Abstract

During aerobic growth on glucose, Escherichia coli produces acetate in the so-called overflow metabolism. DNA microarray analysis was used to determine the global gene expression patterns of chemostat cultivations of E. coli MG1655 that were characterized by different acetate formation rates during aerobic growth on glucose. A correlation analysis identified that expression of ten genes (sdhCDAB, sucB, sucC, acnB, lpdA, fumC and mdh) encoding the TCA cycle enzymes succinate dehydrogenase, α-ketoglutarate dehydrogenase, succinyl-CoA synthetase, aconitase, fumarase and malate dehydrogenase, respectively, and of the acs–yjcH–actP operon for acetate utilization correlated negatively with acetate formation. Relieving transcriptional control of the sdhCDAB–b0725–sucABCD operon by chromosomal promoter exchange mutagenesis yielded a strain with increased specific activities of the TCA cycle enzymes succinate dehydrogenase, α-ketoglutarate dehydrogenase and succinyl-CoA synthetase, which are encoded by this operon. The resulting strain produced less acetate and directed more carbon towards carbon dioxide formation than the parent strain MG1655 while maintaining high growth and glucose consumption rates.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

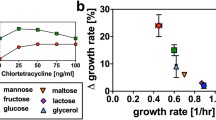

Escherichia coli is able to utilize a variety of carbohydrates and organic acids as sole carbon and energy sources. Rapid aerobic growth of E. coli on glucose, but also on serine, pyruvate, lactate, glucuronate and gluconate, and glucose excess conditions are characterized by the formation and excretion of acetate. This phenomenon, which does not occur during growth on glycerol or fructose, is referred to as overflow metabolism or ‘bacterial Crabtree effect’ (El-Mansi and Holms 1989; Rinas et al. 1989; Luli and Strohl 1990; Holms 1996; Xu et al. 1999a,b; El-Mansi 2004). Upon depletion of acetogenic (acetate-producing) carbon sources, E. coli switches to utilization of the excreted acetate as a source of carbon and energy. Wolfe (2005) defined the acetate switch as the moment when acetate formation equals acetate utilization. In a batch culture using buffered media with glucose, acetate is formed until glucose is nearly exhausted and, after the switch occurred, acetate is co-utilized with glucose. In a batch culture with tryptone-based complex medium, serine and aspartate are utilized first with concomitant acetate formation and when tryptophan is utilized, acetate is re-utilized (Wolfe 2005).

Aerobic acetate production, which increases at high growth rates (El-Mansi and Holms 1989; Majewski and Domach 1990; Holms 1996; Kayser et al. 2005), is supposed to arise from an imbalance between glucose utilization and the demands for biosynthesis and energy metabolism, and several explanations such as improperly controlled glucose uptake, TCA cycle activity or respiratory capacity have been proposed (El-Mansi and Holms 1989; Holms 1996). Under aerobic conditions, acetate is generated from pyruvate either by oxidative decarboxylation by the pyruvate dehydrogenase complex and the following conversion of acetyl-CoA to acetate by phosphotransacetylase and acetate kinase with concomitant formation of ATP (Hansen and Henning 1966). Alternatively, during the transition from exponential growth to the stationary growth phase, pyruvate may be decarboxylated to acetate directly by pyruvate oxidase (Chang et al. 1994). After the acetate switch occurred, acetate is assimilated by acetyl-CoA synthetase, which activates acetate to acetyl-CoA with the concomitant conversion of ATP to AMP and pyrophosphate (Brown et al. 1977; Kumari et al. 1995). The formed acetyl-CoA is metabolized in the TCA cycle to generate energy and reduction equivalents. To fulfill the anaplerotic demand, acetate-growing cells require the glyoxylate cycle. The glyoxylate cycle with its key enzymes isocitrate lyase and malate synthase bypasses the two decarboxylation steps of the TCA cycle catalyzed by isocitrate dehydrogenase and α-ketoglutarate dehydrogenase, and the reaction catalyzed by succinyl-CoA synthetase. The reactions of the glyoxylate cycle catalyze a net formation of a four-carbon biosynthetic precursor from two molecules of acetyl-CoA.

With excess glucose, acetate can accumulate to high concentrations. Acetate and other short-chain fatty acids inhibit growth and deteriorate production (Jensen and Carlsen 1990) as they uncouple the transmembrane proton potential and thus interfere with efficient energy metabolism. Acetic acid diffuses across the plasma membrane and in the cytoplasm a proton is released to form the acetate anion resulting in a decrease of the transmembrane proton potential (Axe and Bailey 1995). To gain insight into the response of E. coli to environmental challenges at the expression level, global gene expression analyses using DNA microarrays (Rhodius et al. 2002; Khodursky et al. 2003) were widely used, e.g. to characterize the responses to exposure to hydrogen peroxide (Zheng et al. 2001) or to elucidate the involved gene regulatory circuits, e.g. by the central regulators of nitrogen metabolism NtrC and Nac (Zimmer et al. 2000) or by the sigma-factor of the general stress response σ S (Weber et al. 2005). DNA microarray analyses revealed the gene expression pattern characterizing the utilization of acetate as a carbon and energy source (Oh et al. 2002). The sole presence of acetate elicited specific gene expression changes, e.g. increased expression of the chemotaxis and flagella genes and motility at neutral pH (Polen et al. 2003). On the other hand, acetic acid is often used as an acidifying agent in acid shock experiments. At low pH, expression of the chemotaxis and flagella, genes and motility increased (Soutourina et al. 2002; Maurer et al. 2005). Moreover, at low pH, the specific acid resistance genes, e.g. gadA, gadBC, the hde genes, which encode glutamate decarboxylase A and B, a glutamate-dependent transport protein and periplasmic proteins, and their regulatory genes gadE, gadX, and gadW are induced and are essential for acid resistance (reviewed in Foster 2004). Acidification of E. coli cultures by aerobic acetate formation during overflow metabolism impairs growth. The inhibitory effects of acetate vary with the carbon source (Lasko et al. 2000), but even under neutral pH conditions, growth and production performance are deteriorated by acetate (Jensen and Carlsen 1990).

E. coli is used in biotechnology for the production of heterologous proteins (Swartz 2001) since recombinant DNA technology has become available (Cohen et al. 1973). E. coli strains were also engineered for the production of fine chemicals and building blocks (Wendisch et al. 2006), e.g. l-phenylalanine (Bongaerts et al. 2001), shikimic acid (Kramer et al. 2003) and l-threonine (Debabov 2003) and 1,3-propanediol (Nakamura et al. 2000), 1,2-propanediol (Altaras and Cameron 1999), succinic acid (Vemuri et al. 2002; Sanchez et al. 2005), d-lactic acid and l-lactic acid (Chang et al. 1999a; Zhou et al. 2003), ethanol (Underwood et al. 2002) and adipic acid (Niu et al. 2002). Because in these production processes media containing glucose as a convenient and inexpensive carbon and energy source for E. coli are typically used, aerobic acetate formation is often observed. To reduce acetate formation, a number of strategies ranging from rational strain improvement to strain selection and process control were followed. E. coli B strains presumably produce less acetate compared to K strains as they constitutively express the glyoxylate cycle genes (Phue and Shiloach 2004), while reduced acetate formation by E. coli Rv308 is not understood (Maurer et al. 1980; Nellis et al. 2005). Glucose uptake was reduced by feeding low glucose concentrations in fed-batch cultivations (Akesson et al. 2001) or by decreasing the expression of ptsG encoding the glucose-specific enzyme II of the phosphoenolpyruvate-dependent phosphotransferase system through overexpression of the transcriptional regulator gene mlc (Hosono et al. 1995; Cho et al. 2005) or by ptsG mutations (Flores et al. 2002). Enhancing anaplerosis via increasing phosphoenolpyruvate carboxylase and/or glyoxylate cycle enzyme levels reduced acetate formation and glucose uptake (Farmer and Liao 1997). Carbon flux towards acetate was redirected to other, in general less toxic by-products such as acetone (Bermejo et al. 1998), acetoin (Aristidou et al. 1994), lactate (Chang et al. 1999b), polyhydroxybutyrate (Chang et al. 1999b) or ethanol (Diaz-Ricci et al. 1991). However, reducing glucose uptake or redirecting flux to other by-products avoids acetate formation symptomatically, but does not identify its molecular cause.

In the present study, DNA microarray analyses revealed gene expression changes correlating with increasing acetate formation in aerobic chemostat cultivations of E. coli MG1655. Consequently, a strain was constructed by directed promoter replacement. This strain produced less acetate and did not produce other incomplete oxidation products. Reduced aerobic acetate formation was achieved while maintaining a high glucose uptake rate.

