The reaction mixture contained ChiAΔ4 mRNA (0.4 mg/ml), T. kodakaraensis S30 extract made from either KC1 or KHR1, and other various ingredients shown in Table 1. The reaction was performed at 60 or 65°C for 60 min, and then the reaction mixture was chilled on ice to stop the reaction.

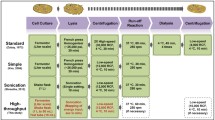

To improve productivity of the system, the method for preparing the S30 extract was first examined using T. kodakaraensis KC1. The modifications tested are listed in Table 2, Batches No. 1 to No. 3, which include modifications in the cell disruption, preincubation, and dialysis steps. Translation activities of S30 extracts were examined at 65°C for 60 min using the initial mixture composition shown in Table 1 (Batches No. 1 to No. 3 in Table 2).

Next, with S30 extract prepared by the improved method, the reaction mixture composition was changed. The concentration of the T. kodakaraensis S30 extract was first varied (from 8.0 to 20 mg/ml) (Fig. 1a). Next, with 16 mg/ml S30 extract, concentrations of reaction constituents were changed within the ranges shown below: 0 to 10 mM magnesium acetate, 0 to 500 mM potassium acetate, 0 to 125 mM ammonium acetate, 0 to 25 mM PEP, 0 to 3 mM (each) 20-amino-acid mixture (20AA mix), and 0 to 6% (w/v) PEG8000 (Figs. 1b–g and 2).

Effect of various reaction constituents on the yield of cell-free protein synthesis using the T. kodakaraensis system. Reaction mixture containing 0.4 mg/ml of ChiAΔ4 mRNA was incubated at 65°C for 90 min, and ChiAΔ4 synthesized was calculated from chitinase activity assay. Concentrations of the following constituents were varied: S30 extract (a), magnesium acetate (b), potassium acetate (c), ammonium acetate (d), PEP (e), 20AA mix (f), and PEG8000 (g). In each graph, the maximum value was set to 100%

a Effect of PEG8000 concentration on ChiAΔ4 synthesis. Reaction mixtures containing 0, 1, 2, 3, 4, 5, and 6% (w/v) of PEG8000 were incubated at 65°C for 90 min and then separated on 12.5% SDS-PAGE gel (lanes 1–7, respectively). The protein synthesized was visualized by rabbit anti-ChiAΔ4 antibodies. b Proposed amino-terminal amino acid sequences and molecular weights of ChiAΔ4 and its derivative devoid of amino-terminal 12 amino acids (ChiAΔ4-M13)

With the above optimized mixture composition (second composition in Table 1), yields of protein synthesis were compared between S30 extracts made from T. kodakaraensis KC1 and KHR1. Reactions were performed at 55, 60, 65, and 70°C for 60 min (Fig. 3) (Batches No. 4 and No. 5 in Table 2).

Effect of reaction temperature on ChiAΔ4 synthesis was compared between S30 extracts made from T. kodakaraensis KC1 (open bars) and T. kodakaraensis KHR1 (filled bars). Reaction mixtures containing 0.4 mg/ml of ChiAΔ4 mRNA were incubated at 55, 60, 65, or 70°C for 60 min. The amount of ChiAΔ4 synthesized was estimated from chitinase activity assay. Results are the average of n = 3 reactions, and error bars represent standard deviations. The maximum value was set to 100%

Using the S30 extract made from KHR1, the concentrations of ATP and GCU mix (mixture of GTP, CTP, and UTP) were changed within the ranges shown below: 0 to 7 mM ATP, and 0 to 5 mM (each) GCU mix (Fig. 4a,b). The initial pH value of Tris–acetate buffer was also varied from 7.0 to 9.0 (Fig. 4c).

Effect of various reaction constituents on the yield of cell-free protein synthesis using the T. kodakaraensis system. Reaction mixture containing 0.4 mg/ml of ChiAΔ4 mRNA was incubated at 65°C for 90 min, and ChiAΔ4 synthesized was calculated by chitinase activity assay. Concentrations or values of the following constituents were varied: ATP (a), GCU mix (b), and initial pH value of Tris–acetate buffer (c). In each graph, the maximum value was set to 100%

Finally, with the reaction mixture composition so far being optimized (3rd composition in Table 1) and S30 extract made from KHR1, the cell-free translation reaction was performed at 65°C (Batch No. 6 in Table 2), and the reaction time course was monitored (Fig. 5).

