Abstract

An online removal of nisin by silicic acid coupled with a micro-filter module was proposed as an alternative to reduce detrimental effects caused by adsorption of nisin onto producer, enzymatic degradation by protease, and product inhibition during fermentation. In this study, silicic acid was successfully used to recover nisin from the fermentation broth of Lactococcus lactis subsp. lactis NIZO 22186. The effect of pH (at 6.8 and 3.0) during adsorption process and several eluents (deionized water, 20% ethanol, 1 M NaCl, and 1 M NaCl + 20% ethanol) for desorption were evaluated in a small batch scale. Higher nisin adsorption onto silicic acid was achieved when the adsorption was carried out at pH 6.8 (67% adsorption) than at pH 3.0 (54% adsorption). The maximum recovery was achieved (47% of nisin was harvested) when the adsorption was carried out at pH 6.8 and 1 M NaCl + 20% ethanol was used as an eluent for desorption. Most importantly, nisin production was significantly enhanced (7,445 IU/ml) when compared with the batch fermentation without the online recovery (1,897 IU/ml). This may possibly be attributed to preventing the loss of nisin due the detrimental effects and a higher biomass density achieved during online recovery process, which stimulated production of nisin during fermentation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nisin is a 34-amino acid antimicrobial polypeptide produced during a fermentation of Lactococcus lactis subsp. lactis. Due to its antimicrobial activity against a wide range of Gram-positive bacteria, including several major food-borne pathogens such as Clostridium and Listeria, nisin has been used extensively in the food industry as a natural food preservative. It is the only bacteriocin that is approved for food applications (FDA 1988) and produced commercially.

Nisin production is affected by several cultural factors such as producer strain, nutrient composition of media, pH, temperature, agitation and aeration, as well as the unique characteristic of nisin production, such as substrate and product inhibition, adsorption of nisin onto the producer cells, and enzymatic degradation (Parente and Ricciardi 1999). A dramatic decrease in nisin level after reaching the peak value was suspected to be a result of proteolytic degradation and/or adsorption of nisin by producer cells. Although nisin-specific protease (nisinase) was previously reported in several bacterial strains including Streptococcus thermophilus (Alifax and Chevalier 1962) and Bacillus cereus (Jarvis and Farr 1971), a conclusive study indicating the presence of nisinase in L. lactis is still missing. On the other hand, adsorption of nisin by the producer cells was a well-established concept and was reported to be dependent on the pH of the culture broth (Hurst and Dring 1968; Lee and Kim 1985). Hurst and Dring (1968) found that at pH 6.80 (controlled fermentation), more than 80% of the nisin synthesized was bound to the cells, whereas at a pH below 6.0, more than 80% of the nisin was in the culture fluid. Yang et al. (1992) showed that the optimal pH for bacteriocin adsorption to cells ranges from pH 5.5 to 6.5, which is in accordance with a dramatic decrease in nisin level observed in controlled-pH fermentation compared to uncontrolled-pH fermentation (De Vuyst and Vandamme 1992). Removal of nisin during fermentation would reduce the chance of the nisin being degraded or adsorbed and thus increase the amount of nisin that can be recovered.

Although nisin production was auto-regulated with the nisin itself acting as an inducer molecule or peptide pheromone (Kuipers et al. 1995), a few studies have suggested the presence of product inhibition caused by nisin and showed that removal of nisin from culture broth during fermentation significantly enhanced nisin production (Kim 1997; Kim et al. 1997; Chinachoti et al. 1997; Tolonen et al. 2004). Kim et al. (1998) found that different nisin producers produced nisin to different ceiling concentrations, and once the host-specific ceiling concentration of nisin was reached, then the nisin production stopped even if the producing strain continued to grow well. On the other hand, when the same host carried transposon from different donors, the concentrations of nisin produced were similar. The product inhibition was believed to be the reason that the strains could not produce nisin beyond their ‘ceiling concentrations’, as increase in nisin resistance by introduction of plasmids containing nisin-immunity determinants has been shown to result in higher nisin production and faster growth rate. Tolonen et al. (2004) reported higher total nisin Z production when a column of Amberlite XAD-4 was integrated into the suspended-reactor system. As the column continuously removed the nisin from the broth, nisin concentration did not decrease and remained high throughout the fermentation period. The achieved maximum nisin concentrations from batch fermentations with and without recovery units were comparable and thus supported the idea of ceiling concentration of nisin proposed by Kim et al. (1997). Results of Tolonen et al. (2004) also showed that the column could remove approximately 80% of nisin from the fermentation broth, but only 57% of nisin could be harvested.