Materials and methods

Bacterial strains and plasmids

The strains and plasmids used in this study are listed in Table 1. Standard methods were used for PCR amplification, plasmid construction and analysis of DNA fragments (Sambrook and Russel 2001). E. coli DH5α was used for cloning. Transformations were performed by the RbCl2 method (Hanahan 1983) or by electroporation (Datsenko and Wanner 2000). To obtain E. coli MG1655 derived strains carrying deletions of gadE, yjcH–actP, yjeJ or sucCD, the primers listed in Table 2 and plasmids pKD13 or pKD4 were used (Datsenko and Wanner 2000). To obtain a ΔPsdh::Ptet mutant derivative of E. coli MG1655, the gene replacement procedure described by Datsenko and Wanner 2000 was used. The FRT-flanked kanamycin-resistance gene of plasmid pKD4 was amplified by PCR using a pair of primers with 44-nt (sdh-up-for) and 50-nt (sdh-up-rev) homology extensions, respectively, and cloned into pGEM-T. The extensions included the DNA regions adjacent to the sdh-promoter and an EcoRI site suitable for cloning (Table 2). The promoter Ptet was amplified from pK19::clpP (Engels et al. 2004) using primers tet-for and tet-rev and cloned into the EcoRI restriction site of pGEM-T–sdh–kan. A DNA fragment containing Ptet, the kanamycin resistance cassette and the homology extensions was amplified using primers pak-for and pak-rev from pGEM-T–Ptet–sdh–kan, treated with DpnI, purified and transformed to MG1655 WT carrying pKD46. Kanamycin-resistant clones were selected and verfied by PCR. Afterwards, the kanamycin resistance gene was removed by the pCP20-encoded recombinase. The resulting strain was designated MG1655ΔPsdh::Ptet. The promoter exchange was verified by PCR using primers sdhC-1 and sdhC-2. Sequence analysis confirmed that no mutations had been introduced by PCR.

Batch cultivations

All batch cultivations were performed in LB (10 g/l tryptone, 5 g/l yeast extract, 10 g/l NaCl) containing 50 mM MOPS, pH 7.2 or in mineral salts medium containing 2 mM KH2PO4, 0.275 mM K2SO4, 50 mM NaCl, 9.52 mM NH4Cl, 0.52 mM MgCl2, 0.5 μM CaCl2, 0.01 mM FeSO4, 0.3 mM thiamine, 4 mM tricine, pH 7.2, and 10 or 100 mM glucose as carbon and energy source. 4-Morpholinopropanesulfonic acid (40 mM, pH 7.2) was added when needed for pH control. Precultures were inoculated from a fresh LB plate and grown in 60 ml of mineral salts medium at 37°C and 120 rpm on a rotary shaker in 500 ml baffled shake flasks. Cells were harvested at mid-exponential phase and used to inoculate a 7.5 l fermenter (Infors, Switzerland) containing 5 l mineral salts medium with 10 mM glucose. Fermentations were conducted in batch-mode at 37°C with an agitation speed of 500 rpm and an air flow rate of 1 l per liter of culture volume an hour. Antifoam 204 (Sigma) was used as antifoam reagent. The pH was kept constant at 7.2 by the addition of 2 M NaOH and 1 M HCl. The pO2 was above 54% throughout the fermentations and above 78% at points of cell harvest. An OD600 of 1 was determined to correspond to 0.39 g/l dry mass.

Chemostat cultivations

For precultures and continuous cultivation of E. coli MG1655 a minimal medium was used according to the culture medium for enterobacteria (Neidhardt and Umbarger 1996). This medium allowed concentration settings of nitrogen, phosphorus or sulfur separately for desired growth limitation in chemostat studies using the same basic media composition. The minimal medium used contained 3-MOPS (4 × 10−3 M), tricine (4 × 10−3 M), FeSO4 (1 × 10−5 M), MgCl2 (1 × 10−3 M), NaCl (5 × 10−2 M), CaCl2 (5 × 10−7 M), tracer salts (3 × 10−9 M (NH4)6(MO7)24, 4 × 10−7 M H3BO4, 3 × 10−8 M CoCl2, 1 × 10−8 M CuSO4, 8 × 10−8 M MnCl2, 1 × 10−8 M ZnSO4) and cofactor thiamine (0.1 g/l). The standard concentration for N-rich, P-rich and S- rich media were 9.5 × 10−3 M NH4Cl, 1.32 × 10−3 M K2HPO4 and 0.29 × 10−3 M K2SO4, respectively. The stock solutions of 3-MOPS and tricine were adjusted to pH 7.2 using KOH. For precultures, the standard concentrations of N-rich, P-rich and S- rich media and 20 mM glucose as sole carbon source were used. For continuous N-limited cultivation, 2.5 mM NH4Cl was used and the glucose concentration in the feed medium was varied from 1.67 to 8.34 mM. Stock solutions and medium for precultures were autoclaved. For continuous culture, 40 L medium were prepared followed by sterile filtering at room temperature (SARTOBRAN P Filter, Sartorius, Göttingen) in autoclaved 50-L bottles (Merck, Darmstadt, Germany).

The continuous cultivations with 2.5 L working volume were performed in a 7.5-L jar LABFORS (INFORS GmbH, Einsbach, Germany) equipped for the control of pH, dissolved oxygen and temperature. The temperature was maintained at 37°C and pH at 7.2 ± 0.1 using 2 M NaOH and 1 M HCl. The agitation speed was kept between 350 and 650 rpm. The aeration rate was set to 0.8 l/l/min. Dissolved oxygen was above 70% compared to the dissolved oxygen obtained at saturation with air bubbling throughout the cultivation. The antifoam reagent Struktol J650 (Schill + Seilacher, Hamburg, Germany) was added at 10 ppm to the prepared fermenter medium.

Precultures were carried out in baffled flasks (500 ml) containing 60 ml minimal medium inoculated from stock culture (−70°C) and grown overnight at 37°C. The fermenter inocula for initial OD600 of about 0.05 were prepared by preculture centrifugation (10 min, 4,500 × g) and resuspending the cells in the medium used for continuous culture (2.5 mM NH4Cl) but without glucose. The continuous culture (2.5 L ± 0.5%) was inoculated and operated in batch-mode in the first 10 h. Subsequently, the continuous mode was started and the dilution rate was increased in three steps until 0.3 h−1 was reached after 15 h. This dilution rate was chosen to avoid aerobic acetate formation at carbon limited conditions (El-Mansi and Holms 1989). The glucose feed concentrations tested were 1.67, 3.33, 3.90, 4.45, 4.72, 5.56 and 8.34 mM. Sterile metal couplers (Stäubli Tec-Systems GmbH, Germany) enabled changing of the reservoir bottles to switch to a new glucose feed. At each condition, the OD600 was constant after five medium replacements. For steady-state conditions and minimizing oscillatory effects, each glucose feed concentration was applied for 15 medium replacements. After 14 medium replacements, several ∼35 ml samples were taken (delay >20 min), chilled on 15 g of ice (−20°C) and centrifuged (3 min, 4,500 × g, 4°C). The pellets were frozen using liquid nitrogen and stored at −20°C for RNA extraction.

Cell growth during cultivation was monitored as the OD600 (UV 1202, Shimadzu) of appropriate diluted samples taken from the culture vessel. CO2 in the fermenter off-gas was measured online by infrared light (Uras 10 E, Hartmann and Braun). The cell-free culture medium obtained by centrifugation of cell culture aliquots (10 min, 6,000 × g) and inactivation (15 min, 80°C) was assayed for d-glucose, organic acids and ammonia.

Analysis of culture supernatants

During cultivation, residual glucose and acetate concentrations were determined enzymatically using kits according to the manufacturer’s instructions (R-Biopharm, Darmstadt, Germany). For determination of excreted organic acids a reverse-phase HPLC Merck Hitachi D-7000 HPLC-system equipped with an Aminex HPX-87H column (150 × 7.8 mm, BioRad) was used. Isocratic elution was performed with 6 mM H2SO4 at a flow rate of 0.6 ml/min and absorption at 215 nm was used for detection. Residual ammonia concentrations were determined by ion chromatography using columns IONPAC CG12A and IONPAC CS12A (4 × 50 mm, 4 × 250 mm, Dionex GmbH). Elution was performed at room temperature with 20 mM methanesulfonic acid at a flow rate of 1 ml/min and conductivity was used for detection (ED 40, Dionex GmbH). Analysis of supernatants by 1H and 13C NMR was performed as decribed previously (Wendisch et al. 1997).