Reaction time course of ChiAΔ4 synthesis. a Detection by activity measurement. Batch reactions were carried out under three different conditions: Batch No. 1 (filled diamonds), Batch No. 4 (filled triangles), and Batch No. 6 (filled circles). Detailed reaction conditions are described in Table 2. Reaction mixtures containing 0.4 mg/ml of ChiAΔ4 mRNA were incubated at 60 or 65°C for up to 90 min, and the ChiAΔ4 synthesized was calculated by chitinase activity assay. Results are the average of n = 3 reactions, and error bars represent standard deviations. b Detection by Western blot analysis. Reaction mixtures (Batch No. 6) incubated at 65°C for 0, 5, 10, 15, 20, 30, 45, 60, or 90 min (lanes 1–9, respectively) were separated on the 12.5% SDS-PAGE gel, and the synthesized protein was visualized by rabbit anti-ChiAΔ4 antibodies. Purified recombinant ChiAΔ4 with a concentration of 200 μg/ml was applied as a positive control (lane 10)

Enzyme assay

The chitinase activity assay was performed according to the procedure described previously (Endoh et al. 2006) using a fluorometric substrate, 4-methylumbelliferyl-β-d-N,N′-diacetyl chitobioside (Sigma). After a 30-min reaction at 90°C, the fluorescence of liberated 4-methylumbelliferone was measured (excitation: ca. 365 nm; emission: 460 nm) with a NanoDrop ND-3300 Fluorospectrometer (NanoDrop Technologies, Wilmington, NC, USA). The amount of the active ChiAΔ4 synthesized was calculated using the specific activity of purified ChiAΔ4 (0.135 nmol min−1 μg−1).

Western blot analysis

After cell-free protein synthesis, 0.1 μl of the reaction mixture was analyzed by sodium dodecyl sulfate-polyacrylamide gel electrophoresis (12.5% acrylamide concentration). Western blot analysis was performed according to the procedure described previously using polyclonal antibodies against ChiAΔ4 (Endoh et al. 2006).

Result

Improvement of lysate preparation method

The preparation method of cell lysate is a crucial step for cell-free protein synthesis, largely affecting yield of total protein synthesis (Endo and Sawasaki 2003; Kim et al. 2006a; Liu et al. 2005). Therefore, we have examined our method of preparing the T. kodakaraensis cell lysate. The setup pressure of French press (2,500, 5,000, 7,500, and 10,000 psi) and the number of passes (one to three passes) were varied at first. In the previous report, three passes at 10,000 psi were employed (Batch No. 1 in Table 2). As a result, the disruption of cells by a single pass with a pressure of 7,500 psi was the best condition, and the level of synthesized protein was increased by approximately 1.5-fold (comparison of Batch No. 1 and Batch No. 2 in Table 2). We also examined the omission of preincubation step, as it was recently reported that this step could be skipped in the lysate preparation of some E. coli strains (Kim et al. 2006a). As a result, the level of synthesized protein was increased by approximately 2.5-fold (comparison of Batch No. 2 and Batch No. 3 in Table 2), indicating that the preincubation step was rather harmful to the T. kodakaraensis lysate. Finally, the effect of dialysis in the last step of lysate preparation was examined, but the omission of the dialysis step slightly decreased the yield of protein synthesis (data not shown).

Optimization of reaction mixture composition I

To achieve a high level of cell-free protein synthesis, an appropriate concentration of each reaction constituent should be determined beforehand (Tarui et al. 2001). In the T. kodakaraensis system, desirable concentrations of each reaction constituent were described in the previous report (Endoh et al. 2006). However, this needs more consideration, as a wide range of reaction conditions remain untested; for some components, only two conditions were tested. In addition to this, as the preparation method of the S30 extract had been changed, we reexamined the conditions of the optimal reaction composition. This time, we introduced a NanoDrop ND-3300 fluorospectrometer for enzyme assay, which enabled us to perform fluorescence measurements in minute samples with high sensitivity. The equipment made possible the fast and accurate measurements of a number of reaction samples.

It is reported that protein concentration of lysate has a significant influence on the yield of protein synthesis in the E. coli system (Pratt 1984). Therefore, we first varied protein concentration of T. kodakaraensis S30 extract. The yield of ChiAΔ4 synthesis increased when increasing the concentration from 8 mg/ml, and then it saturated over 16 mg/ml (Fig. 1a).