Purification steps of large-scale nisin production are commercially sensitive but are suspected to include foam precipitation (frothing), sodium chloride precipitation, centrifugation or ultrafiltration, and spray or drum drying (Hirsch 1950; Kelly et al. 2000). The resulting nisin is centrifuged and dried before being standardized with finely ground salt (NaCl) to achieve an activity of 1 × 106 IU/g (in accordance with 2.5% nisin). On the other hand, laboratory-scale purification of nisin includes an ammonium sulfate precipication step, followed by various combinations of ion-exchange and hydrophobic interaction chromatography, with a final reverse phase-high pressure liquid chromatography purification step (Parente and Ricciardi 1999). Several immunological-based techniques have been developed and tested. Suarez et al. (1997) reported a one-step purification of nisin A using immunoaffinity purification with the specific monoclonal antibody against nisin A. The procedure was highly specific and gave a very high yield of 73%. A technique using a specific monoclonal antibody-coated magnetic bead was developed for recovery of nisin Z (Prioult et al. 2000). A high yield of 62% was obtained; however, when the beads were re-used, the recovery decreased to 27% only after three cycles. Although these procedures provide excellent results in term of yield and purification (Cintas et al. 1998), they are not suitable for large-scale recovery and purification due to a requirement for specific monoclonal antibodies.

For large-scale recovery and purification, several methods based on adsorption/desorption or on phase partitioning have been developed. Yang et al. (1992) developed a method to recover nisin and other bacteriocins by adsorption on producer cells at pH 6.0–6.5, followed by cell separation and desorption at pH 2.0 and 0.1 M NaCl. For large-scale purification, Van’t Hul and Gibbon (1996) suggested that a vortex flow filtration system might replace centrifugation for large-scale recovery. However, the ability of cells to absorb nisin can be exceeded when nisin concentration is very high (Parente and Ricciardi 1999). Boyaval et al. (1998) developed a two-step purification system based on detergent Triton X-114 phase partitioning and adsorption/ desorption on a cation exchange resin. They claimed the process was effective in the recovery of nisin and mesenterocin Y105. However, Triton X-114 is not suitable for a product that requires food-grade standard such as nisin.

Suitable silica adsorbent for online recovery not only has to exhibit excellent nisin adsorption and desorption properties but also has to be compatible to the growth of the producer (being non-toxic and does not remove necessary nutrients from the medium) once it was incorporated into the bioreactor system. Several silica adsorbents, usually a cationic adsorbent that facilitates an electrostatic attraction between the adsorbent and nisin molecule, have been tested either in batch experiment or incorporated into the bioreactor system (Chinachoti et al. 1997; Wan et al. 1996; Tolonen et al. 2004).

Chinachoti et al. (1997) separated nisin Z from fermentation broth using various types of adsorbents, including Amberlite IR-120B, CM Sephadex C-25, Celite, and Sep-Pak tC18, C18, C8, and tC3 cartridges. Sep-Pak C8, a moderate reversed-phase column, was selected because it exhibited moderate adsorption–desorption ability for nisin Z, although it yielded a lower nisin Z adsorption than tC18 column. When the Sep-Pak C8 was incorporated into the batch fermentation, higher cell growth and a 1.7-times greater nisin Z production rate were obtained. Interestingly, the results obtained by Kim (1997) using two-phase liquid–liquid extraction also indicated higher biomass production when nisin was continuously removed from the system.

Both Micro-Cel E (a synthetic calcium silicate from diatomaceous earth) and Hi-Sil HOA (a synthetic ultrafine silicon dioxide) were successfully used for adsorption of nisin (Wan et al. 1996). However, nisin adsorbed on Micro-Cel E can be eluted out only by 1% sodium dodecyl sulfate (SDS), and thus an effective SDS removal technique was required (Coventry et al. 1996). Silicic acid was successfully used to recover 84% of the nisin from fermentation broth (Janes et al. 1998). Although only a threefold purification was achieved, the method was preferable, as it did not require the use of toxic solvent. Therefore, in this study, silicic acid was chosen for removal of nisin Z during fermentation in a biofilm reactor.