Enzyme assays

Cells were disrupted in a French cell press (207 mPa, SLM Aminco Spectronic Instruments). Succinate dehydrogenase was measured at 37°C according to Spencer and Guest 1973 after activation for 20 min with 20 mM succinate.

Succinyl-CoA synthetase was assayed spectrophotometrically at 230 nm according to Bridger and Cohen 1969. α-Ketoglutarate dehydrogenase was measured as described by Guest and Creaghan 1973. The reaction was started with CoA. The measurement was performed at 363 nm and an extinction coefficient of 6,190 M−1cm−1 was used. 1 U of specific enzyme activity was defined as the amount of enzyme required to convert 1 μmol of substrate into specific product per minute per milligram of protein. Citrate synthase was measured according to Weitzman and Dunmore 1969.

Global gene expression analysis

Preparation of RNA and cDNA synthesis were carried out as described (Wendisch et al. 2001; Polen et al. 2003). Equal amounts of total RNA (15–25 μg) were used for random hexamer-primed synthesis of fluorescently labeled cDNA with the fluorescent nucleotide analogues Cy3-dUTP or Cy5-dUTP (Amersham Pharmacia) (Wendisch et al. 2001; Khodursky et al. 2003). The microarrays used (Lehnen et al. 2002; Polen et al. 2003, 2005; Polen and Wendisch 2004) were prepared by robotically spotting PCR products that were generated using the Genosys ORFmer primer set (Genosys Biotechnologies, Cambridgeshire, England) onto poly-l-lysine coated glass microscope slides as described (Khodursky et al. 2000, 2003; Zimmer et al. 2000; Wendisch et al. 2001) and allowed to determine mRNA levels of nearly every gene (94%) of the E. coli MG1655 genome. DNA microarrays were hybridized for 10 h at 65°C to mixtures of Cy3-labeled and Cy5-labeled cDNA probes containing 1 g·l−1 polyA (Sigma, Germany) as competitor, 3X SSC (0.45 M sodium chloride, 0.045 M sodium citrate, nuclease-free) and 25 mM HEPES. After hybridisation arrays were washed in a solution containing 1X SSC and 0.03% SDS and finally in 0.05X SSC. After washing, slides were dried by centrifugation (5 min, 50 × g). Detailed procedures for microarray hybridisation and stringent washing were described (Rhodius et al. 2002; Khodursky et al. 2003). After drying, fluorescence at 532 nm (Cy3-dUTP) and 635 nm (Cy5-dUTP) was determined at 10-μm resolution using an Axon GenePix 4,000 laser scanner (Axon Instruments, CA, USA). Acquired raw fluorescence data were analyzed using GenePix Pro 4.1 (Axon Instruments). For each spot, the background subtracted Cy5/Cy3-ratio of medians was calculated, log-transformed and normalized based on the fluorescence signals of E. coli MG1655 genomic DNA spots (Khodursky et al. 2000, 2003; Zimmer et al. 2000; Wendisch et al. 2001; Polen et al. 2003). For each DNA microarray experiment, these ratios and additional image and experimental data were stored in a mySQL database for further analysis (Polen and Wendisch 2004). For hybridization signals exceeding background noise by at least a factor of three, the log-transformed and normalized Cy5/Cy3-ratio of medians were taken to reflect relative RNA level abundance. When Cy3-fluorescence and Cy5-fluorescence signals were less than threefold above background, signals were not considered further.

For statistical analysis of global gene expression (Arfin et al. 2000; Hommais et al. 2001), p values were calculated based on the Student’s t test using normalized log-transformed RNA levels determined in two independent replicate experiments on the one hand, and the normalized log-transformed ratios of hybridization signals of the genomic DNA spots on the other hand (Polen et al. 2003; Polen and Wendisch 2004). From all gene expression changes, only the genes having at least a twofold expression change (average of the repeated determination) and a p value of p < 0.05 under at least one steady-state growth condition were considered for further analysis. A standard Pearson correlation analysis of gene expression data was used as described (Mansson et al. 2004) to determine to what extent the expression differences determined by DNA microarray experiments and the acetate formation rates of the steady-state conditions of the continuous cultivation correlated. In addition, slopes were calculated from plots of the expression differences of each gene against the differences of the acetate formation rate. As described previously (Mansson et al. 2004), genes that showed high and correlated expression changes were identified by plotting these slopes against the Pearson correlation coefficients.

Results

Aerobic acetate formation of E. coli MG1655 in continuous culture with varied glucose feed concentrations

Aerobic continuous cultivations were performed to characterize the gene expression pattern of E. coli MG1655 cells that is specific for aerobic acetate formation during glucose overflow metabolism. Under the well-defined conditions of chemostat-mode continuous cultivation, secondary effects e.g. due to pH shifts, different aeration or different growth rates are minimal. The dilution rate of the 2.5 l continuous culture of E. coli MG1655 was set to 0.3 h−1 as carbon-limited chemostat cultures of E. coli K-12 typically do not produce acetate at this dilution rate (El-Mansi and Holms 1989). 2.5 mM NH4Cl were used as nitrogen source. The glucose concentration in the feed medium was varied from 1.67 to 8.34 mM (Table 3). After having changed the glucose feed concentration, 15 medium replacements were performed to achieve steady-state conditions. Only then were samples withdrawn for gene expression and metabolite analyses. At glucose feed concentrations of 3.33 mM and above, growth was nitrogen-limited and no residual ammonium could be detected in culture supernatants. The acetate formation rate increased steadily from <0.05 to 9.52 mmol g−1 h−1 with increasing glucose feed concentrations from 3.33 to 5.56 mM. At glucose feed concentrations of 8.34 mM and more, the acetate formation rate remained at about 11 mmol g−1 h−1 and residual glucose could be detected in the culture supernatant (Table 3 and data not shown).

Gene expression changes during increased aerobic acetate formation

The aerobic growth parameters (Table 3) allowed to group the seven steady-state conditions of the continuous cultivation into three groups: (1) glucose-limited growth without aerobic acetate formation (1.67 mM glucose feed; residual concentrations in the culture supernatant were 0.66 mM for ammonium and <0.006 mM glucose); (2) N-limited growth with gradually increased aerobic acetate formation corresponding to gradually increased glucose feed (3.33 to 5.56 mM glucose feed; ammonium and glucose concentrations in the culture supernatants were <0.006 mM); (3) N-limited growth with the maximal aerobic acetate formation (8.34 mM glucose feed; residual concentrations in the culture supernatant were <0.006 mM for ammonium and 2.34 mM glucose). The transcriptome analyses revealed differential expression of 244 genes, which showed statistically significant (p < 0.05) expression changes of a factor of two or more and which can be divided into three groups: conditions of N-excess (19 genes), C-excess (9 genes) and of gradually increasing acetate formation rates (216 genes). Under N-excess conditions, 16 genes of the NtrC regulon showed decreased expression (glnK, amtB, nac, nagA, yhhQ, cbl, glnG, b0296, b1008, b1011–12, b1036, b1486–87, b1932, b1973) and three genes increased expression (osmY, csgD, csgG, see also the Supplementary Table containing the normalized gene expression ratios of all hybridization experiments) as was observed when comparing the transcriptomes at 3.33 and 1.67 mM glucose feed. Under C-excess conditions, five genes (glnH, argT, glnA, atoA, atoB) showed reduced mRNA levels and four genes (gadA, gadB, xasA, yhiM) showed increased mRNA levels (Supplementary Table) as revealed by comparing the transcriptomes at 8.34 and 5.56 mM glucose feed. Comparisons of the transcriptomes at 5.56, 4.72, 4.45 and 3.9 mM, respectively, to that at 3.33 mM glucose feed revealed 216 genes that changed expression under conditions characterized by increasing acetate formation, but not due to N-excess or C-excess (Fig. 1). As revealed by a Pearson correlation analysis, the expression of some genes correlated either positively or negatively with the acetate formation rate (Fig. 1). The function of most of the genes showing a positive correlation to acetate formation was hypothetical or unknown, ten genes belonged to nitrogen and amino acid metabolism. Expression of gadE(yhiE), which encodes an acid stress regulator, along with that of further acid stress genes (yhiW, yhiX and hdeAB) correlated positively to acetate formation (Fig. 1). Therefore, gadE(yhiE) was included in the further analysis. Besides a large number of genes of hypothetical or unknown function, genes showing reduced expression with increased acetate formation belonged to six groups: acetate metabolism, TCA cycle and energy metabolism, central intermediary metabolism, degradation, transport and regulators (Fig. 1). It was noted previously that growth on minimal media with sufficient glucose is characterized by high transcript levels of genes for excretion and metabolism of acetate (Tao et al. 1999). Here, the mRNA levels of the acs–yjcH–actP operon for acetate uptake and utilization (Gimenez et al. 2003) were low with sufficient glucose and increased as acetate formation decreased at limiting glucose concentrations. The acs–yjcH–actP operon and yjeJ cluster together in a Pearson correlation analysis (Fig. 1). Another group of genes, mostly codes for transport systems for uptake of carbon sources, e.g. glucose, ribose, mannose, arabinose, maltose and l-lactate. Expression of these genes is known to be low with sufficient glucose, but increases as the carbon source quality declines (Liu et al. 2005) or, as seen here, as glucose becomes limiting (Fig. 1). Moreover, expression of ten genes (acnB, lpdA, sucB, sucC, sdhCDAB, fumC and mdh) decreased with increasing acetate formation and showed a more dispersed clustering in the Pearson correlation analysis, however, all of them code for enzymes of the TCA cycle (Fig. 1).