Next, with 16 mg/ml of S30 extract concentration employed, suitable concentrations of several mixture ingredients were determined. A sharp peak was detected for magnesium acetate, potassium acetate, ammonium acetate, and PEP at concentrations of 3.0 mM (Fig. 1b), 250 mM (Fig. 1c), 75 mM (Fig. 1d), and 10 mM (Fig. 1e), respectively. As for the 20-amino-acid mixture (20AA mix), the yield of ChiAΔ4 synthesis increased until the 20AA mix concentration reached to 2.0 mM (each), and then it leveled off (Fig. 1f).

Polyethyleneglycol, a common ingredient of the cell-free translation system, is regarded to contribute to the total yield of protein synthesis through stabilization of mRNA. In the T. kodakaraensis system, the optimal PEG8000 concentration was found to be 2.0% (w/v), but over 90% of activity was detected even in the absence of PEG8000 (Fig. 1g). However, when the synthesized protein was detected by Western blot analysis, a band that migrated slightly faster than ChiAΔ4 appeared in the PEG8000-free sample (Fig. 2a). We think that this band corresponds to a read-through product translated from the second methionine (Met13) codon (ChiAΔ4-M13 in Fig. 2b) while retaining a comparable activity to the level of ChiAΔ4. The result in this study indicates that PEG8000 constitutes an important component for producing ChiAΔ4 by the T. kodakaraensis system. Appropriate concentrations of reaction constituents shown in this section were summarized as the second composition in Table 1.

As we have changed preparation method of lysate and reaction mixture composition, temperature profile of reaction was reexamined in the second mixture composition using S30 extract of T. kodakaraensis KC1. Within a range from 55 to 70°C, the maximum yield was obtained at 60°C (Fig. 3), which is a lower temperature than that reported in the previous study (65°C) (Endoh et al. 2006). On the other hand, the yield of ChiAΔ4 synthesized in the condition was notably increased to 74.9 μg/ml (Batch No. 4 in Table 2).

Attempts to increase the reaction temperature optimum

We next examined whether the reaction temperature optimum can be increased. In the previous study, a possibility was suggested that proteinous components in the S30 extract were undergoing thermal degradation over the optimal reaction temperature (Endoh et al. 2006). Therefore, to increase the temperature optimum, it is important to prevent the lysate from thermal degradation.

In Pyrococcus furiosus, a close phylogenetic relative of T. kodakaraensis, there is a transcriptional factor, Phr, responsible for gene expressions of several heat shock proteins (HSPs) (Vierke et al. 2003). A model is proposed that Phr binds to the promoter regions of HSP genes and represses their transcriptions under normal growth temperature. Phr is conserved in several archaeal species, and T. kodakaraensis contains its ortholog gene (TK2291). In this study, we hypothesized that the disruption of the phr gene would result in an increase in HSP levels in cells through derepression of HSP genes. If this is the case, the use of the Δphr strain as a source of S30 extract may result in an increase in the optimal reaction temperature. Therefore, Δphr strain of T. kodakaraensis was constructed (strain KHR1), and S30 extract made from T. kodakaraensis KHR1 was used to examine the temperature profile of reaction. As a result, the maximum yield of ChiAΔ4 was observed at a higher temperature of 65°C (Fig. 3). The yield of ChiAΔ4 synthesized in this condition was 85.0 μg/ml (Batch No. 5 in Table 2), which was significantly higher than the maximum yield using a lysate of KC1 (Batch No. 4 in Table 2).

It was reported that some low molecular substances, known as “compatible solutes”, have a function to protect enzymes against heat inactivation (Borges et al. 2002; Carninci et al. 1998; Ramos et al. 1997). Therefore, we also examined the effects of several compatible solutes added to the T. kodakaraensis system. While the addition of trehalose (50 mM) virtually gave no effect to the yield of protein synthesis at 65°C, its addition at 67 and 69°C resulted in 10–25% increase in yields of protein synthesis. However, yields of protein production observed at 67 and 69°C were still lower than that at 65°C (data not shown). On the other hand, no considerable effects were found by the addition of ectoin (50 mM) or hydroxyectoin (50 mM) at 67°C, while the addition of betaine (50 mM) completely inhibited protein synthesis at 67°C.

Optimization of reaction mixture composition II

Using T. kodakaraensis KHR1 as a source of S30 extract, the concentrations of reaction constituents that were not verified in the previous section were changed. Both ATP and GTP are the essential factors for translation reaction (Tarui et al. 2001). The optimal concentrations of ATP and GCU mix were 3.0 mM (Fig. 4a) and 1.5 mM each (Fig. 4b), respectively. It is well known that all nucleoside triphosphates (NTP) are present as an NTP–Mg2+ complex in the cell (Berg et al. 2002). Followed by an increase in NTP concentration, the optimum concentration of magnesium acetate was changed to 4.0 mM.