In our previous studies, nisin production was improved significantly when using a biofilm reactor in combination with an optimized complex medium (CM), pH profiles, and fed-batch culture (Pongtharangkul and Demirci 2005; 2006a,b). Overall, nisin production in the biofilm reactor was significantly increased by 3.8-fold (2,208 IU/ml) with the suggested CM (Pongtharangkul and Demirci 2006a). A combination of constant pH and autoacidification period was recommended as the appropriate pH profile for batch fermentation of nisin in the biofilm reactor (3,553 IU/ml; Pongtharangkul and Demirci 2006b). In contrast for fed-batch fermentation, constant pH profile enhanced nisin production in biofilm reactor (4,314 IU/ml), whereas the pH profiles that include periods of autoacidification resulted in a significantly lower nisin production due to toxicity of lactic acid in the acidic environment (Pongtharangkul and Demirci 2006b).

In this study, the effect of online recovery on nisin production was evaluated in a pH-controlled batch fermentation. First, optimal conditions for adsorption and desorption of nisin Z on silicic acid were evaluated in a batch manner. The adsorption was tested at two different pH values (3.0 and 6.8), whereas four different types of diluents were tested for desorption of nisin Z. The obtained result was used to construct an online recovery unit that was integrated into the existing biofilm reactor. As a control for comparison, similar fermentation was carried out using the same biofilm reactor but without the online recovery unit.

Materials and methods

Microorganisms and medium

The nisin Z-producing strain used in this study was L. lactis subsp. lactis (Nizo 22186). Nisin activity was quantified using Lactobacillus sakei (ATCC 15521) as the nisin-sensitive test organism as described in our previous study (Pongtharangkul and Demirci 2004). L. lactis and L. sakei were grown at 30°C for 14 h in a CM and Lactobacillus MRS broth (Difco Laboratories, Detroit, MI), respectively. The CM consisted of 40 g of sucrose, 10 g of peptone (Amber Ferm 4015G, Universal Flavors, Milwaukee, WI), 10 g of yeast extract (Ardamine Z, Sensient Bionutrient, Indianapolis, IN), 10 g of KH2PO4, 2 g of NaCl, and 0.2 g of MgSO4·7H2O per liter of deionized (DI) water. The initial pH of CM was adjusted to 6.8 using 4 N NaOH. For a long-term storage, all stock cultures were maintained at −80°C in 20% glycerol.

Adsorption and desorption of nisin on silicic acid

Nisin fermentations were conducted in a 1.25-l Bioflo II fermentor (New Brunswick Scientific, Edison, NJ) with a working volume of 1 l at temperature of 30°C, pH of 6.8, and agitation rate of 100 rpm. The biofilm reactor was set up as described previously (Pongtharangkul and Demirci 2006a). The custom-made solid support called plastic-composite support tubes or “PCS tubes” were manufactured at Iowa State University using a twin-screw co-rotating Brabender PL2000 extruder (model CTSE-V; C.W. Brabender Instruments, South Hackensack, NJ), as described by Ho et al. (1997). The composition of PCS used in this study was chosen according to biofilm formation, nisin production, nitrogen leaching rate, and percent nitrogen content (Pongtharangkul and Demirci 2006a). Briefly, the chosen PCS consisted of 50% polypropylene, 35% soybean hulls, 5% soybean flour, 5% yeast extract, 5% dried bovine albumin, 0.272% sodium acetate, 0.0004% MgCl2•6H2O, and 0.002% NaCl. To construct a biofilm reactor, 12 PCS tubes were bound to the agitator shaft in a grid-like fashion, with six rows of two parallel tubes. The reactor vessel with PCS was sterilized with water at 121°C, whereas sucrose and nitrogenous components with mineral salts were sterilized separately and added to the reactor aseptically. After inoculation with a 14-h culture of L. lactis (1% v/v), at least five fermentation runs were performed to establish biofilm formation on PCS supports. The culture was non-aerated and the pH was controlled at 6.8 by adding 4 N NaOH. Once a stable biofilm was formed, repeated-batch fermentations were carried out in the biofilm reactor by pumping out the previous fermentation broth before aseptically adding a sterile-fresh medium.