Correlation analysis of gene expression differences and acetate formation rates. The data were obtained from the chemostat fermentations summarized in Table 3. (a) The Pearson correlation coefficients are plotted on the abscissa and the slopes calculated from plots of the expression differences of each gene against the differences of the acetate formation rate are plotted on the ordinate (see “Materials and methods” for details). The genes yhiE, yjeJ, the acs–yjcH–actP operon and the TCA cycle genes are plotted as black diamonds. (b) Genes and operons showing either negative or positive correlation between expression and acetate formation are listed. The names of genes depicted in (a) as white circles or black diamonds are given in bold

Acetate formation of gadE, yjcH–actP, yjeJ or sucCD deletion strains

Based on the expression analysis, the role of selected genes for overflow metabolism was studied by deletion mutagenesis. gadE was selected based on the assumption that it might have a regulatory role in overflow metabolism besides being a key regulator of the acid shock response. Mutants carrying deletions of yjcH–actP and yjeJ were generated as these genes showed a very similar expression pattern and clustered together in the Pearson correlation analysis (Fig. 1). As acs encodes acetyl-CoA synthetase for the activation of acetate to acetyl-CoA and therefore is not involved in acetate synthesis, only the genes yjcH–actP of the acs–yjcH–actP operon were deleted. A strain carrying a deletion of sucCD was generated as overflow metabolism also occurs under conditions characterized by the non-cyclic, branched TCA cycle, i.e. when oxaloacetate is formed by anaplerosis and α-ketoglutarate by the oxidative branch of the TCA cycle (Amarasingham and Davis 1965; Schmidt et al. 1999; Fischer and Sauer 2003). A deletion strategy was chosen to generate stable strains and to avoid plasmid copy number effects. To test whether deletion of gadE, yjcH–actP, yjeJ or sucCD affects glucose overflow metabolism, growth, glucose consumption and acetate formation of the mutants and the wild type were compared in batch cultivations with minimal or complex medium containing excess glucose, as overflow metabolism is known to be important under these conditions (El-Mansi and Holms 1989; El-Mansi 2004; Wolfe 2005). On LB + 100 mM glucose, MG1655ΔgadE showed slightly increased glucose consumption and acetate accumulation than MG1655, while growth rates, biomass formation, acetate accumulation and glucose consumption of strains MG1655ΔyjeJ and MG1655ΔyjcH–actP on LB + 100 mM glucose did not differ from those of the parent strain. On glucose minimal medium, growth rates, biomass formation, acetate accumulation and glucose consumption of strains MG1655ΔgadE, MG1655ΔyjeJ and MG1655ΔyjcH–actP did not differ from those of the parent strain E. coli MG1655 (Table 4).

However, E. coli MG1655ΔsucCD showed higher acetate accumulation and lower biomass formation than the parent strain on minimal glucose (Table 4). E. coli MG1655ΔsucCD was not able to use acetate as sole carbon and energy source (data not shown), which is in accordance with the finding that transposon mutants that are unable to grow aerobically on acetate carried insertions in the suc locus (Mat-Jan et al. 1989). On LB medium with 10 mM glucose, the growth of E. coli MG1655 was characterized by an acetate switch (Fig. 2a) as described previously for tryptone broth (Wolfe 2005). In contrast, MG1655ΔsucCD could not re-utilize the acetate formed during growth on minimal medium or LB medium with 10 mM glucose (Fig. 2a,c). On LB medium with 100 mM glucose, a growth condition characterized by the non-cyclic, branched TCA cycle (Amarasingham and Davis 1965; Schmidt et al. 1999; Fischer and Sauer 2003), MG1655ΔsucCD and MG1655 grew and accumulated acetate comparably (Fig. 2b). However, on minimal medium with 100 mM glucose, MG1655ΔsucCD accumulated acetate faster and to higher concentrations than the wild type (Fig. 2d).

Role of increased expression of the sdhCDAB–b0725–sucABCD operon for acetate formation by E. coli MG1655

As the expression of genes for the TCA cycle enzymes succinate dehydrogenase, α-ketoglutarate dehydrogenase and succinyl-CoA synthetase decreased with increasing acetate formation, a strain constitutively expressing the sdhCDAB–b0725–sucABCD operon encoding these enzymes was constructed. The strain MG1655Psdh::Ptet was derived from MG1655 by replacing the native promoter of the sdhCDAB–b0725–sucABCD operon, Psdh, including one CRP and two ArcA binding sites, by the strong promoter Ptet, which is constitutively active in the absence of TetR (Fig. 3 and “Materials and methods”). DNA microarray analysis was used to compare the mRNA levels of genes of the sdhCDAB–b0725–sucABCD operon in the E. coli strains MG1655 and MG1655ΔPsdh::Ptet during growth on minimal medium containing 10 mM glucose. The mRNA levels of sdhD, sdhA, sdhB, b0725, sucC, sucD and of the citrate synthase gene gltA, which is adjacent to the sdhCDAB–b0725–sucABCD operon and transcribed divergently, were shown to be 3.1, 3.9, 3.1, 3.2, 4.8 and 1.6-fold, respectively, higher in MG1655ΔPsdh::Ptet than in MG1655. Accordingly, the specific activities of succinate dehydrogenase (encoded by sdhCDAB), α-ketoglutarate dehydrogenase (sucAB), succinyl-CoA synthetase (sucCD) and citrate synthase (gltA) were higher in E. coli MG1655ΔPsdh::Ptet than in the wild type during growth on LB and on minimal medium with 10 mM glucose (data not shown and Table 5). Thus, introducing the promoter Ptet instead of the native promoter region of the sdhCDAB–b0725–sucABCD operon likely circumvented the transcriptional control of PsdhC and resulted in increased expression of this operon, and as a consequence in increased levels of active enzymes encoded by this operon.

Strategy of the chromosomal replacement of the Psdh promoter by the Ptet promoter in E. coli MG1655. DNA sequences of E. coli strains MG1655 and MG1655ΔPsdh::Ptet upstream of sdhC are listed above and below, respectively, the scheme of the genomic locus. DNA sequences present in both strains are given in white letters and grey shading, the transcriptional start site of Psdh and the start codon of sdhC are underlined, EcoRI sites introduced are given in bold, FRT sequences from pKD4 are given in italics and the promoter sequence of Ptet is underlined and italicized. The CRP binding site is indicated by a line and the centers of ArcA binding sites are indicated by an asterisk according to RegulonDB (version 5.0; Salgado et al. 2006)

To test whether the high levels of these TCA cycle enzymes led to reduced acetate formation by E. coli MG1655ΔPsdh::Ptet, we performed growth experiments in LB medium with 10 or 100 mM glucose and in minimal medium with 10 or 100 mM glucose (Fig. 4, Table 4). In LB medium with 100 mM glucose, E. coli MG1655ΔPsdh::Ptet formed less acetate, but more biomass and utilized more glucose than the wild type (Table 4, Fig. 4b). Moreover, E. coli MG1655ΔPsdh::Ptet was able to re-utilize the formed acetate partially (Fig. 4b). In minimal medium with 100 mM glucose, E. coli MG1655ΔPsdh::Ptet formed less acetate than the wild type, while biomass formation and glucose utilization were unchanged (Table 4, Fig. 4d). On minimal medium or LB medium containing 100 mM glucose, E. coli MG1655 accumulated acetate until the end of cultivation and was not able to utilize glucose completely (Table 4, Fig. 4b,d). On the other hand, when 10 mM glucose was present in minimal medium or LB medium, glucose was utilized completely by E. coli MG1655 and acetate was formed only transiently (Fig. 4a,c). Under these conditions, the transient acetate accumulation by E. coli MG1655ΔPsdh::Ptet was less pronounced than that by MG1655 (Fig. 4a,c). Taken together, E. coli MG1655ΔPsdh::Ptet formed less acetate than E. coli MG1655 on both minimal and complex media when glucose was present at 10 mM or 100 mM, while maintaining high growth and glucose consumption rates.