An addition of spermidine was reported to enhance cell-free protein synthesis in the E. coli (Yin and Swartz 2004) and the insect (Tarui et al. 2001) systems. We also observed that the addition of 0.2 mM spermidine was effective for the T. kodakaraensis system to some extent (about 5%). Finally, initial pH value of Tris–acetate buffer was examined, and the optimal value was determined to be 8.2 (Fig. 4c). The best concentrations or value of reaction constituents shown in this section were summarized as the “third composition” in Table 1.

Reaction time course and yield of protein synthesis

As an overall summary of the present study, cell-free protein synthesis was performed under the best reaction condition (Batch No. 6 in Table 2), and reaction time course was monitored by measuring chitinase activity. The amount of ChiAΔ4 synthesized increased rapidly, exceeding over 100 μg/ml within 15 min of incubation, and was nearly saturated at 30 min (Fig. 5a). The highest concentration of ChiAΔ4 obtained was 115.4 μg/ml (at 30 min), which is about 90 times higher than that in the previous study (Endoh et al. 2006).

To confirm the high productivity of the system, the synthesized ChiAΔ4 was detected by Western blot analysis (Fig. 5b), and the signal intensities were quantified by a chemiluminescence image analyzer. Reaction samples corresponding to incubation times of 20, 30, 45, 60, and 90 min (lanes 5–9) gave about 60 to 68% signal intensities of that of a positive control (lane 10). As the control fraction contained recombinant ChiAΔ4 with a concentration of 200 μg/ml, the data demonstrated that over 100 μg/ml ChiAΔ4 protein was actually produced by the T. kodakaraensis-based cell-free system.

Discussion

In our previous study, the highest concentration of the synthesized protein (ChiAΔ4) by the T. kodakaraensis system was only 1.3 μg/ml (Endoh et al. 2006), which was less than one-hundredth of the optimized E. coli system (Kim and Swartz 1999; Kim and Choi 2000). In this study, through improvements in lysate preparation and reaction mixture composition, as well as genetic modification of T. kodakaraensis, the protein yield of the T. kodakaraensis system was increased to 115.4 μg/ml in 30 min of batch reaction.

In the preparation of E. coli S30 extract, preincubation (runoff) reaction plays an important role to obtain a lysate with high translation activity by terminating ongoing translation reactions (Liu et al. 2005). In our previous lysate preparation, preincubation was performed at 37°C, a relatively low temperature for T. kodakaraensis. However, an elevation of preincubation temperature to 60°C resulted in a dramatic loss of translation activity (unpublished result). On the contrary, omitting the preincubation step rather increased the translation activity by 2.5-fold. At present, it is not clear why preincubation step is harmful for the T. kodakaraensis lysate, but we think that the translational activity of the cell lysate might be lost after incubation at high temperature. Another possibility is that, as T. kodakaraensis is an obligate anaerobe, a long-time exposure to air caused the oxidation of the lysate, which might gave the fatal effect to the translational activity.

The speed of cell-free protein synthesis reported in a batch reaction of the E. coli system was over 300 μg/ml/h (Kim et al. 2006b; Zawada and Swartz 2006). In our optimized T. kodakaraensis system, the highest speed of protein synthesis obtained was approximately 100 μg/ml/15 min (Batch No. 6 in Fig. 5a), which is comparable to the levels of the E. coli system. However, a relatively short duration of reaction in the T. kodakaraensis system (about 30 min) hampers the further increase in protein yield. In the T. kodakaraensis system, PEP is added as an energy substrate for ATP regeneration, but it was reported that PEP is easy to be degraded, especially in cell lysate (Kim and Swartz 1999). Recently, in the E. coli system, adoption of a new energy regeneration system composed of creatine kinase and creatine phosphate significantly contributed to prolong the reaction time (Kigawa et al. 1999). Although the same system cannot be applied to our system that works under high temperatures, developing a means to provide a stable supply of energy will be a key factor in increasing the overall yield of the system.

In the present study, we have determined suitable concentrations of each reaction constituent (the best condition is shown in Table 1 as the third composition). Among them, a high concentration of potassium ion (250 mM) is characteristic to the T. kodakaraensis system comparing to the E. coli system, in which about 100 mM concentration is normally employed (Kim et al. 2006a). The preference for potassium ion may reflect a high intracellular potassium concentration of (hyper)thermophiles (Grayling et al. 1996; Scholz et al. 1992). The requirement of a high potassium concentration (250 to 400 mM) was also reported in the cell-free transcription system operated at 90°C using the P. furiosus RNA polymerase (Hethke et al. 1999). The necessity of high potassium concentration in these systems may be explained by the contribution of potassium ion to the thermostability of biological molecules, such as DNA (Marguet and Forterre 1998) and proteins (Ramos et al. 1997).