Fermentation broth, which was removed from the biofilm reactor after 6 h of fermentation, was filtered using a tangential flow filter unit equipped with hydrophilic polyvinylidene membrane of 0.45 μm nominal pore size and 50 cm2 filtration area (Pellicon® XL Durapore HVMP, Millipore, Bedford, MA) and immediately adjusted to pH 3.0 and 6.8 using concentrated HCl or 4 N NaOH. To create the condition that represents the environment in an online adsorption, the cell-free fermentation broth was not heated to destroy the activity of protease on purpose to mimic online fermentation conditions.

After pH adjustment, 5% (w/v) silicic acid (mesh size 100, Sigma Chemical, St. Louis, MO) was added into 10 ml of pH-adjusted cell-free broth. The samples were stirred at 25°C for 1 h. Then, the silicic acid was separated and washed with sterile DI water (pH 3.0) before resuspending in 10 ml of eluent. Four different eluents were tested: (1) DI water, (2) DI water with 20% ethanol, (3) 1 M NaCl, and (4) 1 M NaCl with 20% ethanol. All eluents were adjusted to pH 3.0 with concentrated HCl. The samples were then stirred for 30 min at 25°C and heated for 10 min at 90°C for desorption. The nisin activity of all fractions collected at different stages of adsorption and desorption was assayed using an agar-well diffusion method. To take into account the loss of nisin due to the adsorption onto the container’s surfaces and degradation during the adsorption process, control treatment (without silicic acid) was carried out along with the samples. Every treatment was replicated three times (n = 3). Then, percent adsorption and percent desorption were calculated as follows:

where % adsorption = percent of nisin that adsorbed onto the silicic acid; % desorption = percent of nisin that can be eluted from the silicic acid based on the amount of adsorbed nisin; % harvest = percent of nisin that can be harvested based on the amount of nisin in the control; N c = nisin activity (IU/ml) in control; N a = nisin activity (IU/ml) in sample after the adsorption; and N d = nisin activity (IU/ml) released into the diluent after the desorption.

Online recovery of nisin from biofilm reactor

Nisin fermentations were conducted in a 1.25-l Bioflo II biofilm fermentor (New Brunswick Scientific) with a working volume of 1 l at 30°C, pH 6.8, and 100 rpm as described earlier. To construct an online recovery unit, a polypropylene bottle (diameter of 100 mm) was filled with sterile silicic acid (pre-treated by autoclaving with deionized water) at a concentration of 5% (w/v). The tangential flow filtration unit and the online recovery unit were connected to the biofilm reactor, as shown in Fig. 1. The flow of supernatant to the recovery unit was adjusted to 2 ml/min. The adsorption or recovery of nisin was started at 3 h of fermentation and each cycle of recovery lasted 1 h. To ensure the complete dispersion of silicic acid in the filtrate, a magnetic stirrer (length, 35 mm) was placed in each bottle, and an agitation was applied at 100 rpm. After each adsorption cycle, the filtrate was circulated back to the biofilm reactor, and the recovery unit was replaced with a similar fresh recovery unit. Overall, the recovery unit was replaced at 3, 4.5, and 6 h of fermentation. Absorbed nisin was eluted using the eluent selected from the previous step in this study. Concentrations of nisin in the biofilm reactor (before and after each recovery cycle) and in the eluent (after desorption) were measured using an agar-well diffusion bioassay (Pongtharangkul and Demirci 2004). The experiment was duplicated (n = 2).

Analysis

Suspended biomass

Suspended-cell density was estimated by absorbance at 600 nm using a spectrophotometry DU series 500 (Beckman, Fullerton, CA). Sterile fermentation medium was used as a blank. Absorbance values were converted into biomass concentration by using a standard curve (y = 0.1663x − 0.0199, where y is biomass [g-dry biomass/l] and x is absorbance at 600 nm).

Agar-well diffusion bioassay

A sample of fermentation broth was immediately adjusted to pH 3.0 using concentrated HCl, and 0.1% v/v of Tween 20 (J.T. Baker, Phillipsburg, NJ) was added to avoid any non-specific adsorption of nisin on the container’s surfaces. Then, the sample was heated at 90°C for 5 min to eliminate the protease activity in the broth. After centrifugation at 2,000×g, 4°C for 10 min (mini centrifuge Model C-1200, National Labnet, Woodbridge, NJ), clear supernatant was collected and kept frozen at −20°C until analysis. Nisin quantifications were performed by an agar-well diffusion bioassay using L. sakei and pre-diffusion at 4°C, as described by Pongtharangkul and Demirci (2004).