To characterize growth, glucose consumption, acetate excretion and CO2 formation, 5 l batch cultivations of E. coli MG1655ΔPsdh::Ptet and E. coli MG1655 (three independent cultivations each) were performed at a constant pH of 7.2 with specific aeration of 1 l h−1 l−1 and quantification of CO2 in the gas phases. Under these conditions, E. coli MG1655 grew with a growth rate of 0.64 ± 0.03 h−1, consumed glucose at a rate of 147 ± 7 nmol min−1 (mg dry weight)−1 and excreted acetate at 100 ± 15 nmol min−1 (mg dry weight)−1. While E. coli MG1655ΔPsdh::Ptet showed a similar growth rate (0.61 ± 0.02 h−1) and glucose uptake rate (149 ± 5 nmol min−1 (mg dry weight)−1), the acetate production rate was decreased about twofold (39 ± 1 nmol min−1 (mg dry weight)−1) compared to E. coli MG1655.

Analysis of supernatants by 13C and 1H NMR did not indicate formation of other incomplete oxidation products besides acetate (data not shown). As can be seen from the carbon balance (Fig. 5), concomitant with reduced conversion of glucose to acetate a higher fraction of the glucose carbon was used for CO2 production by E. coli MG1655ΔPsdh::Ptet compared to the wild type strain MG1655. While the growth rate and the glucose uptake rate of MG1655ΔPsdh::Ptet remained as high as those of MG1655, MG1655ΔPsdh::Ptet directed less carbon to acetate excretion (8.6% compared to 17.7%) and more carbon to CO2 production (38.7% compared to 31.8%). Thus, while as much glucose carbon is directed to biomass formation, the split of by-products between acetate and CO2 was altered to the latter, which is beneficial since acetate not only wastes carbon but can have a negative effect upon the cell by dissipating the proton potential.

Carbon balances of batch fermentations of E. coli MG1655 (a) and MG1655ΔPsdh::Ptet (b) on minimal medium with 10 mM glucose. Values are averages from three independent cultivations of each strain during the exponential growth phase. The fermenter volume was 3.5 l and CO2 was measured in the gas phases using an IR spectrometer

Discussion

Global gene expression was used to characterize acetate formation during glucose overflow metabolism. Expression of the sdhCDAB–b0725–sucABCD operon on the one hand, and of the acs–yjcH–actP operon on the other hand correlated negatively with acetate formation during glucose overflow metabolism in chemostat cultivations (Fig. 1). Subsequently, it was revealed that relieving transcriptional control of the sdhCDAB–b0725–sucABCD operon by chromosomal promoter exchange mutagenesis led to increased specific activities of the TCA cycle enzymes succinate dehydrogenase, α-ketoglutarate dehydrogenase and succinyl-CoA synthetase and in turn to reduced acetate formation in glucose overflow metabolism.

An imbalance between the TCA cycle and glucose uptake or its utilization in glycolysis was previously proposed as a cause of aerobic acetate formation (El-Mansi and Holms 1989). Such imbalances may arise by exceedingly high glucose uptake, a limited TCA cycle capacity or a limited respiratory capacity (El-Mansi and Holms 1989; Majewski and Domach 1990; Holms 1996). A limited TCA cycle capacity was proposed to be due to decreased availability of free CoA upon accumulation of acetyl-CoA, which in turn could lead to a bottleneck in the CoA-dependent conversion of α-ketoglutarate to succinyl-CoA as CoA is sparse (El-Mansi 2004). On the other hand, low activities of α-ketoglutarate dehydrogenase (Amarasingham and Davis 1965; Majewski and Domach 1990) or citrate synthase could lead to low TCA cycle capacities (Holms 1996). However, although flux via citrate synthase was lower on glucose than on fructose, a substrate that does not lead to acetate formation (Holms 1996), overexpression of the citrate synthase gene gltA from an adjustable expression vector did not alter the carbon flux distribution during growth on glucose (Walsh and Koshland 1985). The effect of overexpression of only the α-ketoglutarate dehydrogenase genes sucAB on acetate formation has not been tested previously. Here, replacing the promoter of the sdhCDAB–b0725–sucABCD operon, PsdhC, by the constitutively active Ptet relieved transcriptional control of this operon and presumably also of the oppositely oriented gltA gene. Consequently, the specific activities of the encoded succinate dehydrogenase, α-ketoglutarate dehydrogenase and succinyl-CoA synthetase, which convert α-ketoglutarate to fumarate, and of citrate synthase were higher in MG1655ΔPsdh::Ptet than in the wild type. E. coli MG1655ΔPsdh::Ptet maintained the high growth and glucose consumption rates of MG1655, but directed more carbon to CO2 and less carbon to acetate. The chosen strain improvement strategy, namely, promoter exchange, yielded a stable and marker-free strain exhibiting higher specific activities of four enzymes (succinate dehydrogenase, α-ketoglutarate dehydrogenase, succinyl-CoA synthetase and citrate synthase). While higher speficic activities of citrate synthase alone were not sufficient to reduce acetate formation (Walsh and Koshland 1985), it remains to be studied whether increased levels of all four enzymes or of only some of them are required. In summary, we could show that maintaining a high capacity of the oxidative part of the TCA cycle reduces acetate formation and that acetate formation during glucose overflow metabolism is caused by expression control of the sdhCDAB–b0725–sucABCD operon. Proteome and transcriptome analyses revealed that E. coli mutants, which are unable to excrete acetate as they lack acetate kinase and/or phosphotransacetylase, showed increased expression of TCA cycle genes (Kirkpatrick et al. 2001; Wolfe 2005). It is intriguing to note that E. coli excretes acetate as a result of reduced expression of the sdhCDAB–b0725–sucABCD operon, while expression of this operon and of other TCA cycle genes increases as a consequence of the inability to excrete acetate.

Currently, the transcriptional regulation of the sdhCDAB–b0725–sucABCD operon during glucose overflow metabolism is not fully understood (Wolfe 2005). Transcription mainly initiates from PsdhC, but also from the weaker, internal promoter PsucAB. Transcription from the main promoter, PsdhC, is thought to be activated by cAMP-CRP and was shown to be activated by reduced FNR and phosphorylated ArcA (Park et al. 1997; Shen and Gunsalus 1997; Cunningham and Guest 1998). The putative binding sites for cAMP-CRP and the experimentally verified binding sites for ArcA within PsdhC are absent from E. coli MG1655ΔPsdh::Ptet. As the described fermenter cultivations were performed aerobically with a pO2 exceeding 60%, regulation by ArcA and FNR, which control the aerobic/anaerobic switch is likely to be of minor importance as discussed previously (Park et al. 1997; Perrenoud and Sauer 2005).