T. kodakaraensis is one of the few microorganisms for which the entire genome sequence (Fukui et al. 2005) and genetic transformation technology (Sato et al. 2003, 2005) are both available among hyperthermophiles. In this study, we have utilized these features to construct a gene disruption mutant (Δphr), and an increase in the temperature optimum as well as an increase in the yield of protein synthesis was achieved by using S30 extract made from the mutant. As Phr is suggested to be a transcriptional regulator repressing the HSP expression in normal growth temperature (Vierke et al. 2003), it is proposed that intracellular levels of HSP in the Δphr strain are significantly high. Actually, we found that several proteins, including small heat shock protein, are induced in the Δphr strain (unpublished data). It is very interesting that induction of small numbers of proteins caused an increase in the optimum temperature of cell-free translation, a complex process in which numbers of reactions are concerned. This situation is very similar to a report showing that overexpression of small heat shock protein of a hyperthermophile in E. coli significantly increased the tolerance of cells against heat stress (Laksanalamai et al. 2001). The present result of an increase in the temperature optimum using the Δphr lysate suggested that proteinous substrates are actually undergoing heat inactivation. Therefore, developing a way to prevent heat inactivation of lysate will also be an important topic to prolong reaction duration and thereby to increase the overall yield of the system.

References

Atomi H, Fukui T, Kanai T, Morikawa M, Imanaka T (2004) Description of Thermococcus kodakaraensis sp. nov., a well studied hyperthermophilic archaeon previously reported as Pyrococcus sp. KOD1. Archaea 1:263–267

Berg JM, Tymoczko JL, Stryer L (2002) Biochemistry, 5th edn. Freeman, New York

Borges N, Ramos A, Raven ND, Sharp RJ, Santos H (2002) Comparative study of the thermostabilizing properties of mannosylglycerate and other compatible solutes on model enzymes. Extremophiles 6:209–216

Carninci P, Nishiyama Y, Westover A, Itoh M, Nagaoka S, Sasaki N, Okazaki Y, Muramatsu M, Hayashizaki Y (1998) Thermostabilization and thermoactivation of thermolabile enzymes by trehalose and its application for the synthesis of full length cDNA. Proc Natl Acad Sci USA 95:520–524

Endo Y, Sawasaki T (2003) High-throughput, genome-scale protein production method based on the wheat germ cell-free expression system. Biotechnol Adv 21:695–713

Endoh T, Kanai T, Sato YT, Liu DV, Yoshikawa K, Atomi H, Imanaka T (2006) Cell-free protein synthesis at high temperatures using the lysate of a hyperthermophile. J Biotechnol 126:186–195

Fukui T, Atomi H, Kanai T, Matsumi R, Fujiwara S, Imanaka T (2005) Complete genome sequence of the hyperthermophilic archaeon Thermococcus kodakaraensis KOD1 and comparison with Pyrococcus genomes. Genome Res 15:352–363

Grayling RA, Sandman K, Reeve JN (1996) DNA stability and DNA binding proteins. In: Adams MWW (ed), Enzyme and proteins from hyperthermophilic microorganisms. Academic, California, pp 437–467

Hethke C, Bergerat A, Hausner W, Forterre P, Thomm M (1999) Cell-free transcription at 95°: thermostability of transcriptional components and DNA topology requirements of Pyrococcus transcription. Genetics 152:1325–1333

Jiang X, Oohira K, Iwasaki Y, Nakano H, Ichihara S, Yamane T (2002) Reduction of protein degradation by use of protease-deficient mutants in cell-free protein synthesis system of Escherichia coli. J Biosci Bioeng 93:151–156

Kanai T, Imanaka H, Nakajima A, Uwamori K, Omori Y, Fukui T, Atomi H, Imanaka T (2005) Continuous hydrogen production by the hyperthermophilic archaeon, Thermococcus kodakaraensis KOD1. J Biotechnol 116:271–282

Kawarasaki Y, Kawai T, Nakano H, Yamane T (1995) A long-lived batch reaction system of cell-free protein synthesis. Anal Biochem 226:320–324