Briefly, a stock standard nisin solution (100 IU/ml) was prepared by adding 0.01 g of commercial nisin (106 IU/g, Sigma Chemical) into 100 ml of sterile DI water in which the pH was adjusted to 3.0 using concentrated HCl. Standard nisin solution of 100, 50, 25, 15, 10, 5, and 0 IU/ml were then prepared using the 100-IU/ml nisin stock solution and sterile DI water with pH 3.0 (diluent). The sample from fermentation broth was diluted (×40) using the same diluent solution. The bioassay agar was prepared using MRS (Difco) with 0.75% w/v Bacto agar (Difco) and 1% v/v Tween 20. Then, the sterile agar was inoculated with 1% of the 14-h culture of L. sakei before plating. To ensure that an equivalent number of cells were inoculated into the agar medium each time, the inoculum size was adjusted to reflect an optical cell density reading of 1.7 at 600 nm (approximately 108 CFU/ml of agar medium). Then, the inoculated bioassay agar (25 ml) was aseptically transferred into sterile petri dishes (100 × 15 mm) and allowed to solidify for 1 h. On each plate, five holes were bored using a 7-mm outer diameter stainless steel borer with a slight suction applied. After a 100 μl aliquot of sample was placed into each well, the agar plate was stored at 4°C for 24 h (pre-diffusion step) and then incubated at 30°C for another 24 h. Each sample was performed in triplicate.

The diameter of the inhibition zone around each well was measured horizontally and vertically using a digital caliper (Digimatic caliper, Mitutoyo, Kanagawa, Japan) to the nearest 0.01 mm and then averaged. Diameters of inhibition zones from each nisin standard solution and log10 nisin concentrations were plotted to create a standard curve. The concentration of nisin in the fermentation sample was calculated using the equation of the best-fitted linear line in the standard curve, which should have the correlation coefficient of at least 0.98.

Statistical analysis

All batch recovery treatments were replicated three times (n = 3), whereas the results of online recovery were presented as an average of two replicates (n = 2). The significant difference of the results was evaluated using the generalized linear model (with p < 0.05) and Tukey’s honest significant difference multiple comparison module of the Minitab statistical software package (release 13.30; State College, Pennsylvania).

Results

Adsorption and desorption of nisin on silicic acid

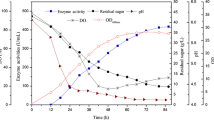

Optimal conditions for adsorption and desorption of nisin Z when using silicic acid as an adsorbent were determined (Figs. 2 and 3). Although an adsorption at pH 6.8 is most practical for an online recovery during fermentation as the pH adjustment of fermentation broth is not required, nisin is found to be most stable and soluble at pH 3.0, and thus the adsorption at pH 3.0 would be most appropriate if a recovery process is conducted at the end of fermentation. Both pH were evaluated in this study due to the lack of information on the topic. Higher percentage of nisin presented in the fermentation broth was adsorbed onto silicic acid at pH 6.8 (68.8%) than at pH 3.0 (54%), possibly as a result of reduced net charge of nisin at pH near neutrality. The holding capacity of silicic acid achieved in this study was approximately 42,600 IU/g-silicic acid. The pH of fermentation broth affected not only the amount of nisin adsorbed onto the silicic acid but also the amount of desorbed nisin as well. Four different types of eluent were tested for desorption process, and the amount of desorbed nisin was reported based on the amount of adsorbed nisin (% desorption) and of total nisin produced (% harvest). As the main applications of nisin are in the food industry, only food-grade eluents were chosen for the recovery process: DI water, NaCl, and ethanol in this study. Although eluent 1 (DI water) and eluent 2 (20% ethanol) completely failed to elute nisin off the silicic acid when the adsorption was conducted at pH 6.8 (0% desorption), they yielded a considerable amount of desorbed nisin (41.9% and 52.8%, respectively) when the adsorption was conducted at pH 3.0. Eluent 3 (1 M NaCl) eluted approximately one seven of the adsorbed nisin at both pH 6.8 and 3.0. Overall, eluent 4 (1 M NaCl + 20% ethanol) with adsorption at pH 6.8 yielded the highest desorption (65.6% desorption) and overall recovery (46.5% harvest) among all the tested treatments and thus was selected for further application in the online recovery. From a fermentation broth with 2,634 IU/ml, approximately 1,880 IU/ml were adsorbed onto silicic acid (5% w/v), and 1,226 IU/ml could be desorbed from the adsorbent.