The chemostat experiments differed by the glucose concentration of the feed medium, but under the equilibrium conditions for which a negative correlation between expression of the TCA cycle genes and acetate formation was observed, no residual glucose could be detected in the cultivation broth. However, as these conditions differed by glucose utilization rates, a glucose repression effect on the transcription of sdhCDAB–b0725–sucABCD operon could be important. The presence of a putative cAMP-CRP binding site, sdh–galK fusion analyses and DNA microarray experiments revealed that glucose repression of Psdh is in part cAMP-CRP dependent (Wilde and Guest 1986; Gosset et al. 2004; Zheng et al. 2004). In addition, sdh–lacZ fusion analyses and DNA microarray experiments revealed carbon control independent of cAMP-CRP and FruR (Park et al. 1995; Takeda et al. 1999). Under aerobic conditions with excess glucose, control of sdhCDAB–b0725–sucABCD transcription by Arc, FNR, FruR and cAMP-CRP will play a minor role and, thus, reduced expression of this operon during glucose overflow metabolism is likely due to the control by the cAMP-CRP independent catabolite control system. This cAMP-CRP independent regulation of sdhCDAB–b0725–sucABCD transcription involves the glucose PTS EIICBGlc (Takeda et al. 1999). Dephosphorylated EIICBGlc sequesters Mlc, which represses ptsG and genes for uptake and utilization of certain other carbohydrates (Plumbridge 2002). However, control of sdhCDAB–b0725–sucABCD transcription by EIICBGlc is independent of Mlc (Takeda et al. 1999). In the chemostat experiments described here, expression of sdhCDAB–b0725–sucABCD was negatively correlated to acetate formation on the one hand, and to the glucose consumption rate on the other hand (Fig. 1, Table 3). Thus, it appears plausible that the more glucose is transported via EIICBGlc, the more pronounced is repression of the sdhCDAB–b0725–sucABCD operon. The fact that ptsG mutants excrete less acetate than parental strains is typically explained by the reduced glucose uptake in these mutants. However, altered regulation of sdhCDAB–b0725–sucABCD expression by EIICBGlc in these mutants likely contributes to the reduction of acetate formation. It is not known whether control by EIICBGlc is direct or indirect or whether metabolites derived from pentoses or trioses (Loomis and Magasanik 1966) or α-ketoglutarate (Daniel and Danchin 1986) are involved. Clearly, more studies are needed to characterize cAMP-CRP independent glucose repression by EIICBGlc.

Transcription control of acs–yjcH–actP is complex and the intergenic region between acs and nrfA is bound by CRP, FNR, IHF, FIS and NarL or NarP and is folded into an ordered nucleoprotein structure that permits the two divergent promoters to be regulated independently (Browning et al. 2002). CRP-dependent activation of the acs promoter acsP2 is counteracted by the binding of FIS or IHF (Browning et al. 2004). As FIS levels are maximal after a shift to fresh medium but decrease during exponential growth, while IHF is present at high levels in the stationary phase, CRP-dependent activation of acs transcription is maximal at the transition from the exponential to the stationary growth phase (Browning et al. 2004). Thus, during batch growth cultivation with glucose minimal media, acs transcription peaks when the acetate concentration is highest. The adjacent genes yjcH and actP are cotranscribed with acs and the acetate permease encoded by actP was shown to catalyze acetate uptake (Gimenez et al. 2003). In the chemostat experiments performed in this study, it is unlikely that levels of IHF or FIS varied at the constant dilution rates. The observed negative correlation between acetate formation and transcription of acs–yjcH–actP can be explained by CRP dependent activation as different glucose concentrations were present in the feed medium. Transcription of acs–yjcH–actP initiation depends absolutely upon cAMP-CRP (Beatty et al. 2003). In the presence of excess glucose, cAMP levels are low and cAMP-CRP thus is unavailable. Therefore, aerobic acetate formation in the presence of excess glucose is negatively correlated with transcription of acs–yjcH–actP due to cAMP-CRP dependent regulation.

With increasing acetate formation, expression of many genes known to be differentially expressed in glucose-grown and acetate-grown cells (Oh et al. 2002) or in cells lacking CRP (Gosset et al. 2004) decreased. For example, the PEP carboxykinase gene pckA, the tryptophanase gene tnaA, and the aspartase gene aspA showed lower expression when acetate is formed in overflow metabolism (Fig. 1) and their expression is lower in glucose-grown cells than in acetate-grown cells (Oh et al. 2002) and it is lower in cells lacking CRP (Gosset et al. 2004). Thus, the observed expression patterns for pckA, tnaA, aspA and others under conditions of aerobic acetate formation can be explained by cAMP-CRP dependent regulation.

Expression of gadE increased with increasing aerobic acetate formation. Formation of acetate during aerobic growth reduces the pH of the surrounding medium if not buffered. E. coli possesses four different systems of acid resistance. Besides a glucose-repressible system, an arginine-dependent and a lysine-dependent system, a glutamate-dependent system exists and is the most effective (Foster 2004). The expression of glutamate-dependent acid resistance genes is induced at low pH and is subject to regulation by GadE, GadW, GadX, TrmE, HNS, TorR, Crp, YdeO, the EvgSA two-component regulatory system and the sigma factor RpoS (reviewed in Foster 2004). This regulation is complexly exhibiting a modular architecture as e.g. induction of the acid resistance genes gadA, gadBC, and hdeBAD in the stationary phase is RpoS-dependent, but induction upon acidic shift is not (Weber et al. 2005). Moreover, expression of the acid resistance genes increased at neutral pH either when acetate was added or when it was formed during overflow metabolism (this work and Polen et al. 2003). As acetate formation by a mutant strain lacking the acid stress regulator gene gadE was comparable to that of the parent strain (Table 4), increased gadE expression is a consequence of acetate formation but does not affect acetate formation. It is conceivable that intracellular acidification during aerobic acetic acid formation might be counteracted by the proton-consuming decarboxylation of glutamate to γ-aminobutyrate by gadA and gadB encoded glutamate decarboxylases even though the pH of the medium is still neutral.

As biotechnological production of fine chemicals and recombinant proteins using E. coli (Wendisch et al. 2006) is often deteriorated by acetate formation, the strain improvement described here might prove useful to optimize industrial producer strains. Relief of transcriptional regulation of the sdhCDAB–b0725–sucABCD operon by replacing the endogenous promoter with a constitutively active promoter resulted in decreased acetate formation, while maintaining high growth and glucose consumption rates. Moreover, this genetic strategy can be easily applied to producer strains endowing them with a reduced capacity to form acetate while maintaining all other characteristics necessary for a high production capability.

References

Akesson M, Hagander P, Axelsson JP (2001) Avoiding acetate accumulation in Escherichia coli cultures using feedback control of glucose feeding. Biotechnol Bioeng 73:223–230

Altaras NE, Cameron DC (1999) Metabolic engineering of a 1,2-propanediol pathway in Escherichia coli. Appl Environ Microbiol 65:1180–1185

Amarasingham CR, Davis BD (1965) Regulation of alpha-ketoglutarate dehydrogenase formation in Escherichia coli. J Biol Chem 240:3664–3668

Arfin SM et al (2000) Global gene expression profiling in Escherichia coli K12. The effects of integration host factor. J Biol Chem 275:29672–29684

Aristidou AA, San K-Y, Bennett GN (1994) Modification of central metabolic pathway in Escherichia coli to reduce acetate accumulation by heterologous expression of the Bacillus subtilis acetolactate synthase gene. Biotechnol Bioeng 44:944–951

Axe DD, Bailey JE (1995) Transport of lactate and acetate through the energized cytoplasmic membrane of Escherichia coli. Biotechnol Bioeng 47:8–19

Beatty CM, Browning DF, Busby SJ, Wolfe AJ (2003) Cyclic AMP receptor protein-dependent activation of the Escherichia coli acsP2 promoter by a synergistic class III mechanism. J Bacteriol 185:5148–5157

Bermejo LL, Welker NE, Papoutsakis ET (1998) Expression of Clostridium acetobutylicum ATCC 824 genes in Escherichia coli for acetone production and acetate detoxification. Appl Environ Microbiol 64:1079–1085

Bongaerts J, Kramer M, Muller U, Raeven L, Wubbolts M (2001) Metabolic engineering for microbial production of aromatic amino acids and derived compounds. Metab Eng 3:289–300

Bridger WA, Cohen LH (1969) The kinetics of inactivation of adenylosuccinate lyase: evidence for a substrate-induced conformational change. Can J Biochem 47:665–672

Brown TD et al (1977) The enzymic interconversion of acetate and acetyl–coenzyme A in Escherichia coli. J Gen Microbiol 102:327–336

Browning DF, Beatty CM, Wolfe AJ, Cole JA, Busby SJ (2002) Independent regulation of the divergent Escherichia coli nrfA and acsP1 promoters by a nucleoprotein assembly at a shared regulatory region. Mol Microbiol 43:687–701

Browning DF, Beatty CM, Sanstad EA, Gunn KE, Busby SJ, Wolfe AJ (2004) Modulation of CRP-dependent transcription at the Escherichia coli acsP2 promoter by nucleoprotein complexes: anti-activation by the nucleoid proteins FIS and IHF. Mol Microbiol 51:241–254

Chang YY, Wang AY, Cronan JE Jr (1994) Expression of Escherichia coli pyruvate oxidase (PoxB) depends on the sigma factor encoded by the rpoS(katF) gene. Mol Microbiol 11:1019–1028

Chang DE, Jung HC, Rhee JS, Pan JG (1999a) Homofermentative production of d- or l-lactate in metabolically engineered Escherichia coli RR1. Appl Environ Microbiol 65:1384–1389