Kigawa T, Yabuki T, Yoshida Y, Tsutsui M, Ito Y, Shibata T, Yokoyama S (1999) Cell-free production and stable-isotope labeling of milligram quantities of proteins. FEBS Lett 442:15–19

Kim RG, Choi CY (2000) Expression-independent consumption of substrates in cell-free expression system from Escherichia coli. J Biotechnol 84:27–32

Kim DM, Swartz JR (1999) Prolonging cell-free protein synthesis with a novel ATP regeneration system. Biotechnol Bioeng 66:180–188

Kim TW, Keum JW, Oh IS, Choi CY, Park CG, Kim DM (2006a) Simple procedures for the construction of a robust and cost-effective cell-free protein synthesis system. J Biotechnol 126:554–561

Kim TW, Kim DM, Choi CY (2006b) Rapid production of milligram quantities of proteins in a batch cell-free protein synthesis system. J Biotechnol 124:373–380

Laksanalamai P, Maeder DL, Robb FT (2001) Regulation and mechanism of action of the small heat shock protein from the hyperthermophilic archaeon Pyrococcus furiosus. J Bacteriol 183:5198–5202

Liu DV, Zawada JF, Swartz JR (2005) Streamlining Escherichia coli S30 extract preparation for economical cell-free protein synthesis. Biotechnol Prog 21:460–465

Marguet E, Forterre P (1998) Protection of DNA by salts against thermodegradation at temperatures typical for hyperthermophiles. Extremophiles 2:115–122

Morikawa M, Izawa Y, Rashid N, Hoaki T, Imanaka T (1994) Purification and characterization of a thermostable thiol protease from a newly isolated hyperthermophilic Pyrococcus sp. Appl Environ Microbiol 60:4559–4566

Nakano H, Tanaka T, Kawarasaki Y, Yamane T (1996) Highly productive cell-free protein synthesis system using condensed wheat-germ extract. J Biotechnol 46:275–282

Pratt JM (1984) Coupled transcription-translation in procaryotic cell-free systems. In: Hames BD, Higgins SJ (eds) Transcription and translation; a practical approach. IRL Press, Oxford, pp 179–207

Ramos A, Raven N, Sharp RJ, Bartolucci S, Rossi M, Cannio R, Lebbink J, van der Oost J, de Vos WM, Santos H (1997) Stabilization of enzymes against thermal stress and freeze-drying by mannosylglycerate. Appl Environ Microbiol 63:4020–4025

Sato T, Fukui T, Atomi H, Imanaka T (2003) Targeted gene disruption by homologous recombination in the hyperthermophilic archaeon Thermococcus kodakaraensis KOD1. J Bacteriol 185:210–220

Sato T, Fukui T, Atomi H, Imanaka T (2005) Improved and versatile transformation system allowing multiple genetic manipulations of the hyperthermophilic archaeon Thermococcus kodakaraensis. Appl Environ Microbiol 71:3889–3899

Scholz S, Sonnenbichler J, Schäfer W, Hensel R (1992) Di-myo-inositol-1,1’-phosphate: a new inositol phosphate isolated from Pyrococcus woesei. FEBS Lett 306:239–242

Tanaka T, Fujiwara S, Nishikori S, Fukui T, Takagi M, Imanaka T (1999) A unique chitinase with dual active sites and triple substrate binding sites from the hyperthermophilic archaeon Pyrococcus kodakaraensis KOD1. Appl Environ Microbiol 65:5338–5344

Tarui H, Murata M, Tani I, Imanishi S, Nishikawa S, Hara T (2001) Establishment and characterization of cell-free translation/glycosylation in insect cell (Spodoptera frugiperda 21) extract prepared with high pressure treatment. Appl Microbiol Biotechnol 55:446–453

Vierke G, Engelmann A, Hebbeln C, Thomm M (2003) A novel archaeal transcriptional regulator of heat shock response. J Biol Chem 278:18–26

Yin G, Swartz JR (2004) Enhancing multiple disulfide bonded protein folding in a cell-free system. Biotechnol Bioeng 86:188–195

Zawada J, Swartz JR (2006) Effects of growth rate on cell extract performance in cell-free protein synthesis. Biotechnol Bioeng 94:618–624

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Endoh, T., Kanai, T. & Imanaka, T. A highly productive system for cell-free protein synthesis using a lysate of the hyperthermophilic archaeon, Thermococcus kodakaraensis . Appl Microbiol Biotechnol 74, 1153–1161 (2007). https://doi.org/10.1007/s00253-006-0753-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-006-0753-3