Online recovery of nisin from biofilm reactor

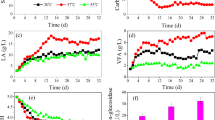

The results clearly indicated the enhancing effect of the online recovery system (a coupling of the tangential flow filter and the recovery unit) on nisin production in the biofilm reactor (Fig. 4). The decreases of nisin concentration right after 4, 5.5 and 7 h of fermentation were caused by the recirculation of the filtrate (approximately 20 IU/ml) after the adsorption step. Comparing to the results from the previous small-scale study (69% adsorption), more than 99% of nisin present in fermentation broth was adsorbed onto the silicic acid during online recovery (data not shown). Higher percent adsorption achieved from an online recovery was a result of longer provided contact time (total of 1 h) between filtrate and silicic acid. Higher percent desorption (approximately 90%) was also achieved from an online recovery, possibly as a result of better mixing provided in the online recovery unit. As for biomass production, the difference of suspended biomass between the system with and without the recovery unit seemed to solely be a result of cell-recycling when using the tangential flow microfilter module. Compared to the system without the recovery unit (0.061 g/l), the maximum biomass obtained from the system with the recovery unit (0.075 g/l) was approximately 15% higher as a result of a 15% reduction in total volume of fermentation broth maintaining in the reactor (before the recycling step).

Approximately 15% of nisin in the fermentation broth could be recovered from each cycle of recovery. The recovered nisin was added up to the nisin concentration presented in the biofilm reactor at a certain time, and the total nisin produced was presented separately as a dotted line in Fig. 4. The maximum nisin produced when using the online recovery (7,445 ± 1,975 IU/ml) was approximately 3.9 times higher than the value achieved using similar biofilm reactor without online recovery (1,897 ± 32 IU/ml).

Discussion

Adsorption of nisin onto silicic acid, unlike the adsorption of nisin onto producer cells which relies on the cationic nature of nisin, was proposed as a result of a multilayer of protein–protein weak and intermediate hydrogen bonds influenced by electrostatic interactions (Janes et al. 1998). Adsorption of nisin Z onto silicic acid was significantly higher at pH near neutrality (Figs. 2 and 3) indicated by higher percent adsorption at pH 6.8 (68.8%) as compared to pH 3.0 (54.0%). The same trend was also reported for the adsorption of nisin A onto silicic acid (Janes et al. 1998). The pH near neutrality at which nisin possesses less positive net charge favors the adsorption process because interactions between polypeptide are generally favored under conditions that reduce the net charge on the molecules.

Heat treatment during the desorption processes was reported as an effective measure to break the hydrogen bonds and thus to enhance desorption of nisin from silicic acid (Janes et al. 1998). Therefore, all eluents were adjusted to pH 3.0, which is the pH where nisin is most stable (Davies et al. 1998). Although eluent 1 (DI water) was successfully used by Janes et al. (1998) to elute nisin A that adsorbed on silicic acid (91% desorption), in this study, it failed to elute adsorbed nisin Z from silicic acid. Only 0.6% of adsorbed nisin was desorbed by eluent 1when the adsorption was conducted at pH 6.8 (Fig. 2). This may be the result of a lower net positive charge of nisin Z molecule compared to nisin A (+2 instead of +3 charges due to the substitution of histidine by asparagine).

When the adsorption was carried out at pH 6.8, addition of NaCl and ethanol separately, as in eluent 2 (0.6% desorption) and 3 (13.5% desorption), did not improve the desorption of nisin as much as when both of them were combined in eluent 4 (65.6% desorption). On the other hand, although the adsorption of nisin onto silicic acid was lower when the adsorption process was conducted at pH 3.0, the adsorbed nisin seemed to be easier to elute (Fig. 3), as indicated by significantly higher percent desorption values when eluent 1 (41.9% desorption) and eluent 2 (52.8% desorption) were used. NaCl and ethanol were used in this study because of their nontoxic nature and ability to weaken or destroy the hydrogen bonds (Chandra 2000). Overall, eluent 4 (1 M NaCl + 20% ethanol) yielded the highest desorption and overall recovery among all the tested treatments, indicating a synergistic effect between NaCl and ethanol. Based on the total nisin activity in fermentation broth, 31% of the nisin did not bind to the silicic acid, 47% of the nisin was harvested, and 22% was unelutable from the silicic acid (this portion included both potentially degraded and irreversibly bounded nisin).