Chang DE, Shin S, Rhee JS, Pan JG (1999b) Acetate metabolism in a pta mutant of Escherichia coli W3110: importance of maintaining acetyl coenzyme A flux for growth and survival. J Bacteriol 181:6656–6663

Cho S, Shin D, Ji GE, Heu S, Ryu S (2005) High-level recombinant protein production by overexpression of Mlc in Escherichia coli. J Biotechnol 119:197–203

Cohen SN, Chang AC, Boyer HW, Helling RB (1973) Construction of biologically functional bacterial plasmids in vitro. Proc Natl Acad Sci USA 70:3240–3244

Cunningham L, Guest JR (1998) Transcription and transcript processing in the sdhCDAB–sucABCD operon of Escherichia coli. Microbiology 144(Pt 8):2113–2123

Daniel J, Danchin A (1986) 2-Ketoglutarate as a possible regulatory metabolite involved in cyclic AMP-dependent catabolite repression in Escherichia coli K12. Biochimie 68:303–310

Datsenko KA, Wanner BL (2000) One-step inactivation of chromosomal genes in Escherichia coli K-12 using PCR products. Proc Natl Acad Sci USA 97:6640–6645

Debabov VG (2003) The threonine story. Adv Biochem Eng Biotechnol 79:113–136

Diaz-Ricci JC, Regan L, Bailey JE (1991) Effect of alteration of the acetic acid synthesis pathway on the fermentation pattern of Escherichia coli. Biotechnol Bioeng 38:1318–1324

El-Mansi M (2004) Flux to acetate and lactate excretions in industrial fermentations: physiological and biochemical implications. J Ind Microbiol Biotechnol 31:295–300

El-Mansi EM, Holms WH (1989) Control of carbon flux to acetate excretion during growth of Escherichia coli in batch and continuous cultures. J Gen Microbiol 135:2875–2883

Engels S, Schweitzer JE, Ludwig C, Bott M, Schaffer S (2004) clpC and clpP1P2 gene expression in Corynebacterium glutamicum is controlled by a regulatory network involving the transcriptional regulators ClgR and HspR as well as the ECF sigma factor sigmaH. Mol Microbiol 52:285–302

Farmer WR, Liao JC (1997) Reduction of aerobic acetate production by Escherichia coli. Appl Environ Microbiol 63:3205–3210

Fischer E, Sauer U (2003) Metabolic flux profiling of Escherichia coli mutants in central carbon metabolism using GC-MS. Eur J Biochem 270:880–891

Flores S, Gosset G, Flores N, de Graaf AA, Bolivar F (2002) Analysis of carbon metabolism in Escherichia coli strains with an inactive phosphotransferase system by (13)C labeling and NMR spectroscopy. Metab Eng 4:124–137

Foster JW (2004) Escherichia coli acid resistance: tales of an amateur acidophile. Nat Rev Microbiol 2:898–907

Gimenez R, Nunez MF, Badia J, Aguilar J, Baldoma L (2003) The gene yjcG, cotranscribed with the gene acs, encodes an acetate permease in Escherichia coli. J Bacteriol 185:6448–6455

Gosset G, Zhang Z, Nayyar S, Cuevas WA, Saier MH Jr (2004) Transcriptome analysis of Crp-dependent catabolite control of gene expression in Escherichia coli. J Bacteriol 186:3516–3524

Guest JR, Creaghan IT (1973) Gene–protein relationships of the alpha-keto acid dehydrogenase complexes of Escherichia coli K12: isolation and characterization of lipoamide dehydrogenase mutants. J Gen Microbiol 75:197–210

Hanahan D (1983) Studies on transformation of Escherichia coli with plasmids. J Mol Biol 166:557–580

Hansen HG, Henning U (1966) Regulation of pyruvate dehydrogenase activity in Escherichia coli K12. Biochim Biophys Acta 122:355–358

Holms H (1996) Flux analysis and control of the central metabolic pathways in Escherichia coli. FEMS Microbiol Rev 19:85–116

Hommais F et al (2001) Large-scale monitoring of pleiotropic regulation of gene expression by the prokaryotic nucleoid-associated protein, H-NS. Mol Microbiol 40:20–36

Hosono K, Kakuda H, Ichihara S (1995) Decreasing accumulation of acetate in a rich medium by Escherichia coli on introduction of genes on a multicopy plasmid. Biosci Biotechnol Biochem 59:256–261

Jensen EB, Carlsen S (1990) Production of recombinant human growth hormone in Escherichia coli: expression of different precursors and physiological effects of glucose, aetate, and salts. Biotechnol Bioeng 36:1–11

Kayser A, Weber J, Hecht V, Rinas U (2005) Metabolic flux analysis of Escherichia coli in glucose-limited continuous culture. I. Growth-rate-dependent metabolic efficiency at steady state. Microbiology 151:693–706

Khodursky AB, Peter BJ, Cozzarelli NR, Botstein D, Brown PO, Yanofsky C (2000) DNA microarray analysis of gene expression in response to physiological and genetic changes that affect tryptophan metabolism in Escherichia coli. Proc Natl Acad Sci USA 97:12170–12175

Khodursky AB, Bernstein JA, Peter BJ, Rhodius V, Wendisch VF, Zimmer DP (2003) Escherichia coli spotted double-strand DNA microarrays: RNA extraction, labeling, hybridization, quality control, and data management. Methods Mol Biol 224:61–78

Kirkpatrick C, Maurer LM, Oyelakin NE, Yoncheva YN, Maurer R, Slonczewski JL (2001) Acetate and formate stress: opposite responses in the proteome of Escherichia coli. J Bacteriol 183:6466–6477

Kramer M et al (2003) Metabolic engineering for microbial production of shikimic acid. Metab Eng 5:277–283

Kumari S, Tishel R, Eisenbach M, Wolfe AJ (1995) Cloning, characterization, and functional expression of acs, the gene which encodes acetyl coenzyme A synthetase in Escherichia coli. J Bacteriol 177:2878–2886

Lasko DR, Zamboni N, Sauer U (2000) Bacterial response to acetate challenge: a comparison of tolerance among species. Appl Microbiol Biotechnol 54:243–247

Lehnen D, Blumer C, Polen T, Wackwitz B, Wendisch VF, Unden G (2002) LrhA as a new transcriptional key regulator of flagella, motility and chemotaxis genes in Escherichia coli. Mol Microbiol 45:521–532

Liu M, Durfee T, Cabrera JE, Zhao K, Jin DJ, Blattner FR (2005) Global transcriptional programs reveal a carbon source foraging strategy by Escherichia coli. J Biol Chem 280:15921–15927

Loomis WF Jr, Magasanik B (1966) Nature of the effector of catabolite repression of beta-galactosidase in Escherichia coli. J Bacteriol 92:170–177

Luli GW, Strohl WR (1990) Comparison of growth, acetate production, and acetate inhibition of Escherichia coli strains in batch and fed-batch fermentations. Appl Environ Microbiol 56:1004–1011

Majewski RA, Domach MM (1990) Simple constrained-optimization view of acetate overflow in Escherichia coli. Biotechnol Bioeng 35:732–738

Mansson R, Tsapogas P, Akerlund M, Lagergren A, Gisler R, Sigvardsson M (2004) Pearson correlation analysis of microarray data allows for the identification of genetic targets for early B-cell factor. J Biol Chem 279:17905–17913

Mat-Jan F, Williams CR, Clark DP (1989) Anaerobic growth defects resulting from gene fusions affecting succinyl-CoA synthetase in Escherichia coli K12. Mol Gen Genet 215:276–280

Maurer R, Meyer B, Ptashne M (1980) Gene regulation at the right operator (OR) bacteriophage lambda. I. OR3 and autogenous negative control by repressor. J Mol Biol 139:147–161

Maurer LM, Yohannes E, Bondurant SS, Radmacher M, Slonczewski JL (2005) pH regulates genes for flagellar motility, catabolism, and oxidative stress in Escherichia coli K-12. J Bacteriol 187:304–319

Nakamura CE et al (2000) U.S. Patent 6,013,494

Neidhardt FC, Umbarger HE (1996) Chemical composition of Escherichia coli. In: Neidhardt FC (ed) Escherichia coli and Salmonella typhimurium: cellular and molecular biology. ASM Press, Washington DC

Nellis DF et al (2005) Preclinical manufacture of an anti-HER2 scFv–PEG–DSPE, liposome-inserting conjugate. 1. Gram-scale production and purification. Biotechnol Prog 21:205–220