It has been shown previously that continuous removal of nisin during fermentation could significantly promote growth and nisin production in L. lactis strain IO-1 (Chinachoti et al. 1997), C2SmPrt− (TnNip; Kim 1997), and LAC48 (Tolonen et al. 2004). The increase in nisin production was explained as a result of lesser product inhibition and lower toxicity exerted on the nisin producer. In this study, the result obtained from the batch fermentation of a biofilm reactor coupling with a microfilter module and an online recovery unit indicated a significant improvement of nisin production over traditional batch fermentation. Nisin production was significantly enhanced (7,445 IU/ml) when compared to the batch fermentation without the online recovery (1,897 IU/ml), possibly as a result of a higher biomass density obtained when using the tangential flow microfilter module. Although there was no evidence to support the idea that nisin removal can promote further growth, as suggested in previous literature (Chinachoti et al. 1997; Kim 1997), temporary higher biomass density developed via the use of the tangential flow filter unit was suspected to stimulate the production of nisin as nisin production exhibits a cell density dependent characteristic (Kuipers et al. 1995). On the other hand, the fact that there was no reduction in suspended biomass (maximum biomass of 0.066 and 0.061 g-dry biomass/l for fermentation with and without recovery unit, respectively) indicated that the silicic acid did not inhibit growth of the nisin producer nor removed necessary nutrients from the fermentation broth and thus was suitable to be used as an online absorbent. Even only 15% of nisin in the fermentation broth was recovered each time, a dramatic increase in nisin production was observed. Therefore, the result clearly indicated that the proposed recovery system has a great potential to enhance nisin production. A more effective process can be achieved simply through a scale-up of the microfilter and the recovery unit so that more nisin can be recovered during fermentation.

References

Alifax PR, Chevalier R (1962) Etude de la nisinase produite par Streptococcus thermophilus. J Dairy Res 29:233–240

Boyaval P, Bhugaloo-Vial P, Duffes F, Metivier A, Dousset X, Marion D (1998) Reacteurs a haute densites cellulaires pur la production de solutions concentrees de bacteriocines. Lait 78:129–133

Chandra A (2000) Effects of ion atmosphere on hydrogen-bond dynamics in aqueous electrolyte solutions. Phys Rev Lett 85(4):768–771

Chinachoti N, Endo N, Sonomoto K, Ishizaki A (1997) Bioreactor systems for efficient production and separation of nisin Z using Lactococcus lactis IO-1. J Fac Agric Kyushu Univ 43:421–436

Cintas LM, Casaus PM, Fernandez F, Hernandez PE (1998) Comparative antimicrobial activity of enterocin L50, pediocin PA-1, nisin A and lactocin S against spoilage and foodborne pathogenic bacteria. Food Microbiol 15:289–298

Coventry MJ, Gordon JB, Alexander M, Hickey MW, Wan J (1996) A food-grade process for isolation and partial purification of bacteriocins of lactic acid bacteria that used diatomite calcium silicate. Appl Environ Microbiol 62(5):1764–1769

Davies EA, Bevis HE, Potter R, Harris J, Williams GC, Delves-Broughton J (1998) The effect of pH on the stability of nisin solution during autoclaving. Lett Appl Microbiol 27:186–187

De Vuyst L, Vandamme EJ (1992) Influence of the carbon source on nisin production in Lactococcus lactis supsp. lactis batch fermentations. J Gen Microbiol 138:571–578

Food and Drug Administration (FDA) (1988) Nisin preparation: affirmation of GRAS status as direct human food ingredient. Federal Register 53, April 6

Hirsch A (1950) The assay of the antibiotic nisin. J Gen Microbiol 4:70–74

Ho K-LG, Pometto AL III, Hinz PN (1997) Optimization of L-(+)-lactic acid production by ring and disc plastic composite supports through repeated-batch biofilm fermentation. Appl Environ Microbiol 63:2533–2542

Hurst A, Dring GJ (1968) The relation of the length of lag phase of growth to the synthesis of nisin and other basic proteins by Streptococcus lactis grown under different conditions. J Gen Microbiol 50:383–390

Janes ME, Nannapaneni R, Proctor A, Johnson MG (1998) Rice hull ash and silicic acid as adsorbents for concentration of bacteriocins. Appl Environ Microbiol 64(11):4403–4409

Jarvis B, Farr J (1971) Partial purification, specificity and mechanism of action of the nisin-inactivating enzyme from Bacillus cereus. Biochem Biophys Acta 227:232–240

Kelly NA, Reuben BG, Rhoades J, Roller S (2000) Solvent extraction of bacteriocins from model solutions and fermentation broths. J Chem Technol Biotechnol 75:777–784

Kim WS (1997) Nisin production by Lactococcus lactis using two-phase batch culture. Lett Appl Microbiol 25:169–171

Kim WS, Hall RJ, Dunn NW (1997) Host specificity of nisin production by Lactococcus lactis. Biotechnol Lett 19:1235–1238

Kim WS, Hall RJ, Dunn NW (1998) Improving nisin production by increasing nisin immunity/resistance genes in the producer organism Lactococcus lactis. Appl Microbiol Biotechnol 50:429–433

Kuipers OP, Beerthuyzen MM, de Ruyter PG, Luesink EJ, de Vos WM (1995) Autoregulation of nisin biosynthesis in Lactococcus lactis by signal-transduction. J Biol Chem 270:27299–27304

Lee SH, Kim HU (1985) Studies on lantibiotic nisin produced by Streptococcus lactis IFO 12007. Kor J Anim Sci 27:476–479

Parente E, Ricciardi A (1999) Production, recovery and purification of bacteriocins from lactic acid bacteria. Appl Microbiol Biotechnol 52:628–638

Pongtharangkul T, Demirci A (2004) Evaluation of agar well diffusion method for nisin quantification. Appl Microbiol Biotechnol 65:268–272

Pongtharangkul T, Demirci A (2005) Effects of pH profiles on nisin production in biofilm reactor. Appl Microbiol Biotechnol 71(6):804–811

Pongtharangkul T, Demirci A (2006a) Evaluation of medium for nisin production in repeated-batch biofilm reactor. Biotechnol Prog 22(1):217–224

Pongtharangkul T, Demirci A (2006b) Effects of fed-batch fermentation and pH profiles on nisin production in suspended-cell and biofilm reactors. Appl Microbiol Biotechnol 73(1):73–79

Prioult G, Turcotte C, Labarre L, Lacroix C, Fliss I (2000) Rapid purification of nisin Z using specific monoclonal antibody-coated magnetic beads. Int Dairy J 10:627–633

Suarez AM, Azcona JI, Rodriquez JM, Sanz B, Hernandez P (1997) One-step purification of nisin A by immunoaffinity chromatography. Appl Environ Microbiol 63:4990–4992

Tolonen M, Saris PEJ, Siika-aho M (2004) Production of nisin with continuous adsorption to Amberlite XAD-4 resin using Lactococcus lactis N8 and L. lactis LAC48. Appl Microbiol Biotechnol 63:659–665

Van’t Hul JS, Gibbon WR (1996) Concentration and recovery of the bacteriocin nisin from Lactococcus lactis subsp. lactis. Biotechnol Appl Biochem 24:251–256

Wan J, Gordon J, Hickey MW, Mawson RF, Coventry MJ (1996) Adsorption of bacteriocins by ingestible silica compounds. J Appl Bacteriol 81(2):167–173

Yang R, Johnson MC, Ray B (1992) Novel method to extract large amount of bacteriocins from lactic acid bacterial. Appl Environ Microbiol 58:3355–3359

Acknowledgement

The authors wish to thank Dr. Anthony L. Pometto III of Iowa State University for the kind supply of PCS tubes used in this research. The funding for this project was provided by the Pennsylvania Agricultural Experiment Station and by a scholarship to Thunyarat Pongtharangkul from the Royal Thai Government.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pongtharangku, T., Demirci, A. Online recovery of nisin during fermentation and its effect on nisin production in biofilm reactor. Appl Microbiol Biotechnol 74, 555–562 (2007). https://doi.org/10.1007/s00253-006-0697-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-006-0697-7