Niu W, Draths KM, Frost JW (2002) Benzene-free synthesis of adipic acid. Biotechnol Prog 18:201–211

Oh MK, Rohlin L, Kao KC, Liao JC (2002) Global expression profiling of acetate-grown Escherichia coli. J Biol Chem 277:13175–13183

Park SJ, Tseng CP, Gunsalus RP (1995) Regulation of succinate dehydrogenase (sdhCDAB) operon expression in Escherichia coli in response to carbon supply and anaerobiosis: role of ArcA and Fnr. Mol Microbiol 15:473–482

Park SJ, Chao G, Gunsalus RP (1997) Aerobic regulation of the sucABCD genes of Escherichia coli, which encode alpha-ketoglutarate dehydrogenase and succinyl coenzyme A synthetase: roles of ArcA, Fnr, and the upstream sdhCDAB promoter. J Bacteriol 179:4138–4142

Perrenoud A, Sauer U (2005) Impact of global transcriptional regulation by ArcA, ArcB, Cra, Crp, Cya, Fnr, and Mlc on glucose catabolism in Escherichia coli. J Bacteriol 187:3171–3179

Phue JN, Shiloach J (2004) Transcription levels of key metabolic genes are the cause for different glucose utilization pathways in E. coli B (BL21) and E. coli K (JM109). J Biotechnol 109:21–30

Plumbridge J (2002) Regulation of gene expression in the PTS in Escherichia coli: the role and interactions of Mlc. Curr Opin Microbiol 5:187–193

Polen T, Wendisch VF (2004) Genomewide expression analysis in amino acid-producing bacteria using DNA microarrays. Appl Biochem Biotechnol 118:215–232

Polen T, Rittmann D, Wendisch VF, Sahm H (2003) DNA microarray analyses of the long-term adaptive response of Escherichia coli to acetate and propionate. Appl Environ Microbiol 69:1759–1774

Polen T, Kramer M, Bongaerts J, Wubbolts M, Wendisch VF (2005) The global gene expression response of Escherichia coli to l-phenylalanine. J Biotechnol 115:221–237

Rhodius V, Van Dyk TK, Gross C, LaRossa RA (2002) Impact of genomic technologies on studies of bacterial gene expression. Annu Rev Microbiol 56:599–624

Rinas U, Kracke-Helm HA, Schügerl K (1989) Glucose as a substrate in recombinant strain fermentation technology. Appl Microbiol Biotechnol 31:163–167

Salgado H, Gama-Castro S, Peralta-Gil M, Diaz-Peredo E, Sanchez-Solano F, Santos-Zavaleta A, Martinez-Flores I, Jimenez-Jacinto V, Bonavides-Martinez C, Segura-Salazar J, Martinez-Antonio A, Collado-Vides J (2006) RegulonDB (version 5.0): Escherichia coli K-12 transcriptional regulatory network, operon organization, and growth conditions. Nucleic Acids Res 34:D394–D397

Sambrook J, Russel D (2001) Molecular cloning: a laboratory manual. 3rd edn. Cold Spring Harbor Laboratoy Press, Cold Spring Harbor, NY

Sanchez AM, Bennett GN, San KY (2005) Efficient succinic acid production from glucose through overexpression of pyruvate carboxylase in an Escherichia coli alcohol dehydrogenase and lactate dehydrogenase mutant. Biotechnol Prog 21:358–365

Schmidt K et al (1999) Quantification of intracellular metabolic fluxes from fractional enrichment and 13C–13C coupling constraints on the isotopomer distribution in labeled biomass components. Metab Eng 1:166–179

Shen J, Gunsalus RP (1997) Role of multiple ArcA recognition sites in anaerobic regulation of succinate dehydrogenase (sdhCDAB) gene expression in Escherichia coli. Mol Microbiol 26:223–236

Soutourina OA, Krin E, Laurent-Winter C, Hommais F, Danchin A, Bertin PN (2002) Regulation of bacterial motility in response to low pH in Escherichia coli: the role of H-NS protein. Microbiology 148:1543–1551

Spencer ME, Guest JR (1973) Isolation and properties of fumarate reductase mutants of Escherichia coli. J Bacteriol 114:563–570

Swartz JR (2001) Advances in Escherichia coli production of therapeutic proteins. Curr Opin Biotechnol 12:195–201

Takeda S, Matsushika A, Mizuno T (1999) Repression of the gene encoding succinate dehydrogenase in response to glucose is mediated by the EIICB(Glc) protein in Escherichia coli. J Biochem (Tokyo) 126:354–360

Tao H, Bausch C, Richmond C, Blattner FR, Conway T (1999) Functional genomics: expression analysis of Escherichia coli growing on minimal and rich media. J Bacteriol 181:6425–6440

Underwood SA, Zhou S, Causey TB, Yomano LP, Shanmugam KT, Ingram LO (2002) Genetic changes to optimize carbon partitioning between ethanol and biosynthesis in ethanologenic Escherichia coli. Appl Environ Microbiol 68:6263–6272

Vemuri GN, Eiteman MA, Altman E (2002) Effects of growth mode and pyruvate carboxylase on succinic acid production by metabolically engineered strains of Escherichia coli. Appl Environ Microbiol 68:1715–1727

Walsh K, Koshland DE Jr (1985) Characterization of rate-controlling steps in vivo by use of an adjustable expression vector. Proc Natl Acad Sci USA 82:3577–3581

Weber H, Polen T, Heuveling J, Wendisch VF, Hengge R (2005) Genome-wide analysis of the general stress response network in Escherichia coli: sigmaS-dependent genes, promoters, and sigma factor selectivity. J Bacteriol 187:1591–1603

Weitzman PD, Dunmore P (1969) Citrate synthases: allosteric regulation and molecular size. Biochim Biophys Acta 171:198–200

Wendisch VF, de Graaf AA, Sahm H (1997) Accurate determination of 13C enrichments in nonprotonated carbon atoms of isotopically enriched amino acids by 1H nuclear magnetic resonance. Anal Biochem 245:196–202

Wendisch VF, Zimmer DP, Khodursky A, Peter B, Cozzarelli N, Kustu S (2001) Isolation of Escherichia coli mRNA and comparison of expression using mRNA and total RNA on DNA microarrays. Anal Biochem 290:205–213

Wendisch VF, Bott M, Eikmanns BJ (2006) Metabolic engineering of Escherichia coli and Corynebacterium glutamicum for biotechnological production of organic acids and amino acids. Curr Opin Microbiol 9:268–274

Wilde RJ, Guest JR (1986) Transcript analysis of the citrate synthase and succinate dehydrogenase genes of Escherichia coli K12. J Gen Microbiol 132:3239–3251

Wolfe AJ (2005) The acetate switch. Microbiol Mol Biol Rev 69:12–50

Xu B, Jahic M, Blomsten G, Enfors SO (1999a) Glucose overflow metabolism and mixed-acid fermentation in aerobic large-scale fed-batch processes. Appl Microbiol Biotechnol 51:564–571

Xu B, Jahic M, Enfors SO (1999b) Modeling of overflow metabolism in batch and fed-batch cultures of Escherichia coli. Biotechnol Prog 15:81–90

Zheng M, Wang X, Templeton LJ, Smulski DR, LaRossa RA, Storz G (2001) DNA microarray-mediated transcriptional profiling of the Escherichia coli response to hydrogen peroxide. J Bacteriol 183:4562–4570

Zheng D, Constantinidou C, Hobman JL, Minchin SD (2004) Identification of the CRP regulon using in vitro and in vivo transcriptional profiling. Nucleic Acids Res 32:5874–5893

Zhou S, Causey TB, Hasona A, Shanmugam KT, Ingram LO (2003) Production of optically pure d-lactic acid in mineral salts medium by metabolically engineered Escherichia coli W3110. Appl Environ Microbiol 69:399–407

Zimmer DP et al (2000) Nitrogen regulatory protein C-controlled genes of Escherichia coli: scavenging as a defense against nitrogen limitation. Proc Natl Acad Sci USA 97:14674–14679

Acknowledgements

We thank Hermann Sahm for the continuous support and Doris Rittmann for the technical assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Andrea Veit and Tino Polen contributed equally to this work.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Veit, A., Polen, T. & Wendisch, V.F. Global gene expression analysis of glucose overflow metabolism in Escherichia coli and reduction of aerobic acetate formation. Appl Microbiol Biotechnol 74, 406–421 (2007). https://doi.org/10.1007/s00253-006-0680-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-006-0680-3